Design Life-Cycle

assess.design.(don't)consume

Ahmed Alsubhi

DES 040 - Section 03

Ikea Stainless Steel Toilet Roll Holder Life Cycle – Raw Materials

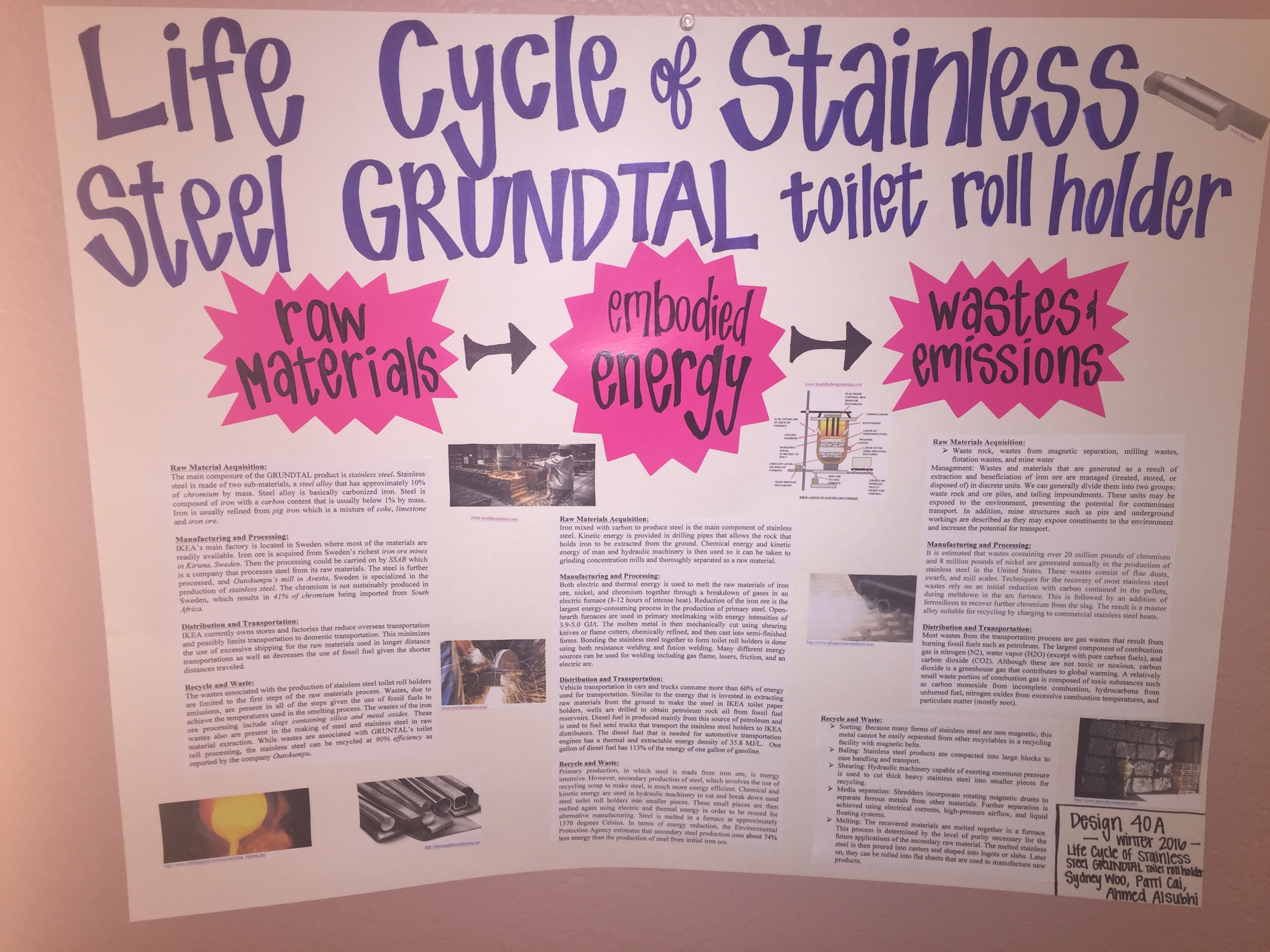

Ikea is a company that was found by Ingvar Kamprad in 1943. The company started as an establishment selling pens, matchboxes, and furniture. The substantial growth of Ikea with a count of almost 300 stores over 36 countries sheds light on their products environmental impact and their life cycle. Whilst mundane the product of interest is present in most households given it being essential (Mega Factories: Ikea). Ikea’s stainless steel toilet roll holder is one of Ikea’s products that is not made of their more popular material, wood. While Ikea’s website provide a significant amount of information on its line of production involving wood, it lacks to mention the life cycle of its stainless steel line of production. Due to the inability of obtaining information regarding the product of interest assumptions were made. The acquisition of the raw materials and the process behind its manufacturing and the recycle and waste management associated with it, these parts of the life cycle of the product were investigated based in Sweden.

Raw Materials

The product of interest is the GRUNDTAL toilet roll holder. The products is made of one material, stainless steel (Ikea toilet accessories). Attempts to contacting Ikea in order to obtain information about the composition of the stainless steel, or the source from which the stainless steel was obtained from. Ikea have responded “Upon further research, we do not have the information you are requesting readily available about the GRUNDTAL toilet paper holder…” Assumptions were made in order to reach a tangible conclusion about the life cycle of the product.

The production and manufacturing is assumed to take place in Sweden given the origin of Ikea as a company and its largest factory’s location (Ikea company information). In order to assess the life cycle of the product the life cycle of stainless steel is investigated. Stainless steel is the result of three processes; smelting of iron ore to produce iron; production of steel; and production of stainless steel.

A key element of stainless steel is iron. Iron is obtained from iron ore through smelting. The iron ore that is obtained usually contains elements alongside iron such as silica, coke, and limestone. The process of smelting is largely done using the blast furnace method. The blast furnace heats the iron ore to a temperature over 3000 Fahrenheit. The iron is preferred to have the least amount of impurities possible, and the materials present in the iron ore contribute to achieve such goal. The limestone reacts with the silica and the coke to form “slags” which will be explained in the waste section. While the coke turning into ash is considered to be a byproduct it contributes to the production of steel. If the end product is steel rather than iron the process is altered slightly (How steel is made: a Brief summary of a Balst Furnace).

Steel is basically carbonized iron. The coke that was present in the iron ore reacts with the limestone in order to form the “slag”. Steel is known to have 1-2.1% of its weight in carbon. By letting a fixed amount of the ash produced by the coke resonate in the molten iron. This process results in the elimination of unwanted impurities such as silica and excess ash which results in the production of steel (How steel is made: a Brief summary of a Balst Furnace). To achieve the final material in interest, stainless steel, one more process has to be undergone. Stainless steel is made up of Steel and a certain percentage of chromium by weight. The minimum amount of chromium present usually is at 10.5% by weight. Other materials are used in the making of stainless steel as alloying elements in order to enhance the structure or alter the properties of the resulting stainless steel. Due to shortage in information from Ikea the basic form of stainless steel is assumed which is steel alloyed with chromium (Internation Stainless Steel Forum). The materials used in the production of stainless steel are assumed to be obtained and manufactured in Sweden.

Manufacturing, Acquisition, and Transportation

One of the largest iron ore reservoirs in the world is in a mountain in Kiruna, Sweden owned by a company called LKAB -Luossavaara-Kiirunavaara AB - (The history of LKAB). The mountain was assumed to hold 602Mt reserve at 48.5% iron since the end of 2008. With a large reserve it is assumed to be the main supplier of iron in Sweden (Kiruna Iron Ore Mine, Sweden). The iron produced by LKAB is largely used in the production of steel at 77% of the iron ore products are utilized by Europe’s steelworks (LKAB). The second step of the manufacturing process is carried on by SSAB - Svenskt Stål AB – which means Swedish Steel. This company is specialized in the processing of raw materials into steel with a history that dates back to 1878, and it is located in Stockholm, Sweden (SSAB in brief). The last step of the manufacturing of stainless steel is assumed to be carried on by Outokumpu. Outokumpu is a company specialized in the production of stainless steel with its largest production facility located in Avesta, Sweden. Outokumpu’s steel supply is mainly recycled locally, but Sweden doesn’t have a sustained chromium line of production (Outokumpu in Sweden). 41% of the chromium supply in Sweden is imported from South Africa. There was no possible way to identify the transportation method of the imports or the distribution between the previously mentioned companies given their customer confidentiality regulations. Due to shortage of information the environmental impact of the transportation correlated to the product was not concluded. However, the manufacturing process have its byproducts associated with each step.

Recycle and Waste

Because stainless steel is the result of a number of processes each process was investigated to find the waste associated with it. In the first step, iron ore smelting, “slags” were mentioned. A slag is the by-product of the smelting of the iron ore. Slags in the iron smelting process usually compose of metal oxides and silica oxides that resulted from the limestone reacting with the molten iron (User Guidelines for Waste and Byproduct Materials in Pavement Construction). Slag is recycled through utilizing it in different applications rather than reusing it in the production of steel. Different types of slag that are the result of different type of steel processing have various applications. Given the shortage of information on the product the application of the resulting slag could not be concluded (Slag, a very usable by-product). LKAB also reports a decreases in the carbon dioxide emitted from the blast furnace by 320 kg. This blast furnace process was also reported to save 1,7 GJ per tonne of steel which correlates to the reduction of carbon dioxide emission (LKAB).

While emissions and by-products are associated with the production of stainless steel the material is considered environmental friendly still. Stainless steel does not degrade when processed, which means that it can be reused in the production of more stainless steel products without limitations. Stainless steel is highly resistant to corrosion, this property results in a longer life expectancy of the product. Reduce the need of periodic replacement substantially. Stainless steel is usually recycled at a rate of 60%. But it has been reported by Outokumpu that the recycle rate could go up to 90%. Stated in Outokumpu’s stainless steel life cycle’s report “Stainless steel can be recycled infinitely to the same high quality material.” The long life expectancy of the product concludes a highly environmental friendly product (Stainless steel life cycle).

Conclusion

All of the information obtained about the products life cycle were based on the assumptions made in the research. While having a substantial amount of by-products and carbon dioxide emission, the production line of stainless steel is to be considered environmentally friendly. The high recycle rate and the applications of the by-products of stainless steel can translate into the product of interest. The life cycle of stainless steel used in the manufacturing of the product concludes small impact on the environment.

Bibliography

"How steel is made: a Brief summary of a Balst Furnace." n.d. Keen Ovens. 13 March 2016.

"Ikea company information." n.d. Ikea. 13 March 2016.

"Ikea toilet accessories." n.d. Ikea. 13 March 2016.

"Internation Stainless Steel Forum." n.d. World Stainless. 13 March 2016.

"Kiruna Iron Ore Mine, Sweden." n.d. Mining Technology. 13 March 2016.

LKAB. "Annual and Sustainability Report 2014 in Brief." 2015.

"Mega Factories: Ikea." n.d. National Geographic Channel. 13 March 2016. <http://www.natgeotv.com/ca/megafactories/ikea-facts>.

"Outokumpu in Sweden." n.d. Outokump. 13 March 2016.

"Slag, a very usable by-product." 15 June 2015. Jernkontoret: The Swedish STeel Producers' Association. 13 March 2016.

"SSAB in brief." n.d. SSAB. 13 March 2016.

"Stainless steel life cycle." n.d. Outokumpu. 13 March 2016.

"The history of LKAB." n.d. LKAB. 13 March 2016.

"User Guidelines for Waste and Byproduct Materials in Pavement Construction." Material Description. n.d.

Sydney Woo

Professor Cogdell

Design 40A

March 14, 2016

Research Project

Life Cycle Analysis of Stainless Steel Toilet Roll Holder

The multinational company IKEA is most commonly known as a company that distributes a wide and unique variety of ready-to-assemble furniture, appliances, and home accessories. Since the vast majority of their products are composed of wood, information on the life cycle of stainless steel products is yet to be explored. IKEA’s GRUNDTAL toilet paper roll holder is designed as one of the most simplistic, yet it is the most common toilet roll holder among households. The holder itself is composed entirely out of stainless steel, so the majority of embodied energy is found in the manufacturing and transportation process of the stainless steel holder. Through the examination of the key energy stages of manufacturing and distribution and transportation in the life cycle of IKEA’S GRUNDTAL stainless steel toilet paper holder, we will gain an insight to how this product serves to be people and planet positive as a major global retailer product.

The Acquisition of Raw Materials:

Iron mixed with carbon to produce steel is the main component of stainless steel. In acquiring the raw materials in order to produce the bulk of stainless steel, kinetic energy is provided in drilling pipes that allows the rock that holds iron to be extracted from the ground. Chemical energy and kinetic energy of man and hydraulic machinery is then used so it can be taken to grinding concentration mills and thoroughly separated as a raw material.

Manufacturing and Processing:

Primary production of steel usually involves using a blast furnace to produce molten iron from iron ore, coal, and coke, using fluxing agents such as limestone to remove any remaining impurities. Both electric and thermal energy is used to melt the raw materials of iron ore, nickel, and chromium together through a breakdown of gases in an electric furnace (8-12 hours of intense heat). Reduction of the iron ore is the largest energy-consuming process in the production of primary steel. Open-hearth furnaces are used in primary steelmaking with energy intensities of 3.9-5.0 GJ/t. The molten metal is then mechanically cut using shearing knives or flame cutters, chemically refined, and then cast into semi-finished forms. Bonding the stainless steel together to form toilet roll holders is done using both resistance welding and fusion welding. Many different energy sources can be used for welding including gas flame, lasers, friction, and an electric arc.

Transportation and Distribution:

IKEA has gradually made efforts to improve the efficiency of product transportation in the way that the company often redesigns its product range and shipments in order to minimize the number of journeys and distances traveled. Packaging the stainless steel products and the way they are packed into delivery trucks play such an important role in the efficiency of transporting goods. Specifically, this impacts the product transport system because the more products their company can fit into a massive container, the fewer journeys they need to make it to distribution sites. Vehicle transportation in cars and trucks consume more than 60% of energy used for total transportation. Moving the products to and from IKEA stores contributes to local emissions. Similar to the energy that is invested in extracting raw materials from the ground to make the stainless steel in IKEA toilet paper holders, wells are drilled to obtain petroleum rock oil from fossil fuel reservoirs. Diesel fuel is produced mainly from this source of petroleum and is used to fuel long-haul trucks that transport the stainless steel holders to IKEA distributors. The diesel fuel that is needed for automotive transportation engines has a thermal and extractable energy density of 35.8 MJ/L. One gallon of diesel fuel has 113 percent of the energy of one gallon of gasoline. Although using diesel is more energy-efficient than using gasoline, IKEA began replacing these conventional fuels in long-haul trucks and using liquefied natural gas instead. In Spain, all the trucks that replenish stock in Valencia now use liquefied natural gas. IKEA is continuing the expansion of this liquefied natural gas in order to aim for a more environmentally efficient means of transportation.

Recycling is the primary energy efficient technology for stainless steel manufacturing. Primary production, in which steel is made from iron ore, is energy intensive. However, secondary production of steel, which involves the use of recycling scrap to make steel, is much more energy efficient. Chemical and kinetic energy are used in hydraulic machinery to cut and break down used steel toilet roll holders into smaller pieces. These small pieces are then melted again using electric and thermal energy in order to be reused for alternative manufacturing. Steel is melted in a furnace at approximately 1370 degrees Celsius. Ultimately, this is one of the most important and admirable qualities about this stainless steel product – it is able to be recycled after it has been thoroughly used by consumers. In terms of energy reduction, the Environmental Protection Agency estimates that secondary steel production uses about 74 percent less energy than the production of steel from initial iron ore. Because the entire holder can be recycled and used all over again, this is an incredible step in the product’s journey of being planet positive.

All in all, the energy that is embodied and saved in all aspects of the life cycle of IKEA’s GRUNDTAL stainless steel toilet roll holder demonstrates a step in the right direction of becoming even more people and planet positive. Companies are constantly questioning the energy that is included in raw material acquisition, production, transportation, and waste management in order to determine new and improved methods for the life cycle of this stainless steel product. The aim to use more sustainable resources for raw materials and fuel is gradually being discovered in order to collaborate with different suppliers and hopefully encourage their overall environmental impacts and efficiency in the future.

Source Citations

"About IKEA." Sustainability Reports. N.p., n.d. Web. 14 Mar. 2016. <http://www.ikea.com/ms/en_GB/about_ikea/read_our_material/index.html>.

Li, Li, Yalin Lei, and Dongyang Pan. "Study of CO2 Emissions in China’s Iron and Steel Industry Based on Economic Input–output Life Cycle Assessment." Nat Hazards Natural Hazards 81.2 (2015): 957-70. Web.

Guilbert, John M., and Charles F. Park, Jr. 1986. The Geology of Ore Deposits, W.H. Freeman and Company, New York, New York.

N.p., n.d. Web. <http://www.eia.gov/todayinenergy/detail.cfm?id=9991>.

Price, L., J. Sinton, E. Worrell, D. Phylipsen, H. Xiulian, and L. Ji. "Energy Use and Carbon Dioxide Emissions from Steel Production in China." Energy 27.5 (2002): 429-46. Web.

Quader, M. Abdul, Shamsuddin Ahmed, S.z. Dawal, and Y. Nukman. "Present Needs, Recent Progress and Future Trends of Energy-efficient Ultra-Low Carbon Dioxide (CO2) Steelmaking (ULCOS) Program." Renewable and Sustainable Energy Reviews 55 (2016): 537-49. Web.

"U.S. Energy Information Administration - EIA - Independent Statistics and Analysis." Recycling Is the Primary Energy Efficiency Technology for Aluminum and Steel Manufacturing. N.p., n.d. Web.

U.S. Environmental Protection Agency, Industrial Technology Division. 1985(b) (September). Guideline Manual for Iron and Steel Manufacturing Pretreatment Standards. Washington, D.C.

Weiss, N.L., (editor). 1985. SME Mineral Processing Handbook, Volumes 1 and Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc. New York, New York.

Worrell, Ernst, N. Martin, and L. Price. "Energy Efficiency and Carbon Dioxide Emissions Reduction Opportunities in the U.S. Iron and Steel Sector." (1999): n. pag. Web.

Patti Cai

Professor Cogdell

DES40A- Section03

Winter2016

Research essay

Grundtal Toilet Roll Holder Life Cycle—Wastes

Grundtal Toilet roll holder is the simplest one in design in Ikea’s toilet roll holder series but is also the most applicable and durable one. The entire holder, combining the plug, tube and wall bracket, is made of stainless steel. My research focuses on wastes generated from the whole life cycle of this stainless steel product, which includes wastes from its raw material’s mining process, its fabricating process, and its final recycling process.

Firstly, why does the producer or designer use stainless steel as the basic material of their product? When choosing the material for production placed in the bathroom, the producer should be first of all considering the material’s ability on moisture resistance. Being long placed in a humid environment, metals will be corroded; the deterioration or breakage of metals inside products will cause them losing their original uses. So an anti-corrosive and moisture-resistant material is needed for bathroom appliance.

Stainless steel is the material that perfectly matches these requirements. Its remarkable resistance to corrosion is due to a chromium-rich oxide film which forms on the surface. When ordinary carbon steel is exposed to rain water, for example, it corrodes forming a brown iron oxide, commonly called rust, on the surface. This is not protective and eventually the entire piece of steel will corrode and be converted to rust. But when enough chromium (more than about 10%) is added to ordinary steel, the oxide on the surface is transformed - it is very thin, virtually invisible and protective in a wide range of corrosive media. (Coates, 2016).

The first step of the whole production of Grundtal toilet paper holder is the mining process of ore materials. After that, ores are produced to iron and then to stainless steel. Wastes are generated from the very first step of the production chain. Extraction and beneficiation process produces iron or steel. "Extraction" is defined as removing ore material from a deposit and encompasses all activities prior to beneficiation. "Beneficiation" of iron includes concentration, generally by physical removal of unwanted gangue; also considered beneficiation is the regulation of product size or other steps such as agglomeration to improve its chemical or physical characteristics prior to processing. Most ores extracted today, however, must undergo a number of beneficiation procedures to upgrade the iron content and prepare the concentrate for the blast furnace. Technological advancements at blast furnace operations require ore feed of a specific size, structure, and chemical make-up for optimum efficiency (Weiss, 1985)

So it is inevitable that the iron ore extraction and beneficiation process discharge various kinds of wastes and other materials: Waste rock, wastes from magnetic separation, milling wastes, flotation wastes, and mine water. Each kind of waste has its own recycling or managing method accordingly:

- Waste Rock is the material that overlies the ore body and the other rock that has to be removed to gain access to the ore. The quantity and composition of waste rock vary greatly between sites. These wastes contain minerals associated with the ore body and host rock. The materials can occur in a wide range of particle sizes owing to variations in ore formations and differences in mining methods. In many operations, waste rock is disposed of in piles located near the mine (Van Ness 1980). It also can be used in dams or other on- or off-site construction. Overburden and waste rock removed from the mine are stored or disposed of in unlined piles onsite. These piles may also be referred to as mine rock dumps or mine dumps. As appropriate, topsoil may be segregated from overburden and mine development rock, and stored for later use in reclamation and revegetation. These dumps are generally unsaturated and provide an environment that can foster acid generation if sulfide minerals, oxygen, and water are present. However, in Minnesota and Michigan, where most crude iron ore is produced, sulfide-bearing minerals are present in only one unique geologic environment, according to the American Iron Ore Association (Guilbert 1986), so acid generation should not be a problem elsewhere. Ore is also stored in piles at the mine or mill before beneficiation.

- For milling dust, most mills use a wet milling operation and employ water to control dust from crushing and grinding. Slurried value-bearing process water from dust control contains both suspended and dissolved solids. The solid content of the slurry varies with each operation, ranging between 30 and 60 percent. The dust control slurry is typically pumped to a ball mill overflow/hydro cyclone feed sump for further beneficiation (U.S. EPA 1976)

- Magnetic separation wastes and material is the primary wastes from magnetic separation are tailings made up of gangue in the form of coarse- and fine-grained particles and waste water slurry in the case of wet separation. Particulate wastes from dry separation may also be slurried. Following separation of solids in a thickener or settling pond, solids are sent to a tailings impoundment and most of the liquid component can be recycled to the mill or discharged if water quality criteria are met.

- Flotation wastes and materials discharge from a typical floatation cell system is mostly gangue material and small quantities of unrecovered iron minerals. The liquid component of flotation waste is usually water, along with any remaining reagents not consumed in the flotation process. The liquid component may then be used in other mining activities as needed or discharged if water quality criteria are met. The characteristics of tailings from the flotation process vary, depending on the ore, reagents, and processes used.

- Gravity concentration wastes and materials from gravity concentration are mainly tailings. Tailings are characterized by fine particle size and varying mineralogical and chemical composition (Aleshin 1978). Tailings typically take the form of a slurry consisting of water, with solids from flotation, magnetic separation, and/or agglomeration. This material has minimal value at present but is produced in extremely large quantities. The solid content of this kind of slurry varies with each operation, ranging between 30 and 60 percent. Following the separation of solids, process water may be recycled to the mill or discharged if water quality criteria are met.

- Agglomeration Wastes and Material contains carbon dioxide, sulfur compounds, chlorides, and fluoride metals and other ores. These wastes are usually collected using cyclones, electrostatic precipitators, and scrubbing equipment and create both dry and slurry forms of waste. The waste is commonly combined with waste water generated during other production operations for treatment (typically settling and/or thickening). Solids are returned for recycling through the process, and the liquid component can be recycled to the mill or discharged (U.S. EPA 1985b).

- Mine water consists of water that collects in mine workings, both surface and underground, as a result of inflow of rain or surface water, and ground water seepage. As discussed previously, mine water may be used and recycled to the beneficiation circuit, pumped to tailings impoundments for storage prior to recycling or for disposal, or discharged to surface water under an NPDES permit. (Technical Resource Document, 1994)

After raw materials are extracted and beneficiated, they are processed into iron and then into stainless steel, through the furnacing and fabrication processes, more wastes are generated at the same time. It is estimated that wastes containing over 20 million lb of chromium and 8 million lb of nickel are generated annually in the production of stainless steel in the United States. These wastes, consisting of flue dusts, swarfs and mill scale are virtually all sent to dumps and landfills because of the lack of an acceptable recycling technology. However, the Bureau of Mines of the United States Department of the Interior, whose activities include conservation of mineral resources by the recovery of metal values from industrial wastes, developed a method for recovering over 80 % of the chromium and 90 % of the iron and nickel contained in pelletized mixtures of these stainless steel wastes. The Bureau's two-stage recovery technique relies on an initial reduction with carbon contained in the pellets, during meltdown in the arc furnace. This is followed by an addition of ferrosilicon to recover further chromium from the slag. The result is a master alloy suitable for recycling by charging to commercial stainless steel heats. In addition to offering a method for recovery of wasted critical metals, this procedure also helps to solve problems of storage and waste disposal, particularly of electric furnace bag house dusts. (Powell, 1975; Barnard, 1977)

Finally, after Grundtal Toilet roll holder is being used and disposed of, there are still five more steps needed to actually recycle the product, which are sorting, baling, shearing, media separation and melting. Most alloys are very similar in appearance. Sophisticated identification technologies, including X-ray spectrometry, are used to separate and prepare each type. Recycling stainless steel is a similar process to the one used for other ferrous metals:

- Sorting: Because many forms of stainless steel are non-magnetic, this metal cannot be easily separated from other recyclables in a recycling facility with magnetic belts.

- Baling: Stainless steel products are compacted into large blocks to improve ease of handling and transport.

- Shearing: Hydraulic machinery capable of exerting enormous pressure is used to cut thick heavy stainless steel into smaller pieces.

- Media separation: Shredders incorporate rotating magnetic drums to separate ferrous metals from other materials. Further separation is achieved using electrical currents, high-pressure air flow, and liquid floating systems.

- Melting: The recovered materials are melted together in a furnace. This process is determined by the level of purity necessary for the future applications of the secondary raw material. The melted stainless steel is then poured into casters and shaped into ingots or slabs. Later on, they can be rolled into flat sheets that are used to manufacture new products. (BIR, 2016)

Conclusion:

After doing this research, it becomes clear to me that when we considering waste is not only about the finally disposed product, but also about every kind of waste and material coming out during the whole production chain. Also, in order to achieve sustainability, producers should pay attention not only to the recycling method associated with the end product, but to every step combined in the whole life cycle.

Bibliography:

Gary Coates, Technical Director, Nickel Institute and Dr. David Jenkinson, Director Nickel Institute Australasia. “What Is Stainless Steel?” Web. 11 Mar. 2016. <https://web.archive.org/web/20060924043735/http://www.nickelinstitute.org/index.cfm/ci_id/11021.htm>.

Weiss, N.L., (editor). 1985. SME Mineral Processing Handbook, Volumes 1 and 2. Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc. New York, New York.

Van Ness, M., (editor). 1980. Proceedings of the 7th. Mineral Waste Utilization Symposium. Cosponsored by the U.S. DOI, Bureau of Mines and IIT Research Institute. Chicago, Illinois.

Guilbert, John M., and Charles F. Park, Jr. 1986. The Geology of Ore Deposits, W.H. Freeman and Company, New York, New York.

U.S. Environmental Protection Agency, Industrial Environmental Research Laboratory. 1976 (June). Metals Mining and Milling Process Profiles with Environmental Aspects. Prepared by Battelle Columbus Laboratories for U.S. Environmental Protection Agency. NTIS Publication No. 256394. Washington, D.C.

U.S. Environmental Protection Agency, Industrial Technology Division. 1985(b) (September). Guideline Manual for Iron and Steel Manufacturing Pretreatment Standards. Washington, D.C.

Aleshin, E., (editor). 1978. Proceedings of the 6th. Mineral Waste Utilization Symposium. Cosponsored by the U.S. Bureau of Mines and IIT Research Institute. Chicago, Illinois.

Technical Resource Document: Extraction and Beneficiation of Ores and Minerals. Washington, DC: U.S. Environmental Protection Agency, Office of Solid Waste, Special Waste Branch, 1994. Print.

H. E. Powell, W. M. Dressel and R. L. Crosby, Converting stainless steel furnace flue dusts and wastes to a recyclable alloy, Bu Mines RI 8039 (1975).

P. G. Barnard, W. M. Dressel and M. M. Fine, Arc furnace recycling of chromium-nickel from stainless steel wastes, Bu Mines RI 8218 (1977).

"- BIR - Bureau of International Recycling." - BIR - Bureau of International Recycling. Web. 12 Mar. 2016. <http://www.bir.org/industry/stainless-steel/>.