Design Life-Cycle

assess.design.(don't)consume

Saleh Oweis

Arianna Walker, Gustavo Resende

Design 40A

Professor Cogdell

Raw Material of Adidas Slides

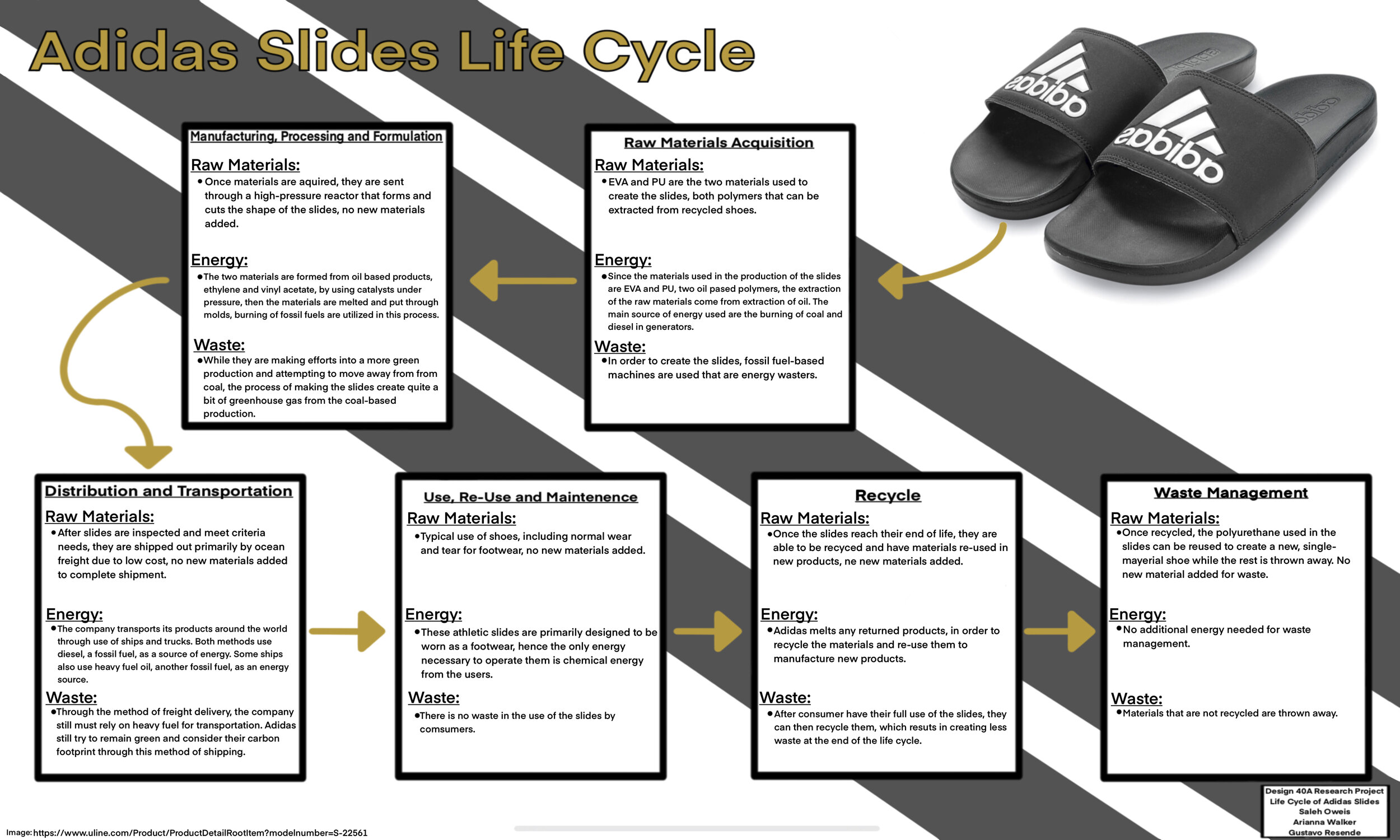

Adidas is a sportswear company that is recognized around the world with their notorious three stripes logo. Within their company they have many different products ranging from casual and athletic clothing to footwear for all different sports and lifestyles. From running shoes to soccer and football cleats, Adidas is known for providing top of the line footwear for any and every occasion. One specific product that has become more and more popular with both athletes and anyone who is looking for the best option in comfort and style is their slides, which are redesigned flip-flops that allows the owner to slide their foot in and out the footwear with ease. This style that adidas has adopted is not only an easy product to slip on and off, but also a stylish product that goes well with many outfit choices. Throughout this paper I will be going more in depth on the raw materials that Adidas use in order to produce the slides on a large scale while looking into the full life cycle of this product from extraction of raw materials to the recycling process of thrown away slides.

Using Adidas official website, it is specified that their slides are created from two distinct materials; EVA (Ethylene-Vinyl Acetate) for the footbed and PU (polyurethane) for the slides’ upper [7]. In more detail, EVA is a copolymer, which is a polymer derived from more than once species of monomers. In the case of EVA, those monomers are ethylene and vinyl acetate [4]. When combined at the right ratio, ethylene and vinyl acetate come together to make a plastic-like material that is both athletic and durable which for Adidas, is ideal for the outsole and upper band of the slides which will be seeing the most wear and tear for normal everyday use. The polyurethane that adidas use is a water-based version that becomes a foam-like material used in the footbed of the slides to provide comfort to the wearers of them while also providing a more environmentally friendly product overall. Polyurethane is also considered a polymer, created from the monomers isocyanates, polyols and an additive, hydroxybenzotriazole, which helps protect the foam against light degradation [11]. Now that there is some knowledge on the materials Adidas use to create these slides, we can move on to the topic of how these materials are extracted from the Earth and the manufacturing process they undergo to result in the product we recognize.

As for how these raw materials are extracted from the Earth, one resource that Adidas utilizes is reusing materials from recycled products. With the ability to reuse recycled products, the extraction of the materials needed to create slides is simplified. In order to extract these materials, Adidas turn to their numerous factories, which are located around the in Europe, Africa, America, and Asia, which has the most factories compared to the other continent [6]. However, when these materials are not extracted from recycled shoes, EVA and PU and created in a different process. As for the production process, Both EVA and PU are results of a high-pressure reactor that combines the monomers that make up the two materials, they are then transformed into their final shapes and are ready to be combined to create the slides [11]. Once the slides are made, the next step is to begin manufacturing on a larger scale in order to fulfill the popularity of the slides are. In order to provide for the demand these slides will have, machines are used in the factories to produce uniform products in the different sizes needed to consumers. Once these slides have been created to fit Adidas quality expectations, they are ready to start packing and shipping out around the world to be sold in a variety of different stores.

To fulfill these shipments from factories to shops, Adidas uses three mains kinds of transportation which are air, ocean freight and by land. Most shipments are transported by ocean freight due to that having the lowest cost and best shipping time. When prepping these slides for shipping, no new materials are added in order to maintain their shape during transportation [13]. This is because the materials used are both foam and plastic-like which don't need anything added in order for them to hold their shape. Once the products reached their main destination they are then sent out again by land in order to reach their respective stores in which they will be put on display and available for consumers to buy.

Once consumers purchase their own pair of Adidas slides, their use can differ from person to person. Some will use them as shower shoes in a setting such as college dorms where restroom facilities are shared between students. Others will use them as a “mediator” for the time between heading to a practice or game for a sports team and having to put on your particular footwear, meaning individuals will wear the slide to avoid having to wear shoes where they would have to tie and untie each time they have to switch to putting on the sports shoes. These people wearing slides instead of, for example, basketball shoes means their basketball shoes will last long due to the person not having to wear them out but having them on in the streets. The other way slides are used by consumers is for fashion and comfort, with Adidas being a such a well known company, wearing these slides have a nice look when paired with other adidas products such as soccer pants. They also provide a convenient option for footwear while also being comfortable enough to be chosen over sneakers for the day. Once that person has gotten all their miles out of the slides, most will turn to throwing them away or recycling them and look for a new pair. When looking for a way to get rid of their unwanted, an individual can decide on a few different ways to go about this. One option is a program that Adidas launched in 2012 which allows people to return their used pair of slides to be recycled by Adidas and turned into new products as stated previously when discussing extraction of materials [9]. The material that is lost likely to be reused is the polyurethane, which can be extracted and used a new single-material shoe which results in the cycling continuing for the next product made [8].

To reiterate the main topic of this essay, Adidas is a well known company that produces slides that are both convenient and comfortable. These slides are made from two distinct materials, polyurethane for the upper and outsole of the slides and ethylene-vinyl acetate for the footbed. Both these materials are composed of monomers, that when combined at the right ration become a sturdy and durable plastic and foam that makes up the slides. Once the slides are created and meet the expectations of Adidas, they are prepared for shipment to retail stores around the world. When shipping no new materials are added in order to preserve the slides. Adidas opt for ocean transport due to the lower cost of shipping method when compared to air or land freight. Once consumers purchase their own pair of slides, the way the slides can be used is up to them as the reason for purchasing a pair can differ from person to person. From using them as shower shoes to using them for sports and fashion, Adidas slides are a wonderful option when looking for a stylish and comfortable choice of footwear.

Bibliography

[1] “Adidas Group.” Adidas SER 2010 | Our Performance > Environment, http://sustainabilityreport.adidas-group.com/en/SER2010/our-performance/environment/Default.aspx.

[2] “Adidas Rolls Out New Environmental Strategy.” SGB Media Online, 29 Mar. 2011, https://sgbonline.com/adidas-rolls-out-new-environmental-strategy/.

[3] “Chemical Footprint.” Adidas, https://www.adidas-group.com/en/sustainability/products/chemical-footprint/.

[4] Entec Polymers. “Ethylene Vinyl Acetate Copolymer (EVA).” Ethylene Vinyl Acetate Copolymer (EVA) | Entec Polymers, www.entecpolymers.com/products/resin-types/ethylene-vinyl-acetate-copolymer-eva.

[5] “Extraction of Raw Materials.” Adidas Shoes Commodity Chain, 28 Apr. 2015, https://adidasshoescommoditychain.wordpress.com/extraction-of-raw-materials-2/.

[6] Grahame, Anthony, and University of Sussex. “What Countries Manufacture Adidas?” Career Trend, 19 Feb. 2019, https://careertrend.com/info-8187202-countries-manufacture-adidas.html.

[7] “Materials.” Adidas, https://www.adidas-group.com/en/sustainability/products/materials/.

[8] Moore, Kaleigh. “Adidas Ramps Up Sustainability Efforts With Increased Focus on Recycled Materials.” Adweek, Adweek, 23 July 2019, https://www.adweek.com/brand-marketing/adidas-ramps-up-sustainability-efforts/.

[9] Morgan, Clancy. “Adidas Is Turning Plastic Ocean Waste into Sneakers and Sportswear.” Business Insider, Business Insider, 2 Sept. 2019, https://www.businessinsider.com/adidas-sneakers-plastic-bottles-ocean-waste-recycle-pollution-2019-8.

[10] O'Connell, Liam. “The Adidas Group's Global Footwear Production 2008-2018.” Statista, 22 Mar. 2019, https://www.statista.com/statistics/227015/the-adidas-groups-footwear-production-worldwide/.

[11] “Polyurethane.” How Products Are Made,

www.madehow.com/Volume-6/Polyurethane.html.

[12] Raps, Daniel, et al. “Past and Present Developments in Polymer Bead Foams and Bead Foaming Technology.” Polymer, Elsevier, 7 Nov. 2014, https://www.sciencedirect.com/science/article/pii/S003238611401012X.

[13] “Transportation.” Adidas Shoes Commodity Chain, 29 Apr. 2015, https://adidasshoescommoditychain.wordpress.com/transportation/.

Gustavo Resende Coelho

Saleh Oweis, Arianna Walker

DES 40A - FQ 2019

Professor Cogdell

Adidas Athletic Slides: Embodied Energy

Nowadays, it is nearly impossible to become overwhelmed when shopping for a new pair of shoes, given all the different designs, technologies, and brands. Such phenomenon can be argued to be a result from the competition between multiple multinational companies, for instance, Adidas AG. Adidas is a multinational corporation known for its design and manufacturing of athletic clothing and accessories, whose mission statement is “to be the global leader in the sporting goods industry with brands built on a passion for sports and a sporting lifestyle” [1]. Having said that, the three stripe company is constantly researching and developing new types of shoes, whether that is to improve comfort and aesthetics, or simply to improve how efficient and environmentally friendly their life-cycles are. Among Adidas’ wide product portfolio, their athletic slides are widely common between both athletes as well as casual users, due to their simplicity, comfort, price, and efficiency. As a result of such demand, Adidas attempts to find efficient and sustainable ways to manufacture and transport its Adilette Cloudfoam Athletic Slides, in order to minimize energy use in all stages of its product lifestyle.

According to one of Adidas’ principles, the company “embraces creativity and diversity” when it comes to developing their brand and products, as they are “socially and environmentally responsible” for everything they do and make [2]. Having said that, the clothing corporation spends thousands of dollars every year in order to reduce energy waste, and efficiently use its resources in order to manufacture and deliver the best product they can to their customers. When it comes to the Adilette Cloudfoam Athletic Slides, Adidas does no different. From acquiring and transporting raw materials, to manufacturing, and finally recycling its products, the multinational attempts to find sustainable ways to minimize the embodied energy in each of the stages. Therefore, when designing manufacturing techniques, the company needs to stay creative and diverse, as innovation is key to finding ways to conserve energy.

Although the athletic slides in discussion are one of the company’s best sellers according to their website, the design is one of the simplest, as they are composed from two main materials, EVA (Ethylene-vinyl acetate) foam and PUR (Polyurethane Rubber) foam. When designing their products, Adidas heavily focuses on the materials to be used, as they dictate how the product can be used, and for how long. EVA, which has great properties when it comes to shoe making, as it is a great shoe’s sole option due to its “good cushioning properties”, as well as its ability to “withstand a massive amount of wear and tear” [3]. EVA is also very easily found, as it is widely available from hundreds of global suppliers [3]. PUR, on the other hand, is used for the slide’s upper band due to its tensile strength, toughness, flexibility, and cut resistance. Like EVA, PUR can also be widely found from hundreds of global suppliers [3]. Both materials are oil-based, which means petroleum needs to be acquired in order to process and manufacture them. The three striped brand, unlike many others, owns factories around the world which extract and process such oil in order to transform it into different types of plastics and rubbers. The extraction of crude oil from the ground is usually made with drilling rigs and wells, which usually are powered by diesel generators, using on average 20 to 30 cubic meters per day [5]. However, the company’s material choice lessens this energy consumption, as PU uses low energy moulding and EVA is “not energy intensive” [3]. Having said that, the company uses specific types of materials which can be easily found globally, requiring not much energy to transport, as well as specific types of materials which do not depend on energy intensive manufacturing processes.

As mentioned before, the two materials used in the design of the Adilette Cloudfoam Athletic Slides are oil based polymers which can be used in various manufacturing processes for product productions. EVA, being a thermoplastic, can be injection moulded, extruded, blow moulded, and thermoformed, giving the company many different ways to produce the same results. On the other hand, PUR can only be used in injection moulding, restricting the company from any other manufacturing methods [3]. Hence, in the production of the athletic slides, Adidas uses injection moulding in its factories in order to produce the different parts of the shoe. Although it is very hard to estimate how much energy is embodied in the injection moulding process due to the unknown factory capabilities and machine efficiency, it is possible to estimate it. Assuming that the machines have a medium efficiency with a part to maximum machine volume ratio of about 30, the electricity consumption is about 85 KWh/kg, or 3.05 MJ/kg (megajoules per kilogram) [4]. Although most of this energy is generated from the burning of fossil fuels, most likely coal, the company has made efforts to shift towards a greener energy. As a result of such an immense amount of energy, the manufacturing and processing phase of the product’s life cycle is the source of most of the embodied energy in such design.

When it comes to transporting their product, Adidas chooses sea freight as their main shipping method from overseas, along with trucks as their main local shipping method. This decision is mainly done due to the relative low price of the shipping method, as well as the location of factories in relation to their physical stores. The decision is also impacted by the company’s consideration regarding carbon emissions – “even though our products have to deliver, it does not mean they cannot be made in a sustainable way” [6]. For the most part, sea freights burn diesel or heavy fuel oil in order to feed their propulsion systems, which is known for contributing to global warming. However, when compared to airplanes, the maritime method creates about 98% less of greenhouse gases, according to a Defra (Department for Environment, Food and Rural Affairs) study [7]. An average ship carrying 2 tonnes of goods for a 5000km distance will produce the equivalent of 150kg of CO2 [7]. Therefore, although it is not the ideal scenario, Adidas uses shipping in an attempt to reduce their carbon emissions. Furthermore, when it comes to trucks delivering their goods from point to point, diesel is most likely used inside the engine. According to the Department of Energy, 1 gallon of diesel used is equivalent to 33.7 KWh of energy [8].

After the customer has purchased the product, and starts to use it, no energy is required in order to operate and maintain the shoes. These athletic slides are primarily designed to be worn as footwear, hence the only energy that is necessary to operate them is chemical energy from the users. Additionally, since these are so durable and strong, users rarely need to maintain it, and if they do so, all is done by hand for most of the time.

At the end of the product’s life cycle, Adidas focuses on recycling and reusing parts in order to produce more slides, or even other products. In 2012 the company launched a recycling program called “Sustainable Footprint”, which aims to raise consumer awareness and initiative. The program provides customers with the ability to bring their old shoes to different physical stores in order to recycle. The recycling of the athletic slides is possible due to the composition of the raw materials. Both polymers are easily recycled by heating processes, resulting in melting, and finally casting. Since both EVA and PUR are easily melted, due to their low melting points, not a lot of energy is required for recycling [3]. The heating process is mainly fed by coal or natural gas. In addition, in 2015, Adidas partnered with Parley for the Oceans in an initiative to recycle the plastic waste found in the oceans. The two companies have developed a few different shoes, and have so far sold millions of pairs [10].

In conclusion, although Adidas attempts to find ways to minimize the energy consumption in their operations, the product life cycle of Adilette Cloudfoam Athletic Slides, like most other products, is energy intensive. It is clear to observe which stages of the life cycle are the ones that consume the most energy, as raw material acquisition, manufacturing, and processing require massive different forms of energy, whether that is mechanical, electrical, or thermal. Furthermore, Adidas has put great amounts of resources in order to reduce carbon emissions, as they have been attempting to shift towards greener energy. In the past decade, the company has observed a “30% reduction in carbon emissions per square meter across the company” [11].

Bibliography:

[1] “Adidas Mission Statement 2019: Adidas Mission & Vision Analysis.” Mission Statement Academy, Adidas, 11 Oct. 2019, mission-statement.com/adidas/.

[2] “Adidas Group Strategic Business Plan Booklet.” Adidas, 2012. adidas-group.com/media/filer_public/2013/07/31/adidas_gb_2012_en_booklet_en.pdf

[3] Lefteri, Chris. Materials for Design, Laurence King Publishing, 2014. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=1876185.

[4] Elduque, Ana, et al. “Electricity Consumption Estimation of the Polymer Material Injection-Molding Manufacturing Process: Empirical Model and Application.” MDPI, 16 Sept. 2018.

[5] “How to Power Offshore Oil & Gas Rigs? Current & Future Trends.” New & Used Generators, Ends and Engines | Houston, TX | Worldwide Power Products, 2019, www.wpowerproducts.com/news/how-to-power-offshore-oil-rigs/.

[6] “Environmental Approach.” Adidas, Adidas, 2019, www.adidas-group.com/en/sustainability/compliance/environmental-approach/#/umgang-mit-dem-klimawandel/.

[7] Siegle, L. "How ethical is shipping goods by sea." The Guardian. Retrieved September 5 (2014): 2017.

[8] Loveday, Steven. “What Is MPGe?” U.S. News & World Report, U.S. News & World Report, 5 July 2018, cars.usnews.com/cars-trucks/what-is-mpge.

[9] “End-life.” Adidas Group, n.d. Web. 28 Apr. 2015, http://www.adidas-group.com/en/sustainability/products/end-life/

[10] Ismael, Amir. “Adidas Sold 1 Million Pairs of Sneakers Made from Ocean Waste in 2017 - Now the Company Is Introducing a Line of Recycled Clothing and Taking Steps to Become Even More Sustainable.” Business Insider, Business Insider, 19 May 2018, www.businessinsider.com/adidas-parley-outdoor-collection-sustainability-2018-5.

[11] Pratt, David. “Adidas Targets Annual Energy Consumption with New Sustainability Plan.” Current, 18 Apr. 2016, www.current-news.co.uk/news/adidas-targets-annual-energy-consumption-with-new-sustainability-plan.

[12] "Transportation Energy Futures Series." Energy Analysis:. US Department of Energy, n.d. Web. Feb. 2013.

[13] Loulos, Vasilis. "Strategic initiatives for sustainability performance." (2016).

[14] Morgan, Clancy. “Adidas Is Turning Plastic Ocean Waste into Sneakers and Sportswear.” Business Insider, Business Insider, 2 Sept. 2019, www.businessinsider.com/adidas-sneakers-plastic-bottles-ocean-waste-recycle-pollution-2019-8.

[15] “U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Use of Energy for Transportation - U.S. Energy Information Administration (EIA), 10 May 2019, www.eia.gov/energyexplained/use-of-energy/transportation.php.

[16] “How Adidas Makes Shoes.” Page Redirection, 28 Oct. 2017, sneakerfactory.net/sneakers/2017/10/how-adidas-makes-shoes/.