Design Life-Cycle

assess.design.(don't)consume

Lifecycle Assessment of an Umbrella

Catherine Morales-Sandoval

Professor Cogdell

Design 40A

15 March 2018

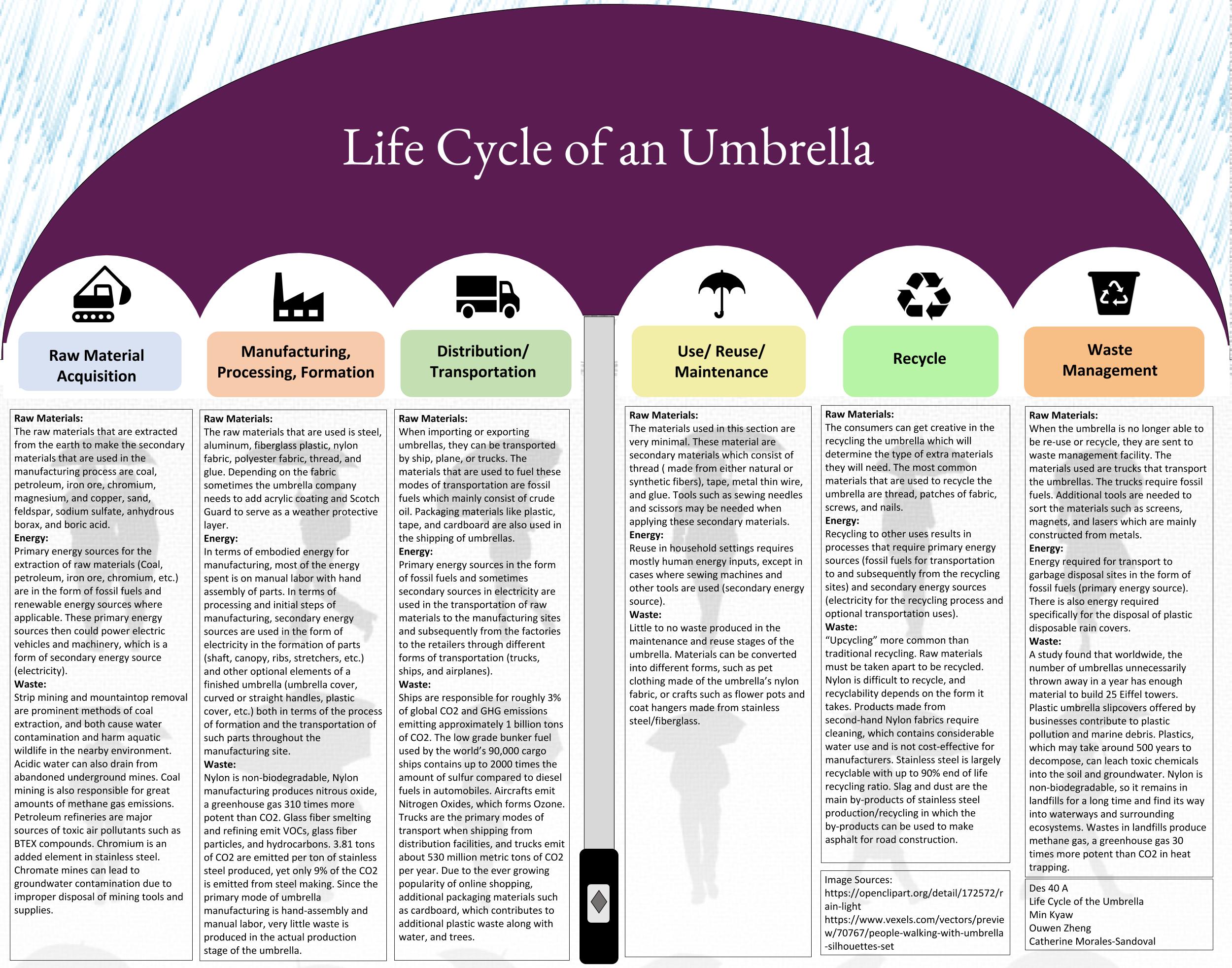

Raw Materials: Umbrella

Umbrellas have come a long way since the invention of them. The umbrellas during this time were meant to shade a person from the sun. Now the umbrellas serve to protect the people from the rain which means the umbrellas need to be durable and study to withstand weather conditions. The umbrellas we used today are composed of many parts that come from the extraction of raw materials to the formation of the umbrella, which the manufacturers’ have authority over. Once the umbrellas are in the hands of the consumers, the consumers carry on the life cycle of the umbrella. When we compare the bulk of the materials used in earlier stages of the umbrella’s life cycle to the later stages, we find that the consumers use the least amount of materials which can be sustainable if the consumers choose to add these materials instead of purchasing new umbrellas.

The umbrella has many different components. What makes up the umbrella are the shaft, runner, stretcher, rib, and canopy (“Umbrella”). These components consist of secondary raw materials. The secondary raw materials that are typically used to make the shaft are steel, aluminum, fiberglass, or plastic (“Umbrella”). The runner, which moves along the shaft to allow for the umbrella to open or closed, is either made from metal or plastics (“Umbrella”). The ribs and stretchers, which form the u-shape of the umbrella, are made of steel or another type of metal (“Umbrella”). As for the canopy, the material used is either nylon or polyester (“Umbrella”). All these materials are not naturally found in the earth and ready to use. These materials require a series of steps before manufactures can purchase them and used them in the production of the umbrellas.

Many of the umbrella components can be placed under the category of plastics. Plastics are something thought of as one material; however, according to Chris Woodford, in “Plastics: A simple introduction,” there are many different types of plastics. For example, nylon and polyester stem under the category of plastics because of the chemicals that make up these materials. These chemicals depend on the chains of polymers. Polymers are composed of repeated monomers that mainly consist of carbon and can be bonded with hydrogen, oxygen, sulfur, and nitrogen (Woodford, “Plastics”). The raw materials that go into creating polymers are carbon based which consist of materials like coal, petroleum, and natural gas (Woodford, “Plastics”). When the raw materials, such as crude oil, are extracted, it goes through a heating processing known as fractional distillation in which different sizes are hydrocarbons are separated and extracted (Woodford, “Plastics”). To make nylon, a process called condensation polymerization is used which joins two hydrocarbon chains, adipic acid and hexamethylene diamine, and removes a water molecule to make a larger hydrocarbon chain (Woodford, “Nylon”). As for polyester, a process called polymerization is used. This process is a chemical reaction consisting of a petroleum by-product, alcohol, and carboxylic acid which mix to form a monomer compound called ester (“How is Polyester Made?”). Other chemicals are added when making polymers such as colorants which allow plastics to be different colors, plasticizers which allow plastics to be flexible when shaping, stabilizers which prevent the plastics from damaging due to heat or sunlight, and fillers which use low-cost minerals instead of expensive oil-based hydrocarbons (Woodford, “Plastics”). Once these plastics are made they are then heated and are stretched to make thin fibers which are used as thread. Polyesters fibers can be combined with cotton or wool by spinning them together to make a different thread (“How is Polyester Made?”). The threads can then be sewn together to make what is known as nylon and polyester fabrics.

Stainless steel can be used as the shaft of the umbrella. Stainless steel is an alloy, meaning it is composed of more than one metal. To create stainless steel, we need to combine different metals. Stainless steel is composed of iron-based alloys consisting of chromium and carbon; stainless steel may also contain nickel, molybdenum, manganese, silicon, and copper (Cross et al). The different metals are then combined to create stainless steel which then goes through the process of “welding, grinding, cutting, polishing, and forming” (Cross et al). During the welding process, the metals are melted together at high temperatures. After the metals are combined, they go through a series of heating and cooling to get the desired structure of steel (Stainless Steel). Stainless steel may go through additional steps once the manufacturer receives the material to reshape to their desired state.

Fiberglass is another secondary raw material that can be used in the frame or shaft of the umbrella. Fiberglass mainly consist of sand, but can include chemicals such as “feldspar, sodium sulfate, anhydrous borax, and boric acid” (EPA). These raw materials need to be heated at high temperatures which depending on the type of heat application can be fueled by either gas or oil (EPA). The use of fiberglass is more common in larger golf umbrellas than hand umbrellas.

The construction of the umbrella consists of combining all the secondary materials together. Workers mostly do this process in assembly all the parts together (Admin). The added materials that go into assembling the umbrella are screws, thread, glue, and thin metal wire (Admin). Sometimes the nylon and polyester fabric that is used already have an “acrylic coating on the underside and a Scotch Guard coating on top” depending on the warehouses the umbrella companies get their fabric from (“How Umbrellas are Made”). If the umbrellas do not have a coating on them the umbrella company will add it onto the umbrella (Admin). It is not said as to which type of thread is used in the umbrella companies; however, there are two types that they can use which are natural or synthetic fiber. If the thread is made from natural fibers, the materials used can either be cotton, wool, silk, or linen; however, if the thread is made of synthetic fibers, the material used is either rayon, polyester, or nylon (“Let's Talk About Thread”). Thread is used to sew the fabric together. However, before the panels are sewn together a machine needs to cut the fabric into individual panels such that they curve to the shape of the rib (“Umbrella Making Process”). Once the canopy is ready, a metal ferrule is used along with glue and is glued through “the tip of the umbrella that passes through the canopy” (“Umbrella Making Process”). The handle, which can be made from plastic or metal, is attached to the shaft by using glue or screws (“Umbrella Making Process”). At the tips of the ribs, once the canopy is attached to the ribs using wire or thread, plastic can be used to cover the ends. If the plastic is attached to the ends, then they can be glued, screwed, or sewn on at the tips of the ribs (“Umbrella Making Process”). After the umbrella has the canopy, ribs, stretchers, shaft, and handle attached, they are ready to be packaged and distributed for consumer consumption.

Umbrellas are manufacture in different parts of the world. Most of the manufacturers of umbrellas seem to come from China (“EUROPAGES”). There was little information on how the umbrellas are package when sent to a department store. Hfumbrela, an umbrella company based in China, did list what they did after they finish creating a set of umbrellas. The umbrellas are pack into cartons and typically there are five “inner cartons in each outer carton” which each carton containing sixty umbrellas (Admin). It is assumed other manufactures go through a similar process in using carton and some form of plastic to package the umbrellas. As for online consumer purchase, the umbrella comes in a cardboard box or a plastic packaging depending on the size of the umbrella. The mode of transport to export umbrellas to different regions of the world is by using cargo ships, aircraft, trucks, and trailers. The fuel source that is used to fuel these mode of transport is crude oil which is process and refined to become diesel (“How Is Diesel Fuel...”). Once the umbrellas are shipped out, the consumers continue the life cycle of the umbrella.

The umbrella does not require many new secondary materials when trying to prolong its life. Depending on what part of the umbrella gets damage there may be a way to fix it. If the canopy of the umbrella gets torn, the consumer can use a piece of similar fabric to patch over the tear, or depending on the size of the tear, thread can be used instead which will require minimal stitching (“How to Repair an Umbrella”). Over time the stretchers may get loose, to fix this, thin metal wire can be used to strengthen the connections between the stretcher and ribs (“How to Repair an Umbrella”). When the umbrella passes its life expectancy, such that it can no longer be repaired, people can recycle the materials before sending it to the landfill.

Umbrellas may seem non-versatile since they are initially intended to shield people from the rain. However, people have come up with innovative ways to reuse the materials. People mainly reuse the fabric. The ways people reuse the fabric are by creating clothing, bags, pillow cases, and larger fabric canopies (Cathy). The added materials needed to create something new using fabric is a sewing machine which requires thread (“How to make a reusable grocery bag...”). The metal frame can also be reused to make household items. For example, a magazine rack can be made by adjusting the metal frames like a box like structure (Cathy). People have also use the frame as decoration or art. Other materials that are possibly used in attaching metals together are thread, glue, tape, and screws.

It’s up to the consumers discretion on how they want to make use of the materials. According to Valentina Palladino in “Push Back Against the Elements with New Flexible, Super-Strong Umbrella,” a study done by Ginkgo stated that the number of umbrellas sent to the landfill is enough to build 25 Eiffel Towers. According to the story written on “Ginkgo umbrella,” “about 1 billion umbrellas are broken, lost, and improperly disposed of” every year. It seems that the umbrellas aren’t reaching its optimal efficiency such that manufacturers are putting in multiple amounts of materials for it to be wasted due to consumer interaction with the umbrella. Although, the consumer does not control what decisions the manufacturers take in choosing the material, they can improve the effects of what happens afterward when the umbrella reaches the end of its life cycle.

Umbrellas tend to just be throw in the landfill, but there are different options that can be taken to properly disposed of umbrellas. An umbrella is mainly composed of plastics and metals. What the consumer can do is properly separate the material and place them in their respective recycling bin. This way when the waste goes through the series of steps at the waste management facilities, the materials will be sorted to its respective categories. According to Katie Peek in “How It Works: Inside the Machine That Separates Your Recyclables,” the facilities use large “automated system of conveyor belts, screens, magnets, and lasers” to separate the material from plastic, metal, and paper. The machines used are mainly composed of metals materials. Additional materials that go into waste management is fossil fuels to power the trucks and mobile machines that are used to transport the materials

After following the umbrella from cradle to grave, the amount of raw materials used before the umbrella gets to the consumer is far greater than the amount that is used when the consumer has control over the umbrella. Although the consumer does not make the decisions in which materials are used, they can help limit the waste we send to the landfill by breaking down the components. Since umbrellas consist of more than component, a future improvement in the design of the umbrella could be to limit the amount of component pieces used which could possibly help consumers in the disassembly of the umbrella.

Bibliography

Admin. “Umbrella Manufacturing Process.” Hfumbrella, hfumbrella, 30 Jan. 2017, www.hfumbrella.com/umbrella-manufacturing-process-2/.

Cathy. “35 Ways To Reuse and Recycle Umbrellas.” Green Eco Services, Green Eco Services, 1 Mar. 2011, www.greenecoservices.com/35-ways-to-reuse-and-recycle-umbrellas/.

Cross, H. J., J. Beach, et al. Manufacture, processing and use of stainless steel. A review of the health effects. Bruxelles, Belgium, EUROFER, Euroepan Confederation of Iron and Steel Industries. Jan. 1999, www.worldstainless.org/Files/issf/non-image-files/PDF/1999HealthEffectsofStainlessSteels.pdf.

EPA.“AP-42, Fifth Edition, Volume I Chapter 11:Mineral Products Industry.” EPA, Environmental Protection Agency, 27 Sept. 2016, www3.epa.gov/ttn/chief/ap42/ch11/final/c11s13.pdf

“EUROPAGES - umbrella manufacturer.” Umbrella manufacturer companies, EUROPAGES, www.europages.co.uk/companies/umbrella%20manufacturer.html.

“Ginkgo umbrella.” Indiegogo, Indiegogo, Inc., 10 Apr. 2013, www.indiegogo.com/projects/ginkgo-umbrella#/.

“How Is Diesel Fuel Made From Crude Oil?” Kendrick Oil, Kendrick Oil Company, 19 July 2017, www.kendrickoil.com/how-is-diesel-fuel-made-from-crude-oil/.

“How is Polyester Made?” Craftech Industries, 7 Apr. 2017, www.craftechind.com/how-is-polyester-made/.

“How to make a reusable grocery bag out of a busted umbrella.” Everyday Crafty Goodness, Wood Press, 5 July 2008, everydaycraftygoodness.wordpress.com/2008/07/05/ how-to-make-a-reusable-grocery-bag-out-of-a-busted-umbrella/.

“How to Repair an Umbrella.” Umbrellifynet, www.umbrellify.net/how-to-repair-an-umbrella/.

“Let's Talk About Thread.” Superior Threads, Superior Threads, www.superiorthreads.com/education/thread-characteristics.

Palladino, Valentina. “Push Back Against the Elements With New Flexible, Super-Strong Umbrella.” Wired, Conde Nast, 4 June 2017, www.wired.com/2013/05/recyclable-ginkgo-umbrella/.

Peek, Katie. “How It Works: Inside The Machine That Separates Your Recyclables.” Popular Science, Popular Science, 28 Aug. 2013, www.popsci.com/technology/article/2013-07/How-it-works-recycling-machines-separate-junk-type.

“Stainless Steel.” How Products Are Made, Advameg, Inc., www.madehow.com/Volume-1/Stainless-Steel.html

“Umbrella.” How Products Are Made, Advameg, Inc., www.madehow.com/Volume-1/Umbrella.html.

“Umbrella Making Process.” Textile Exchange. www.teonline.com/knowledge-centre/umbrella-making-process.html

Woodford, Chris. “Plastics: A simple introduction.” Explain that Stuff, 18 Jan. 2018, www.explainthatstuff.com/plastics.html.

Woodford, Chris. “Nylon.” Explain that Stuff, 7 Feb. 2018, www.explainthatstuff.com/Nylon.html

Ouwen Zheng

Professor Cogdell

DES40A, Winter 2018

15 March 2018

Embodied Energy of Umbrella Life Cycle

Introduction

The earliest recordings of the umbrella date back as far as the year 21 A.D. in Ancient China1 and it has been an essential tool throughout human history ever since. Umbrellas serve the functions of sunshade and/or rain cover and sometimes decorative purposes. Many varieties of umbrellas are made for weather conditions and more importantly personal preferences in design and function (size and convenience, color, mechanical vs manual, etc.). The many unique umbrella designs combined with its steady demand lead to many varieties of raw materials and the associated energy spent during the acquisition process. It also leads to waste management issues relating to energy as well. These issues could be further complicated by the uses of certain materials over certain alternatives (fossil fuels vs renewable energy sources). It is essential to understand how the life cycle of the umbrella, specifically the embodied energy of the process, can impact the environments and areas of industry as it undergoes its life cycle. Although the amount of embodied energy use in the umbrella lifecycle shows that the manufacturing process is relatively efficient, there are ways of making the process more efficient both environmentally and economically through uses of alternative primary sources of energy and personal choices regarding recycling and reuse.

Raw Materials Acquisition

There are ways to improve efficiency and reduce pollution to the environment in the acquisition process of primary raw materials (coal, petroleum, iron ore, chromium, magnesium, copper, sand, feldspar, sodium sulfate, anhydrous borax, and boric acid) required for umbrella manufacturing.

The most obvious method of decreasing pollution is to utilize other primary energy sources such as solar power and wind power (to generate electricity used in electric vehicles), rather than fossil fuels in both the vehicles and machinery that help to mine the primary raw materials and in the processing of secondary raw materials as well. This also helps to reduce the costs in the raw materials acquisition process by eliminating the needs of acquiring fossil fuels altogether and instead opting to use electricity generated through renewable energy sources. In 2016, about 34% of U.S. electricity generation originated from natural gas. Not only is natural gas utilized in creating steam for electricity generation, it is also used in producing hot combustion gases passing through gas turbines to produce electricity as well. Coal was second behind natural gas in terms of electricity generation and accounted for about 30% overall and in contrast petroleum only accounted for less than 1% of the electricity generation in 2016.2

Manufacturing, Processing, and Formulation

For the secondary raw materials involved in the umbrella life cycle: nylon, polyester, stainless steel, aluminum, and fiberglass, there are ways to improve efficiency in the chemical processing in terms of specific processing mechanisms (from primary to secondary raw materials).

In the process of nylon manufacturing, condensation polymerization (secondary energy source in the form of chemical energy) occurs as two hydrocarbon chains (adipic acid and hexamethylene diamine) join together and lead to the removal of a single water molecule to create a larger hydrocarbon chain.3 Polyester, on the other hand, undergoes polymerization (secondary energy source as well), a chemical reaction where a petroleum by-product, alcohol, and carboxylic acid mix together to create ester, a monomer compound.4 In order for the plastics to become different colors to suit different designs, other chemicals (specifically colorants) are mixed into the process. Plasticizers are also added in order for the plastics to be susceptible to bending with flexibility, and stabilizers are added as well to further prevent damages to the plastics from sunlight and/or heat.5 When the plastics (nylon and polyester) are prepared adequately, they then are heated and stretched mechanically to create threads from thin fibers, which can be made into different varieties of threads in combination with cotton or wool (through spinning, which requires primary energy sources).4 Ultimately, the threads are sewn together to create fabrics of nylon and polyester.

Stainless steel, being an alloy, is composed of alloys that are iron-based and consist of chromium and carbon. They may also contain nickel, molybdenum, manganese, silicon, and copper.6 The welding process, during which metals are forged together at extremely high temperatures, and the subsequent processes of heating and cooling all require high amounts of energy that is most likely outputted through the burning of fossil fuels. Similarly, there could be reductions in greenhouse gas emissions if the electricity sources were changed to renewable energy sources (wind, solar, nuclear, etc.).

Another secondary raw material is fiberglass. It is used in the construction of the shaft or the frame of the umbrella. Fiberglass is mainly composed of sand, but can also include such chemicals as feldspar, sodium sulfate, anhydrous borax, and boric acid.7 In order to form the fiberglass, high temperatures are required and thus there is the burning of fossil fuels and the opportunity to reduce such energy uses and choosing renewable options instead.

Most of the remaining portions of umbrella manufacturing rely upon manual assembly by factory workers of the now fully formed umbrella parts. There is the possibility of replacing certain human processing steps with machinery that could improve overall efficiency and reduce energy costs. But it is essential to avoid using fossil fuels as the source of energy due to the fact that fossil fuels are much less efficient than most renewable energy sources, such as wind.8

Distribution and Transportation

The distribution and transportation of umbrellas involve basic elements of transport (truck, air, train, ship, etc.) and thus there is great potential in reducing energy costs. Depending upon the sources and destinations of the finished umbrella products, there is variation in terms of how much transportation is required.

There was limited information regarding the scale of umbrella imports and exports but there are umbrella manufacturers throughout the world, so it is assumed that all forms of transportation are most likely involved in the process. Airplanes utilize aviation gasoline, trucks utilize diesel fuel, ships burn residual fuel oil, and electric vehicles are mostly used in public mass transit systems.9 Petroleum accounted for about 92% of total energy use in the U.S. transportation sector in 2016, biofuels (i.e., ethanol and biodiesel) accounted for about 5% and natural gas about 3%, while electricity accounted for less than 1% of the energy used.9 Obviously electric trucks are not a major source of product transport and diesel fuel is the preferred fuel and diesel burning vehicles make up the majority of transportational vehicles. If electric trucks, such as the recently introduced Tesla Semi, can take up a larger share of the transportation sector, not only will there be a decrease in cost as a result of the transition from diesel fuel to electricity (preferably from a renewable primary energy source), there will also be more efficiency in terms of fuel usage (electric vehicles are more efficient than gasoline and diesel powered vehicles).10

Use/Re-Use/Maintenance

The energy spent in the maintenance and re-usage of umbrellas is heavily dependent on the user’s personal preferences. The usage of an umbrella does not involve more than human energy inputs in operating the umbrella itself. But when the umbrella is damaged, the user can choose to either repair through maintenance measures, which would still require mostly human energy inputs, except where machinery is involved (secondary energy source of electricity would be used), or simply re-use or re-utilize the umbrella to create other accessories. Examples of such re-uses include: clothing, magazine racks, household décor, etc.11 The only energy inputs other than human energy inputs would be the use of electricity for such tools as sewing machines and other necessary tools. The choice to re-use the umbrella saves quite a bit of energy, especially in recycling and also waste management.

Recycle

If the umbrella is utilized for other purposes and disassembled in that manner, then it would not undergo the recycling process, but there are obviously still cases where the umbrella may be beyond repair but still salvageable for its separate parts for re-use elsewhere. Such recycling processes would require energy uses in a recycling facility to transport various parts that are most likely initially sorted by human operators, with human energy inputs and energy required to operate the facility. There is further energy inputs required if certain parts need to be molded into another form or mended before it can be recycled and processed through the facility. In the cases of parts that can no longer be recycled, it leads to waste management measures.

Waste Management

A main part of waste management is the operational energy used in waste treatment facilities to sort through materials that arrive at the facility. There is additional energy inputs in the vehicles that operate onsite to transport the waste to the dumping site, where many forms of waste disposal measures are utilized, each requiring similar amounts of energy inputs since the umbrella parts are simply not recyclable anymore.

An interesting part of the umbrella life cycle and its waste management is the involvement of disposable plastic umbrella covers, which are mostly found at the entrances of buildings on rainy days. In Hong Kong, the problem is especially prevalent as most people use the covers only once before throwing the cover away, and in a city with such high human density, it creates significant amounts of waste and associated energy wastes to process the rain covers.12 There could be a significant amount of energy saved if people simply choose not to use such covers or re-use them again if possible.

Conclusion

The umbrella life cycle is heavily energy dependent in its earlier stages from raw materials acquisition to the processing of primary raw materials into secondary primary materials and the subsequent transportation of products after assembly. Although the assembly process is quite efficient as it is mostly manual labor, there are many areas where energy use can be reduced in both cost and environmental damages by simply opting for renewable energy sources. Electric vehicles use in the acquisition of raw materials and transportations to and from the factory and subsequently to and from both the recycling and waste management facilities can significantly decrease the cost and increase the efficiency in terms of fuel use and environmental improvements as well.

The embodied energy in the umbrella life cycle, outside of the energy spent before its arrival to the store, can be almost entirely efficient if creative re-usage ideas are developed and employed by the users of the products.

Notes

1. Needham, Joseph. Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2: Mechanical Engineering. Taipei: Caves Books, Ltd. Page 70, 1986.

2. EPA. “Electricity in the United States.” EPA, 10 May 2017, https://www.eia.gov/energyexplained/index.cfm?page=electricity_in_the_united_states

3. Woodford, Chris. “Nylon.” Explain that Stuff, 7 Feb. 2018, www.explainthatstuff.com/Nylon.html

4. “How is Polyester Made?” Craftech Industries, 7 Apr. 2017, www.craftechind.com/how-is-polyester-made/.

5. Woodford, Chris. “Plastics: A simple introduction.” Explain that Stuff, 18 Jan. 2018, www.explainthatstuff.com/plastics.html.

6. Cross, H. J., J. Beach, et al. Manufacture, processing and use of stainless steel. A review of the health effects. Bruxelles, Belgium, EUROFER, Euroepan Confederation of Iron and Steel Industries. Jan. 1999, www.worldstainless.org/Files/issf/non-image-files/PDF/1999HealthEffectsofStainlessSteels.pdf.

7. EPA.“AP-42, Fifth Edition, Volume I Chapter 11:Mineral Products Industry.” EPA, Environmental Protection Agency, 27 Sept. 2016, www3.epa.gov/ttn/chief/ap42/ch11/final/c11s13.pdf

8. Johnston, Adam. “Wind Energy More Energy Efficient than Fossil Fuels.” Clean Technica, 18 July 2012, https://cleantechnica.com/2012/07/18/wind-energy-energy-efficient-fossil-fuels-uk/

9. EIA. “Energy Use for Transportation.” EIA, U.S. Energy Information Administration, 17 May 2017, https://www.eia.gov/energyexplained/?page=us_energy_transportation.

10. Sebastian, Blanco. “Electric Cars Win on Energy Efficiency vs Hydrogen, Gasoline, Diesel: Analysis.” Green Car Reports, 10 Oct. 2017, https://www.greencarreports.com/news/1113175_electric-cars-win-on-energy-efficiency-vs-hydrogen-gasoline-diesel-analysis

11. Cathy. “35 Ways To Reuse and Recycle Umbrellas.” Green Eco Services, Green Eco Services, 1 Mar. 2011, www.greenecoservices.com/35-ways-to-reuse-and-recycle-umbrellas/.

12. Pradhan, Sai. “Stop the Waste and Say ‘No’ to Throw-away Umbrella Covers.” Hong Kong Free Press, 21 Sept. 2015, https://www.hongkongfp.com/2015/09/21/stop-the-waste-and-say-no-to-throw-away-umbrella-covers/

Bibliography

Cathy. “35 Ways To Reuse and Recycle Umbrellas.” Green Eco Services, Green Eco Services, 1 Mar. 2011, www.greenecoservices.com/35-ways-to-reuse-and-recycle-umbrellas/.

Cross, H. J., J. Beach, et al. Manufacture, processing and use of stainless steel. A review of the health effects. Bruxelles, Belgium, EUROFER, Euroepan Confederation of Iron and Steel Industries. Jan. 1999, www.worldstainless.org/Files/issf/non-image-files/PDF/1999HealthEffectsofStainlessSteels.pdf.

EIA. “Energy Use for Transportation.” EIA, U.S. Energy Information Administration, 17 May 2017, https://www.eia.gov/energyexplained/?page=us_energy_transportation.

EPA.“AP-42, Fifth Edition, Volume I Chapter 11:Mineral Products Industry.” EPA, Environmental Protection Agency, 27 Sept. 2016, www3.epa.gov/ttn/chief/ap42/ch11/final/c11s13.pdf

EPA. “Electricity in the United States.” EPA, 10 May 2017, https://www.eia.gov/energyexplained/index.cfm?page=electricity_in_the_united_states

“EUROPAGES - umbrella manufacturer.” Umbrella manufacturer companies, EUROPAGES, www.europages.co.uk/companies/umbrella%20manufacturer.html.

“How is Polyester Made?” Craftech Industries, 7 Apr. 2017, www.craftechind.com/how-is-polyester-made/.

“How to make a reusable grocery bag out of a busted umbrella.” Everyday Crafty Goodness,

Wood Press, 5 July 2008, everydaycraftygoodness.wordpress.com/2008/07/05/ how-to-make-a-reusable-grocery-bag-out-of-a-busted-umbrella/.

“How to Repair an Umbrella.” Umbrellifynet, www.umbrellify.net/how-to-repair-an-umbrella/.

Johnston, Adam. “Wind Energy More Energy Efficient than Fossil Fuels.” Clean Technica, 18 July 2012, https://cleantechnica.com/2012/07/18/wind-energy-energy-efficient-fossil-fuels-uk/

Needham, Joseph. Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2: Mechanical Engineering. Taipei: Caves Books, Ltd. Page 70, 1986.

Peek, Katie. “How It Works: Inside The Machine That Separates Your Recyclables.” Popular Science, Popular Science, 28 Aug. 2013, www.popsci.com/technology/article/2013-07/How-it-works-recycling-machines-separate-junk-type.

Pradhan, Sai. “Stop the Waste and Say ‘No’ to Throw-away Umbrella Covers.” Hong Kong Free Press, 21 Sept. 2015, https://www.hongkongfp.com/2015/09/21/stop-the-waste-and-say-no-to-throw-away-umbrella-covers/

Sebastian, Blanco. “Electric Cars Win on Energy Efficiency vs Hydrogen, Gasoline, Diesel: Analysis.” Green Car Reports, 10 Oct. 2017, https://www.greencarreports.com/news/1113175_electric-cars-win-on-energy-efficiency-vs-hydrogen-gasoline-diesel-analysis

“Umbrella.” How Products Are Made, Advameg, Inc., www.madehow.com/Volume-1/Umbrella.html.

Woodford, Chris. “Plastics: A simple introduction.” Explain that Stuff, 18 Jan. 2018, www.explainthatstuff.com/plastics.html.

Woodford, Chris. “Nylon.” Explain that Stuff, 7 Feb. 2018, www.explainthatstuff.com/Nylon.html.

Min Khant Kyaw

Professor Christina Cogdell

DES40A, Winter 2018

11 March 2018

Life Cycle Assessment: Waste and Emissions of an Umbrella

The story of the umbrella spans centuries across numerous civilizations. Regarded as a handheld device for protection against the sun or rain, the umbrella truly resembles human technological advancements and triumphs, requiring the world itself to conform to our needs. The history of the umbrella began with the appearance of parasols in Ancient Egypt, which were exclusively for use by nobility and royalty to protect themselves from sunlight (“Umbrella Manufacturing Process”). Currently, umbrellas are easily accessible by all people and have claimed the status of an essential household item. Worldwide, an average person owns 2.4 umbrellas per year and 33 million umbrellas are sold each year in the U.S alone (“Global Umbrella Survey Results”). Due to the modern age of mass production and unprecedented scales of consumerism, it has become increasingly more important to examine a product’s overall impact on the environment/natural habitats, wildlife, and human health. An important consideration to make involves analysis of the waste and pollution of a product throughout its lifecycle to determine the magnitude of the product’s environmental impact and concerns. Through investigation of numerous stages of the umbrella’s lifecycle, a majority of the waste and pollution produced by the umbrella is accumulated during the stages of distribution/transportation and raw material acquisition/manufacturing. Assembly/manufacturing process of the umbrella itself can be deemed the least wasteful in the lifecycle. Examining the life cycle of the umbrella portrays a disparity in the amount of waste and pollution produced in the respective stages of the umbrella’s lifecycle, specifically highlighting the unsustainability of current transportation methods and raw material acquisition practices. Additionally, it offers a window of insight into numerous factors that contribute to waste and pollution of the umbrella, allowing us to contemplate on implementing design changes and promoting sustainable production and consumer methods.

Processes involved in acquisition of major raw materials required to initiate the lifecycle of an umbrella lead to greenhouse gas emissions, water contamination, health concerns and various other forms of environmental degradation. Coal and Petroleum are raw materials essential for the production of secondary materials which constitute the umbrella. Coal byproducts, and polymer from chemicals found in Petroleum make up Nylon (“Nylon, a Petroleum Polymer.”). In regard to coal extraction, strip mining and mountaintop removal are the most prominent methods. Strip mining calls for the removal of soil and rock above coal deposits, which leads to destruction of landscapes and wildlife habitats (“Coal and the Environment.”). Draining from valleys created as consequence of mountaintop removal contain pollutants, which contaminate nearby waterways and harm aquatic wildlife (“Coal and the Environment.”). Underground coal mines have a lesser scale of environmental degradation, yet still present the possibility of acidic water draining into groundwater reserves if abandoned or not properly maintained. Coal mining is also a major culprit for methane gas emissions, a greenhouse gas with higher global warming potential than CO2. (“Coal and the Environment.”). Petroleum refineries are responsible for hazardous pollutants such as benzene, toluene, ethylbenzene, and xylene (BTEX) compounds, all of which are suspected to be cancer-causing agents and tied to numerous respiratory conditions (“Oil and the Environment.”). Chromium is an added element in stainless steel production, which gives stainless steel its “finished” look. Improper disposal of mining tools and supplies can lead to groundwater contamination from chromate mines, and human exposure to and consumption of Chromium may cause health problems such as nosebleeds, allergic reactions, and skin rash (Chromium and its negative effects on the environment.”). The aforementioned primary raw materials accrue a considerable amount of waste and emissions, which continues to expand when the raw materials are converted to secondary raw materials used in production of the umbrella.

Once the stage of raw material acquisition is complete, the primary raw materials must be transformed into secondary raw materials usable in the production of an umbrella. Throughout the manufacturing process of the secondary raw materials, notable amounts of greenhouse gases are emitted. The secondary raw materials which are the main components of an umbrella include Nylon, stainless steel, and fiberglass. Nylon is the most commonly used fabric for the canopy of the umbrella (“Umbrella Manufacturing Process.”). Stainless steel is the material which makes up the shaft and stretchers of the umbrella (“Umbrella Manufacturing Process.”). Fiberglass material is incorporated in the umbrella as the ribs, which maintains the integrity of the umbrella’s shape when expanded (“Umbrella Manufacturing Process.”). Nylon manufacturing produces Nitrous Oxide, 310 times more potent than CO2 as a greenhouse gas (Compilation of air pollutant emission factors “6.9 Synthetic Fibers”). Refining and smelting of glass fiber emit volatile organic compounds (VOCs), such as glass fiber particles and hydrocarbons ((Compilation of air pollutant emission factors “11.13 Glass Fiber Manufacturing”). Amongst the umbrella’s secondary raw materials, stainless steel can be considered the least wasteful. Stainless steel production is very well interwoven with its recycling process. Stainless steel objects are produced with an average recycled stainless-steel content of about 60% with other steel alloys and old scraps (“The Recycling of Stainless Steel”). However, the re-melting process of stainless steel emits 3.81 tons of CO2 for every ton of stainless steel produced.

Despite a considerable amount of emissions and waste accumulated during secondary raw materials manufacturing, the actual process of umbrella manufacturing produce little to no waste due to the fact that the primary mode of umbrella manufacturing consists of hand-assembly process and manual labor. However, it is important to consider the potential of airborne and waterborne diseases due to insufficient working conditions and unregulated sites.

A majority of current umbrella production usually occur overseas, primarily in China and Europe. Therefore, umbrellas are more commonly imported than they are domestically produced. Intercontinental transportation is required, whether it be via cargo planes or container ships. These two transportation methods are responsible for astronomical amounts of greenhouse gas emissions and emits a majority of CO2 prevalent throughout the entire lifecycle. Container ships are responsible for 3% of global annual CO2 and greenhouse gas emissions, emitting approximately 1 billion tons of CO2 (Olmer, Naya). Low grade bunker fuel used by the world’s 90,000 cargo ships contain up to 2000 times the amount of sulfur in automobiles’ diesel fuels (Olmer, Naya). Cargo planes emit Nitrogen Oxide, forming Ozone in the atmosphere (“Airplane Emissions”). Nitrogen Oxide created at such high altitudes leads to greater concentration of Ozone than ground emissions, in which Airplane emissions contribute to greater global warming impact (“Airplane Emissions”). Once products reach distribution facilities, trucks assume the duty of delivering the umbrellas to retail stores and households alike. Commercial trucks produce approximately 530 million metric tons of CO2 per year, which makes up about 12.5% of total CO2 emissions (“Big Trucks Emit Huge Amounts of Carbon Every Year. The EPA Is About to Do Something About It”). Due to the ever-growing popularity of online shopping, more and more truck deliveries are in place to meet customer demands, exacerbating the amount of trucks’ CO2 and greenhouse gas emissions. Furthermore, additional packaging materials such as cardboards and bubble wraps are required to ship umbrellas in contrast to directly purchasing them at the store, which contributes to additional plastic waste along with water and trees.

Once an umbrella is finally obtained by customers, maintenance and use/reuse of the product produces minimal waste so long as customers utilize the umbrella adequately and with some degree of care. Materials from the umbrella can be easily converted into other useful forms without requirement of additional materials. For instance, Nylon fabric from the canopy of the umbrella can be used to make kites, pet clothing, and other fashion accessories. The stretchers and ribs of an umbrella can be extracted to make hangers for clothes, flower pots, and can also be utilized to make baby mobiles.

After an umbrella has reached its end of product lifetime, the components of the product can be recycled in various manners rather than being discarded immediately. In the case of the umbrella, “upcycling” of the product is far more common than traditional recycling. The Nylon fabric in the umbrella is difficult to recycle, and the recyclability of it is dependent on the form it takes (Bennett, Sophia). Second-hand Nylon fabrics are required to be cleaned prior to making products, which many manufacturers do not consider to be cost-effective due to the amount of water and energy input into a product which does not retain its complete properties after previous usage (Bennett, Sophia). Stainless steel, however, is a material that is largely recyclable with up to 90% end of life recycling ratio (“The Recycling of Stainless Steel”). Stainless steel recycling is a self-sustaining process, and as aforementioned, is largely tied with its production process (“The Recycling of Stainless Steel”). Yet, the re-melting of Stainless Steel for recycling/production produce slag and dust as its main byproducts. Fortunately, slag and dust can be used to make asphalt for road construction (“The Recycling of Stainless Steel”).

Despite efforts to encourage recycling and reusing, umbrellas are commonly discarded needlessly. One study found that worldwide, the number of umbrellas unnecessarily thrown away in a year has enough material to construct 25 Eiffel towers (O’Connor, John). In addition to discarded umbrellas, additional waste is produced due to certain business practices. It is a common occurrence for public spaces and businesses to offer customers plastic slipcovers, and doing so contributes to plastic pollution and marine debris. Plastics in the landfills which may take around 500 years to decompose has the potential to leach toxic into the soil and groundwater (Fischer, Douglas). Nylon fabric is a non-biodegradable material, and essentially remains in landfills for a long time and finds its way into waterways and surrounding ecosystems. Total accumulated wastes in the landfills primarily leads to emission of methane gas, a greenhouse gas which is 30 times more potent than CO2 in its heat trapping ability (Fischer, Douglas).

Analysis of the umbrella’s life cycle confirms that a huge sum of waste, pollution, and emissions of the umbrella are accrued during the stages of raw material acquisition, and transportation. Natural environments are disrupted and large scale environmental degradation such as ground water contamination occur during raw materials acquisition. Since the umbrella industry is largely overseas, astronomical amounts of greenhouse gases such as CO2 and Nitrogen Oxide are emitted during import of the umbrellas and domestic distribution to retail stores. A few challenges faced in the evaluation of the umbrella’s life cycle were in finding statistics on precise locations and mileages covered for transportation of the umbrella. Additionally, although umbrella assembly produces minimal waste, information on working conditions within factories and workshops along with operations to power the work facilities are lacking, which prevents examining the potential of airborne and waterborne emissions/diseases. Despite numerous environmental and sustainability concerns raised throughout the umbrella’s lifecycle, the umbrella is versatile product with great potential for sustainable improvements. The umbrella has diverse options in “upcycling” in which the product can be converted to numerous forms which permits the components of the umbrellas to be used for different purposes. Assessment of the umbrella’s lifecycle pinpoints several changes able to be made to strive for an end goal of sustainability. Due to the fact that a majority of umbrella manufacturing is accomplished overseas, switching over to cleaner burning fuels such as nuclear for container ships, and Hydrogen fuel cell in trucks would dramatically reduce the amount of emissions in transportation of the umbrella. Moreover, consumers have a considerable impact on the waste and emissions of the umbrella’s life cycle based on their usage, handling, and purchasing of the product. A great multitude of people tend to purchase numerous affordable umbrellas, which is an unsustainable practice that expands the total amount of waste within the product’s lifecycle. Seemingly surprising, it far more economically favorable and sustainable to invest in a well-produced, sturdy umbrella rather than purchasing brittle, cheaply made umbrellas which are likely to be discarded in a short time.

Works Cited

Admin. “Umbrella Manufacturing Process.” Hfumbrella, Hfumbrella, 4 Feb. 2017, www.hfumbrella.com/umbrella-manufacturing-process-2/.

“Airplane Emissions.” Center for Biological Diversity, www.biologicaldiversity.org/programs/climate_law_institute/transportation_and_global_warming/airplane_emissions/.

Bennett, Sophia. “How to Recycle Nylon.” RecycleNation, ERI, 25 Nov. 2014, recyclenation.com/2014/11/recycle-nylon/.

“Big Trucks Emit Huge Amounts Of Carbon Every Year. The EPA Is About To Do Something About It.” ThinkProgress, ThinkProgress, 2 June 2015, thinkprogress.org/big-trucks-emit-huge-amounts-of-carbon-every-year-the-epa-is-about-to-do-something-about-it-5c402732888/.

www.eia.gov/energyexplained/index.cfm?page=oil_environment.

“Chromium and its negative effects on the environment.” Case Studies, NAGT, 14 Nov. 2016, serc.carleton.edu/NAGTWorkshops/health/case_studies/chromium.html.

“Coal and the Environment.” Coal and the Environment - Energy Explained, Your Guide To Understanding Energy - Energy Information Administration, U.S. department of Energy, www.eia.gov/energyexplained/index.cfm?page=coal_environment.

Compilation of air pollutant emission factors. “6.9 Synthetic Fibers” U.S. Environmental Protection Agency, 1995.

Compilation of air pollutant emission factors. “11.13 Glass Fiber Manufacturing” U.S. Environmental Protection Agency, 1995.

Fischer, Douglas. “The environmental toll of plastics.” Environmental Health News, RebelMouse, 20 Dec. 2017, www.ehn.org/plastic-environmental-impact-2501923191.html.

“Global Umbrella Survey Results.” Sunnycomb, Tumblr, 30 June 2014, sunnycomb.tumblr.com/post/90373669845/global-umbrella-survey-results.

“Nylon, a Petroleum Polymer.” American Oil & Gas Historical Society, 26 Feb. 2018, aoghs.org/products/petroleum-product-nylon-fiber/.

O'Connor, John. “Cheap Umbrellas: How They Threaten the Environment.” 'BrellaBox, 3 June 2016, www.brellaboxnyc.com/eiffel-tower-broken-umbrellas/.

“Oil and the Environment.” Oil and the Environment - Energy Explained, Your Guide To Understanding Energy - Energy Information Administration, U.S. department of Energy,

Olmer, Naya. “GREENHOUSE GAS EMISSIONS FROM GLOBAL SHIPPING, 2013–2015.” Icct, The International Council On Clean Transportation, Oct. 2017, www.theicct.org/sites/default/files/publications/Global-shipping-GHG-emissions-2013-2015_ICCT-Report_17102017_vF.pdf.

“The Recycling of Stainless Steel.” The Recycling of Stainless Steel, ISSF, www.worldstainless.org/Files/issf/Animations/Recycling/Flash.html.