Design Life-Cycle

assess.design.(don't)consume

Faress Zwain (Materials)

Lizzy Marples (Embodied Energy)

Paola Simbulan (Waste & Emissions)

SAS 43 (DES 40A)

Professor Cogdell

Apple Watch Series 4: Materials

Every year, new technological innovations and inventions arise and continue to push our world closer to becoming completely digital. It used to amaze how companies such as Apple fit the tech of a computer into something as small as a phone, and now even smaller products such as Watches can encompass greater technology than ever before. However, with all of these new technological inventions comes increased waste and emissions that we have to consider to limit detrimental environmental impacts. In the past, unnecessary amounts of materials were used in the life cycles of many digital devices such as computers, smartphones, and now smartwatches. Many of our finite material resources are becoming increasingly rare as they are used for only one device before being disposed of. The unintended environmental consequences of this reckless use of material in the production, transportation, use, and recycling of devices, specifically Apple Watches, has influenced companies such as Apple to take steps to not only limit the amount of material used but to also consider the type of material and its prolonged effects on the environment.

Breaking down the components of digital devices back into individual raw materials for recycling has a history of being a difficult task. The raw materials used in manufacturing Apple Watches: copper, cobalt, iron, tin, nickel, ceramic(clay), silicon, crude oil, and salt are extracted from the Earth and its crust. These materials are then either used directly in the watch or to create secondary materials including glass- made from silicon and heat, nylon- from carbon fibers, steel- from smelting iron and adding carbon, and plastic- from cellulose, crude oil, and salt. The creation of these secondary materials, as well as the creation of parts such as circuit boards often involve the chemical bonding of different materials, which is why separation is not easy. Generally, small amounts of copper are the only materials that can be recycled from circuit boards. Other metals such as gold, tin, and silver make such a miniscule percentage of the materials in circuit boards that they are deemed non cost-effective to salvage by companies. Most companies are unwilling to increase costs to boost recycling since they can make more profit by wasting materials and building new parts. Additionally, the majority of a circuit board, which is made of resin and glass fiber cloth, cannot be recycled due to the fact that it cannot be broken down into its original materials(Newbury, Can Printed Circuit Boards be Reused or Recycled?). As a result, circuit boards are piled up in landfills, creating massive buildups of non-degradable materials. Another unfortunate fact about circuit boards is that not only can they not be recycled, but they also cannot be reused. According to studies by Newbury Electronics, the reuse of printed circuit boards or components of printed circuit boards is both economically and practically inefficient. The costs required to take apart, retest, and reinsert components of circuit boards easily surpasses that of manufacturing new parts. Another part of the Apple Watch that has little to no recycling benefits is the wristband. Made of fluoroelastomer, a type of synthetic rubber consisting of chlorine, fluorine, and carbon, the wristband cannot be recycled and is rarely reused by Apple itself(Stern Rubber Company, Rubber that you Wear). In the future, it may be necessary for companies to choose helping the environment over lower costs, but for now it seems unlikely that any company would take a step forward and sacrifice a higher revenue for a healthier environment. Consequently, Apple focuses on decreasing the environmental impact of other parts of the Apple Watch to accomodate for the waste created by parts such as circuit boards and wristbands.

One method Apple uses to decrease its material footprint is banning specific harmful substances from being used in the production, transportation, use, or recycling of any of its products. Some of the banned substances include: arsenic, mercury, brominated flame retardants, polyvinyl chloride(PVC), and beryllium(Apple Watch Series 4 Environmental Report). All of these listed chemicals are dangerous and damage the environment in a variety of ways. Arsenic and mercury are highly toxic and can contaminate groundwater when leaked; when the water is contaminated, the impacts are easily widespread since countless people will ingest the toxic chemicals(World Health Organization). Beryllium and polyvinyl chloride, which are also poisonous, are most commonly leaked by evaporating into the air in the form of tiny particles. These particles, if ingested, can cause harm to the lungs, especially for young children(Department of Human Services). Finally, polyvinyl chloride is detrimental to the environment because we have not yet discovered a way to break the chemical down effectively. As a result, the production of PVC is creating a large, non-degradable buildup that is highly likely to cause future problems(US National Library of Medicine). It may be necessary to find ways to safely use and dispose of these chemicals in the future, but for now avoiding use seems like the only viable solution to preserve the environment. Apple is taking a major step forward towards a healthier environment by banning these chemicals from being used in the life cycle of Apple Watches.

Apple has made several major changes to its packaging of products for the sake of the environment. For Apple Watches in particular, a key change was creating the casing of the Watch out of aluminum. Aluminum is a “material highly desired by recyclers,”(Apple Watch Series 4 Environmental Report) meaning that the waste products from the casing are slim, if any. A second important change was simply decreasing the size of the packaging. By making the packaging for the Apple Watch more compact, less materials would be needed in production, leading to a lighter overall package. This may not seem that important, but it comes into play when regarding transportation: a lighter package allows Apple to transport or distribute the same amount of product with the use of less fuel. Although I did not find specific transportation methods used by Apple in my research, whether Apple ships its products by sea or by air, it can be inferred that the use of fossil fuels in this transportation process will be reduced due to a smaller size and weight of the products. Less fossil fuels indicates less greenhouse gas emissions, which allows for less environmental damage. And, for Apple itself, less use of fossil fuels means lower transportation costs, resulting in increased profit. The last significant change Apple made in its packaging was shifting towards highly recyclable materials for retail packaging. Over 99 percent of the packaging that Apple Watches are sold in are now recyclable; if we break that down, 0.3 grams of the packing is plastic, 1.2 grams are microfiber, and the remaining 339 grams fiber consist entirely of recycled materials, bamboo, and sugarcane. “This retail packaging... contains 66 percent less plastic than previous generation Apple Watch packaging and at least 36 percent recycled content”(Apple Watch Series 4 Environmental Report). Nearly two-thirds less plastic in the packaging indicates decreased waste emissions and an increased percentage of the packaging that can be recycled. As we can see, this is a huge step forward in the right direction; Apple is taking a leading stance in preserving the environment and is setting a precedent for other companies to follow.

The final method that Apple uses to decrease material use and waste is by encouraging its customers to dispose of Apple Watches properly. Apple does this by paying customers for turning in old devices and giving them store credit that they can use to purchase new Apple devices. This not only stimulates sales for Apple by giving customers incentives to buy Apple’s new products, but also ensures that old devices can be recycled properly and efficiently. Apple can either resell the old Watches for discounted prices or reuse certain materials in the product and recycle or dispose of the rest. This prevents customers from leaving old devices in their homes or from throwing them away, both of which would waste valuable materials. According to a study conducted by a recent Gallup survey, almost half of all consumers will renew their smart device every two years. This means that for Apple, with tens of millions of Apple Watch sales each year, the amount of “outdated”, potentially recyclable devices is tremendous. Each individual device at first may not seem valuable enough to recycle properly; however, any reduction in the amount of materials used, no matter how insignificant it may seem, will eventually add up and make a difference.

Apple’s shift towards environmentally beneficial production, transportation, and waste management methods have not only been effective in creating change internally. Being such a large company, Apple has the power to influence people and other companies to follow in its footsteps. Lisa Jackson, VP of Apple’s environmental initiatives states that “We’ve made it a priority to hold our suppliers accountable to the same environmental standards we observe and hope that our collaboration will show others what is possible. While we are proud of our announcement today, we won’t stop driving change within our industry to support the clean energy transition happening globally”(Patently Apple). We can imply that the statement “hold our suppliers accountable” means Apple’s partners are also seeking to decrease material consumption in the life cycle of products similar to the Apple Watch. Apple, being one of the largest global companies out there, understands the capability it has to induce change and as a result is changing its use of materials in its products to benefit the environment.

By making changes to its use of materials in the processes of production, transportation, use, and recycling of Apple Watches, Apple is setting a precedent for companies to follow in the future. It can be difficult for a company to sacrifice lower costs for a lower material footprint, but Apple has found ways for a company to aid the environment and increase revenue at the same time. Apple’s reduction in the amount of material used in creating packaging for Watches, encouragement of customers to cash in old devices, and consideration of using highly valued recyclable materials are all ways in which Apple spends less money while simultaneously decreasing its harm to the environment. Reducing the material in packaging allows Apple to reduce its fuel consumption when transporting and distributing watches due to lighter loads. Encouraging customers to cash in old devices for store credit encourages people to buy Apple’s new products while increasing the amount of devices that are properly recycled. Apple choosing to eliminate harmful, toxic substances from all aspects of the life cycle of Apple Watches and using commonly needed materials such as Aluminum for watch cases ensures that little to none of the material will be wasted during the recycling process. In today’s technological world, many digital products involve unnecessary amounts of material in their production, transportation, use, and recycling processes. This is not only rapidly decreasing our finite supply of many of these materials, but also harming the environment. Apple has realized the direction our technological but wasteful world is taking us and has begun to take steps to prevent the further detriment of the environment. Although the issue at hand has not been solved, Apple’s efforts have shown the world that fixing the environment is still a possibility.

Bibliography

Mashable. “How the Apple Watch Is Made.” Mashable, 15 Mar. 2015, https://mashable.com/2015/03/15/apple-Watch-how-its-made/.

“Printed Circuit Board.” How Products Are Made, http://www.madehow.com/Volume-2/Printed-Circuit-Board.html.

ACDi, and ACDi. “Recycling Printed Circuit Boards.” ACDI, 25 May 2018, https://www.acdi.com/recycling-printed-circuit-boards/.

Apple Watch Series 4 Environmental Report. Apple Inc, Sept. 2018, https://www.apple.com/environment/pdf/products/watch/Apple_Watch_Series4_GPS_PER_sept2018.pdf.

“Apple Has Reduced Its Carbon Footprint for the Third Consecutive Year through the Company's Supplier Clean Energy Program.” Patently Apple, https://www.patentlyapple.com/patently-apple/2019/04/apple-has-reduced-its-carbon-footprint-for-the-third-consecutive-year-through-the-companys-supplier-clean-energy-program.html.

Environmental Responsibility Report. Apple Inc, 2019, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2019.pdf.

Szalatkiewicz, Jakub. Metals Content in Printed Circuit Board Waste. Industrial Research Institute for Automation and Measurements, 20 June 2013, https://pdfs.semanticscholar.org/1a33/0bfbc29f70e492c18ed6dfd7a85c2d836f58.pdf.

“Can Printed Circuit Boards Be Reused or Recycled?: Newbury Electronics.” Newbury Electronics Blog, 8 May 2019, http://www.news.newburyelectronics.co.uk/newbury-blog/can-printed-circuit-boards-be-reused-or-recycled/.

Stern Rubber Company. “Rubber That You May Be Wearing.” Stern Rubber Company - Est. 1969, https://sternrubber.com/blog/flouroelastomers-you-wear.

“Arsenic.” World Health Organization, World Health Organization, https://www.who.int/news-room/fact-sheets/detail/arsenic.

Segev, Osnat, et al. “Environmental Impact of Flame Retardants (Persistence and Biodegradability).” International Journal of Environmental Research and Public Health, Molecular Diversity Preservation International (MDPI), Feb. 2009, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2672362/.

L. Johnson. “Department of Human Services: PVC – a Major Source of Phthalates.” Department of Human Services | PVC – a Major Source of Phthalates, https://www.state.nj.us/humanservices/opmrdd/health/pvc.html.

Kline, Daniel B. “How Often Does the Average American Replace His or Her Smartphone?” The Motley Fool, The Motley Fool, 15 July 2015, https://www.fool.com/investing/general/2015/07/15/how-often-does-the-average-american-replace-his-or.aspx.

Embodied Energy: Apple Watch Series 4

Apple Inc tries to appear as though they are completely transparent throughout the entire life cycle of their products by preparing environmental reports each year that are accessible to the public. While Apple is one of the tech giants that are publicly pursuing meaningful efforts to reduce carbon emissions and turn to more environmentally friendly practices, the overwhelming quantity of Apple electronics produced each year are doomed to do damage regardless. There has been a variety of studies researching the embodied energy of the Iphone in recent years, unveiling the true damage these smartphones are doing to the environment. Instead of focusing on the Iphone, this paper aims to deconstruct the embodied energy accumulated in the life of an Apple Watch Series 4. The Apple watch may be small in size, but the energy consumed throughout its entire lifecycle is very high due to the extraction of raw materials, manufacturing, transportation processes.

The apple watch begins its life deep beneath the earth's surface across different regions of the world as raw metals including aluminum, steel, copper, cobalt, nickel, lithium, and chromium. Adapting calculations from an Iphone, an estimated 28 pounds of ore would have to be mined to produce the metals that one 48 gram Apple Watch consists of. (Merchant 2018) Aluminum and steel are the predominant metals found in the watch. Aluminum is one of the most abundant metallic elements in the earth's crust, compromising 8% of the planet's soil and rocks. (2019) The most useful ore for producing aluminum is bauxite which consists of 45-60% aluminum oxide, the rest consists of iron, sand, and other metals. (1976) For every four pounds of bauxite, two pounds of alumina can be produced and from every two pounds of alumina, one pound of aluminum can be made. (2017) In terms of energy that means that four times the amount of energy has to use in order to mine one unit of aluminum. Once aluminum is mined it goes through The Bayer Process and then The Hall-heroult Process which subsequently produces a massive amount of carbon emissions.The production of new aluminum results in around 1% of global annual greenhouse gas (GHG) emissions and the smelting process consume about 4% of the global electricity output. (Tyabji & Nelson) Apple recently released they are teaming up with the companies Alcoa and Rio Tinto to produce new technology that will reduce emissions due to the aluminum smelting process by 25%.

Another component of the Apple watch that makes up a good portion of the Apple Watch's body is its lithium-ion battery. One of the main metals in lithium-ion battery is cobalt. Lithium-ion batteries have significantly increased in popularity in the last years spiking the demand for cobalt by 300%. (Kara 2018) About 60% of the worlds cobalt resides in third world country, the Domincan Republic of Congo. This increase in demand has significantly affected the quality of life of communities located near mines and 20% of the supply produced is mined by locals. There is an estimated 55,000 miners and 35,000 of them children. The conditions of those who work in and around the mines are squalid: reduced life-expectancy, higher infant mortality rate, higher prevalence rate of HIV, diarrhoea, hepatitis, meningitis, bilharziosis, cholera, typhoid, tetanus, typhus, malaria, yellow fever, tuberculosis, musculoskeletal disorders, respiratory disorders and headaches. (Tsurukawa, Prakash, & Manhart 2011) One day of work mining cobalt in the Congo consumes 452 million joules of of human labor. It is important to note that the carbon footprint section of Apples environmental report, there is no mention of mining raw materials before going into production and also makes it incredibly hard to locate the locations of every supplier they obtain their materials from.

All of the separate parts of the Apple Watch Series 4 are then sent to a manufacturing facility called Quanta Computer in Chongqing China where majority of watches assembly is done. The production process by far uses the most amount of energy, creates the most greenhouse gas emissions, and pollutes the surrounding environment. The Apple Environmental report states that 71% of the Greenhouse Gas Emissions for Apple Watch Series 4 (GPS) are from production. (Apple) The production phase of an Apple Watch Series 4 produces 26.6 kg CO2 greenhouse gas emissions. (Apple) Apple came out in 2018 saying that in the United States they use 100% renewable energy and 87% in all of their global facilities. This is thought to be widely misleading due to the fact that apple “feeds the unreliable, stop-and-go power from their on-site solar panels into the local utility power network, making the system less reliable and more expensive.” (Epstein 2016) This is directly supported by Apples environmental report stating that in actuality, “Apple’s flagship data center in Maiden, NC, for example draws from the local Duke Energy grid with 51% nuclear power, 38% coal power, and less than 1% renewable sources in 2014.” (Epstein 2016) While Apple has made improvements since 2014, there is still little information supporting Apples claims in using renewable resources aside from what Apple themselves reveal to the public. Further, although their facilities may run on some renewable energy there is still energy being consumed during the transportation of materials to manufacturer and then to the United States for packaging.

Once the Apple Watch Series 4 are ready to be transported to the United States from Quanta Electronics, they are loaded into a Boeing 777. The Boeing 777 is a long rage airplane that is typically used by Apple to transport its products to the United States. The distance from China to the United States is about 11,671 kilometers, this air travel distance is equal to 7,252 miles. The Boeing 777 on average with a full load capacity uses on average 6.5 gallons a mile, meaning one trip from China to the United States would consume 47,297 gallons of fuel which equates to about 6 million megajoules. (Clayton) (U.S. Energy Information Administration) Once in the United States they watches are packaged and sent off to distribution centers that then transport the watches to stores around the country.

As technology is continuously advances exponentially the lifespan of products still seem to be short in part due to consumers wanting the latest and greatest as well as older technology not having the ability to adapt to new updates. The average Apple Watch Series 4 is predicted to have a lifespan of three to four years. Apple has designed a trade in program that allows consumers to receive money for their old Apple products in an attempt to improve the recycling aspect of their corporation. Once the old product is traded in they are sent to a robot named Daisy to be disassembled in an attempt to reclaim precious metals and materials to use in new products. Daisy can disassemble 200 phones in an hour, while she only deconstructs phone at the moment this new technology could be pivotable for the future of electronics. (Apple)

Further, in the case of the traded in Apple Watch Series 4, the parts will be either repurposed to fix other watches or responsibly recycled. An incredible two thirds of products will be passed on to new owners according to Apple's website. (Apple) While this newly implemented recycling program has a positive outlook for the future, it is important to remember that approximately 71.2 Apple watch units have been sold since the original in 2015. In retrospect Apple has only received 1 million Apple devices since beginning this program. (Apple) Therefore, Apple may be moving in the right direction but that damage is still and has already been done.

The process of mining, manufacturing, and distributing the Apple Watch Series 4 uses a considerable amount of energy. Most of the energy consumed is during the mining and manufacturing process due to the amount of different materials that need to be accumulated before even going into production. While transportation consumes considerably less energy than manufacturing, it is still incredibly high from materials being transported from a variety of countries around the world to the final product being shipped from China to the United States and then making its way to stores in all 50 states. It's important to acknowledge that this report has been on one specific Apple product and that the amount of energy consumed by all electronics made around the world is vast and exponentially damaging. Apple has already began the journey in making their electronics follow a cradle to cradle design, but there is still a great amount of progress to be made until they are successful.

Works Cited

“Aluminium.” Wikipedia, Wikimedia Foundation, 14 Nov. 2019, https://en.wikipedia.org/wiki/Aluminium.

“Aluminum.” How Products Are Made, http://www.madehow.com/Volume-5/Aluminum.html.

“Apple Adds Earth Day Donations to Trade-in and Recycling Program.” Apple Newsroom, 19 Nov. 2019, https://www.apple.com/newsroom/2018/04/apple-adds-earth-day-donations-to-trade-in-and-recycling-program/.

Clayton, Jack. “1 Air Mile.” Blue Sky Model, http://blueskymodel.org/air-mile.

“Distance from China to United States.” Distance Between Cities, https://www.distancefromto.net/distance-from-china-to-united-states.

Epstein, Alex. “The Truth About Apple's '100% Renewable' Energy Usage.” Forbes, Forbes Magazine, 13 Jan. 2016, https://www.forbes.com/sites/alexepstein/2016/01/08/the-truth-about-apples-100-renewable-energy-usage/#27e87acc189c.

Kara, Siddharth. “Is Your Phone Tainted by the Misery of 35,000 Children in Congo's Mines? | Siddharth Kara.” The Guardian, Guardian News and Media, 12 Oct. 2018, https://www.theguardian.com/global-development/2018/oct/12/phone-misery-children-congo-cobalt-mines-drc.

Merchant, Brian. “Everything That's Inside Your IPhone.” Vice, 15 Aug. 2017, https://www.vice.com/en_us/article/433wyq/everything-thats-inside-your-iphone.

Merchant, Brian. The One Device: the Secret History of the IPhone. Corgi Books, 2018.

Mineral Facts and Problems. U.S. Dept. of Interior, Bureau of Mines, 1976.

“Primary Production.” Primary Production | The Aluminum Association, The Aluminum Association , 12 Jan. 2017, https://www.aluminum.org/industries/production/primary-production.

Tsurukawa, Nicolas, et al. “Social Impacts of Artisanal Cobalt Mining in Katanga, Democratic Republic of Congo.” Öko-Institut EV, Freiburg, Nov. 2011, http://resourcefever.com/publications/reports/OEKO_2011_cobalt_mining_congo.pdf.

Tyabji , Nico, and William Nelson. “Mitigating Emissions from Aluminum.” Columbia Climate Center: Columbia University . Google , http://climate.columbia.edu/files/2012/04/GNCS-Aluminum-Factsheet.pdf.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Energy Conversion Calculators - U.S. Energy Information Administration (EIA), Search Results Web Result with Site Links U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/units-and-calculators/energy-conversion-calculators.php.

Apple Watch Series 4: Waste and Emissions

Apple is one of the most well-known companies in the world. They are the epitome of the tech industry due to their sleek, simple design and their impeccable performance and capabilities. The product that my group and I decided to do our research on in the Apple Watch Series. It is basically a small iPhone on your wrist that mainly focuses on time and activity. It includes features like call and text messaging, much like a regular iPhone. As many people are now aware of, climate change and taking care of the environment is a big part of keeping us and future generations from ruining the earth. Things like greenhouse gasses and solid waste are causing the earth to heat up, resulting in the imbalance of the earth’s ecosystem, which messes with the natural cycle of all living creatures on the earth, as well as the materials that are used from the earth. Although Apple is mindful of where they get their raw materials and the conservation of energy to create the Apple Watch Series 4, what has been seen through research is that there is still a significant amount of waste created due to how the materials they use will be disposed of and the waste and emissions it creates to produce it.

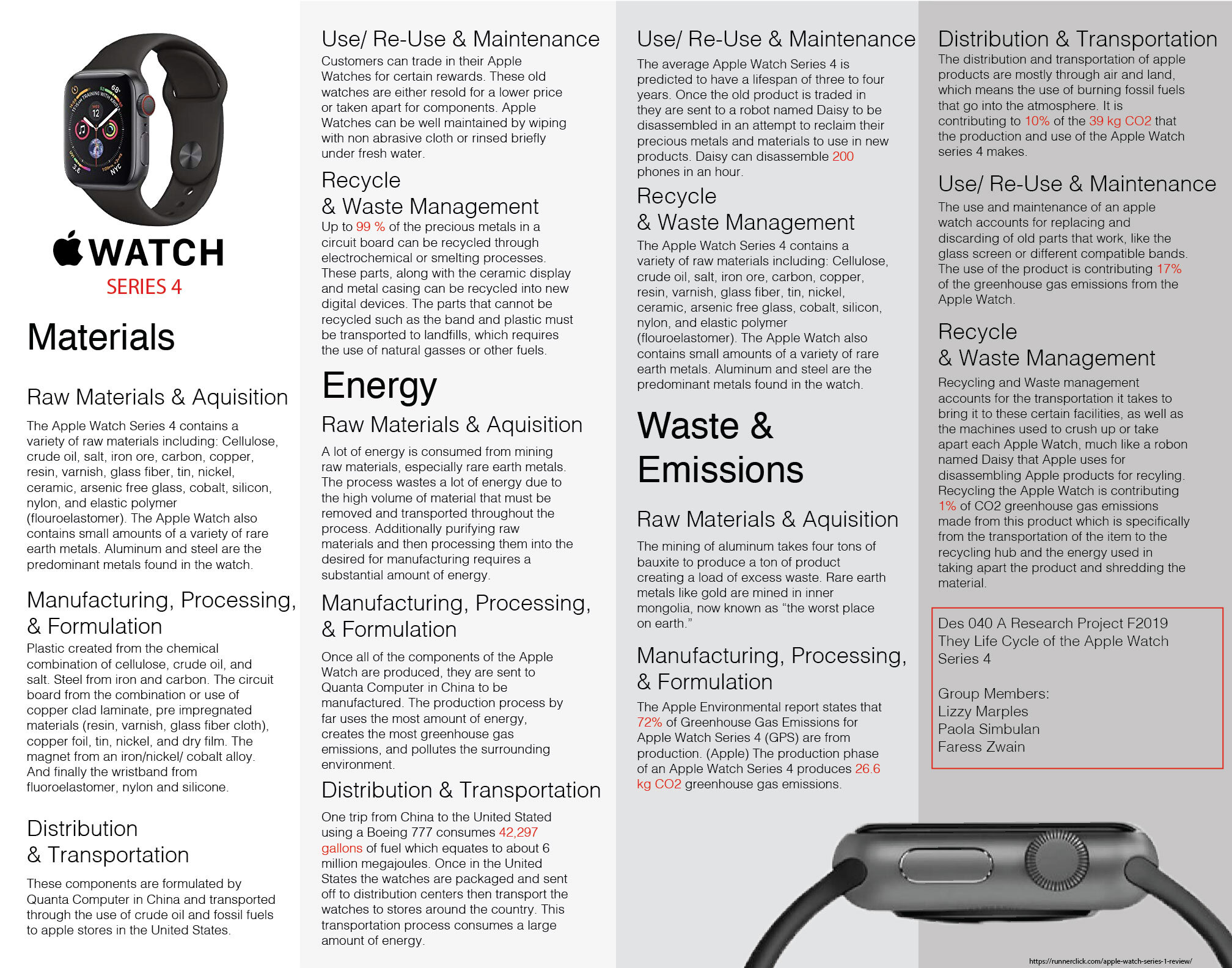

Since the release of the first Apple Watch in 2015, Apple is continuing to strive for a cleaner, greener, way of producing their products. For example, Apple is now using aluminum that was smelted using hydroelectricity rather than fossil fuels, which greatly reduces the greenhouse gasses that are going into the atmosphere. They now also redesigned the way they process and manufacture their watches by using old and left-over aluminum from their different products. Apple is surrounding their newer product designs, like the Apple Watch Series 4, around the use of more sustainable materials that are able to be easily recycled and reused for future products. They also want materials that are durable so their products can last and there will be less of a chance in consuming more materials and to prolong the life cycle of their products. The materials that are used to create the Apple Watch Series 4 are plastic (cellulose, crude oil, and salt), iron ore, carbon, copper, resin, varnish, glass fiber, tin, nickel, ceramic, arsenic free glass, cobalt, silicon, nylon, and elastic polymer (Fluor elastomer). Since Apple products in general are in very high demand, their suppliers that have to harvest the raw materials needed to do so in large portions to be able to supply the demand, which takes up a large amount of energy. The mining of certain metals like aluminum takes four tons of bauxite to produce a ton of product creating a load of excess waste. Rare earth metals like gold are mined in inner Mongolia, now known as “the worst place on earth.”

The largest contributor to the emissions of greenhouse gasses from the production and use of the Apple Watch Series 4 is the manufacturing, processing, and formulating of the product. Manufacturing, processing, and formulating the Apple Watch causes a significant amount of damage to the environment compared to the other steps throughout this process. According to the Apple Watch Series 4 environmental report, they have decreased their greenhouse gas emissions by 12% through Apple's Supplier Clean Energy program. This allows their current watch manufacturers and suppliers to create their own environmentally friendly ways of using energy through the development of their own renewable energy to be able to continue on reducing greenhouse gas emissions in their future productions. According to an article of Vice.com called "Everything That's Inside Your iPhone", Apple has cut ties with as many as 22 manufacturing companies in 2016 because they were not able to meet Apple's standards in terms of labor and human rights for the production and extraction of their products. Combining the raw materials using different machines and factories means more airborne waste, like greenhouse gasses that go into the atmosphere. The Apple Environmental report states that 72% of greenhouse gas emissions for the Apple Watch Series 4 (GPS) are from production. The production phase of an Apple Watch Series 4 produces 26.6 kg of CO2 greenhouse gas emissions.

Due to the large supply and demand of Apple products, specifically the Apple Watch Series 4, there is a good amount of fossil fuels that are burned up through the use of cars, trucks, boats, and planes. A trip from China to the US uses up 42,297 gallons of fuel, when using a Boeing 777, and that is still not including the fossil fuels burned when using land transportation. The distribution and transportation of Apple products are mostly through air and land, which means the use of burning fossil fuels that go into the atmosphere. It is contributing to 10% of the 39 kg of CO2 that the production and use of the Apple Watch Series 4 makes. Although those numbers are staggering, transportation isn't the largest contributor to the greenhouse gas emissions from apple products.

The use and maintenance of an Apple Watch accounts for replacing and discarding of old parts that work, like the glass screen or different compatible bands. With the Apple Watch Series 4, Apple promotes customization for the products that they sell, whether it be a case, screen protector, or a new band. The use of more and more of these means the higher possibility of these products ending up in landfills across the globe or recycling facilities. It also means more consumption of raw materials and use of energy throughout the whole manufacturing process. These extra amenities promoted with the Apple watch doesn't always necessarily mean that it

is only for customization, but also rather for repair and replace when needed. Although the average lifespan of the Apple Watch Series 4 is predicted to be around three to four years, the use of the product is contributing 17% of the greenhouse gas emissions from the Apple Watch.

Apple as a whole brand is very conscious of the environmental part of producing their products. They take initiative to find the greenest suppliers and manufacturers. In efforts on encouraging the recycling of their products, Apple has a program called Apple GiveBack, where the customers can trade in their old Apple products, or old products from a company owned by Apple, for credit through a gift card to use on future purchases. If the product is very old and has little to no value, the company will take it and recycle it for free although they won't give the customer store credit. They strive to not waste any material they create, so they take apart and harvest all of the old parts from the old Apple Products and recycle it. They have a robot designed to take apart old Apple products, named Daisy, so they can reuse the metals, glass, plastic, etc. for future projects of the company, as well as the current products they put out now. The Apple Watch Series 4 has many parts of it that can be recycled for future use, but there are some parts of it that is either very difficult to take apart and recycle, or just plain impossible, due to the chemical bonds and impure forms of the material compared to when it was first assembled. Recycling and waste management accounts for the transportation it takes to bring it to these certain facilities, as well as the machine used to crush up or take apart each Apple Watch. Recycling the Apple Watch is contributing 1% of CO2 greenhouse gas emissions made from the transportation of the item to the recycling hub and the energy used in taking apart the product and shredding the material.

Although Apple is striving to be sustainable and more environmentally friendly, the amount of Apple products that end up in landfills have grown exponentially within the past couple of years. According to Apple Insider, in 2018, Apple had sent 36.5 million pounds of waste to landfills all across the globe. The environmental report of the Apple Watch Series 4 didn't include any statistics or mention of where the Apple Watch goes if it isn't recycled. They are very focused on emphasizing that Apple is getting better in terms of recycling and getting materials from an environmentally friendly manufacturer, but they never mention anything about all the waste Apple creates that goes into the landfill when people don't recycle their products and even packaging. This shows that Apple isn't taking full responsibility of all the damage they are doing to the environment, although it is better than most tech companies. The amount of product they are producing has to come with some baggage because it is inevitable that they don't have large amounts of waste that ends up in the landfills. Apple's hazardous waste has grown and will continue to grow, not because of the way they are handling and manufacturing these products, but simply because of the volume their products, like the Apple Watch Series 4, are being produced. As time goes on, Apple will surely produce more and more products for the demand of the consumers, but Apple is still at fault here. Rather than them promoting the reuse of their old materials, they want their consumers to buy more and more by continually putting out newer products.

Though Apple is mindful of where they gather their materials, the amount of energy they use, and the recycling and disposing of the Apple Watch Series 4, due to the high supply and demand of the product, there are still greenhouse gasses that get put out into the ozone layer. The more fossil fuels that are burned and the more greenhouse gasses that is emitted into the environment, the warmer the planet gets. This warming is what is causing our climate to change which is very dangerous to the health of the people, animals, and ecosystems throughout the whole world. Knowing that, people should be more mindful of the amount of product they consume unnecessarily. Nowadays people get new things not because they need it, but because it is what is now popular in society. Rather than continuing to produce more and more updated versions of the Apple Watch, or any other Apple product in general, Apple should promote the reuse of their old products, or make their products now have a longer life cycle, to really show that they care about the environment. Although recycling and reusing is better for the earth rather than just throwing everything in a landfill, the best thing people can do to protect the environment and help prevent the further worsening of climate change is to reduce the use of products in general, especially when it isn't very necessary.

Works Cited

“Apple Releases 13th Annual Supplier Responsibility Progress Report.” Apple Newsroom, 20 Nov. 2019, www.apple.com/mz/newsroom/2019/03/apple-releases-13th-annual-supplier-responsibility-progress-report/.

“Apple Reaches Landfill Landmark.” Supply Management, 8 Mar. 2019, www.cips.org/en/supply-management/news/2019/march/apple-reaches-landfill-landmark/

“Apple Vows 100% Recycled Marterials.” Computer & Technology Resource Center, 28 Apr. 2017, ewastecollective.org/apple-vows-100-recycled-marterials/.

Apple Watch Series 4 Environmental Report. Apple Inc, Sept. 2018, https://www.apple.com/environment/pdf/products/watch/Apple_Watch_Series4_GPS_PER_sept2018.pdf.

Chow, Lorraine. “Ever Wonder What's Happened to the More Than 570 Million IPhones Sold Since 2007?” EcoWatch, EcoWatch, 22 Mar. 2019, www.ecowatch.com/ever-wonder-whats-happened-to-the-more-than-570-million-iphones-sold-s-1882178171.html.

Environmental Responsibility Report. Apple Inc, 2019, https://www.apple.com/environment/pdf/Apple_Environmental_Responsibility_Report_2019.pdf.

Epstein, Alex. “The Truth About Apple's '100% Renewable' Energy Usage.” Forbes, Forbes Magazine, 13 Jan. 2016, https://www.forbes.com/sites/alexepstein/2016/01/08/the-truth-about-apples-100-renewable-energy-usage/#27e87acc189c.

Kvande, Halvor, and Per Arne Drabløs. "The aluminum smelting process and innovative

alternative technologies." Journal of occupational and environmental medicine 56.5 Suppl (2014): S23.

Mashable. “How the Apple Watch Is Made.” Mashable, 15 Mar. 2015, https://mashable.com/2015/03/15/apple-Watch-how-its-made/.

Merchant, Brian. “Everything That's Inside Your IPhone.” Vice, 15 Aug. 2017, https://www.vice.com/en_us/article/433wyq/everything-thats-inside-your-iphone.

Staff, and Staff. “Rio Tinto Collaboration With Apple On Carbon-Free Aluminium

Production To Move Forward.” Aluminium Insider, 12 Mar. 2019, https://aluminiuminsider.com/rio-tinto-collaboration-with-apple-on-carbon-free-aluminium-production-to-move-forward/.

Zhang, Hui, et al. "Investigation of the residual heat recovery and carbon emission mitigation

potential in a Chinese steel making plant: A hybrid material/energy flow analysis case

study." Sustainable Energy Technologies and Assessments 2 (2013): 67-80.