Design Life-Cycle

assess.design.(don't)consume

Daphne Tran

Professor Christina Cogdell

DES40A

14 March 2023

Life Cycle of Winsor and Newton Watercolor Paints: Raw Materials

Winsor and Newton is a London based company founded in 1832 that produces fine art products for consumer use. One of their most popular items is their watercolor paint tubes. Seeing that the company has been around for almost two centuries, the standard for what ingredients are most commonly used in consumer based products has changed quite drastically over the years that Winsor and Newton have been manufacturing art supplies. Even beyond the products themselves, the materials and methods in which these paints are manufactured, consumed, and disposed of has also shifted alongside our developing society. Analyzing the raw materials used throughout the complete life cycle of Winsor and Newton watercolor paint tubes as they currently are can help serve as a basis to compare to any future changes in this process.

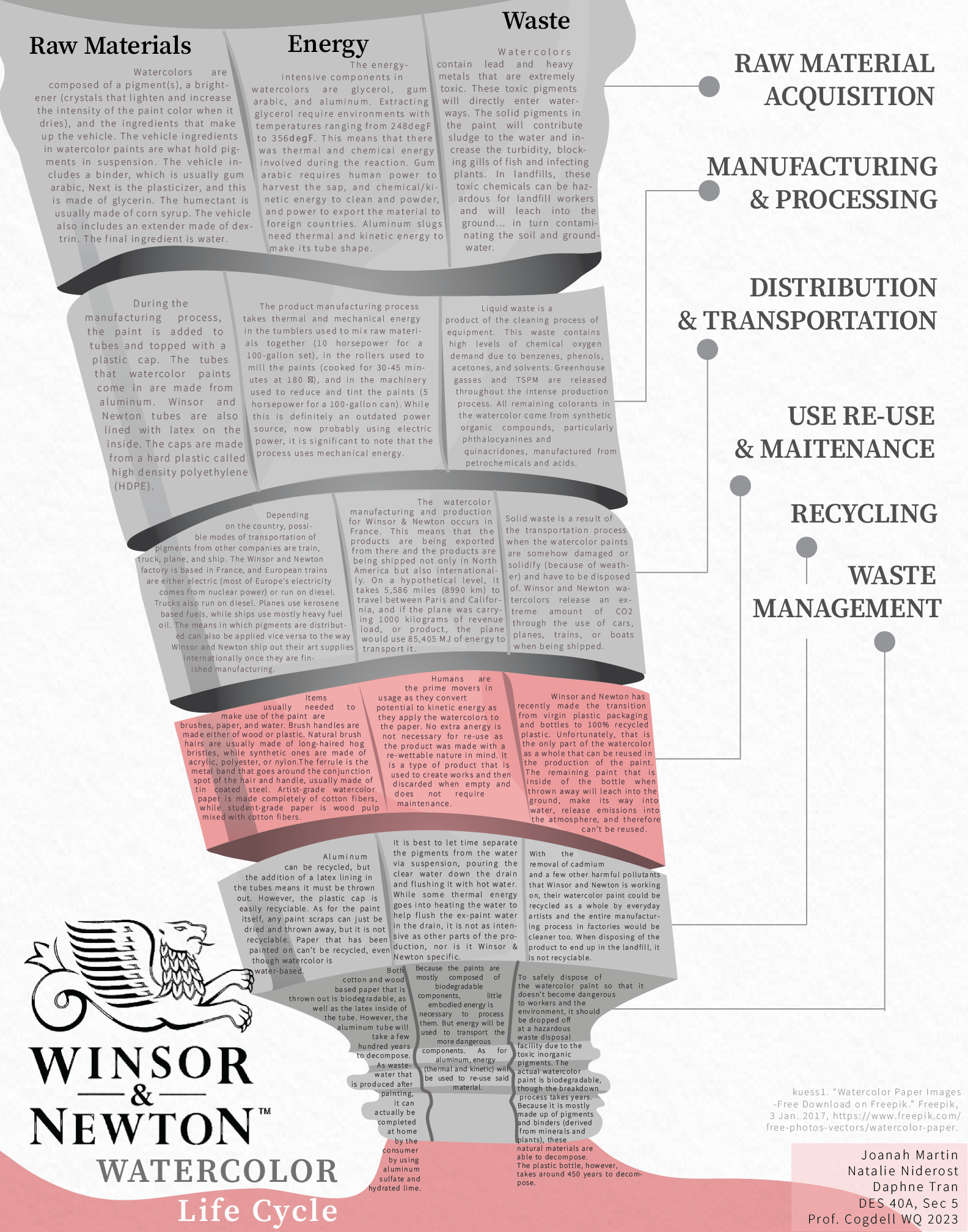

First, and most importantly, are the components that make up the paint itself. Watercolors are composed of a pigment(s), a brightener (crystals that lighten and increase the intensity of the paint color when it dries), and the ingredients that make up the vehicle. The vehicle ingredients in watercolor paints are what hold pigments in suspension, which gives the paint the ability to be picked up with a brush and binded to the paper. The vehicle includes a binder, which is usually gum arabic, and helps to bind the paint to what it’s being painted on. Next is the plasticizer, which is what allows watercolors to be rewettable after drying out, and this is made of glycerin. The humectant is what is used to help the paint retain moisture, and is usually made of corn syrup. The vehicle also includes an extender made of dextrin, which helps thicken the paint. The final ingredient is water and it helps to dissolve and suspend the ingredients from the brush to the paper, evaporating to leave the ingredients on the paper dry and binded. Winsor and Newton pigments were originally made from natural ingredients that were ground using a glass muller (flattened doorknob shaped tool) and a slab of glass. Each color of paint obviously needed a different material to achieve, but two examples are ultramarine and ochre. Ultramarine is a type of rock that had to be processed and ground many times before getting a small amount of the blue-ish pigment. As for ochre, it could be easily made with soft, brown rocks from the ground. However, these colors, as well as most of their other colors, are now made using synthetic materials. Synthetic pigments make up almost all of the pigment types today, almost fully replacing their natural counterparts. The most widely used pigment is titanium dioxide, which acts as a white base for paints. It is produced by mining ilmenite and using the sulfate (combining with sulfuric acid) or chloride process (combining with chlorine and carbon coke) to separate the mineral from its ore. Iron oxide is an extremely popular pigment as well, providing reds, oranges, and yellows. Iron oxide comes from the steelmaking process. Steel is treated with hydrochloric acid to remove impurities, and when this acid is recycled, the byproduct is iron oxide. The next ingredient in watercolor paints is the brightener, and one of the more common materials used as a brightener is alumina trihydrate. It’s a white-ish powder that is made from grounding up the mineral bauxite. To bind the paint to the paper, gum arabic is used, and is a naturally occurring hardened sap that is collected from acacia trees in northern Africa. The trees are tapped for its gum, and then the gum is dissolved, and filtered for impurities before being mixed into the paint. Plasticizer, usually made of glycerin, can come from both plants and animals. Soybeans, palm, and animal tallow are the most common sources of glycerin. The fat from an animal or plant is put through hydrolysis (using water to split fat into glycerol and oil) or transesterification (using alcohol to split fatty acids and glycerol). The humectant is made of corn syrup most of the time. Corn syrup comes from the hydrolysis of cornstarch, but using enzymes instead of water. It can also be made by combining acids with the cornstarch. Dextrin is what is used as the extender in the paint. It is also produced through the hydrolysis of starches (like wheat, corn, or potato), which is then roasted dry, turning it into dextrin. Overall, the components in Winsor and Newton watercolor paints have stayed relatively consistent overtime, only making alterations between using the natural or synthetic version of materials.

During the manufacturing process, the paint is added to tubes and topped with a plastic cap. The tubes that watercolor paints come in are made from aluminum. Aluminum comes from the clay mineral bauxite, which is mined out of the ground. After it is washed and grinded, caustic soda and steam heat is added to create a sodium aluminate solution. From this solution, crystals of aluminum are formed and smelted to create pure aluminum. The material can then be heated up and rolled into sheets before becoming paint tubes. Winsor and Newton tubes are also lined with latex on the inside. Latex comes from collecting the substance that lies beneath the bark of rubber trees, and putting this liquid through a centrifuge to remove some of the water content. The insides of paint tubes are then lined with heated liquid latex and left to dry. There is also plastic used for the cap. These are made from a hard plastic called high density polyethylene (HDPE), which can be formed by applying high heat to petroleum (that is extracted from deep within the ground). Previously, these tubes and the cap that comes with it were made of tin, which were much less flexible compared to aluminum.

Related to the manufacturing process is the distribution of pigments from other companies to Winsor and Newton, and what materials are involved in that process. Pigments are supplied by the same few manufacturers to almost all paint companies. These include companies from Germany and Switzerland, the United Kingdom, the United States, Japan, India, and China. However, Winsor and Newton manufacture their own products in France at the Lefranc and Bourgeois factory. This means that pigments must be imported from many other countries into France. There isn’t much information on how these pigments are transported, but it can be assumed which methods are used based on geography. Presumably, pigments coming from Germany and Switzerland are either driven or imported by train because they are right next to France. However, planes are still a possibility. European trains are either electric (most of Europe’s electricity comes from nuclear power) or run on diesel. Diesel comes from petroleum oil that is put through fractional distillation, or the process of heating up the oil so that certain components of the mixture vaporize and then get turned back into liquid, thus separating the oil into different parts. Trucks also run on diesel. Every other country must import pigments through ships or by plane because they are much farther from France and are disconnected by water, but most likely by ship because 80-90% of all internationally traded goods are none so by sea. Planes use kerosene based fuels instead of regular gasoline because it lasts longer, burns at higher temperatures and freezes at lower, and is cheaper. Kerosene nowadays comes from petroleum oil that is extracted from the ground and is then fractionally distilled. As for ships, they use mostly heavy fuel oil. Heavy fuel oil is actually made as a byproduct of the fractional distillation process, and comes in a tar-like consistency. The means in which pigments are distributed can also be applied vice versa to the way Winsor and Newton ship out their art supplies internationally once they are finished manufacturing.

Once the watercolor paints reach are sent out for sale at the consumer level, the items usually needed to make use of the products are brushes, paper, and water. Brushes are composed of a handle and the brush hairs. Handles are made either of wood or plastic. As for the hair, there are natural and synthetic versions. Natural brushes are usually made of long-haired hog bristles, while synthetic ones are made of acrylic, polyester, or nylon. For watercolors specifically, synthetic brushes are more likely to be used because they are better for picking up water-based paints. The hairs are adhered to the handle with epoxy. The ferrule is the metal band that goes around the conjunction spot of the hair and handle, usually made of tin coated steel. Watercolor paper needs to be thick and absorbent enough to withstand the amount of water used in watercolor painting. As a result, artist-grade watercolor paper is made completely of cotton fibers, while student-grade paper is wood pulp mixed with cotton fibers. These few, and relatively simple items are the only essentials that are needed for someone who uses watercolor paints.

Once the consumer has used up their watercolors, there are components of the paint and items that are needed to use the paint that may or may not be recyclable. As mentioned previously, Winsor and Newton use a latex lined aluminum paint tube topped with a HDPE cap. Aluminum can be recycled, but the addition of a latex lining means it must be thrown out. However, the plastic cap is easily recyclable. As for the paint itself, any paint scraps can just be dried and thrown away, but it is not recyclable. Paper that has been painted on can’t be recycled, even though watercolor is water-based. This is because once paper has been wet, the paper fibers have been damaged and can no longer be recycled. Additionally, higher-grade watercolor paper is made from cotton fibers, which can’t be recycled either. Many of the items in or involved with watercolor painting must be thrown out and processed by waste management.

Once the consumer has thrown out their watercolor paints and items associated, recycling what they can, these components are likely to end up at the landfill. Both cotton and wood based paper that is thrown out is biodegradable, as well as the latex inside of the tube, so they do not need extra substances in order to throw away properly. However, the aluminum tube will take a few hundred years to decompose. As wastewater that is produced after painting, it can actually be completed at home by the consumer by using aluminum sulfate and hydrated lime. This is probably similar to how the water were to be treated if simply dumped down the drain for waste management to handle. When these two ingredients are added to wastewater, the solid (paint) will sink to the bottom and leave clear water at the top. The solids should be thrown away, and the water can then be flushed, or go through the next stages of wastewater treatment if in a facility. The two should be separated because sometimes the pigments can be harmful (like cadmium and cobalt), and it would be dangerous if they leaked into water reservoirs. Although many of the components used in the production and use of watercolor paints are to be thrown out, most are either biodegradable or don’t take very much effort to be disposed of properly.

Changes to the life cycle of Winsor and Newton watercolors over the two centuries they have been in production have been relatively minimal, so should we expect much to change going forward? Rather, would it be possible to make alterations in the materials they currently use to manufacture items as a way to address current environmental pressures? For example, their paint tubes could be lined with another product on the inside so that they are recyclable. Another idea is replacing the cadmium and cobalt used in some of their paints entirely? If every manufacturing company were to make small, but better decisions in the raw materials they use, it could perhaps make enough of a difference to impact our environment positively.

Bibliography

Young, Aurora O. “Is Watercolor Paint Toxic to the Skin? Is Lead in It?” A.O.Y. Art Center, A.O.Y. Art Center, 30 Oct. 2022, https://www.aoyartcenter.org/is-watercolor-paint-toxic-to-the-skin.

Pozzi, Federica, et al. “Winsor & Newton Original Handbooks: A Surface-Enhanced Raman Scattering (SERS) and Raman Spectral Database of Dyes from Modern Watercolor Pigments.” Heritage Science, vol. 1, no. 1, 2013, p. 23., https://doi.org/10.1186/2050-7445-1-23.

Newman, R., et al. “Analysis of Watercolor Pigments in a Box Owned by Winslow Homer.” Journal of the American Institute for Conservation, vol. 19, no. 2, 1980, pp. 103–105., https://doi.org/10.1179/019713680806028867.

“Sources of Food Ingredients: Gum Acacia.” Food Ingredient Facts, International Food Additives Council, 12 Feb. 2021, https://www.foodingredientfacts.org/facts-on-food-ingredients/sources-of-food-ingredients/gum-acacia/.

Kremer Pigmente GmbH & Co. KG. “Watercolor Based on Gum Arabic.” Kremer Pigmente Online Shop, Kremer Pigmente, https://www.kremer-pigmente.com/en/information/recipes/watercolor-based-on-gum-arabic/#:~:text=Gum%20Arabic%20is%20often%20used,breaks%20with%20a%20glassy%20fracture.

Editor. “What's next for Artist Paint Tubes?” The Art Treehouse, The Art Treehouse, 27 Apr. 2019, https://arttreehouse.com/artstore/whats-next-for-artist-paint-tubes/#:~:text=Currently%2C%20aluminum%20has%20replaced%20tin,for%20historical%20and%20marketing%20purposes.

“Our History.” Winsor & Newton - North America, Winsor & Newton, 26 Mar. 2020, https://www.winsornewton.com/na/heritage/our-history/.

“From the Archives: The History of the Metal Paint Tube.” Winsor & Newton - North America, Winsor & Newton, 9 Mar. 2022, https://www.winsornewton.com/na/articles/art-history/history-metal-paint-tube/.

Magazine, Smithsonian. “Never Underestimate the Power of a Paint Tube.” Smithsonian.com, Smithsonian Institution, 1 May 2013, https://www.smithsonianmag.com/arts-culture/never-underestimate-the-power-of-a-paint-tube-36637764/.

MacEvoy, Bruce. “Paints.” Handprint, Handprint, 1 Aug. 2015, https://www.handprint.com/HP/WCL/pigmt1.html.

“Paint.” How Products Are Made, How Products Are Made, http://www.madehow.com/Volume-1/Paint.html.

Artists Network. “Water-Based Paint Disposal.” Artists Network, 29 Jan. 2008, https://www.artistsnetwork.com/magazine/water-based-paint-disposal/.

Baadmin. “The Manufacturing Basics of Aluminium.” BA Systems, BA Systems, 28 Oct. 2021, https://www.basystems.co.uk/blog/aluminium-manufacturing-basics/.

“Paint.” How Products Are Made, How Products Are Made, http://www.madehow.com/Volume-1/Paint.html.

Joanah Martin

DES 040A, Sec. 5

Prof. Cogdell

15 March 2023

Winsor & Newton Watercolors: Embodied Energy

"Winsor & Newton Ltd. has always been one of the main art materials suppliers in the world, manufacturing a wide assortment of fine art products" (Pozzi et al.). The specific product being explored in this paper is Winsor & Newton watercolors, which come in tubes. Chemist William Winsor and businessman Henry Newton collaborated to create a product that was re-wettable and has since created "industrial standards, new formulations, vibrant new colours and convenient packaging" ("The Golden Age of Watercolour"). They were revolutionary in the standardization of the medium. With this, it does take much energy not only to create the product but also to distribute the watercolors. The chemical inputs and human power required for the production of raw materials, the electrical and kinetic energy needed for product manufacturing, and the fuel for the transportation and distribution of Winsor & Newton watercolor paints contribute to the majority of the input required in its life cycle. However, this also presents opportunities for improvement through transitions from potential energy sources (like fossil fuels) to something more sustainable.

One aspect of the life cycle where the energy input is high is the production of raw materials. While there are many components in watercolors, the energy-intensive ones are glycerol, gum arabic, and aluminum. Glycerol itself is a byproduct of biodiesel production, which researchers from the Institute of Comprehensive Utilization of Plant Resources at Kaili University say has a complicated extraction process that requires high energy consumption, specifically for paints, glycerol-carbonate from propylene chlorination (Li et al.). While there are various ways and catalysts to produce glycerol-carbonate, almost all the reactions required environments with temperatures ranging from 120 degrees Celsius (℃) to 180℃, or 248 degrees Fahrenheit (℉) to 356℉ (Li et al.). This means that energy was required to keep the environments at a high temperature in a stable manner. This also means that there was thermal and chemical energy involved during the reaction itself to create glycerol-carbonate products.

Another notable raw material is gum arabic (GA). In an article published by Seema Patel and Arun Goyal, from the Bioinformatics and Medical Informatics Research Center at San Diego State University and the Department of Biotechnology at the Indian Institute of Technology, respectively, they touch on the location where GA is predominantly harvested and exported. They write, "Sudan is the largest exporter, accounting for up to 80% of the trade, followed by Nigeria. The dried saps are harvested…cleaned of extraneous materials, kibbled or powdered, and exported" (Patel and Goyal). First off, energy is used by human workers and farmers to harvest the sap. Second, when it says it is cleaned and powdered, it suggests it goes through a process that is either chemical or kinetic—either way, a process that needs energy. Finally, it needs energy to export the material to foreign countries—for Winsor & Newton specifically, as their production is based in France, there are 2856 miles of air distance (Sharing Culture).

The last material to be discussed in depth is the aluminum needed to create the aluminum tube packaging. It typically comes from aluminum slugs and blanks that need to be shaped into a tube. Tube Council, a website explaining the processes used to create different types of tubes, writes that making an aluminum tube calls for an extrusion press to roughly form a tube. During extrusion, "it is passed through a process [that] makes the metal malleable. This is done at about 460 degrees [celsius]" or 860℉ (The Tube Council). This means that in order to create an aluminum tube, it requires a high thermal energy input as well as kinetic energy to form the necessary shape.

This is not to say that no energy goes into the other materials: additives, pigments, fillers, or solvents. The pigments, natural and synthetic, require energy to produce and export, but more needs to be revealed about specific processing, thus making it difficult to understand what power is needed (Pozzi et al.). But there has been action—albeit applied to another medium of paints called coatings that have some material similarities to watercolors–to decrease the amount of energy going into making the paints. One major point being addressed is the increase in manufacturing efficiency, specifically "approaches for heat recovery…and general process optimization to improve yields and reduce cycle times…for all industrial processes used in [the] paint and coatings industry" (American Coatings Association). Though just saying that there are actions taken in manufacturing does little to explain the actual energy inputs needed for watercolors, The product manufacturing process takes thermal and mechanical energy in the tumblers used to mix raw materials together, in the rollers used to mill the paints, and in the machinery used to reduce and tint the paints. An article published in 1949, "Paint and Varnish Manufacture," by Will H. Shearon explained the processes and the amounts of energy needed during each step. During the mixing process, it takes 10 horsepower (hp) (7457 watts) to mix a 100-gallon set and 15 hp (11185.5 watts) for a 200-gallon mixer (Shearon et al.). This showcases the amount of energy put into mass-mixing watercolors. The roller used to mill the paints is to ensure all the raw materials and pigments are properly emulsified and heterogeneous. When the emulsifying agent is added (for Winsor & Newton, it’s most likely the GA), it is "cooked for 30-45 minutes at 180℉" (Shearon et al.). During this process, it takes thermal energy to heat up the mixture and kinetic energy to emulsify the mixture with pigments in the three-roll mill. Finally, in the reduction and tinting mixers, a 5 hp (3728 watts) motor was used for a 100-gallon can using compressed air (Shearon et al.). While this is definitely an outdated power source, now probably using electric power, it is significant to note that the process uses mechanical energy. Despite the age of the article and how the energy efficiency during manufacturing has most likely increased with better technology and how much larger the production scale Winsor & Newton has, this is a good basis to understand the general energy input. A lot of kinetic energy is used to mix the paints together, reduce, and tint the paint—a 100-gallon set can total up to 11,185 watts of power. There is also the thermal energy used when initially emulsifying the paint and the mechanical energy needed in the three-mill rolling process itself. The production process is quite energy-intensive.

As stated previously, much of the watercolor manufacturing and production for Winsor & Newton occurs in France. This means that the products are being exported from there; as suggested by their shipping and delivery page, the products are being shipped not only in North America but also internationally ("Shipping"). According to the IEA, 9.5 MJ/RTK is the average amount of energy used in international aviation in 2021. MJ/RTK refers to the number of megajoules of energy used when a metric ton (1000 kilograms) of revenue load is carried one km (IEA). In a general sense, this means that a lot of energy, most likely powered by fossil fuels, is used when shipping the product. On a hypothetical level, it takes 5,586 miles (8990 km) to travel between Paris and California, and if the plane was carrying 1000 kilograms of revenue load, or product, the plane would use 85,405 MJ of energy to transport it. To put this in perspective with the production process, that is equivalent to 23,723,611 watts. This is only shipping to CA, not counting the other countries to which shipping is possible. It is important to note that during the history of aviation, there have been improvements in creating greater energy efficiency, but it is not enough to keep up with the activity. Transportation requires a lot of energy, so it needs a proper power source to supply it. As of 2021, it contributed to over 2% of global energy-related CO2 emissions, or around 720 metric tons of carbon dioxide (IEA). Due to this extremely negative impact, it can be argued that a more sustainable and greenhouse gas-emitting fuel source will be necessary for future aviation travel.

While the raw materials, production, and transportation of watercolors use a majority of the embodied energy in their life cycle, it is important to touch on the other aspects of that cycle: its use and reuse, maintenance, and waste management. Truthfully, there is not much to say regarding its use and maintenance. It is a type of product that is used to create works and then discarded when empty. It is also a type of product that does not require maintenance. As for the last aspect, it is possible to recycle old watercolor paint water. According to a blog post about recycling paints by Russell McLendon, it is best to let time separate the pigments from the water via suspension, writing "you can pour [the clear water] down the drain, and flush it with hot water" and then wiping away the excess paint pigments (McLendom). While some thermal energy goes into heating the water to help flush the ex-paint water in the drain, it is not as intensive as other parts of the production, nor is it Winsor & Newton specific—this is just a generally recommended practice to dispose of watercolors.

The production of the raw materials to make watercolors, particularly in glycerol, requires chemical and kinetic energy to create. However, there have been initiatives to decrease the amount of energy used in some aspects of the raw materials and in the production of the paint. On the topic of producing the watercolors themselves, it takes quite a bit of thermal and kinetic energy to create large batches for mass production. Finally, for transportation, while there have been improvements in energy efficiency in aviation, it is not enough to offset the activity. Much has changed since watercolors were first created, including the different energies needed and the energy efficiencies. It is energy intensive in the raw materials, production, and transportation sections of its life cycle.

Works Cited

American Coatings Association. Coatings Industry Innovations Enable Energy Conservation. https://www.paint.org/coatingstech-magazine/articles/coatings-industry-innovations-enable-energy-conservation/.

IEA. Aviation. www.iea.org/fuels-and-technologies/aviation.

Li, Xue-Lian, et al. “A Review of Catalytic Upgrading of Biodiesel Waste Glycerol to Valuable Products.” Current Green Chemistry, vol. 7, no. 3, Dec. 2020, pp. 259–66. DOI.org (Crossref), https://doi.org/10.2174/2213346107666200108114217.

McLendom, Russell. Can Paint Be Recycled? https://www.treehugger.com/paint-recycling-5184379.

Patel, Seema, and Arun Goyal. “Applications of Natural Polymer Gum Arabic: A Review.” International Journal of Food Properties, vol. 18, no. 5, May 2015, pp. 986–98. DOI.org (Crossref), https://doi.org/10.1080/10942912.2013.809541.

Pozzi, Federica, et al. “Winsor & Newton Original Handbooks: A Surface-Enhanced Raman Scattering (SERS) and Raman Spectral Database of Dyes from Modern Watercolor Pigments.” Heritage Science, vol. 1, no. 1, 2013, p. 23. DOI.org (Crossref), https://doi.org/10.1186/2050-7445-1-23.

Shearon, Will H., et al. “PAINT AND VARNISH MANUFACTURE.” Industrial & Engineering Chemistry, vol. 41, no. 6, June 1949, pp. 1088–97. DOI.org (Crossref), https://doi.org/10.1021/ie50474a002.

The Tube Council. How Aluminum Tubes Are Made. https://tube.org/how-aluminum-tubes-are-made/.

Sharing Culture. Where Are Winsor Newton Watercolors Made? https://www.sharingculture.com.au/where-are-winsor-newton-watercolors-made.

Winsor & Newton. Shipping & Delivery. https://www.winsornewton.com/na/shipping-delivery/.

Winsor & Newton. Winsor & Newton and The Golden Age of Watercolour: 1750-1850. https://www.winsornewton.com/na/articles/art-history/winsor-newton-and-the-golden-age-of-watercolour-1750-1850/.

Natalie Niderost

Daphne Tran and Joanah Martin

DES 40

Professor Cogdell

Winsor and Newton Watercolor: Waste and Emissions

Winsor and Newton watercolor is a well known product used for high quality painting because of its superior pigmentation and re-wettability. This specific watercolor does last longer than other watercolors because of the re-wettability aspect but there is still a lot of waste left over. After using this product, there are plastics, and many different chemical wastes and pigments left over that can’t be recycled. It is important to study its sustainability because of the major waste that is involved after being “finished” with the product. Examining its environmental impact from a life cycle perspective shows that the toxic inorganic pigments (lead carbonate, cobalt, cadmium, manganese, etc.) contribute to the most environmental damage, although there are other components such as transportation and atmospheric emissions released that further disrupt the environment.

Winsor and Newton watercolor paint has not been studied already in this class. There has been research done on spray paints, chalk, and paint brushes (for example)… but nothing on watercolors. Since our group have chosen watercolors, we will contribute entirely new waste products and processes to the website for people to learn about. Winsor and Newton watercolor paints are different from other paints studied because of their hazardous pigments in their product. This watercolor is a high quality paint because of the smooth texture and convenient re-wettability property. Winsor and Newton has taken responsibility for the fact that they do use harmful chemicals such as cadmium and lead to achieve this quality of paint, realizing that these are dangerous for entire ecosystems, workers in landfills exposed to this waste, and emissions that are released into the atmosphere as a result of of these toxic pigments. Other paints such as acrylic paint or different brands of watercolor paints are safer since they don’t use toxic inorganic pigments. Winsor and Newton watercolor paint will be able to contribute differences in the wastes and process of how these waste and emissions affect the environment.

Before diving into the waste and emissions process, it is beneficial to know the materials that are left over after using the watercolor. Because of Winsor and Newton’s re-wettability component, their watercolor lasts significantly longer than other brands since artists can continue using the product even after it has dried out. After throwing the remaining product away, there are many materials and chemicals that are leftover. All of the plastic packaging of the watercolor tube is obviously thrown away but the chemicals, heavy metals, solvents, and oils in the remaining bits of paint after then left too. The main toxic inorganic pigment used in watercolor paint is basic lead carbonate but all lead pigments, cadmium pigments, chrome yellow, zinc yellow, and titanium dioxide are inorganic pigments as well. All remaining colorants in the watercolor come from synthetic organic compounds, for example phthalocyanines and quinacridones, which are manufactured from petrochemicals and acids. Materials used to bind and thin the paint (achieve the physical textures) are glycerin, gum arabic, honey, and ox gall. Each of these substances contribute to environmental releases and climate change, which can now be assessed after identifying all of the waste involved in the watercolor after it is used.

It’s important to consider that although a lot of the environmental damage comes from the physical materials and substances used in the paint itself, there is also a lot of damage coming from the energy used to make the product. Watercolor that contains lead and heavy metals is extremely toxic to humans and animals, which is dangerous when these watercolors are disposed of. When not disposed of at all, these toxic pigments (along with the plastic packaging) will directly enter waterways. These pigments are toxic to all living beings in water, as the solid pigments in the paint will contribute sludge to the water and increase the turbidity, directly blocking gills of fish and infecting plants. When disposed of in landfills, these toxic chemicals can be potentially hazardous for landfill workers and will leach into the ground… in turn contaminating the soil and groundwater. A liquid waste is a result of the cleaning process of equipment in the manufacturing of the product. This waste contains high levels of chemical oxygen demand due to phenols, acetones, benzenes, and solvents. Another waste emissions issue is that of airborne contaminants. Greenhouse gasses and total suspended particulate matter are released throughout the intense production process. Watercolor paint is high in Volatile Organic Compounds which react with oxygen to contribute further to the ozone layer. VOCs are the vapor emissions resulting from solvents used in the paint. Solid waste is generated from any sort of defect in the containers, pigment color, paint texture, lid shape, etc. or solid plastic containers being thrown away after use. Solid waste is also a result of the transportation process when the watercolor paints are somehow damaged, solidify from harsh weather, etc. Transportation is another waste involved in the production and after-life process of watercolors. These watercolors have to be shipped to every artist using them and every different manufacturing factory they have to be produced at so there is an extreme amount of CO2 being released through the use of cars, planes, or boats. Each of these waste components further contributes to climate change and environmental damage, but there are some ways Winsor and Newton is working towards a more sustainable watercolor and some ways that we can better dispose of these substances.

Winsor and Newton plans to start making cadmium free alternatives and use energy that comes from renewable resources, hoping to make their business carbon neutral by 2025. Winsor and Newton is also creating a more sustainable packaging for their paints, that of which is reduced in weight so there is much less plastic involved. To safely dispose of the watercolor paint so that it doesn’t become dangerous to workers and the environment, they should be dropped off at a hazardous waste disposal facility, not just thrown in the trash to go to a landfill. With the removal of cadmium and a few other harmful pollutants that Winsor and Newton uses, their watercolor paint could be recycled as a whole by everyday artists and the entire manufacturing process in factories would be cleaner because of it as well. The actual watercolor paint is biodegradable, though the breakdown process takes years. Because they are mostly made up of pigments and binders (derived from minerals and plants), these natural materials are able to decompose. The plastic bottle, however, takes around 450 years to decompose. By now understanding the recycling and decomposition processes, the “full circle” system can be achieved.

When a product is designed, there is most likely a full circle movement. This means that the end of the life cycle of the product will then re-contribute back to the start of creating this product again. After the watercolor is disposed of, waste and emissions disperse and absorb in waterways, atmosphere, soil, etc. There are components that can be recycled and reused for the reproduction of the product. Winsor and Newton has recently made the transition from virgin plastic packaging and bottles to 100% recycled plastic. Unfortunately, that is the only part of the watercolor as a whole that can be reused in the production of the paint. The remaining paint that is inside of the bottle when thrown away will leach into the ground, make its way into water, release emissions into the atmosphere, and therefore can’t be recycled and reused.

It is important to understand the sustainability of Winsor and Newton watercolor because of the major waste that is involved after being “finished” with the product. After researching the environmental impact this watercolor has in regards to its life cycle, we are able to see that the pigments, heavy metals, and solvents contribute to serious environmental damage. Our group can conclude that although Winsor and Newton is moving toward a more sustainable product, there are still safer and more environmentally friendly options to choose from. We have also learned about the specific pigments and chemicals used to achieve the physical appearance of this paint as well as how these components affect the entire manufacturing process, being derived from the ground, being used around humans, and the waste that disperses on the Earth. The convenient properties that Winsor and Newton watercolor contains outcompete most, but it is important to consider the damage caused by this paint and make the decision if it is worth it to contribute to this damage.

Bibliography

“A Brief History of Watercolor Painting: Blog: Escape Motions.” Celebrate 10 Years of Escape Motions!, 20 Feb. 2019, https://www.escapemotions.com/blog/a-brief-history-of-watercolor-painting.

“Better for You, Better for the Planet: How to Choose and Use Our Oils, Mediums and Varnishes Sustainably.” Winsor & Newton - UK, 7 Mar. 2023, https://www.winsornewton.com/uk/articles/art-materials/better-for-the-planet-more-sustainable-paint-mediums-and-varnishes/.

Carla, et al. “Disposing Paint Waste.” Eco Painting Inc, 21 Aug. 2022, https://ecopainting.ca/eco-painting/environmental-tips/disposing-paint-waste/.

“Helping Artists Make Sustainable Choices.” Winsor & Newton - ROW, 23 Feb. 2023, https://www.winsornewton.com/row/sustainability/.

Friberg, Lars. “Cadmium in the environment.” (1971).

Improvemypaintings. “What You Need to Know about Watercolor Pigments.” Artists Network, 11 Dec. 2017, https://www.artistsnetwork.com/art-mediums/watercolor/watercolor-painting-what-you-need-to-know-about-watercolor-pigments/.

Kenneth. “Watercolor vs Acrylic Paint: What Is the Difference?” ACRYLICUS.COM, 8 Jan. 2022, https://www.acrylicus.com/watercolor-vs-acrylic-paint/#:~:text=Watercolor%20paint%20comes%20from%20a%20high%20textured%20pigment%2C,the%20color%20of%20the%20pigment%2C%20hiding%2C%20or%20viscosity.

“Section 10: Painting and Drawing.” Environmental Health & Safety | Baylor University, https://www.baylor.edu/ehs/index.php?id=94372#waterbased.

The Pros and Cons of Winsor & Newton Watercolors. https://huckleberryfineart.com/the-pros-and-cons-of-winsor-newton-watercolors/.

The Negative Environmental Impact of Watercolor Paint. https://huckleberryfineart.com/the-negative-environmental-impact-of-watercolor-paint/.

“Types of Waste in the Paint and Related Products Industry.” Oliver + Batlle, marketingDT360. Https://Oliverbatlle.com/Wp-Content/Uploads/2020/04/logosin60-300x87.Png, 4 Feb. 2021, https://oliverbatlle.com/en/types-of-waste-in-the-paint-industry/.