Design Life-Cycle

assess.design.(don't)consume

Sowon Yang

Christina Cogdell

Des 40A

9 December 2014

Diaper Raw Materials

General Background and History

Marion Donovan, who invented the first disposable diaper, was born in 1917 in Fort Wayne, Indiana. She spent most of her time at the manufacturing plant run by her father and uncle. Her inspiration of making disposable diapers was from her youngest baby. Changing and washing the baby’s diaper over and over again frustrated her. When she invented the disposable diaper, people did not acknowledge it. She thought her first disposable diaper looked like a boat, so she named it “Boater.” At first, the Boater was strong and absorbent, but did not convey water away from the baby’s skin. Later, she made it to convey water away from the baby’s skin; however, people did not acknowledge it until decades later in 1961, when Victor Mills created Pampers in inspiration of Donovan’s disposable diaper (Marion). Although it has many positive impacts such as making diapering easier, it creates negative impacts on our environment.

Had using disposable diaper rather than cloth diaper made a better impact on our environment? This is hard to tell. In the ABC news article, “The water and energy required to wash and dry cloth diapers also take their toll, particularly as energy resources became strained (Onion).” How about disposable diaper? It is said that a baby, in his or her 2 ½ years of diapering period, will need over 6,000 disposable diapers. To make such amount of disposable diaper, we need to cut down more than three billions of trees every year. Making disposable diaper not only cause trees to cut down, but also create toxic chemical on earth (Beil).

Raw Material Acquisition

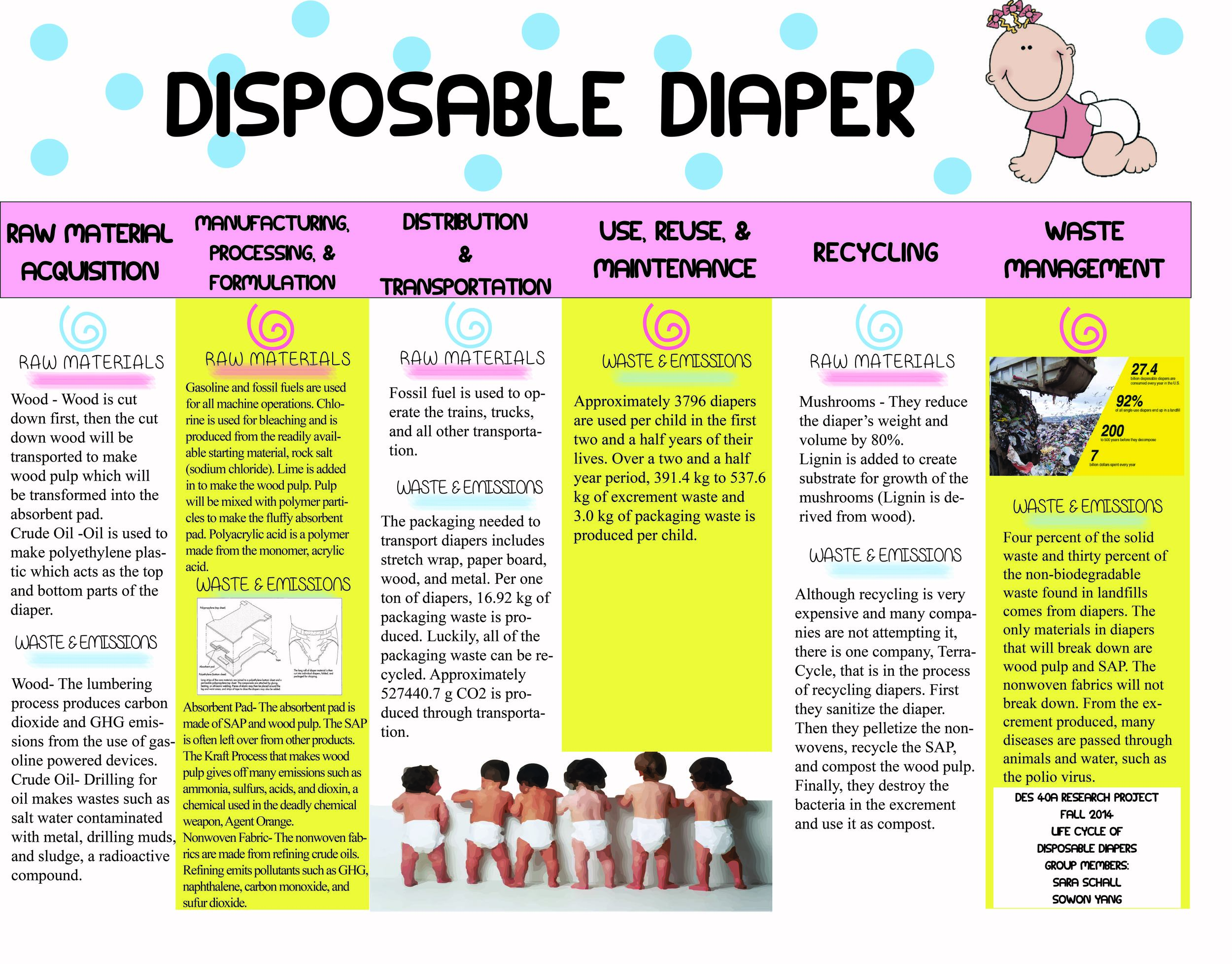

The major raw materials that are used in making a disposable diaper are trees, and crude oil. The components of making a disposable diaper are the following: waterproof wood pulp, and synthetic polyacrylate (Cloth Diapering). In disposable diaper, polyethylene plastic is used and the raw material for this is the oil; it takes 1 cup of crude oil to make the plastic for one disposable diaper. A baby in his or her diapering period uses 6,500 diapers and it takes 1,625 quarts of oil. It is said that the amount of oil to keep babies dry for their entire diapering period takes more than the amount of lubricate it takes for all cars people would ever own in their life (The Many Dangerous). Where do crude oils come from? The component of crude oils are following: 84% Carbon, 14% Hydrogen, 3% Sulfur, less than 1% Nitrogen, less than 1% Oxygen, less than 1% Metals, and less than 1% Salts. The crude oil is known as petroleum, and is made naturally from decaying plants animals. Because the crude oil contains hydrocarbons, it is used in so many different substances. Hydrocarbons are molecules that contain hydrogen (Freudenrich). The synthetic polyacrylate is a super-absorbent crystal; the crystal comes from the super-absorbent layer. The sodium polyacrylate is the layer consists of paper fluff and a chemical absorbent. The article “What is the crystalline substance found in disposable diapers?” says, “This sodium polyacrylate is an amazing water absorber -- it can absorb 200 to 300 times its weight in tap water (even more if the water is distilled) and hold it in a gooey gel. Sodium polyacrylate is a polymer, meaning that is consists of chains of identical units (monomers). The monomer for sodium polyacrylate is --CH2--CH (CO2Na) -- (What is the Crystalline).”

Manufacturing Process

The wood that is used to make diapers go through many different stages: Wood to lumber and to wood pulp then to diapers. The process of manufacturing wood to lumber is the following: First, select the trees that will be cut down. In this stage, it is important to note that there are no existing roads in that area for wood to be cut and graded. They use gasoline-powered chain saws for tree felling. Once the tree is down, the limbs will be cut to the appropriate size for transportation. When transporting the cut down trees, diesel-powered tractors called skidders are used to drag the fallen tree sections to a cleared area for loading, but if the terrain is steep, a self-propelled yard is used. The article “How Products Are Made,” says that “The yarder has a telescoping hydraulic tower that can be raised to a height of 110 ft (33.5 m). Guy wires support the tower, and cables are run from the top of the tower down the steep slopes to retrieve the felled trees. The tree sections, or logs, are then loaded on trucks using wheeled log loaders.” Lastly, the trees will be on their way to lumber mills on public highways. When the trees arrive, giant mobile unloaders grab the entire truckload in piles. When the cut is made, they remove a piece of wood called a slab. The outer slabs are usually thrown away or use as a pulp (How Products). They make woodchip from the sawmill. First, they are sized for screening and then the sorted chips are washed. The woodchips are composed of 50% water, 25% cellulose fiber (this is what the mills need to make pulp), and 25% lignin (this is a natural glue that holds the wood fiber together). The woodchips will be placed in digester with a chemical called white liquor. The woodchips will begin to break down as the heat and pressure increase inside the container. In final process, lime will be added. However, the lignin might still exist. To remove all the remaining lignin, the pulp will be washed with bleach and water (IdForestProducts). Because this bleaching is done with chlorine gas that creates a toxic substances dioxin, it affects human health negatively; dioxin associates with birth defects, miscarriage, cancer, and genetic damage (Beil). The pulp, after it is bleached, will be mixed with polymer particles to make fluffy absorbent materials, which will be used as diaper core. At the debarking station, rollers compress padding to make the diaper core to be slim. Then, a cylindrical cutter slices the diaper core. Plastic film wraps around and merges with another stream of fabric. The equipment pulls elastic bands into other layers of fabric to make leg cuffs. Absorbent core later meets up with backside of the diaper that has been cut with machine. The other layer of fabric will be adhered (Jerry). Other materials that are used to make disposable diaper are ancillary elastic threads, hot melt adhesives, strips of tape or other closures, and inks used for printing decorations (How Products). Elastic comes from rubber which are used in cuffs, for the waist and the legs (How Are Elastic).

Distribution and Transportation

There were no information about the raw materials that are used on the disposable diaper in the stage of transportation and distribution. It is assumed that trains, and many other transportation methods are transporting the disposable diapers. In that case, the raw material that is used to start the engine of trains is the fossil fuel.

Use and Maintenance

A great amount of disposable diapers are being used worldwide. In the United States alone, it is calculated that 40.37 millions diapers are used each day by babies in the 0-2 age group and 467 diapers are used every second. There are 9,612,520 babies in the United States. The total world consumption is estimated to be 1,375 million diapers every day. The weight of a diaper is about 45 grams. If we calculated based on this fact, 1,816 tons of diapers are used in everyday in the United States (The Disposable Diaper).

Recycle

Decomposing diapers takes about 500 years, and it provides greenhouse gas emission, and releases methane into the air (Environmental). However, there is a new way of decomposing disposable diapers faster. In the article, “Mushrooms the Answer to Disposable Diaper Waste?” says, “a team of researchers in Mexico - the world’s third largest consumer of those ever-so-convenient nappies - has experimented with the hypothesis that oyster mushrooms could break down the diapers much more quickly because the fungus feed on cellulose, and because non-organic compounds in the diapers retain liquids.” The team, first, sterilized diapers containing only liquid waste, ground them up, and added lignin to create a substrate for growth of the mushrooms. Lastly, they add mushroom spores. The mushroom reduces the diapers’ weight and volume by about 80 percent (Mushrooms).

Waste Management

There are 20 billions of diapers are thrown away every year in the United States. Those thrown away diapers take about 500 and more years to decompose, and contains petroleum, plastics, perfumes, wood pulp, and dioxins (Disposables vs. Cloth Diaper) Diapers can be safely decomposed through the solid management system. The United States Environmental Protection Agency calculated that there was about 1.5 percent of total municipal solid waste in year 2010. Disposable diapers occupies between 5 to 40 percent of the landfilled (Diapers and Solid). However, no information found about the raw materials that are used to manage the disposable diaper waste.

Conclusion

Disposable diapers create a lot of trashes, and it also has serious health risks to both environment and people. For example, in bleaching process, and all other manufacturing process that contain chemical such as dioxin can cause cancer. In the United States alone, more than 200,000 trees are cut downs, and it take 3.4 billion gallons of fuels in each year to manufacture disposable diapers. This can affect the climate change because Carbon Dioxide is released into the air when fuels are used. There are about 20 billion disposable diapers dumped in landfills in each year, and it comes out to be more than 3.5 million tons of waste (Environmental).

Bibliography

Beil, Susan Crawford. "Cloth Diapering 101 : Diaper Dilemma (Part 2) : Punkin Butt." Cloth Diapering 101 : Diaper Dilemma (Part 2) : Punkin Butt. N.p., n.d. Web. 26 Nov. 2014.

"Diapers and Solid Waste Disposal." Diapers and Solid Waste Disposal. N.p., n.d. Web. 4 Dec. 2014.

"Disposables vs Cloth Diapers | Diaper Experts." Cloth Diaper Experts. N.p., n.d. Web. 23 Oct. 2014.

"Environmental Impact of Disposable Diapers." LIVESTRONG.COM. LIVESTRONG.COM, 15 June 2010. Web. 2 Dec. 2014.

Freudenrich, Ph.D. Craig. HowStuffWorks. HowStuffWorks.com, n.d. Web. 12 Nov. 2014.

"How Are Elastic Bands Made?" EHow. Demand Media, 30 Apr. 2009. Web. 22 Nov. 2014.

"How Products Are Made." How Lumber Is Made. N.p., n.d. Web. 07 Nov. 2014.

IdForestProducts. “The Making of Pulp.” Online video clip. Youtube. Youtube, 19 Oct. 2012. Web. 6 Dec. 2014.

Jerry Holzer. “How It’s Made - Disposable Diapers.” Online video clip. Youtube. Youtube, 10 Jan. 2009. Web. 21 Nov. 2014.

"Marion Donovan." : Inventor of Disposable Diapers. N.p., n.d. Web. 23 Nov. 2014.

"Mushrooms the Answer to Disposable Diaper Waste?" Sustainablog. N.p., n.d. Web. 3 Dec. 2014.

Onion, Amanda. "The Diaper Debate: Are Disposables as Green as Cloth?" ABC News. ABC News Network, 26 May 2005. Web. 27 Nov. 2014.

"The Disposable Diaper Industry Source." The Disposable Diaper Industry Source. N.p., n.d. Web. 15 Oct. 2014.

"The Many Dangers of Disposable Diapers | Small Footprint Family." Small Footprint Family RSS. N.p., n.d. Web. 21 Nov. 2014.

"What Is the Crystalline Substance Found in Disposable Diapers? - HowStuffWorks." HowStuffWorks. N.p., n.d. Web. 18 Nov. 2014.

Sara Schall

Professor Christina Cogdell

DES 040A

9 December 2014

Diaper Wastes and Emissions

The first disposable diaper was created in 1946 by a woman named Marion Donovan. It had a waterproof outer layer that protected an inside cloth diaper. As designers began to understand the convenience and impact the disposable diaper could offer, more efficient designs quickly followed. However, until the sixties, the diaper was considered a luxury item, used only for long trips or special occasions. The disposable diaper as known today was first made in 1982 with the introduction of SAP. The United States used approximately 18.6 billion diapers in 2006 ("The Disposable Diaper Industry Source"). As the population rises, the use for disposable diapers will only increase. Unfortunately, the impact and risks on the environment, manufacturers, and consumers far outweighs the convenience of the disposable diaper.

Raw Materials Acquisition

The two main raw materials used in the formation of diapers are wood and crude oil. Gas powered chain saws are used to cut down the trees. The trees are dragged by diesel powered tractors and transported to the lumber mill by truck. These oil powered devices give off carbon dioxide and GHG. In the mill it is put through many machines that debark and cut the lumber into pieces. The scraps are used in pulp processing found in disposable diapers.

Drilling for crude oil creates many dangerous wastes, such as “salt water mixed with various metals and hydrocarbons” and “drilling muds and chemicals that are used in and produced by the drilling process” (“Crude Oil”). These wastes can contaminate the land, air, ground water, and surface water, especially if the oil leaks out of its holding container (“Crude Oil”). When oil is taken out of the ground a liquid called “formation water” follows it ("Oil and Gas Production Wastes"). When the water is separated from the oil it is referred to as “produced water” ("Oil and Gas Production Wastes"). Produced water contains uranium and thorium’s radioactive decay product radium and radium’s decay products. Either the products stay in the water or it becomes sludge ("Oil and Gas Production Wastes"). Sludge is “oily, loose material often containing silica compounds, but may also contain large amounts of barium. Dried sludge, with a low oil content, looks and feels similar to soil” ("Oil and Gas Production Wastes").

Just from the raw materials acquisition, the waste and emissions are already extremely high in regards to carbon dioxide production and greenhouse gas production. The radioactivity found in the sludge is a large concern not only for the oil workers, but also for the environment surrounding the drilling site.

Manufacturing, Processing, and Formulation

There are three main components that make up diapers. The first is the absorbent pad. It is made from the combination of Superabsorbent Polymer and wood pulp. The hydrocarbons that make up the SAP are both found naturally and made synthetically. When it is made synthetically, UV light and catalysts are added to the hydrocarbon to remove the salts. Often the SAP are “left over from production lines of other chemical industries. The polymer particles are too small for other applications, but they are well suited for use in diapers” ("How Products Are Made").

Wood pulp is made from the left over wood chips from saw mills. The wood chips are put through the Kraft Process. If they are too small, they are burned to provide steam for the reactions. First the wood is put into a machine called the Digester. In the Digester the wood chips are combined with a chemical called White Liquor and heated until the White Liquor and the wood’s glue, lignin, combine (IdForestProducts). The “production of cooking liquor” results in emissions such as ammonia, hydrogen sulfide, sulphur dioxide, mercaptan, chromate, sulphur, calcium carbonate, zinc, sulphuric acid, lead fumes, asbestos, and sulphurous acid (Sieswerda and Soskolne). This new mixture, called Black Liquor, is heated until the excess water evaporates and the lignin is burned (IdForestProducts). Many chemicals are released in this process “methyl mercaptan and dimethyl sulfide are formed in reactions with the wood component, lignin. Dimethyl disulfide is formed through the oxidation of mercaptan groups derived from the lignin. These compounds are emitted from many points within a mill, but the main sources are the digester/blow tank systems and the direct contact evaporator” (US EPA, Office of Air & Radiation). The resulting mixture, Green Liquor is cooked with lime and is changed back into White Liquor to start the process again (IdForestProducts). The production of pulp emits chemicals such as lime, magnesium, and aniline (Sieswerda and Soskolne). The remaining cellulose “is bleached with chlorine gas, producing toxic chemicals known as organochlorines. The most notorious of organochlorines is dioxin, which is one of the most toxic substances ever made by humans…One of the primary components of Agent Orange was dioxin” (Beil). Organochlorines from the process are found in the water surrounding the plant and often in the diapers themselves. Employees working at the plants have stated numerous health problems such as “fatigue, female-organ problems, slow-healing wounds and weight loss” (Beil). Luckily, plants have begun to replace chlorine bleach with the less dangerous hydrogen peroxide bleach (Beil). Other emissions from the bleaching process include chlorine compounds, ozone, hydrogen peroxide, boron compounds, and caustic acids (Sieswerda and Soskolne).

Second is the nonwoven fabric. It has two layers, the polypropylene top sheet and the polyethylene bottom sheet. Both chemicals are made from the petroleum product, naphtha, through the refining of crude oil. Naphtha is the step in the refining process right before the production of gasoline. The refining process emits air pollutants such as sulfur dioxide, oxides of nitrogen, carbon monoxide, and particulate matter. The effects of these pollutants include respiratory effects, irregular heartbeats, and chronic bronchitis. The more dangerous air pollutants, benzene, 1,3-butadiene, naphthalene, and PAHs, cause neurological problems, blood disorders, cardiovascular problems, cancer, and skin disorders. Other pollutants include Volatile Organic Compounds and Greenhouse gases (US EPA).

Third is the elastic found around the leg cuffs. This elastic is most likely polychloroprene, a petrochemical based synthetic rubber. It is made by chlorinating butadiene or isoprene ("Neoprene (CR) (chemical Compound)"). Byproducts of the production of chloroprene include hydrochloric acid, 1-chloro-1,3-butadiene, trichlorobutenes and tetrachlorobutanes, and butadiene dimer ("Chloroprene"). Unfortunately no more information could be found on the wastes or emissions given off during the production of polychloroprene.

The production of the three main components of the disposable diaper gives way to many dangerous emissions and waste. These pollutants can lead to serious health problems for workers and may even be left over in the resulting diaper product.

Distribution and Transportation

The packaging needed to transport diapers includes stretch wrap, paper board, wood, and metal. Per one ton of diapers 16.92 kg of packaging waste is produced. Luckily all of the packaging waste can be recycled (Aumonier and Collins 44). Aumonier and Collins guessed that the transport from factory to retail outlets was approximately 310.68 miles. This translates to approximately 486,583.1 g CO2 ("Greenhouse Gas Emissions from a Typical Passenger Vehicle"). Over a two and a half year period Aumonier and Collins guessed that the transport from home to store and back was approximately 108.5 miles. This translates to approximately 40857.6 g CO2 ("Greenhouse Gas Emissions from a Typical Passenger Vehicle").

The packaging used to transport disposable diapers is luckily all recyclable. Unfortunately, the amount of carbon dioxide created as a result of transport is much too large and greatly effects the air quality and environment.

Use, Re-Use, and Maintenance

Disposable diapers are used only once, so only the use part of this section is viable. Approximately 3796 diapers are used every two and a half years per child. This is the same as 169.5 kg of diapers bought. Because there is no set data for urine and feces waste amounts, two scenarios are feasible. The first is called the Geigy scenario. It states that 391.4 kg excrement waste will be produced in a two and a half year period. The mixed scenario states that 537.6 kg of excrement waste will be produced. Both agree that 3.0 kg of diaper packaging waste will be produced (Aumonier and Collins 45-46).

Because most consumers of diapers do not flush the excrement waste from the diapers, a huge amount of dangerous, bacteria-filled filth is sitting in America’s landfills. The sheer amount of diapers limits the amount of excrement that can break down.

Recycling

Diaper makers have looked into the benefits of recycling, but have found that it is much too expensive and difficult a process. Some cities burn diapers for energy. Unfortunately incinerators release chemicals as well as fecal matter into the air (Beil). One company, TerraCycle, is experimenting with recycling. They begin their process by sanitizing the diaper. They then break it down into individual parts. The plastics are turned into pellets which in turn can be turned into plastic lumber, outdoor furniture, or fence posts. The SAP can be recycled. The wood pulp is composted. The main problem is the fecal matter. They have found a way to kill all the bacteria. Once the bacteria are gone, all the remaining material can be composted ("Under Cover: Recycling Disposable Diapers”). Because this is a fairly new and experimental process, no data has been collected for the emissions given off by the pelleting process or the sanitization process.

Hopefully this new recycling plan will come into effect soon. As of now only a few key components of the disposable diaper can be recycled at all. The rest is thrown into landfills for many decades.

Waste Management

Every two and a half years about two tons of waste is made per baby (Beil). They also “make up the 3rd largest single consumer item in our waste system - following newspapers and beverage containers” and “account for nearly 4% of the total amount of solid waste, and 30% of the non-biodegradable waste” (Beil). In fact, it takes approximately five hundred years for one diaper to break down (Beil). Only the wood pulp and SAP of a diaper is biodegradable ("Disposable Diapers"). Unfortunately, “the polyethylene and polyester sheets are not biodegradable; neither is the elastic used for better fit, nor the polypropylene used for the tape that is employed as a fastener” ("Disposable Diapers"). In the UK, 13.5kg of fluff pulp waste out of 18.1kg of fluff pulp waste per ton of diapers produced is put into landfills. Similarly, 16.7kg of SAP waste out of 22.3kg of SAP waste per ton of diapers produced is put into landfills (Aumonier and Collins 44). Also found in landfills is the polio virus from vaccinations. The virus may live for a few weeks and may be spread by animals and may leak into groundwater (Beil).

The extensive amount of non-biodegradable waste disposable diapers produce is filling up the landfills and greatly hurting the surrounding environment and water sources. The continued use of disposable diapers will only increase the amount of waste build up that will never break down.

Assumptions and Mistakes

The oil refining and wood pulping processes are the basic processes not the specific ones used for diaper making. It was assumed that the elastic used in diaper manufacturing was the synthetic rubber, polychloroprene. The mileage from the factory to the store and the store to the home was an estimation.

Conclusion

Overall, the amount of wastes and emissions from the disposable diaper’s life cycle far overshadows its usefulness. The disposable diaper adds huge amounts of waste into landfills and creates many pollutants throughout its life that greatly hurt the producers, consumers, and environment. Luckily, there are a few other options for more sustainable diapers, such as biodegradable diapers and cloth diapers that can be washed.

Bibliography

Aumonier, Simon, and Michael Collins. "Life Cycle Assessment of Disposable and Reusable Nappies in the UK." (n.d.): n. pag. Environment Agency. Web. 7 Dec. 2014.

Beil, Susan C. "Cloth Diapering 101: Diaper Dilemma (Part 2): Punkin Butt." Cloth Diapering 101: Diaper Dilemma (Part 2): Punkin Butt. Punkin Butt, 11 Apr. 2012. Web. 28 Oct. 2014.

"Chloroprene." Chloroprene (n.d.): n. pag. International Agency for Research on Cancer. IARC. Web. 7 Dec. 2014.

"Crude Oil." Window on State Government. Susan Combs, n.d. Web. 06 Dec. 2014.

"Disposable Diapers." Chemistry Explained. Advameg, Inc., n.d. Web. 06 Dec. 2014.

"Greenhouse Gas Emissions from a Typical Passenger Vehicle." Greenhouse Gas Emissions from a Typical Passenger Vehicle (EPA-420-F-14-040, May 2014) (n.d.): n. pag. EPA. Environmental Protection Agency. Web. 7 Dec. 2014.

"How Products Are Made." How Disposable Diaper Is Made. N.p., n.d. Web. 21 Oct. 2014.

IdForestProducts. “The Making of Pulp.” Online video clip. Youtube. Youtube, 19 Oct. 2012. Web. 6 Dec. 2014.

"Neoprene (CR) (chemical Compound)." Encyclopedia Britannica Online. Encyclopedia Britannica, n.d. Web. 09 Dec. 2014.

"Oil and Gas Production Wastes." EPA. Environmental Protection Agency, 5 Dec. 2014. Web. 07 Dec. 2014.

Sieswerda, Lee E., and Colin L. Soskolne. "Cancer Risk Associated with Pulp and Paper Mills: A Review of Occupational and Community Epidemiology." Public Health Agency of Canada. Public Health Agency of Canada, 2010. Web. 06 Dec. 2014

Schiller, Ben. "The Foul--But Very Necessary--Business of Diaper Recycling." Co.Exist. Fast Company & Inc, 13 Sept. 2011. Web. 28 Oct. 2014.

"The Disposable Diaper Industry Source." The Disposable Diaper Industry Source. Richer Investment Diaper Consulting, n.d. Web. 27 Oct. 2014.

"The Many Dangers of Disposable Diapers | Small Footprint Family." Small Footprint Family RSS. Small Footprint Family, n.d. Web. 28 Oct. 2014.

"Under Cover: Recycling Disposable Diapers." The Sustainable Manufacturer Network. Sustainable Manufacturer Network, 25 July 2012. Web. 28 Oct. 2014.

US EPA. "Addressing Air Emissions from the Petroleum Refinery Sector Risk and Technology Review and New Source Risk and Technology Review and New Source Performance Standard Rulemaking." (n.d.): n. pag. US EPA. Web. 7 Dec. 2014.

US EPA, Office of Air & Radiation. "Chemical Wood Pulping." AP-42, CH 10.2: Chemical Wood Pulping 1 (1990): n. pag. Technology Transfer Network Clearinghouse for Inventories & Emissions Factors. US EPA, 19 Feb. 2014. Web. 6 Dec. 2014.