Design Life-Cycle

assess.design.(don't)consume

Erin Martin

Cogdell, Section 1

DES 40A

9 December 2014

The Wind Turbine: Energy

Wind energy

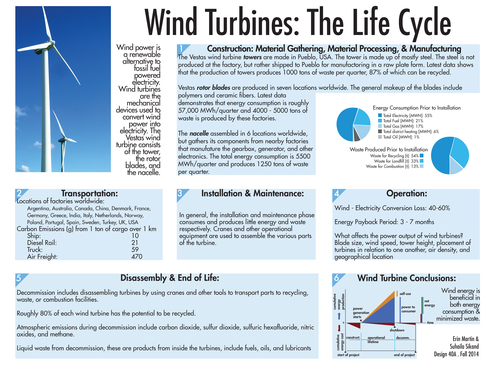

Wind Energy is a renewable energy obtained from the kinetic energy flow in the air. It is currently the energy source with the highest returns in power output. Wind energy has continued to grow substantially over the past few years; it has more than tripled since 2008 (AWEA). In 2013, wind power supplied energy to 4.3% of the United States (AWEA). It supplies even more today.

Wind Turbines

Wind turbines are large mechanisms used to harness wind power to generate electrical power. Typically their life expectancy is twenty years, however there is a large amount of research being done to lengthen the life span of a wind turbine with new advances in technology (Wind Energy Technology). To clarify, wind turbines, although they are similar in appearance, are not windmills. Windmills are used for mechanical work, like pumping water or grinding corn, while wind turbines supply electricity. The reason I chose to discuss the energy in a wind turbine’s life cycle is because I wanted to compare the costs of energy to how much energy is yielded.

Parameters:

This paper will discuss some of the key components of a land-based wind turbine. Because the wind turbine is made up of over 3000 parts, there will be some lack of depth in certain areas including the processing of raw materials. Specific information regarding small aspects of the turbine, including, paints, bolts and wires will also not be included. Some of the procedures in manufacturing are extensive and require scientific analysis. My paper will focus rather on the larger components, and general procedures. The analysis will not include the cement platform that holds the wind turbine in place, because it varies greatly on types of soil and weather (Wilburn). Vestas is one of the global leaders in wind turbine manufacturing. For this life cycle assessment, I will be evaluating the energy inputs and outputs of Vestas wind turbines.

Components and Construction:

A wind turbine has three major components; the tower, the blades and the nacelle (Platzer). Wind turbines are primarily composed of large amounts of steel, but other materials, such as composites, ductile iron, concrete, aluminum, copper and adhesives, are also used ()

Vestas’s Main Wind Turbine Materials and Masses

Blades: 57m.

Steel: 5.4tons. Carbon Fiber: 3.69 tons Cast Iron: 8.5 tons. Fiberglass/ reinforced plastic: 7.96 tons

Nacelle 12m

Steel: 165 tons Fiberglass/ reinforced plastic: 6.4 tons Copper : 2.34 tons Lubricant: 601.6 Aluminum: .54 tons Cast Iron: 16.47 tons

Tower: tower base: diameter of 16ft

Steel 165 ton

Info. from Haapala K.R. and Prempreeda P.

I created the above diagram to separate the components in a visual and straightforward way. My life cycle assessment does not include the energy used to obtain all the raw materials; however, it is important to note the use of carbon fiber in making the blades. Carbon fiber is a strong, lightweight material, and is optimal for reducing the wind turbine’s weight substantially (Zoltek). It helps build longer blades that do not buckle under compression, which in turn produces more power (Gagnon et al.). The problem with carbon fiber is that its production requires a lot of energy. The manufacturing plants run on fossil fuel powered electricity to produce these carbon fibers made with mechanical and chemical techniques (Zoltek). Currently carbon fiber production is 5x more energy intensive per lb than steel production (Zoltek). The majority of the energy costs in a wind turbine’s life cycle are produced in the obtaining of raw materials and the manufacturing of the wind turbine components due to the amount of fossil fuel based manufacturing plants.

Wind turbines are manufactured in pieces. Facilities all over the world build parts of wind turbines or machinery used to make, transport and assemble them. Each component is from a different manufacturing plant. This means that there is a rather widespread network of fossil fuel based manufacturing plants used to build a single turbine.

Transportation:

One of the main challenges of wind energy today is efficient transport. The problem is the large scale of the wind turbines and the large distances required for transport. Wind energy is global, therefore ships and planes are used. Although ships are the more efficient option, cargo ships and planes both require energy rich fuel (Vessel Discharges). On the local scale, usually eight to ten large rigs are needed to deliver each commercial size turbine, in which, according to load size laws, each load is overweight and oversized (Brown). Therefore, specialized work has to go into moving each piece of the turbine from one place to another. Truck operators have to study the route prior to movement for height and weight clearances, to obtain permits from multiple jurisdictions, and arrange for escorts and traffic operators (Franco). They hinder traffic because at times they have to occupy multiple lanes, cannot take regular turns, are too tall for some tunnels, and too heavy for some bridges (Franco). Currently, there are manufacturing companies that make trailers specific to carrying a wind turbine (Brown). With all of these aspects of aided transportation in mind, one can see the excessive energy use in the transportation phase. There are fossil fuels being used with almost every vehicle or operating system used to help this transport. This includes the police escorts, the manufacturing of the wind turbine trailers, and the trailers themselves.

Installation:

The installation phase of a wind turbines life cycle is comprised of using heavy duty machinery to lift, place, and connect wind turbines. One of the machines used is a diesel powered crane that lifts all of the major separated components in place while workers place them together and add adhesives. Like the other steps, this step in the life cycle is dependent on fossil fuels and human labor.

Operation:

According to Bentz’ law, (which predicts the power that can be extracted depending on the velocity of air that enters the turbine and the velocity of the air going out) the theoretical maximum amount of electrical power that we can obtain is 59.3% of the wind’s kinetic energy (Sustainable Energy). This is when the velocity of the wind exiting the turbine is 1/3 of the original velocity. The power curve on page 6 provided by Vestas, combined with the equation that allows us to know the theoretical maximum portrays a real life situation where 6MW of wind power on average converts to 2.6 MW of electrical power. Therefore the amount of energy lost in the conversion process is between 40-60% (Sustainable Energy).

Things that affect the efficiency/ power output of a wind turbine:

How many wind turbines per area: Each wind turbine in relation to their diameter (d) must be at least the length of 5 diameters apart to achieve maximum output (Hau). This is because “wind turbines slow down the wind, and disturb the flow in a wider area than their immediate rotor diameter” (Sustainable Energy).

Height of the turbine: Higher up, wind has a higher velocity. Wind lower to the ground encounters more obstacles, has friction, and slows down (Sustainable Energy).

Wind-speeds: Varying wind-speeds can alter the power output of a turbine. There is a range in which we have to maintain the turbine speed with brakes because the wind is too strong.

Blade size: The longer the blade the more wind it captures. However, when the blade is bigger, more materials are used, and more space is required for each turbine.

According to a previous life cycle assessment, it takes 4-7 months for a wind turbine to recover all the energy wasted throughout the life cycle of the wind turbine (Haapala et al.). However, this most likely did not calculate the energy use of extracting and manufacturing the complex materials used to make turbines, and would thus take much longer.

Decommission:

Approximately 80% of the materials used to make a wind turbine are recyclable (Fisher). That leaves 20% of the material in tons left for incineration and landfill. When a wind turbine has reached the end of its life it has to be taken down by the same cranes that hoisted it up, and transported by the same fuel hungry trucks (Brown).

Conclusion:

Wind energy is considered a safe renewable energy source that helps clean the world. However based on my findings, that statement has a few shortcomings. Each stage of the life cycle is dependent on fossil fuels. Vestas believes that in order to combat the growth of energy consumption all over the world, we need to “replace finite fossil fuels” with wind, the “natural renewable resource” (Vestas). How can we replace fossil fuels when the replacement is ultimately a byproduct of fossil fuels? Although wind energy is renewable, the materials we use to harness it are not. Although wind may be natural, wind turbines are not. Although we may think wind energy is clean, in all truth, it is not.

Works Cited

"Aluminum Production Wastes." EPA. Environmental Protection Agency, n.d. Web. 23 Nov. 2014. <http://www.epa.gov/radiation/tenorm/aluminum.html>.

Assessment of Research Needs for Wind Turbine Rotor Materials Technology. Washington, D.C.: National Academy, 1991. Print.

Brown, Justin. "Transporting Wind Turbines: An Oversized Challenge." Inbound Logistics (2012): n. pag. Web. 7 Dec. 2014. <www.inboundlogistics.com/cms/articls/transporting-wind-turbines-an-oversized-challenge/>.

D. Souza, Neil, Erhi Gbegbaje-Das, and Peter Shonfield, Dr. Life Cycle Assessment of Electricity Production from a V112 Turbine Wind Plant. Rep. PE North West Europe ApS, Feb. 2011. Web. 18 Nov. 2014. <http://www.vestas.com/~/media/vestas/about/sustainability/pdfs/lca_v112_study_report_2011.pdf>.

Franco, Mark D. "Project Dating Back To 2003 Gets Built In NY." NAWindPower.com. American Wind Energy Assocaition/ Mobil Industrial Lubricants, 2014. Web. 2 Dec. 2014. <www.nawindpower.copm%2Fissues%2FNAW1312%2FFEAT_05_Project-Dating-Back-To-2013-Gets-Built-In-NY.html>.

Fisher, Angelina, and Bill Flanagan. Life Cycle GHG Assessment of a 2.5MW Wind Turbine. Rep. GE, 2010. Web. 20 Nov. 2014. <http://www.lcacenter.org/LCAX/presentations-final/220.pdf>.

Gagnon, Luc, Camille Bélanger, and Yohji Uchiyama. "Life-cycle Assessment of Electricity Generation Options: The Status of Research in Year 2001." Energy Policy 30.14 (2002): 1267-278.Science Direct. Web. 8 Dec. 2014.

Haapala, Karl R., and Preedanood Prempreeda. "Comparative Life Cycle Assessment of 2.0 MW Wind Turbines." Int. J. Sustainable Manufacturing 3.2 (2014): 170-85. Ourenergypolicy.org. Web.

Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics. Berlin: Springer, 2006. Print.

"How Wind Works." Wind Energy Foundation. N.p., n.d. Web. 26 Oct. 2014. <http://www.windenergyfoundation.org/about-wind-energy/how-wind-works>.

Jha, A. R. Wind Turbine Technology. Boca Raton, FL: CRC, 2011. Print.

Martínez, E., F. Sanz, S. Pellegrini, E. Jiménez, and J. Blanco. "Life Cycle Assessment of a Multi-megawatt Wind Turbine." Renewable Energy 34.3 (2009): 667-73. Science Direct. Web. 7 Dec. 2014.

Platzer, Michaela. U.S. Wind Turbine Manufacturing: Federal Support for an Emerging Industry. Rep. Congressional Research Service, 18 Dec. 2012. Web. 26 Oct. 2014. <http://fas.org/sgp/crs/misc/R42023.pdf>.

"Steel Manufacturing Sector." Government of Canada, Environment Canada. N.p., n.d. Web. 23 Nov. 2014. <https://www.ec.gc.ca/toxiques-toxics/Default.asp?lang=En&n=C5039DE5-1&xml=E76BCCD8-0882-4D6B-BE1E-69C4FD0E9934>.

Sustainable Energy. Perf. "Wind Energy" Youtube/Wind Energy. Online Video Clip, 3 Sept. 2014. Web. 7 Dec. 2014. <https://www.youtube.com/watch?v=eOLxJ-U_o9I&index=1&list=LLLG769XJgS3gjxnA3KH3Hyg>.

"Vessel Discharges." World Shipping Council - Partners in Trade. N.p., n.d. Web. 07 Dec. 2014. <http://www.worldshipping.org/industry-issues/environment/vessel-discharges>.

"Vestas by the Numbers." Vestas. N.p., n.d. Web. 02 Dec. 2014. <http://data.vestas.com/worldwide/waste/>.

Vestas. Vestas.com. N.p., n.d. Web. 10 Dec. 2014. <http://www.vestas.com/en/about/discover_wind#!why-wind>.

Wind Energy: The Fastest Growing Power Source. Rep. N.p.: n.p., n.d. Environmental Case Study: Wind Energy. World Steel Assosiation. Web. 26 Oct. 2014. <https://www.steel.org/~/media/Files/SRI/Media%20Center/WindEnergyCaseStudy.pdf>

"Wind Turbine Technology: Fundamental Concepts in Wind Turbine Engineering, Second Edition."ASME DC. N.p., n.d. Web. 28 Oct. 2014.

Wilburn, David R. Wind Energy in the United States and Materials Required for the Land-based Wind Turbine Industry from 2010 through 2030. USGS Numbered Series. Reston, VA: U.S. Geological Survey, 2011. 2011-5036. United States Geological Survey. United States Department of the Interior. Web. 26 Oct. 2014. <http://pubs.usgs.gov/sir/2011/5036/>.

Zoltek. "How Is It Made? Zoltek Carbon Fiber." Zoltek .com. Zoltek, 2014. Web. 8 Dec. 2014. <http://www.zoltek.com/carbonfiber/how-is-it-made/>.

Suhaila Sikand

12/9/2014

Design 40A

Cogdell Section 1

Life Cycle Assessment of Wind Turbines: Waste and Emissions

Background:

A wind turbine is a mechanical device used to cultivate wind in order to generate electricity and power. The turbine consists of three overarching parts: the tower, the blades, and the nacelle. The tower of a wind turbine is the structure supporting the elevated blade and nacelle. Rotor blades are the panels designed to catch the wind by turning to provide power. The nacelle are the components inside the turbine which allow the movement of the blades to generate useable power. Generators, gearboxes, and transformers are among the parts of the nacelle (D’Souza, 2011).

Parameters of Research:

Life cycle assessments can be very extensive as they may elaborate on the very distant impacts of the specific cycle. In order to provide a brief analysis of the waste from the life cycle of wind turbines, I have set parameters of the extent of my personal research.

My research and analysis is based off the wind turbines of the danish company, Vestas Wind Systems A/S as the company is currently a world leader in the wind industry. The wind turbines I am focusing on are the onshore turbines that can benefit both personal and industrial use. I have chosen to exclude the foundations of turbines as these are heavily dependent on the location of the turbine. The height of groundwater, the land, and the climate effect the materials and quantity used to ground a turbine. Due to the ability to transport items globally and taking into account local substitutions, accurate analysis cannot be determined until proper studies have been conducted to account for such variables. A life cycle assessment investigates five broad stages of the life of an object: construction, transportation, installation, operation, and dismantling/end of life. I have chosen to investigate transportation generally as described above, but to also include any means of transportation needed throughout the life cycle. This includes, but is not limited to, the transportation of raw materials, assembled parts, repair parts, servicing, dismantling, and materials to the appropriate plants for management.

Raw Materials:

The waste of a wind turbine is dependent on the material makeup and locations of such resources in order to properly evaluate the waste output. A wind turbine is usually composed of the following materials: 84% iron materials and steel, 7% glass composites and carbon, 5% polymers, 1% aluminum and aluminum alloys, 1% copper and copper alloys, less than 1% processed polymers, less than 1% electronics, and less than 1% fuel and other fluids. Wind turbine towers are composed of mostly steel while the rotor blades are primarily polymers and ceramic fibers. The nacelle is composed of electrical wires and electrical related (D’Souza, 2011). In addition to raw materials that compose the wind turbine, there are materials used in the construction phase that are not present in the final result, yet are necessary for the process. Water is a critical resource in manufacturing as it cools the production process. China, USA/Canada, and Norway consume the most water as Greece, Turkey, France, Portugal, and Australia consume the least amount of water.

Construction:

General trends of life cycle studies describe the construction and dismantling stages as the largest producers of waste. The construction phase consists of raw material extraction and processing as well as the manufacturing of the actual parts of the turbine. Despite some materials circling the life cycle by being recycled resources, the waste produced by processing non-recyclable materials and assembling parts far outweighs the other stages of the life cycle in terms of waste production. Overall, the construction phase produces 6.05 grams of carbon dioxide per kilowatt hour and 10.4 grams of methane gas (“LCA in Wind Energy”). This phase of the life cycle also produces a significant amount of bulk waste, hazardous waste, human toxicity soil and water, and global warming potential. Turbine towers are manufactured in one plant which receives the steel in raw plates that need to be “cleaned, beveled, cut, rolled and welded into shells” (D’Souza, 2011). In the past couple years, the carbon dioxide emissions solely from tower manufacturing facilities has been on a decline, with less than 20% of these emissions as a direct source from Vestas facilities. In addition to carbon dioxide, hazardous waste has decreased in recent years (“Vestas by the Numbers”).

Installation:

Installation is the second phase of the life cycle, yet has a very small waste comparatively to other stages. The stage is the on site erection of the wind turbine. To install the turbines, the parts must be transported to the site, and takes several vehicles as one blade can often occupy an entire truck. Once on site, cranes are governed to erect the turbine into place after the turbine is assembled on the ground. This step emits some carbon dioxide, nitrogen oxides, sulfur oxides, and other particles (“LCA in Wind Energy”). There is little bulk waste in this phase.

Operation:

Similar to the installation phase, the operation phase of the life cycle of a wind turbine produces little waste as the energy put in is a natural primary mechanical source. There are few greenhouse gas emissions and even fewer waste particles. Although the payback period for energy ranges between three and seven months, there is a waste of energy to convert the wind power to electrical power. With current turbine designs, anywhere between forty and sixty percent of the cultivated power is lost when transforming the power into electricity (Sustainable Energy, 2014). This stage, however, does include any repairs and maintenance needed during the turbine’s life. Like any mechanical device, damages occur, and repairs are often necessary to provide an alternative to investing in a new turbine.

Decommission:

When a wind turbine has exhausted its life, it must be disassembled and decommissioned. This process can be viewed as the reversal of the combination of the construction and installation phase. The decommission phase requires taking apart the turbine and relocating its parts to be transported to the appropriate facility. There are three main facilities that process these parts: a recycling plant, a landfill, and an incinerator.

In order to break apart the windmill, heavy equipment, such as cranes, must be used to disassemble the product. Equipment as such, emits waste and adds to the cycle. Transportation is also needed throughout this phase to ship various pieces of the turbine to its respective processing plant.

During this stage of the life cycle, greenhouse gases including carbon dioxide, sulfuric oxides, sulfur hexafluoride, nitric oxides, and methane are released into the atmosphere. While these emissions are less than that of the construction phase, they still account for roughly 10% of the gases released (“LCA in Wind Energy”).

In addition, other wastes are produced and/or released while dismantling wind turbines. Liquid wastes, which are from the turbines themselves, in the form of lubricants, fuels, and other oils can be a resulting byproduct of the wind industry. These wastes are incinerated and cannot revolve around the cycle again.

On the other hand, approximately eighty percent of a given turbine can be recycled. The remaining percent is either dumped in a landfill or combusted. The polymers used in the turbine are divided evenly among recycling and landfills while 95% of cables are reused (D'Souza, 2011). Aluminum, copper and steel have a ninety percent recycling rate with the remaining ten percent being transported to a landfill. Aluminum can undergo two different processes to be recycled. Smelting and remelting both produce wrought alloys and use scrap to produce their alloys. Secondary smelting is a more common form of aluminum recycling. This method uses old, unwanted, low grade scrap to produce a casting alloy. Theoretically, these recycled materials could continue cycling the chain until they exhaust their life from excessive downcycling.

Transportation:

Throughout the entirety of a wind turbine’s life cycle, transportation is needed to accomplish a number of tasks. Factories, installation sites, and end-of-life processing plants are global industries that require a global network.

Manufacturing wind turbines involves transportation of materials to the plants, as well as transportation of final products. Vestas, in particular, has manufacturing plants in nineteen countries. Rotor blades, for example, are produced in Lem, Daimiel, Taranto, Windsor, Lauchhammer, Brighton, and Tianjin (“Vestas by the Numbers”). While the vast distribution of these facilities allow for decreased transportation from the facilities to the installation site, the raw materials must travel globally to reach the plant.

In general, there are four methods of shipment: ship, rail, truck, and air freight. Each produces its own waste. Over one kilometer, transporting one ton of cargo emits the following grams of carbon dioxide: 10 for ships, 21 for diesel rails, 59 for trucking, and 470 for air freight (Carbon Emissions). Maritime vessels is the least waste-producing option to transport large goods.

There are several environmental issues, nonetheless, that arise from the use of maritime vessels. Since ships come in direct contact with water, in which life travels, they can cause numerous problems while in transport. Ballast water, which is used to keep steel balanced in water, is discharged into non-native environments. The water often contains forms of life and can cause a transfer of viruses or invasive species to dominate the ecosystem. Maritime vessels also dump waste such as sewage, gray water, and deck runoff into the waters and can cause a number of problems including a shift in acidity. One of the trade industry’s solutions is anti-fouling. This is an agent that reduces the ability for different forms of life to latch onto ships and cause problems due to displacement (“Vessel Discharges”). Because the industry adopted such agents, the fuel efficiency has increased, thus lowering greenhouse gas emissions. Maritime vessels emit carbon dioxide, sulfuric oxides, nitric oxides, and other particulate matter (“Air Emissions”).

Wind turbines, however, are often located inland of the coastline and must use trucking to transport parts. However, trucking also has its drawbacks in addition to the higher levels of greenhouse gas emissions. In order to transport the large and oversized parts (i.e. blade diameters can range anywhere from eighty meters to greater than 120 meters) associated with wind turbines, truckers need to work closely with local governments to meet the standards of safety and traffic control. Each trucker needs an escort and is usually directed to the longer and more indirect routes to avoid disturbing regular traffic (Brown, 2012). These precautions consume more fuel thus release more emissions.

Conclusions:

Although wind energy requires the third largest amount of land, it emits the least amount of carbon dioxide and minimal amounts of other greenhouse gases. It also ranks third in the energy payback ratio (Gagnon, 2002). Wind energy is one of the most viable sources of renewable energy available and has the potential to produce a significant amount of the world’s power needs.

Bibliography

"Aluminum Production Wastes." EPA. Environmental Protection Agency, n.d. Web. 23 Nov. 2014. <http://www.epa.gov/radiation/tenorm/aluminum.html>.

Assessment of Research Needs for Wind Turbine Rotor Materials Technology. Washington, D.C.: National Academy, 1991. Print.

Brown, Justin. "Transporting Wind Turbines: An Oversized Challenge." Inbound Logistics (2012): n. pag. Web. 7 Dec. 2014. <www.inboundlogistics.com/cms/articls/transporting-wind-turbines-an-oversized-challenge/>.

"Carbon Emissions." World Shipping Council - Partners in Trade. N.p., n.d. Web. 07 Dec. 2014. <http://www.worldshipping.org/industry-issues/environment/air-emissions/carbon-emissions>.

"Common Uses for Slag." National Slag Association. N.p., n.d. Web. 02 Dec. 2014.

"Copper Mining and Production Wastes." EPA. Environmental Protection Agency, n.d. Web. 23 Nov. 2014. <http://www.epa.gov/radiation/tenorm/copper.html>.

David, Wilburn R. Wind Energy in the United States and Materials Required for the Land-based Wind Turbine Industry from 2010 through 2030. USGS Numbered Series. Reston, VA: U.S. Geological Survey, 2011. 2011-5036. United States Geological Survey. United States Department of the Interior. Web. 26 Oct. 2014. <http://pubs.usgs.gov/sir/2011/5036/>.

D‘Souza, Neil, Erhi Gbegbaje-Das, and Peter Shonfield, Dr. Life Cycle Assessment of Electricity Production from a V112 Turbine Wind Plant. Rep. PE North West Europe ApS, Feb. 2011. Web. 18 Nov. 2014. <http://www.vestas.com/~/media/vestas/about/sustainability/pdfs/lca_v112_study_report_2011.pdf>.

Fisher, Angelina, and Bill Flanagan. Life Cycle GHG Assessment of a 2.5MW Wind Turbine. Rep. GE, 2010. Web. 20 Nov. 2014. <http://www.lcacenter.org/LCAX/presentations-final/220.pdf>.

Gagnon, Luc, Camille Bélanger, and Yohji Uchiyama. "Life-cycle Assessment of Electricity Generation Options: The Status of Research in Year 2001." Energy Policy 30.14 (2002): 1267-278. Science Direct. Web. 8 Dec. 2014.

Hau, E., and E. Hau. Wind Turbines: Fundamentals, Technologies, Application, Economics. Berlin: Springer, 2006. Print.

"How Wind Works." Wind Energy Foundation. N.p., n.d. Web. 26 Oct. 2014. <http://www.windenergyfoundation.org/about-wind-energy/how-wind-works>.

Jha, A. R. Wind Turbine Technology. Boca Raton, FL: CRC, 2011. Print.

"LCA in Wind Energy: Environmental Impact Through the Whole Chain." Wind Energy The Facts. N.p., n.d. Web. 26 Oct. 2014. <http://www.wind-energy-the-facts.org/lca-in-wind-energy.html>.

Martínez, E., F. Sanz, S. Pellegrini, E. Jiménez, and J. Blanco. "Life Cycle Assessment of a Multi-megawatt Wind Turbine." Renewable Energy 34.3 (2009): 667-73. Science Direct. Web. 7 Dec. 2014.

Platzer, Michaela. U.S. Wind Turbine Manufacturing: Federal Support for an Emerging Industry. Rep. Congressional Research Service, 18 Dec. 2012. Web. 26 Oct. 2014. <http://fas.org/sgp/crs/misc/R42023.pdf>.

Schlesinger, Mark E. Aluminum Recycling. Boca Raton, FL: CRC/Taylor & Francis Group, 2007. CRC Net Base. Web. 25 Nov. 2014. <https://vpn.lib.ucdavis.edu/isbn/,DanaInfo=www.crcnetbase.com+084939662X>.

"Steel Manufacturing Sector." Government of Canada, Environment Canada. N.p., n.d. Web. 23 Nov. 2014. <https://www.ec.gc.ca/toxiques-toxics/Default.asp?lang=En&n=C5039DE5-1&xml=E76BCCD8-0882-4D6B-BE1E-69C4FD0E9934>.

Sustainable Energy. Perf. "Wind Energy" Youtube/Wind Energy. Online Video Clip, 3 Sept. 2014. Web. 7 Dec. 2014. <https://www.youtube.com/watch?v=eOLxJ-U_o9I&index=1&list=LLLG769XJgS3gjxnA3KH3Hyg>.

"Vessel Discharges." World Shipping Council - Partners in Trade. N.p., n.d. Web. 07 Dec. 2014. <http://www.worldshipping.org/industry-issues/environment/vessel-discharges>.

"Vestas by the Numbers." Vestas. N.p., n.d. Web. 02 Dec. 2014. <http://data.vestas.com/worldwide/waste/>.

Wind Energy: The Fastest Growing Power Source. Rep. N.p.: n.p., n.d. Environmental Case Study: Wind Energy. World Steel Assosiation. Web. 26 Oct. 2014. <https://www.steel.org/~/media/Files/SRI/Media%20Center/WindEnergyCaseStudy.pdf>.

"Wind Turbine Technology: Fundamental Concepts in Wind Turbine Engineering, Second Edition." ASME DC. N.p., n.d. Web. 28 Oct. 2014.