Design Life-Cycle

assess.design.(don't)consume

Ayla Shaffer

Cogdell

DES 40A Fall 2018

December 3, 2018

The Lifecycle of a Candle: Raw Materials

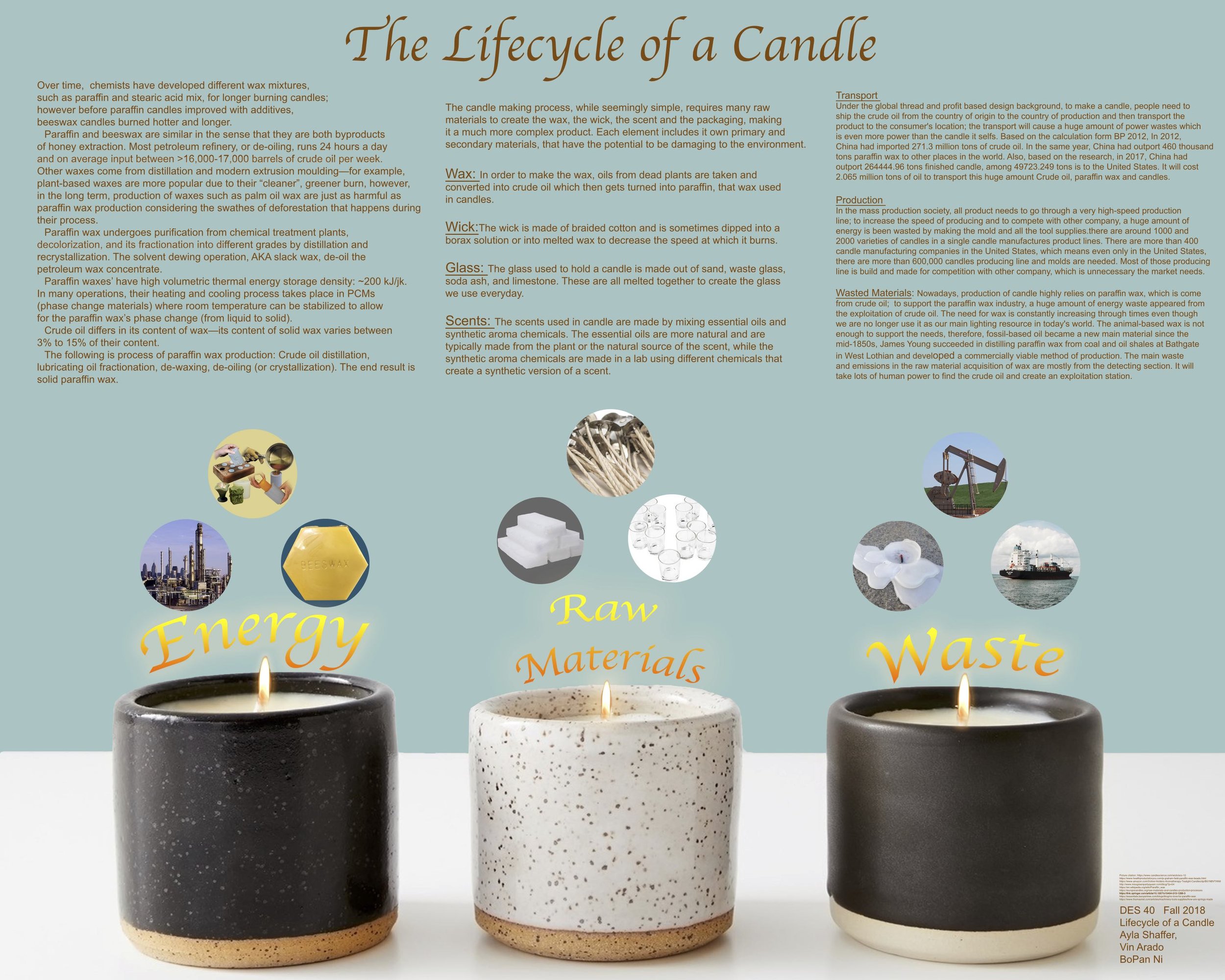

Candles have been an important item throughout history. For thousands of years, candles have been used around the world to improve everyday life. The first candles were used around 3000 B.C and were made from Tallow, or animal fat (“A Short History of Candles”). As time went on, more civilizations started making candles out of beeswax, tree nuts, or fruits but eventually the use of beeswax became the most well-known candle making process during the 18th Century alongside Tallow (“Types of Candle Wax & Wax Ingredients | NCA”). During the 1800s, a new candle making process was created that involved making candles out of a wax called paraffin. Since candles have been a popular household item for centuries, it is important to understand how they are made and if they have a negative impact on the environment. The candle making process, while seemingly simple, requires many raw materials to create the wax, the wick, the scent and the packaging, making it a much more complex product. Each element includes its own primary and secondary materials, which have the potential to be damaging to the environment.

The basic element of a candle is the wax. Nowadays most candles are made from paraffin wax. The process for making paraffin wax is very complex, and is described in full by D. Minenko from General Wax: “...plants produce a layer of wax on their leaves and stems. Material from dead plants… eventually became buried beneath the surface of the earth. After a long period of time, forces of heat and pressure turned the slowly decaying plant material into crude oil, otherwise known as petroleum….Petroleum companies "harvest" the crude oil and process it. They refine the oil, separating the different properties...The refinery will process the wax into a clean, clear liquid, or as a solid milky white block, and make it available to companies who may have a use for it” (Minenko). The final product of that refinery process results in the creation of paraffin wax. The wax is then used in candles all over the world. The wax also contains carbon and hydrocarbons allowing it to burn yellow and at a certain speed (“Types of Candle Wax”). The process for making this wax is, for the most part, very elaborate and requires a lot of steps to retract the elements involved in its creation. Even though this is a complicated process, it is a product that is in high demand. In the article called “Types of Candle Wax & Wax Ingredients” by the National Candle Association, as quoted above, they explain that, “An estimated 1 billion pounds of wax are used in the candles sold each year in the United States” (NCA). In order to satisfy the demand for candles in the U.S, more and more paraffin wax needs to be created. That is just the numbers for the United States, but many other countries use candles with paraffin wax as well, which most likely greatly increases that number. Candles, while mostly made of wax, also needs a wick in order to light it.

A candle’s wick is another important element in the candle making process. A wick is the string like material that is typically in the center of the candle that allows it to hold a flame. The wick tends to be made out of braided cotton, and as the melted wax travels up the wick, it continues to fuel the flame (Wikipedia, “Candle Wick”). The design of the wick also tends to affect the how the candle works. In the article, “What Is A Candle Wick Made Of?” written by Joseph Kiprop, he explains that, “A wick's features such as; stiffness, diameter, tethering, and fire-resistance will influence the manner in which a flame burns….Braided and knitted wicks are of high quality, and they burn longer than loosely twisted wicks” (Kiprop). The wicks are an essential part of the candle and is one of the more simple materials in the candle making process since it is mostly made of cotton. However, sometimes the wick is dipped into a borax solution and then melted candle wax to keep it from burning too quickly (Wikipedia, “Candle Wick”). Other wicks can be made with a metal center or made of wood, but the most common wick is the one made from braided cotton. While some candles can consist of those two materials, it’s more common for a candle to have a scent and some sort of packaging as well.

The most common packaging for a candle is a glass container; the glass, while considered a raw material, is made up of a lot of secondary materials. In an article called “What Is Glass? | How Is Glass Made?” it explains the process of glass making and what materials from the earth are used to create the glass we tend to use every day: “In a commercial glass plant, sand is mixed with waste glass (from recycling collections), soda ash (sodium carbonate), and limestone (calcium carbonate) and heated in a furnace” (Woodford). The glass making process can be complicated and involves many steps to create the containers that typically hold candles. In order to create a container, these materials need to be melted, then distributed into molds that, when cooled, result in a glass container to hold a candle (“How Glass Is Made? - The Art of Glass Making”). The container sizes and shapes depend on the mold used, meaning some candles require a container that is made of more glass and materials for a bigger mold than others. While not all candles use glass containers, it is one of the most common packaging and should be accounted for in the candle’s lifecycle.

Another common characteristic of a candle is its scent. It is not required for a candle to have a scent, but nowadays, people tend to buy candles specifically for their unique smells. About 80% of candles in the United States are scented candles (“Types of Fragrance Candles & Oils | NCA”). Since candles can have thousands of different scents, it’s almost impossible to explain the process for each one. In an article by Frank Asbury, he explains the logistics of a scented candle, “A typical scented candle may have from 2% to 5% fragrance or more. A paraffin wax structure is great for holding the fragrance and while the surface of the candle may lose scent the interior of a candle will hold the scent for many years and be released when the candle burns” (Asbury). The candle wax keeps the scent fresh for a long time, making it a good investment for consumers. The scents are usually created with a mix of essential oils and synthetic aroma chemicals (“Types of Fragrance Candles & Oils | NCA”). Essential oils come from the plant or the natural source of the scent, but the synthetic aroma chemicals are more complicated. An example of a synthetic aroma chemical is one created by a company called Advanced Biotech. They created a synthetic raspberry scent with the chemical formula of 4-(p-Hydroxyphenyl)-2-Butanone and an Empirical formula of C10H12O2 (Advanced Biotech). The synthetic scents have more secondary materials involved in its creation, meaning it needs more time and energy to create. The combination of both the essential oils and synthetic scents, creates a longer lasting aroma. All of these materials have an effect of the environment but some are more damaging than others.

The elements of a candle each have their own effect on the environment. The wax, since it comes from plants, can have a negative effect on the environment since it isn’t sustainable. Eventually the plants used to create paraffin wax will likely run out. It is important to limit the amount of wax wasted, in order to preserve the materials used to create it. Another aspect of the wax that could be harmful to the environment, and to people is that it could have toxins in it. An article called “No Love for: Paraffin Wax” by the Banyan Tree Gallery explains that, “In 2009, a study by South Carolina State University found that burning paraffin wax candles give off harmful fumes (toluene and benzene) which is linked to asthma and lung cancer…. It is also reported that frequent lighting of multiple paraffin candles in an unventilated space could lead to problems commonly associated with paraffin wax: irritation of skin and respiratory tract” (Banyan Tree Gallery). The side effects of using paraffin wax could potentially harm it’s users as well as the environment around it. It is unclear how much exposure is required to have these side effects, however. More research should be done on the effects of paraffin wax considering over a billion pounds are used each year. The wicks used in candles don’t have a significant impact on the environment since they are mostly constructed of cotton. It most likely releases a small amount of carbon or fumes, but it shouldn’t harm the environment in a way that should cause concern. The glass involved in creating the containers for the candle uses recycled glass to make new glass. This helps limit the amount of glass that is wasted, but doesn’t reuse enough glass to make glass a sustainable primary material. The secondary materials used in the making of glass have the potential to run out eventually. The benefit of using glass is that it can be melted down or recycled and made into something new, reducing the amount of discarded glass. Lastly, the scent used in candles don’t really create a lot of waste since it gets burned off with the wax and the wick. The making of the scent, however, can use a lot of chemicals that could have a long term negative effect when released into the air. Due to the small amount of oils and chemicals infused into one candle, the fumes wouldn’t be strong enough to cause severe damage. Candles aren’t the most environmentally damaging product, but certain materials and processes can be improved to limit the amount of environmental harm.

A candle involves multiple raw materials that contribute to its overall lifecycle. Since almost every home has at least one candle, it’s important to understand its effects on the environment and what materials make up the structure of a candle. Being a more complex product, candles are made up of many more primary and secondary materials than it seems. Knowing what goes into a candle and its packaging, helps determine if candles are harmful to the environment. Candles, while they have the potential to have long term environmental effects, have very little negative repercussions due to the simplicity and recyclable aspects of the product.

Work Cited

ABT (Advanced Biotech). “RASPBERRY KETONE SYNTHETIC 2058.” Advanced Biotech, 2018, www.adv-bio.com/raspberry-ketone-synthetic-2058/.

Asbury, Frank. “How Do Candles Get Their Scent?” Quora, 25 May 2016, www.quora.com/How-do-candles-get-their-scent.

“A Short History of Candles.” Candle History | Millhouse Candles, www.millhousecandles.com/history.php.

Banyan Tree Gallery. “No Love for: Paraffin Wax.” Banyan Tree Essentials, Banyan Tree Essentials, 4 June 2018, essentials.banyantree.com/blogs/blog/no-love-for-paraffin-wax.

“Glass Making.” Glass Making, www.believersinglass.com/GlassMaking.php.

“How Glass Is Made? - The Art of Glass Making.” Glass Timeline - Important Dates and Facts, 2018, www.historyofglass.com/glass-making-process/how-glass-is-made/.

Kiprop, Joseph. “What Is A Candle Wick Made Of?” World Atlas, Worldatlas, 15 May 2018, www.worldatlas.com/articles/what-is-a-candle-wick-made-of.html.

Minenko, D. “Main Waxes Used in Candlemaking. Paraffin and Beewax.” GeneralWax.com, www.generalwax.com/candle-making/about-candle-wax.php.

“Types of Candle Wax & Wax Ingredients | NCA.” National Candle Association, candles.org/elements-of-a-candle/wax/.

“Types of Fragrance Candles & Oils | NCA.” National Candle Association, candles.org/elements-of-a-candle/fragrance/.

Wikipedia. “Candle Wick.” Wikipedia, Wikimedia Foundation, 8 Oct. 2018, en.wikipedia.org/wiki/Candle_wick.

Woodford, Chris. “What Is Glass? | How Is Glass Made?” Explain That Stuff, 29 June 2018, www.explainthatstuff.com/glass.html.

Hannah Arado

05 Corado

DES40A: Cogdell

Energy

6 December 2018

The Paraffin Candle: Life Cycle Assessment

The candle-making industry reached its peak during the Industrial Revolution when candles were the world’s main source of light and imperial European nations took advantage of their colonies’ resources for their products. The Chinese are credited for creating the earliest candles made from whale fat during its Qin Dynasty around 200 B.C., while the Egyptians were noted for making their candles by dripping beeswax or tallow onto native rush stems. Now, candle-making techniques and global access to resources allow for the variation and proliferation of candles. This paper will synthesize the evolution of the energy processes involved in the production of the various types of candle, scented and unscented, with their holders.

In the late 19th century, Scottish chemist James Young, known as Paraffin Young, successfully distilled paraffin wax from coal and oil at the Bathgate oil refinery in West Lothian, Scotland and developed a commercial method of paraffin production. Thus, candles could be made inexpensively and in high quality. Paraffin wax candles were more desirable because they also left no odor like tallow candles; however at this point, paraffin wax candles still had a very low melting point, 37°C (99°F), compared to other waxes such as beeswax. The solution was the introduction of stearic acid (with a melting point of 65°C), developed prior by Michel Eugene Chevreul in the 1820s as a purified animal fatty acids, to the paraffin mix—its melting point raised to 80°C (176°F). Alongside paraffin wax, microcrystalline wax is another byproduct of oil refinery and is much more adhesive due to its higher molecular weight and fine crystalline structure. Microcrystalline wax can be cut and carved into finer shapes and sizes and allows for more detailing than paraffin wax. Combining paraffin and microcrystalline is commonly practiced to create multiple-layered pillar candles. During the Industrial Revolution, chemist George Wilson successfully developed the integration of a steam distillation technique which allowed candle manufacturers to source from more types of raw materials such as skin fat, bone fat, and industrial grease.

Despite the increased reliance on electricity for lighting, the use of candles in the U.S. in particular has actually increased since the early 1990s with choice and occasion for use. Candles can be decorative and ceremonial—with a society’s leisure time comes opportunity to use an object, whose previous purpose was entirely functional, for aesthetic purpose. Before paraffin and microcrystalline waxes, candles were usually made from beeswax and tallow. Beeswax is separated from honey during the extraction of the latter. The high flammability of beeswax, due to its high alcohol composition, allow for its candle type to burn brighter and hotter at 62 to 64 °C (144 to 147 °F), thus “cleaner”, compared to paraffin. Like beeswax, paraffin is a byproduct from a main substance during its processing; gasoline, kerosene, lubrication oil, heating oil, asphalt base, and other products are the main results of petroleum refinery. Oil companies separate the undesirable wax from the oil and and process it into a clear liquid or a solid, white block to sell to companies that find use for it. The atmospheric distillation units in refineries leave behind waxes due to their higher boiling ranges. During the de-waxing process, the oil temperature is maintained above pour point to prevent the solid waxes from precipitating and blocking the oil filters. As the oil undergoes solvent extractions, the paraffin is enriched by the process’ byproducts and results in a mixture of oil and wax called slack wax. Chemically, paraffin made up of heavy, long-chain alkanes and can be dissolved in toluene or in xylene. Thus, toluene is mixed with the waxy raffinate to dissolve it into a liquid; while methyl ethyl ketone (MEK) dissolves the wax at low temperatures and allows for the wax to precipitate. The latter wax mix follows three steps in processing: crystallization, filtration, and solvent recovery. The feedstock (wax) and the solvent are cooled by their heat exchange and a cold filter from a chilling medium in the refinery machine’s double pipe exchangers. Cooling is usually maintained between -15°C to -7°C (5°F to 20°F); the slurry leaving the chillers is filtered by a rotary vacuum—the wax cake is then washed with a spray of cold solvent before discharge. The wax cake is separated from the oil filtrate and solvent at this point to be packaged and sold.

According to the National Candle Association, 1 billion pounds of wax are used in producing the candles sold each year in the U.S. Meanwhile, the exact quantity of paraffin candle imports from China cannot be determined due to how most candles are mixed-substance (paraffin and beeswax, paraffin and microcrystalline, etc.), however as the National Candle Association requested U.S. customs for an anti circumvention inquiry and found that in 2005, paraffin candle imports from China equated to the value of $126,034,894, or 59,328,534 kg. This year, the Court of International Trade upheld the customs duty on paraffin candle imports from China. Paraffin candles all over the world remain a hot international trade item, shipping between continents annually. In mass-production, the wick is made from twisted cotton cord, which is then stiffened by a tank of liquid paraffin wax. The machine passes these stiffened wicks over a cooling drum which hardens the wax and winds the cord onto a spool. During candle pressing, the hot paraffin travels from its holding tank to an array of sprinklers inside a refrigerated chamber—the consistent principle for candle-making is heating the wax and then hardening it with cold contact (air or a surface). Refrigerated chambers inside most candle-making stations are six meters or taller—inside, sprinklers expend the wax up into cold air. The wax precipitation fall and crust into wax flakes on the base of the refrigerated chamber. These chambers transfer these fallen flakes into a hydraulic press, where they are formed into candles using zero-heat pressure. Here, a tunnel for the wick is created by this hydraulic press. At this point in the process the air is maintained to be less than 25°C to prevent the wax flakes from sticking together and damaging the machines. Then, the candles are loaded onto the wicking machine, which may offer varying shapes such as hexagons and squares. In another method of candle making, wicks are loaded onto a dipping machine which then dips them into liquid paraffin—when the wick is coated through a circuit until it forms a candle. For dyed candles, the paraffin liquid is dyed at first. When wick is dipped and exposed to cold air, the color will harden along with the wax. To maximize supply, the excess paraffin wax is scraped off, melted, and used for the next batch of candles. Altar candles made for the Vatican are required to be a mix of paraffin and 66% beeswax by law—these speciality candles are made on a manually operated dipper where a worker flips the frame of the dipper 90 times to equalize the wax and maintain its cylindrical shapes. To catch the drip of melting wax, manufacturers commonly craft candles complete with their holders or followers, made from glass or metals. In many candle manufacturing factories, these holders are crafted outside and shipped over or they’re automatically crafted in the same facilities.

After production and use, the paraffin candle does not burn without leaving behind a variety of negative consequences to the environment. Besides the obvious fossil fuel dependence of candle-making, paraffin wax may emit harmful chemicals such as toluene (the solvent used in its making) and benzene as it is being burned. The candle can also create dye toxins in the area from its coloring. Burning a candle in a regularly vented area wouldn’t cause the same extreme effects as smoking cigarettes, however frequently burning paraffin candles in tight, unventilated spaces can lead to lung cancer and the development of asthma. The National Candle Association claims that paraffin wax in the U.S. is non-toxic and approved by the U.S. Food and Drug Administration; most candles produced today are made from food-based paraffin. Paraffin waxes’ chemical composition determines that they are able to dissolve with lipophilic solvents. In a household, excess or unwanted leftover candle wax may be dissolved with vegetable oil. This solution would be disposed of in a waste bin, sent to the landfill, and there, the leftover candle will break down as a decomposable substance.

As mentioned before, even when the light bulb became the main source of light for most of the world in this age, candles remain a popular product today as their uses have expanded beyond religious or functional to aesthetic and decorative everyday purposes. However, there are still areas of the world that depend on candles, paraffin or otherwise, as their main source of light in their households. As the efficiency and design in the various processes of energy involved in the paraffin candles and their holders evolve through the 19th to 21st century, the industry sees the reduction of waste and hazard through the reuse of their wax and the versatility of distillation machines. The discovery of more collection and production techniques bolstered the use of different wax sources, moving the focus away from oil. Paraffin candles are seen as less “clean” than greener candles such as carnauba wax, beeswax, and soy wax. Candles may not expend as much waste as a car—paraffin candles release approximately ten grams of carbon dioxide burning for an hour, but made from crude oil, they are an example of our dependence on fossil fuels. However, despite the cleaner output of beeswax or palm oil wax candles, their production still requires the extraction of supply through deforestation and changing the natural environment in developing countries such as Indonesia, India, and the Philippines. As humans continue to take and take from the environment and ignore its implications, our forests and air will keep degrading--even candle-making has its consequences.

Bibliography

Bougies.Info - How to make Candles.Info. “How to Make Candles.info • Microcrystalline Waxes.” Howtomakecandles.info, www.howtomakecandles.info/cm_article.asp?ID=WAXES0004.

CandleScience. “The Problem with Palm Wax.” CandleScience - Candle and Soap Making Supplies, www.candlescience.com/learning/the-problem-with-palm-wax.

D.Minenko, minenko@shaw.ca. “Main Waxes Used in Candlemaking. Paraffin and Beewax.” GeneralWax.com, www.generalwax.com/candle-making/about-candle-wax.php.

“Item # 10-0212, Organic Carnauba Wax On Frank B. Ross Co.” Search Results On Frank B. Ross Co., waxes.frankbross.com/item/all-categories/carnauba-wax/10-0212.

Karydas, Thanos. “The Environmental Impact of Wax.” DOMINATOR Wax.

NIIR Project Consultancy Services. “Paraffin Wax - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue, Plant Economics in Project Reports & Profiles.” NIIR Project Consultancy Services, www.niir.org/profile-project-reports/profile/2508/paraffin-wax-manufacturing

“Palm Wax Burn Characteristics.” LightWorks Candles, www.lightworkscandles.com/palm-wax-burn-characteristics.html.

Obeid, Mohammed & Akeiber, Hussein & Wahid, Mazlan & Mahdi, Taha & N. Jassim, Naser. (2016). Production application of paraffin waxes refining process in Iraq and used as phase change materials. International Journal of Advanced Research. 4. 96-100.

BoPan Ni

ID:916176468

DES 040A

Research paper Thesis Statement

Prof: C. Cogdell

12. 5. 2018

The Waste of Candles

In today's mass-production society, the energy which human use is becoming more and more efficient. Old basic energy resource like Candle has become a symbol of tradition. However, people today not only use those old style product but also spend a lot more energy to producing those products. Therefore, our group put our attention on traditional lighting resources-- Candle to show how many energy we wasted on producing candle. The candle is just a simple small product which made by wax which made by oil and flammable center line. However, under the international trade and profit center design background, to finish the making process, a simple candle can be transported many times from middle east to Aisa, which made the production of candle becomes very wasteful. Not only the candle but also all of the product we are consuming today have the same huge waste, this kind of wasteful production style could accelerate the energy use and finally run out of usable energy for human society; Thus, to show and stop the dangerous consequence, this research will investigate the waste from processing a candle and list the data to show the average waist to make a single candle based on raw material mining, production, product transport, exhaust and product recycling.

Nowadays, production of candle highly relies on paraffin wax, which is come from crude oil; to support the paraffin wax industry, a huge amount of energy waste appeared from the exploitation of crude oil. Before people start to use crude oil as our main energy resources, the wax of candles is mostly animal-based waxes, which use the animal as raw material. Romans began making true dipped candles from tallow, beginning around 500 BC. The need for wax is constantly increasing through times even though we are no longer use it as our main lighting resource in today's world. The animal-based wax is not enough to support the needs, therefore, fossil-based oil became a new main material since the mid-1850s, James Young succeeded in distilling paraffin wax from coal and oil shales at Bathgate in West Lothian and developed a commercially viable method of production. (HISTORY OF CANDLES) The main waste and emissions in the raw material acquisition of wax are mostly from the detecting section. It will take lots of human power to find the crude oil and create an exploitation station. To stabilize the paraffin wax from crude oil, people need to create a huge tower and huge oil tank for stabilizing the crude oil. Paraffin waxes’ have high volumetric thermal energy storage density: ~200 kJ/jk. In many operations, their heating and cooling process takes place in PCMs (phase change materials) where room temperature can be stabilized to allow for the paraffin wax’s phase change (from liquid to solid).

In the mass production society, all product needs to go through a very high-speed production line; to increase the speed of producing and to offer more candle shape to customers, a huge amount of energy is been wasted by making the mold and all the tool supplies. Based on data from national candle association, there are around 1000 and 2000 varieties of candles in a single candle manufactures product lines. More than 1 billion pounds of wax are used in producing the candles sold each year in the U.S. It is estimated that more than 10,000 different candle scents are available to U.S. consumers. Candles come in an endless variety of sizes and shapes, from tapers, votives, pillars, and tealights to container/jar candles, floating candles, liturgical candles, outdoor candles, novelty candles, utility candles and birthday candles. (Candle fact) Furthermore, in 2005, the United States imported 94,381.144 tons paraffin wax candle from other countries. There are more than 400 candle manufacturing companies in the United States, which means even only in the United States, there are more than 600,000 candles producing line and molds are needed. Most of those producing line is build and made for competition with other company, which is unnecessary for just satisfy the market needs.

Under the global thread and profit based design background, to make a candle, people need to ship the crude oil from the country of origin to the country of production and then transport the product to the consumer's location; the transport will cause a huge amount of power wastes which is even more power than the candle it selfs. China is the biggest paraffin wax outport country, based on the calculation form CHYXX, In 2012, China had imported 271.3 million tons of crude oil. (2012-2017年中国原油产量及进口量统计 ) In the same year, China had outport 460 thousand tons paraffin wax to other places in the world. Also, based on the research, in 2017, China had outport 264444.96 tons finished candle, among 49723.249 tons is to the United States. According to eia.gov, there is five level of tankers in nowadays trade market: General Purpose, Medium Range, Long Range, VLCC, and ULCC. Averagely those tankers can carry around 75,034 tons crude oil。(Hamilton) Based on the Chinese import, in 2012, there are over 3615 tankers are working for traveling crude oil to China per year. Usually, it will take 19 days for tankers sail from the middle east to China and burn 30 tons oil per day. After calculation, it will cust 2.06 million tons of oil to transport those crude oils. Then after it been produced into paraffin wax and candles, China will ship it to other countries, which will cost 5503.27 tons of oil for transport. Under the profit society, those transaction seems reasonable, however, it cost a huge amount of extra energy due to transport. Which also means a huge amount of CO2 will be produced during the transport.

The candle as a lighting resource has its own efficiency, Most energies inside candle are been wasted by heat, furthermore, candle lost its function and becomes a symbol, which makes it very wasteful. Based on the research, the efficiency of the candle as light is only around 0.01%. Most energy is just been wasted as heat. Which means, use candles as the lightning resource is a very inefficiency choice. However, people nowadays do not only use more candles, but use it in an even more wasteful way, and also consume more candle in the market. Based on the research from the National Candle Association, Candles are used in 7 out of 10 U.S. households. (FACTS & FIGURES ABOUT CANDLES) Nowadays, people buy candles for the celebration instead of using it for lightning. Candles are used for birthday, for emotion atmosphere, and also for the smell. It slowly becomes a symbols in people's daily life. Symbols usually don't have the original function anymore, it's more based on fun and traditions; Thus, it makes candles even more inefficiency.

There is almost no recycling of candle in today's candle usage because the candle is main to burn entirely; However, most candle only been used less than 70%. Because part of the wax will melt and drop down during candle burning after the string burns out. Most people will just through the rest wax away. There is no specific recycling systems for candles so usually candles will just go with the regular trash into the trash burning factory. As we know, most candles are made from crude oil, which is a type of unrecyclable fossil energy; just let 30%candles burn for nothing is a very wasteful way.

In conclusion, due to the global trade and profit based design, to supply the candle market, the transportation will waste tons of fuel and discharge a huge amount of greenhouse gas into the air. Use candles as lighting or traditions is extremely inefficiency due to it becomes a symbol today. The style of the candle is too fractionalized due to the competition on market, which will cost many unnecessary materials and energy to build the production line. Furthermore, it has nearly no recycled use and it is very easy to be waste during use. Although a single candle won't affect a lot to our environment, however, on large scale, it still produced much unnecessary waste and pollution.

Bibliography

“FACTS & FIGURES ABOUT CANDLES ” NCA National candles association , 2018. http://candles.org/facts-figures-2/europecandles.org/raw-materials-and-candles-production-processes.

"Oil tanker sizes range from general purpose to ultra-large crude carriers on AFRA scale."T. Mason Hamilton. EIA, 2014,September 16. https://www.eia.gov/todayinenergy/detail.php?id=17991

"2012-2017年中国原油产量及进口量统计" CHYXX, Apr, 12, 2018, http://www.chyxx.com/industry/201804/629483.html

“HISTORY OF CANDLES ” NCA National candles association , 2018. http://candles.org/facts-figures-2/europecandles.org/raw-materials-and-candles-production-processes.