Design Life-Cycle

assess.design.(don't)consume

Krishelle Diaz

DES 40A 01

Professor Cogdell

2 December 2021

Disinfectant Wipes: Raw Materials

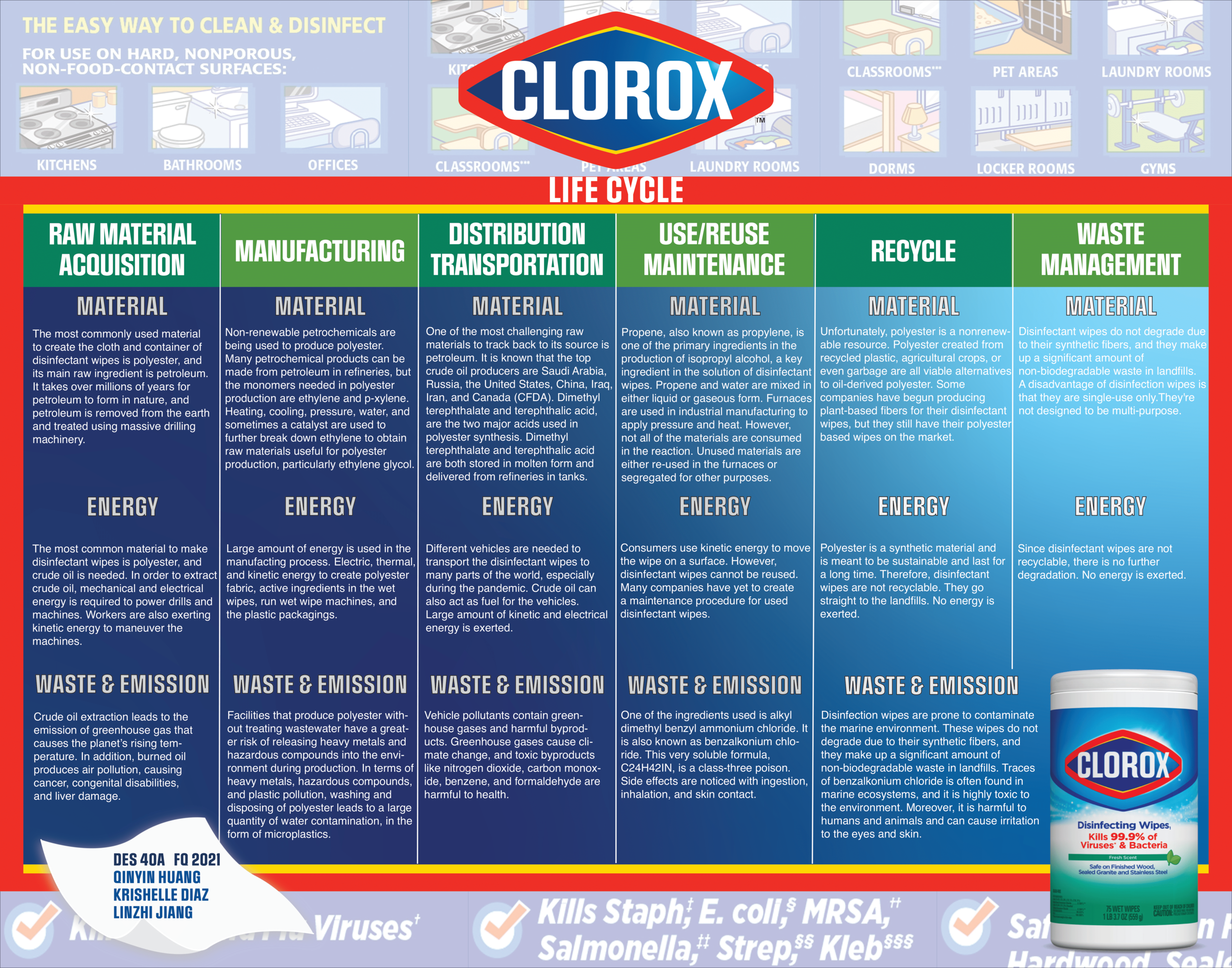

Disinfectant Wipes are pre-dampened cloth containing an active solution that is intended to kill and prevent bacteria from spreading. Disinfectant wipes have become fundamental for everyone due to COVID-19. It is now being mass-produced and highly consumed by people all over the world. Almost anywhere a person has been, it is quickly sanitized by using a disinfectant wipe. It's very accessible and convenient to use, but the process of creating and producing disinfectant wipes is much more complex. Especially during the pandemic, production is at an all-time high, and there is not a lot of information being given to the general public on how much the materials being extracted to make this product are affecting our environment. The amount of materials being consumed to make disinfectant wipes varies from different companies, but the most common concerning trait for the majority of disinfecting wipes is that they are not biodegradable. From the acquisition of the materials to manufacturing the product and distributing it, the materials being extracted and utilized are negatively impacting the environment. The life-cycle of disinfectant wipes affects our bodies, the air, the animals, the sewage system, and the ocean.

The most commonly used material to create the cloth and container of disinfectant wipes is polyester, and its main raw ingredient is petroleum. Polyester is a synthetic fiber that is manufactured. Although it is made from a synthetic fiber, its raw materials are still derived from nature. It is a type of plastic that is typically made from petroleum, a nonrenewable resource that has a major negative influence on the environment throughout its production, usage, and disposal. One of the most challenging raw materials to track back to its source is petroleum. It is known that the top crude oil producers are Saudi Arabia, Russia, the United States, China, Iraq, Iran, and Canada (CFDA). Right now, the consumption of petroleum is far quicker than it can be produced naturally. It takes over millions of years for petroleum to form in nature, and petroleum is removed from the earth and treated using massive drilling machinery. It is then carried to refineries where the molecules are broken down into useful ingredients by using heat, fuel, electricity, high pressure, solvents, and catalysts.

Non-renewable petrochemicals are being used to produce polyester. Many petrochemical products can be made from petroleum in refineries, but the monomers needed in polyester production are ethylene and p-xylene. Heating, cooling, pressure, water, and sometimes a catalyst are used to further break down ethylene to obtain raw materials useful for polyester production, particularly ethylene glycol. Dimethyl terephthalate and terephthalic acid, both chemical molecules made from P-xylene, are the two major acids used in polyester synthesis. Dimethyl terephthalate and terephthalic acid are both stored in molten form and delivered from refineries in tanks. Polyethylene terephthalate, the same material used in plastic soda bottles, is made using a polymerization process in which ethylene glycol, terephthalic acid, and depending on the procedure dimethyl terephthalate are mixed together under high pressure and heat (CFDA). The end product is a honey-like liquid that is extruded, dried, and cut into plastic pellets. Polyethylene terephthalate plastic pellets are melted and extruded through tiny holes known as spinnerets to create long threads, which are then cooled to harden into polyester fibers. Melt spinning is the term for this procedure. To make fibers of varying quality, the form and quantity of holes can be changed. Polyester yarn is made by twisting these strands together and winding them onto bobbins, where they are ready to be woven into fabric. One of the major concerns is facilities that produce polyester without treating wastewater have a greater risk of releasing heavy metals and hazardous compounds into the environment during production. Washing and disposing of polyester leads to a large quantity of water contamination, in the form of microplastics. Additionally, having polyester in the disinfectant wipes further negatively impacts the environment because they are easily mistaken to be flushable and biodegradable, and it leads to not only contamination, but sewage, landfill, and ocean problems.

It's important to keep in mind that components vary by product, however, the ones being addressed are common ingredients among disinfecting wipes. The formulated solution that fights bacteria is an important aspect of disinfectant wipes, and Alkyl dimethyl benzyl ammonium chloride is one of the key active ingredients that are commonly found in disinfectant wipes. Clorox and Lysol both utilize Alkyl dimethyl benzyl ammonium chloride in their wipes. Alkyl dimethyl benzyl ammonium chloride, more commonly known as Benzalkonium chloride, has a wide range of applications because of its broad-spectrum antibacterial properties against bacteria, fungi, and viruses. It is a quaternary ammonium compound produced by methylating a primary amine from fatty acid or a mixture of fatty acids to generate dimethyl alkylamine. The benzyl chloride is then used to quaternize it. They are often marketed as a blend of chemicals with various alkyl chain lengths ranging from C8 to C18, with C12 and C14 derivatives having stronger biocide action. Traces of benzalkonium chloride is often found in marine ecosystems and it is highly toxic to the environment. Moreover, it is known that benzalkonium chloride is toxic to humans and animals and can cause irritation to the eyes and skin.

Another common ingredient found in the solution of disinfectant wipes is Isopropyl alcohol, which according to Clorox's smart label, is used as a solvent in glass and all-purpose cleaning products. Its antimicrobial properties make it useful in disinfecting products. Propene, also known as propylene, is one of the primary ingredients in the production of isopropyl alcohol. This substance is derived from fossil fuels, such as petroleum, natural gas, and even coal. Propene is one of the byproducts of oil refining, which breaks down fossil fuels into component substances. Poly(propene) is made in various proportions, ranging from 55% in North America and 57% in Europe to 90% in the Middle East (Essential Chemical Industry). For many years, two methods have produced the vast majority of propene: steam cracking of naphtha and catalytic cracking of gas oil. Both procedures create a variety of additional chemicals, including significant amounts of ethene. Because propene and the other fossil fuel byproducts have different boiling temperatures, heat is used to separate propene from the other chemicals. Water is the other essential component in the production of isopropyl alcohol (Sciencing). Propene and water are combined in a process known as hydration. Propene and water are mixed in either liquid or gaseous form. When the two substances are mixed, a solid acidic catalyst (a component that stimulates chemical reactions) must be present. Furnaces are used in industrial manufacturing to apply pressure and heat. However, because not all of the materials are consumed in the reaction, a method for classifying and recycling waste materials and byproducts is used. Unused materials are either re-used in the furnaces or segregated for other purposes.

Citric Acid is another key ingredient in the chemical makeup of disinfectant wipes. Citric acid is a natural acid that is utilized in laundry detergents, dishwashing soaps, and hard surface cleaners as a builder (SmartLabel). It removes soap scum and mineral scale deposits from toilets, bathtubs, and sinks that are left behind by hard water. Builders work similarly to water softeners, removing calcium, magnesium, and other ions from tap water that can obstruct cleaning. It is one of the most extensively used organic acids, with a global yearly output of 2.1 million tons in 2016 (Kirimura & Yoshioka, 2019). In the food industry, it is used as an acidulant and preservative, while in the pharmaceutical and cosmetic industries, it is utilized as a complexing agent and as a starting material for functional compounds.

Citric acid is produced solely by fermentation with the filamentous fungus Aspergillus niger. Many industrial enzymes and chemical compounds rely on filamentous fungi for synthesis. Because high-level enzyme release is a prevalent trait of their decomposer lifestyle, fungal-based systems have significant benefits over bacterial-based systems for protein production. Furthermore, due to crucial processes shared in gene expression with other eukaryotic organisms, filamentous fungus become the vehicle of choice in the large-scale creation of recombinant proteins of eukaryotic origin (N.S.Parachin & M.Bettiga, 2011). In comparison to bacteria, filamentous fungi are more complicated and have a lower understanding of their physiology, which has slowed their development as highly efficient factories for the manufacture of heterologous proteins. Overall, filamentous fungi have several disadvantages, including an oxygen demand for development, a poor rate of ethanol generation, and manufacturing byproducts such as glycerol and organic acids, similar to yeasts other than S. cerevisiae.

Citric acid is found in abundance in various plants, particularly citrus fruits such as lemon and orange. Citric acid's vast abundance in the animal and plant worlds confirms its benign nature, and the Joint FAO/WHO Expert Committee on Food Additives currently considers it to be generally recognized as safe (GRAS). It is an organic carboxylic acid that can be extracted from citrus juice by combining it with calcium oxide to generate calcium citrate, an insoluble precipitate that can be collected by filtration; the citric acid can then be recovered from its calcium salt by combining it with sulfuric acid. Citric acid can be synthesized chemically, but it is more expensive than fungal fermentation. Citric acid is still manufactured in modest quantities from citrus fruits in Mexico and South America, where they are economically available (Ghasem D. Najafpour, 2007).

The COVID-19 outbreak has resulted in an increase in the manufacture and use of wet wipes for disinfection, sanitizing, and medicinal applications, as well as personal protective equipment. Seventh Generation, for example, uses polyester spun lace in its wipes as well as personal protective equipment(PPE) such as masks, medical gowns, and medical wipes. Demand for a variety of wet wipes such as baby wipes, facial wipes, moist flushable wipes, and household wipes has exploded since the outbreak of COVID-19, owing to increased global awareness of sanitation and personal hygiene, as well as increased cross-contamination issues fueled by social media and other promotional media (V.C. Shruti & G. Kutralam-Muniasamy, 2021). As a result, a higher percentage of people who had never used disinfectant wipes are now using them. Furthermore, disinfectants and medical wipes have mostly been used in the medical field, hotels and restaurants, schools, and universities to disinfect surfaces on a large scale as a preventative precaution in the ongoing pandemic. Additionally, to successfully counteract COVID-19 spread, sanitizing wipes have been supplied to travelers flying. Many wipes producers have expanded production to satisfy worldwide demand. Clorox, for example, raised its wipes production from 1 million packages per day in 2020 to 1.5 million packages per day in the first quarter of 2021, according to a recent report (Stankiewicz, 2021 ). The global wipes market is expected to develop at a compound annual growth rate (CAGR) of 5.3 percent from $39.6 billion in 2020 to $41.69 billion in 2021 (V.C. Shruti & G. Kutralam-Muniasamy, 2021).

Disinfectant wipes are one of the most important debris items among COVID-19's plastic wastes, and we need to be more aware of the problems they cause. From the acquisition of the materials to manufacturing the product and distributing it, the materials being extracted and utilized to make this product is negatively impacting the environment. Disinfectant wipes do not degrade due to their synthetic fibers, and they make up a significant amount of non-biodegradable waste in landfills. Currently, scientists, politicians, and waste management experts are working together to make instructional materials more available to the public, which enables them to properly use and dispose of personal protective equipment (PPE) and other health and safety items, to reduce some of the littering related to the pandemic (V.C. Shruti & G. Kutralam-Muniasamy, 2021). Unfortunately, there are not a lot of alternatives to disinfecting wipes and the materials that they are made out of. Polyester created from recycled plastic, agricultural crops, or even garbage are all viable alternatives to oil-derived polyester. Some companies have begun producing plant-based fibers for their disinfectant wipes, but they still have their polyester based wipes on the market. The best alternative to disinfectant wipes as of now is a disinfectant cleaning solution, which is sold in stores and can be made at home.

Works Cited

“ Polyester | Materials Index.” CFDA, https://cfda.com/resources/materials/detail/polyester.

Can Disinfecting Wipes Be Reused?, https://health-desk.org/articles/can-disinfecting-wipes-be-reused.

“Citric Acid.” Citric Acid - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/biochemistry-genetics-and-molecular-biology/citric-acid.

Dianne, et al. “Clorox vs. Lysol: Which Disinfecting Wipes Kill More Germs?” Prudent Reviews, 3 Aug. 2021, https://prudentreviews.com/clorox-vs-lysol/#DifferencesBetweenCloroxandLysolDisinfectingWipes.

Favors, LaTasha. “How Is Isopropyl Alcohol Made?” Sciencing, 31 Dec. 2020, https://sciencing.com/isopropyl-alcohol-made-5574730.html.

“Filamentous Fungus.” Filamentous Fungus - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/biochemistry-genetics-and-molecular-biology/filamentous-fungus.

Garrity, Katie. “Are Disinfectant Wipes Compostable?” Green Matters, Green Matters, 6 Apr. 2020, https://www.greenmatters.com/p/are-disinfectant-wipes-compostable.

“Isopropyl Alcohol.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/science/isopropyl-alcohol.

Lili Li, Margaret Frey. “Biodegradability Study on Cotton and Polyester Fabrics - Lili Li, Margaret Frey, Kristie J Browning, 2010.” SAGE Journals, https://journals.sagepub.com/doi/10.1177/155892501000500406.

Merchel Piovesan Pereira, Beatriz, and Ilias Tagkopoulos. “Benzalkonium Chlorides: Uses, Regulatory Status, and Microbial Resistance.” Applied and Environmental Microbiology, American Society for Microbiology, 17 June 2019, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6581159/.

“Propene (Propylene).” Propene (Propylene), https://www.essentialchemicalindustry.org/chemicals/propene.html.

Puracy. “Benzalkonium Chloride 0.1%.” Puracy, 9 June 2020, https://puracy.com/blogs/ingredients/benzalkonium-chloride-01.

Rb. “LYSOL® Disinfecting Wipes.” SmartLabel - Lysol® Lysol® Disinfecting Wipes - Lemon & Lime Blossom (Canister), http://www.rbnainfo.com/smart-label.php?productLineId=665.

Shruti, V.C., et al. “Wet Wipes Contribution to Microfiber Contamination under Covid-19 ERA: An Important but Overlooked Problem.” Environmental Challenges, Elsevier, 2 Sept. 2021, https://www.sciencedirect.com/science/article/pii/S2667010021002468.

SmartLabel. “SmartLabel® Clorox.” SmartLabel, http://www.smartlabel.org/products.

Stankiewicz, Kevin. “Clorox Making 1.5 Million Canisters of Wipes per Day to Meet Covid Demand, CEO Says.” CNBC, CNBC, 19 Feb. 2021, https://www.cnbc.com/2021/02/19/clorox-expanding-production-of-disinfectant-wipes-amid-covid-ceo-linda-rendle.html.

Qinyin Huang

DES 40A 01

Professor Cogdell

2 December, 2021

Disinfectant Wipes: Embodied Energy

A disinfectant wipe is a piece of cloth that is dampened with a solution containing active ingredients to kill and prevent bacteria. Disinfectant wipes are practical and became an essential in our daily lives amid the pandemic. It is now mass-produced, distributed all around the world, and highly consumed by people. In most households and institutions, you will always see disinfectant wipes present. It’s simple and efficient to use, but the embodied energy of the raw materials, the manufacturing process, and the output of waste of disinfectant wipes are much more complex. The amount of energy used to extract the materials needed can vary depending on the material of the fabric and the solution created by different companies. Forms of energy can also vary throughout the entire production. From extracting materials to the mass production by machines and to the eventual waste and emission of the wipes, the amount of energy spent making these wipes can greatly affect the environment. In the entire life cycle of disinfectant wipes, it produces and releases harmful chemicals that contribute to air pollution and water pollution.

One common material used for the fabric of disinfectant wipes is polyester. Polyester is a type of nonwoven fabric made with plastic, and it is one of the most mass-produced synthetic fabrics that can be used for a wide range of products. (Polyester) Not only is plastic used to make polyester for the wipes, but it’s also used to make the containers of the disinfectant wipes. Plastic is made from crude oil that is extracted from underneath the Earth’s surface, and the extraction, transportation, and distribution of crude oil lead to an immense amount of greenhouse gases emissions. Extracting crude oil from the ground requires oil wells, which are essentially drilling a hole into Earth’s surface. These drills are powered by mechanical and electrical energy. The extraction and mining of crude oil also increase the use of fossil fuels, further contributing to an increase in greenhouse gas emissions. It is estimated that producing polyester and plastic-based fabric used up around 342 million barrels of crude oil. (Polyester)

It’s important to note that every product varies in ingredients, and the ones mentioned are common amongst disinfectant wipes. An essential part of disinfectant wipes is the formulated solution that combats bacteria, and one of the key active ingredients is Alkyl dimethyl benzyl ammonium chloride. (SmartLabel) To produce this antibacterial ingredient, thermal and kinetic energy is required for dialkyl methylamine and alkylene glycol to combine. Propene is a chemical found in fossil fuels, and it is used to make another key ingredient is Isopropanol alcohol, an antimicrobial compound made from propene and water through a chemical process called hydration. Another key component in the solution is citric acid, which is found in many cleaning products. Citric acid may be found in fruits, but there is a way to mass-produce industrial citric acid. Citric acid serves as builders that soften the water and removes ions that can stand in the way of cleaning. Filamentous fungus Aspergillus niger needs to be fermented, and there are three main steps: submerged, surface, and solid fermentation. (Kirimura & Yoshioka, 2019) The process of making all these ingredients means there is chemical energy involved. Equipment is needed and powered to make and store these ingredients. Fossil fuels and kinetic energy is needed to deliver these ingredients to the designated factories where it gets developed into disinfectant wipes.

In manufacturing disinfectant wipes, petroleum is the primary material that goes through a chemical process to produce polyester, which would require thermal energy, kinetic energy, and electricity to run equipment. In addition, petroleum needs to go through a chemical reaction called polymerization, which requires high temperature, to make ethylene. Ethylene is the secondary material that creates the fibers needed to produce polyester. The fibers are then spun, stretched, and dried into sheets of polyester. (Polyester) Once the materials are obtained, disinfectant wipes can be made from wet wipe machines in factories that utilize fossil fuels, which produce more airborne wastes. Wet wipes machines have different sections that operate certain components that altogether create disinfectant wipes. In the folding stage, the machine folds the polyester fabric in preparation for it to be manufactured into a wipe. The folded fabric later goes through a slitter rewinder where it gets cut into appropriate sizes and proportions. The fabric is then transferred to a machine where it gets dampened with the formulated solution. The moistened wipes will then go through its packaging process to get ready for distribution. (Wet wipe machine: The Complete Guide) As for the package of the disinfectant wipes, it is made of Polyethylene Terephthalate (PET), which is a type of plastic within the family related to polyester. PET requires ethylene glycol and terephthalic acid, which forms into resin pellets. These resin pellets are later heated up and molded into the desired shape for the product. (About PET) This means that PET goes through physical and chemical processing. Thermal energy, kinetic energy, and electrical energy are also required to manufacture the packaging of disinfectant wipes.

Besides drilling crude oil to mass-produce plastic, crude oil can be used to produce other products that can be used as fuel for transportation and power. This would require an oil refinery where crude oil gets processed into other products, which needs thermal, mechanical, and electrical energy. Transporting disinfectant wipes will require vehicles powered by fossil fuels for the products to reach a great range and many destinations. Because of the pandemic, health institutions, public buildings, and households all use disinfectant wipes to ensure cleanliness and subdue the spread of COVID-19, which means there’s a greater demand for disinfectant wipes. However, there was a period of time during the pandemic where companies that manufactured disinfectant wipes were facing shortages due to the high consumer needs. It can be inferred that these companies have to invest more in materials, factories, and fuel to subdue the shortage. This in turn will lead to greater use of fossil fuels to run more manufacturing factories and machines to produce more disinfectant wipes and to distribute them. Equipment and vehicles are not the only things that do the work, workers also have to put in kinetic energy into the manufacturing and distribution process. Although they might not put in as much work as the equipment does, the machinery and vehicles can’t run without the effort of the workers.

It has been advised by health professionals that disinfectant wipes should not be reused as it can increase the likelihood that germs will spread and move around. (Can disinfecting wipes be reused? 2020) In actual use, kinetic energy is required from the user to move the wipe to clean the surface. In addition, the active ingredients in disinfectant wipes are interacting with the bacterias on surfaces. Since it can’t be reused, the used disinfectant wipes serve no further purpose. One of the characteristics of polyester is its high durability. Among consumers, polyester is considered a more sustainable material, which can be linked to its lack of degradability. Scientists took various types of fabrics under certain controlled environments to test and compare the biodegradability of each material. Because the fibers in polyester are not natural, they found that polyester fabric showed little signs of degradation, and the fabric remained its whole form and was deemed as non-compostable. (Frey, Margaret) The slight degradation is not much of great news because polyester simply can’t degrade at a rate that doesn’t negatively affect the environment. It will take an extremely long time for polyester fabric to biodegrade properly. Therefore, disinfectant wipes are not recyclable and create an issue for the environment. Once they are used and thrown away, the disinfectant wipes go straight into the landfill. To add to that, this means there is little to no form of energy in the reuse and recycle stage of disinfectant wipes.

Once it ends up in the landfill, the lifecycle of disinfectant wipes ends there. Disinfectant wipes, in general, should not be disposed of in the toilet as it will lead to clogging and great consequences in the sewage system. However, there are many incidents where people do as such. There are wipes that are advertised to be flushable but it does not guarantee that the wipes will smoothly flow through the sewage system. Even if thrown away properly, disinfectant wipes will end up in the landfills and contribute to the pre-existing problems. Because it can’t biodegrade, the wipes will remain and accumulate in the landfills. Removing disinfectant wipes from sewage systems and landfills requires the attention and work of machinery and people, thus needing electrical energy and kinetic energy. The exponential rate of use of disinfectant wipes during COVID-19 means that disinfectant wipes have become a major threat as disinfectant wipes have been shown to release microfiber and microplastic, which is dangerous to marine life and coastline pollution. (Shruti et al.) To help remove microplastic from oceans and bodies of water, filtration systems have been designed to help filter out harmful particles.

The making of disinfectant wipes extrudes energy at almost every stage of its life cycle. Most of the energy used is getting the raw materials, manufacturing, and distributing. These companies focus on the production phase the most, but it’s these stages that most negatively impact the environment. Companies should start investing in energy towards maintenance, recycling, and waste emission of disinfectant wipes, and thorough procedures must be established to target these stages. Polyester may be cheap and accessible, but the overall process to obtain and make polyester is extremely harmful to the environment, especially to the atmosphere and nearby ecosystems. There are companies who use materials other than polyester for the fabrics for their wipes, like cotton or viscose. Even though it may seem like a more environmentally friendly alternative, it still remains a threat to our environment regardless of the material. Crude oil is an essential material needed to create disinfectant wipes, but our world is constantly drilling oil and using disinfectant wipes at a rapid rate, way faster than the rate of natural production of crude oil. As previously mentioned, manufacturing and transporting materials and disinfectant wipes all require fossil fuels, which is known to have high greenhouse gas emissions. Although disinfectant wipes have become a staple in our lives, it’s important to evaluate the environmental impact it is currently causing and the potential threat it holds in the future.

Works Cited

Polyester . CFDA. (n.d.). Retrieved November 25, 2021, from https://cfda.com/resources/materials/detail/polyester#:~:text=To%20make%20polyester%20fibers%2C%20PET,to%20harden%20into%20a%20fiber.&text=These%20fibers%20are%20twisted%20together,to%20be%20woven%20into%20fabric.

Shruti, V. C., Pérez-Guevara, F., & Kutralam-Muniasamy, G. (2021, September 2). Wet wipes contribution to microfiber contamination under covid-19 ERA: An important but overlooked problem. Environmental Challenges. Retrieved November 25, 2021, from https://www.sciencedirect.com/science/article/pii/S2667010021002468.

Kirimura, K., & Yoshioka, I. (2019, July 31). Citric acid. Comprehensive Biotechnology (Third Edition). Retrieved November 25, 2021, from https://www.sciencedirect.com/science/article/pii/B9780444640468001579.

Can disinfecting wipes be reused? (2020, May 22). Retrieved November 25, 2021, from https://health-desk.org/articles/can-disinfecting-wipes-be-reused#:~:text=Disinfectant%20wipes%20should%20never%20be,harmful%20in%20the%20current%20pandemic.&text=This%20means%20the%20surface%20needs,the%20size%20of%20the%20surface.

Frey, Margaret, et al. “Biodegradability Study on Cotton and Polyester Fabrics.” SAGE Journals, 1 Dec. 2010, journals.sagepub.com/doi/abs/10.1177/155892501000500406.

Zhang, Yuting, et al. “Life-Cycle Environmental Impact Assessment and Plastic Pollution Prevention Measures of Wet Wipes.” Resources, Conservation and Recycling, Elsevier, 24 July 2021,www.sciencedirect.com/science/article/pii/S0921344921004122?casa_token=tXWPF4os2eMAAAAA%3Aatkiop1MGFFC_77UhkpXxSjyPGtlN8K348ZQFtgkuTDmb4jW7G4dwvYvqRq_JitAoxFDkwSB56g.

SmartLabel. (n.d.). Clorox® Disinfecting Wipes, Bleach Free Cleaning Wipes – Orange Fusion®, 35 Count (Package May Vary). SmartLabel. Retrieved November 25, 2021, from https://smartlabel.labelinsight.com/product/6075824/company.

Wet wipe machine: The Complete Guide. SaintyTec. (2019, April 30). Retrieved November 26, 2021, from https://www.saintytec.com/wet-wipe-machine/.

Hurd, Josh. “Clorox Wipes Ingredients: 3 Key Ingredients.” H2ouse, 13 Sept. 2021, www.h2ouse.org/clorox-wipes-ingredients/.

PET Resin Association. (n.d.). About PET. About PET | PETRA: Information on the Use, Benefits & Safety of PET Plastic. Retrieved November 26, 2021, from http://www.petresin.org/aboutpet.asp.

Linzhi Jiang

DES 40

Professor Cogdell

December 1st, 2021

Disinfectant Wipes: Waste and Emissions

The disinfectant wipe has become one of the must-have products globally due to the pandemic starting two years ago. Consumers dispose of disinfectant wipes into trash bins, which is the last time most people see them. Meanwhile, some are flushed into pipes and interfere with sewage collections. Those wipes that end up in landfills are mostly not disposable and increase the amount of trash every day. Different disinfectants on the wipe surface also cause various disposal solutions.

I. Introduction

Wipes often appear as a premade fabric with a solvent that disinfectants. However, a paper towel can also be considered a wipe, according to the EPA (the United States Environmental Protection Agency). “A “wipe” is defined in the regulations as a woven or non-woven shop towel, rag, pad, or swab made of wood pulp, fabric, cotton, polyester blends, or other material. (40 CFR section 260.10)” But, paper towel does not contain disinfecting solvent on which disinfectant wipes do.

II. From the Earth

Polyester spun lace, the most common raw material for disinfectant wipes, is made from crude oil. Extraction of crude oil can cause various environmental severe issues. First, toxic substances can leak from oil plants and wipes and harm people who live around. Also, the noise can cause animals to leave their habitats and be in danger. One of the most significant problems is the emission of greenhouse gases like carbon dioxide produced in the extraction process.

III. Increasing Consumption under Pandemic

The consumption of disinfectant wipes is increasing over these two years after the pandemic outbreak, as we have seen shortages of disinfectant wipes at the beginning of the pandemic. Thus, disinfectant wipes are in great demand after the pandemic began, and their disposal methods become one of the concerned problems.

IV. Flushable or Not Flushable

Are disinfectant wipes flushable, and why is this important? “Flushable” wipes that plumb into pipes and sewers cause intensive problems for cities because those are not flushable. What makes disinfectant wipes flushable or not? Disinfectant wipes are “mostly made of textile materials, including, but are not limited to, cellulosic fibers (cotton, wood pulp, viscose, lyocell) and thermoplastic fibers,” according to Xinyu Song, Lutz Vossebein & Andrea Zille’s “Efficacy of disinfectant-impregnated wipes used for surface disinfection in hospitals: a review.” Plastic fibers like polyester and PVC make wipes not flushable as plastic does not degrade and plumb pipes. Even though plastic is not flushable, some market sharers still advertise their products to be flushable. The Washington Post says this in its report named “Flushable wipes are terrible for plumbing” that flushable wipe holds together better than paper towels, which make them hard to flush down building drain and outside buried sewer without enough water. One brand of wipes collaborates how flushable their product is due to the different materials used. The introduction video shows degrading wipes made of plant-based fibers in water, enhancing its quality to be flushable.

V. Landfill

Disinfectant wipes ended up in landfills is the most common disposal method. They are usually made of synthetic fibers like plastic that prevent them from being compostable or recyclable, as explained by Katie Garrity in the “Are Disinfectant Wipes Compostable?” In order to deal with these fibers wipes, “Clorox came out with its own brand of compostable wipes after many environmental activists took issue with the not-so eco-friendly aspect of disinfectant wipes.” However, these wipes do not disinfect while other disinfectant wipes are not recyclable, which cannot protect customers from coronavirus.

VI. One the Way

After disinfectant wipes are manufactured in factories, they are transported to markets. Transportation can generate greenhouse gases, it becomes considerable as disinfectant wipes are becoming much more vital today when every household stack a few for precaution. Even though disinfectant wipes experienced a couple of shortages at the beginning of the pandemic, they are still popular.

VII. Disinfectants

Disinfectant wipes contain effective disinfectants to kill bacterias, germs, and viruses. However, they are often hazardous to the environment. One of the ingredients used is alkyl dimethyl benzyl ammonium chloride. It is also known as benzalkonium chloride. This very soluble formula, C24H42IN, is a class-three poison. Side effects are noticed with ingestion, inhalation, and skin contact. After disinfectant wipes are disposed of in landfills, their remaining toxic substance will continue to contaminate the ground and water.

VIII. Conclusion

Disinfectant wipes contribute to our society's health by their high efficiency in killing bacteria, germs, and viruses. Especially under the pandemic circumstance, disinfectant wipes have become one of the handful and cheapest products for consumers to buy. However, its toxic substances need to be handled well, and consumers have to learn how and where to dispose of wipes. The production of disinfectant wipes needs to be refined to generate fewer greenhouse gases and less harm to communities and the environment. Even wipes were invented over decades; there is still a lot to improve.

References

“Frequent Questions About Implementing the Regulations for Solvent-Contaminated Wipes.” EPA, Environmental Protection Agency, https://www.epa.gov/hwgenerators/frequent-questions-about-implementing-regulations-solvent-contaminated-wipes.

Song, Xinyu. “Efficacy of Disinfectant-Impregnated Wipes Used for Surface Disinfection in Hospitals: A Review.” Antimicrobial Resistance & Infection Control, 19 Aug. 2019, aricjournal.biomedcentral.com/articles/10.1186/s13756-019-0595-2.

Carter, Tim. “Flushable Wipes Are Terrible for Plumbing.” Washington Post, 26 Mar. 2020, www.washingtonpost.com/business/2019/05/21/flushable-wipes-are-terrible-plumbing.

“Fresh Care Flushable Wipes | Cottonelle®.” Fresh Care Flushable Wipes, 2021, www.cottonelle.com/en-us/products/cottonelle-fresh-care-flushable-wipes.

Garrity, Katie. “Are Disinfectant Wipes Compostable? The Answer Is Surprising.” Green Matters, 7 Apr. 2020, www.greenmatters.com/p/are-disinfectant-wipes-compostable.

“Clorox Disinfecting Wipes, Orange Cleaner Rating.” Clorox Disinfecting Wipes, 2021, www.ewg.org/guides/cleaners/2046-CloroxDisinfectingWipesOrange.

Disinfecting Wipes - Good Growth Blog.” The Clorox Company, 13 Feb. 2020, www.thecloroxcompany.com/blog/inventing-clorox-disinfecting-wipes.

---. “Inside the Creation of Clorox Disinfecting Wipes - Good Growth Blog.” The Clorox Company, 13 Feb. 2020, www.thecloroxcompany.com/blog/inventing-clorox-disinfecting-wipes/.

Gao, Michelle. “Why Disinfectant Wipes Aren’t Returning as Fast as Toilet Paper.” CNBC, 25 July 2020, www.cnbc.com/2020/07/24/why-disinfectant-wipes-arent-returning-as-fast-as-toilet-paper.html.

Garrity, Katie. “Are Disinfectant Wipes Compostable? The Answer Is Surprising.” Green Matters, 7 Apr. 2020, www.greenmatters.com/p/are-disinfectant-wipes-compostable.

Hurd, Josh. “Clorox Wipes Ingredients: 3 Key Ingredients.” H2ouse, 13 Sept. 2021, www.h2ouse.org/clorox-wipes-ingredients.

“Is It Okay to Flush Disinfecting Wipes?” US EPA, 5 Apr. 2021, www.epa.gov/coronavirus/it-okay-flush-disinfecting-wipes.

Lawless, Phillip. “A Guide To Greener Schools.” Cleaning & Maintenance Management, 17 Dec. 2019, www.cmmonline.com/articles/university-makes-disinfecting-wipes-for-campus.

Stankiewicz, Kevin. “Clorox Making 1.5 Million Canisters of Wipes per Day to Meet Covid Demand, CEO Says.” CNBC, 20 Feb. 2021, www.cnbc.com/2021/02/19/clorox-expanding-production-of-disinfectant-wipes-amid-covid-ceo-linda-rendle.html.

The Clorox Company. “Product Stewardship.” The Clorox Company, 6 Oct. 2021, www.thecloroxcompany.com/responsibility/healthy-lives/product-stewardship.

Bliss, Rosalie Marion. “New Cotton Disposable Disinfecting Wipes Effective, Biodegradable.” Lhys Org, 28 June 2016, phys.org/news/2016-06-cotton-disposable-disinfecting-effective-biodegradable.html.