Design Life-Cycle

assess.design.(don't)consume

Zoey Ward

Christina Cogdell

Des 040A

Design Life Cycle Poster

6 December 2018

Raw Materials: The Life Cycle of a Hockey Rink

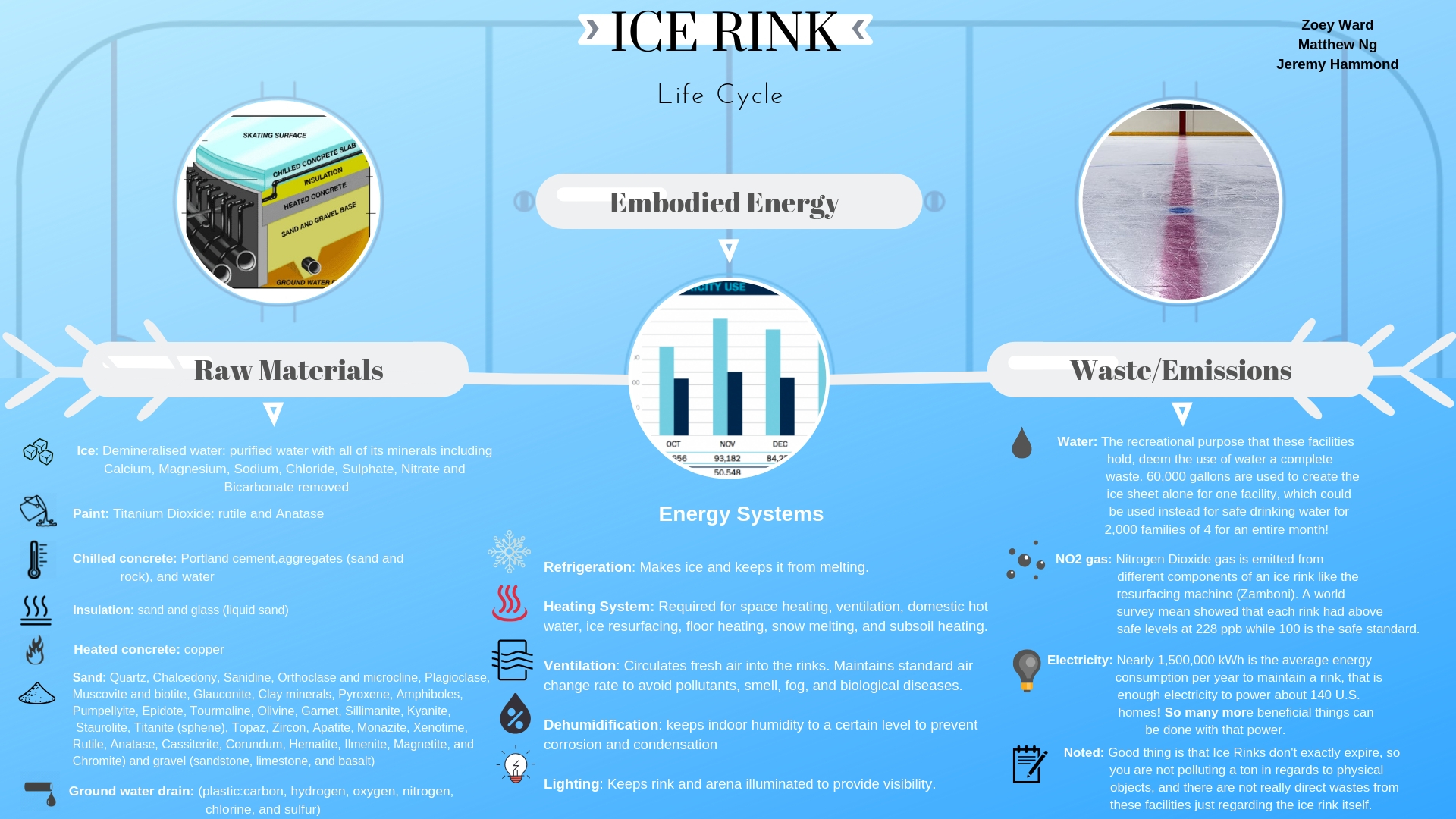

Many people, worldwide, enjoy the activities that happen on hockey rinks but rarely do they think about the activity that happened under their feet in order for the rink to come into existence.There is a lot of science behind the raw materials of a hockey rink, from the actual materials used, to the breakdown of what the materials are made of. Many people do not think of the changes that a hockey rink goes through before it becomes the actual rink; this includes the fact that it first starts off as a basketball court. The main purpose of researching raw materials of a hockey rink is to break down the materials from from the beginning of its life cycle to the end of its waste cycle (as it pertains to added materials in the cycle) and to figure out if we are going through the right procedures to make these items used to make the rink, as well as recycle them.

The first two categories in the life cycle of the raw materials of a hockey rink are the acquisition and the manufacturing. The materials that go into building a hockey rink start with the basketball court. Although the rink is the most important part, it is still good to provide background as it pertains to the transformation of the court. Almost all professional hockey teams share their arenas with basketball teams. Usually the hockey rink is built underneath the basketball court and when it’s time to play hockey, the layers of the basketball court are stripped away. The layers of a basketball court from top to bottom consist of maple flooring (maple trees), plywood (hardwoods/softwoods: ash, maple, mahogany, oak, and teak, douglas fir, pine, cedar, spruce, and redwood), pine board (timber: cellulose fibers), and a foam layer (polyurethane/natural latex:sap of the rubber tree/Hevea Brasiliensis). When it’s time to play hockey, the staff in the arena remove the maple flooring square by square, then the plywood, and then comes the layer of foam. In order to set up the hockey rink, after all the materials from the basketball court are removed, the water for the hockey rink must be restored; The ice consists of 5 layers. A very important element of the ice is the paint (Titanium Dioxide: rutile and anatase) because in order to make the ice super white, it must be mixed in with the water. After the the five layers of ice (Demineralised water: purified water with all of its minerals, Calcium, Magnesium, Sodium, Chloride, Sulphate, Nitrate and Bicarbonate, removed), the next layers from top to bottom consist of chilled concrete (portland cement,aggregates (sand and rock), and water), insulation (sand and glass (liquid sand)), heated concrete, sand (Quartz, Chalcedony, Sanidine, Orthoclase and microcline, Plagioclase, Muscovite and biotite, Glauconite, Clay minerals, Pyroxene, Amphiboles, Pumpellyite, Epidote, Tourmaline, Olivine, Garnet, Sillimanite, Kyanite, Staurolite, Titanite (sphene), Topaz, Zircon, Apatite, Monazite, Xenotime, Rutile, Anatase, Cassiterite, Corundum, Hematite, Ilmenite, Magnetite, and Chromite) and gravel (sandstone, limestone, and basalt), and a ground water drain (plastic:carbon, hydrogen, oxygen, nitrogen, chlorine, and sulfur). There are not many new raw materials added during the manufacturing process. The only things that could be considered added materials are the components that are used to cool the chilled concrete and heat the heated concrete. When it comes to chilled concrete, the only feature that is added is nitrogen; It is added into the concrete mix before laying it down as a layer. As far as the heated concrete, pipes that circulate hot water are added. Although Acquisition and manufacturing are very important to the raw material life cycle of a hockey rink, the following categories are just as significant.

The next two categories in the life cycle hockey rink pertaining to raw materials are transportation and maintenance. In transportation there are two main vehicles, concrete trucks and dump trucks. Concrete trucks use compressed natural gas which “increases the environmental performance of the construction process”. Dump trucks, which are used for sand and gravel, run on diesel fuel. The maintenance of a hockey rink consists of taking care of the ice. In order to take care of the ice a Zamboni machine is needed. A Zamboni is a machine that smooths over the ice. An article titled “How Ice Rinks Work” by Melissa Russell-Ausley breaks down the steps that the Zamboni takes by stating, “Most Zamboni machines have a thick blade. The blade scrapes a 1/16-inch to 1/8-inch layer of ice off the ice surface. The rougher the ice surface, the deeper the blade cuts. Just above the blade is a horizontal, rotating screw, or auger. The auger gathers the shaved ice, or snow, and rotates it up to a vertical auger, where a spinning blade picks up the moving snow and throws it into the bucket. Under the bucket, there are two tanks of water, one for "washing" the ice as it's shaved and one for making ice. As the resurfacing machine moves over the ice, the blade shaves layers of the ice off. Water from the wash-water tank is pumped over to a cleaner that blasts the water into the deep cuts in the ice and forces out dirt and debris. The excess water left on the ice is squeegeed off with a rubber blade (known as a towel) at the back end of the machine and vacuumed up. The hot water loosens the crystal structure of the old ice underneath, so the new ice will form a solid bond with the old ice, instead of a separate layer that chips off easily. The last step is to resurface the ice. Warm water from the second water tank is pumped over to the squeegee blade and spread evenly over the ice. This softens and fills in the deep cuts in the ice and helps to even out its surface”. All of the maintenance that happens because of the Zamboni would not be able to happen without the fuel that it runs on, and that fuel is propane; If it does not run on propane then it is powered by electricity.What is interesting about this process is that depending on the Zamboni model, it can hold up to 211 to 264 gallons of water. Being that the acquisition, manufacturing, recycling, and waste have been discussed, what happens in the coming categories may be the most crucial aspect in the life cycle of a hockey rink.

The last two categories as they pertain to the hockey rink’s life cycle are recycling and waste. The material that is recycled throughout this whole process is water. Many arenas have maintenance machines (Zambonis) that repurpose the water that has already been laid down as much as possible to help the planet by conserving water (Zambonis have a mechanism that allows them to clean the water after pulling it up from the surface). The article, First Recycled Water Hockey Arena In U.S. Opens, by Sara Jerome, states, “Using this type of water — recycled, reclaimed water — is a great bonus that we had in this area,” he said, per the report. “Some other places don’t have it as readily available as we do. And it’s great that we’re able to take advantage of it.” Not only is this method sustainable, but it also saves money. Recycled water can save up to 500,000- to 600,000-gallons of water per season. As far as waste, there isn’t much as long as the water is being recycled.

The major question throughout the whole research process of the life cycle of a hockey rink is what can be done to maintain environmental sustainability when it comes to building hockey rinks? The answer to this question posed is to continue to reuse all of the materials used to layer the hockey rink as much as possible. In the case of the hockey rink, the materials are very durable, and if anything but the water needed to be recycled or taken out, then the whole structure would have to be taken apart(that is why dependable materials were chosen so this does not happen often).The fewer materials that have to constantly be replaced, the better. So far the recycling of water is proving to be the most effective and most sustainable because it saves hundreds of thousand of gallons of water annually. The design of a hockey rink is super effective and sustainable as well because the materials that are used for it are impervious and long lasting.

Work Cited

“Aqua (Distilled Water) - Skin Care Ingredients Dictionary | Hylunia.”

“What Is Demineralised Water? Deionised or Distilled Water?” Vintage Road Haulage

Natural Organic Make-up - Titanium Dioxide: Toxic or Safe?

Concrete Network. “Concrete and Cement Information.” The Concrete Network,

Concrete Network, 15 Aug. 2018.

Concrete Network. “Radiant Floor Heating - How to Heat Concrete Floors.” The Concrete Network, Concrete Network, 15 Jan. 2015.

“Surprising Insulation: What It's Actually Made Of.” Clean Crawls: Residential Home Attic & Crawl Space Insulation Contractor, 8 Aug. 2017.

“What Is Glass? | How Is Glass Made?” Explain That Stuff, 29 June 2018.

“Sand Minerals.” Sandatlas

“How Is Gravel Made?” Midwest Industrial Supply, 10 Apr. 2018.

International Rice Commission Newsletter Vol. 48, FAO of the UN.

“Plastics.” The Basics: Polymer Definition and Properties.

“How You Outfit an Aircraft Carrier for a Basketball Game.” Charles Apple,

Vermont Woods Studios. “Maple Wood.” Vermont Woods Studios: Fine Furniture and Home Decor.

“Plywood.” How Products Are Made.

“Pine.” Wikipedia, Wikimedia Foundation, 25 Nov. 2018

Harris, William. “How Timber Works.” HowStuffWorks Science, HowStuffWorks, 8 Mar. 2018.

“How Are Latex Mattresses Made?” European Bedding.

“How Does a Basketball Court Change Into an Ice Hockey Rink?” Wonderopolis.

Matthew Ng

Professor Cogdell

SAS 043

6 December 2018

Embodied Energy in Ice Rinks

In today’s American society, a popular form of entertainment is professional sports. With over thirty five major cities participating in professional sports, teams need a facility to play their games. For NFL, each team gets their own stadium so there are thirty football stadiums scattered across the nation. The MLB has 30 teams so there are 30 baseball stadiums across the nation. But for the two indoor sports which are NBA (basketball) and NHL (hockey), these sports are played in their own complexes called arenas. Growing up in Los Angeles where the major sports arena of the city, Staples Center, shares the complex with two basketball teams, the Los Angeles Lakers and Los Angeles Clippers, with a hockey team, the Los Angeles Kings, I was always amazed on how there can be a hockey game at 12:30 PM on a Sunday afternoon and then a basketball game at 6:30 PM in the evening. It is intriguing how the staff is able to freeze over a small pond and then melt it within a span of two hours to prepare for a basketball game. With at least forty one hockey games played per season in each hockey arena, a lot of energy must be consumed at each of these hockey rinks to maintain the ideal characteristics for a fair hockey match. This paper will educate the reader on the procedure of installing an ice rink, the systems that are involved in maintaining good ice hockey conditions, the process of uninstalling an ice rink, and the embodied energy that goes into executing each of these actions all while analyzing the life cycle of a typical ice rink.

To fully understand the article, it is important to understand the procedure to build an ice rink. The process begins in the refrigeration room of the arena. A powerful compressor in the room pumps coolant fluid called brinewater which is usually water infused with methanol or saline [xii]. The brinewater is pumped through pipes that run through the concrete floor which then cools the concrete to a nice 7.7 to 9 degrees Centigrade [xii], which is the temperature so water can freeze when it touches the concrete. If the concrete was any colder, the concrete would cause the soil to freeze which would not be environmentally friendly [iii]. After cooling the concrete, water is then sprayed on top of the concrete in even two millimeter thick layers for around two to three layers. Due to the cold concrete, the water freezes in seconds. Once the initial layers have froze over, another three layers are added on, but instead of water, white water-based paint is sprayed on. The paint mix is not sprayed first because it would dry on the concrete which would damage the floor. Once the paint freezes, the designs of the hockey rink are painted on, and then a final few layers of water are sprayed on to protect the paint designs. The final thickness of the hockey rink is four centimeters. The total water consumption to make the hockey rink is a grand total of 50,000 liters of water which is equivalent to 300 bathtubs. This process is only done during the beginning of the season before the first game. The frozen pond is left in the arena throughout the season and if the arena is shared with an NBA team, the rink gets covered and then woodboards are placed to make a basketball court, or if there is a concert or another event, the arena staff just build over the ice rink [xii].

Once the ice rink is installed, the arena is required to maintain certain standards to keep the ice smooth and clean both when in use and not in use. This is done through the five main ice rink energy systems which are: refrigeration, heating, dehumidification, ventilation, and lighting [ii].

The refrigeration system is the most important energy system because it makes the ice and keeps the ice from melting. The refrigeration system is often compared to the human heart as it is the guard to keep the ice in its ideal form [ii]. There are three different kinds of refrigeration systems, direct, indirect, and partly indirect. The direct system directly pumps the refrigerant directly below the ice pads and the refrigeration pipes serve as a large evaporator. However, this system was proven to not be environmentally friendly due to its high refrigerant charge which has been tested to contribute to global warming [viii]. The next system is the indirect system which uses the primary refrigerant, (often ammonia [vii]), to cool a secondary refrigerant (brine) and distributes it below the ice pad and then back to the evaporator. This system is not as environmentally unfriendly because it only uses the more hazardous primary refrigerant to cool brine which then cools the ice. This calls for less primary refrigerant charge. Lastly, the partly indirect system is a hybrid of the two. Either the evaporator or condenser is connected to the source by secondary fluid for heat exchange and cools by a direct system. The most common system is the indirect system because it is the most environmentally friendly. The refrigeration energy system uses forty-three percent of the total energy consumed by an ice rink. To break it down further, the compressors use eighty percent of the refrigeration energy, ten percent from he brine pumps, and 5 percent a piece from coolant pumps and dry cooler fans. The refrigeration system uses the largest chunk of energy compared to the other systems, so it would be ideal to go the most efficient method to reduce over consumption of energy. After all, in the entire world, refrigeration systems that are not only found in hockey rinks but also your household refrigerators, cold storages, and air conditioners, use fifteen to twenty percent of the world’s electricity [ii], and hockey rinks are one of the biggest contributors due to the large body of ice. Although at this point in time, the ice rinks’ refrigeration systems are the most efficient they can be, there is still room for improvement. As technology advances, people should use this technology to upgrade these refrigeration systems to be more and more efficient. This way, we can leave a smaller carbon footprint while enjoying the entertainment and pleasure of ice hockey.

The next system is the heating system. The heating system is crucial because it is the opposing force that keeps the room temperature at a certain level, maintains domestic hot water temperatures, keeps the sitting area at a comfortable temperature, heats the subsoil, and ice resurfacing water. The heating system is like homeostasis whereas it keeps the internal functions in a balance. The heating system is usually powered by fossil fuels or electricity. An alternative and more environmentally friendly method of power is through the heat rejections of condenser and desuperheater [viii], because it would not require a third party energy source and instead recycle any excess energy from the refrigeration systems. The heat pumped out by the refrigeration system can cover a great amount of the heating demand, sometimes even fulfill 100 percent of the need [ix]. The amount of energy the heating system varies depending on the selected heating system layout. An inefficient heating system would use eleven percent of its energy for heating and forty-two percent for refrigeration, while on the other hand, efficient rinks would use forty-two percent for heating and only twenty-three percent for refrigeration [x]. Essentially, the characteristic that is used to determine an efficient ice rink to an efficient ice rink is the amount of energy the heating uses versus refrigeration. If more heating is used, then the more efficient the ice rink’s energy systems are. This is due to the fact that more efficient ice rink energy systems would use excess heat to power their heating systems while less efficient ice rinks would use more energy to power refrigeration. This is known as heat recovery which is a form of energy saving measures [x].

The next energy system is the dehumidification system. The dehumidification system serves as the white blood cells of ice rinks as they keep the humidity of the air at a certain level to prevent any moisture in the air which can corrode metal, rot any wood structures, and cause fog and condensation which shows the ice is gradually melting which does not meet the standards for an ideal hockey game. It protects the ice from any elements that can change the shape of the rink. There are two methods of dehumidifying the air. The first method is to cool the air below dew point. Using the cold brine in the refrigeration system, the cooling coils within the system cause the water content in the air passing through the system to condensate. This method is usually integrated into the ventilation or refrigeration systems [x]. The other method involves a water absorbent material, like silica gel, on a rotating wheel that is integrated into the ventilation system. This causes the water content within the air to absorb into the gel, and then the drier air exits the system. The dehumidification system uses only six percent of the total energy consumed [ii] of an ice rink because it is often integrated to other systems. The first three systems all require a distribution system as they need to be used in certain areas of the rink to maximize efficiency and to prevent any over use [vi].

The fourth energy system is the ventilation system. The ventilation system is like a brita filter in a sense that it filters away pollutants, odors, fog, and germs all while providing fresh air to be circulated in the arena, similar to how a brita filter gives you clean drinking water while filtering out any unwanted chemicals. The ventilation system that is used in the hockey rink versus in public areas such as bathrooms, locker rooms, or corridors are different to maintain hockey the best ice quality for the rink [iv]. For designing a ventilation system, other variables such as heat emission and ice resurfacing mechanism. The ventilation system is programmed to power fans at different degrees to maintain the right air quality. The ventilation system only uses nine percent of the total energy.

The last energy system that is used in an ice rink is the lighting system. This system does what its name says, it lights up the rink so it is visible for everyone to see. This way, all spectators, players, and cameras are able to view the rink at a comfortable level. To light a hockey rink comfortably without any glare, it takes around 800 to 1500 lumens. There are six common light bulbs that are used in hockey rinks. It is usually a combination of the six. Fluorescent lights are good energy and efficiency. Halide lights are good for lighting but have bad control so they are used less. Sodium pressure lights are used for emergency lights because they have poor color rendering. Induction lamps have long lives but are expensive. The last kind of lights are halogen lights which are the most ideal due to their versatility in cost, color rendering, dimming abilities, and efficiency. All six of these lights are commonly used due to the low heat emissions that may change the overall ambient temperature that may cause the other systems to work harder [ix]. Overall, the lights use around ten percent of the total energy consumption of a hockey rink. This variable can easily be controlled but are optimized to fit efficiency, visibility, and heat emission.

Once the season ends, the arena crew come together to take apart the ice rink. They start by shutting off the refrigeration system and use the heating system to soften the ice. The crew uses picks to break the ice into a slush and it is then drained. By the end of the season, an average hockey rink has consumed 1.5 million kWh of energy, which can power up to 140 US homes. Multiply this by twenty-four different arenas across continental United States, then that is 36 million kWh of energy. The NHL hockey rink is a large consumer of energy due to the five refrigeration systems that work together to keep the rink at an ideal quality to play at least forty-two hockey games a year. Although it may seem to be a lot of energy without even accounting for concession stand energy, powering the jumbotron, speakers, or even broadcasting games, people are working to find more efficient ways to bring the leisure of professional hockey to all of its fans.

Bibliography

[i] Blades, Russell W. “US5536411A - Water and Energy Recovery Process for an Ice Rink.” Google Patents, Google, 1994, patents.google.com/patent/US5536411A/en.

[ii] “Energy and Exergy Analyses of Ice Rink Buildings at Varying Reference Temperatures.” Energy and Buildings, Elsevier, 20 Mar. 2010, www.sciencedirect.com/science/article/pii/S0378778810000885.

[iii] “Energy Efficiency In the Ice Rink.” Arch News, 2000, https://www.achrnews.com/articles/84022-energy-efficiency-in-the-ice-rink

[iv] “Energy Usage Ice Arenas.” Real Ice, www.realice.ca/energy-usage-ice-arenas/.

[v] “Experimental Validation of a Computational Fluid Dynamics Model for IAQ Applications in Ice Rink Arenas .” Purdue Engineering, engineering.purdue.edu/~yanchen/paper/2001-5.pdf.

[vi] Kovach Bruce F “US4467619A - Method of Using Frozen Salt Water to Maintain a Low Cost,

[vii] Low Energy Consuming Indoor or Outdoor Ice Rink.” Google Patents, Google,

patents.google.com/patent/US4467619A/en.

[viii] Mazyar, Karampour. “MEASUREMENT AND MODELLING OF ICE RINK HEAT LOADS.” DIVA, 17 Jan. 2012, www.diva-portal.org/smash/record.jsf?pid=diva2%3A478941&dswid=-4764.

[ix] Nichols, Laurier. ASHRAE Journal, 2009, edge.rit.edu/content/R12420/public/Ice%20Arena%20Research.pdf.

[x] “Managing Energy Costs in Ice Rinks.” E Source Customer , 2016, www.xcelenergy.com/staticfiles/xe/PDF/Marketing/MN-Bus-Custom-Efficiency-Ice-Rink-Savings-Suggestions.pdf.

[xi] Russell-Ausley, Melissa. “How Ice Rinks Work.” HowStuffWorks, HowStuffWorks, 1 Apr. 2000, entertainment.howstuffworks.com/ice-rink6.htm.

[xii] “Science of Hockey.” Exploratorium: the Museum of Science, Art and Human Perception, 2005, www.exploratorium.edu/hockey/ice3.html.

[xiii] Yann, Kolasniewski. “Evaluation and Modeling of Ice Rink Usage.” INSA, 2017, eprints2.insa-strasbourg.fr/3110/1/Yann_Kolasniewski_Thesis_-_FV_without_Appendix_for_PDF.pdf .

Jeremy Hammond

Cogdell

DES 40A

Ice Rink Waste/Emissions

It's coming along Christmas time here in 2018 and activities like Ice Skating and snowball fighting are being enjoyed for their relative festiveness. Wouldn't it be wonderful if you could partake in these activities all throughout the year? Well lucky for us, facilities like Ice Rinks are kept cool all year round! Now, introductory talk aside, this paper is meant to do a few things, and that is explain the Life Cycle of an Ice Rink and where improvements need to be made. Ice rinks in the U.S. have been under some recent heat in the past decade for the extreme amount of energy usage, and harmful/wasteful emissions they go through and give off. Organizations and companies like the NHL and various Ice Rink manufactures have gone to greater measures to preserve the activities that need these facilities to operate on by starting in the direction of a “greener” future. However, these measures being taken arent happening nearly fast enough. It is imperative that Ice Rinks, by means of legislation or personal action need to be made substantially greener thereby reducing its wastes/emissions problem, a problem that has gone as far as creating an unsafe environment for athletes that use these facilities daily. To be specific, water consumption, carbon monoxide emissions, and energy use need to be substantially cut down in order to make ice rinks a viable recreational facility.

First off, what exactly is an Ice Rink and what are they used for? Ice Rinks are large Flat slates of ice that are rectangular with rounded corners, roughly about 85ft. by 200ft. Typically they are walled off and indoors. The Purpose of the large flat of ice is so that you can glide upon the surface using ice skates. These “fields” of sorts are used for various sports and recreational activities such as ice hockey, figure skating, speed skating, and various others that even work their way into the stage of the Winter Olympic Games.

It only makes sense to talk about how these facilities are built next. The slick ice surface that allows for skating is maintained by pumping a specific type of cold liquid through pipes in concrete that chills a thin layer of water on top. That is an extremely condensed form of the process, however since we want to go into more detail, let's first take a look at how we acquire the materials that allow for that process and see if there are wastes that aren't possibly worth the task. The main components that go into an Ice Rink are concrete, steel, sand, brine water, water, and paint. According to the United States Department of Labor, The only really harmful process of acquiring these materials would be that of the production of concrete. The real fact that over 10% of people that make up the concrete manufacturing labor force experience a job related injury each year is frightening. That's pretty astonishing to say the least, and even more surprising is that 42 people died in just one year of production! The major health risks that go along side of this are incredible as well from chemical burns, Overexertion, and respiratory tract irritation. Its safe to say that there are some health concerns and problems that should be acted upon to create a safer work environment for these people. However, we must also understand at the sametime that these conditions will improve over time and that this isn't directly caused by the demand for concrete so to speak. You may be also concerned about the process involved with the mining of ores and process of making steel because that must be horrible for the environment right? Quite surprisingly, the process of mining the ores necessary is aimed at quite high standards and practices that minimize any environmental damage. It would come down to the specific company if they got lazy and allowed for something like acid rock drainage to impact the environment. But for the most part, air contamination, physical disturbances, and public safety are worries of the past as our technology becomes cleaner and cleaner. All goes the same for the process for creating steel itself with those ores. The steel industry focuses on sustainable development and recycling all of its outputs or emissions to the best of their ability. The steel in our case goes into the production of steel pipes that are laid both for heating and cooling purposes. To squeeze together all of these resources to produce an Ice Rink is best described in different layers. The main layers from bottom to top are; a thick sand layer, with heating steel pipes running through it, a thick layer of concrete with cooling steel pipes running through it with brine water in those pipes, then several layers of Ice and paint that form the few inches thick pane of ice stretching across the whole rink. The image on my teams poster shows a semi accurate proportion from layer to layer which demonstrates better than words on the cross section of the facility.

Next, it is extremely important to bring up the issue at this point. It isn't inherently noticeable what exactly the waste/emissions issue would be compared to most products. Well if it doesn't really have much to do with the acquisition of materials, or even direct wastes back into the environment by use of the product, then what is it? Well through my findings, I have found some easily noticeable, and not so easily noticeable waste issues that need to be corrected to sanction the use and production of these facilities. As mentioned, some of these aren't inherently emissions or wastes, however they belong here for how much of a waste some of these should be. It was truly difficult finding vary many waste and emissions from Ice Rinks but I was able to rack together what my findings allowed for. To start, the first truly astonishing feat of absolute wastefulness would be the injustice of how much water is used to comprise just one Ice Rink. A hafty 60,000 gallons of water is used just for the initial Ice layers! That doesn't even calculate the resurfacing water used throughout its lifetime to maintain that pristine sheet of ice.. The major theme when talking about these waste’s I would like people to understand is that considering an Ice Rink is serves purely recreational purposes, any limited resource it uses to create and maintain is sort of silly really. The fact that 60,000 gallons of water that could be used as drinking water for 2,000 families of 4 for an entire month shows you just how much water that is. Also considering that massive amounts of water are used for applications such as Ice Rinks when there are clean water problems around the world is almost insulting really. The practical use of fresh water like that is so much more useful than for recreational purposes. The next rather important emission problem that Ice Rinks have is that of a health concern. This is the the problem of Nitrogen Dioxide gas being pass safe levels inside of Ice Rink facilities. This has lead to players becoming extremely sick just from using the facility itself. The culprit here is actually the fuel fired ice resurfacers used, also known as “Zamboni’s”. The fact that there are extreme health concerns and risks because of an emission from a piece of equipment used that these facilities are so reluctant to change is irresponsible and just a horrible practice. Part of the reason for the unwillingness to change systems is partly due to the fact that a Zamboni can run you about 100,000 dollars. The third waste I would like to talk about is the extremely poor energy usage that these facilities have. It's quite astonishing really at about a 1,500,000 kWh average yearly use throughout the country for each rink. That is enough electricity to power 140 average U.S. homes for the same amount of time as one Ice Rink. Of course companies have “attempted” to cut back and become greener, like the NHL for example. The NHL is the National Hockey League and they have a so called Green Initiative to limit the amount of electricity used and CO2 emissions. However we must take into account that an organization as big as the NHL has the funds to do so, and the reality is that only 32 Arena Ice Rinks are managed by the NHL. Which is insignificant to the total 2,035 Ice Hockey rinks in the US currently. So smaller locally funded rinks can't exactly afford these greener alternatives as quickly as the NHL for example.

After looking at the wastes/emissions I have gathered through my findings, it's important to note before any conclusions that Ice Rinks don't exactly expire as a normal product would. Even when the Ice Rink isn't in use by teams or what not it is used for recreational purposes and never sees an “unused” period almost ever. It's also important to note that there aren't any direct wastes from the “product” itself that is damaging the environment. It is also important to note that this Product can be compared to a closed economy. It can be compared to this in the fact that since these materials that go into the production of Ice Rinks can't ever be recycled or retrieved because of its life span, you practically lose those forever and don't rotate back into the economy of usable materials.

In conclusion, after taking into consideration the ways and amounts that the resources are used, it seems rather clear that an action needs to be taken. An action either legislatively or socially needs to be made in order to significantly decrease the uses of these materials and emissions. I would even go as far as saying by half, in order to make the recreational facility of an Ice Rink a viable product to use with what limited resources we have on our earth.

Bibliography

A-Gas. “Find Products | Find A-Gas Services.” A-Gas Group,

www.agas.com/products-services/.

Benson, Corey. Proposed Renovations for Lansing Chapman Rink Energy Efficiency

Improvements . 2011, sustainability.williams.edu/files/2010/09/corey_rink.pdf.

Chillers, Berg. “Recreational Chiller Ice Rink Cooling Systems | Berg.” Berg Chilling Systems

Inc., berg-group.com/products/ice-rinks/ice-rink-chiller-systems/.

“Comparative Study of Refrigerations Systems for Ice Rinks - HTML Version.” Natural

Resources Canada, 21 Jan. 2016, www.nrcan.gc.ca/energy/efficiency/buildings/research/publications/16002#_Toc364163197.

Everything Ice.“Everything Ice - Ice Rink Design, Construction and Installation.”

Everything-Ice, www.everything-ice.com/.

“How Can Metal Mining Impact the Environment?” American Geosciences Institute, 30 Oct.

2017,

www.americangeosciences.org/critical-issues/faq/how-can-metal-mining-impact-environ

ment.

National Research Council (US) Subcommittee on Rocket-Emission Toxicants. “ACUTE

TOXICITY OF NITROGEN DIOXIDE.” Current Neurology and Neuroscience Reports., U.S. National Library of Medicine, 1 Jan. 1998, www.ncbi.nlm.nih.gov/books/NBK230446/.

“NHL.com.” NHL Green - Greener Rinks, 2017,

www. greenerrinks.nhl.com/desktop/index.html?page=2.

Pelham, T, et al. Exposure to Carbon Monoxide and Nitrogen Dioxide in Enclosed Ice Arenas.

Group.bmj.com, www.ncel.net/articles/Exposure%20to%20CO%20and%20NO2%20in%20enclosed%20ice%20arenas_3.pdf.

Rajecki, Ron. Ice Rinks Consider Future Options Beyond R-22. BMP Media

www.achrnews.com/articles/134405-ice-rinks-consider-future-options-beyond-r-22

Tutumlu, Hakan. “Investigating Thermal Performance of an Ice Rink Cooling System with an

Underground Thermal Storage Tank.” Sage Journals, 2017, journals.sagepub.com/doi/full/10.1177/0144598717723644.

“UNITED STATES DEPARTMENT OF LABOR.” Occupational Safety and Health

Administration, www.osha.gov/Publications/concrete_manufacturing.html.

Yoon, Dong-Wan. SURVEILLANCE OF INDOOR AIR QUALITY IN ICE SKATING RINKS .

1996, ac.els-cdn.com/0160412096000165/1-s2.0-0160412096000165-main.pdf?_tid=b96c6798-1b11-47ae-92ea-e118c0b8a7c4&acdnat=1540935311_31246fdadf147ebb50b9526a827c60db.