Design Life-Cycle

assess.design.(don't)consume

Raw Materials Essay

Bethany Tinklenberg

Professor Cogdell

DES 40A, Fall 2016

December 1, 2016

Bureo Board Raw Materials

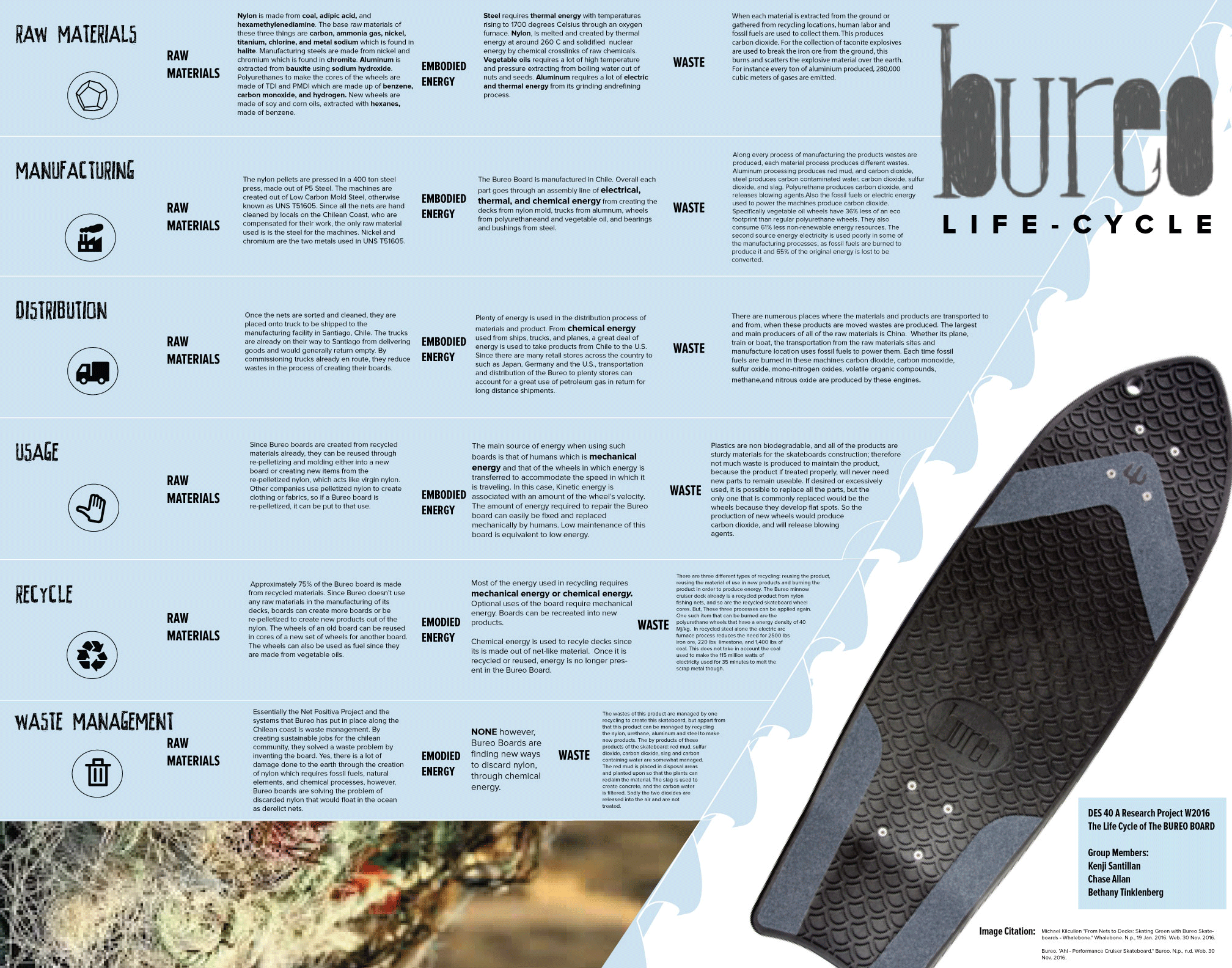

Approximately 88% of the ocean is polluted with plastic debris.[1] 10% of that pollution are fish nets that have been torn, broken, and abandoned at sea.[2] The official name for fish net waste is derelict fishing nets, and as far as polluted ocean plastic goes, these nets are the most dangerous. They take decades to begin to decompose and they kill marine life. Since the webbing is practically invisible underwater, dolphins, seals, and other marine mammals can get caught in the webbing and drown. Marine life aren’t the only organisms impacted since divers and swimmers can also get tangled in these dangerous derelict nets.[3]

With Chile being the sixth largest fishing industry in the world, fisherman off of the Chilean Coast use multiple nets within a single trip, often having to throw some away due to holes, snags, or general wear from use. With no system to collect these retired nets, fishermen were either forced to keep nets at home, which caused health issues, or burn the nets on the beach, which created toxic smoke. Neither was the ideal outcome, so many would be tossed to sea.[4] The startup company Bureo created a new system for net collection and recycling, accurately known as Net Positiva. Net Positiva encourages fishermen to bring their net wastes to shore, aiding to save the seas and reduce pollution, in exchange for compensation.[5] Through this initiative, Bureo aims to give back to the community by creating jobs, recycling local waste, and engaging the Chilean coastal community through their recycled fishnet skateboards. By examining the lifecycle of these boards, and the nylon, oils, metals and plastics used to create their parts, we will determine if Bureo Boards are as sustainable as they appear to be.

Bureo’s Net Positiva program allowed the company to collect materials for their boards as well as clear the oceans of derelict nets. They encourage local fishermen to drop their used nets into bins, and locals are then paid to clean the nets and sort them. Each Bureo board skate deck is made of 30 square feet of fishnet. Fishnets are made from a synthetic material, called nylon. Nylon is made from three raw materials: coal, adipic acid, and hexamethylenediamine.[6] Working from complex chemicals to basic raw materials, the following explains the creation of nylon. Coal is the carbon part of nylon. Adipic acid and hexamethylenediamine are created in labs and can be further broken down into their raw materials, as follows. Adipic acid is made by the oxidation of cyclohexenes in air by cobalt catalysts.[7] Hexamethylenediamine (C6H16N2) is made by reducing adiponitrile with sodium and alcohol.[8] 88% of produced hexamethylenediamine and 100% of produced adiponitrile is solely used for the creation of nylon. Adiponitrile is made through the chlorination of butadiene and dichloroethylene, reacted with 35% sodium cyanide.[9] Sodium cyanide is created by heating sodium amide with carbon, and sodium amide is made with dry ammonia gas passed over metal sodium.[10] Butadiene is created by mixing titanium tetrachloride and cobalt salt.[11] Titanium tetrachloride is made when titanium is heated with carbon in a current of chlorine.[12] Cobalt salt is extracted from nickel.[13] The result are the base raw materials of nylon: carbon, ammonia gas, nickel, and metal sodium.

Since Bureo’s nets are all donated, recycled, and vary greatly, we cannot accurately know who manufactures them. The only thing that all the nets have in common is that they are made out of nylon, specifically nylon 6.6.[14] The base raw materials as explained in the previous paragraph are carbon, ammonia gas, nickel, and metal sodium, which is found in halite. Since we don’t know which specific companies manufacture these nets, we have to assume that their raw materials are extracted from the world’s more common sources. Halite is extracted in the United States and Canada as well as Pakistan.[15] Ammonia can be found from the waste of living organisms.[16] Coal is mostly mined in the United States, China, and Australia.[17] Nickel is extracted using the Mond Process, or extractive metallurgy, and mined in Russia, Canada, Columbia, Indonesia, Australia, China, and South Africa. [18]

Once the collected nets are sorted and cleaned, they are placed onto trucks to be shipped to the manufacturing facility in Santiago, Chile. The trucks are already on their way to Santiago from delivering goods and would generally return empty. By commissioning trucks already en route Bureo reduces wastes, usage of fossil fuels, and raw materials in the process of creating their boards. When the nets arrive, they are shredded, melted, and molded into pellets of nylon. The pellets are pressed in a 400 ton steel press, made out of P5 Steel. The machines used are created out of Low Carbon Mold Steel, otherwise known as UNS T51605.[19] Since all the nets are hand cleaned by locals on the Chilean Coast, who are compensated for their work, the only raw material used is the steel for the machines. As of October 2016, Asia is the largest producer of crude steel at 94.3 million tons.[20] Nickel, mentioned above, and chromium are two metals used in UNS T51605. Chromium is not naturally occurring so it has to be oxidized and separated from the mineral chromite, which is most commonly mined in South Africa. Chromium is used in the making of steel, generally stainless steel.[21] Once the pellets are pressed by machines into board decks, they are cooled and checked for flaws before being shipped to America for assembly. I know that Bureo ships its decks from Chile to America but was not able to find exactly how they ship the boards.

Within the skateboard, there are different components: the deck, which Bureo creates themselves, as well as trucks, wheels, and cores which they purchase from other companies. Bureo gets their trucks, a t-shaped part that holds the wheels, from Paris Truck Co. The trucks are made of 356.2 virgin aluminum, with a gravity molded baseplate and hanger.[22] Bureo’s least sustainable part would be these trucks, since they use virgin aluminum rather than a recycled material like the rest of their board. Since aluminum does not occur naturally, it has to be isolated from other materials. This process takes a lot of electricity, so aluminum smelters are often located near power plants. The process of extracting aluminum is threefold. First, bauxite must be extracted from open air mines. 4-5 tons of bauxite produces 1 ton of pure aluminum so it is heavily mined. 73% of bauxite is mined from Guinea, Brazil, Jamaica, Australia, and India. Guinea is most popular for its bauxite because it is the highest quality, meaning that at least 50% of the stone is aluminum oxide. Once mined, the bauxite is processed using the Bayer process--bauxite is heated with caustic soda (NaOH) to separate the aluminum oxide from the rock. The result is aluminum oxide and ballast, otherwise known as red mud. Although red mud can be seen as a waste product, it is also recyclable and can be treated as a raw material for the creation of aluminum scandium alloys, concrete, and cast iron production. The land that is filled with the red mud can also be reused once treated. Once the aluminum oxide (Al2O3) is separated from the bauxite, is is combined with cryolite, a substance that is synthetically made of hydrofluoric acid, aluminum hydroxide, and soda. A current of electricity is run through a chamber containing the aluminum oxide and cryolite, and pure aluminum is made while CO2 is released. For every ton of aluminum, 280,000 cubic meters of gas is released, thus making the trucks the least sustainable part of the Bureo Boards.[23]

Bureo outsources the creation of the skateboard’s wheels to a company called Satori Movement. Satori movement, like Bureo, prides itself on creating its products with sustainability in mind. When creating the wheels, Satori Movement takes old wheels and shaves them down to recycle the cores. Once cut to the core, they mold a new wheel around the old core. Since the cores are made of old wheels, we cannot source exactly where the wheels originated. However, skateboard wheels are generally made of polyurethane, which we can trace to its raw materials. Polyurethane is a polymer which means that it is made up of monomers that link into chains through a process called condensation.[24] Polyurethane is completely synthetic and made up of three parts: diisocyanates, polyols, and stabilizers. The diisocyanates that go into polyurethane are toluene diisocyanate (TDI) and polymeric isocyanate (PMDI). TDI is made up of a mixture of nitrogen, hydrogen, and toluene. Toluene consists of benzene and methanol, the latter, comprised of carbon monoxide and hydrogen. PDMI is made generally with aniline formaldehyde polyamines (C7H9NO). The second part of polyurethanes are polyols, made of polyethylene glycol and hydroxy polyethers. The latter is comprised of ethylene, propylene, glycerol, sucrose, and ethylene oxides. Lastly, a stabilizer is added to the polyurethane mixture, in this case, hydroxybenzotriazole (C6H5N3O).[25] These are what the old wheels collected for cores are generally made of.

Satori Movement strives to create more ethically sourced wheels made of vegetable oils, specifically soy and corn oil.[26] Taking the old core that would traditionally be placed in a landfill, they shave down the uneven parts into a small core. Then, they form a new wheel around the recycled core. Corn is harvested and collected, then expeller-pressed. It processed using hexane and isohexane; the solvents are then evaporated from the oil and reused to reduce wastes. The oil is then alkali-treated which removes impurities, phosphatides, and fatty acids, as well as bleaches the oil. When manufacturing soy oils, they are treated similarly, however, soybeans are first dried, then flaked, then pressed. Hexanes are again applied to extract the oil, then reused.[27] Hexane (C6H14) is a non-polar solvent, often used in vegetable oil extractions and in glues. It is extracted from benzene.[28] The wheels are then baked for 2-3 hours at 212℉ to set them.[29] The vegetable oils are used in place of polyurethanes, as vegetable oils are more sustainable. Once used, the wheels can be recycled into cores for new wheels again, or burned for fuel.

Bureo has created a great initiative to collect, clean, and reuse fishnets that would otherwise kill marine life or sit in landfills. But is the board as sustainable as it appears to be? Most of it, yes. The wheels that Bureo uses, made of corn and soy oil and recycled cores, are sustainable and sturdy. Yet the other outsourced parts of the Bureo board should definitely be reconsidered, since extracting the raw materials and chemically combining them is detrimental to the our environment. Since aluminum is easily recycled and recast, and since creating it takes inordinate amounts of materials and energy, Bureo would do well to use recycled trucks as it would further speak to their mission of sustainability. The chemicals that go into nylon nets are also harmful to the ecosystem when produced, and require a lot of chemical processes. However, in this area, Bureo actually succeeds. The company is not creating the nylon, they are recycling it. Thus, they take a product in the death of its lifecycle and give it new life by using materials that would traditionally go into landfills or the ocean. By allowing these materials to be created into something new, Bureo is no longer responsible for the creation of the nylon nets and the damage that it does to the earth. Their responsibility is their Net Positiva initiative--cleaning the oceans and creating a sustainable recycling program, jobs, and skateboards for the Chilean coastal community, all while saving the ocean.

[1] http://www.pnas.org/content/111/28/10239.full.pdf

[2] https://www.greenbiz.com/article/net-gain-fighting-ocean-pollution

[3] http://wdfw.wa.gov/fishing/derelict/

[4] https://www.youtube.com/watch?v=E0DMk7zuNhs

[5] https://bureo.co/pages/net-positiva

[6] goo.gl/D2pZW2

[7] https://pubchem.ncbi.nlm.nih.gov/compound/adipic%20acid#section=Consumer-Uses

[8] https://pubchem.ncbi.nlm.nih.gov/compound/16402#section=Methods-of-Manufacturing

[9] https://pubchem.ncbi.nlm.nih.gov/compound/adiponitrile

[10] https://pubchem.ncbi.nlm.nih.gov/compound/sodium%20cyanide

[11] https://pubchem.ncbi.nlm.nih.gov/compound/butadiene

[12] https://pubchem.ncbi.nlm.nih.gov/compound/titanium%20tetrachloride

[13] https://pubchem.ncbi.nlm.nih.gov/compound/cobalt

[14] http://textilefashionstudy.com/polyamide-fiber-physical-and-chemical-properties-of-nylon-6-6/

[15] http://www.minerals.net/mineral/halite.aspx

[16] http://ammoniabmp.colostate.edu/link%20pages/where%20does%20ammonia%20come%20from.html

[17] http://www.mining-technology.com/features/feature-the-10-biggest-coal-mines-in-the-world/

[18] https://www.nickelinstitute.org/NickelUseInSociety/AboutNickel/HowNickelIsProduced.aspx

[19] http://www.azom.com/article.aspx?ArticleID=6237#2

[20]http://www.worldsteel.org/statistics/crude-steel-production0.html

[21] http://www.chemicool.com/elements/chromium.html

[22] http://www.paristruckco.com/products/reverse-kingpin-trucks/paris-180mm-longboard-skateboard-truck/

[23] http://www.aluminiumleader.com/production/how_aluminium_is_produced/

[24] http://www.madehow.com/Volume-6/Polyurethane.html

[25] http://www.polyurethanes.org/uploads/documents/eco_tdi.pdf

[26] http://www.cultureskate.com/products.cfm?CatID=99

[27] https://www3.epa.gov/ttnchie1/ap42/ch09/final/c9s11-1.pdf

[28] https://pubchem.ncbi.nlm.nih.gov/compound/n-hexane

[29] http://www.distrupol.com/Elastollan_Processing_Recommendations.pdf

Bibliography

"1,6-Hexanediamine | C6H16N2 - PubChem." National Center for Biotechnology Information. U.S. National Library of Medicine, n.d. Web. 01 Dec. 2016.

"How Aluminium Is Produced." How Aluminium Is Produced. N.p., n.d. Web. 26 Oct. 2016.

"How Nickel Is Produced." Nickel Institute. Nickel Institute, n.d. Web. 30 Nov. 2016.

Averett, Nancy. "Meet the Chilean Upstart Turning Sea Pollution into Skateboards." GreenBiz. GreenBiz Group, 13 Jan. 2015. Web. 15 Nov. 2016.

AZoM. "P5 Tool Steel (UNS T51605) Low-Carbon Mold Steel." AZoM.com. AZo Network, 11 June 2013. Web. 26 Nov. 2016.

Boustead, I. "Tolylene Diisocyanate (TDI)." Eco-profiles of the European Plastics Industry(n.d.): n. pag. Polyurethanes.org. Plastics Europe, Mar. 2005. Web. Nov. 2016.

Bureo. "Net Positiva." Bureo. N.p., n.d. Web. Nov. 2016.

Carothers, William H. Linear Condensation Polymers. Du Pont, assignee. Patent US2071250 A. 16 Feb. 1937. Print.

Friedman, Herschel. "The Mineral Halite." Halite Salt: The Mineral Halite Information and Pictures. Minerals.net, 2016. Web. 29 Nov. 2016.

Holmes, D. R., Bunn, C. W. and Smith, D. J. (1955), The crystal structure of polycaproamide: Nylon 6. J. Polym. Sci., 17: 159–177. doi:10.1002/pol.1955.120178401

Ince, Walter H. "Preparation of Adipic Acid and Some of Its Derivatives." Chemical Society, London 67 (1895): 155-59. Books.google.com. Google. Web. 2016.

International, Maxxis. "How a Tire Is Made." How a Tire Is Made. Maxxis Tires USA, 2016. Web. 24 Oct. 2016.

Kable. "The 10 Biggest Coal Mines in the World." Mining Technology. Kable Intelligence Limited, 2016. Web. 29 Nov. 2016.

Kilcullen, Micheal. "From Nets to Decks: Skating Green with Bureo Skateboards." Whalebone. Whalebone Media, 19 Jan. 2016. Web. 26 Oct. 2016.

Kim S, Thiessen PA, Bolton EE, Chen J, Fu G, Gindulyte A, Han L, He J, He S, Shoemaker BA, Wang J, Yu B, Zhang J, Bryant SH. PubChem Substance and Compound databases. Nucleic Acids Res.2016 Jan 4; 44(D1):D1202-13. Epub 2015 Sep. 22.

Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, 1997. Print.

McDonough, William, and Michael Braungart. "The Cradle-to-Cradle Alternative." William McDonough. State of the World, 2004. Web. 26 Nov. 2016.

MEC. "Chromium - Periodic Table of Elements." Minerals Education Coalition. Black and Veatch Corporation, 2015. Web. 29 Nov. 2016.

Oertel, G. Polyurethane Handbook. Second ed. Munich: Carl Hanser Publishers, 1993. Print.

Oxvig, Ulla, and Ulrik Jes Hansen. "Materials Science." Fishing Gears. Copenhagen: Fisheries Circle, 2007. 11-22. Print.

Peter Jeppsson. “Processing and recycling polyurethand as thermo and thermosetting plastics. Lund Institute of Technology, Lund University 2005. <http://www.pmahome.org/files/9614/1468/3279/Processing_and_recycling.pdf>.

Quadrini, F., L. Santo, T. Oskorus, W. Wasniowski, and E. Musacchi. "Production of Rubber Goods Made of 100% Ground Tire Rubber." Volume 1: Processing (2016): 1-4. Web. 24 Oct. 2016.

Rabanne, Paco, and Philip Stark. "How Aluminium Is Produced." How Aluminium Is Produced. UC Rusal, 2015. Web. 26 Nov. 2016.

S, Kawai. Fishing Net. Momoi Fishing Net Mfg Co Ltd, assignee. Patent US3793822 A. 26 Feb. 1974. Print.

Seymour, Raymond, and Charles Carraher. Polymer Chemistry. New York: Marcel Dekker,1992. Print.

Stewart, Doug. "Chromium." Chemicool Periodic Table. Chemicool.com. 16 Oct. 2012. Web. 11/28/2016

Team, The Small Matters. "How Is Nylon Made?" OpenLearn. The Open University, 26 Sept. 2005. Web. 24 Oct. 2016.

Ulrich, Henri. The Chemistry and Technology of Isocyanates. New York: John Wiley & Sons, 1996. Print.

WDFW. "Derelict (Abandoned) Fishing Gear Removal Project." Washington Department of Fish & Wildlife. WDFW Fish Program, n.d. Web. 15 Nov. 2016.

Weinberger, Charles B. "Synthetic Fiber." Encyclopedic Dictionary of Polymers(1996): 947. Print.

Woodford, Chris. "Nylon--The Science of Synthetic Textiles." Explain That Stuff. Explain That Stuff, 18 June 2016. Web. 24 Oct. 2016.

WSA. "Crude Steel Production 2016-2015." Worldsteel.org. World Steel Association, 24 Nov. 2016. Web. 30 Nov. 2016.

Embodied Energy Essay

Kenji Santillan

Professor Cogdell

DES40A Fall 2016

December 1, 2016

It is recorded that 10% of the oceans pollution is directed towards fishing nets. Ben, David, and Kevin, co-founders of the Bureo skateboard, decide to resolve this problem by taking apart these wasteful nets from fisherman to turn them into personalized skateboards known as Bureo Boards. The Bureo Board is a unique board mainly made and inspired by wasteful nets off the coast of Chile. Unlike other skateboards such as the Penny Board and long board, this company’s board emphasizes its unique quality of reusing wasteful material to create a polished product with at the same time saving our environment’s oceans. By preventing further harm to the environment the company accomplishes minimizing the amount of embodied energy in manufacturing raw materials into components of such types of boards distributed across the United Stated where it used and recycled.

The Bureo Board is made out of a few raw materials, which include steel, nylon, plastic polyurethane elastomers and veggie oil. It takes on average 6-15 mega joules to produce one kilogram of steel. Of that energy 70% is dependent of coal. The production of steel requires thermal energy with temperatures rising to 1700° C through an oxygen furnace. Another method utilizes electric energy from an electric furnace with rising temperatures of 1600 ° C in addition to recycled scraps of steel (How is Steel Produced). Nylon, otherwise known as thermoplastic, is melted and created by thermal energy at around 260° C (Du Pont). Plastic polyurethane is solidified and cooled through nuclear energy by chemical crosslinks of raw chemicals. The creation of vegetable oils requires a lot of high temperature and pressure extracting from boiling water out of nuts and seeds. These nets are made out of nylon. These Nets are woven into grid-like structures from this nylon thread. Nylon is created through chemical energy in combining adipic acid and hexmethylene diamine. Salt is then used to purify the components where it is heated and reacted to form nylon to 285 degrees Celsius with the production of water (Du Pont). These components are mixed and created under chemical and thermal energy from factory machines.

The main deck of the board is first made out of nets made out of nylon. First the nets are collected from Net Positiva, a recycling fishnet recycling program, where fisherman and workers of the program collect wasted fishnets near Chile’s coast . This process requires a lot of labor-intensive human energy or gravitational energy when transferring loads of fishnets on trucks to recycling centers. The nets are then sorted, shredded through mechanical energy and re-palletized to become these skateboards (Bureo). The pellets of these boards are compressed by aluminum thru machine and thermal energy to shape its signature fish deck design.

Like any other skateboard, trucks play a key component in durability when being used. The creation of aluminum requires a lot of energy from its grinding and refining process. Bauxite is first collected and processed through an electric powered grinding machine. Once it is grinded down chemical and thermal energy is used to separate alumina out of the Bauxite through hot solutions of caustic and lime (How Aluminum Is Produced). After, the mixture is heated and filtered out, where electricity from opposite nodes react to form CO2 resulting into liquid aluminum. An extrusion process of thermal energy is casted on the liquid aluminum to heat and shape it the way it should be used for (How Aluminum Is Produced). Through nuclear energy these trucks are then heated with silicone into the alloy to give it more durability. The shape of the truck determines the truck’s ability to turn and move across different pavements.

The bearings and bushings of the board is made out of steel from aluminum machinery. In supply and collaboration with Paris Trucks, Satori Movement, and Bustem Bearings, bearings are enables the board to rotates as the bushings provide support (Kailee). From steel comes the construction of these components for the Bureo board. Thermal energy is used to shape them and chemical energy is added to lubricate the parts of the board for a smooth usability.

Plastic polyurethane elastomers and veggie oil is used to make wheels of the board. This is done through a mixing chemical energy process of urethane and catalyst. Once the mixing is complete the liquid is poured into a mold and then heated in an oven where there are shaped into a wheel. After, the mold is then insulated on the ground to cool in order to go through them faster.

Efficient energy is used in transporting the many components of the Bureo board. Luckily the Bureo board houses the manufacturing of shredding nets under the Santiago Recycle near the coast of where most nets are fount in Chile (Waste Shredding Machines). Nonetheless plenty of energy is used in the distribution process of materials and product. From chemical energy used from ships, trucks, and planes, a great deal of energy is used to take products from Chile to the U.S. Since there are many retail stores across the country to such as Japan, Germany and the U.S., transportation and distribution of the Bureo to plenty stores can account for a great use of petroleum gas in return for long distance shipments (Goods Movement). The import of products from Chile to the U.S requires a distance of 5,241 miles on plane; therefor, in addition to all the distribution across other parts of the world, it has been recorded that an airplane has released more that 70,000 tons of CO2 when shipping these products (Food Miles). Since transportation accounts for 25% of world’s energy, energy trade across countries may serve as a direct economic benefit for users or a drawback to the environment (Transportation and Energy).

After the Bureo Board is completely made and distributed, users from around the world can take part in riding this fun vehicle. Since the board is usually pushed along pavement, energy is accumulated over time through long distances. The longer the distance, the more energy is required to push the board at an accelerating pace. The main source of energy when using such boards is that of humans which is mechanical energy and that of the wheels in which energy is transferred to accommodate the speed in which it is traveling. In this case, kinetic energy is associated with an amount of the wheel’s velocity (Skateboard Re-charging). The amount of energy required to repair the Bureo board can easily be fixed and replaced mechanically by humans. Low maintenance of this board is equivalent to low energy. Regardless of its maintenance, more energy is used when a new shipment of the trucks wheels or bearings, are bought and distributed at your door or a local post office.

Since the Board has a unique way of using recycled fishing net material into a usable product, it is safe to say that the Bureo Board is easily recyclable. Most of the energy used in recycling requires mechanical energy or chemical energy. Optional uses of the board require mechanical energy. Humans can take parts of the board to create new furniture or create similar such products. Bearings and trucks can be easily passed down to new decks and vice versa through human activity from mechanical energy. Less chemical energy is used to recycle decks since it is made out of net-like material since. Once it is recycled or reused, energy is no longer present in the Bureo Board.

The Bureo Board is an environmentally friendly vehicle that works to save the environment from pollution and the further damaging of organisms that live amongst the ocean. After doing plenty research in the Bureo Board, it is evident that energy plays a key roll in creating a remarkable product. Locally, energy is reduced with a unique way of taking the wasted net material into local recycling facilities. Energy is especially conserved in creating these decks with the benefits of reducing the damage of the environment. Although fuel and gas emission’s used in distributing this product may use up a lot of energy, the Bureo Board is a product that is worth producing for the benefit and well-being of the world around us.

Bibliography:

Bradstreet, Kailee. "Upstarts: Bureo Skateboards." GrindTV.com. N.p., 16 Apr. 2014. Web. 30 Nov. 2016.

Bureo. "Shop Bureo." Bureo. N.p., n.d. Web. 30 Nov. 2016.

"Food Miles." NRDC: Food Miles: How Far Your Food Travels Has Serious Consequences for Your Health and the Climate (pdf) (n.d.): n. pag. Web.

“Goods Movement Life Cycle Assessment ofGreenhouse Gas Reduction Goals.” Journal of Industrial Ecology 20.2 (2015): 317-28. Web of Science. Web. 25 Oct. 2016

“How Aluminum is Produced.” How Aluminum is Produced. N.p.,n.d, Web, 26, Oct. 2016

"How It's Made." How Aluminium Is Made - Norsk Hydro. N.p., n.d. Web. 30 Nov. 2016.

"How Is Steel Produced?" World Coal Association. N.p., n.d. Web. 30 Nov. 2016.

"Kinetic Energy Project – Skateboard Re-charging." Nelramon's Blog. N.p., 09 Mar. 2011. Web. 01 Dec. 2016.

Oris, White Jesse, and Du Pont. "Patent US3076026 - Process for the Simultaneous Production of Hydroxylamine and Adipic Acid." Google Books. N.p., n.d. Web. 26 Oct. 2016.

Rodrigue, Dr. Jean-Paul. "Transportation and Energy." Transportation and Energy. N.p., n.d. Web. 30 Nov. 2016.

SciDev.Net.”Greener Nylon Production Cu Costs and Pollution.” SciDev.Net.N.P,

n.d. Web 26 Oct. 2016.

"Waste Shredding Machines." Coparm Srl. N.p., n.d. Web. 30 Nov. 2016.

Waste Essay

The Bureo Minnow Cruiser skateboard is stated to be an environmentally friendly product, by a company who started the Net Positiva collection of fishing nets. I want to know, is the company as ecofriendly as they could be? My goal is to lay out all the wastes produced within the Minnow Cruiser skateboards complex life cycle, and to cover all the steps of the life cycle within six sub-categories. The sub-categories are: Raw material Acquisition, manufacturing processing and formulation, distribution and transportation, use/re-use/maintenance, recycling, and waste management.

First I will cover the goal of the organization and what materials they use in production. Then looking at the process of refinement into useable skateboard parts we will collect all the data regarding the emissions of gasses, environmental impacts, labor used for net collection and the production of wastes within these processes.

The Bureo Minnow Cruiser skateboard was created by a group of three guys who saw an opportunity to preserve the oceans wild life and natural ecology. They are doing so by setting up a process of collecting nets that were normally burned, lost at sea or discarded in landfills. The company’s name came from a native Chilean people the Mapuche and Bureo means the waves in their language, fitting because they are trying to keep the waves clean. [1] Part of their goal was to stop what is called “Ghost Fishing” where used fishing nets tumble around the ocean floor killing lots of life, the other part was to raise awareness and stop inappropriate disposal of fishing nets. [2]

Fishermen first collect the fishing nets they no longer use. They are later cleaned by the local communities to later be taken to the factory for the recycling process. The start of the life cycle is heavily reliant on human labor, but it does help solve the problem of plastics in our ocean as the UN has reported 10% of the plastic in the oceans are fishing nets. [3] During the human labor collection of nets no wastes are produced during cleaning, but the trucks used to transport the nets do produce co2 and other gases.

Once at the factory the nylon nets are mulched up into smaller particles, and then are melted down into pellets. The pellets are then used to form the Minnow cruiser by pouring the liquid pellets of nylon into molds. After some time, the skateboards are taken out and shaved into the final skateboard deck. [4] I question here if the process could eliminate a step of cooling the liquid nylon into pellets, and then reheating them to form the deck, as energy is unnecessarily wasted to turn them back into a liquid state.

Next we look at all the other components of a skateboard not made by Bureo. They include Bustin Co bushings, Satori Movement wheels, Divine Wheel co bushings, and Paris Truck co Trucks. All of these products use different raw materials and refinement processes of manufacturing. The materials they use are: p5 steel, thermoplastic polyurethane elastomers, T5 and T6 virgin aluminum, corn and soy vegie oil, skate designed grease and the blowing agents used in production.

Each of these materials must be collected as part of the first step. There are many places to collect them, and since the companies do not list a specific place, I will collect data from the leading manufactures of the materials. I will also look at what each of these production grade materials are made from, and where they originate from as well.

Virgin aluminum is manufactured from bauxite, and then using one of two processes it is converted to alumina, and red mud. “Red mud is a thick red-brown paste consisting of silicon, iron, titanium and other compounds. It's disposed of in special isolated areas, called mud disposal areas. Mud disposal areas are designed to prevent the seepage of alkali contained in the mud into ground water. Once a mud disposal area has been filled up, the territory can be reclaimed by burying it in sand, ash or dirt and planting certain types of trees and plants there. While full reclamation can take years, in the end the territory will return to its original state. Experts don't regard red mud as a waste because it can be used as a raw material. For example, scandium can be made from it and then used in aluminum scandium alloys. [5].

Once the alumina is made we need to add another component cryolite to make the aluminum. “cryolite is made by mixing hydrofluoric acid with aluminum hydroxide and soda.”[6]. Once we have the two materials combined a electric reduction process takes place to make the aluminum, and “for every tonne of aluminum produced, 280,000 cubic metres of gases are emitted.”[7] Looking specifically at our skateboard we know that T5 and T6 aluminum is used in the skateboard trucks, which are specifically heat-treated by different processes. Over 100 aluminum alloys are used in industry by adding different metals into them, they can also be treated by different coatings and cooling processes. [8]

In the skateboard bearings we know that P5 Stainless steel is used. To determine the wastes of this product I will look at the recycling process of scrap steel, and the possibility of new steel formation in both an Electric arc furnace, and a blast furnace. A blast furnace needs a few different components to create the molten pig iron that is turned to steel they are: coke, lime, oxygen, scrap metal and/or taconite. Coke is a form of coal that was processed by heating regular coal to around 2012 degrees Fahrenheit in the absence of oxygen. This is the energy dense material used to heat the blast furnace to 2400 degrees Fahrenheit for melting [9]. Taconite is an iron ore that is extracted from the ground by blasting rock into many particles. When melted by a blast furnace it produces a few products, which include co2, sulfur dioxide, slag, and carbon contaminated water and the pig iron [10]. Co2 and the slag are both waste products. Slag is a mixture of lime, silicates, aluminum oxides, magnesium oxides, manganese oxides, and ferrites. [11] We know that co2 just goes up into the air as a gas, but the slag is different in that we cool it and use it to make concrete.

Next on the list of materials is the thermoplastic polyurethane elastomer that is what the wheels are made out of. Also included in this process are additives, which include a blowing agent, and other stabilizers. This process takes a liquid elastollan and pours it into molds; next the additives are used to cure the wheels to the proper hardness and resistivity. Then the molds are heated into the final shape, and they are shaved. In the Satori wheels they recycle old skateboard wheel cores and then use soy and corn oil as the elastollan. This is a better process because not as much harmful materials are produced as we don’t make as much when recycling the old cores. This process still releases carbon dioxide, but it has a 36% lower footprint than the regular process. [12] As for the blowing agent, it is a type of gas that has been regulated heavily by the government, as it is a replacement for CFC’s, which were attributed to destroying the ozone. It is very hard to find any information about what exactly the effects of this product are as it is newer and the information about it is hard to find. On Honeywell’s website it lists a few of their products and claims that they are non ozone depleting and that they do not have that large or no global warming effects. [13]

Second on the list is the manufacturing process. I mentioned a little of the manufacturing process above, but not all of the specifics. Both the aluminum and the steel, require a ton of energy to be made. Electric arc furnaces for steel arc 115 million watts of electricity for 35 minutes per each batch, and the plants electricity bill is 7-8 million dollars a month. [14] As for the aluminum” The constant voltage at the electrodes of each reduction cell varies in the range of between 4 and 6 volts, while the amperage can reach 300, 400 KA and more”[15]. Watts are found by multiplying the volts by the amps in this case 6*400,000= 2.4 million watts. The sad part about all the electricity that we are using is that it’s a secondary energy source and to use it we already have wasted 65% of the original energy to heat. [16] In these processes we use fossil fuels to make electricity, which has its own waste of carbon dioxide. In addition to the electricity use we use fossil fuels to extract ores with machines. To further complicate the process some materials are blasted from the earth by explosives.

Third, we look at the transportation of the materials from each collection location, through the refinement process, and to the end destination. Each individual material is collected at different places where they naturally are found in the earth. They are transferred from the natural location to purification and refinement plants where the specific material and grade is produced, and then it is shipped to each skate company’s assembly locations where each product is constructed. The largest bauxite producer is china. The largest crude steel producers are in Asia. “The worlds biggest open pit iron mine can be found near Hibbing, Minnesota”[17]. The leading market for cryolite comes from pacific Asia and china. The largest producer of coal is also china [18]. Yet another anomaly china is the leading producer of nylon [19]. As you can clearly see a lot of raw materials and refined ones are produced in china. After china produces the main materials they are sent to the companies manufacture plants in: Costa mesa California, McKinleyville California, and Brooklyn New York. Now china might not produce the materials these companies use, but I cannot find where the companies source them. The Bureo skateboard deck is manufactured in Santiago Chile then it is exported for assembly with the other parts. It along with the other parts are shipped to Bureo’s assembly location in Los Angeles California. [20] Once the board is assembled it is off to the retailers, and the board owners houses, that could be anywhere in the world.

Fourth we look at the maintenance required to keep the product in action. A plastic skateboard is very robust, and a few of the components do not biodegrade [21]. Use of these robust materials keeps the skateboard practically maintenance free. Regular use of the tail during stopping minimally reduces the surface of the tail after each stop during riding. Not often do skateboarders stop this way though as there are other ways to slow down the board without grinding the tail on the pavement, which means that the skateboard tail really doesn’t suffer that much, or that it simply depends on the person whether it suffers at all. The steel bushings and the aluminum trucks are extremely durable, and never come into contact with any forces that break them, but they could be scratched by rocks or railings, but that’s about it. It is possible for the bushings become compressed, and loose a lot of their elasticity; moreover, bushings can crack and crumble to the point they are totally unusable. Yet, bushings are fairly unheard of being replaced, because as long as they are still tightly secured in the trucks and they don’t cause the skateboard to completely malfunction then they wont be replaced. Bearings, another part of skateboards tend to rust or seize up, but for that to happen the skateboard has to be sitting still for a long time for the failure to chemically develop, or lots of debris have to permeate through the bearings, casing seizure. In the event of such a seizure the bearings can be cleaned and put back on the skateboard for continued use. In fact the bearing manufacture for this product boasts that you can ride them till they die, and that it will take a while. The only thing that occurs more regularly is a flat spot developing on the skateboard wheels. It is possible when the board is slid sideways to slow down when a board is going down hill, or simply is going to fast. Not many regular riders do this, but the Bureo Minnow Cruiser is used by some long boarders who frequently slow down the board in this manner. Since all the materials are durable it is not common for more materials to be produced to maintain the product. To maintain this product there are no wastes produced, unless a new part has to be manufactured. When the new part is manufactured the same wastes as before will be produced.

Fifth, we will discuss the possibilities or recycling this skateboard into other things later in its life. “There are three different types of recycling: reusing the product, reusing the material for use in new products and burning the product in order to produce energy”[22]. As you may have gathered the nylon skateboard, and wheel cores are already recycled products, but it’s still possible to again recycle these products. Looking at each manufactures part of the skateboard we know that some are or could be made from reclaimed materials, but what stands out more is, that the trucks are made out of virgin aluminum. This means while the rest of the skateboard parts are sourced from eco conscious companies, the trucks are not, they are new and have not previously been recycled. Returning to the recycling of the skateboard, other people can use the whole skateboard again, but if we want to separate it to make new products or create energy we can. The aluminum and steel can be melted down back to the liquid metals for other uses. The nylon and polyurethane can both be mechanically shredded or chemically separated back to their original chemical products. [23] The wheels can be burned as a fuel as they have an energy density of 40 MJ/kg, as does the nylon [24]. Although burning the wheels and the nylon will produce a thick cloud of co2.

The six and final part of the life cycle we will discuss the waste management of each component of the Minnow Cruiser. The wastes produced in this whole process include: carbon dioxide, slag, sulfur dioxide, red mud, and carbon containing water. The life cycle wastes could also include less than optimized use of electricity and fossil fuels. If the skateboard is not recycled after its life it could also become another waste. As stated above each part can be recycled for a similar use, a new use or burned for energy. All of which can be done and will produce more wastes. Steel production produces carbon dioxide slag and contaminated water, all of these wastes are treated except the gas released in the air. The slag is used to make other products and the water is filtered. In aluminum production red mud is produced, which can be used to make other materials, or planting on it will reclaim the material. Polyurethane produces co2 and releases blowing agents as wastes, these are not treated. Lastly nylon production produces waste co2 and the product itself can become a waste when discarded.

At the end of the whole life cycle assessment I want to say that not every product or material is as heavily looked into and evaluated for its impacts. I do not have access to each file about the exact material amounts used and the measures of energy to specifically produce that amount and waste produced from those, therefore further research could be done. This is what is called a cradle- to- grave, life cycle assessment where the total scope of the product is evaluated from the raw acquisition of materials, to the recycling of the product.

All in all the production of the Bureo minnow cruiser uses a ton of energy materials and resources to produce, but the nylon board in itself is fairly ecofriendly. The materials are collected and manufactured around the world, mostly in china, and they are collected by blasting, digging, drilling, et cetera. When the materials are extracted they are ready for shipment. To ship by any of the three common sources of transportation, trains, planes, and boats, will require a lot of energy. Each time the materials are transported or processed new emissions and wastes are produced that have their own different impacts on the earth. The most talked about emission from transportation is carbon dioxide, but other green house gasses are produced in the movement of products. Once the skateboard has finished all of its transportation from resource collection sites in other countries and, manufacture buildings it is ready to be sold. Selling the product again requires transportation to new retailer sites, or to the owner’s door. Once the owner is in possession not much is produced in terms of waste as the product is non-biodegradable, and is fairly sturdy. If a rare replacement is made the individual replacement part will have to be thrown through the same large process until it shows up at the owners door, this will produce the exact same production wastes. Finally the last step of the life cycle is the recycling of the product. We know that the product could be reused by any other person for its originally intend use, or it could be separated mechanical/chemically for new products. Also the materials could be burned to create energy. One thing that is great about this products recycling is that it already uses recycled products in both the skateboard deck and the wheels. This is a big plus, and it’s an even better that the whole thing can be reclaimed again.

[1] http://observers.france24.com/en/20151231-meet-entrepreneurs-making-skateboards-out-discarded-fishing-nets

[2] http://observers.france24.com/en/20151231-meet-entrepreneurs-making-skateboards-out-discarded-fishing-nets

[3] http://observers.france24.com/en/20151231-meet-entrepreneurs-making-skateboards-out-discarded-fishing-nets

[4] http://whalebonemag.com/from-nets-to-decks-skating-green-with-bureo-skateboards/

[5] http://www.aluminiumleader.com/production/how_aluminium_is_produced/

[6] http://www.transparencymarketresearch.com/cryolite-market.html

[7] http://www.aluminiumleader.com/production/how_aluminium_is_produced/

[8] http://www.aluminiumleader.com/production/how_aluminium_is_produced/

[9] https://www.worldcoal.org/coal/uses-coal/how-steel-produced

[10] http://www.nationalslag.org/steel-furnace-slag

[11] http://www.nationalslag.org/steel-furnace-slag

[12] http://skateandannoy.com/blog/2008/12/bio-thane/

[13] https://www.honeywell-blowingagents.com/regulation/

[14] https://www.youtube.com/watch?v=865OqMzp1Zw

[15] http://www.aluminiumleader.com/production/how_aluminium_is_produced/

[16] http://insideenergy.org/2015/11/06/lost-in-transmission-how-much-electricity-disappears-between-a-power-plant-and-your-plug/

[17] http://www.losapos.com/openpitmines

[18] http://www.worldatlas.com/articles/the-top-10-coal-producers-worldwide.html

[19] http://www.icis.com/resources/news/2010/08/30/9388327/china-strengthens-position-in-nylon-fibers/

[21] https://www.thegrommet.com/bureo-minnow-complete-cruiser-skateboard

[21] http://www.slideshare.net/ronakv1/recycling-of-polyurethane-wastes

[22] http://www.pmahome.org/files/9614/1468/3279/Processing_and_recycling.pdf

[23] http://www.slideshare.net/ronakv1/recycling-of-polyurethane-wastes

[24] http://www.pmahome.org/files/9614/1468/3279/Processing_and_recycling.pdf

Bibliography

Michael Kilcullen. “From Nets to Decks: Skating Green with Bureo Skateboards - Whalebone.” Whalebone, 19 Jan. 2016, whalebonemag.com/from-nets-to-decks-skating-green-with- bureo-skateboards/.

Poulet, Maëva. “Making Skateboards out of Discarded Fishing Nets.” The France 24 Observers, 20 July 2016, observers.france24.com/en/20151231-meet-entrepreneurs-making- skateboards-out-discarded-fishing-nets.

AZoM, “P5 Tool Steel (UNS T51605)- Low-Carbon Mold Steel.” AZO Materials, 20 Sep. 2012, www.azom.com/article.aspx?ArticleID=6237.

AZoM, Ferrous and Non-Ferrous Metals Stockist. “Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalco.” AZO materials, Aalco , 17 May, 2005, www.azom.com/article.aspx?ArticleID=2863#2.

All About Aluminium. “How Aluminium Is Produced.” How Aluminium Is Produced,www.aluminiumleader.com/production/how_aluminium_is_produced/.

World Steel Association. “Crude Steel Production 2016-2015.” World Steel Association - Crude Steel Production 2016-2015, 21 Nov. 2016, www.worldsteel.org/statistics/crude- steel-production0.html.

Vaghani , Ronak, and Dr ANaGha S Sabnis. “Recycling of Polyurethane Foam Wastes.” LinkedIn Slide Share , 18 Feb. 2016, www.slideshare.net/ronakv1/recycling-ofpolyurethane-wastes.

How Products are made. “Polyurethane.” How Polyurethane Is Made - Material, Production Process, Making, History, Used, Processing, Parts, Steps, www.madehow.com/Volume6/Polyurethane.html.

Peter Jeppsson. “Processing and recycling polyurethand as thermo and thermosetting plastic.” Lund Institute of Technology, Lund University 2005. http://www.pmahome.org/files/9614/1468/3279/Processing_and_recycling.pdf

Niklas von der Assen, and André Bardow. “Life Cycle Assessment of Polyols for Polyurethane Production Using CO 2 as Feedstock: Insights from an Industrial Case Study.” Life Cycle Assessment of Polyols for Polyurethane Production Using CO 2 as Feedstock: Insights from an Industrial Case Study - Green Chemistry (RSC Publishing) DOI:10.1039/C4GC00513A, Royal Society of Chemistry, pubs.rsc.org/en/content/articlehtml/2014/gc/c4gc00513a.

Piumarta, Timothy et al. “Patent US7125083 - Wheel with Dual Density.” Google Books, www.google.com/patents/US7125083.

Other Planet Products. “Technology - Wheels.” Other Planet Skate, www.otherplanetskate.com/pages/technology-wheels.

BASF. “Thermoplastic Polyurethane Elastomers (TPU).” BASF, www.distrupol.com/Elastollan_Processing_Recommendations.pdf.

BASF. “Thermoplastic Polyurethane Elastomers Elastollan Cable Sheathings.” BASF, www.apstpe.com/media/pdf/ElastollanTPU-8WireCable.pdf.

“Primary Metals.” The Steel Making Industry, www.istc.illinois.edu/info/library_docs/manuals/primmetals/chapter2.htm.

Transparency Market Research. “Cryolite Market- Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2013-2019.” Global Industry Analysis,Growth,Trends and Forecast 2019, www.transparencymarketresearch.com/cryolite-market.html.

LosApos.“The Worlds Deepest, Biggest and Deadliest Open Pit Mines.” The Worlds Deepest, Biggest and Deadliest Open Pit Mines | LosApos, www.losapos.com/openpitmines.

World Coal Association. “How Is Steel Produced?” World Coal Association, www.worldcoal.org/coal/uses-coal/how-steel-produced.

ICIS “China strengthens position in nylon fibers.” ICIS Chemical Business, www.icis.com/resources/news/2010/08/30/9388327/china-strengthens-position-in-nylon- fibers/. 30 Aug, 2010.

Extreme TV. “The story of how SDI’s Flat Roll Division recycles scrap into new carbon- steel products.”Steel Dynamics Inc. https://www.youtube.com/watch?v=865OqMzp1Zw.

National Slag Association. “Steel Furnace Slag.” Steel Furnace Slag | National Slag Association, www.nationalslag.org/steel-furnace-slag.

Skate and Annoy. “Biothane Soy-Based Urethane.” Kilwag Skate and Annoy, 8 Dec. 2008, skateandannoy.com/blog/2008/12/bio-thane/. 8 Dec, 2008.

Jordan Wrifs-Brock. “Lost In Transmission: How Much Electricity Disappears Between A Power Plant And Your Plug?” Inside Energy, 14 Oct. 2016, insideenergy.org/2015/11/06/lost-in-transmission-how-much-electricity-disappears- between-a-power-plant-and-your-plug/.

Worldatlas. “The Top 10 Coal Producers Worldwide.” WorldAtlas, 28 July 2016, www.worldatlas.com/articles/the-top-10-coal-producers-worldwide.html.

Michigan State University “Mini-mills: The new look of Steel Mills.” Minmills, geo.msu.edu/extra/geogmich/minmills.html.

Honeywell. “Regulations | Blowing Agents.” Blowing Agents, www.honeywell- blowingagents.com/regulation/.

Grommet, The. “Bureo | Recycled Fishnet Skateboards.” The Grommet, 6 June 2016, www.thegrommet.com/bureo-minnow-complete-cruiser-skateboard.

Poulet, Maëva. “Making Skateboards out of Discarded Fishing Nets.” The France 24 Observers, 20 July 2016, observers.france24.com/en/20151231-meet-entrepreneurs-making- skateboards-out-discarded-fishing-nets