Design Life-Cycle

assess.design.(don't)consume

Daniel Ramos

April Perez, Abby Sommer

DES 040A

Professor Cogdell

DES 040A Research Paper:

An Analysis of the Energy Usage of a Onewheel XR Board

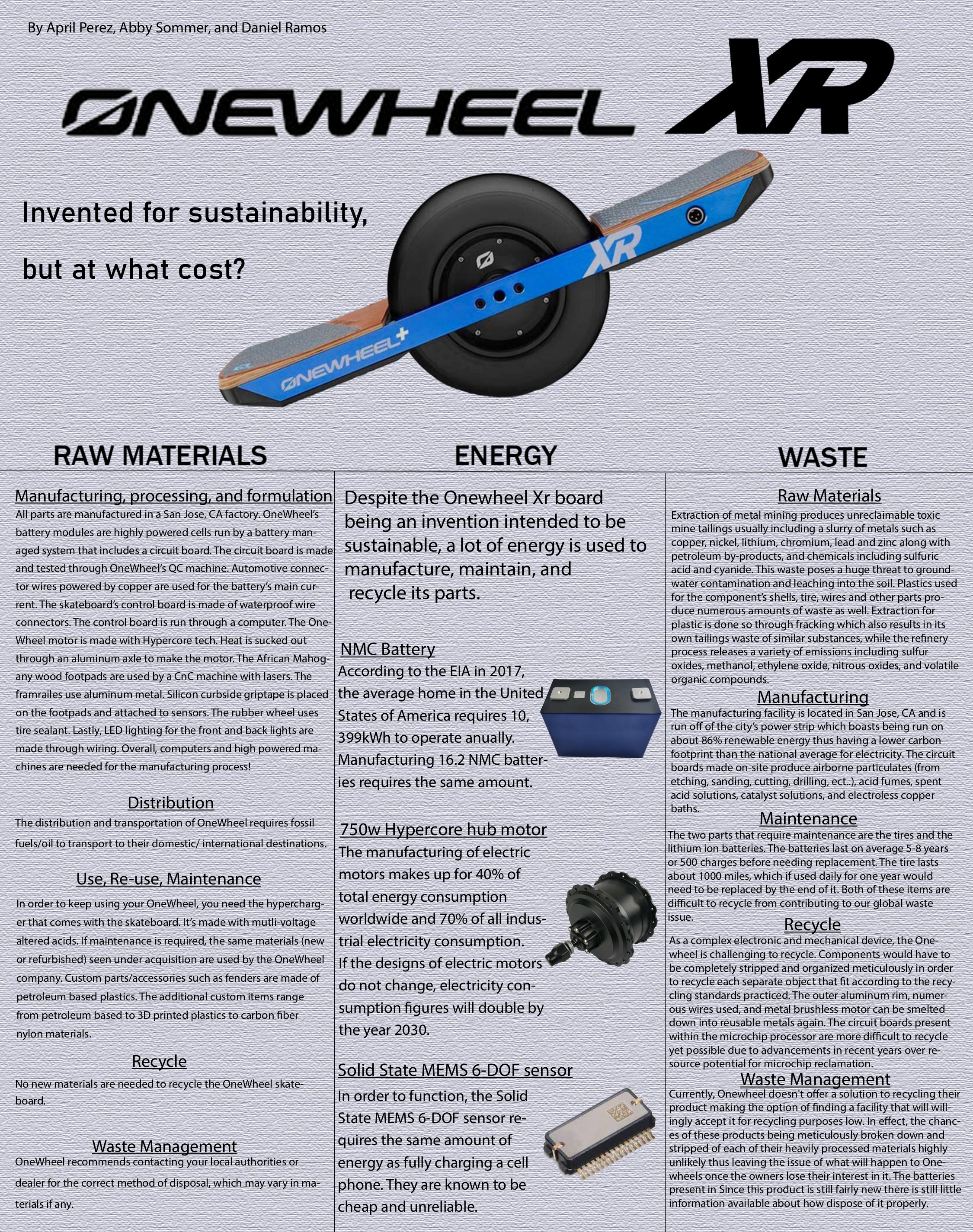

Since the beginning of time, humans have used a variety of forms of transportation in order to make their lives easier. From the use of animals, to engines, to battery-powered vehicles, our means of transportation never fails to innovate. In the midst of this constant innovation, the energy required to power our transportation has exponentially increased. In efforts to provide sustainable replacements for transportation, battery-powered motors were introduced. In our current era, you could find bicycles, cars, and even skateboards that are powered by batteries. Specifically, an up-incoming product, the Onewheel XR board, has satisfied the market’s need for a fast, efficient, gasless form of transportation. Although this product does not require gas, the energy used to produce it should raise more concern than it currently does. As a society, we trust and blindly accept that the introduction of these innovative solutions automatically provide a more sustainable solution, but are we wrong about the Onewheel XR board? From its wheels to its motor, the Onewheel XR board is a byproduct of our earth’s constant need to innovate for intended good, but what is often not considered is the energy used when producing the board, which, in reality, negates the positive intention behind it.

The Onewheel XR board would not be able to function without its battery, a NMC battery, which frankly, has a very inefficient life cycle itself. The extended name of NMC is Lithium-Nickel-Manganese-Cobalt-Oxide. NMC is the go-to cathode powder to create batteries for e-bikes, power tools, and a variety of other electric powertrains. While electric, battery-powered solutions, in some cases, may be objectively more efficient than other forms of power, lithium batteries like NMC are extremely wasteful. Manufacturing a lithium battery requires a certain amount of electricity. The electricity demand of manufacturing a lithium battery is an astounding 586 - 2318 MJ. To put that in perspective, in 2017, the EIA conducted a study that revealed that the average home in the United States of America requires 10,399 kWh to operate annually. Furthermore, converting the amount of megajoules it takes to manufacture a lithium-ion battery to kWh, it would require roughly 643kWh in order to manufacture one of these batteries. Looking at the bigger picture, the same amount of energy used up manufacturing 16.2 lithium-ion batteries could actually power the average home in the United States of America for an entire year. Looking back at its life cycle, NMC batteries, in particular, have a much shorter lifespan than other lithium batteries, containing a useful lifecycle, ranging from 3000 - 5000 cycles. NMC batteries are advertised to be a far more durable and efficient substitute for other lithium batteries, but they have a significantly higher chance of combustion. Compared to a LFP battery, another form of lithium battery, a NMC battery has a flashpoint of 419 degrees Fahrenheit, while the LFP battery yields a flashpoint of 518 degrees Fahrenheit. These data entries basically indicate that NMC batteries have a higher probability to ignite and burn, given the correct circumstances. These statistics are very eye-opening, as they shed light on the harsh reality of battery-powered innovations that our world continues to produce. Although battery-powered innovations are considered to be more efficient for humans to use, it is our world’s responsibility to understand the consequences of these innovations, specifically using cheap Lithium-Ion batteries like NMC batteries. Using cheaper means of production to create products like the NMC battery greatly decreases the quality of them, and they have a destructive effect on the environment and the resources taken. At home, if you find yourself looking into a battery-powered skateboard or bike, consider how your purchase, and the purchases of many others around you, may bring you and this earth harm.

In order for the Onewheel XR board to send signals that monitor motion and provide the correct voltage to the direct drive hub motor, the Onewheel company uses Solid State Micro - Eletro - Mechanical - Systems 6 Degrees of Freedom inertial sensors, or in Layman's terms, MEMS 6-DOF sensors. The way that the Solid State MEMS 6-DOF sensor works is the device essentially combining a XYZ-axis gyroscope and XYZ-axis accelerometer with Digital SPI Interface to allow unsurpassed bias stability and noise performance for safety-critical automotive applications. This new sensor secures much higher levels of Advanced Driver-Assistance Systems (ADAS) and Automated Driving (AD) functionality through combining data with Global Navigation Satellite Systems (GNSS) and a variety of perception sensors such as camera, radar, and lidar. The Solid State MEMS 6-DOF sensors make up a small portion of the energy output and input that the Onewheel XR board produces and requires, but it is more energy than it needs to use. The energy input that is required by the sensors used by the Onewheel XR board ranges from 3.2-5.25V per usage. In comparison to the Solid State MEMS 6-DOF sensors’ energy requirements, most small consumer electronics are powered by 3.2-5V of electricity. Referring back to the ubiquitous usage of Lithium-Ion batteries, such as the NMC battery, these Solid State MEMS 6-DOF sensors are used so often because of their low cost of manufacturing and production. So, the amount of energy required to power one of these sensors has more to do with the point of view that does a better job of benefiting the economy of said company. Although bad for the environment in its waste concerns, the reality is that the outstandingly low cost to produce small output electronic products heavily outweighs any environmental concern that could potentially be brought up to oppose this production. The constant need for innovation drives companies and consumers to believe that it is absolutely necessary to build cheap and to buy cheap. As we can see with the NMC batteries, when you create a product with cheaper materials, it puts consumers and this planet in danger.

The high majority of modern vehicles on our planet require motors to operate reliably and efficiently, and in order to power these strong transportation motors, excessive energy consumption is the cheapest solution. The Onewheel XR board contains a 750w Hypercore hub motor. The Hypercore hub motor can deliver an impressive 750w of electricity per second, which would be classified as the rate of energy used. Though, questions and speculations have been raised regarding the true sustainability of electric motors in general. To answer many of these questions and speculations, it is stated that the manufacturing of electric motors makes up to 40% of total energy consumption worldwide and 70% of industrial electricity consumption. With the rising use of electric motors in skateboards, bikes, and cars, that energy consumption percentage is likely set to exponentially increase over a short period of time. In fact, if electric motor manufacturers do not change the design of their energy - hungry motors, we can unfortunately expect these energy and electricity consumption figures to double by the year 2030. This is a wake up call for Earth because our world cannot sustain and overcome the rising demand for energy. Due to consumers desiring to operate electrically motorized vehicles at faster and slower speeds, companies felt the pressure to innovate beyond our world’s capacity, leading us to electric motors that required an unreasonable and an unsustainable amount of energy.

Now that we know about the energy from usage and manufacturing for most of the parts on the Onewheel XR board, let us direct our attention to the maintenance of the board. The Solid State MEMS 6-DOF sensor and the motor do not really require any serious maintenance unless they malfunction, but the Vega tires and the NMC battery do. Lithium-ion batteries typically have a lifetime that lasts, on average, 5-8years, or once the battery has been charged 500 times. Vega tires can be expected to last upwards of 1000 miles, depending on the terrain that the tire typically rubs up against. If the Onewheel were someone’s short - commuter choice of transportation, and it was used every single day for a year, then the tire would indefinitely need to be replaced by the end of that year. Admittedly, it was very difficult to find the statistics or studies on the energy behind maintaining a wheel, so that process is unknown, likely because there’s no real “maintenance” other than replacing it and sending the tire to be recycled or to sit in a landfill. As for the battery, it usually takes 3.2-5V to charge, at a 3C charging rate, and if done 500 times, a lot of energy is expended in the process.

As for recycling and waste management of the Onewheel XR board, the board yields a plethora of complexities. Due to its mechanical anatomy and what its parts are made of, it is highly difficult to create a solution that is safe for the environment and energy efficient. According to the EPA and the Onewheel company, in order to recycle their board, they would have to strip the entire board of its parts, separate the individual parts, and then proceed to recycle and reuse appropriately. There are no statistics that allow consumers to see the amount of energy that goes into the recycling and waste management process because Onewheel simply does not offer a solution. Economically, it is inefficient for them to spend money on creating a sustainable recycling system, so they would rather allow our landfills to become more crowded, turning away from the issue.

When a consumer wants something done, companies will do nearly anything it takes in order to fulfill the desire of the consumer. It is a common misconception that our world is in dire need of constant innovation, making the lives of people around the world much easier. As the years become months and those months become days, we discover more holes and inconsistencies left by the predecessors of this earth. The people of the past, especially during the Industrial Revolution, believed that it was only right to innovate constantly in order to be aligned with the desires of the consumers. Though, more often than not, we find ourselves reaping the dangerous consequences of this arrogant desire to innovate. Consumers want things to be more efficient for them to use; They want things to be faster, slower, more aesthetically pleasing, anything, as long as it makes their lives easier. Through research and a multitude of new issues arising, we have noticed the dangerous increase in electricity usage and industrial energy consumption. If we, as a collective Earth, do not open our eyes to the obvious consequences of our energy consumption, then the holes and inconsistencies of our predecessors will only become larger and more apparent, leaving our future generations to clean up the mess that we failed to fix.

“Onewheel Pint vs. Onewheel+ XR.” Onewheel // Future Motion, https://onewheel.com/pages/onewheel-pint-vs-onewheel-xr.

“Update of Life Cycle Analysis of Lithium-ion Batteries in the GREET model.” Systems Assessment Group. file:///C:/Users/Phyzekz/Downloads/Battery%20Update_GREET2017%20(1).pdf

Ahmed, Shabbir, et al. “Cost and Energy Demand of Producing Nickel Manganese Cobalt Cathode Material for Lithium Ion Batteries.” Journal of Power Sources, Elsevier, 5 Jan. 2017, https://www.osti.gov/pages/biblio/1368567.

Cloud, Maria. “What Is the Energy Density of a Lithium-Ion Battery?” Home, https://www.fluxpower.com/blog/what-is-the-energy-density-of-a-lithium-ion-battery.

“(PDF) Lithium-Ion Vehicle Battery Production Status 2019 on Energy Use, CO 2 Emissions, Use of Metals, Products Environmental Footprint, and Recycling.” ResearchGate, https://www.researchgate.net/publication/339237011_Lithium-Ion_Vehicle_Battery_Production_Status_2019_on_Energy_Use_CO_2_Emissions_Use_of_Metals_Products_Environmental_Footprint_and_Recycling.

“Category : Linimnco (NMC) Batteries.” BatterySpace.com/AA Portable Power Corp. Tel: 510-525-2328, https://www.batteryspace.com/LiNiMnCo-Cells/Packs.aspx#:~:text=Lithium%20Nickel%20Manganese%20Cobalt%20Oxide,%2Dscooter%20and%20E%2Dbike.

“How Are Tires Made?” Michelin, https://www.michelinman.com/auto/tips-and-advice/advice-auto/tires-101/how-are-tires-made.

DMU11 - E-Komponenten: ANGST+Pfister Sensors and Power. https://sensorsandpower.angst-pfister.com/fileadmin/products/datasheets/191/DMU11_1640-21436-0051-E-0519.pdf.

Chris Woodford. Last updated: August 21. “How Do Brushless Hub Motors Work?” Explain That Stuff, 21 Aug. 2020, https://www.explainthatstuff.com/hubmotors.html.

“The Sustainability of Electric Motors.” Sphera, 18 Jan. 2021, https://sphera.com/spark/the-sustainability-of-electric-motors/.

“What Is a Kilowatt-Hour (Kwh) and What Can It Power?” ElectricityPlans, https://electricityplans.com/kwh-kilowatt-hour-can-power/#:~:text=According%20to%20the%20EIA%2C%20in,867%20kWh%20%2F%2030%20days.

Abby Sommer

DES 40A

Professor Cogdell

Waste and Emissions Created by the Onewheel

Over the last five years the product Onewheel XR has taken the world by storm. Featuring one large motorized wheel within the center of the board and running entirely on a rechargeable battery, this electric board can travel over a wide variety of terrains hitting speeds up to 19mph and distances of 18 miles. The motorized board accelerates by use of sensors located within the center of the footpad giving the users a hands free and seamless ride. Onewheel utilizes digital technology to create an experience that mimics the “float and carve” elements surfing first provided the board sport community. Designed within Santa Cruz, California, this American based company produces all of its components and parts within their manufacturing facility in San Jose, California. Since its first release in 2015, this electric board’s community has logged over 52,000,000 miles being dubbed one of the next “micromobility” forms of transportation [1] and is both an economic and more environmentally friendly way to travel. Although this personal transportation device provides an eco-friendly solution to commuting and getting around, the materials required to make this product rely heavily on extraction of heavy metals and chemically altered substances contributing to the global waste and emissions predicament our modern society currently faces.

Today digital technology is everywhere. Use of circuit boards, rechargeable batteries, LED lights, and screens can be found just about at every corner of our modern society. As our informational golden age has begun to peak, so has our global capacity to consume our planet's readily available resources for these products. In effect to this, demand for these raw materials have created such a pressure for mass production that our large scale extraction methods have created destructive ecological problems worldwide. Onewheel defines its experience through use of digital technology including components such as lithium ion batteries, microchips, sensors, motors and LED lights all of which require extraction of heavy metals from the earth. Some of these metals include copper, aluminum, iron, cobalt, manganese and lithium to name just a few of the elements that are commonly involved within these components. Mining by default is an extremely destructive process to any environment. Lithium mining for example is responsible for soil, air and most notably, water contamination. In order to extract this valuable mineral, it takes around 500,000 gallons of water to produce only a ton of lithium [2] posing a huge threat to the limited water supplies available. Additionally the process of extraction has resulted in massive chemical spills into the local’s water supplies and streams, killing fish, livestock and people who consume this intoxicated water. In just about every heavy metals mining operation, a surplus of chemical waste is produced called mine tailings consisting of a toxic mix of crushed rock, water, heavy metals,and toxic chemicals including petroleum by-products, sulfuric acid and cyanide [3]. With the Onewheel being heavily reliant upon conducting metals to operate these digital components, copper is used quite frequently in this product. Just like the rest of these metals listed, the extraction mining process comes once again at an environmental cost. Due to the use of acids used to extract copper, other present minerals such as pyrite and sulfide found at these sites concentrate to produce radionuclides, when exposed to air and water they can react to form sulfuric acid which is prone to leaching other harsh elements such as uranium subsequently producing acid mine drainage, which subsequently contributes to groundwater contamination [4]. Similarly, the extraction of aluminum also produces a similar radioactive waste called red mud which contains iron, aluminum, calcium and sodium at a high alkali content. Currently the United States does not approve of any secondary use of this waste product so there is no reclamation value to clean it up [5]. Out of all the raw materials accounted for in the Onewheel, the metals used for this product’s electronic and mechanical components largely makes up for the majority of the product’s ecological footprint.

Within the manufacturing process, the Onewheel produces a fairly low amount of waste and emissions. At their manufacturing plant located in the southern end of San Jose, California the facility is run on largely renewable energy. According to The City of San Jose’s website, 45% of the electricity provided to the city comes from renewable energy sources along with 41% coming from hydroelectric. As of January 2020, only 14% of San Jose’s power emissions come from carbon emitting resources [6]. One of these carbon producing energy plants includes Metcalf Energy Center located in the Silicon Valley which produces electricity through steam combustion turbines running off of methane gasses [7] that uses “advanced air emissions control technologies”[8]. Even considering that, the energy being provided to Onewheel’s manufacturing facility is being run on comparatively greener energy as opposed to the Nation's average power sources. According to a study done in 2020 by the US Energy Information Administration, about 60.6% of our country’s electricity is produced by fossil fuels with 40.5% being natural gas, and 19.3% from coal and 0.2% from other sources [9]. Although not run entirely on zero emissions, the Onewheel’s manufacturing plant runs on a comparatively more sustainably powered grid of electricity. Within the manufacturing process a few chemicals and air pollutants are produced while making the components for their devices. The creation of circuit boards made on site for example requires a long list of acid and alkali based chemicals in order to follow the subtractive based process it takes to create it. Wastes in total, include airborne particulates (from etching, sanding, cutting, drilling, ect..), acid fumes, spent acid solutions, catalyst solutions, and electroless copper baths [10]. The rest of the components used aren't specified if they are produced directly in the facility, but all of the components are hand-pieced together on site. Overall the manufacturing process does not produce a significant amount of waste or emissions since it can all be fairly contained at the site.

Although the energy used to power the manufacturing facility uses a fairly low emissions electricity source, a large part of the Onewheel’s carbon footprint can be pinpointed down to the transportation of the finished product across the country and world. The Onewheel is shipped all around the world at over 750 store locations, all of which are produced and shipped out from its manufacturing facility in San Jose, California. Onewheel uses shipping providers such as UPS and FedEx to send out their shipments, both of which at the moment aren't entirely carbon neutral companies. Although as of now these companies are working to provide carbon offsetting, such as UPS’s Carbon Neutral Shipping option [11] or FedEx’s pledge to become carbon-neutral by 2040 [12], Onewheel currently does not offer any of these carbon offsetting options in their shipping services at checkout. It is unclear if this company imports a large portion of its secondary materials or if it is all completely processed on site. One imported material is the specialized rubber tire central to this product, which is made from a formula one race tire manufacturer shipped in Italy [13]. Unfortunately with no proposed plans for carbon offsetting or current greener shipping options, Onewheel’s global distribution system for their product contributes to transportation emissions.

Maintenance for the Onewheel is relatively minute for such a complex product. One of the most common parts that require replacement is the tire and the battery. Assuming the user follows the battery maintenance instructions, including storing the board indoors in mild temperatures, not fully charging or draining the battery every time and only doing occasional overnight charges around once a month, the battery should last for 500 or more charges [14]. According to various Onewheel forums, users have said their batteries last on average 5-8 years before requiring replacements. The second and probably most prolific replacement for this product includes the tire which lasts around 1000 miles on average [14]. Users stated that this usually requires a replacement around the first year if ridden on an average 3 miles per day. In order to use this motorized board properly, it requires charging for on average 110 minutes via the 110 V AC input charger. In total this uses 0.368 Kwh per charge which based on comparison to the distance and speeds it is able to accelerate to, is a significantly small amount of energy consumption [15]. Interestingly when calculating all of the charges done to produce Onewheels landmark achievement of 52,000,000 collective miles in the community [1], only about 1,275,733 Kwh have been used globally to charge this device in total [own calculations]. Once again to put this into perspective, that would be the equivalent of a 500 Mw coal power plant running for only 3.5 hours to charge all of those 52,000,000 miles ridden by users [own calculations]. Considering the “maintenance” of charging this product, the general emissions produced collectively are relatively small. This once again shows the potential that electric transportation can have in the future for our society at reducing our fossil fuel impact by switching our reliance from petroleum based transportation to electric batteries. In reality, this relative emissions estimate could be even smaller since I calculated focusing solely on the energy sourcing from a coal plant. If users run their homes off of solar or renewable energy the general energy emissions may have been a smaller amount in total. Onewheel builds their product to last offering a 2000 km warranty to back up their product. Through use of numerous tests within the manufacturing process via their customized “QC Devices” (which test the microchip processors), Onewheels are tested routinely throughout building their product giving a greater assurance to the consumer that the components will be less likely to fail when purchased [13]. Subsequently their manufacturing commitment to use high quality components enforces a long lifespan to prevent both component failure and need for wasteful replacement.

As a complex electronic and mechanical device, the Onewheel is challenging to recycle. Components would have to be completely stripped and organized meticulously in order to recycle each separate object that fit according to the recycling standards practiced. The outer aluminum rim, numerous wires used, and metal brushless motor can be smelted down into reusable metals again. The circuit boards present within the microchip processor are more difficult to recycle yet possible due to advancements in recent years over resource potential for microchip reclamation [16]. Currently, Onewheel doesn't offer a solution to recycling their product making the option of finding a facility that will willingly accept it for recycling purposes low. In effect, the chances of these products being meticulously broken down and stripped of each of their heavily processed materials highly unlikely thus leaving the issue of what will happen to Onewheels once the owners lose their interest in it.

Even in this day and age as our societal values shift to a more environmentally conscious mindset, it is incredibly hard to run an internationally distributed product and maintain zero emissions or ecological impacts on the environment. Due to our globalized economy, raw materials have to travel thousands of miles to get from extraction to processing. The strain of high demand for our ever growing population's needs and desires have led to unethical extraction methods prioritizing efficiency and quantity over sustainability measures. One single product being created may not have a global impact upon the environment, yet due to our industrial scale and modern living expectations, we have stretched our processing methods to an extreme. The Onewheel is a product that follows a relatively ethical mindset of manufacturing at the loss of reliance on our current system’s exploitation of resources. The leading harm of the life cycle of the Onewheel is the extraction of all the metals and petroleum based materials required for its components. Being a compex technologically based product results in an instant footprint on wastes and emissions created. In order for the Onewheel to fix these imprints it will have to derive its minerals from sustainably sourced metal mines, work to reuse old plastics for their products along with reusing pre-used metals. To cut off external emissions contributed by their facility’s power strip, the installation of solar panels can solve this issue providing a direct green energy standard to their manufacturing process. Emissions can be reduced in transportation by implementing only carbon offset shipping services. Onewheel maintains a high standard of quality that builds their products to last for many years to come; by shifting some of their services and distribution methods to center around sustainable practices, their products' life cycle can easily shift to a sustainably produced product. Just like many other modern companies, the shift may take some additional time and finances but will have a long lasting positive impact on both the company's integral ethical code and commitment to the future.

Bibliography

[1] Fons, Garin, and Onewheel. “50-Million Miles: Onewheel Achieves Micromobility Milestone.” 50-Million Miles: Onewheel Achieves Micromobility Milestone, 10 June 2021, https://www.prnewswire.com/news-releases/50-million-miles-onewheel-achieves-micromobility-milestone-301309592.html.

[2] Katwala, Amit. “The Spiralling Environmental Cost of Our Lithium Battery Addiction.” WIRED UK, 5 Aug. 2018, https://www.wired.co.uk/article/lithium-batteries-environment-impact.

[3] “Tailings.” Earthworks, 17 June 2021, https://earthworks.org/issues/tailings/.

[4] United States, Congress, Department of Interior of the Interior. TENORM: Copper Mining and Production Wastes, Environmental Protection Agency . https://www.epa.gov/radiation/tenorm-copper-mining-and-production-wastes.

[5] United States, Congress, Department of Interior of the Interior. TENORM: Bauxite and Alumina Production Wastes, Environmental Protection Agency . https://www.epa.gov/radiation/tenorm-bauxite-and-alumina-production-wastes.

[6] “SAN JOSE CLEAN ENERGY SERVICE GETS CLEANER IN 2020, RATES REMAIN 1% BELOW PG&E.” City of San Jose Blog , 16 Jan. 2020, https://www.sanjoseca.gov/Home/Components/News/News/646/4765.

[7] United States, Congress, California Energy Commission . Metcalf Energy Center, California Energy Commision. https://www.energy.ca.gov/powerplant/combined-cycle/metcalf-energy-center.

[8] Calpine Power Company . “Metcalf Energy Center.” Calpine, https://www.calpine.com/metcalf-energy-center.

[9] “What Is U.S. Electricity Generation by Energy Source?” Frequently Asked Questions (FAQs) - U.S. Energy Information Administration (EIA), U.S. Energy Information Administration (EIA), 2 Nov. 2021, https://www.eia.gov/tools/faqs/faq.php?id=427&t=3.

[10] Leu, David, et al. 1st ed., United States Environmental Protection Agency, Cincinnati, Ohio, 1990, pp. 1–83, GUIDES TO POLLUTION PREVENTION: The Printed Circuit Board Manufacturing Industry. https://archive.epa.gov/sectors/web/pdf/01050.pdf

[11] Peirce, Freddie. “What You Need to Know about UPS Green Shipping and Carbon Footprints: Logistics.” Supply Chain Digital, 17 May 2020, https://supplychaindigital.com/logistics-1/what-you-need-know-about-ups-green-shipping-and-carbon-footprints.

[12] “Fedex Commits to Carbon-Neutral Operations by 2040.” FedEx Newsroom, FedEx, 3 Mar. 2021, https://newsroom.fedex.com/newsroom/sustainability2021/.

[13] Chan, Norman, director. Adam Savage Builds a Onewheel Electric Skateboard! Performance by Kyle Doerksen, and Adam Savage, Tested, 21 June 2018, https://www.tested.com/making/833809-adam-savage-builds-onewheel-electric-skateboard/. Accessed 29 Nov. 2021.

[14] C, Andy. “How Long Does a Onewheel Last? Battery, Tires (the Answers!): The Tech Leaders.” The Tech Leaders | Technology and Ridables, 11 Aug. 2020, https://thetechleaders.com/how-long-does-a-onewheel-last-battery-tires-the-answers/.

[15] W, Micheal. “Cost of Electricity to Charge a Onewheel in Los Angeles.” Onewheel Forum, Onewheel, 14 Dec. 2017, https://community.onewheel.com/topic/6717/cost-of-electricity-to-charge-a-onewheel-in-los-angeles.

[16] Printed Circuit Board Recycling Methods, Environmental Protection Agency , 2012, pp. 1–10. Workshop Materials on WEEE Management. https://www.epa.gov/sites/default/files/2014-05/documents/handout-10-circuitboards.pdf

April Perez

Daniel Ramos, Abby Sommer

DES 40A

Professor Cogdell

Life Cycle Paper

With the rise of technology over the past few decades, it comes to no surprise that mankind’s products are converting to electronic devices. One of the most successful examples of this is the Onewheel XR electric skateboard. Created and designed by Kyle Doerkenson in Santa Cruz, California, the Onewheel XR skateboard has been a successful technological innovation. Differentiating itself with not only its one wheel but its mission to save the planet. Onewheel was designed to create change not only in the skateboard industry or even transportation industry, but in sustainability for a better Earth. With top speeds of 19 mph at a 12-18 mile range, the XR credits this to its Hypercore ™ brushless motor. Like any other product in today’s age, the XR is technologically savvy with its own intelligent LED lights, sensors, and app connectivity. Although Onewheel has done a great job with technological utilization, what steps were taken to make all parts of the XR board possible? Everything starts from nothing, therefore it is important to take a look at where it all began; the raw materials. There is no doubt that the Onewheel Xr board was created with the most advanced technology and intention to create a better Earth, but within this creation, its raw materials have not been as sustainable or great for the environment.

The first step in creating this board was finding out where to find the necessary materials to make this board a technological reality. The Onewheel XR board is fundamentally made of these materials: a 750W Hypercore(™) hub motor, an NMC battery, solid state MEMS 6-DOF sensors, an ItalianVega rubber tire, billet alluminum frame rails, African Mahogany wood footpads, silicon carbide sandpaper grip tape, and intelligent LED lighting. But within each of these necessary raw material components, comes its own process. When looking at the 750W Hypercore ™ hub motor, it is essentially an electric motor. Electric motor material is essentially made up of either powder material or electrical steel [1]. The powder material is most commonly used and is made up of heavy metal extractions. These metals consist of iron, cobalt, and nickel, all metals essential for the future of sustainability []. The next material is the NMC battery, also known as Lithium-Nickel-Manganese-Cobalt-Oxide (NMC is the abbreviated version). The NMC battery is made up of 1-1-1 ratio of nickel, cobalt, and manganese. Given the high expense of cobalt and its limited supply, this is not the best when it comes to sustainability or making a better earth [2]. The third component of the XR board are the MEMS 6-DOF sensors short for microelectromechanical systems with six degrees of function, or axis of rotation.

Works Cited

“Engineering the Onewheel Experience with Additive Manufacturing.” Stratasys, https://www.stratasys.com/explore/case-study/one-wheel.

“Onewheel Accessories - the Comprehensive Onewheel Accessory Informatio.” The Float Life, https://thefloatlife.com/pages/onewheel-accessories.

“Onewheel off-Road E-Skateboard.” The Electric Wheels, 24 June 2021, https://theelectricwheels.com/electric-skateboards/onewheel-off-road-e-skateboard/.

“Onewheel Pint vs. Onewheel+ XR.” Onewheel // Future Motion, https://onewheel.com/pages/onewheel-pint-vs-onewheel-xr.

Savage, Adam. Adam Savage Builds a Onewheel Electric Skateboard! - Youtube. https://www.youtube.com/watch?v=2ZjxvW17cZ0.

“Science behind the Sport: Board Materials.” Science Behind the Sport | West Virginia University, https://sciencebehindthesport.wvu.edu/science-behind-skateboarding/board-materials

“Science behind the Sport: One Wheel.” Science Behind the Sport | West Virginia University, https://sciencebehindthesport.wvu.edu/science-behind-skateboarding/one-wheel.

TechCrunch. Onewheel Factory Tour - YouTube. https://www.youtube.com/watch?v=KrPRvP2H_v0.

Accardo, Antonella, et al. “Life Cycle Assessment of an NMC Battery for Application to Electric Light-Duty Commercial Vehicles and Comparison with a Sodium-Nickel-Chloride Battery.” Applied Sciences, vol. 11, no. 3, 2021, p. 1160., https://doi.org/10.3390/app11031160.

Technology, Horizon. “Electric Motor Design 101: Choosing a Best-Fit Material.” Electric Motor Design 101: Choosing a Best-Fit Material, https://www.horizontechnology.biz/blog/best-materials-for-electric-motor-design.