Design Life-Cycle

assess.design.(don't)consume

Iyesha Puri

DES 40A, Fall 2016

December 1, 2016

Raspberry Pi LifeCycle: Materials

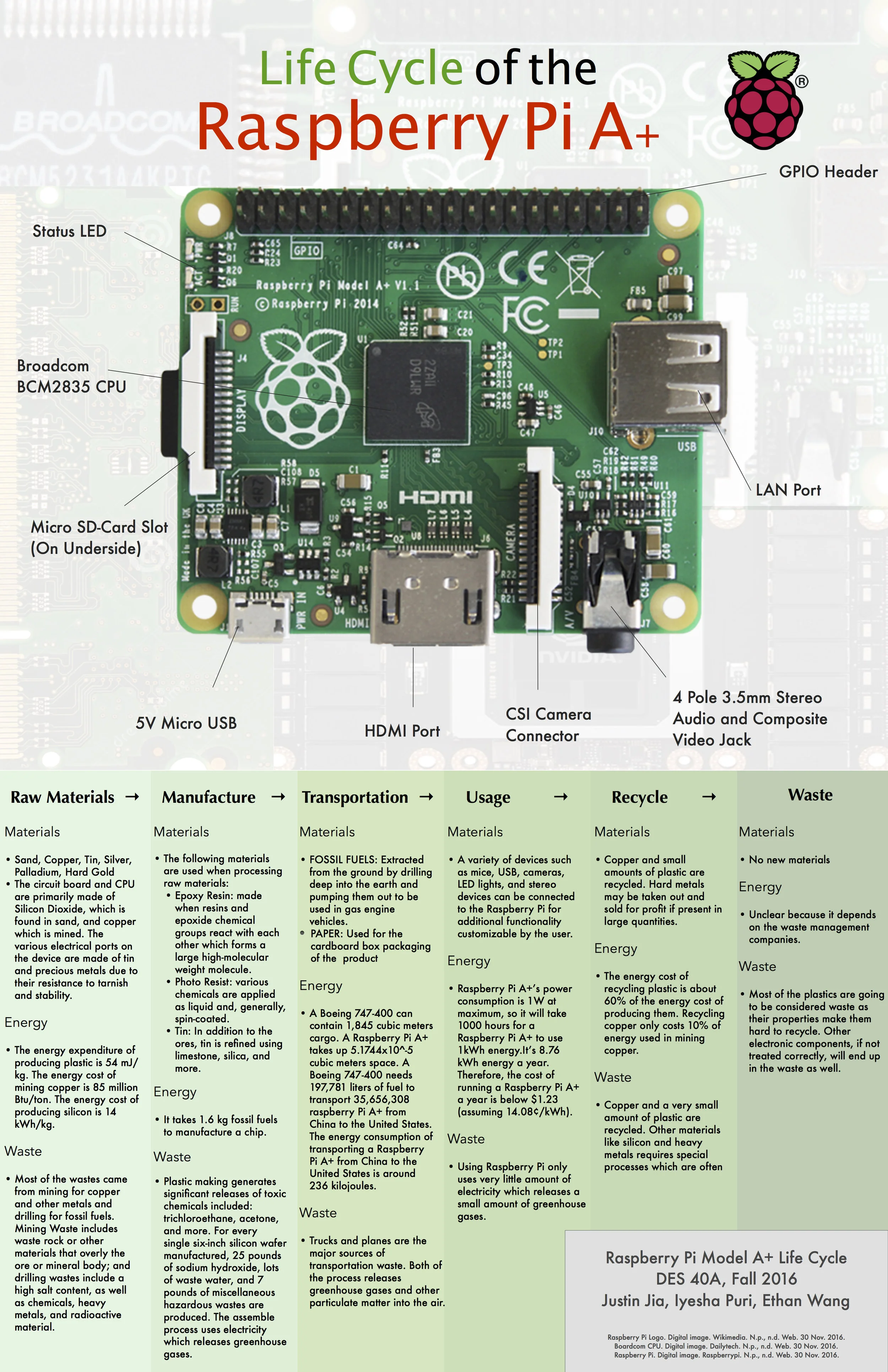

I’ll be honest, the first time someone mentioned the word ‘Raspberry Pi’ to me, I undoubtedly thought of the food item; soon enough, I realized that a pie made no sense in the given context and I was enlightened with knowledge of this new technology. So, how did this peculiar name come to be? “Raspberry” is an homage to early computer companies being named after fruit, like Apple, Tangerine Computer Systems, and Acorn (which ultimately inspired this microcomputer’s design). The “Pi” derives from the original idea to make a small computer to run only the Python programming language (Chen). In fact, today there even exists a Banana Pi and Orange Pi, both of which are competitors with the Raspberry Pi. It’s interesting that when many competitor products have similar functionality, we use aesthetics or size to choose the “best one”, but almost never base our decision off of the life cycle of the product: the energy usage and sustainability. The evaluation of a product should primarily rely on its life cycle and its environmental impacts. Through this project, we aim to break down the processes of the Raspberry Pi to assess its entire life cycle, emphasizing upon the materials, energy, and waste.

The Raspberry Pi is essentially a cheap credit-card sized micro PC which was developed as a response to the lack of a computer-literate younger generation, attempting to make computing more accessible around the globe. It is a versatile product that can function as a proper desktop computer, but is most generally used as an add-on functionality to smart devices.

Like most digital technology, the Raspberry Pi is composed of a variety of intricate components, each with its own set of raw materials and production processes. Its basic structure consists of a circuit board, Broadcom CPU, and various electrical connectors. The lifecycle of each of these components begins with variety raw materials, which go through prolonged processes to end up a certain way in the finished product (Raspberry Pi Hardware).

The frame of the Raspberry Pi is essentially the circuit board, whose two major constituents are fiberglass, which provides insulation, and copper, which forms conductive pathways. Although it is difficult to pinpoint the birthplace of this fiberglass and copper, it is safe to assume that the sand used for fiberglass is being mined in sand quarries in Asia, which has led to its rapid economic growth and boom in construction. The sand that is found in most deserts is “unsuitable for concrete and land reclaiming since wind erosion process form round grains that do not bind well.” However, this extraction process plays a toll on the biodiversity; the volume being extracted is having a major impact on rivers, deltas and coastal and marine ecosystems (Green Facts).

With the acquisition of these raw materials, molten glass is ejected to produce glass fibres woven to create a sheet of fiberglass fabric. The sheet is infused with epoxy resin and heated to harden the resin. Next, a photosensitive material called photo-resist is applied to both sides of the copper-clad laminate; here, ultraviolet light is used rather than visible light so the board can be handled safely in daylight. Next, the board is immersed in a chemical solution to develop the latent image. Finally, the board is electroplated with tin, which, once again, only adheres to those areas of the board that will form the pads and tracks. The tin serves three purposes: “it prevents the copper tarnishing; it provides a surface that can be soldered to more easily than copper; and it acts as a resist (after first removing the remaining photo-resist).” Lastly, solder paste, a mixture of solder powder and flux, is printed onto pads on the top surface of the board where the contacts of the surface-mounting components will be melted. (Tech Radar).

Within the circuit board lies the most essential component of any electronic device, its CPU. Sand contains high percentages of silicon in the form of silicon dioxide, the base ingredient for semiconductor manufacturing. This sand is mined in the same manner as that of the sand used in the circuit board. After silicon is extracted from the sand, it is purified in multiple steps to reach the Electronic Grade Silicon used in semiconductors. Electronic Grade Silicon may only contain one alien atom per one billion Silicon atoms. One big crystal is grown from the purified silicon called an ingot. The ingot is cut with a very thin saw into individual silicon slices (called wafers), each of which are then polished to a flawless mirror-smooth surface. A photo resist liquid is then poured onto the wafer while it spins at high speed, depositing a thin and even resist layer across the entire surface. Next, an ultraviolet laser is shone through masks and a lens causing tiny illuminated UV lines on the surface. Everywhere these lines strike the resist, a chemical reaction takes place making those portions soluble. The soluble photoresist material is then completely dissolved by a chemical solvent. From there, an etching chemical is used to partially dissolve (or etch) away a tiny quantity of the polished semiconductor material (the substrate) (Anthes).

Aside from the circuit board and CPU, there are various electrical ports on the device that the user can use to connect various devices to. Precious Metals are commonly used in connector applications for their resistance to tarnish and stability in unfavorable environments. Typically, these are Silver, Palladium or Hard Gold based – or they may also be multilayer systems such as gold-capped palladium in order to reduce precious metal usage. “Tin is a widely used electrical contact finish due to its malleability and the ability to easily displace tin oxide at the mating surfaces.” Additionally, tin plating can be combined with Noble Metal contacts to provide corrosion resistance to the connector spring alloy (Materion).

Although the principal stages of material usage in the Raspberry Pi life cycle are raw material acquisition and manufacturing, the subsequent processes of distribution, use, recycling, and waste management introduce new materials. Many consumers do not consider fossil fuels in a life cycle of a product, but important to realize that in order to transport and distribute materials to different production sites and retail locations, large quantities of fossil fuels are consumed. The raw materials required for fossil fuels are oil and coal, both of which are harvested underground, and are used to fuel engines for transport vehicles; however, most of the United States’ fossil fuels are outsourced from Saudi Arabia, Venezuela, or Mexico, so one can imagine how much extra materials and energy are required to obtain fossil fuels in the first place. In addition, recycled paper is used for the packaging (US Energy Information Administration).

Since the Raspberry Pi is so customizable, the use phase of the Raspberry Pi varies from consumer to consumer. In general, most consumers use the ports on the device to connect other devices. In an article titled, “Top 10 things to Connect to your Raspberry Pi”, the most interesting devices I found were movement sensors, which are great for security systems or robotic sensors and USB wifi dongles, which can connect your Raspberry Pi to a network without any cables (Hawkins). As far as maintenance of the device goes, only the Raspberry Pi’s software needs to be updated for security patches and improvements, but the hardware usually stays intact.

Most would think that the cycle of a product ends here, but there is a lot of behind the scenes work in terms of recycling and waste management that must be accounted for. Recycling and waste management are less materials heavy, and more energy and waste heavy; but there are interesting facts to note. With the continuous change in technology, electronic devices are disposed of and upgraded on a regular basis by both individuals and businesses. This continual change generates a huge amount of waste computers which need to be recycled. The computers can be stripped down and all of the internal components removed (batteries removed, metal frames dismantled etc), and the remainder of the components can be refined for precious metal recovery. Computer components contain an array of precious metals (Gold, Silver and Palladium). They also have a high percentage copper content. All of these metals can be recovered through a refining process, allowing the components to be fully recycled and no waste ending up in landfill. However, for a device as small as a Raspberry Pi, there isn’t nearly enough precious metal in the device that would justify the energy needed to remove precious metals; however, in larger devices, this is a common practice (AWA Refiners).

To conclude, although the final product of the Raspberry Pi is as small as a credit card, its life cycle requires a lengthy list of materials to create, transport, maintain, and recycle. This goes to show that if a simple product has a this complicated a life cycle, life cycles of larger objects are even more so. By going through a thorough life cycle assessment, we hope to bring awareness to consumerism and emphasize the importance of environmentally friendly products. When various electronic products have the same functionality, our decision should stem from the life cycle of the product. At the end of the day, what uses the least energy and leaves the cleanest footprint on our Earth?

Bibliography:

Anthes, Gary. "Making Microchips." Computerworld. Computerworld, 08 July 2002. Web. 01 Dec. 2016.

Chen, Francis. "What Is the Story behind the Name "Raspberry Pi"?" Quora. N.p., 16 June 2014. Web. 27 Nov. 2016.

"ELECTROPLATED CONNECTOR MATERIALS." Electroplated Connector Materials. Materion, n.d. Web. 01 Dec. 2016.

Hawkins, Matt. "Top 10 Things to Connect to Your Raspberry Pi." Raspberry Pi Spy. N.p., 19 Mar. 2013. Web. 01 Dec. 2016.

"How Motherboards Are Made: A Miracle of Modern Electronics." TechRadar. TechRadar The Source for Tech Buying Advice, 15 Aug. 2010. Web. 01 Dec. 2016.

"Product Of The Week – Motherboards." AWA Refiners Limited. N.p., n.d. Web. 01 Dec. 2016.

"Raspberry Pi Hardware." Raspberry Pi Hardware Documentation. Raspberry Pi Foundation, n.d. Web. 01 Dec. 2016.

"The Mining of Sand, a Non-renewable Resource." Green Facts. N.p., n.d. Web. 01 Dec. 2016.

"U.S. Crude Oil Imports." U.S. Crude Oil Imports. US Energy Information Administration, 30 Nov. 2016. Web. 01 Dec. 2016.

Justin Jia

Full Energy Life-cycle of Raspberry Pi A+

Raspberry Pi A+ is a tiny yet fully functional and affordable single-board computer. Compared to its predecessor Raspberry Pi A, it delivers stronger performances yet consumes less power (“Raspberry pi model A+.”). Built from low-cost components, the Raspberry Pi A+ operates at a maximal cost of $1.23 a year, when running 24 hours a day and 7 days a week. Although the energy consumption of a Raspberry Pi A+ is relatively low compared to other computing devices, one cannot ignore the energy cost accumulated throughout the lifecycle of Raspberry Pi A+, including the energy used in acquiring, processing, and manufacturing of the raw materials used to create the devices, distributing the devices to end users, running the devices, recycling or disposing them.

The energy used of acquiring raw materials of the Raspberry Pi A+ is relatively low, since the Pi does not need a lot of materials and most of them are pretty common raw materials that can be easily acquired. Most of the raw materials used to manufacture the Raspberry Pi A+ are copper, plastic, and silicon (glass fibers). The Raspberry Pi A+ can be treated as a single PCB board. Usually a PCB board is made from 30% metals (mostly copper), 40% glass fibers (mostly silicon), and 30% other materials (mostly plastic), as shown in Metals Content in Printed Circuit Board Waste (Szałatkiewicz). According to RoHS Certificate of Compliance, each of other rare or toxic materials, like Lead, Mercury, and Cadmium, accounts for less than 0.1% of the total materials used to build a Raspberry Pi A+, so the energy cost related to extracting those materials can be ignored. Based on the data from Energy for Plastic, the energy expenditure of producing plastic ranges from 36,000 kilojoules per kilograms to 54,000 kilojoules per kilograms (Hamman). According to Energy Used in the Copper Industry, “mining uses about 20 percent of the total energy requirement; milling around 40 percent; and smelting, converting, and refining the remaining 40 percent.” (Office of Technology Assessment) In combination, the energy cost of mining copper is estimated to be 85 million Btu per ton. Converting to kilojoules and kilograms, it is equal to 98,855 kilojoules per kilograms (Office of Technology Assessment). Based on the data from Refining Silicon, the energy cost of producing silicon is between 14 kilowatt-hour per kilograms and 16 kilowatt-hour per kilograms (PVEducation). Using kilojoules as the unit, they are equivalent to 50,400 kilojoules per kilograms and 57,600 kilojoules per kilograms. The website Pi Zero vs A+ Pro and Cons states that a Raspberry Pi A+ weights about 23 grams (Mike). Ignoring other rare materials, one can say that a Raspberry Pi A+ is roughly made from 30% copper, 40% silicon, and 30% plastic. Therefore, to produce a Raspberry Pi, at least 6.9 grams copper, 9.2 grams silicon, and 6.9 grams plastic are needed at minimum. It needs 682 joules, 530 joules, and 373 joules of energy to acquire each of them representatively. Hence, the total energy used for acquiring raw materials of a Raspberry Pi A+ is roughly around 1.6 kilojoules. Although the number does not include the energy used for acquiring other raw materials used for packaging, nor accounting intermediate materials may be used during the process, it’s still a relatively low number.

However, the cost of manufacturing the Raspberry Pi A+ is a lot higher than the cost of acquiring the raw materials. As shown in the Raspberry Pi A+ Data-sheet, the Pi has a design similar to a full size computer. It features: a Broadcom BCM2835 chip, a 700 MHz Low Power ARM1176JZFS Applications Processor, a Dual Core VideoCore IV® Multimedia Co-Processor, a 512 MB SDRAM, and 7 different ports including a 40 pin GPIO connector, a HDMI Digital AV Output, a 3,5mm headphone jack AV Output, aUSB 2.0 Connector, a 15 pin MIPI Camera Connector, a 15 pin Display Connector, and a Micro USB Socket (“Raspberry Pi”). Although the energy cost of manufacturing each specific components is not available to the public, one can find manufacturing energy consumption studies of similar products. According to The 1.7 Kilogram Microchip: Energy and Material Use in the Production of Semiconductor Devices, usually it takes 1.6 kilograms fossil fuels to manufacture a silicon chip. (Willams, Ayres, and Heller). If using coal as the primary energy source, 1.6 kilograms coal can produce about 46,892 kilojoules energy (“Convert Kilograms Hard Coal to Joules - Energy Converter”). The Raspberry Pi A+ features 3 chips and 7 connectors on board, so the manufacturing process will use at least hundreds of thousands of kilojoules energy. The manufacturing process accounts for most of the energy consumption in the entire lifecycle of the Raspberry Pi A+.

The energy consumption of transportation cannot be ignored as well. Most of the energy used during the transportation is coming from airplane from China to the United States, since Raspberry Pi A+ is made in China, according the the label on the chip. A Boeing 747-400 with 240,000 liters of fuel can fly approximately 8,800 miles (MacKay). Distance from China to the United States is 7,252 miles (“Distance from China to United States”), and a Boeing 747-400 can contain 1,845 cubic meters cargo (“Boeing 747 400F Specs, Payload Capacity, Cost, Pictures”). In this case, ignoring the package, the size of a Raspberry Pi A+ is 66x56x14mm, which will take up to 5.1744x10^-5 cubic meters space (“Raspberry Pi.”). Therefore, a Boeing 747-400 needs 197,781 liters of fuel to transport 35,656,308 raspberry Pi A+ from China to the United States. For each individual Raspberry Pi A+, it will cost around 5.5 milliliters of aviation fuel. According to Energy Density of Aviation Fuel, the energy density of aviation fuel is around 43,000 kilojoules per kilograms (Elert). So the energy consumption of transporting a Raspberry Pi A+ from the factory to the end user (assuming located in the United States) is above 236 kilojoules.

The cost of running a Raspberry Pi A+ a year is below 1.23 UC Dollars (this number may vary depending on the energy tariff). According to Raspberry Pi Model A+, Raspberry Pi A+’s power consumption is 1 Watt at maximum, so it will take 1000 hours for a Raspberry Pi A+ to use 1kWh energy (“Raspberry pi model A+.”). A year has 8760 hours (assuming 365 days a year), so at maximum, a Raspberry Pi A+ will use 8.76 kWh energy, or 31,536 kilojoules of energy, per year. According to Electricity Local, the average commercial electricity rate in Davis is 14.08¢/kWh (“Davis, CA Electricity Rates”). As a result, the overall cost of running a Raspberry Pi A+ for a year is about 1.23 UC Dollars for the worst case scenario. Because in real life the Pi will not keep running at full speed all of the time, the actual cost should be a lot lower than the estimated cost. If it is running at 75% of the maximum power in average, the cost should decreases to 0.92 UC Dollars. It’s about 23,000 kilojoules energy. Assuming the average lifetime of a Raspberry Pi A+ is 3 years, the total running energy is still less than 100,000 kilojoules.

The energy life-cycle of Raspberry Pi A+ should also accounts for the energy used during the recycling process of the product, since energy is also required during recycling and disposal. Although recycling usually consumes more energy than landfilling, which usually does not need energy, it is still more energy efficient than acquiring raw materials. According to Recycling of Plastics, the energy cost of recycling plastic is about 60% of the energy cost of producing plastics from oil (“Recycling of Plastics”). Benefits of Recycling also claims that recycling copper only costs 10% of energy used in mining copper, which usually needs a lot of energy (“Copper Recycling and Sustainability - Benefits of Recycling”). Recycling other materials used in the Raspberry Pi A+, like silicon, gold and sliver are also beneficial. Recycling can not only minimize the waste, but also reduce the energy consumption if viewing from the entire life cycle.

The overall energy cost of a Raspberry Pi A+ is a lot more than just the running energy cost of the device. To be more specific, the running energy cost only accounts for less than 50% of the overall energy cost. The entire energy lifecycle includes energy used in acquiring raw materials like copper, silicon, and plastic, manufacturing the components, like the CPU, GPU, RAM and other ports, assembling them together, transporting the finished product from the factory to end users, running the device, and finally recycling the waste. Although the Raspberry Pi A+ is a relatively energy efficient device comparing to its peers, one cannot ignore the overall energy cost of the device. However, a Raspberry Pi A+ is still a lot more eco-friendly and cost less overall energy comparing to full size computers. Using it to replace other full size computers in a bigger system can still greatly decrease the overall energy consumption and benefit the environment.“Boeing 747 400F specs, Payload capacity, cost, pictures.” AircraftCompare. 2015. Web. 1 Dec. 2016.

“Convert kilograms hard coal to joules - energy converter.” Unit Juggler. 2008. Web. 1 Dec. 2016.

“Copper recycling and sustainability - benefits of recycling.” copper. schoolscience, n.d. Web. 1 Dec. 2016.

“Davis, CA electricity rates.” Electricity Local. Electricity Local, 2016. Web. 1 Dec. 2016.

“Distance from china to United States.” DistanceFromTo. 2009. Web. 1 Dec. 2016.

Elert, Glenn. “Energy density of aviation fuel.” The Physics Factbook. 2003. Web. 1 Dec. 2016.

Hamman, Curtis. “Energy for plastic.” Physics 240. 24 Oct. 2010. Web. 1 Dec. 2016.

MacKay, David. Sustainable energy - without the hot air. n.d. Web. 1 Dec. 2016.

Mike. “Pi Zero vs A+ - pros and cons.” Raspberry Pi. 26 Nov. 2015. Web. 1 Dec. 2016.

Office of Technology Assessment. Copper: Technology and Competitiveness. Washington, D.C.: U.S. Government Printing Office, 1988. Print.

PVEducation. Refining Silicon. n.d. Web. 30 Nov. 2016.

“Raspberry pi model A+.” RS Online. 2012. Web. 1 Dec. 2016.

“Raspberry Pi.” RS Components. n.d. Web. 1 Dec. 2016.

“Recycling of Plastics.” Recycling of Plastics. n.d. Web. 1 Dec. 2016.

Szałatkiewicz, Jakub. “Metals Content in Printed Circuit Board Waste.” Pol. J. Environ. Stud 23.6 (2014): 2. Print.

Willams, Eric, Robert Ayres, and Miriam Heller. “The 1.7 Kilogram Microchip: Energy and Material Use in the Production of Semiconductor Devices.” American Chemical Society (n.d.): n.pag. Print.

Ethan Wang

Waste and Emission of Raspberry Pi

The Raspberry Pi is a credit card-sized computer that plugs into your TV or keyboard. It is a capable little computer which can be used in electronics projects, and for many of the things that your desktop PC does, like spreadsheets, word processing, internet browsing, and playing games (raspberrypi). It is a product which most people value due to its capability as a mini computer; however, using the device is only one part of its life cycle. From acquiring materials to manufacturing to recycling, it is very important to consider waste management when one considers the lifespan of a Raspberry Pi, especially the waste generated from using electricity as well as all the copper, silicon, and plastic that got thrown away once a Raspberry Pi go on retirement.

The beginning of a Raspberry Pi starts with collecting all of its raw materials. During the mining process of copper and silicon, waste rock or other materials that overlay the ore or mineral body are left over when the valuable fraction is separated from the parts that are not going to be used (Nagaraj). These waste materials are called tailings or mining dumps, and they are usually disposed into tailing ponds, which is a wet storage area for these wastes that allows them to be continuously submerged (CBC News). Tailing ponds all need to be designed correctly and are able to store mining wastes indefinitely. Once a tailing pond is filled, the water can be drained behind it and the process poses no risk (Gavett). Sony Global, which is responsible for assembling the Raspberry Pi, has over 250 suppliers, though it was not clear online which specific suppliers were supplying these materials for the Raspberry Pi (Sony).

The other main material of a Raspberry Pi is plastic acquired through chemical reaction. Oil and natural gas are the major raw materials used to manufacture plastics, and both of them are collected via oil wells (ecologycenter). Drilling waste is roduced by oil wells, which has a high salt content, as well as chemicals, heavy metals, and radioactive material. Due to the fact that drilling waste can cause serious harm to the environment, the oil and gas industry use injection wells to dispose of waste materials where they are processed so they can be stored safely (stateimpact).

While Song Global puts different pieces together to manufacture a Raspberry Pi, the first step of the manufacturing is making plastic. The plastics production process often begins by treating components of crude oil or natural gas in a high pressure environment. This process results in the conversion of these components into hydrocarbon monomers such as ethylene and propylene. Monomers are then chemically bonded into chains called polymers. A special catalyst is added during bonding to speed up the process and when the monomers are finished combining, plastic is created (americanchemistry). During the whole process, while not much solid waste is made, most toxic chemicals are released into the air. Significant releases of toxic chemicals include: trichloroethane, acetone, methylene chloride, styrene and more. Other major emissions from plastic production processes include sulfur oxides, nitrous oxides, methanol, ethylene oxide, and volatile organic compounds (americanchemistry). Despite plastic being one of the most commonly used materials in the world, its negative environmental impact causes some serious concerns.

Besides plastic, silicon wafers that are used to make circuit boards play a huge part in a Raspberry Pi. The two main chemicals used to make silicon wafers are arsenic and silicon. Although silicon is not toxic, arsenic is highly toxic if absorbed through skin, so the production process can be hazardous. In addition, for every single six-inch silicon wafer manufactured, 25 pounds of sodium hydroxide, 2,840 gallons of waste water, and 7 pounds of miscellaneous hazardous wastes are produced (UVIC). When we consider that 6 million Raspberry Pis have been made to date, the environmental costs are enormous (Sony).

Eventually, all materials are put together in Sony’s UK manufacturing plant in Pencoed, South Wales (raspberrypi). In its factory, most waste that is produced during the making of a Raspberry Pi is due to the use of electricity. While there are various ways to produce electricity such as using nuclear power, natural gas, and coal, people are slowly starting to use more renewable energy sources. The main source of electricity generation is still fossil fuel. As a result, it releases nitrogen oxides, carbon monoxide, other greenhouse gases, and atmospheric particulate matter into the air. Because the modern society still heavily depends upon electricity, in order to minimize the negative environmental impact of electricity production, more renewable energy needs to be put into use.

Once a Raspberry Pi is finally finished in the factory, it is ready to be boxed and distributed. Since Raspberry Pis are being sold all over the globe, the transportation methods would include planes and tracks. Planes used for transportation consume a special type of fuel called jet fuel, which is a mixture of a large number of different hydrocarbons (ICAO). During flight, aircraft engines emit heat, noise, particulates as well as gases. Among all the chemicals that are being emitted, carbon dioxide, water vapor, hydrocarbons, carbon monoxide, nitrogen oxides, sulfur oxides and black carbon interact amongst themselves and with the atmosphere, causing the greenhouse effect. According to a study in Finland, during a long distance flight, one hundred and thirteen grams of carbon dioxide are released every time the plane travels one kilometer (LIPASTO). Because global warming has become a more and more urgent concern, people are trying to cut the level of greenhouse gas emissions by increasing aircraft efficiency as well as operation efficiency (aviationbenefits). Similarly, while transporting on tracks or on rail roads, greenhouse gases such as carbon dioxide, carbon monoxide, and nitrogen oxides are released as well (LIPASTO). To fix this problem, car companies have attempted to make more and more hybrid vehicles. Even though most of those companies are aiming at everyday consumers, such technology is slow to apply to current methods of shipping and distribution.

Using a Raspberry Pi is fairly simple; it is like a mini computer. So just like a normal computer, a Raspberry Pi is powered using electricity. According to a study, a Raspberry Pi only has a power of point five two watts (raspi). On the other hand, just like everything else that uses electricity, using the Raspberry Pi is going to release nitrogen oxides, carbon monoxide, other greenhouse gases, and atmospheric particulate matter into the air due to electricity generation through fossil fuel. However, since a Raspberry Pi uses a very little amount of electricity, the environmental impact it causes is very minimal.

The first Raspberry Pi came out in 2012, and the Raspberry Pi Model A+ was just released last year. Such mini computers last for a long time, so there are barely any retired Raspberry Pis. However, they will stop working eventually, and the materials that they are made of such as copper, silicon, and plastic will get recycled or disposed just like other electronic components.

Copper has a history of ten thousand years; it is the best non-precious metal conductor of electricity, and as a result, copper has been picked as the main material for conductors in Raspberry Pis (Leblanc). However, copper waste is iron-rich hazardous waste containing heavy metals such as zinc, cobalt, and lead which would cause harm to the environment (Coruh). Consequently, copper waste cannot be disposed of in its direct form and therefore requires treatment to be stabilized prior to disposal. On the other hand, copper has a really high recycle value as it holds 90 percent of new copper’s value. As a result, it has the potential to be nearly completely recovered after its life in a Raspberry Pi. Both disposal and recycling processes release greenhouse gases. However, the process energy to manufacture one ton of copper from raw materials is 109.23 million Btu, whereas the energy required to recycle one ton of copper waste is around 10 million Btu: the energy requirements for recycled copper are nearly ninety percent less than the processing of new copper from virgin ore (U.S. Environmental Protection Agency Office of Solid Waste). The amount of greenhouse gases are significantly lower for copper recycling which is why, in terms of environmental impact as well as sustainability, copper recycling is the preferable method for obtaining copper.

The other main material for the Raspberry Pi is plastic. It usually can be very dangerous to the environment because chemicals leached from plastics are harmful to the land as well as human health. If deposed of directly, plastics will stay in the environment for a long time because of its stable chemical structure. On the other hand, if plastics are destroyed by incineration, it will pollute the air, land and water and exposes workers to toxic chemicals, including carcinogens (Kosior, Hopewell and Dvorak). Raspberry Pi contains mainly three types of plastic: polymethylpentene (PMP), polyvinyl chloride, and epoxy resin. PMP is considered eco-friendly as it is halogen-free; however, it would still take years to decompose in the environment. PMP is not recycled often due to its high recycling cost; but since a Raspberry Pi only contains a small amount of PMP, the environmental impact is minimal (AZoM). On the other hand, polyvinyl chloride, also known as PVC, is not so environmental friendly as it contains chemicals that may cause cancer. Also it is not degradable so items made from PVC will retain their form for decades (Thornton). What is worse is that PVC is difficult for recycling due to the presence of heavy metals such as lead and cadmium; it has to be treated separately from other wastes. As a result, a very small percentage of PVC is recycled (Bloch). Lastly, epoxy resin is eco-friendly just like PMP, but it also takes years to decompose (westsystem). Moreover, epoxy resin cannot be mechanically recycled, except to be potentially re-used once it has been size-reduced. This is because epoxy resin is permanently cross-linked in manufacture, and therefore cannot be re-melted and re-formed (Yuen).

A retired Raspberry Pi also contains other electronic waste such as silicon, and other minor yet toxic substances (Wath). Releasing these substances into the environment would be hazardous, and we do have the technology to recycle them. Advanced Technology Materials Inc. (ATMI) has developed a selective chemical process: hydrometallurgical processing that recovers valuable materials from electronics using a “green chemistry” technology. The process is cost-effective, environmentally safe, and does not require shredding or grinding, thus reducing the loss of precious metals. However, it does require the electronics to be separated from other everyday wastes (Baeyens, Lettieri, and Salem). Nowadays in 2016, we do have the tools to recycle the non-environmental friendly materials within a Raspberry Pi. However, it also often requires the awareness of consumers as they need to recycle their Raspberry Pi at specific locations (Namias). Though it is a tough task, as more and more campaigns are advocating for our precious environment, greater numbers of people are going to realize the importance of recycling and moving towards a sustainable future.

Bibliography

"Aircraft Engine Emissions." Aircraft Engine Emissions. N.p., n.d. Web. 30 Nov. 2016.

"Contract Manufacturing." Contract Electronics Manufacturing | Sony UK TEC. N.p., n.d. Web. 30 Nov.

2016.

Al-Salem, S.M, P. S, and J. Baeyens. "Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review." Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. N.p., Oct. 2009. Web. 26 Oct. 2016.

Coruh, S. "Treatment of Copper Industry Waste and Production of Sintered Glass-ceramic." Waste

Management & Research 24.3 (2006): 234-41. Web.

"Deep Injection Wells." NPR. NPR, n.d. Web. 30 Nov. 2016.

"Environmental Concerns." Enviornmental Concerns. N.p., n.d. Web. 30 Nov. 2016.

"Environmental Efficiency." Environmental Efficiency : Aviation: Benefits Beyond Borders. N.p., n.d. Web. 30 Nov. 2016.

"Environmentally-friendly Epoxy Resins | JEC Group." Environmentally-friendly Epoxy Resins | JEC Group. N.p., n.d. Web. 30 Nov. 2016.

"Environmental Impacts of Polyvinyl Chloride Building Materials." N.p., n.d. Web. 30 Nov. 2016.

FrontLine. "Tailings Dams Where Mining Waste Is Stored Forever." PBS. PBS, n.d. Web. 30 Nov. 2016.

"Green Living Tips." Green Living Tips RSS. N.p., n.d. Web. 30 Nov. 2016.

Leblanc, Ricky. "Copper Recycling and Its Importance." The Balance. N.p., 1 Aug. 2016. Web. 15 Nov. 2016.

Leblanc, Ricky. "The Facts on Copper Recycling." The Balance. N.p., 31 Aug. 2016. Web. 15 Nov. 2016.

"LIPASTO Data." LIPASTO. N.p., n.d. Web. 30 Nov. 2016.

Lytle, By Claire Le Guern. "When The Mermaids Cry: The Great Plastic Tide." Plastic Pollution. N.p., Apr. 2016. Web. 26 Oct. 2016.

"Material Properties of the Cross-linked Epoxy Resin Compound Predicted by Molecular Dynamics Simulation." Material Properties of the Cross-linked Epoxy Resin Compound Predicted by Molecular Dynamics Simulation. N.p., n.d. Web. 30 Nov. 2016.

"Minerals Recovery and Processing." Minerals Recovery and Processing - Kirk-Othmer Encyclopedia of Chemical Technology - Nagaraj - Wiley Online Library. N.p., n.d. Web. 29 Nov. 2016.

Namias, Jennifer. "THE FUTURE OF ELECTRONIC WASTE RECYCLING IN THE UNITED ..." N.p., July 2013. Web. 16 Nov. 2016.

"Plastics." Lifecycle of a Plastic Product. N.p., n.d. Web. 30 Nov. 2016.

"Plastics Recycling: Challenges and Opportunities." Plastics Recycling: Challenges and Opportunities |Philosophical Transactions of the Royal Society B: Biological Sciences. N.p., n.d. Web. 30 Nov. 2016.

"Pollution and Hazards from Manufacturing." Ecology Center. N.p., n.d. Web. 30 Nov. 2016.

"Polymethylpentene (PMP) / TPX Plastic Recycling” AZoM. N.p., n.d. Web. 30 Nov. 2016.

News, CBC. "Tailings Ponds for Mining and Oilsands Waste: FAQs - Technology & Science - CBC

News." CBCnews. CBC/Radio Canada, 2014. Web. 29 Nov. 2016.

"Raspberry Pi A How Much Power Does It Need?" RasPi.TV. N.p., 2014. Web. 30 Nov. 2016.

Raspberry_Pi. "Raspberry Pi FAQs - Frequently Asked Questions." Raspberry Pi. N.p., n.d. Web. 29 Nov. 2016.

"Silicon Wafer." Silicon Wafer | Environmental Impact. N.p., n.d. Web. 30 Nov. 2016.

"Sony Corporation Global Headquarters." Sony Global - Reducing Waste Generation. N.p., n.d. Web. 30 Nov. 2016.

"Sony Corporation Global Headquarters." Sony Global - Responsible Supply Chain. N.p., n.d. Web. 29 Nov. 2016.

"Third IMO Greenhouse Gas Study 2014’." N.p., n.d. Web. 30 Nov. 2016.

"Streamlined Life-Cycle Greenhouse Gas Emission Factors for Copper Wire." U.S. Environmental Protection Agency Office of Solid Waste, n.d. Web. 26 Oct. 2016.

Wasserman, Elizabeth. "Your Security Resource." How to Dispose of Computers, Cables, Keyboards, Mice and More. N.p., n.d. Web. 16 Nov. 2016.

Wath, Sushant B., P. S. Dutt, and T. Chakrabarti. "E-waste Scenario in India, Its Management and Implications." Environmental Monitoring and Assessment 172.1-4 (2010): 249-62. Web.