Design Life-Cycle

assess.design.(don't)consume

Yuchen Xu

Stephanie Wang, Michelle Liu

DES 40A

Professor Cogdell

16 March 2023

Life Cycle of the Flute: Raw materials

Introduction

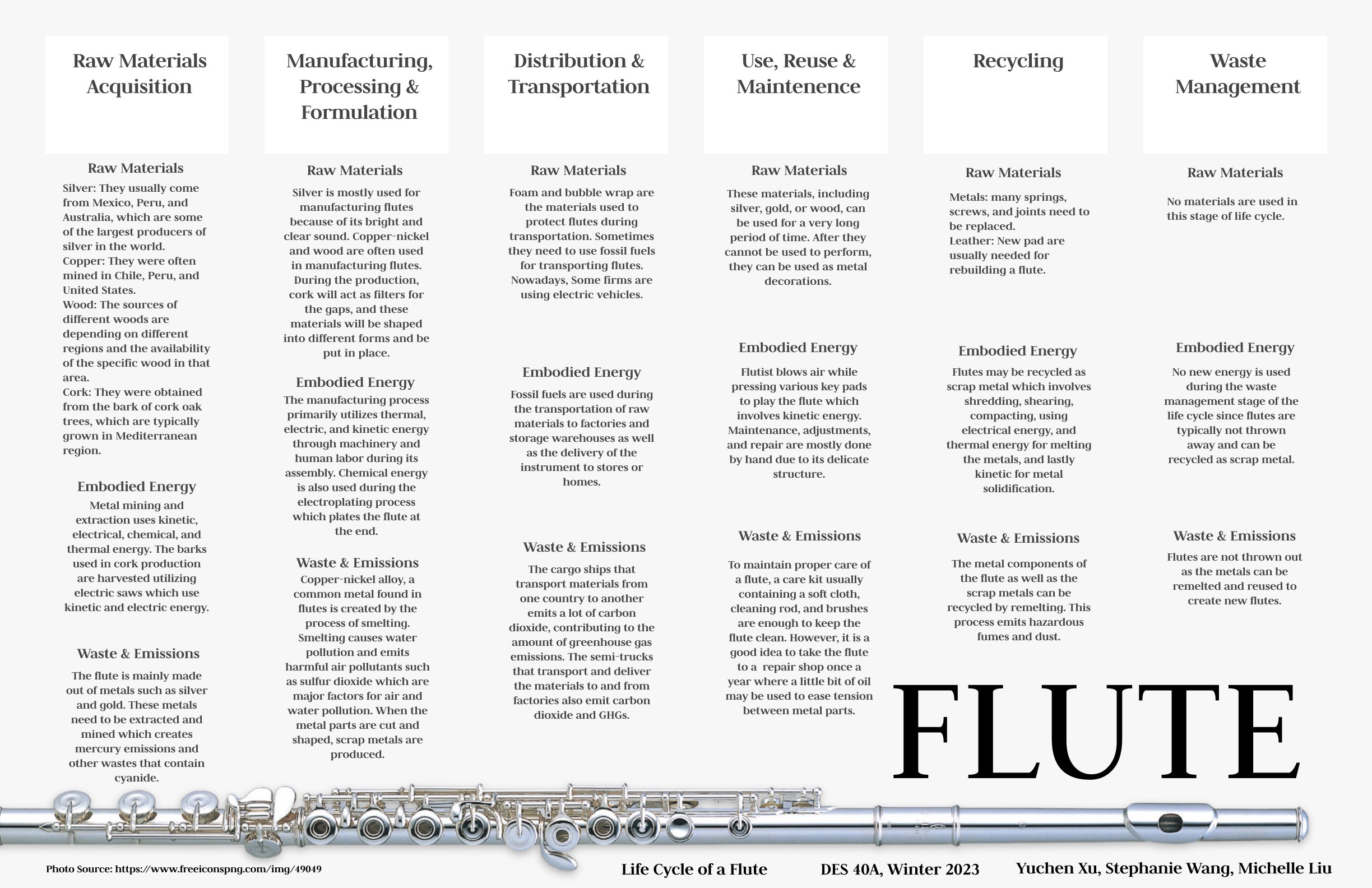

Making musical instruments has always been a fascinating topic, and creating flutes is no exception. Flutes are unique instruments that produce soothing, harmonious tones. The type of raw materials used in their manufacturing impacts the sound's quality. The most common materials used to make flutes are bronze, wood, cork, copper-nickel, gold, silver, and copper-nickel (Hadiya et al.). Each of these materials has distinct sound characteristics that contribute to the flute's overall tone. This paper aims to examine the various raw materials used in flutes' life cycle, including the acquisition, processing, transportation, maintenance, reuse, recycling, and waste management. It also aims to understand the flute production method and its environmental effects.

Manufacturing, processing, and formulation

There are several steps involved in the manufacturing of flutes, from obtaining raw materials to processing, formulation, use, upkeep, and waste management. To thoroughly understand the flute production process, I will explore these stages in greater depth.

According to Holtzapple, the raw materials used in the production of flutes are crucial because they affect the instrument's general performance and sound quality. Silver is the material that is most frequently used because it creates a bright, clear sound that is perfect for classical and orchestral music. Silver is also easy to work with, making it a preferred material for flute producers. Copper-nickel is another material that is used to make flutes. It makes a well-balanced sound with a clear wood tone in all registers. According to Wang, it is widely used because it is less expensive than silver and a good substitute for intermediate and novice flutes. Due to its high price, gold, a precious metal, is not frequently used to manufacture flutes. When played softly, it lends a flute a unique shine and creates a bright sound that can be heard from a great distance (Wang et al.). Wood is also used in the production of flutes, giving the instrument a soft and warm tone that is pleasing to play and fascinating to listen to. According to Yang, granadilla, rosewood, and boxwood are some of the most frequently used wood types. A pad made of cork is stuck to the top of a key to fill the hole. This keeps air from escaping and makes a loud, reliable sound. Last but not least, bronze has a range of about two octaves and can create both soft and loud sounds.

Processing and formulation come next after the raw ingredients have been located. This step uses various tools and methods to cut and shape the materials into the desired shape and size. According to Yang, wood is typically cut with a saw and chisels, while silver and copper-nickel are naturally shaped on a lathe. Similarly, the flute's body is next connected to the keys, and cork cushions are added to ensure air tightness. The flute is assembled, polished, and evaluated for performance and sound quality.

Distribution and transportation

According to Wang, distribution and transportation are essential in the manufacture of flutes because they guarantee prompt and effective delivery of the instruments to customers, wholesalers, and merchants. Distributors must accurately store flutes during transportation and distribution to avoid damage. For instance, flutes should be kept dry and cool to prevent harm from humidity and temperature changes. In addition, they must be kept upright and out of direct sunlight to avoid fading and warping. To avoid any damage during transit, the flutes must be packaged safely after they are manufactured. This step entails putting the finished flutes in the proper cases or boxes, including protective packing materials like foam or bubble wrap, and labeling the packages with the appropriate shipping information (many of them are made of plastic). Also, distributors and logistics companies usually take care of getting the goods from the manufacturer to the customer. They are responsible for planning the transport of the flutes to the correct locations. To ensure the flutes arrive at their locations on schedule and in good condition, they frequently use various transportation methods, including ships, trucks, and airplanes.

Herdt states that the choice of transportation mode can impact the environment. For instance, compared to using trains or working with logistics firms that use electric or hybrid vehicles, shipping flutes by truck can result in higher carbon emissions. Many of them are also using fossil fuel as the power source, which is not an environmentally friendly way to transport. Due to the adverse effects of these emissions on the environment, flute producers constantly work to reduce the carbon footprint of transportation by deciding on more environmentally friendly means of transport (Wang et al.).

Use, reuse and maintenance

Use of Flutes

Flutes are unique instruments that make sounds that are comforting and pleasant when played. In the same way, flutes are used by musicians of all skill levels, from beginners to experts. Also, flutes are used in different kinds of music, like jazz, modern, folk, and classical. But orchestras, bands, and groups also use flutes (Yang et al. 209). Most intermediate and advanced flutes are made of silver, gold, or wood. Beginner flutes, on the other hand, are usually made of copper-nickel. Even so, the level of skill, playing style, and musical genre of the player affect the choice of material (Yang et al. 207).

Reuse of Flutes

According to Streitov, flutes can be reused and handed down from one family to the next. Because of this, adequately maintained flutes can last for many years or even millennia. Even so, with appropriate care, the instrument can continue to produce high-quality music even if the sound quality degrades over time (Streitová). Flutes can also be recycled and used for different things, like ornamentation or as a collectible, because they were made of durable materials such as silver, bronze, and wood. Therefore, Streitová, asserts that recycled flutes can be turned into vases, lamps, or other ornaments.

Maintenance of Flutes

Streitova claims that flutes can be reused and passed down from one family to the next. Due to this, flutes that are properly maintained can last for many years. Even if the instrument's sound quality degrades over time, it can continue to produce high-quality music if it is properly maintained (Streitova). Because they are made of durable materials such as silver, bronze, and wood, flutes can also be recycled and used for other purposes, such as ornamentation or as collectibles.

Recycling

The flute has experienced numerous design and construction changes over the years. The flute's raw materials influence its sound quality and timbre, including wood, silver, gold, copper, and bronze (Kolomiets et al.). Flutes' lifecycles, like those of all products, do, however, come to a stop with the disposal. Therefore, recycling flutes have become crucial for sustainable flute production and disposal to minimize waste and environmental effects. According to Streitová, recovering and reusing flute parts or materials to make new flutes or other goods is referred to as recycling of flutes. Besides that, Kolomiets claim that flute recycling reduces waste and environmental impact and conserves raw materials and energy used in flute production. Due to this, the recycling process can differ based on the fluted material, but generally speaking, it entails the following steps:

Collection and Sorting

The collection and sorting of used flutes are the first stages in the recycling process. Flutes can be gathered from private sellers, music retailers, educational institutions, or music producers. Following collection, the flutes are sorted by the substance they are made of, such as wood, silver, gold, or copper.

Disassembly

Once the flutes have been sorted, they are disassembled to separate the various parts, such as the head joint, body, foot joint, keys, pads, and screws. Depending on the material of the flutes, the process of taking them apart may need special tools like pliers or screwdrivers.

Cleaning and refurbishing

The flute components are disassembled, cleaned, and refurbished to remove grime, oil, and debris. The parts may be polished, buffed, or re-plated as part of the refurbishing process to regain their initial luster and shine. This stage is essential for ensuring the recycled components are of high quality and adheres to the specifications for manufacturing new flutes.

Reassembly

A new flute is made by reassembling the flute components after they have been cleaned and restored. New pads, screws, or springs might be needed depending on how the recycled components were assembled. So many small metal components need to be replaced. The rebuilt flute is then tested to ensure it performs well and adheres to the necessary sound quality requirements (Uhlmann et al.).

Benefits of Recycling flutes

Conservation of raw materials:

Recycling flutes reduces the need for new raw materials, such as metal ores or wood, which are finite resources. Recycling used flutes lessen the demand for new raw materials, and the existing resources can be conserved for other uses (Dimitriadis et al.).

Reduction of environmental impact:

The use of energy and resources during the production of flutes affects the environment, just like other manufacturing processes. Flutes can be recycled to lessen the amount of waste dumped in landfills and lessen the environmental effect of flute production.

Promotion of sustainability

Fluting recycling encourages sustainability by promoting the use of renewable resources, lowering waste, and saving energy. Similarly, recycling supports the circular economy by establishing a closed-loop system that allows reusing materials and trash to be kept to a minimum.

Waste management

Masih says that dealing with the waste made when making flutes and getting rid of it properly are two different things. These steps involve waste reduction, material recycling, and appropriate waste disposal. Similarly, flute producers can reduce waste by implementing effective production techniques that minimize the use of raw materials and lower waste output. They can make use of eco-friendly products like bamboo, which is renewable and degradable. In addition, materials and parts used in making flutes, such as wood, metal, and cork, can be recycled and used to create new flutes or other goods. This practice saves resources and lessens the amount of garbage that is dumped in landfills. Proper garbage disposal is essential for avoiding environmental pollution. (Tian et al.)

Conclusion

The process of making flutes is complicated and involves many steps, such as getting the raw materials, distributing, and transporting them, and using, maintaining, and getting rid of the waste. The choice of raw materials has a big effect on how well the instrument works and sounds in general. To reduce their adverse effects on the environment, flute makers should adopt sustainable practices and think about the instrument's end of life. Also, logistics companies and distributors of flutes should use green transportation methods to cut down on their carbon footprint. Lastly, flute players should take care of their instruments regularly to make sure they last long and work well. Promoting sustainability and reducing environmental harm requires knowledge of the flute manufacturing process and its effects on the environment.

Bibliography

Dimitriadis, Dimitrios, et al. "Flute: A scalable, extensible framework for high-performance federated learning simulations." arXiv preprint, 2022.

Hadiya, Umeshkumar B., Farrukh Javed, and Kuldeepsinh Y. Jadeja. "Approach towards enhancing sanitation in Godavari village through sustainable solid waste management." Int Res J Eng Technol, 2018, pp. 2067-2072.

Herdt, Gilbert H. "Fetish and fantasy in Sambia initiation." Rituals of manhood, 2017, pp. 44-98.

Holtzapple, Emilee, Cheryl A. Telmer, and Natasa Miskov-Zivanov. "FLUTE: Fast and reliable knowledge retrieval from biomedical literature." Database, 2020 (2020).

Kolomiets, A., et al. "The titanium 3D-printed flute: New prospects of additive manufacturing for musical wind instruments design." Journal of New Music Research, 2021, pp. 1-17.

Masih, Ms. Ankita. "Waste Management Strategies for Sustainable Development." EARTH-II, pp. 111.

Streitová, Monika. "Types of Vibratos in Contemporary Music and the Possibility of their use in Flute Pedagogy." American Journal of Art and Design, 2020, pp. 97.

Tian, Xun, et al. "Flute type micropores activated carbon from cotton stalk for high performance supercapacitors." Journal of Power Sources, 2017, pp. 88-96.

Uhlmann, E., et al. "Increasing the productivity and quality of flute grinding processes through the use of layered grinding wheels." Procedia Manufacturing, 2019, pp. 754-761.

Wang, Zhemin, et al. "A flute-inspired broadband piezoelectric vibration energy harvesting device with mechanical intelligent design." Applied Energy, 2021.

Yang, Zhao, et al. "Phosphorylation of G protein-coupled receptors: from the barcode hypothesis to the flute model." Molecular pharmacology, 2017, pp. 201-210.

Stephanie Wang

Michelle Liu, Yuchen Xu

DES40A A06

Professor Cogdell

16 March 2023

Embodied Energy in the Design Life Cycle of the Flute

The flute is a common musical instrument used by many professional musicians, students as well as hobbyists for performance, practice, etc. It is interesting to study its sustainability because of its long lasting lifespan if maintained with proper care. Examining its environmental impact from a life cycle perspective shows that raw material acquisition, manufacturing, and transportation contribute to the most environmental impact. The fossil fuels, thermal, and electrical energy inputs required for raw materials acquisition, product manufacturing, and the transportation and distribution of the flute contribute to significant portions of its environmental impact, however this also presents opportunities for improvement through transitioning from using nonrenewable energy sources to renewable ones as well as recycling to conserve resources and energy.

The flute is made of three main removable parts: a headjoint, a bodyjoint, and a footjoint. The headjoint comprises a crown, which is the cap at the top, a head cork that is attached to the inside of the headpiece, a lip plate, and an embouchure hole within the lip plate where air is blown to make sounds. The bodyjoint includes a barrel, a rod system, and keys, which are mounted onto the rod. Lastly, the footjoint has two or three more keys depending on the type, adding up to a total of 16 keys in modern concert flutes.

The life cycle of the flute, beginning with the raw material acquisition, primarily consists of metals and corks. Therefore to acquire these raw materials, metal mining and extraction as well as bark harvesting of cork oaks are essential processes that consume great amounts of energy. Flutes are usually made of silver or silver plated copper-nickel, and other times for gold, or wood, each producing different sounds and requiring different playing methods. Silver which is the main raw material of flutes are first mined and extracted as ores using explosives on the surface or underground mines, then separated from the ores through a froth flotation process, in which “crushed ore is placed in a bath. Air bubbles are blown through the mixture to carry the silver to the top of the bath where it forms froth. The silver-rich froth is skimmed from the bath and smelted so that it can be separated from other metals” (The Natural Sapphire Company). Through these procedures, thermal energy is involved in the use of explosives as well as the smelting of the silver froth, while chemical energy is found in the interaction of a concentrate and the ores during the froth flotation process, in which a mineral-concentrated froth is formed while hydrophobic materials are separated from hydrophilic ones. Electric energy is also consumed through the use of machinery in addition to human labor which utilizes kinetic energy. According to “Environmental Risks and Challenges of Anthropogenic Metals Flows and Cycles,” the average primary energy that goes into silver production is 1500 MJ/kg (van der Voet et al).

The other main material of a flute is the cork in its head piece and keypads. Corks are harvested from barks of cork oaks by hand which is a use of kinetic energy. The cork planks are first boiled, applying thermal energy, then cut and punched into corks with electric saws and punching machines, then sorted by hand by factory workers, consuming both electric and kinetic energy.

During the manufacturing stage, metal sheets are rolled into tubes for constructing the body and die casted into various delicate parts of the flute. Different chemical solutions are also involved in protecting the metals and aiding in soldering (How Products Are Made). Through these processes electric energy is consumed in the machines that shape, cut, drill, and solder the metals along with careful handwork and assembly which utilizes kinetic energy. Meanwhile, chemical energy is found in the electroplating process, in which flutes are immersed in an electrolytic bat solution where an electrochemical oxidation reaction occurs, plating the metal with a barrier of protection. It also reduces friction and metal corrosion as well as give it a brighter shine for decorative purposes (BYJU’S). Overall, the flute making process after the production of all of its various parts is primarily handwork by flute making professionals due to the strict requirements and intricacy of the art of flute making. Therefore, the majority of the energy consumed during this stage is kinetic and electric energy.

As for distribution and transportation involved in the life cycle of the flute, fossil fuel is the main source of energy that is consumed by vehicles and cargo ships. Raw materials, especially silver, with its largest producing countries being “Mexico, Peru, the United States, Canada, Australia, and Chile” (The Natural Sapphire Company), are often transported across the sea via cargo ships which consume about “225 tons of bunker fuel per day at 24 knots” (Rodrigue) while at sea at a normal speed, generating around “350 kW to a few megawatts” (Electro-Technical Officer).

The same also applies for corks which are primarily grown and produced in only two parts of the world: the Mediterranean region of Europe – particularly the Iberian Peninsula, where Portugal and Spain produce more than 80% of the world's cork – and Northwest Africa” (Barth). Therefore, both of the primary raw materials of the flute,the metals and the cork, require extensive amounts of nonrenewable energy, that is fossil fuel, to import them overseas through container ships. There are significant amounts of energy consumed in the transportation of raw materials as compared to the transportation of the final product using trucks or mobile vehicles to travel between storage warehouses, distribution to stores, and delivery to customers’ homes.

In the next stage of the life cycle, that is, the use, repair and maintenance of the flute, in which kinetic energy appears to be the primary if not the only energy consumed. First of all, to assemble the flute, the headjoint is twisted into the barrel at the top of the bodyjoint, and the same is done for the footjoint. Then, to play the flute, a flutist would blow air into the mouthpiece to produce sounds. As various keys are pressed on the flute, air that is blown into the embouchure hole is restricted at various lengths within the tube, producing sounds at different pitches until the air leaves the flute through the footjoint or sound holes (Yamaha).

Cork is also an important component in the mechanism besides being a part of the padding in the keys. The cork stopper in the headjoint, which is attached to the crown (cap), aids the flute in staying in tune while a piece of reflective plate attached to its bottom, facing the keys within the tube, helps redirect the flutist’s breath toward the other side. The motion of air and sound waves involved in playing the flute are all examples of kinetic energy.

Maintenance is crucial for flutists, as even twisting the crown or the cap of the flute could cause the reflective plate to shift, seriously damaging the flute and would require repair. Regular professional maintenance however, “should be carried out every one to two years, depending on how often the instrument is played and how well it is cared for. Regular servicing will keep an instrument in top playing condition and prolong its life” (All Flutes Plus). Maintenance and repair are also mostly done by hand without the use of electric tools due to the intricate structure of the flute, such as stripping the instrument, cleaning, re-oiling, polishing, adjusting, changing damaged pads or corks, etc., which all consumes kinetic energy. Regular maintenance does not require nonrenewable energy and also prolongs flute’s life, which makes flutes a relatively sustainable product, for a well-maintained flute can expect to last a bit over a decade. The only other possible scenario for energy consumption besides kinetic energy is the use of fossil fuel while driving to the repair shop and back.

At the last stages of the life cycle are the recycling of the flute as well as waste management. As mentioned earlier, flutes have a long shelf life as long as they are well-cared for. In addition, flutes are generally not thrown away if not re-sold or donated. However, it is also possible to recycle flutes by taking them to a recycling center or a scrap yard for metal recycling. The scrap metal recycling process in the case of a flute involves three main steps: preparation, melting and purification, and solidification. The preparation stage consists of shredding, shearing, and compacting the metals to make it easier to melt, utilizing electrical energy in the machinery. Next, the metals are “melted down and purified by steel mills. This is done in order to remove any impurities from the scrap,” using both thermal and electrical energy (Saini). Lastly, the molten metal is solidified into various shapes for use. Additionally, all of the steps of the recycling process requires human labor, which would involve kinetic energy.

As for waste management, no new energy is used at this stage of the life cycle since flutes are typically not thrown away and can be recycled as scrap metals.

The environmental impact of the flute life cycle regarding energy consumption predominantly lies in the use of fossil fuel for transportation of raw materials and the final product overseas as well as the mining of the metals which is heavily invasive to the environment. Some consequences include: sinkhole formation, destruction of wildlife habitat, loss of biodiversity, soil and water contamination, hazardous byproducts, etc. (Saini). Therefore, scrap metal recycling is a great way to reduce the enviornmental burden, since completely banning mining would devastate millions of workers’ and their families’ livelihoods. It is a great method to preserve the environment, the natural resources, and conserving energy.

Bibliography

All Flutes Plus. “Flute Repair Guide.” All Flutes Plus the Definitive Flute Centre, All Flutes Plus, 10 Oct. 2017, https://www.allflutesplus.com/guide/flute-repair-guide/.

Discovery. How It's Made - Flute. YouTube, Discovery, 29 Dec. 2006, https://www.youtube.com/watch?v=DHSu0trGkRg. Accessed 10 Feb. 2023.

Electro-Technical Officer. “Power Supply on Different Types of Ships.” ETO Electro-Technical Officer, The Electro Technical Officer (ETO), 23 Oct. 2020, https://electrotechnical-officer.com/power-supply-on-different-types-of-ships/#:~:text=Cargo%20ship%20power%20requirements,handling%20cargo%20while%20in%20port.

Energy Education. “Silver.” Energy Education, Energy Education, 2016, https://energyeducation.ca/encyclopedia/Silver.

Flute World. “Yamaha 677H/677HCT.” Flute World, Flute World, 1 Apr. 2022, https://www.fluteworld.com/product/yamaha-yfl-677h-677hct/.

Goode, Jamie. “How Cork Is Made An Illustrated Guide to the Cork Production Process.” Wineanorak.com, Jamie Goode, 2023, https://www.wineanorak.com/corks/howcorkismade.htm.

How Products Are Made. “How Flute Is Made - Material, History, Used, Parts, Components, Machine, History, Raw Materials, Design.” How Products Are Made, Advameg, Inc., http://www.madehow.com/Volume-5/Flute.html.

Pearl Drums Global. “Pearl Flute Factory Tour | Pearl 75th Anniversary.” YouTube, Pearl Drums Global, 23 Aug. 2021, https://www.youtube.com/watch?v=nVAXxctbZhk. Accessed 10 Feb. 2023.

JL Smith and Company. “Article Flute Materials.” JL Smith and Company, J.L. Smith & Co., https://www.jlsmithco.com/article-flute-materials/.

Napa Recycling and Waste Services. “Scrap Metal.” Napa Recycling and Waste Services, Citizen Communications, LLC, 2 Oct. 2022, https://naparecycling.com/guide/scrap-metal/.

The Natural Sapphire Company. “Silver Mining and Refining.” The Natural Sapphire Company, The Natural Sapphire Company, 28 Jan. 2018, https://www.thenaturalsapphirecompany.com/education/precious-metal-mining-refining-techniques/silver-mining-refining/#:~:text=Today%2C%20the%20cupellation%20process%20involves,furnaces%2C%20a%20process%20called%20cupellation.

Saini, Jatinder. “Scrap Metal Recycling 101 [A Complete Metal Scrapper's Guide].” Verichek Technical Services, Verichek, 2 Feb. 2023, https://verichek.net/scrap-metal-recycling.html.

Van der Voet, Ester, et al. Environmental Risks and Challenges of Anthropogenic Metals Flows and Cycles. United Nations Environment Programme, 2013.

Yamaha. “Flute.” Yamaha Make Waves, Yamaha Corporation, https://www.yamaha.com/en/musical_instrument_guide/flute/.

Michelle Liu

Stephanie Wang, Yuchen Xu

DES 40A

Professor Cogdell

Design Life Cycle of the Flute: Waste and Emissions

The flute is a type of woodwind instrument that can be made out of various materials, most commonly metal and wood. Flutes are played by blowing air across the opening on the mouthpiece located at one end of the instrument. They are primarily used in classical and jazz music and have many different types. The most common type is the western concert flute (Bradley). It is interesting to study its sustainability because of how almost the whole instrument is made of metals. Examining the flute from a life cycle perspective shows that the production of flutes contributes the most environmental impact. The majority of waste and emissions when making the flute comes from acquiring raw materials and manufacturing processes in the form of harmful gasses which contributes to significant environmental and social impacts.

Since the flute is mainly made out of metal, I will be focusing on the metal materials and how these raw materials are acquired. One of the main metals used in flutes is silver which is mostly “found in the Americas, with Mexico, Peru and Chile” supplying the most (Reddy). Since silver is usually found in alloys, mercury is needed for the process of amalgamation (Star). Amalgamation is important for mining to be able to recover particles of metal (Hoffman). The first step of the process is to burn the silver ore to remove any sulfur. Then silver and mercury are combined to create an amalgam (Tingley). After removing mercury from the amalgam, a silver bullion is left. Not only is amalgamation used to extract silver, it is also used to extract gold, another common metal found in flutes. Mineral industries can use the same extraction process as silver, involving the use of mercury. The use of mercury is extremely harmful as it is often lost to the environment and can also create health problems. Approximately 90% of mercury in the U.S. is used for gold and silver extraction and about 60-65% of the mercury lost is released to the atmosphere (Nriagu). Mercury that is released into the air will eventually sink back to the ground or is washed into water where specific microbes convert it into methylmercury (US EPA). This poisonous form accumulates in “fish, shellfish, and animals that eat fish.” Because people from all over the world consume fish, more people will be exposed to mercury (US EPA). The workers involved in extracting the metals also have constant exposure to mercury. Long-term exposure to mercury may cause kidney damage, nervous systems problems, and vision/hearing loss (WorkSafeBC). Therefore gold and silver mining with mercury is harmful and is a great factor in atmospheric mercury pollution (Nriagu).

A more common process used to extract gold from ores is the process of cyanide leaching. Through this process, a few grams of gold can be extracted from a rock. This means that the amount of waste containing cyanide is a lot greater than the small amount of gold. Residue, tailings, and waters are the different wastes that contain cyanide. This is extremely harmful to the environment as bodies of water can become contaminated and ultimately affect humans and animals (Lottermoser).

In the manufacturing stage, copper-nickel alloy, the most common metal found in flutes, is created. This stage produces pollution in many different forms. To form the alloy, copper is smelted under oxidizing conditions in an electric furnace. From there, nickel is added to it. The oxidizing smelting allows for gasses like hydrogen to be eliminated from the metal but the toxic fumes released during this stage can be dangerous for workers. Repeated long-term exposure to just the heavy metals already “lowers energy levels and damages the functioning[s]” of organs (Stawicky and Ossig; Jaishankar et al.). Smelting is a common practice in the metal production industry, however it can be a hazard to the environment as it produces various wastes that cause water and air pollution (Anderson Engineering). Smelting produces slag which is a solid waste containing a high concentration of metallic mixture and is likely to contaminate nearby waters and soils (USGS). The smelting process also emits air pollutants such as sulfur dioxide and hydrogen fluoride. These pollutants can trigger or worsen health problems. If sulfuric acid mist is formed, acid rain could be another harmful effect of smelting. Acid rain is extremely harmful to the environment because it can dissolve nutrients in soil, harming trees and forests. Eventually, the “aluminum that is released to the soil ends up in lakes and streams” and the increase in acidity is dangerous for aquatic organisms (Thomas). Lastly, wastewater containing chemicals and residue is also produced. If it is not neutralized, and is immediately drained, the wastewater would contaminate the surrounding environment, harming plant and animal life (Anderson Engineering). Once the metals are acquired and created, they are cut and shaped into smaller pieces (AAA Metals Company). Thus, it is also inevitable that scrap metals will be produced.

After acquiring raw and manufactured materials, a ship may be used to transport the materials from one country to another for manufacturing the flute. Cargo ships are the most common ships used to transport larger bulk shipments (Shipoverseas). For every metric ton of goods shipped per kilometer, 16.14 grams of carbon dioxide (CO2) is emitted. Because shipping is commonly used to import and export goods in many countries, the amount of shipping emission accounts for a great percentage of greenhouse gas emissions (Kilgore). Currently worldwide shipping accounts for about 3 percent of greenhouse gas emissions but it is predicted to reach 17 percent or more by 2050. Therefore, it is crucial for the industry to cut down on its carbon footprint (Phillips). Once the materials are shipped to the destination country, they need to be transported to the factory to begin the manufacturing process.

Trucks, particularly semi-trucks are the most common means of transporting large materials such as metal (Curri). Semi-trucks run on diesel fuel (diesel), a combustible liquid used as fuel in diesel engines. Diesel produces “more energy upon combustion compared to gasoline”. In addition, semi-trucks are known to use diesel fuel because of its cheaper running costs and efficiency (Mickey Parts). However, diesel fuel contributes to air pollution because it emits great quantities of air pollutants such as “sulfur, solid carbon particulates, and CO2” (Smoot). To put it into perspective, the U.S. Energy Information Administration estimated that in just 2021, diesel fuel consumption resulted in 472 million metric tons of CO2. This is about 10% of the total U.S energy related CO2 emissions in 2021 (US Energy Information Administration). In order to slow down the rate of global warming, we must minimize the negative impacts of diesel by reducing the sulfur levels and controlling methane leaks. But ultimately, the best option is to switch to an alternative fuel source such as electricity, hydrogen, and natural gas to name a few (Smoot).

During the step of use and maintenance, cleaning the flute is important to keep it in good condition. Usually, keeping it clean and dry with a soft cloth and swab is enough to take good care of the flute. However, it is recommended to take the flute to a repair service once a year for thorough cleaning and adjustment (FluteWorld). Sometimes the flute technician will use oil to ease tension between the metal parts (Music & Arts). Therefore, there will be some oil remnants left on the cloth.

If the flute becomes unplayable, it is best to recycle it instead of throwing it away. The metal parts of a flute as well as the scrap metals from the manufacturing stage can be collected, sorted, then processed before it gets put into a large furnace to be melted (GLE Scrap Metal). Once the metal scraps are in the furnace, “fuel and an oxygen-rich oxidant” are added to the furnace. Then, the fuel and oxidant are combusted to produce heat which melts the solid metal and removes the molten metal (Jarry and Tsiava). A great amount of energy is used to melt the metal but fortunately it is a lot less compared to producing new metal. Therefore, it is important to recycle metals instead of throwing them away to reduce the production of new metals (Conserve Energy Future). If a scrap metal of copper-nickel is recycled, it is possible that “hazardous dust or fumes” can be “inhaled or come in contact with the skin or eyes” (EPSI Metals).

It was challenging for me to find information about the waste management aspect of flutes. When taken care of properly, flutes usually last up to 13 years (Instrumental Quest). But only a few parts of the flute may need to be replaced for the flute to last for decades. Therefore, only when a part of the flute is replaced, it can be thrown out or for the most part recycled at a recycling facility (LoadUp).

Creating a flute does emit various forms of harmful waste however, the amount generated is insignificant compared to the long lifespan of the flute. If the flute had a very short lifespan, producing it would not be worth it. In addition, if we make an effort to switch over to a more environmentally friendly energy such as fossil fuels to electricity or natural gasses, the amount of waste emitted will be significantly less. Overall, it was interesting to research the life cycle of a flute because in general, instruments usually last a long time and I was not aware of the waste generated by creating the instrument.

Bibliography

AAA Metals Company. “A Guide to Metal Cutting | Comparing Metal Cutting Methods.” AAA Metals Company Inc, 28 Oct. 2021, https://www.aaa-metals.com/blog/metal-cutting-guide/.

Anderson Engineering. “Mining, Smelters, Water Pollution, and Environmental Remediation Anderson Engineering Company, Inc. | Engineering Design, Environmental, Survey Anderson Engineering | Structural - Survey - Environment.” Https://Www.Andersoneng.Com/, https://www.andersoneng.com/mining-smelters-water-pollution-and-environmental-remediation/. Accessed 12 Mar. 2023.

Bradley. “Advantages and Disadvantages of Playing Flute.” MusicalHow.Com, 19 Nov. 2020, https://www.musicalhow.com/advantages-and-disadvantages-of-playing-flute/.

Conserve Energy Future. Metal Recycling: How to Recycle Metal and Its Importance - Conserve Energy Future. 19 Jan. 2013, https://www.conserve-energy-future.com/recyclingmetal.php.

Curri. The Modern Logistics Platform for the Industrial Supply Chain | Curri. https://www.curri.com/fleet-vehicles/semi-truck-delivery. Accessed 12 Mar. 2023.

EPSI Metals. Copper Nickel Alloy - ESPI Metals. Dec. 2014, https://www.espimetals.com/index.php/msds/539-Copper%20Nickel%20Alloy.

FluteWorld. “Flute Repair and Restoration | Clean, Oil, Adjust at Flute World.” Flute World, https://www.fluteworld.com/repairs/. Accessed 9 Mar. 2023.

GLE Scrap Metal. “How Is Metal Recycled? Your Guide to the Process of Metal Recycling.” GLE Scrap Metal, 27 Jan. 2022, https://glescrap.com/blog/recycling-firms-process-scrap-metal-goes-sold-manufacturers/.

Hoffman, James Edward. Gold Processing | Britannica. https://www.britannica.com/technology/gold-processing. Accessed 14 Mar. 2023.

Instrumental Quest. How Long Will a Flute Last? - Instrumental Quest. https://instrumentalquest.com/how-long-will-a-flute-last/. Accessed 9 Feb. 2023.

Jaishankar, Monisha, et al. “Toxicity, Mechanism and Health Effects of Some Heavy Metals.” Interdisciplinary Toxicology, vol. 7, no. 2, June 2014, pp. 60–72. PubMed Central, https://doi.org/10.2478/intox-2014-0009.

Jarry, Luc, and Rémi Tsiava. Process for Melting Scrap Metal. EP2601324A1, 12 June 2013, https://patents.google.com/patent/EP2601324A1/en.

Kilgore, Georgette. “Air Freight vs Sea Freight Carbon Footprint (The Real Numbers in 2023).” 8 Billion Trees: Carbon Offset Projects & Ecological Footprint Calculators, 30 June 2022, https://8billiontrees.com/carbon-offsets-credits/carbon-ecological-footprint-calculators/air-freight-vs-sea-freight-carbon-footprint/.

LoadUp. What to Do With Old Musical Instruments | LoadUp. https://goloadup.com/what-do-with-old-musical-instruments/. Accessed 8 Mar. 2023.

Lottermoser, Bernd. “Mine Wastes: Characterization, Treatment, Environmental Impacts.” Choice Reviews Online, vol. 45, no. 05, Jan. 2008, pp. 45-2630-45–2630. DOI.org (Crossref), https://doi.org/10.5860/CHOICE.45-2630.

Mickey Parts. Why Do Semi-Trucks Run On Diesel? - Mickey Parts. 18 Nov. 2018, https://www.mickeyparts.com/pages/why-do-semi-trucks-run-on-diesel/.

Music & Arts. “Proper Care & Maintenance of a Flute.” The Vault at Music & Arts, 17 Feb. 2016, https://thevault.musicarts.com/proper-care-and-maintenance-of-a-flute/.

Nriagu, Jerome O. “Mercury Pollution from the Past Mining of Gold and Silver in the Americas.” Science of The Total Environment, vol. 149, no. 3, June 1994, pp. 167–81. ScienceDirect, https://doi.org/10.1016/0048-9697(94)90177-5.

Phillips, Anna. “Ship Pollution Is Rising as the U.S. Waits for World Leaders to Act.” Washington Post, 6 June 2022. www.washingtonpost.com, https://www.washingtonpost.com/climate-environment/2022/06/06/shipping-carbon-emissions-biden-climate/.

Reddy, Rohan. “Silver, Explained – Global X ETFs.” Global X, 9 June 2022, https://www.globalxetfs.com/silver-explained-2/.

Shipoverseas. “6 Different Types of International Ships.” Ship Overseas, 20 Dec. 2018, https://www.shipoverseas.com/blog/2018/12/20/6-different-types-of-international-ships/.

Smoot, Grace. “What Is the Carbon Footprint of Diesel Fuel? A Life-Cycle Assessment.” Impactful Ninja, https://impactful.ninja/the-carbon-footprint-of-diesel-fuel/. Accessed 12 Mar. 2023.

Star, William Ascarza Special to the Arizona Daily. “Mine Tales: Mercury a Catalyst in Mining Gold, Silver.” Arizona Daily Star, 24 May 2015, https://tucson.com/news/local/mine-tales-mercury-a-catalyst-in-mining-gold-silver/article_f155ada7-337c-5364-a8cc-db9b7e9724b8.html.

Stawicky, Wolfgang, and Horst Ossig. Method of Making Copper-Nickel Alloys. US3891426A, 24 June 1975, https://patents.google.com/patent/US3891426A/en.

Thomas, Erin. “Breakdown: What Is Acid Rain & Why Is It Harmful?” Https://Www.Actionnews5.Com, https://www.actionnews5.com/2021/12/01/breakdown-what-is-acid-rain-why-is-it-harmful/. Accessed 14 Mar. 2023.

Tingley, J. V. Salt and Silver. https://nbmg.unr.edu/_docs/Newsletters/nl7a.htm. Accessed 10 Mar. 2023.

US Energy Information Administration. Diesel Fuel and the Environment - U.S. Energy Information Administration (EIA). https://www.eia.gov/energyexplained/diesel-fuel/diesel-and-the-environment.php. Accessed 12 Mar. 2023.

US EPA, OITA. Mercury Emissions: The Global Context. 27 Feb. 2014, https://www.epa.gov/international-cooperation/mercury-emissions-global-context.

USGS. Slag-What Is It Good for? | U.S. Geological Survey. https://www.usgs.gov/news/science-snippet/slag-what-it-good. Accessed 12 Mar. 2023.

WorkSafeBC. Mercury - WorkSafeBC. https://www.worksafebc.com/en/health-safety/hazards-exposures/mercury. Accessed 15 Mar. 2023.