Design Life-Cycle

assess.design.(don't)consume

Raz Yardeny

Alexander Arellano, Rey’Zarria McMillon Perkins

DES 40A

Professor Cogdell

Materials in the Life Cycle of Converse Chuck Taylor Shoes

Converse, and specifically Chuck Taylors, are one of the most popular sneakers on the market today. In 2020, the reselling giant StockX saw Converse have the fourth highest amount of trades among all shoe brands (Einhorn). What stands out to consumers the most about Converse shoes is how little seems to go into them, with very few materials and an extremely simple design they manage to remain fashionable and popular to the masses. However, when looking closer the lines of what makes up this seemingly simple shoe start to get blurred. Converse and their parent company, Nike, have a list of all the factories they use to create secondary materials for their products, as well as to completely manufacture them. For something that seems to be such a simple process, this list for shoes made by Converse spans over twelve factories in at least five countries. This vast web of factories and production lines poses some serious questions: what goes on in the process of making these shoes? Where are these primary materials coming from? What’s being used to create a shoe that claims to be just rubber and canvas? Although these questions are not answered directly by Converse, the shoe’s popularity lives on, with the appeal staying consistently high for years and years. What we know is that the major materials involved in the production of Chuck Taylors are cotton canvas and rubber, which are largely focused on in the raw materials acquisition and manufacturing parts of the shoe’s life cycle and have a profound impact on their surrounding environments.

The first material used in Converse’s Chuck Taylors is cotton canvas which, as the name suggests, is made of cotton. Most cotton that is used for canvas like that which is found in Converse’s products “often comes from China, South Korea, or Turkey” (World101). The Nike/Converse manufacturing map shows raw material production coming from China, which means that the cotton used by them likely exclusively comes from China. Cotton as a raw material, though common and popular, has quite the impact on the planet. The International Trade Centre credited cotton production with “between 0.3% and 1% of total global GHG emissions”. However, they also calculated that “only 5%–10% of the total emissions” were a result of production and that a much greater 20%-30% could be attributed to manufacturing and that the greatest source of greenhouse gas emissions actually came from consumption, totaling 30%-60% of their calculated emissions (ix). Those first two percentages say a whole lot about cotton’s effects on the planet as a primary raw material, not to mention the chemicals that it is combined with to create the secondary raw material which is cotton canvas. Although cotton canvas can often be treated with polyvinyl chloride, Converse “uses some eco-friendly materials including organic and recycled cotton and polyester” (Wolfe). This means that although the action of producing and manufacturing the cotton canvas may be problematic for the environment, at least Converse steps up to the plate when it comes to recycling cotton. Cotton is extremely difficult to pick, whether by machine or by hand. Converse likely uses machines, as they have a very staunch stance against human trafficking and forced labor. However, some of these machines aren’t all that accurate when it comes to picking, and “many of the bolls end up being picked before they are ripe and are then discarded” (Tokens). Before being made into canvas, the cotton is cleaned and the short fibers are smoothed out to become longer. These fibers, or strings, are then spun into yarn, and woven into the canvas material that is found in the shoe. The entire process, from the initial raw material acquisition to the final product of cotton canvas, in Chuck Taylors and in general, leaves a lot of waste behind.

The other classic component of the Chuck Taylor is the rubber sole and toe cap. However, how much of it is really rubber? Well, about half of the sole is actually made of felt, so there go the ‘classic’ and ‘basic’ descriptors of the shoe (Ortiz). The reasoning for this is cheaper transport - a shoe with that much felt in the sole can be considered a “slipper” and therefore has a tariff of 3% from China compared to the 25% a company would have to pay to ship regular shoes. Unfortunately, what Converse saves in money, they lose in sustainability and product quality. Felt is commonly made of wool, other animal fur, or for a cheaper price-point acrylic, acrylonitrile, or rayon (Sewport). While animal fur is natural, it does create concern with animal rights and the waste that is made from caring for these animals. With the cheaper options, which Converse likely uses, the felt fibers “are made by dissolving a polymer in various artificial chemicals and spinning the resulting substance” (Sewport). All of these chemicals help cheapen the product even more, which makes for greater profits for Converse. However, materials like rayon have a severely negative effect on their environment. The other material in the gum rubber shoes is obviously rubber. Converse’s website claims to use “[n]atural [r]ubber as opposed to synthetic,” which would make sense as they would lose a lot of their history as a company if they switched to synthetic rubber (Converse U.K.). Natural rubber is obviously better for the environment than its synthetic counterpart which uses crude oil as its principle raw material, but it still has its flaws. As the demand for rubber increases, natural rubber trees which most often “[come] from Thailand, Indonesia, or Vietnam” (World101) are grown, causing the industry to be “expected to be the leading cause of deforestation in mainland Southeast Asia in the near future” (WWF). This rubber is cured through vulcanization, a process where sulfur is used to heat the rubber, causing sulfur to stick onto the free bond found in rubber’s molecular structure, “creating a crosslink between chains” and making the resulting rubber less flexible and loose (Rubber-Cal). Although the actual The end-product has “higher tensile strength and resistance to swelling and abrasion, and is elastic over a greater range of temperatures” (Britannica). The materials that go into the ‘rubber’ sole of a Chuck Taylor aren’t great, but at least Converse gets natural rubber, even though it seems that this option will also become an issue very soon.

After all these primary raw materials are collected and the secondary raw materials are produced, it is time for the actual manufacturing of the shoe to begin. The shoe begins with the rubber base, connecting the outsole to the bottom sole of the shoe. After that, the toe cap is cut to size and “the upper then receives a pre-wrap before the rubber outsole is attached” (How Converse All Stars are Made: Vulcanized Process). That is followed by an outer wrap being applied and the toe being glued down and the heel plate with the Converse logo being added. All of this final production occurs mostly in Vietnam and Brazil, and less so in Argentina, Italy, and mainland China (Nike Manufacturing Map). The main reasoning for this is the extremely high tariffs coming from China, and the ease of keeping shoe production where rubber comes from in regards to Vietnam and Brazil. These products are then shipped around the world to distributors, who then ship the shoes to different retailers to be sold to consumers. These steps do not have much going on in terms of raw materials besides the oil and gasoline used to ship the shoes around the world.

When it comes to use, reuse, and maintenance, there isn’t much that Converse as a company can do for the consumer. There are no real materials in the Chuck Taylor that are created for maintenance or anything besides the shoe itself involved in use or reuse. The shoes themselves are built to last, though. Finally, in terms of recycling, Converse does release shoes made from old scraps and knits that are lost in the manufacturing process in a line they call Converse Renew. This, along with the option to recycle shoes at select outlet stores, helps Converse minimize waste and help act more sustainably.

Converse is a popular brand, and according to their vice president and general manager Geoff Cottrill sold “more than 270,000 pairs of Chuck Taylors a day, 365 days a year” totaling about 100 million Chucks a year (Sommer). The shoe itself can be considered a modern classic, with a simple design consisting of what seems to be very few materials and never breaking from the formula that made it big in the first place. A cotton canvas body, a rubber base, some metal eyelets and some simple stitching come together to form the Chuck, a staple piece of popular culture. Since there was so much information given earlier in the paper, a simplified recap is in order. Chuck Taylor begins with raw cotton grown in China and gum rubber from trees grown in Vietnam and Brazil. The production process of cotton has some significantly negative effects on the environment but when it comes to Converse specifically, at least the shoes are not treated with any harmful chemicals and are instead kept largely natural and organic. The cotton is transformed into cotton canvas which then dyed and molded into the shape of the shoe. The gum rubber process is much cleaner and better for the environment. Converse proudly claims that they exclusively use natural gum rubber, with no synthetic rubber made from fossil fuels. What they fail to mention is the roughly 50% of the sole is made of that natural gum rubber, and the other half is felt, which helps the shoe be considered a slipper for tariff-dodging purposes. The ‘rubber’ sole is vulcanized, meaning sulfur is added and the mixture is heated at a high temperature until the rubber has stiffened. Then, the shoe is simply pieced and stitched together in two layers and the product is shipped to wherever it needs to go. The entire production process for Converse shoes is quite complex and not transparent at all. Every avenue seems to be blocked when trying to find where they get materials and how they use them to create their shoes. There are some really good things Converse does as a brand when it comes to making the Chuck Taylors, but there are also some terrible things they do for the sake of saving money and lowering overhead costs. Overall, the Chuck Taylor is an iconic shoe for the Converse brand, and with its two main materials - cotton canvas and rubber - it is bound to continue with its popularity for the foreseeable future, hopefully with gradual changes to its production methods to be as sustainable as possible for the price it sells at.

Works Cited

Albers, Kyle, et al. “Analyzing the Environmental Impacts of Simple Shoes – A Life Cycle Assessment of the Supply Chain and Evaluation of End-of-Life Management Options.” Edited by John Melack and Patricia Holden, Bren School of Environmental Science and Management, UCSB, 21 Mar. 2008.

Ames, Kimberly A. "ELASTOMERS FOR SHOE APPLICATIONS." Rubber Chemistry and Technology, vol. 77, no. 3, 2004, pp. 413-475.

Castellanos, Matthew, director. Tyler, the Creator Learns About How the Converse One Star Is Made. YouTube, Vice TV, 10 Aug. 2017, youtu.be/-EoT4Isp-nU. Accessed 27 Nov. 2021.

The Editors of Encyclopaedia Britannica. "Vulcanization". Encyclopaedia Britannica. Edited by The Editors of Encyclopaedia Britannica, July 20, 1998.

Einhorn, Jesse. “Stockx Snapshot: Current Culture Index.” StockX News, StockX, 13 Jan. 2021, stockx.com/news/current-culture-index-2021/.

“The Globe-Trotting Journey of a Sneaker.” YouTube, World101, 18 June 2019, www.youtube.com/watch?v=vmyH2YFR2cw.

“How Converse All Stars Are Made: Vulcanized Process.” How Shoes Are Made: The Sneaker Factory, 19 July 2020, https://www.sneakerfactory.net/2017/10/how-converse-all-stars-are-made-vulcanized-process/.

International Trade Centre (ITC), Cotton and Climate Change: Impacts and Options to Migrate and Adapt, Geneva: ITC, 2011. (Technical paper) Doc. No. MAR-11-200, p. ix.

“Making Rubber Stronger: How to Vulcanize Rubber.” Rubber-Cal, www.rubbercal.com/industrial-rubber/how-to-vulcanize-rubber/#bottom.

“Making the Production of Rubber Better for the Planet.” World Wildlife Magazine, 2016, www.worldwildlife.org/magazine/issues/winter-2016/articles/making-the-production-of-rubber-better-for-the-planet.

“Nike Manufacturing Map.” Aug. 2021. NIKE Inc.

Nunez, Kirsten. “What Is the Difference in Converse One Star & Converse All Star?” Our Everyday Life, 5 Feb. 2019, oureverydaylife.com/what-is-the-difference-in-converse-one-star-converse-all-star-12511078.html.

Ortiz, Gerald. “Ever Notice That Converse Chuck Taylors Have Fuzzy Soles? Here's Why.” Gear Patrol, Gear Patrol, 1 June 2021, https://www.gearpatrol.com/style/a715423/converse-chuck-taylor-fuzzy-soles/.

Peterson, Hal. Chucks!: The Phenomenon of Converse: Chuck Taylor All Stars. Skyhorse Publishing, 2016.

“Product Materials and Technology.” Converse.com, Converse UK, https://www.converse.com/uk/en/product-materials-and-technology/product-materials-faq.html.

“Running on Air.” Popular Mechanics; New York, May 1994, pp. 35–37.

Sewport Support Team. “What Is Canvas Fabric: Properties, How Its Made and Where.” Sewport, Sewport, 21 June 2021, sewport.com/fabrics-directory/canvas-fabric.

Sommer, Jeff. “Converse Treads Carefully in Updating Well-Worn Chuck Taylor Brand.” The New York Times, 1 Aug. 2015, www.nytimes.com/2015/08/02/your-money/converse-treads-carefully-in-updating-well-worn-chuck-taylor-brand.html.

Tokens, Eve. “How Is Cotton Made Into Fabric?” The Creative Curator, 26 May 2021, www.thecreativecurator.com/how-is-cotton-made-into-fabric/.

Wolfe, Isobella. “How Ethical Is Converse?” Good On You, 20 Jan. 2021, goodonyou.eco/how-ethical-is-converse/.

Alexander Arellano

Raz Yardeny, Rey’Zarria McMillon Perkins

DES 40A

Professor Cogdell

Energy in the Production of Converse

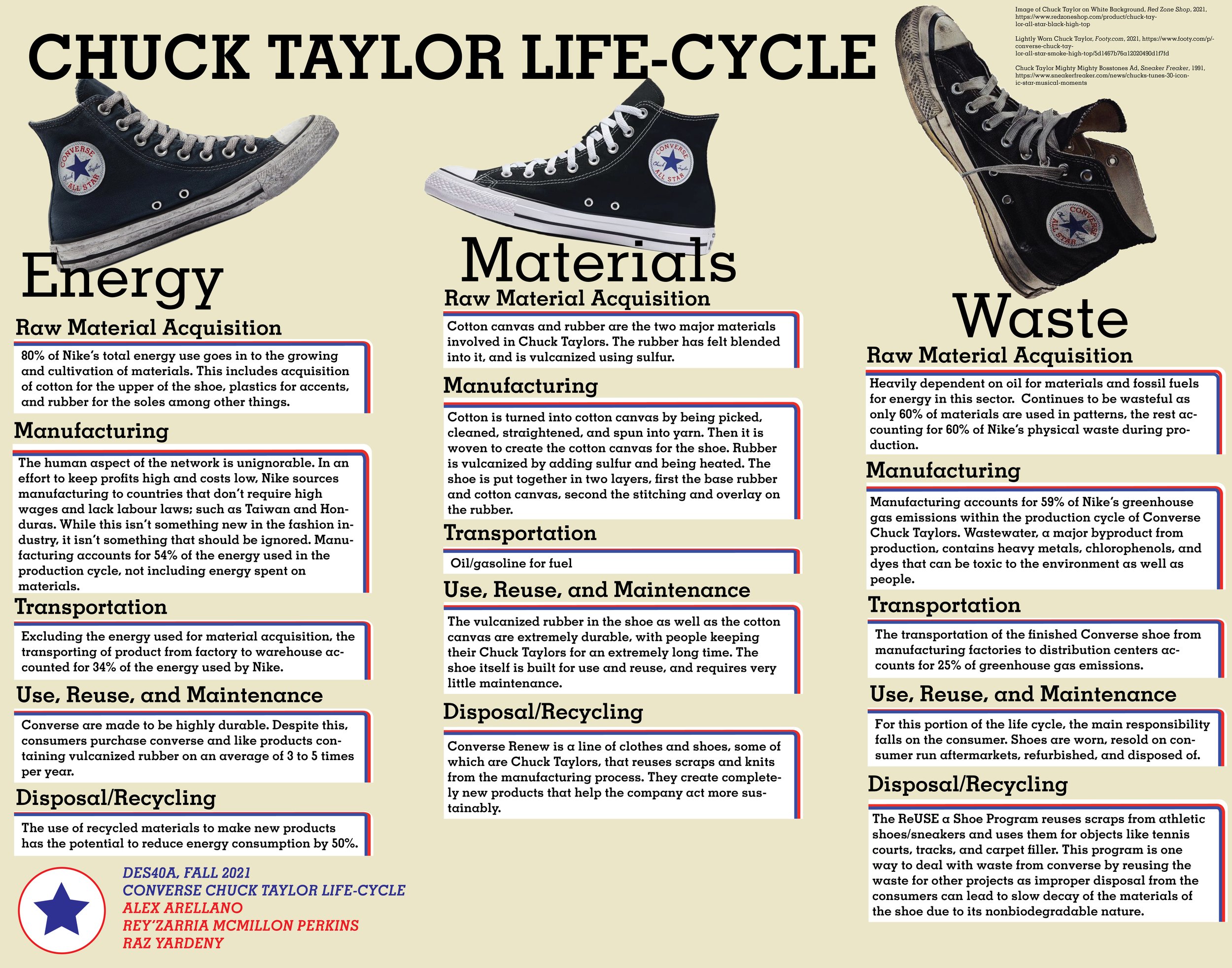

With an astounding 80% of Nike’s energy consumption during the Converse Chuck Taylor production being consumed through material acquisition of mainly rubber and cotton, Nike’s current effort to improve their environmental impact is only a start. With use of recycled materials to produce new shoes reducing energy consumption by 50%( Rebecca Henderson, Richard M. Locke, Christopher Lyddy, Cate Reavis, 5), continued reliance of their current system demonstrates Nike values their profit margins over their promise of reducing their environmental impact.

When thinking about energy, a lot goes into the growing and cultivation of materials. Nike has such a large network, they don’t rely on just one producer for their raw materials. One of the most important materials is cotton, for example. We have to consider the energy, land and resources that go into its production. ” beginning with seed companies and growers and continuing through the chain to spinners, weavers and garment makers”(Harris). This process becomes increasingly hard to wrap your head around when it comes to the amount of energy and resources that go into producing a singular shoe, but the human input is almost unimaginable. Along every step of the way there are human hands and networks that go to further the process. As previously mentioned, Nike has built a massive network that brings shoes to shelves. When Converse was sold to Nike, they became a part of this worldwide network. Materials are being sourced from all across the globe. “Most gum rubber, which is used for soles, comes from Thailand, Indonesia, or Vietnam. The cotton for the canvas often comes from China, South Korea, or Turkey. Shoelaces can be crafted out of German polyester or Chinese nylon. Once sourced, these pieces will typically be shipped to Vietnam for assembly”(World 101, Globe Trotting Journey of a Sneaker). The transporting of product from factory to warehouse accounted for 34% of Nike’s energy use, footwear manufacturing accounted for 54%, respectively. These figures included Nike and its contract factories’ operations, but excluded materials supply chains, which comprised up to 80% of the total energy required to produce a shoe (Rebecca Henderson, Richard M. Locke, Christopher Lyddy, Cate Reavis, 3). With most of the Nike energy consumption being in the material acquisition, it puts into perspective how large their entire operation is. Following the acquisition of materials, they are being shipped from all over the globe in large quantities. Yet, the energy consumed during transportation is only a fraction of what goes into cultivating needed materials. The human mover factor is also something to be taken into consideration, an immense amount of energy is already being used within transportation, and the converse has yet to be assembled. The human factor is crucial to the operation, without the countless factory workers and human infrastructures, the quality product bought by Nike is impossible.

Since the ’90s, Nike has been the subject of criticism because of its unlawful practices regarding workers. This includes child labor, unjust pay for factory workers, and overexposure to toxins. Though this is nothing new in the fashion industry, especially in the wake of fast fashion, it is still important to consider when speaking about the energy that goes into creating a product. To keep production costs low and profits high, converse is sourced from countries such as Vietnam and Honduras, which don’t require high wages and legislation that provide workers with rights that protect them. This not only results in them having to work in poor conditions, but exposes them to dangerous byproducts which could have serious health implications if they remain in constant exposure. It is stated that workers are exposed to an excessive amount of airborne particulates. The Cold Cement and Vulcanization of converse shoes expose workers to several chemical byproducts, most notably Zinc Stearate and Ammonia. Through regular exposure only irritation occurs, toxic exposure is possible through the regular maintenance of the equipment(Levy). A majority of the energy input that goes into the process of producing converse is human. Disregarding this human involvement and the effects that it has on the workers would be ignorant. These shoes are made to be affordable and high quality, which may be enticing to customers, but come at the cost of the countless factory workers that bring the product to shelves. Despite their essential role, many companies such as Nike treat workers as expendable. The covid-19 pandemic that swept the world demonstrates how the human aspect of the production cycle is valued. As previously mentioned, Nike is aiming to keep costs low and profits high. Not only does this result in low wages and poor conditions for workers, but does not guarantee that Nike won’t pick up their operation and move it to somewhere that would be willing to work under such factors. With the pandemic, we see that Nike moved operations from countries not willing to work to their operating countries that were (Waste360, Turning Plastics into Sustainable Products and Lives ). Putting strain on their already existing factories with the supply that would have been sent to their other factories. This demonstrates that if one place or group of workers isn’t willing to do what Nike is asking of them in the conditions they are put in, they will move to workers that will.

Nike has recently taken on the task to reduce emissions by 50% by the year 2025(Wolfe). While this is a great endeavor they’ve taken on, this only takes into consideration the waste produced as a result of production processes. This promise only seems to go into reducing the waste produced, not the means of obtaining energy needed to keep the production process running. Seeming to be Nike’s main claim to this promise is their shoe recycling program, “Nike Grind”. Nike created this recycling initiative, requiring the cooperation of customers, creating dropoff areas for used shoes. These shoes are then ground up and used for material in other Nike products and apparel, not just Converse Chuck Taylors. There are other programs as well such as “Reuse-a-Shoe”. These are then processed and used to create physical spaces and other objects such as parks and art pieces( Havich, Just for Kicks ). This and reusing material to create more products that would later go on shelves are a starting point for the company. Once shoes are sold the end of the product’s life is decided by the consumer. Vulcanized rubber is used in several products such as tires because of its durability. The main reason why this material is used in shoes such as converse. Not only does it go to create a high-quality product, but it is relatively inexpensive to manufacture. The issue lies within consumer habits. In “developed countries” such as the United States, the average consumer purchases 3-5 shoes containing vulcanized rubber yearly(Ames, Elastomers for Shoe Application). This means this furthers the cycle of production, promoting further use of energy. Consumer patterns seem to disregard these shoes’ high durability. While Nike has a line of Converse shoes made for the most part recycled material, it is obvious that they aren’t pushing them as much as conventional pairs. With a majority of advertising being for the classic Converse Chuck Taylor. In addition, this is a practice that could be applied more regularly to the base model. Energy saved that could have been a contributor to their promise of reducing energy use and emissions. While Nike is responsible for its environmental impact, consumers share just as much influence. Companies like Nike are only trying to keep up with consumer patterns and fashion trends. For a difference to truly be made, there is a required joint effort on behalf of the producer and the consumer. This being considered is where things get difficult. Companies are competing with each other for the business of customers. What most attracts customers is the best quality at the best price. In a continuous cycle to cut corners as a means to reduce production costs, companies often find themselves opting for undesirable means for manufacturing their products. Undesirable means that result in humanitarian issues involving factory workers, as well as environmental issues as a result of neglect, willingly and unwillingly.

Nike promised to reduce their energy consumption by 50% in the coming years, not an easy feat, but a goal that is completely possible. A goal that would require the sacrifice of profit, but would result in a reduced environmental impact. On behalf of Nike, this would require changes to their production infrastructure and maybe even the product itself. The energy used in the process of acquiring needed materials is a clear issue. An issue that seems to have viable solutions on the end of production. But an issue that will persist if consumer trends and production infrastructures continue the way they are.

Works Cited

Ames, Kimberly A. “ELASTOMERS FOR SHOE APPLICATIONS.” Rubber Chemistry and Technology, Vol. 77, Iss.3, July/ August 2004, https://www.proquest.com/econlit/docview/220669012/C5795A7CB02F48B8PQ/1.

BSB, Levy. 1975, Health Hazard Evaluation/Toxicity Determination Report H.H.E. 75-15-250, Converse Rubber Company, Malden, Massachusetts, https://www.proquest.com/reports/health-hazard-evaluation-toxicity-determination/docview/29721788/se-2?accountid=14505.

“Episode 61: Turning Plastics into Sustainable Products & Lives.” Waste360. 2021, New York.

“The Globe-Trotting Journey of a Sneaker.” World101. Council of Foreign Relations, 2021.

Harris, Drew. “Where Real Product Quality Starts.” Quality and Statistics: Total Quality Management, Vol. 6, Iss. 1, 2008, https://www.proquest.com/materialscienceengineering/docview/228851031/1A3CB7504E5146C1PQ/7?accountid=14505.

Havich, Michelle M. “Just For Kicks.” Materials Science & Engineering Collection, Vol. 25, Iss. 8, 2013, https://www.proquest.com/materialscienceengineering/docview/1440472721/CFBC27488CFA49D4PQ/1?accountid=14505. Accessed 2021.

Henderson, Rebecca, et al. MITSloan School of Management, Cambridge, MA, 2009, Nike Considered: Getting Traction on Sustainability , http://dln.jaipuria.ac.in:8080/jspui/bitstream/123456789/2809/1/Nike%20Considered%20Getting%20Traction%20on%20Sustainability%20.pdf. Accessed 2021.

Motawi, Wade. “How Converse All Stars Are Made: Vulcanized Process.” How Shoes Are Made: The Sneaker Factory, SneakerFactory, 19 July 2020, https://www.sneakerfactory.net/2017/10/how-converse-all-stars-are-made-vulcanized-process/.

Peterson, Hal. Chucks!: The Phenomenon of Converse: Chuck Taylor All Stars. Skyhorse Publishing, 2016.

Wolfe, Isabella. “How Ethical Is Converse?” Good On You, 11 Aug. 2021, https://goodonyou.eco/how-ethical-is-converse/.

ReyZarria McMillon Perkins

Alex Arellano, Raz Yardeny

Christina Cogdell

Design 40A

2 December, 2021

Converse Waste Management

Front and center, on the Converse Renew campaign page, are the words “Waste Not. Want Now.” Converse has been running a renewable materials program, claiming that they “[reengineer] knit and repurposed scraps from the manufacturing process to move” towards “a zero-waste future” (Converse, 1). However, Converse’s ReUSE program has many downfalls when it comes to its overall sustainability and its ratio of recycling shoes to the production of shoes. Furthermore, the shoes that are not processed and repurposed in the ReUSE program have many harmful effects on the environment as the materials they are made of degrade. In this essay, I will be discussing how Converse (Nike) handles their waste by using their ReUSE Program, what materials do what damage to the environment, and the outcome of recycling the materials.

Waste from Converse begins during production. Wastewater created by converse during production has to pass the ZDHC MRSL Manufacturing Restricted Substance List, a list composed of hundreds of chemicals and their acceptable concentrations. These chemicals consist of different solvents, heavy metals, pigments, dyes, chlorophenols, etc. Converse states that they only release safe water into our environment but after further research, Converse is allowed to release hundreds of different chemicals, just in specific concentrations. For example, the Manufacturing Restricted Substance List states that converse can release up to 250 ppm of several carcinogenic dyes in their wastewater (ZDHC, 1). In the header of this document, it even states that these cancer-causing dyes “should no longer be used in the dyeing of textiles”, but Converse is still permitted to use and release these chemicals into the environment if they are under acceptable concentrations. However, even these allowed concentrations are extremely damaging for the environment around factories. Additionally, since Converse was taken over by Nike, the production of converse shoes moved out of the United States. The production of the canvas and the polyester part of the shoe moved to factories in India and China, and other parts of the shoe are made in Vietnam and Indonesia. (Holmes, 1) Environmental guidelines are looser in these countries, allowing higher amounts of toxic chemicals to be released during the production and processing of Converse shoes. To add to this, these factories being overseas allows consumers in the United States and other countries to be blind to the environmental impacts of these chemicals that are undoubtedly harming wildlife and ecosystems around these factories. The article, written by RUGILE PALEVICIUTE, about the sustainability of sneakers, brings up the carbon impact of shoe production. The carbon footprint of all sneaker production makes up 1.4% of global greenhouse gas emissions (GHG), compared to air travel, which accounts for 2.5% of GHG emissions. And in 2013, MIT “found that a typical pair of running shoes generates 13.6 kilograms of CO2 emissions” (Fashion, 1). Shoe production is a huge market, with a notable carbon footprint. This is why Converse is putting so much emphasis on its ReUSE program. There is a direct correlation between shoe production and environmental damage. Wastewater from factories is allowed to contain and release toxic chemicals, including carcinogenic ones, which can accumulate in our natural environment, harming ecosystems, workers, and people living around these factories. Carbon released from shoe production is another waste output that is contributing to 1.4% of carbon outputs. This meaning, that shoe production is playing a role in our climate crisis, further threatening our natural environment. Converse is fully aware of their role in environmental damage and is actively trying to combat these issues by running its sustainability program. However, there are still many complexities to recycling and repurposing shoes that limit the sustainability of their ReUSE program.

The ReUSE program of converse is a good start to tackling the issues of waste and sustainability. Converse sneaker recycling not only recycles converse, but participants can also recycle other brands of sneakers and athletic shoes. The shoes that are participating in the “ReUSE a Shoe” program are not reused for shoes, however, parts like the rubber soles are used for places like playgrounds, tennis courts, and tracks. Other parts of the sneakers like the leather and cotton material were used for things like carpet cushions. (Bratcher, 2020). Although these materials are not being put into something more environmentally friendly, it does save a lot of money, time, energy, and waste that could have been created.

Most converses are discarded as waste, left to degrade into our environment. 100 million pairs of converse are sold every year and only 25 million have been recycled during the whole span of the program which started in 2011 (Bratcher, 1) This means that on average, 250,000 pairs of converse were put through the ReUSE-a-Shoe program a year, while ~100 million were sold. The materials that make up Converse have varying rates of decomposition and effects on our environment. For instance, the cloth part of the shoe is made of canvas. Canvas made from organic cotton “doesn’t destroy ecosystems and is known to improve soil quality” and is sustainable if “PVC is used” (The Impacts of Canvas,1). However, Converse does not specify that they used organic canvas and degrades into the environment with few negative effects . Other parts of the shoe like the rubber soles and the polyester shoe strings are not biodegradable.

However, recycling the shoe may not be the most environmentally friendly. On the surface, it looks good for the brand to say that they recycle but other waste methods are not only safer for the environment but also are cheaper. From 2011 until 2020, a graph was generated by Nike Inc. Worldwide Headquarters about the volume of waste created by them. Besides Nikes’ ReUSE A Shoe Program, they also have a Zero Waste Program which Nike states is “ Nike's journey toward zero carbon and zero waste to help protect the future of sport (Nike, 1). On the chart, Nike has produced 1,226 metric tons of waste in the year 2011, and as the years increase, the number of waste increases as well. By the year 2018, Nike reported that they had almost 5,300 metric tons of waste (Volume of Waste, 1). Not only does this go against both of Nikes’ waste plans and policies but it also shows how ineffective their current waste treatment has been over the years. Also, the amount of energy and money that is put into Unlike simply disposing waste into a landfill, recycling and reusing materials is a more complicated process that includes more steps like sorting, shredding, more sorting, and reprocessing. With this process having more steps, more energy is being used which depending on the energy sources can be even more dangerous to our environment.

In conclusion, Converse shoes have been a favorite among millions of people but not in our environment. With the ReUSE a Shoe Program, thousands of people have helped the environment by recycling and reusing their old athletic shoes. However, other pairs of Converses that are not recycled and are thrown away do become harmful to the environment because of the materials like the canvas, rubber sole, and polyester shoe strings not being biodegradable.

Works Cited

Bratcher, Rory. “Converse Sneaker Recycling.” Home Guides | SF Gate, 17 Nov. 2020, https://homeguides.sfgate.com/converse-sneaker-recycling-79257.html.

“Converse Announce Plan to Reduce, Reuse and... Renew?” Sneaker Freaker, https://www.sneakerfreaker.com/news/converse-look-to-reduce-reuse-and-renew.

Fashion, Ethical. “How Sustainable Are Sneakers? the Environmental Impact of Sneaker Production.” MAKE FASHION BETTER, MAKE FASHION BETTER, 4 Sept. 2021, https://www.makefashionbetter.com/blog/environmental-impact-of-sneaker-production.

Holmes, Jonathan. “What Materials Are Used to Make Converse Shoes?” Cement Answers, https://cementanswers.com/what-materials-are-used-to-make-converse-shoes/.

Keady, Jim. “The Dumping and Burning of Nike Scrap Shoe Rubber.” HuffPost, HuffPost, 25 May 2011, https://www.huffpost.com/entry/the-dumping-and-burning-o_b_643763.

Marie, Adriane. “Is Canvas Good or Bad? 2022 Fabric Material Textile Guide for Home Environment Animals Laborers.” HEALabel, HEALabel, 15 Nov. 2021, https://healabel.com/c-fabrics-materials-textiles/canvas.

“Nike Sustainability. Move to Zero.” Nike.com, 2019, https://www.nike.com/sustainability.

Stalkos, Theodoros, et al. End-of-Life Management of Shoes and the Role of Biodegradable Materials. Centre for Sustainable Manufacturing and Reuse/Recycling Technologies (SMART), Wolfson School of Mechanical and Manufacturing Engineering, Loughborough University, UK, 2006, https://mech.kuleuven.be/lce2006/171.pdf.

“Turning Plastics into Sustainable Products & Lives.” SoundCloud, https://soundcloud.com/nothingwasted/turning-plastics-into-sustainable-products-lives.

“Waste.” Nike Purpose, https://purpose.nike.com/waste.

“ZDHC Manufacturing Restricted Substance List.” ZDHC MRSL V2.0, ZDHC Foundation, 2021, https://mrsl.roadmaptozero.com/MRSL2_0?guidance=1.