Design Life-Cycle

assess.design.(don't)consume

Aida Yuan

Xiang Li, William Boyd

DES40A

Professor Cogdell

3/10/2023

Raw Materials in the Life Cycle of Patagonia’s Nano Puff Jacket

Introduction

The waste produced from the fashion industry has been coming to the top of environmental concerns. Clothing factories being responsibly for quite a large portion of the waste in our world. Especially, with the trend of fast fashion which has caused the demand and supply of clothing to skyrocket. In turn, increasing the waste from the production, transportation, and consumption of clothing. The term “made from recycled materials” are words that we often see on tags of the clothes we buy. Items made of recycled materials are becoming more and more preferred, as they help decrease the amount of waste that gets dumped into landfills. Recycled materials also help in preserving natural and raw resources. Many clothing companies have also switch to producing with recycled materials. Patagonia being a company that had started with the goal and making clothing that people will wear while trying to save the planet from byproducts and waste. One of their most popular products is Patagonia’s Nano Puff Jacket, designed as a piece of clothing customers can wear to go hiking, have fun in the snow, or just to wear in everyday life. Patagonia promotes the jacket as being made of recycled and environmentally friendly materials, but it turns of that the jacket and the raw materials in its life cycle made not be the most sustainable and environmentally friendly.

Primary Material

The Nano Puff Jacket is a product that Patagonia promotes as a piece that is made also entirely of recycled materials. Most specific, the jacket consists of 100% recycled polyester. Recycled polyester is an ideal material as it polyester that is collected from landfills and repurposed, helping to minimized the amount of plastics from entering landfills and oceans. Though recycled polyester has a lower tensile strength and is stiffer than organic polyester, it is still a strong and durable material. It also has barrier properties which makes it a good choice for Patagonia’s Nano Puff Jacket. (Majumdar 2020) The Nano Puff Jacket being designed to follow Patagonia’s purpose of making clothing fit for hiking in while helping the environment.

The process of repurposing polyester is one that required many steps and stages. First, recycled polyester is made from recyclable waste that is collected from municipal waste. Recycled polyester is essentially polyester that is repurposed, so it keeps most of the same materials of polyester. Polyester, the not yet recycled version, is a synthetic fabric. Polyester also has hundreds of different varies which consist of all types of chemicals and all types of different combinations. Though all polyester is made of the same core materials, which consists of crude oil, and combining ethylene glycol and terephthalic acid. (Stanes, Gibson 2017) Crude oil is a fossil fuel that naturally occurs, this means that crude oil is made of dead organisms like algae and plankton, hydrogen and carbon atoms. All of which are combined and placed under high heat and pressure to create crude oil. (“Howden” 2019)

Even with designated recycling bins, not all reusable plastic waste is collected into the correct bins. So, all the waste is collected and sorted by either by hand or machines which require manpower and electricity to power the machines. They sort out the plastics and existing polyester materials and do a thorough inspection to see if the material is reusable. The collected materials are then chopped into smaller pieces and are put through a cleaning phase. This phase gets rid of any leftover labels, and food remnants. After the material has been cleaned, it is then put though a heating process that gets rid of any impurities the reusable waste may still have. The material is then turned into finer pieces and span into yard that can be weaved and finally, the yard is sent to the weaving department of companies. (Randy Cow 2020)

Secondary Materials

Along with recycled polyester, Patagonia also adds other materials to create their Nano Puff Jackets. One of the most used features in the Nano Puff Jacket are the zippers. The zippers that are used on the Nano Puff Jacketa are coil chain zippers. These zippers are made of nylon. (Fashiondioxide 2023) Nylon is also know are polymer fabric and is a stretchy material that is made from a variety of different synthetic polymers, which are derived from petroleum oil. (Sewport n.d.) But the zippers are not stretchy and are not used gently, so there is another raw material used to create the stringers. Along with nylon, these zippers are also made of plastic that help give zippers the durability and strength to be used repeatedly. (FixnZip 2021) Plastic is a material that is made from the combination of cellulose, natural gas, crude oil, coal, and natural gases.. There are also some byproducts that are added in, such as starch, vegetable fats and oils, and other natural substances. (Baheti) Another crucial part of the zippers are the tabs. The Nano Puff zippers tabs are made of stainless steel. Stainless steel is one of the elements on the periodic table, being a metal that is resistant to corrosion and heat. (Jensen, Frawley, Haynes) This metal is also the metal that is used in mostly all other types of zippers, the resistant to corrosion helps keep it durable and steady in the long run. Along with the tab, Patagonia also included a cord at the end of the tab with a small plastic piece attached to it, which are made from the same materials as the stringer. The cord being made from recycled nylon, which consist of nylon waste, a combination of different synthetic polymers. The small plastic piece made from crude oil, natural gases, and a few other materials.

The Nano Puff Jacket is offered in a variety of different colors. Patagonia uses synthetic dyes. They state that synthetic dyes stick to fabrics better then natural dyes. (Patagonia 2023) Synthetic dyes are the result of the combining different types of chemicals. Though synthetic dyes are generally made from two main chemicals. The atoms and electrons in the chromophore groups are used to bring in color. While lone pairs of electrons in auxochrome groups are used to enhance the color. As for the specific colors, they are added using different synthetic pigments, synthetic pigments being made from metal compounds. Some synthetic dyes may also contain binders and thinners to help them stick to fabrics. (Soni, Kumar, Sharma, Jayaprakash 2021)

Manufacturing

Patagonia is the founder of the Fair-Trade Association. They are an organization that makes sures employees of companies are given fair wages and safe work environments. (Fair Labor 2023) Companies that work with this association need to pay a fee that either goes into worker’s paychecks or it can be voted to fund a healthcare facility or daycare. Patagonia does not personally own factories, but they send out people to inspect the factories to make sure they are in safe conditions. Patagonia credits the Nano Puff Jacket to Vietnam, where it is put together by workers and shipped out to retail stores. (Patagonia 2023) While finding exactly how Patagonia produces their products were difficult to find, it led to a video on the Patagonia cite that showed the products being produced in factories. Where workers work to cut and sew together the pieces to create full garments. After the pieces are put together, they are fold and packed individually in plastic bags. They get placed into cardboards and shipped to different retail stores. (Patagonia 2023)

Transportation and Distribution

Overall, it seems like Patagonia is very efficient when it comes to their transportation. Patagonia sources from manufacturing plants that are close to their shipping ports and suppliers of their raw materials. (Just Trade 2014) With their sources, suppliers, and ports being close together Patagonia can lower the cost and environmental impacts that would be the consequence of having to transfer goods long distance. Patagonia is also sold in retail stores all around the world. Orders that are placed in their US website is shipped from a location in Northern Nevada. While they have hundreds of locations around the world. They also distribute their products to be sold at different retail store. As for raw materials, there are a lot of human energy and gasoline that goes into transporting and distributing products.

Waste and Recyclability

Even though recycled polyester minimizes the amount of plastic that reaches landfills. Recycled polyester is made of polyester, which is a synthetic fabric. Each time is reused and washed polyester is reused it decreases in quality and will eventually become unrefusable. There is also the problem of microplastics. Every time a synthetic is washed is sheds microplastics which are carried away by the wastewater into oceans. (Cho 2021) The materials used in the production of zippers also contribute to the release of carbon dioxide in the air. Along with the transportation with the use of cars. The synthetic dyes are also a problem. As natural dyes are biodegradable and don’t contain as many chemicals. Synthetic dyes are mainly made of chemicals. The wastewater produced from factories can carry these chemicals into large bodies of water that pollute the water and affect marine life. It can also contaminate the air and soil used for agriculture, negatively affect human health and agriculture. (Assoune n.d.)

Conclusion

Patagonia started as a small company that wanted to make products that consumers will enjoy while trying to decrease waste that is thrown into our environmental. The Nano Puff Jacket is one of the many products that Patagonia promote as a product that is made of 100% recycled materials. But as it turns out, the main material of Patagonia’s Nano Puff jacket, recycled polyester, is sustainable in the short term. The polyester will eventually become too worn to reusable. This means that the material will end up in our landfills eventually. Not to mention the waste from the synthetic dyes and the materials of the zipper are not environmentally friendly in anyway. Overall, contradicting their message of creating clothing that do not create harmful byproduct. Hopefully in the future Patagonia will be able to fully transition to making products that are solely sustainable and environmentally friendly.

Patagonia. Men’s Nano Puff Jacket, 2023. https://www.patagonia.com/product/mens-nano-puff-jacket/84212.html. Accessed 15 March 2023.

Patagonia. Recycled Polyester, 2023. https://www.patagonia.com/our-footprint/recycled-polyester.html. Accessed 15 March 2023.

Periyasamy, Aravin P., Militky, Jiri. “LCA (Life Cycle Assessment) on Recycled Polyester.” Environmental Footprints of Recycled Polyester. 11 July 2019, pp 1-30. https://link.springer.com/chapter/10.1007/978-981-13-9578-9_1#citeas. Accessed on 15 March 2023.

Majumdar, Abhijit. “Circular fashion: Properties of fabrics made from mechanically recycled polyethylene terephthalate (PET) bottle.” Resources, Conservation and Recycling, vol. 161, October 2020, https://www.sciencedirect.com/science/article/pii/S0921344920302330. Accessed 15 March 2023.

Randy Cow. How Do You Turn Plastic Into Wearable Material, 25 January 2020, https://www.randycow.com/en-us/blogs/milk-round/how-do-you-turn-plastic-into-wearable-material. Accessed 15 March 2023.

Fair Labor. The Fair Labor Association promotes human rights at work, 2023. https://www.fairlabor.org. Accessed 15 March 2023.

Patagonia. Patagonia Clothing: Made Where? How? Why?, 2023. https://www.patagonia.com/stories/patagonia-clothing-made-where-how-why/story-18467.html. Accessed 15 March 2023.

Poddar, Prisha. Integrating sustainability into the Textile Supple Chain-comparing the case of H&M and Patagonia. Scholarly, August 2021, https://scholarly.co/wp-content/uploads/2021/08/Research-Paper-Prisha-Poddar.pdf. Accessed on 15 March 2023.

Patagonia. Fair Trade, 2023. https://www.patagonia.com/our-footprint/fair-trade.html. Accessed 15 March 2023.

Patagonia. Shipping Information, 2023. https://help.patagonia.com/s/article/Shipping-Information. Accessed 15 March 2023.

Patagonia. Synthetic Dyes, 2023. https://www.patagonia.com/our-footprint/synthetic-dyes.html. Accessed 15 March 2023.

Stanes, Elyese. “Materials that linger: An embodied geography of polyester clothes.” Geoforum, vol. 85, October 2017, pp 27-36, https://www.sciencedirect.com/science/article/pii/S0016718517301835#b0135. Accessed 15 March 2023.

How Products are Made. Zipper, n.d, http://www.madehow.com/Volume-1/Zipper.html. Accessed 15 March 2023.

GTNEXUS. A Clear View of the Supple Chain, 2015, https://www.scmr.com/wp_content/gtnexus_wp_patagonia_020116.pdf. Accessed 15 March 2023.

Royal Talens. Tips and Techniques Types of pigments, n.d., https://www.royaltalens.com/en/inspiration/tips-techniques/types-of-pigments/. Accessed 15 March 2023.

Howden. Where Does Crude Oil Come From?, November 2019, https://www.howden.com/en-us/articles/pcog/where-does-crude-oil-come-from. Accessed 15 March 2023.

Justtradeplnu. “Patagonia-Distribution/Trade And Transport (Economic Aspect).” Just Trade, 16 April 2014, https://justtradeplnu.wordpress.com/2014/04/16/patagonia-distribution-trade-transport-economic-aspect/. Accessed 15 March 2023.

Cho, Renee. “Why Fashion Needs to Be More Sustainable.” Columbia Climate School Climate, Earth, and Society, 10 June, 2021, https://news.climate.columbia.edu/2021/06/10/why-fashion-needs-to-be-more-sustainable/. Accessed 10, 2021.

Fashiondioxide. How Zippers are Made | Raw Materials, Manufacturing and Quality Control, n.d, https://www.fashiondioxide.com/how-zippers-are-made-raw-materials-manufacturing-and-quality-control/. Accessed 15 March 2023.

Sewport Support Team, “What is Nylon Fabric: Properties, How its Made and Where.” Sewport, 15 March 2023, https://sewport.com/fabrics-directory/nylon-fabric. Accessed 15 March, 2023.

FixnZip, A Complete Guide to the Different Types of Zippers, 16 June, 2021, https://www.fixnzip.com/a-complete-guide-to-the-different-types-of-zippers/. Accesssed 16 March 2023.

Plastics Europe. How Plastics are made, 2023, https://plasticseurope.org/plastics-explained/how-plastics-are-made/. Accessed 15 March 2023.

Lellis, Bruno, Favaro-Polonia, Cintia Z., Pamphile, Joao A., Polonio, Julio C. “Effects of textile dyes of health and the environment and bioremediation potential of living organisms.” Biotechnology Research and Innovation, vol.3, no.2, July-December 2019, https://www.sciencedirect.com/science/article/pii/S2452072119300413. Accessed 15 March 2023.

Soni, I., Kumar P., Sharma S., Jayaprakash Gururaj K. “A Short Review on Electrochemical Sensing of Commercial Dyes in Real Samples Using Carbon Past Electrodes.” Electrochem, vol. 2, no.2, 16 May 2023, https://www.mdpi.com/2673-3293/2/2/20. Accessed 15 March 2023.

Assoune, Alex. “How Do Textile Dyes Harm Our Environment And Health.” Panaprium, n.d, https://www.panaprium.com/blogs/i/dyes-environment. Accessed 15 March 2023.

William Boyd

Aida Yuan, Xiang Li

DES 40A

Winter 2023

Professor Cogdell

Lifecycle Assessment of Patagonia Nano Puff Jacket With Focus on Embodied Energy

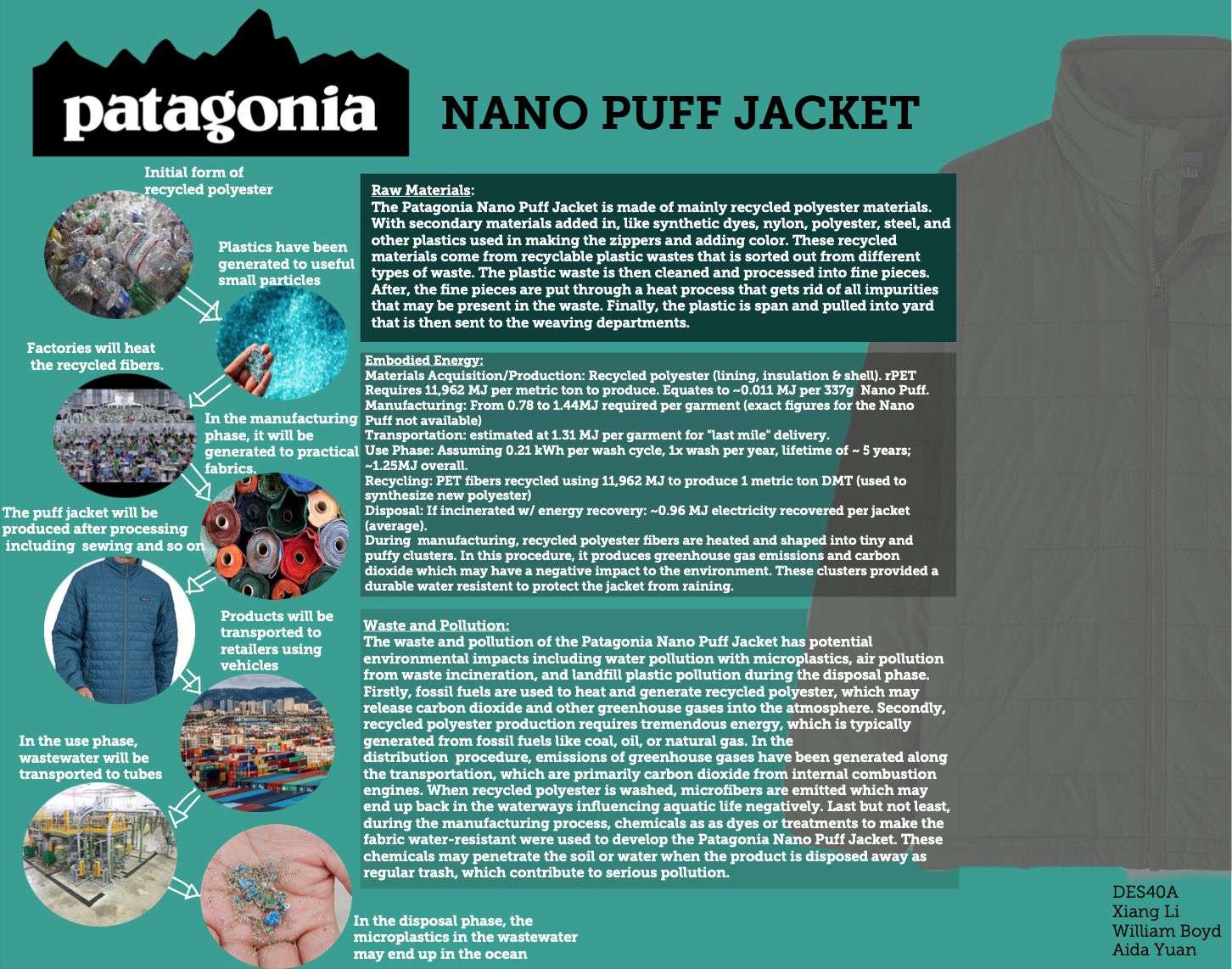

In the manufacture of a typical synthetic sportswear garment, energy use is a significant factor in overall lifecycle emissions. Energy is expended throughout every stage of a product’s full lifecycle, but at the same time energy usage can vary greatly between various lifecycle stages. The customer use phase, where the garment is worn and used for (ideally) many years, represents a modest source of energy usage as the garment is laundered and dried. This is due to the infrequent laundering needs of the Nano Puff jacket. Production of the garment requires significant amounts of energy for spinning, weaving, assembling and dyeing. Surprisingly, the distribution phase, where the finished garment is shipped to a customer’s address, is perhaps the most energy-intensive leg of the entire process.And lastly, acquisition of raw materials and end-of-life processing all require less energy, but are still areas where improvements in efficiency can be realized.

The lifecycle processes of extracting and/or synthesizing the Nano Puff’s raw materials require only modest amounts of energy when compared with later stages. The jacket is produced using 100% recycled polyester fiber (PET, polyethylene terephthalate) throughout (shell, lining, insulation), although it does incorporate small amounts of steel, nylon and elastane in the zippers and cuffs. Since the vast majority of the Nano Puff’s material is sourced from recycled PET, this results in energy savings during the production process.

(DMT produced w/ raw materials: oil/nat gas)

(DMT produced using rPET)

(Data from Patagonia’s Common Threads initiative, via Teijin)

As is illustrated by these tables, the production of one metric ton of DMT (dimethyl terephthalate, the primary precursor chemical for PET, although terephthalic acid can also be used.) requires 72,422 MJ of energy when oil or natural gas are used as feedstocks, and 11,962 MJ when recycled polyester is used instead. This demonstrates that there is an approximately 84% difference in energy requirements between the production of virgin and recycled polyester (Common Threads Initiative / Patagonia).

Similar to most outdoor clothing, the Nano Puff jacket is relatively complex in design and construction, which leads to a more involved and therefore energy-intensive assembly process. Energy use figures (electricity) for production stages of the garment are estimated at between 0.78 and 1.44 MJ per item of clothing manufactured (Cay, A.). It is worth noting that this data comes from a review conducted of a Turkish textile factory, while Patagonia’s Nano Puff jackets are produced in a factory in Ho Chi Minh City, Vietnam. Neither Patagonia nor the factory company (Kwang Viet Garment Co.) provide figures on energy use during their garment assembly processes, so the figures stated above are only estimates.

After being manufactured, the next step in a garment’s life cycle is its distribution and transportation to its point of sale, whether that is a warehouse for an online store, or a physical retail location. Patagonia’s Common Threads Initiative study found that overseas shipping of garments and textile waste (by container) does not produce the greatest impact, but rather that the "last-mile" delivery of garments to consumer’s homes does (typically via delivery trucks). That said, this study did investigate the energy usage of garments being collected from homes and shipped to retail locations for processing. However, since the delivery of a Nano Puff jacket would proceed in an identical but reversed manner (retail location > customer’s residence) one can make the assumption that energy required for transportation would be the same. Patagonia has calculated that it takes 3504MJ on average to transport 1.11 tons of garments in this scenario, which gives ~1.31MJ per individual 337-gram jacket. This all operates under the assumption that transportation to and from a customer’s residence carries the same energetic requirements. In summary, this figure establishes the transportation phase as one of the (if not the) most energy-intensive stages of the Nano Puff jacket’s life-cycle.

The use phase is oftentimes the most energy-intensive phase of a garment’s lifecycle, due to the repeated instances of laundering, drying and possibly ironing taking place over the years a typical garment is kept in use. This energy usage does vary between garment types, with tops and undergarments being washed and dried far more frequently than, for example, sportswear (JRC IMPRO-Textiles). In the case of this paper’s focus, Patagonia’s Nano Puff jacket, its use phase requires a smaller amount of energy on average because it only requires infrequent laundering (1-2x per year is recommended for similar down-insulated jackets). The data presented in the European Commission’s IMPRO-Textiles report states that the average washing machine in the EU uses 0.21 kWh per kilogram clothing every wash cycle. When this is applied to the figure of 1-2x washes per year, along with a lifespan of five years and an average 337g weight, it follows that the use cycle of the average Nano Puff jacket requires 1.25MJ in lifetime use phase energy.

Modest use-phase energy needs, as described above, likely only apply to garments such as the Nano Puff jacket; worn in colder conditions and / or while inactive, where perspiration and bacterial growth are less significant factors.

As a garment becomes riddled with holes, rips and patches, its fabric pills or fades and it becomes unsuitable for repair, reuse or consignment; its owner usually begins to consider recycling or other end-of-life options. The recycling of garments typically proceeds one of two ways: Open Loop Recycling (OLR) or Closed Loop Recycling (CLR). In OLR, a garment is broken down into its base components which can then be repurposed into new materials or products; it enters into a new product life cycle that may be completely different from the original (ex: PTE bottles into textiles). It is termed "open" loop because it only diverts material from landfills or incineration temporarily. In CLR, however, the garment in question is broken down and its materials are re-incorporated into its original production system. This way, the raw materials ideally don’t leave the system and can be repeatedly recycled (Muthu, Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing). Repurposing a garment through either OLR or CLR processes requires, on average, a lower energy investment than any other step of the lifecycle save disposal/incineration (JRC IMPRO-Textiles). In the case of PET fibers, which make up 100% of the Nano Puff Jacket (small amounts of metal are used in the zipper sliders, as well as elastane in the cuffs, but there is insufficient data to be found on non-PET components of the jacket) (Patagonia), recycling requires energy on par with the raw materials processing stage, with 11,962 MJ energy required to recycle 1.1 tons of polyester fabric into one ton of DMT.

When it comes to disposing of a garment, incineration or relegation to a landfill are the two common options. Of the two, incineration can actually lower the overall lifecycle emissions of the product when it is processed in an energy-recovering facility, which produces electricity by burning waste. According to Ecoinvent, 1.36 MJ of heat and 2.86 MJ of electricity are recovered on average for 1 kg of textile incinerated [JRC IMPRO-Textiles]. Applying this figure to the 337g weight of the Nano Puff jacket, we get an average of 0.96382 MJ electricity recovered. Assuming the entire jacket (not just components that are hard to recycle) is incinerated, this represents a significant amount of harvestable energy. This energy return can essentially offset some of the electricity required to manufacture and maintain the garment in the first place, lowering its overall lifecycle emissions.

In conclusion, the most effective by far way to lower the lifetime energy impact of an item of clothing is to keep it in use as long as possible. With garments as well-constructed as Patagonia’s, this becomes more realistic for the consumer. When considering their Nano Puff Jacket, the fact that it requires so little laundering or drying only adds to these points. Because of this, the use phase of the Nano Puff requires little energy compared with the manufacturing and transportation phases, which both rely on heavy, often inefficient machinery. With the Nano Puff Jacket, its higher up-front retail cost translates into longevity and a reduced environmental and energy impact, making it a worthwhile investment.

Bibliography

Rodie, J. B. (2010). "From waste to worth". Textile World, 160(6), 24-26. https://www.proquest.com/trade-journals/waste-worth/docview/818752308/se-2

Schut, Jan H. "Sustainability Drives Innovation at Leading RPET Processors". Plastics Technology, vol. 56, no. 1, 2010, pp. 20-23. ProQuest, https://www.proquest.com/trade-journals/sustainability-drives-innovation-at-leading-rpet/docview/208308718/se-2.

Qian, Weiran, et al. “Carbon Footprint and Water Footprint Assessment of Virgin and Recycled Polyester Textiles.” Carbon Footprint and Water Footprint Assessment of Virgin and Recycled Polyester Textiles, Textile Research Journal, 1 Jan. 1970, https://pubag.nal.usda.gov/catalog/7561291.

Tamoor, Muhammad, et al. "The Cradle-to-Cradle Life Cycle Assessment of Polyethylene Terephthalate: Environmental Perspective". Molecules, vol. 27, no. 5, 2022, pp. 1599. ProQuest, https://www.proquest.com/scholarly-journals/cradle-life-cycle-assessment-polyethylene/docview/2637763833/se-2, doi:https://doi.org/10.3390/molecules27051599.

Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing, edited by Subramanian Senthilkannan Muthu, Elsevier Science & Technology, 2015. ProQuest Ebook Central, https://www.proquest.com/legacydocview/EBC/2110660?accountid=14505.

Business for Social Responsibility. Apparel Industry Life Cycle Carbon Mapping - BSR. 2009, www.bsr.org/reports/BSR_Apparel_Supply_Chain_Carbon_Report.pdf.

SAJN Nikolina. "Environmental Impact of the Textile and Clothing Industry: What Consumers Need to Know". Think Tank | European Parliament, 17 Jan. 2019, www.europarl.europa.eu/thinktank/en/document/EPRS_BRI(2019)633143.

Yasin, S., Behary, N., Rovero, G. et al. "Statistical analysis of use-phase energy consumption of textile products". Int J Life Cycle Assess 21, 1776–1788 (2016). https://doi.org/10.1007/s11367-016-1129-2.

Patagonia. Patagonia’s Common Threads Garment Recycling Program: A Detailed Analysis. www.patagonia.com/on/demandware.static/Sites-patagonia-us-Site/Library-Sites-PatagoniaShared/en_US/PDF-US/common_threads_whitepaper.pdf.

Bartl, A. "Textiles production and end-of-life management options". Plastic Waste and Recycling, 2020, 251–279. https://doi.org/10.1016/B978-0-12-817880-5.00010-4.

Adrien, B et al. “Environmental Improvement Potential of textiles (IMPRO Textiles).” (2014).

Palacios-Mateo, Cristina, et al. “Analysis of the Polyester Clothing Value Chain to Identify Key Intervention Points for Sustainability - Environmental Sciences Europe.” SpringerOpen, Springer Berlin Heidelberg, 6 Jan. 2021, https://enveurope.springeropen.com/articles/10.1186/s12302-020-00447-x.

Muthu, Subramanian Senthilkannan. Assessing the environmental impact of textiles and the clothing supply chain. Woodhead publishing, 2020.

Çay, A. (2018). Energy consumption and energy saving potential in clothing industry. Energy, 159, 74–85. https://doi.org/10.1016/J.ENERGY.2018.06.128

Xiang Li

Aida Yuan, William Boyd

Professor Cogdell

DES 40A

March 12, 2023

The Waste and Pollution Phase of Patagonia Nano Puff Jacket

The Patagonia Nano Puff Jacket is famous for its eco-friendly and sustainable recycled polyester material that is widely used around the world. However, the production, use, and disposal of this product have been found contributing to several significant environmental issues, including water waste and air pollution. With an emphasis on the emission procedure of the Patagonia Nano Puff Jacket, there are some unnoticeable ways of discharging pollution which have negative impacts on the environment. The disposal of the Patagonia Nano Puff Jacket has hidden environmental impacts as synthetic fibers in the puff jacket may take hundreds of years to decompose. This is evident in every phase of the life cycle, which highlights how the generation of waste and pollution has seriously devastating effects on ecological systems.

The extraction of raw materials for Patagonia Nano Puff Jacket may contribute to waste and pollution during the procedure within different forms, such as gas or water emission. The main composition of the raw materials of this product includes recycled polyester and plastic. It requires a large amount of recycled polyester when producing the jacket's insulation, outer shell, lining, and thread. The acquisition of recycled polyester, particularly the extraction of synthetic fibers, influences majorly on greenhouse gas emission. When acquiring recycled polyester, it utilizes fossil fuels which may releases primarily carbon dioxide and other greenhouse gases into the atmosphere. Similarly, it involves the extraction and processing of fossil fuels, which contribute to greenhouse gas emissions when acquiring plastic that would be used in zipper. Plastic pollution is a significant environmental problem that it takes hundreds of years to decompose. Additionally, the acquisition of recycled polyester for Patagonia Nano Puff Jacket has impact on oceans and water bodies. The procedure involves the use of chemicals, such as ethylene glycol and dimethyl terephthalate, which has the potential to be toxic and pollute water bodies if not treated appropriately. Finally, the acquisition of recycled polyester for Patagonia Nano Puff Jacket requires the use of natural resources such as petroleum and minerals. The mining and exploitation of these materials may result in environmental damage and resource depletion. Also, the toxic byproducts during mining may hurt workers’ health in a long-term view. Considering the demonstration of the waste and pollution caused by raw materials, it is also crucial to point out that the manufacturing phase of the Patagonia Nano Puff Jacket may significantly affect emission.

The manufacturing of recycled polyester used in Patagonia Nano Puff Jacket is responsible for substantial pollution, including greenhouse gas emissions, water pollution, and hazardous chemical waste. The formulation phase of the jacket involves several processes such as extracting materials, cutting, sewing, and finishing. Firstly, the manufacturing process of recycled polyester requires tremendous energy, which is often generated from non-renewable sources such as coal, oil, or natural gas. Within the procedure, it produces greenhouse gas emissions and carbon dioxide which have a negative impact to the environment. Additionally, the extraction of these resources can contribute to resource depletion. Secondly, the manufacturing process of recycled polyester utilizes a significant amount of water to wash the materials. It may contaminate water sources with chemicals and dyes in the factories, including solvents and detergents. “It is estimated that “58% of the wastewater from urban areas and 81% of industrial wastes are discharged directly into water bodies with no or inadequate treatment results in contamination of 73% of the water bodies” stated by Vargas (Vargas-Gonzalez et al. 1). As a result, those waste products can end up in water bodies and landfill outside the factories which leads to pollution influencing animals and human’s health. Thirdly, chemicals include solvents and detergents are used during the production process of recycled polyester. It could be severely harmful to the environment if these substances are not properly disposed. Also, toxic chemicals in the wastewater which are produced during the formulation have the potential to pollute waterways and threaten aquatic life. Overall, the waste and pollution produced in the manufacturing process of recycled polyester has a significant impact on the environment. The polluted emission is still occurring during the distribution phase even though the formulation stage has end.

The distribution phase of Patagonia Nano Puff Jacket involves the transportation of the jacket from the manufacturing facility to customers and energy consumption which may contribute to greenhouse gases emission and air pollution. The jacket is normally distributed through a series of transportation stages, including transit from the factory to the distributor by ship, truck, or plane; from the distributor to the retailer by truck or plane; and from the retailer to the customer by automobile, truck, or plane. In this procedure, emissions of greenhouse gases have been generated along the transportation, which are primarily carbon dioxide from internal combustion engines that typically use gasoline and diesel. Each of these phases has the potential to increase greenhouse gas emissions, which may ultimately contribute to global warming. The distribution of the jacket also requires a large amount of energy consumption, including loading and unloading the truck, running the factory and retail stores, and delivering. Each of these activities would cause energy consumption, which overall increases the carbon footprint. Additionally, the packaging materials used to ship the Patagonia Nano Puff jacket, such as cardboard boxes, plastic bags, and protective coverings, may contribute to waste and pollution if not disposed appropriately. Primarily, the distribution phase of Patagonia Nano Puff Jacket causes air waste and pollution. When it moves on to the next stage which is use and maintenance phase, the emission would mainly in the form of water.

The use and maintenance phase of Patagonia Nano Puff Jacket may contribute to water pollutants such as microfibers, energy use and landfill waste. Chemicals from laundry detergent and fabric softener may leak into the water system when customers wash the puff jacket. Sunanda explained that “Approximately 13 million tons microfibers all over the world along with coastal waste are entering the ocean yearly from which around 3 million tons are entering through rivers” (Mishra et al. 247). Moreover, washing jackets might discharge synthetic microfibers in the water bodies which would harm aquatic life and contaminate waterways. Some customers choose to dry clean their Patagonia Nano Puff Jacket, which involves the use of potentially toxic chemicals. These substances have the possibility of polluting the air, groundwater, and landfill. The energy used for the jacket's washing and dry-cleaning leads to greenhouse gas emissions. Also, using a dryer to dry the jacket rather than letting it air dry will consume more energy which may have a negative impact on the environment. Subsequently, while the Patagonia Nano Puff jacket is made to be durable and resilient, there are still a possible number of waste and pollution generated during use and maintenance. As the puff jacket has been used for some time, customers may repair or recycle it which enters the recycle stage.

The recycle phase of Patagonia Nano Puff Jacket involves the remake and recycling the product from the consumers which may release pollutants as greenhouse gases, toxic chemicals, and scrap waste in air, water, or landfill. The process includes shredding the jacket into small pieces using laser cut and scissor cut which are then melted down and collected to make new polyester fibers for new products. Moreover, Ramasamy expressed that “scissor cut samples showed a higher release of microfiber than the laser cut sample due to its mechanical damage during the cutting” (Ramasamy and Subramanian 41600). However, some materials might be incapable of being efficiently separated which contributes to useless waste, including leftover scraps from the manufacturing process. There could be additional waste produced from those procedures due to the recycling process. Synthetic material recycling can lead to the discharge of contaminants like greenhouse gases and hazardous chemicals, which might exacerbate air and water pollution. Moreover, Patagonia company has promoted a recycle program called Worn Wear which basically states customers may trade in and purchase used products. This is an ideal approach while it still produces waste and pollution during transportation. Vehicles and trucks that employed to transit used puff jackets will generate air pollution as greenhouse gases and carbon dioxide which is harmful for the environment. Overall, the Patagonia’s Worn Wear Program would be the most effective and sustainable strategy compared with others. Despite of recycling used products, there are still a significant amount of puff jackets are being disposed by customers, retailers, and factories which leads to the disposal phase.

The disposal phase Patagonia Nano Puff Jacket involves plastic pollution in landfill, air emission caused by incineration, and water pollution containing microplastics. Moreover, severe chemical pollution may influence in a wide range, including air, water, and landfill which should be brought attention to all of us. Firstly, if the puff jacket has been disposed directly into the ground, it won’t biodegrade since it is recycled polyester. Synthetic materials as recycled polyester take a long time to break down which contributes to the accumulation of non-biodegradable waste. Secondly, when the puff jacket has been disposed within a special treatment as incineration, it can release hazardous pollutants into the air, including redundant carbon dioxide, nitrogen oxides, and sulfur dioxide. These contaminants may increase air pollution and have negative impacts on human health and the environment. Thirdly, if the jacket is not disposed of properly and ultimately ended up in waterways, it can discharge microplastics into the water. De Falco investigated that “the release of microfibers from garments with a mixed composition of polyester/ cotton/ modal is still very strong after 10 washing cycles and is mainly composed by cellulosic microfibers” (De Falco et al., 8). Scientists discovered that when recycled polyester is washed, microfibers are emitted which can eventually end up in streams. Significantly, aquatic life may be harmed by these microplastics. Moreover, it has the potential to enter the food chain. Pauly argues that “With this, they have reported that microplastics could be the potential reason for causing cancer” (Pauly et al. 1998). Microplastic particles that are consumed by people can't simply pass through the body but remaining in it which has an adverse effect on a human's health. Lastly, in the manufacturing phase, Patagonia Nano Puff Jacket has used chemicals that are hazardous to the environment, such as dyes or treatments to make the material water-resistant. When disposing the product as in regular trash, these chemicals have the possibility of leaching into the ground or water which contribute to pollution. The waste and pollution can be significantly hazardous if the disposal has not been taken properly. Patagonia company has identified this environmental issue and develops several sustainable solutions.

With the awareness of the severe environmental waste and pollution, Patagonia has promoted another recycling approach called Rethread program which attempts to establish a retail recycling program for used garments. In order to increase the lifespan of products, the program encourages customers to send their old items for recycling and reuse. However, it has been found that the retail recycling program had an insignificantly slight impact. On the other hand, Drochytka explored the possibilities for thermal utilization of waste polyester. According to the study, waste polyester could be burned to generate energy which may lower the demand for fossil fuels. In summary, the sustainable approaches may mitigate slightly on waste and pollution which emphasizes the necessity of utilizing more sustainable materials at the first place.

In conclusion, even as a worldwide popular clothing, the Patagonia Nano Puff Jacket nevertheless contributes to waste and pollution issues. From raw material extraction to disposal, each stage of the jacket's life cycle contributes to environmental damage in different aspects. Primarily, synthetic recycled polyester material is the major cause of waste and pollution of Patagonia Puff Nano Jacket. Furthermore, washing jackets may trigger the discharge of microplastics, leading to environmental degradation. To minimize the effects of manufacturing and disposal on the environment, it is vital to consider the complete life cycle of the products we purchase. Overall, the Patagonia Nano Puff Jacket which is manufactured from recycled polyester and plastic would generate waste and pollution throughout its life cycle, especially at the disposal phase. Hopefully, Patagonia Cooperative could be able to develop and utilize more eco-friendly materials in the future.

Works Citation

Bosco, Mary-Clare. “From Yosemite to a Global Market: How Patagonia, Inc. Has Created an Environmentally Sustainable and Socially Equitable Model of Supply-Chain Management.” Semantic Scholar, May 2017, https://www.semanticscholar.org/paper/From-Yosemite-to-a-Global-Market%3A-How-Patagonia%2C-anBosco/35174c18d09ad75214e620fa3860fc137bba134f.

De Falco, Francesca, et al. “The Contribution of Washing Processes of Synthetic Clothes to Microplastic Pollution.” Nature News, Nature Publishing Group, 29 Apr. 2019, https://www.nature.com/articles/s41598-019-43023-x.

Drochytka, Rostislav, et al. “Performance Evaluation and Research of Alternative Thermal Insulation Based on Waste Polyester Fibers.” Procedia Engineering, 20 July 2017, https://www.sciencedirect.com/science/article/pii/S1877705817321033.

Ganesh, Lamichhane, et al. “Analysis of Microfibers in Waste Water from Washing Machines”, Theseus. 2018, https://www.theseus.fi/bitstream/handle/10024/141278/Lamichhane_Ganesh.pdf?sequence=1.

Mishra, Sunanda, et al. “Emerging Microfiber Pollution and Its Remediation.” SpringerLink, Springer Singapore, 17 Apr. 2021, https://link.springer.com/chapter/10.1007/978-981-15-5499-5_9.

Madrigal. “Patagonia Rethread: Creating a Retail Recycling Program for Post-Consumer Clothing.” ScholarWork, California State Polytechnic University, Pomona, 26 June 2020, https://scholarworks.calstate.edu/concern/theses/00000524m?locale=en.

Palacios-Mateo C, Yvonne, et al. “Analysis of the Polyester Clothing Value Chain to Identify Key Intervention Points for Sustainability.” Environmental Sciences Europe, U.S. National Library of Medicine, 6 Jan. 2021, https://pubmed.ncbi.nlm.nih.gov/33432280/.

Pauly JL., Stegmeier SJ, and Allaart HA. “Inhaled Cellulosic and Plastic Fibers Found in Human Lung Tissue.” Cancer Epidemiol Biomarkers Prev., U.S. National Library of Medicine, 1998, https://pubmed.ncbi.nlm.nih.gov/9610792/.

Periyasamy, A., J. Militký. “LCA (Life Cycle Assessment) on Recycled Polyester: Semantic Scholar.” Environmental Footprints of Recycled Polyester, Jan. 2020, https://www.semanticscholar.org/paper/LCA-(Life-Cycle-Assessment)-on-Recycled-Polyester-Periyasamy-Militk%C3%BD/4aa91546bda417756380cfef9eaa38b5895f210b.

Qian, Weiren, et al. “Carbon Footprint and Water Footprint Assessment” Sage Journals, 9 Apr. 2021, https://journals.sagepub.com/doi/10.1177/00405175211006213.

Ramasamy, Rathinamoorthy, and Raja Balasaraswathi Subramanian. “Synthetic Textile and Microfiber Pollution: A Review on Mitigation Strategies.” SpringerLink, Springer Berlin Heidelberg, 8 June 2021, https://link.springer.com/article/10.1007/s11356-021-14763-z.

Vargas-Gonzalez HH, Arreola-Lizarraga JA, and Mendoza-Salgado RA., “Effects of Sewage Discharge on Trophic State and Water Quality in a Coastal Ecosystem of the Gulf of California.” TheScientificWorldJournal, U.S. National Library of Medicine, 24 Feb. 2014, https://pubmed.ncbi.nlm.nih.gov/24711731/.

Wang, Yaqun. “Production and Waste Treatment of Polyesters: Application of Bioresources and Biotechniques.” Taylor & Francis, Apr. 2022, https://www.tandfonline.com/doi/full/10.1080/07388551.2022.2039590.

Zhou, Quan, and Lingbo Meng. “Environmental Perspectives of Textile Waste, Environmental Pollution and Recycling.” Taylor & Francis, 5 Apr. 2022, https://www.tandfonline.com/doi/full/10.1080/21622515.2021.2017000?scroll=top&needAccess=true&role=tab.