Design Life-Cycle

assess.design.(don't)consume

Oliver Xie

Atticus King, Ray Belen

DES 40A

Professor Cogdell

The Evolution of Transparent TV Manufacturing

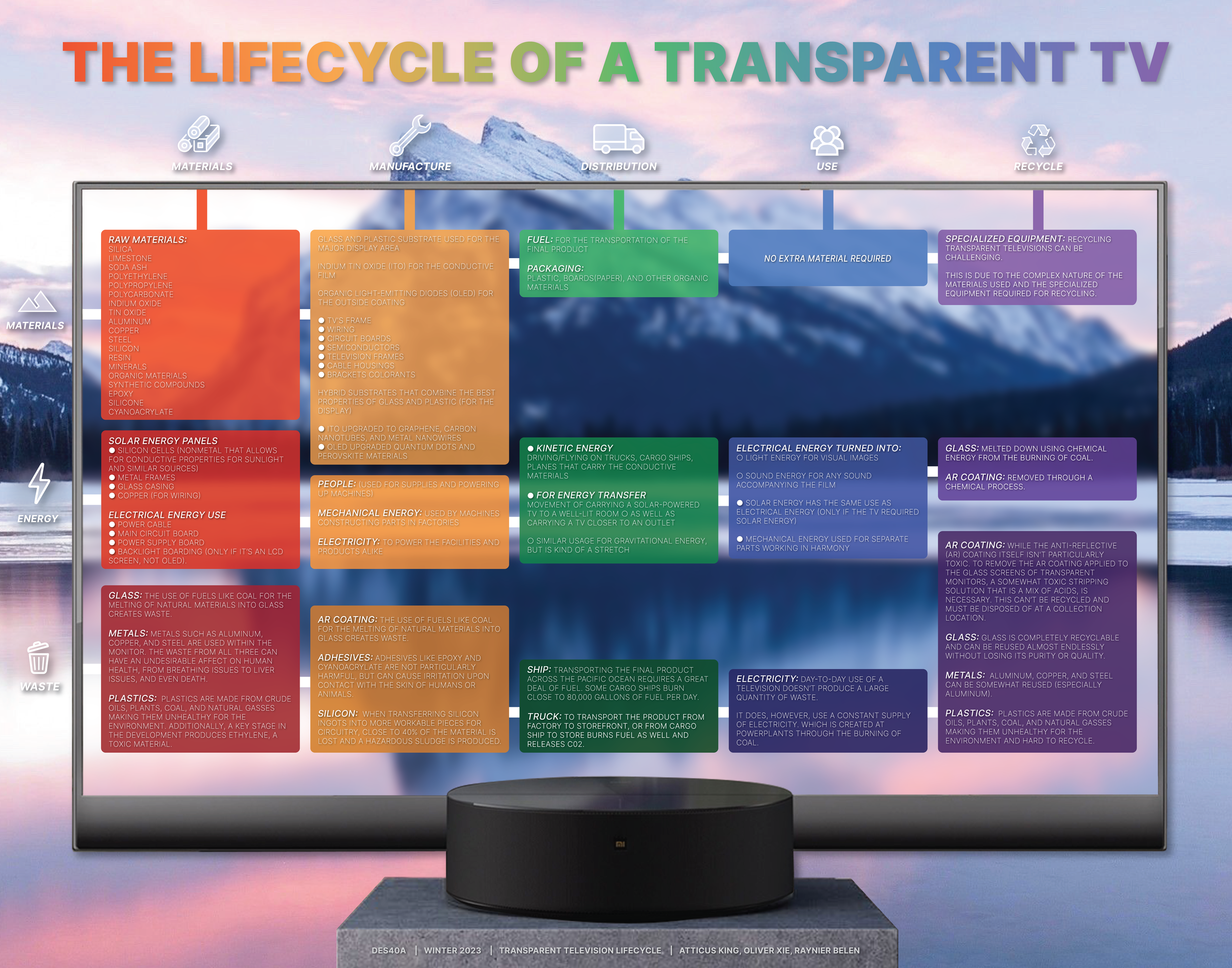

As the rapid development of technology goes on, the transparent TV/display emerged as a cutting-edge technology in the display realm. Traditional displays like television or computer monitor provide a viewing experience by blocking the view of what is behind the screen(Brain Ch.10). However, transparent television offers an immersive viewing experience by blending in with the environment. In other words, transparent TV could let users see what is behind the screen while watching it. Overall, transparent television’s revolutionary changes in display interactions caused more electronic companies to start to manufacture it. On August 16, 2020, Xiaomi claimed the Mi TV LUX to be the world’s first mass-produced transparent OLED TV(Steffen 1). However, transparent television is still in its infancy. Throughout the life cycle of the transparent TV, this product still needs a lot of improvements, especially in its raw material acquisition and product manufacturing. To turn transparent TV into a better product, researchers and manufacturers are gradually improving transparent TV manufacturing and its facilities.

The major difference between a transparent TV and a regular TV is its display area, which is made of varied materials. First of all, the transparent TV's major display area is made of special substrate materials. It is a critical component that determines the transparency and durability of the display. In general, two types of substrates are used in transparent TV: glass and plastic. Glass is made of silica, limestone, and soda ash and it is a popular substrate material due to its excellent transparency and scratch resistance. However, this glass might be special for different companies. For instance, Xiaomi's Lux TV is made of special tempered glass(MioT 1). On the other hand, the plastic substrate is mainly made of polyethylene, polypropylene, and polycarbonate(Saran et al. 1). Due to its lightweight and extension properties, it is suitable to create a larger display or specific devices. Another important part of the transparent TV is the choice of conductive films. Transparent conductive films are used to apply a voltage to the display. The most commonly used transparent conductive film is indium tin oxide(ITO) and it is made of indium oxide and tin oxide(Meyer 17.2.1). ITO has excellent electrical conductivity and transparency, making it an ideal material for transparent displays. Last but not least, organic materials are used to create the light-emitting surface of the display. The most commonly used organic material is organic light-emitting diodes, which is OLED. The materials used to make OLED displays can include carbon-based compounds, such as polyfluorene or polyphenylene vinylene, as well as other organic compounds(Choi 1). OLEDs offer several advantages over traditional displays, including high brightness, contrast, color gamut, and low power consumption. All of these materials are critical to making a transparent TV display area.

Although transparent TV is a cutting-edge technology, it still has similar components as regular TV. Most of its components are made of a common material: metals. The metals in TV production include aluminum, copper, steel, and others. These metals are mainly used in the production of the TV's frame, wiring, and circuit boards(Television 1). Among those metals, silicon plays an important role. Silicon is a key component of television circuitry. It is used to produce semiconductors, which are essential components of televisions(Avins 70). Despite metals, plastics are another great portion of material. Plastics are used in the production of television frames, as well as in internal components such as cable housings and brackets. Common plastics used in television production include ABS (acrylonitrile butadiene styrene) and polycarbonate(Plastic Europe 1). To decorate the plastic, various materials are used in the coloring process. For external coloring, it requires pigment to paint. On the other hand, internal coloring requires colorants and resin mixed it up inside the plastic(Toyocolor 1). The colorant is mainly made of minerals, organic materials, and synthetic compounds(Harris 236). Last but not least, to assemble those components together, adhesives play an important role. Common adhesives used in television production include epoxy, silicone, and cyanoacrylate(Bitzer 210).

Once the manufacturing is done, it is worth considering the materials used in distribution. For the distribution of the transparent TV, except using normal transportation and fuels, the packaging of the TV takes a great portion of material usage. Typically, electronic devices such as televisions are packaged with materials such as foam and cardboard. Foams are usually made of polyurethane and polystyrene(Agnė 1). On the other hand, cardboard is commonly made of wood and fibers(Quim 1). These synthesized materials help absorb shock and prevent damage to the delicate electronic components inside the television(Blackwell Ch.14). In the case of a transparent OLED display, additional care may be required to prevent damage to the display itself. The manufacturer may use special packaging materials or techniques, such as reinforced foam padding or protective films, to ensure that the display remains intact during transport. It's also worth noting that packaging practices can vary depending on the manufacturer, so the materials used to pack a transparent TV may differ between brands and models.

Although all of these materials are important materials to build a transparent TV, they have different problems that needed to be resolved. The glass substrate of transparent tv is brittle and heavy compared with regular TV glass. This problem makes it unsuitable under certain conditions. Compared with glass substrates, plastic substrates are lightweight and flexible. However, plastic substrates are less transparent than glass. It also can be easily scratched, reducing the overall durability of the display. To overcome these limitations, researchers are exploring the use of hybrid substrates that combine the best properties of glass and plastic(Choi 1). On the other hand, ITO also has several limitations, including high cost, brittleness, and limited flexibility. To overcome these disadvantages, researchers are exploring the use of alternative materials such as graphene, carbon nanotubes, and metal nanowires (Zheng et al. ch.4 ). These materials offer excellent conductivity and transparency and are more flexible and durable than ITO. Last but not least, OLED also can be improved. OLED has low durability and poor performance at high temperatures. To decrease the effect of these limitations, researchers are exploring the use of alternative materials, like quantum dots and perovskite materials(Jou 1). These materials offer excellent optical properties, durability, and stability which make them ideal for use in transparent TV. Overall, the evolution of the transparent TV's display creation reflects multiple difficulties in creating this cutting-edge device. However, people’s continuous efforts are gradually improving transparent TV.

On the other hand, more and more scientists are researching the saving of the common raw materials and synthetic materials that are used by the manufacturer (Toolkit 1). Since electronics already caused a lot of waste and pollution and it is critical to decreasing the deleterious effect of transparent TV production(Islam 1). For instance, the use of recycled materials is a great improvement for transparent TV manufacturing. To reduce the waste generated during regular component production, manufacturers start to implement recycled materials, including glass, plastic, and organic materials. They optimize production processes to minimize waste generation, and adopt environmentally friendly production technologies(Cole et al. 3.3). Moreover, people are discovering more materials to replace the old designs, including both manufacturing and facilities(Paviet 1). Those recycled and new materials can also save some resources and be applied in different realms, like the packaging. All of these are great signs of manufacturing evolution. Despite saving the materials on manufacturing, recycling transparent TV can help to reduce waste and conserve natural resources. However, recycling transparent TV can be challenging due to the complex nature of the materials used and the specialized equipment required for recycling. It makes it challenging to effectively recycle these products(Asante 1). To overcome these challenges, the community is gradually establishing an effective recycling infrastructure and incentivizing consumers and manufacturers to recycle transparent TV(Toolkit 1). The evolution of manufacturing ultimately leads to improvements in the community and facilities. Although the recycling and production of Transparent TVs required a lot of circumstances, its benefits are invaluable for the future production of transparent TV.

In conclusion, the production of transparent TV not only represents the advancement in display technology but also reflects the gradual improvements of material and facility evolution. The evolution of transparent TV manufacturing showcases people’s effort to enhance the overall manufacture of transparent TV and protect the future environment. Although the transparent display is mainly used under certain high-tech conditions, it is worth expecting to see more creative and groundbreaking developments in transparent TV production.

Works Cited Page:

Agnė Kairytė, Mikelis Kirpluks, Aiga Ivdre, Ugis Cabulis, Saulius Vaitkus, Ina Pundienė, Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact, Journal of Cleaner Production, Volume 183, 2018, Pages 760-771, ISSN 0959-6526, https://doi.org/10.1016/j.jclepro.2018.02.164.

Asante, Kwadwo Ansong. “E-Waste Recycling in Africa: Risks and Opportunities.” Current Opinion in Green and Sustainable Chemistry, Elsevier, vol. 18, 9 Apr. 2019, p 109-117 www.sciencedirect.com/science/article/pii/S2452223618301445#section-cited-by.

Bitzer, T. N. Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing. Springer Netherlands, 2009.

Blackwell, Glenn R. The Electronic Packaging Handbook. CRC Press, 2000.

Brain, Marshall. “How Television Works.” HowStuffWorks, HowStuffWorks, 26 Nov. 2006, electronics.howstuffworks.com/tv.htm#pt10.

Choi, Seongwook et al. “Hybrid-Type Transparent Organic Light Emitting Diode with High Contrast Using Switchable Windows.” International journal of molecular sciences vol. 24,2 1097. 6 Jan. 2023, doi:10.3390/ijms24021097

Cole, Christine, et al. “Assessing Barriers to Reuse of Electrical and Electronic Equipment, a UK Perspective.” Resources, Conservation & Recycling: X, Elsevier, vol.1, 27 June 2019, www.sciencedirect.com/science/article/pii/S2590289X19300015.

Harris, Ronald M. Coloring Technology for Plastics. Plastics Design Library, 1999.

“How Plastics Are Made • Plastics Europe.” Plastics Europe, 3 May 2022, plasticseurope.org/plastics-explained/how-plastics-are-made/#:~:text=Plastics%20are%20made%20from%20natural,%2C%20of%20course%2C%20crude%20oil.

Islam, Md Tasbirul. “Young Consumers' e-Waste Awareness, Consumption, Disposal, and Recycling Behavior: A Case Study of University Students in Sydney, Australia.” Journal of Cleaner Production, Elsevier, vol. 282, 4 Oct. 2020, www.sciencedirect.com/science/article/pii/S0959652620345340.

J. Avins, "Integrated Circuits in Television Receivers," in IEEE Transactions on Broadcast and Television Receivers, vol. 12, no. 3, pp. 70-74, July 1966, doi:10.1109/TBTR1.1966.4319994.

Jou, Jwo-Huei. “Extraordinarily High Efficiency Improvement for OLEDs with High Surface-Charge Polymeric Nanodots.” The ACS Guide to Scholarly Communication - ACS Publications, 26 June 2010, pubs.acs.org/doi/full/10.1021/acsguide.40303.

Meyer, J., Görrn, P., & Riedl, T. (2014, March 27). Transparent OLED displays. Organic Light-Emitting Diodes (OLEDs). Retrieved February 28, 2023, from https://www.sciencedirect.com/science/article/pii/B9780857094254500178

“Miot Wholesaler.” MiOT Wholesaler, miot-global.com/tv-sets/mi-tv-lux/.

Neerja Saran, Kunjal Parikh, Dong-Seok Suh, Edgar Muñoz, Harsha Kolla, and Sanjeev K. Manohar. Journal of the American Chemical Society 2004 126 (14), 4462-4463 DOI: 10.1021/ja037273p

Paviet-Hartmann, Patricia, Kerlin, William, and Bakhtiar, Steven. TREATMENT OF GASEOUS EFFLUENTS ISSUED FROM RECYCLING – A REVIEW OF THE CURRENT PRACTICES AND PROSPECTIVE IMPROVEMENTS. United States: N. p., 2010. Web.

Quim Tarrés, M. Àngels Pèlach, Manel Alcalà, Marc Delgado-Aguilar, Cardboard boxes as raw material for high-performance papers through the implementation of alternative technologies: More than closing the loop, Journal of Industrial and Engineering Chemistry, Volume 54, 2017, Pages 52-58, SSN 1226-086X, https://doi.org/10.1016/j.jiec.2017.05.016.

Steffen, Luana. “The World's First Mass-Produced Transparent TV, by Xiaomi.” Intelligent Living, 7 Sept. 2020, www.intelligentliving.co/worlds-first-mass-produced-transparent-tv/.

“Television.” How Products Are Made, www.madehow.com/Volume-3/Television.html#:~:text=1%20Almost%20all%20television%20housings,assembled%20to%20complete%20the%20housing.

“Toolkit: Green Production Guide.” Green Production Guide |, 8 Mar. 2023, www.greenproductionguide.com/tools/.

TOYOCOLOR. “What Is the ‘Plastic Colorants’?” What Is the "Plastic Colorants"? | Products | TOYOCOLOR, www.toyo-color.com/en/products/plastic_colorants/about.html#:~:text=Plastics%20(resin)%20are%20nearly%20colorless,coloring%20the%20surface%20of%20plastics.

Zheng, Qingbin, et al. “Graphene Oxide-Based Transparent Conductive Films.” Progress in Materials Science, Pergamon, 25 Mar. 2014, www.sciencedirect.com/science/article/pii/S0079642514000279.

Raynier Cedric Belen

Oliver Xie, Atticus King

DES40A

Professor Cogdell

The Energy of Transparent TVs

When looking back on the history of television, it’s astounding to see how society has come from using antennas on rounded, bulky TV’s to flat screens that utilize a wireless signal. Television was and still is an intriguing invention that has a booming industry behind it because of how immersive and engaging activities are with television. As technology advances, it allows innovators to improve upon already efficient inventions and lead them into a direction that would make them “more of” something. An example to note would be the transparent televisions that were developed to have a clear screen, similar to looking through a glass table (Faulkner 2020). Many companies have developed their own version of a “transparent TV”, which includes Samsung, LG, and by far the most successful and recent, Xiaomi. A major thing that each companies’ version of the transparent televisions have is that, it accomplishes its goal of increasing the aspect of immersion and engagement because of the sleek design blending into its surroundings; furthermore, it has the novelty of being able to see through it which is the focal point that got people hooked. Another plus side is that due to this innovation, the components used in creating a transparent television require less energy (Awa-abuon 2021) which reduces harmful emissions and detriment to the Earth. The energy life cycle of transparent televisions is an intricate one as it utilizes various types at various stages; for example, chemical energy for recycling and basic kinetic energy for transportation. Regardless of the process, the creation of the transparent TV may be one of the ways for energy to be more efficiently used in the future.

When looking at the transparent television, there are two forms of energy utilized in the actual activation of the television, electrical energy and/or solar energy. The basics of electrical energy is that it employs the components with conductive elements to allow the energy to be usable . It has a whole system of parts that enables this to happen, and it usually includes the power cable, main circuit board, and the power supply board (Chung et. al 2015). Alongside wiring, as these components work in tandem, they’re able to successfully provide energy for the television. On the other hand, some companies have taken advantage of the solar-harnessing technology and tried to apply it to this creation, such as Samsung (Stewart 2011). The way this works is that the solar panels are built onto the hardware of the television and works with a similar process of electrical conductibility, just with solar energy. The same power cable and power supply boards are used to transport that energy; however, different materials are used in order to actually harness the power of the sun. In order for that to happen, they had to create solar panels. Components of a solar panel on these televisions included: metal frames, glass casing, copper for wiring, and most importantly, silicon cells (Solar Technology Offices 2023). Silicon cells are the nonmetals that conduct sunlight and similar sources, then turn them into usable energy. After the solar panels have conducted an adequate amount of solar energy, that energy is then used to power the television; to add on, the surplus solar energy is usually kept in an energy bank and used on days where the sun doesn’t shine, or in the night (Clifford 2022). Those are the main sources of energy used to power the actual television.

The next step of the energy cycle WITHIN the transparent television, is the conversion of energies to make images appear and sounds heard. A brief description of what happens after the television is powered up, is the energy is then turned into light and sound energy to convey whatever watching experience the viewer is having. In the instance where an LCD, LED, or OLED screen is involved, the light emitting diodes are powered by whatever type of energy was used (electrical and/or solar) and are rearranged into patterns as individual pixels on the screen that shows the vibrant colors and vivid movement of the film (Lee et. al 2022). The interesting attribute that sets the transparent television apart from other televisions is since it has a clear background, this indicates that there is no backlit board (a component other television models have in order to make the images appear more vibrant against a backdrop). Having no backlit board means that all the energy gained from powering the TV can go to focusing on the vibrancy and brightness of the individual light-emitting diodes; furthermore, this is where the “less energy” part takes place, since the backlit board takes up more energy overall compared to if the energy went into refining the diodes (Chung et. al 2015). Meanwhile, sound energy is produced from the television’s speaker. Going through the same process that the light energy conversion underwent, just through a different television component (the speaker and other sound systems, if there are any). So that would conclude how the energy is utilized and converted WITHIN the television.

After understanding how different energies cycle through the television, there are still other forms of energy involved in the CREATION of the actual television itself. The general energy used to create these televisions would be mechanical energy and kinetic energy (MadeHow 2023). These energies come from the utilization of several different tools and machines used to build the television. Ranging from the motion of hacking a nail in with a hammer to operating a piece of machinery that gets into the nooks and crannies of each hardware. A more specific look into the process of building a transparent television would be to lay out the materials needed for the television screen (usually an OLED screen) without the backlit board piece, piece that together with machinery, then mount it onto the television stand and frame to hold it in, while also maintaining the desired aesthetic of the company (E3 2021). The process of creating the actual transparent tv is fairly simple, nothing super out of the blue. Occasionally, if it does end up being solar-powered, then solar panels are installed into the stand and the wirings are concealed within the frame to still maintain the sleek, clean appearance (Staff 2021). Honestly speaking, kinetic energy and mechanical energy is all that is needed for the creation of any type of technology.

The middle part of the energy life cycle would be how these televisions are transported, whether that’s getting to the designated purchaser or just going to be recycled. To put into vague terms, transportation is usually done by vehicles. Whether it’s by truck, by cargo ship, and/or plane, vehicles are the main (and only) form of transportation. However, in order to power the vehicles that do the heavy lifting, kinetic, gravitational, and chemical energy (into electrical energy) are needed (Rodrigue 2020). Kinetic energy is represented through the people operating the said vehicle and the gravitational energy comes down to the geography of the terrain that they pass through. Chemical energy on the other hand, is more intricate and is represented by the fuel used to power the vehicles (Rodrigue 2020). The main source of chemical energy is petroleum, which is chemically altered into either a gas or steam, that goes through the vehicles’ turbines to generate electricity (World Nuclear Associate 2023). Once the turbines have generated enough electricity, it fuels the vehicle enough to get through and to their destination. The process of energy is a lot more intricate and complicated once it comes to the transportation aspect of the television.

Lastly, the energy aspect of the recycling segment of the life cycle. When it comes to physically recycling the television, most of the components would have to be taken apart and sent to different facilities for whatever the process is. For this portion, the prominent forms of energy utilized are chemical, potential (heat), and mechanical. Some of the components of the television, such as the anti-reflective coating, would need a chemical reaction in order to make it recyclable. In this case, you would submerge the coating into a mixture of alcohol and saltwater in order to break it down, then later use a tool to scrape the coating off of the surface (a form of mechanical energy) (Deziel 2018). Other materials such as the glass used, would be molten down into a malleable material for other products (a form of heat potential energy). Then other solid components such as the frames would most likely just be broken down into smaller pieces and/or repurposed for a different project (MadeHow 2023). The concluding part of the energy life cycle of a transparent television includes a lot of different energies in order to keep our world healthy.

While the television industry keeps growing and creating bombastic products such as the transparent television, the energy cycle for any general tv remains about the same. It is completely dependent on what type of materials were used and how they interact with each other. Regardless of how differently built televisions are, they seem to follow the same footprint. However one thing that will set transparent televisions apart from its older counterparts would be the decrease in the energy consumption of the actual television. All in all, the external life cycle remains the same, but the internal one is a step in the right direction for energy conservation.

Work Cited

Awa-abuon, John. “How Does a Transparent TV Work?” MUO, 16 June 2021, https://www.makeuseof.com/how-does-a-transparent-tv-work/.

Chung, Jin, et al. “Towards Highly Efficient and Highly Transparent Oleds: Advanced Considerations for Emission Zone Coupled with Capping Layer Design.” Optics Express, vol. 23, no. 21, 2015, p. 27306., https://doi.org/10.1364/oe.23.027306.

Clifford, Becky. “Renewable Solar Energy: How Does It Work and Can It Meet Demand?” OUPblog, 19 Apr. 2022, https://blog.oup.com/2022/05/renewable-solar-energy-how-does-it-work-and-can-it-meet-demand/.

Deziel, Chris. “How to Remove Anti-Reflective Coating from Eyeglasses.” Sciencing, 2 Mar. 2019, https://sciencing.com/remove-antireflective-coating-eyeglasses-7631108.html.

Displays, E3. “Transparent and Flexible OLED Displays Are Transforming Traditional Viewing.” E3 Display AZ, 9 Mar. 2021, https://www.e3displays.com/transparent-and-flexible-oled-displays-are-transforming-traditional-viewing/.

Faulkner, Cameron. “Xiaomi's See-through OLED TV Is a Transparent Attempt at Attention, and It's Working.” The Verge, The Verge, 11 Aug. 2020, https://www.theverge.com/2020/8/11/21363861/xiaomi-oled-tv-transparent-mi-lux-china-specs-price-release.

Lee, Junwoo, et al. “RGB‐Color Textile‐Based Flexible and Transparent Oleds Considering Aesthetics.” Advanced Materials Interfaces, vol. 10, no. 2, 2022, p. 2202114., https://doi.org/10.1002/admi.202202114.

Rodrigue, Jean-Paul. “4.1 – Transportation and Energy: The Geography of Transport Systems.” The Geography of Transport Systems | The Spatial Organization of Transportation and Mobility, 9 Jan. 2023, https://transportgeography.org/contents/chapter4/transportation-and-energy/.

Solar Energy Technologies Offices. “Solar Photovoltaic Cell Basics.” Energy.gov, https://www.energy.gov/eere/solar/solar-photovoltaic-cell-basics#:~:text=Silicon%20is%2C%20by%20far%2C%20the,semiconductor%20used%20in%20computer%20chips.

Staff, Grist. “Meet the Zero-Energy Transparent TV.” Grist, 8 Apr. 2021, https://grist.org/cleantech/2011-03-10-meet-the-zero-energy-transparent-tv/.

Stewart, Lea. Samsung Unveils Solar-Powered Zero Energy Transparent TV. https://inhabitat.com/samsung-unveils-solar-powered-zero-energy-transparent-tv/.

“Television.” How Products Are Made, http://www.madehow.com/Volume-3/Television.html#:~:text=1%20Almost%20all%20television%20housings,assembled%20to%20complete%20the%20housing.

“Where Does Our Electricity Come from?” World Nuclear Association, https://world-nuclear.org/nuclear-essentials/where-does-our-electricity-come-from.aspx#:~:text=Fossil%20fuel%20power%20plants%20burn,drive%20turbines%20which%20generate%20electricity.

Atticus King

DES 40A

Professor Cogdell

March 2023

Transparent TV Waste and Emissions

The evolution of televisions and monitors from the standard and typical towards transparency has actually had a positive effect on the renewability and sustainability of the product, this is because it now uses far less plastics in the design and instead much more glass. However, this new evolution of the TV has been developed purely in Asia, which means that to reach the leading target consumers in the United States the product must cross the Pacific Ocean in a process that burns thousands of gallons of fuel a day. Nevertheless, Transparent TVs can still be considered a less wasteful evolution in the ever evolving television design.

In the heart of the 20th century, the use of the TV within households escalated exponentially and effectively dethroned the established reign of the radio, which had held dominion over most of the nation’s livingrooms since the late 1920s (Hur). The interesting thing about this technological evolution is that radios had been utilized as furniture, possessing wood panels, a recyclable twine mesh covering the speakers, and metal dials to blend it into the living room. A list of materials that is obviously more renewable than a mostly plastic design. As transition from radio to television took place, people saw the new product as an upgrade and replacement for the old standard, and continued to use the same natural materials in production. However, as technology progressed with time, the late 20th century saw a myriad of improvements and developments to the television’s place within the household, evolving into an eye-catching centerpiece in the living room. This began the use of more plastics in the design as screen size grew ever larger, as well as cutting corners for easier manufacturing and distribution sent the product on a less sustainable path. Luckily, the new transparent televisions strive to fix some of the overarching issues of their predecessors, doing so by dealing with less metal and plastic and more glass.

During the raw material acquisition phase, the five most central materials in the production of transparent TVs are: metals, plastics, silicon, optical films (thin chemical coatings), adhesives, and glass. When it comes to the bigger picture in waste, such as the health of the planet, this is a slightly less wasteful phase in television production (although processing silicon and aluminum does leave behind toxic waste), because many of the processes in this phase mostly have a negative effect on a small scale, challenging the health of the people who work closely with them.

Metals: The circuit boards, frame, and wiring in transparent televisions contain metals such as Aluminum, copper, and steel (Television). In the case of waste, all three can have an affect on human health, especially when exposed to metal dusts for too long. Aluminum exposure can create long-term lung and breathing issues, as well as “abnormal chest x-rays” (Aluminum). Copper can affect the liver, and even cause death in severe instances, especially when there is long term exposure and build up (Copper Poisoning). Lastly, and the most dangerous of the three, when steel is heated for molding highly toxic Zinc fumes are released. These can make their way into food and create catastrophic health problems (Galvanized Steel). During the extraction of Aluminum from the Bauxite or within which it naturally resides, immense amounts of electricity must be used. A process that can be traced back to the burning of fossil fuels at local power plants.

Plastics: Even with a plastic-reduced design, transparent TVs still contain a small amount, particularly in the supporting base and buttons. The raw materials that create plastics are crude oils, plants, coal, and natural gasses. These are refined and compounded into the products propane and ethane, which are then heat treated into the monomers ethylene and propylene. Finally, Ethylene and Propylene are combined into a powder that forms plastic when melted (How Are Plastics Made?). When it comes to the waste produced by this process, it's worth noting that Ethylene is typically considered a toxic material to humans, while Propylene is quite safe even finding use in food and medication (What is Propylene?).

Anti-Reflective (AR) Coating: The AR coating is a thinly applied layer on transparent TVs that is used to make sure that the image remains visible and colorful on the clear monitor. This coating is applied through vaporization, a process that takes place in a vacuum. TV manufacturers use a completely sealed chamber to create the vacuum, before allowing the product to be evaporated onto the glass. Because of this, no toxic gasses could possibly escape during the careful procedure (AR Toxic Waste?). Luckily, however, there isn’t even any toxicity to worry about. As Anti-Reflective coating is created from refined silica, a common mineral found all around us.

Silicon: An essential component in circuitry. When transferring silicon ingots into more workable pieces for circuitry, close to 40% of the material is lost (Silicon Waste). A hazardous sludge is also produced at Silicon processing locations. This sludge contains some of the lost material, along with a silicon carbide. Processes to clear up or find other uses for this sludge have commonly proved fruitless, so it remains a problem for the future.

Adhesives: Often used adhesives in the creation of televisions (such as in circuit boards) are epoxy and cyanoacrylate (super glue). Neither of these are particularly harmful, however both can cause irritation upon contact skin.

At factories, the raw materials must be assembled into the final televisions in a highly efficient assembly-line manufacturing process. Most of the waste produced in this phase has to do with powering the factories themselves, such as the use of constant electricity. Or when applying optical films (such as the AR coating) that make the screen look brighter and more beautiful, a vacuum chamber and various sterilizing chemicals must be utilized. The other processes in this state of television production simply require assembling the previously obtained raw materials. For example, thin sheets of glass must be joined together with an epoxy adhesive, a layer of silicon must be added, and millions of small metal transistor parts must be attached, along with thousands of small LEDs.

After manufacture is complete, but before the product can be shipped around the world, the final TVs must be packaged into cardboard boxes with styrofoam insulation for distribution. Typically, as long as cardboard isn’t covered with a chemical or plastic film, it can be easily recycled. However, styrofoam is non-biodegradable and non-recyclable, taking up to 500 years to simply decompose (Styrofoam).

Once packaged, transparent TVs are shipped from the factory to the shelves in an extensive 6,000 mile journey. This is because the TVs are created and distributed by the world famous companies Samsung, LG, Xiaomi, and Sony, which are all based out of the Eastern Asian countries Japan, China, and South Korea. To get to the anxiously waiting market of 300 million excited American consumers, new TVs must journey by cargo ship across the Pacific Ocean to North America. A shipping journey that takes over 3-4 weeks to reach its destination on the West Coast of the U.S., or close to 5 weeks if the destination is on the East Coast (Shipping Container’s Journey 1). Which is significant when aware of the fact that an individual cargo ship burns close to 80,000 gallons of fuel each day. Because of this, the transportation and distribution process uses a significant amount of fossil fuels in the trans-pacific transfer that takes place.

Luckily for households around the world, TVs don’t expel any dangerous fumes or sludge waste from daily use. They also don’t directly require fossil fuels or zinc batteries to operate. They do, however, require a constant supply of electricity while turned on (remaining passive when not in use). While electricity doesn’t seem to create waste on the surface or in the house, local power plants function by burning coal and fossil fuels. Which means that the use of transparent TVs contribute to this waste, even if minorly.

Because glass is a far more reusable material than plastic, the increased use of glass in transparent televisions immediately provides them a boost in recyclability. This is because, unlike plastic, glass is nearly completely recyclable and can be reused almost endlessly without losing its purity or quality (Glass 1). However, in order to remove the anti-reflective (AR) coating that is applied to the glass screens of transparent monitors, a somewhat toxic stripping solution that is a mix of acids, is necessary (AR Toxic Waste?). This solution can’t be recycled and must be disposed of at a collection location.

All in all, from the mid 1950s until the early 2020s, the generated waste involved in the production of the television has followed a distinct trend: it started renewable and has progressed towards a far less renewable place. Hopefully, however, as transparent all-glass television popularity continues to rise and these TVs see growth in use, the upward trend in wastefulness will begin to slow down and eventually reverse.

Works Cited:

“AR Toxic Waste?” OptiBoard. https://www.optiboard.com/forums/showthread.php/9064-Ar-Toxic-Waste.

“A Shipping Container’s Journey from China to USA.” American Trailer Rentals, https://americantrailerrentals.com/cargo-ships-shipping-containers/#:~:text=Shipping%20Containers%20Around%20the%20World,to%20the%20US%20East%20Coast.

Barruetabena, Leire. “Study of OLED End of Life Treatments.” Oct 2011. https://www.researchgate.net/publication/236840073_STUDY_OF_OLED_END_OF_LIFE_TREATMENTS.

Cho, Kyung. Choi, Seungyeop. et al. “RGB-Color Textile-Based Flexible and Transparent OLEDs Considering Aesthetics.” Wiley Online Library, 4 Dec 2022. https://onlinelibrary.wiley.com/doi/full/10.1002/admi.202202114.

Clarke, Rebecca. “Can Plastic Film be Recycled?” Treehugger, 25 Jun 2021. https://www.treehugger.com/can-plastic-film-be-recycled-5188299.

“Copper Poisoning.” Mount Sinai, https://www.mountsinai.org/health-library/poison/copper-poisoning#:~:text=Sudden%20(acute)%20copper%20poisoning%20is,is%20to%20the%20body's%20organs.

“Crushing it: Keeping glass out of landfills.” Corning. https://www.corning.com/worldwide/en/sustainability/articles/processes/supply-chain-management/waste-management-recycling-.html.

“Electronic Waste Facts.” The World Counts. https://www.theworldcounts.com/stories/electronic-waste-facts.

“From Silicon Waste to Batteries.” Jiaxing Huang Group, https://jxhuang.mccormick.northwestern.edu/discoveries-and-stories/better-living/waste-to-batteries/.

“Galvanized Steel Toxic?” Bucket Outlet, https://www.bucket-outlet.com/Is-Galvanized-Steel-Toxic.htm#:~:text=Zinc%20fumes%20are%20set%20free,be%20used%20for%20food%20cooking.

“Glass Recycling Facts.” Glass Packaging Institute. Glass Packaging Institute, n.d. https://www.gpi.org/glass-recycling-facts.

“How Are Plastics Made?” This is Plastics, https://thisisplastics.com/plastics-101/how-are-plastics-made/#:~:text=Plastics%20are%20made%20from%20raw,refined%20into%20ethane%20and%20propane.&text=Ethane%20and%20propane%20are%20then,them%20into%20ethylene%20and%20propylene.&text=These%20materials%20are%20combined%20together%20to%20create%20different%20polymers.

Hur, Johnson. “History of the Television.” BeBusinessed.com, https://bebusinessed.com/history/history-of-the-television/.

Lasker, Alex. “Introducing the World’s First Mass-Produced Transparent Television.” In the Know, Oct 2020. https://www.intheknow.com/post/transparent-television-mi-tv-lux/.

Miller, Olivia. “How to Dispose of Silicone.” Ethical Shift, 18 Aug 2022. https://www.ethicalshift.com/recycle/disposing/chemicals/how-to-dispose-of-silicone/.

Paben, Jared. “California may add OLED devices and others to recycling program.” EscapNews, 14 Jan 2021. https://resource-recycling.com/e-scrap/2021/01/14/california-may-add-oled-devices-and-others-to-recycling-program/.

“Styrofoam: Why is it harmful, and alternatives.” Colgate University, 10 Nov 2011. http://blogs.colgate.edu/sustainability/2011/11/10/styrofoam-why-it-is-harmful-alternatives/#:~:text=Styrofoam%20is%20non%2Dbiodegradable%20and,landfills%20are%20there%20to%20stay.

“Television.” How Products are Made. http://www.madehow.com/Volume-3/Television.html#:~:text=1%20Almost%20all%20television%20housings,assembled%20to%20complete%20the%20housing.

“What is Aluminium?” Agency for Toxic Substances and Disease Registry, https://wwwn.cdc.gov/TSP/ToxFAQs/ToxFAQsDetails.aspx?faqid=190&toxid=34#:~:text=Exposure%20to%20aluminum%20is%20usually,or%20abnormal%20chest%20X%2Drays.

“What is Propylene Glycol?” Agency for Toxic Substances and Disease Registry, https://www.atsdr.cdc.gov/csem/ethylene-propylene-glycol/propylene_glycol.html#:~:text=Ethylene%20glycol%20is%20a%20potent,additive%20for%20foods%20and%20medications.