Design Life-Cycle

assess.design.(don't)consume

Eleanor, Bemis

Claire, Shirley

DES 40A

Professor Cogdell

Rainbow Sandals Raw Materials

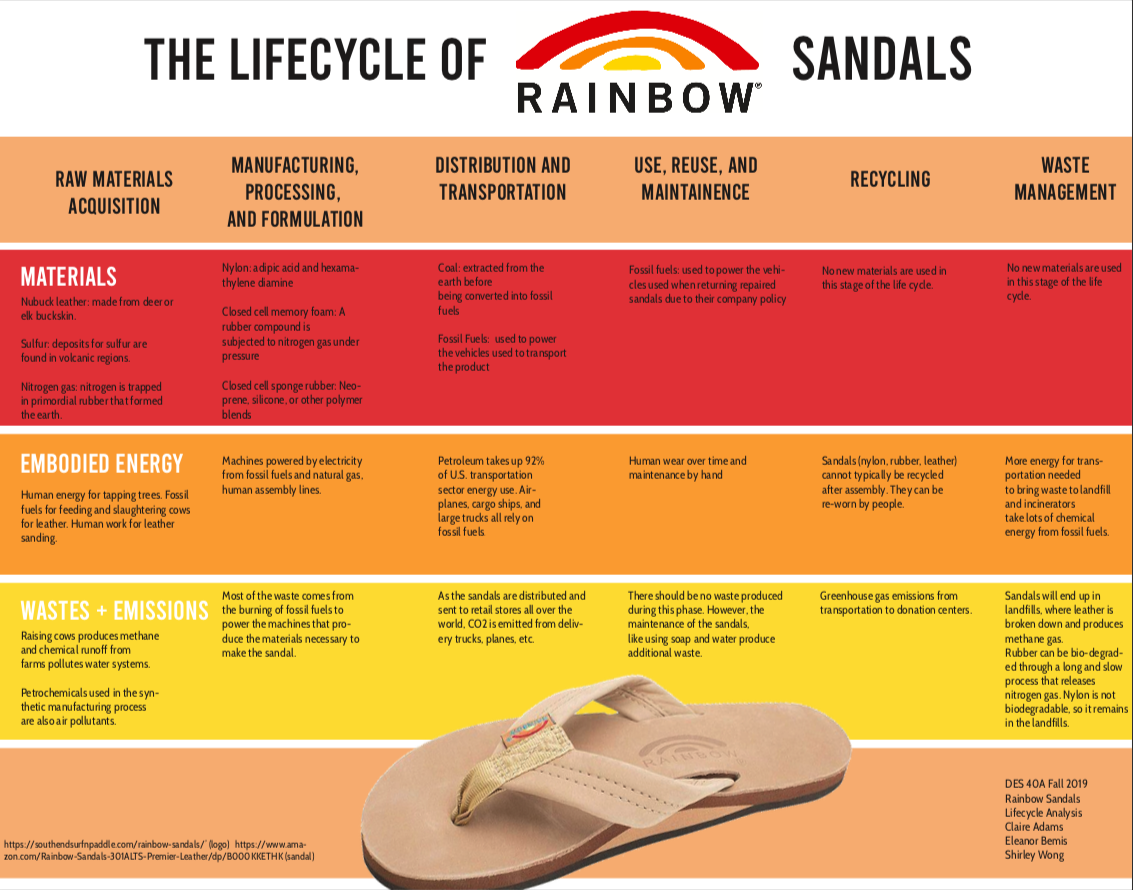

The life cycle of rainbow sandals is dependent on sourcing the correct raw materials to create the 301 ALTS sandal. The 301 ALTS sandal is the most popular sandal produced by the company. There are four materials that make up the rainbow sandal. The bottom sole is made from a synthetic rubber, the arch support is made from closed cell memory foam, the top sole comes from nubuck leather and the strap is made from nylon (Rainbow Sandals, 2019). This paper will explore all processes in the life cycle, ranging from how the materials are acquired to how they’re processed, distributed, used/reused and the waste management that occurs after their use. Rainbow Sandals attempt to have a socially conscious design process and yet they fall short numerous times when trading environmental costs for comfort.

Out of the four materials that appear on the sandal, nubuck leather is the only raw material that maintains its form throughout the manufacturing process. Two other raw materials, nitrogen gas and sulfur, aid in the production process for the closed cell rubber and closed cell memory foam. The acquisition of these materials will be discussed below.

Nubuck leather makes up the sole of the sandal and is one of the raw materials used in manufacturing process (Rainbow Sandals, 2019). Nubuck leather comes from the buckskin of a deer or an elk and is typically a byproduct of the meat and dairy industry (Compo, 2019). Since the leather is made from the outside of an animal hide, it is more durable and long lasting than other types of leather. In recent years, nubuck leather has been made from calfskin because it is softer (Compo, 2019). The company did not specify which type of animal their leather came from. While nubuck leather makes up a large portion of the sandal, other materials also contribute to its construction.

Sulfur is a chemical element used to make the rubber compound needed to create closed cell memory foam. Sulfur deposits can be found in volcanic regions or in other minerals such as iron sulfide, lead sulfide, calcium sulfate and magnesium sulfate (Chemicool, 2012). Sulfur is extracted through the Frasch process which involves melting sulfur deposits and then using compressed air to lift the sulfur from the deposits (Britannica, 2006).

Nitrogen gas is needed to form the synthetic closed cell rubber material that makes up the bottom sole of the sandal. Nitrogen gas is found in the air. It is believed that it was originally trapped in primordial rubber and has slowly been seeping out of the earth's crust ever since the big bang occured (BBC). Nitrogen gas can be extracted in two ways. The first is via fractional distillation of liquid air. This process involves cooling liquid air, isolating nitrogen, separating it and then collecting it (Nigen, 2018). The second and more common way is via nitrogen generators which are more environmentally friendly and require less maintenance (Nigen, 2018). Thus far, we’ve covered the raw material elements needed for sandal construction. In the next section, this paper will discuss the manufacturing process of the four core materials used in the sandal construction.

The manufacturing process of nubuck leather is relatively simple. After the leather has been acquired, it is sanded or buffed on the grain side for softness. This process also gives the leather a nap of protein fibers which makes it stronger overall (Best Leather, 2019). Unlike suede, nubuck leather does not oxidize and thus does not have a napped texture (Pop, 2017). Once the leather arrives at the Rainbow Sandals factory, it is cut into the basic shape of the slipper with a die cut machine and then glued to the other material layers in order to form the sandal (Rainbow Sandals, 2019). Nubuck leather makes up the sandal’s top sole but the process is more complex for the arch support and bottom sole.

The arch support is made from closed cell memory foam. Closed cell memory foam is manufactured by subjecting a rubber compound to a gas, such as nitrogen, under high pressure (Amerisleep, 2019). The rubber compound is manufactured via a synthetic reproduction process that combines petroleum and natural gas. A mixture of polyols (alcohol derived from petroleum products or plant oils) isocyanates and reacting agents, including sulfur, are whipped into a froth and poured into a mold (Amerisleep, 2019). The mixture is then infused with gas which scales the level of density the material can have and then is cured (Amerisleep, 2019). Once the material is inert (meaning it is no longer reactive), it is cut into pieces to make mattresses and other products such as the arch support found in the rainbow sandals. Closed cell memory foam is not an environmentally conscious material, however, it provides a degree of comfort the manufactures are willing to sacrifice for.

Due to the overuse of rubber trees, a synthetic substitute for the material needed to be developed in order to make the sole of the sandal. Closed cell sponge rubber is made from neoprene, silicone or other polymer blends (RK Rubber, 2019). The material is made in buns (meaning it is expanded via gas) and then cut to thickness (Phelps, 2019). During the manufacturing process, the closed cells are expanded with the nitrogen gas generated during the curing stage of the cycle (Phelps, 2019). This process aids in reducing the amount of natural resources exploited, however, the byproduct of this manufacturing process has an adverse effect on the environment. The process of extracting the elements needed to form closed cell rubber, specifically some of the petrochemicals that can be used in the process significantly pollutes the air and the environment (Phelps, 2019). While some of this can be avoided with air scrubbers and proper handling of materials it is important to note the impact every material has on the environment.

The manufacturing process for nylon goes as follows. The monomers needed to create nylon are adipic acid and hexamethylenediamine.These molecules combine to create polymer chains which are connected by an amide group, containing a nitrogen atom (The Open University, 2005). To extract the fibers, the polymer is warmed and long strong fibers are drawn out to make nylon. Overall, these are the materials needed to create the sandal. The subsequent distribution of these raw materials also holds key importance in analyzing to the overall life cycle of the sandal.

Two new materials are introduced in the distribution and transportation phase of the product cycle. These materials are coal and fossil fuels. Coal is extracted from the earth and is then converted into the fossil fuels needed to power the vehicles for transporting the product. Outlined below are the transportation cycles for each original material, their detail varies depending on the information that was available.

The majority of nubuck leather comes from China, which exports 30% of its product to the U.S. (Conseil National du Cuir, 2018). The general supply chain goes as follows. Butches slaughter the animals to produce raw skins used in leather production. These skins are then purchased by agents who sell them to local tanneries for processing. After the leather has been tanned, it is shipped to other countries where it is usually treated again to fit specific brand requirements (Portland State University, 2019).

The distribution and transportation of closed cell memory foam, nylon and rubber all involves packaging the respective materials and then shipping them all over the world. Factories that produce memory foam are located all around the world. The majority of Nylon is produced in factories in northeast Asia (Open University, 2005). After the nylon has been produced it is packaged, shipped and exported to other countries.

Most factories that produce synthetic rubber are in China, Malaysia and Thailand (Kyger, 2019). After the rubber has been manufactured it is packaged and then shipped worldwide. The US imports around 1.3 billion dollars worth of rubber a year (Kyger, 2019). Understanding the distribution and transportation of these materials, brings us to our next category of how these materials are then used and reused.

The materials enter the use and reuse phase once they are combined to make the sandal itself. Once the sandal is made it can be used and reused as many times as the owner would like. The company developed a Repair, Reuse and Recycle program, encouraging customers to donate their old sandals in exchange for a discounted new pair (Sandals Company, 2019). The materials cannot be reused once they’re embedded within the sandal. However the sandal’s durability means that the product is designed to last for years and should not break down easily. Understanding the sandal’s structure aids in learning about the recycling process that occurs next.

All materials can be recycled differently after they’ve been discarded. Nubuck leather isn’t biodegradable because it has been tanned with chemicals. That being said, the whole leather scraps can be recycled into other small goods such as bags, belts and wallets. Leather can also be mechanically reprocessed by grinding it up into shreds, mixing it with water and then adding binding agents such as natural rubber and acacia wood bark (Planet Ark, 2018).

It is impossible to break closed cell memory foam back down to its original plastic polymer. However, the material can be shredded and formed into another foam product (ex: car seat padding). This process is challenging given the relationship between the significant amount of memory foam needed to form another product and the small amount of memory foam in each sandal. The market for reclaimed memory foam is also very small due to its ability to be replicated at a cheap cost.

Rubber can be recycled or refurbished into entirely new products. While its can be challenging to maintain the characteristics of rubber when recycling, the process is important since it degrades very slowly. When rubber is recycled it is devulcanized, allowing it to be remodeled into other products (Planet Ark, 2018). Unfortunately this process involves lots of high heat and toxic chemicals but it is still somewhat better than throwing the material away.

Nylon can be recycled from within spinning factories that make it but it is challenging to recycle after its been manufactured into the sandal due to its chemical makeup. Unfortunately most of the materials used to make Rainbow sandals are thrown out with the sandal, regardless of their recycling properties. That being said, the sandals themselves are designed to last for years. Credit should be given to the sandals durability, as it reduces the likelihood of consumers buying cheaper alternatives.

In conclusion, the life cycle of Rainbow Sandals shows strength in the design of the sandal. The product is made to last a long time and is inherently functional. That being said, there are serious flaws in the overall lifecycle of the product. Specifically, production of the synthetic rubber and memory foam create chemicals that are extremely toxic for the environment. These materials are what set Rainbow Sandals apart from its competitors as they provide a degree of comfort that is unparalleled. However, this, coupled with the fossil fuels needed to ship the sandals from their factory in China to the US, are not good indicators of an environmentally conscious product design. Overall, the company attempts to be intentional with its ecological impact in the durable design of the sandal but falls short when it comes to the construction, recycling and reuse of the specific materials involved.

Bibliography

Amerisleep. “How a Memory Foam Mattress Is Made.” How to Make a Memory Foam Mattress, 2019, http://www.amerisleep.ca/how-to-make-a-memory-foam-mattress.html.

Best Leather. “What Is Nubuck Leather?” BestLeather.org, 2019, https://bestleather.org/types-of-leather/nubuck/.

Compo, Mel. “Nubuck Vs Suede - What's the Difference?” Stridewise.com, 7 July 2019, https://stridewise.com/nubuck-vs-suede/.

Conseil National du Cuir (CNC). “Global Trade in the Leather Sector in 2016: the Key Figures.” The Leather Sector in Figures: Global Trade in 2016, 24 Jan. 2018, https://conseilnationalducuir.org/en/press/releases/2018-01-24.

Group, SgT. “The Leather Supply Chain's 5 Key Risks And How To Overcome Them.” SgT Group, 4 July 2018, https://www.sgtgroup.net/textile-quality-management-blog/the-leather-supply-chains-5-key-risks-and-how-to-overcome-them.

Hustrulid, William Andrew. “Frasch Process.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 17 Nov. 2006, https://www.britannica.com/technology/Frasch-process.

Kyger, Lauren. “American Rubber Band Makers in a Bind.” TradeVistas, 22 Aug. 2019, https://tradevistas.org/american-rubber-band-makers-bind/.

Matthews, Robert. “Where Does the Nitrogen in the Air Come from?” BBC Science Focus Magazine, https://www.sciencefocus.com/planet-earth/where-does-the-nitrogen-in-the-air-come-from/.

NiGen. “How to Separate Nitrogen From Air: Ways to Extract Nitrogen From Air.” NiGen, NiGen, 22 May 2018, https://nigen.com/how-separate-nitrogen-from-air-ways-extract-nitrogen/.

Open Learn. “How Is Nylon Made?” OpenLearn, The Open University, 26 Sept. 2005, https://www.open.edu/openlearn/science-maths-technology/science/chemistry/how-nylon-made.

Patagonia . “Recycled Nylon Fabric.” Patagonia, 2019, https://www.patagonia.com/recycled-nylon.html.

Phelps . “Closed Cell Sponge Rubber and It's Applications: Phelps Industrial Products.” Phelps Gaskets, Packing and Seals , 14 Mar. 2019, https://www.phelpsgaskets.com/blog/closed-cell-sponge-rubber-and-its-applications.

Planet Ark . “Leather.” Business Recycling, 2018, https://businessrecycling.com.au/recycle/leather.

Pop, Alex. “Leather, Suede, and Nubuck. What's The Difference?” Leathercaresupply.com, Leathercaresupply.com, 20 Dec. 2017, https://www.leathercaresupply.com/blogs/knowledge-base/leather-suede-and-nubuck-whats-the-difference.

Portland State University . “ECOPOL.” ECOPOL, Portland State University , 2019, https://leathersustainability.weebly.com/.

Rainbow Sandals. “Construction Rainbow Sandals.” Construction | Rainbow Sandals, 2019, https://www.rainbowsandals.com/rainbow-story/sandal-construction

Rainbow Sandals. “History: Rainbow Sandals.” History | Rainbow Sandals, 2019, https://www.rainbowsandals.com/rainbow-story/history.

“Recycled Nylon Fabric.” Patagonia, 2019, https://www.patagonia.com/recycled-nylon.html.

RK Rubber . “Sponge Rubber Materials.” Sponge Rubber Materials, 2019, https://rkrubber.com/sponge-rubber.cfm.

"Sulfur." Chemicool Periodic Table. Chemicool.com. 18 Oct. 2012. Web. 12/3/2019 https://www.chemicool.com/elements/sulfur.html.

Claire Adams

Shirley Wong, Eleanor Bemis

DES 40A

Professor Cogdell

Embodied Energy for Rainbow Sandals, 301-Alts

Rainbow Sandals were initially created in a garage in Laguna Beach. The location reflects the culture revolving around sandals, being predominantly surfers and beach goers.The goal of the company, as it grew and moved to San Clemente, was to create environmentally-friendly sandals that will “never end up in a landfill.'' However, like any fast growing company, not all those goals are met. The raw materials that make up the brand’s 301-Alts are predominantly nubuck leather, rubber, nylon, and chemicals that go into closed-cell memory foam. All held together by a glue solvent, methyl ethyl ketone, which is branded as being ‘green’. The whole manufacturing of these sandals was originally solely done in the warehouse in San Clemente, but certain regulations forced the company to place over 75% of their production process in China. The embodied energy of the entire life cycle of Rainbow Sandals, 301 Alts, is a mix of environmentally conscious processes and several sacrifices that can cause more harm than good; from the acquisition of nubuck leather, the formation of the shoe by hand, overseas shipment of Rainbows manufactured in China, to the company’s inability to break their reliance on fossil fuels.

Raw materials acquisition use immense amounts of energy, mainly mechanical and chemical. The top of the shoe is layered with a material called nubuck, a type of “top-grain” leather. The process of raising and slaughtering cattle takes a lot of energy. Just to feed the cows, food must be grown for them and shipped to the slaughter houses. The machines used to kill the cows take a lot of energy, specifically fossil fuels. A mix of chemical energy and mechanical go into the process of creating nubuck, ending with human labor for buffing the surface to make it smooth. Another raw material used is rubber, for the bottom of the shoe. Typically, rubber is tapped in a latex form from a rubber tree. The energy to extract this material is mainly human oriented, as tapping is the process of cutting into the tree and peeling back bark in order to get the substance- before it is commercially processed. The sponge rubber for the shoe is meant to last for a long time of wear, while bound with the glue solvent. The ‘comfortable arch that molds to the foot’ is the cause of closed-cell memory foam. A mixture of chemicals go into the making of memory foam, specifically those derived from petroleum products or plant oils. Predominantly, this process utilizes machines to mix the chemicals, pour it into a mold, and infused with gas agents and polymer mixture, to make it closed-cell. Products like neoprene are used in the process of making this memory foam. The initial formulation of all of the materials is held together by a very controversial glue.

Glue used in formulation led to production being moved to China to protect the air quality in California. The glue used to bind it together, branded as “environmentally friendly glue”, is actually quite harmful to the atmosphere. Known as methyl ethyl ketone, this solvent is a colorless, flammable liquid. The Air Quality Management District of the federal government limited the factory in San Clemente to making only 1,000 sandals per day, so production had to be moved to China. Even though it is VOC-free, the fire department of San Clemente does not allow heavy use of such glue in the area because of how flammable it is. This solvent becomes a gas when exposed to air, and can cause irritation in the eyes, nose, and throat. The outsourcing of most of the production to China is a double-edged sword. The solvent is as harmful when exposed to air and enters the atmosphere as it is flammable, so production was moved to China for environmentally conscious reasons. And yet, the shipping to and from China takes immense amounts of fossil fuels, be it overseas in cargo ships, or by airplanes, the amount of fuels such as petroleum gas needed for shipping is detrimental; especially when it comes to the amount of greenhouse gases (those trapped in the atmosphere and can hold heat, contributing to global warming) that are released through the transportation processes. While fossil fuels dominate the energy used for the majority of the life cycle, mechanical energy comes into play for the assembly of the sandals.

Once the materials are acquired, assembly lines in factories place and glue the materials together. Some machinery is used to trace and cut out the shape of the shoe, but humans are a part of the rest of the formulation process. Workers themselves do not need a lot of energy to function (food, chemical, water, etc.), but the machinery used does. Electricity that is derived from petroleum and natural gas sources is utilized for industry, but not as much as transportation. The majority of the energy in the whole lifecycle for Rainbows is used in the transportation of goods; to and from China, San Clemente, and other consumers around the world.

Distribution and transportation use the most amount of energy, relying on fossil fuels, as transportation is in place almost the entirety of the sandal’s lifecycle. After raw materials are obtained, they must be shipped to both the factory in San Clemente, and factories in China. Data from the US Energy Information Administration lists that in terms of overall energy consumption in the US, transportation takes up 28%. For commercial trucks, planes, and ships, different fuel forms are used depending on the size and weight of the vehicle. For shipping within the US, large semi trucks and airplanes use distillate fuels. Distillate fuels are a fraction of petroleum products, which include those made from crude oil, natural gas processing, and gasoline. Shipping to and from China mostly use residual fuel, as they are big cargo and crate ships, that usually do not just carry products of Rainbow Sandals. Petroleum is the number one type of energy used, as it takes up 92% of the total US transportation sector energy use (U.S. Energy Information Administration- Independent Statistics and Analysis). The reason petroleum is such a widely used fuel source is because it has one of the highest energy densities of all fuel sources. Petroleum, or crude oil, has an energy density of approximately 45 MJ/kg (Energy Density of Petroleum). The only problem is that because this energy density is so high, it is used for transportation and other energy consuming activities all over the world, leading to the decline of availability of petroleum. For distribution, orders can be placed for the product anywhere on earth, and they are shipped from either san Clemente or China. The same principles for transportation methods and fuel use apply, however, the use of airplanes is more utilized for shipping the product to consumers. It is a fast transportation process, however commercial airlines rely on an immense amount of jet fuel (petroleum). In terms of overall consumption, transportation takes up the most energy needed for the process of transportation and distribution of materials and products.

The part of this sandal’s lifecycle that takes the least amount of energy is the use, re-use, and recycling. People simply wear the sandals down, and the glue helps them last several years. The maintenance process for this shoe involves the opportunity to return the shoe to the warehouse in San Clemente, where they will give you a discount for another pair, and the used sandals will be donated. The company has instilled a Repair-Reuse-Recycle program for this specific purpose. Not much recycling can actually be accomplished with these sandals because of the raw materials. The glue makes the sandals almost impossible to recycle, so the energy that goes into it is simply that from a landfill or incinerator. Despite this, these shoes typically can be worn over great amounts of time and used by different people.

The embodied energy of Rainbow Sandals’ 301-Alts, is a combination of mechanical energy (humans) and chemical energy (petroleum). In terms of energy consumption, transportation outweighs all of the other stages of the lifecycle of Rainbow sandals. The use of petroleum as fuel is a great energy source because of its high energy density, but the initial energy that is needed for transportation cannot be kept up solely by the use of crude oils. The Rainbow Sandals’ brand goal is to consume as little energy as needed in the process of creating Rainbow Sandals. And though human energy does not take up a large chunk of the embodied energy, it plays a big role throughout the life of 301-Alts. From the hand-sanded nubuck, the assembly line of putting all the materials together, to the distribution of the product- people play a key role in this product’s life-cycle. The overall energy consumption of the entire life cycle of Rainbow Sandals, 301 Alts, is a mix of environmentally conscious processes and several sacrifices that can cause more harm than good; from the acquisition of nubuck leather, the formation of the shoe by hand, overseas shipment of Rainbows manufactured in China, to the company’s inability to sever themselves from fossil fuels.

Bibliography

Connor, Jackie. “Rainbows Owner: 3 of 4 Sandals Made in China Because of EPA Regs.” San Clemente, CA Patch, Patch, 10 Mar. 2011, https://patch.com/california/sanclemente/rainbows-owner-3-of-4-sandals-made-in-china-because-of-epa-regs.

Elert, Glenn. “Energy Density of Petroleum.” Energy Density of Petroleum - The Physics Factbook, https://hypertextbook.com/facts/2002/KarolShepelsky.shtml.

Henning, Kristen. “Made In America: Rainbow Sandals Factory Tour.” Footwear News, Footwear News, 28 Apr. 2015, https://footwearnews.com/2015/focus/athletic-outdoor/american-made-rainbow-sandals-factory-tour-26084/.

“How Is Nylon Made?” OpenLearn, The Open University, 26 Sept. 2005, https://www.open.edu/openlearn/science-maths-technology/science/chemistry/how-nylon-made.

“How a Memory Foam Mattress Is Made.” How to Make a Memory Foam Mattress, http://www.amerisleep.ca/how-to-make-a-memory-foam-mattress.html.

Morini, Antonio Augusto, et al. “Early-Stage Materials Selection Based on Embodied Energy and Carbon Footprint.” Materials & Design, Elsevier, 16 May 2019, https://www.sciencedirect.com/science/article/pii/S0264127519302990.

“Rainbow Sandals.” World's Best Made Sandals since 1974, https://www.rainbowsandals.com/ProductDetail/AMERICANAWIDML00_.

“Rainbow Sandals.” Shipping Information and FAQ's | Rainbow Sandals, https://www.rainbowsandals.com/customer-service/shipping-faq's.

“Sandal Construction: Rainbow Sandals.” Sandal Construction | Rainbow Sandals, https://www.rainbowsandals.com/rainbow-story/sandal-construction.

“Story Map Journal.” Arcgis.com, https://www.arcgis.com/apps/MapJournal/index.html?appid=b736b13f92cc4a1fb6951f65d35262a9

Sorokanich, Lara. “How To Make Leather.” Popular Mechanics, Popular Mechanics, 25 June 2018, https://www.popularmechanics.com/technology/news/a22143/how-to-make-leather/.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Use of Energy for Transportation - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/use-of-energy/transportation.php.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Use of Energy in Industry - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/use-of-energy/industry.php.

“What Is Nubuck Leather?” BestLeather.org, https://bestleather.org/types-of-leather/nubuck/.

Shirley Wong

Claire Adams, Eleanor Bemis

DES 40A

Professor Cogdell

Rainbow Sandals Waste and Emissions

Rainbow Sandals is a California based company that is best known for their comfortable and high quality sandals which are made to mold to individuals’ feet. The company first started in founder’s, Jay “Sparky” Longley’s garage in Laguna Beach. The location reflects the company’s brand, which revolves around the beach and surfing culture. The sandals are available in surfer’s outfitters and surf shops across the California coast. The company’s goal is “to make a quality product that will not end up as landfill” (Rainbow Sandals). They clearly take pride in the fact that their sandals are created by hand and are long lasting, which brings into question the overall environmental friendliness of the company. Our group’s focus was to analyze whether Rainbow Sandals company was an environmentally conscious company or not, since they are known for making their quality sandals by hand. From examining the waste and emissions produced during the lifecycle of the 301 Alts Rainbow Sandal, certain initiatives the company has helped to reduce material waste, but there are still areas where they can improve on like in eliminating greenhouse gas emissions, energy consumption, and the overuse of fossil fuels.

From the very start of the sandal production process, most of the raw materials used to make the sandals already produce great harm to the environment. The main component of the sandal is nubuck leather. Leather is from cows and raising cows produces a lot of waste that is harmful to both the environment and humans. Cows produce methane, a gas that is 23 times more harmful than carbon dioxide (CFAES). Besides their gas, cow’s manure also poses a problem. The phosphorus and nitrogen in the manure, after it is used on farmland as a fertilizer, can run off with rainfall into waterways, which then pollute the water systems (CFAES). This contributes to algal blooms that turn the water green and produce toxins that make drinking water undrinkable. Throughout the processing of leather, it produces waterborne, airborne, and solid wastes. In almost every step of the process, the resulting wastewater has shown to release toxic components like salt, blood, dirt, hair, alkaline solutions, and non-exhausted chromium (Environmental Hazards of Leather). Sulfur is an element needed to make the rubber compound for the closed cell memory foam. Sulfur is extracted from volcanic regions using the Frasch process. During this process, hot water and air are used to force the sulfur out. The energy used to get the water to such high temperatures requires fossil fuels (ScienceViews). Nitrogen gas is another raw material needed to form the synthetic closed cell rubber material for the bottom sole of the sandal. Nitrogen gas itself has already harmful effects on the environment. Nitrogenous gases play an important role in global climate change, since it’s a greenhouse gas that traps a lot of heat in the atmosphere. Nitrogen is most commonly extracted via nitrogen generators and is the most environmentally friendly method. Generated nitrogen consumes less energy and creates fewer greenhouse gases, compared to the energy needed to power a “cryogenic air separation plant” and the energy needed to transport the liquid nitrogen from the plant to the facility. (A Sustainable Approach to the Supply of Nitrogen).

During the manufacturing process, the majority of the waste comes from the burning of fossil fuel to power the machinery used to mass produce the sandals. The strap is made of nylon and the processing of nylon requires a great amount of energy. Because nylon does not exist in nature, it is formed “from dead, organic substances found deep within the earth, which is then extracted and undergoes a chemical reaction” (Explain That Stuff). In this process, large amounts of water are used, which leads to environmental contamination and pollution. Closed cell memory foam is what the midsole is made of which is what gives the sandal the infamous arch support that molds to the contour of one’s foot. To make closed-cell memory foam, a chemical powder decomposes under the heat and pressure that is added and during this process, nitrogen gas is released into the environment. The nitrogen gas gives the closed-cell sponge rubber its strong compression properties.

The distribution and transportation of Rainbow Sandals contributes quite a lot of waste in the form of carbon dioxide emissions. Since they no longer fully manufacture all their sandals in their San Clemente factory, Rainbow Sandals ship more than 75% of their production to China. As a result, fossil fuels are being burned as materials are being transported. It was not specified the exact modes of transportation that are used to transport the sandals to and from China and to retailers worldwide, but whether it is on trucks, planes, or ships, the carbon dioxide emissions released into the atmosphere are abundant.

During the utilization of Rainbow Sandals, there should be no waste emissions if they are worn properly. Ideally, the sandals should not have to end up in the landfill because they are made of strong materials and use technology that makes it durable and long-lasting. For example, the nylon strap is made with “2000lb test nylon webbing to prevent stretching” and the “Box ‘X’ Stitch is used in parachutes to secure the toe piece” (Rainbow Sandals). Despite all the design choices that are made to make the sandal long lasting, maintenance of the sandal itself requires soap and water. Overtime, the usage of these products can add up and produce a lot of additional waste during the consumption stage. However, the waste from these extra products should not undermine the overall longevity of these sandals. They do have a “Rainbow Guarantee” policy in place where the sandals are eligible for warranty until they have been worn through the top or bottom layer of the sole (Rainbow Sandals). For the most part, wearing Rainbow Sandals is not a major threat in terms of releasing toxic wastes into the environment.

Rainbow Sandals has a Repair, Reuse, Recycle program that allows consumers to return their sandals that are past warranty, but not beyond repair. The repaired shoes are then donated to the homeless, orphaned, and natural disaster victims (Rainbow Sandals). Throughout the process of transporting and donating the shoes, it releases pollutants like carbon dioxide into the air. Despite greenhouse gases being released during the recycling stage, this should not discredit the recycling program that is in place. It makes more sense to extend the life of each sandal than to avoid emitting greenhouse gases from transportation.

Even though Rainbow Sandals encourages consumers to recycle their sandals, many will inevitably end up in landfills. When they are sent to a landfill, the leather is broken down to produce methane, a powerful greenhouse gas, and is resistant to biodegradation for long periods of time (Biodegradability of Leather). The rubber that makes up the bottom sole degrades slowly. During the process, some nitrogen based products are also released into the environment. The nylon straps of the sandals are not biodegradable at all, so it will remain in the landfills.

After an extensive examination of the manufacturing and production process of Rainbow Sandals, we are able to see that the amount of material waste has diminished and thus lowered the need for additional processes. Even though to make Rainbow Sandals requires only three raw materials, the processes behind making/extracting these materials release a great amount of harmful gases and fossil fuels into the environment. Furthermore, since Rainbow Sandals are now mostly being assembled in China, we can see that fossil fuels are necessary to power the transportation from the factories in China to the United States and then from the Rainbow Sandals manufacturing center to retail stores and consumers nationwide. From all my research, I have come to realize that it is difficult for a company to be 100% environmentally friendly, despite how they may advertise themselves. While they have made significant changes to their production processes and put in place recycling programs that have helped to lessen the resources being used there is no doubt still going to be loopholes where harmful wastes are released into the environment.

Bibliography

"Biodegradability of Leather." (2011). BLC Leather Technology Centre. Web. 7 Dec. 2014.

http://theconversation.com/nitrogen-pollution-the-forgotten-element-of-climate-change-69348

Brown, Jay R., Guiffrida, Alfred L. “Carbon Emissions Comparison of Last Mile Delivery versus Customer Pickup.” Taylor & Francis, www.tandfonline.com/doi/full/10.1080/13675567.2014.907397.

Connor, Jackie. “Rainbows Owner: 3 of 4 Sandals Made in China Because of EPA Regs.” San Clemente, CA Patch, Patch, 10 Mar. 2011, patch.com/california/sanclemente/rainbows-owner-3-of-4-sandals-made-in-china-because-of-epa-regs.

“Environmental Hazards of Leather.” PETA, 22 June 2010, www.peta.org/issues/animals-used-for-clothing/leather-industry/leather-environmental-hazards/.

Henning, Kristen. “Made In America: Rainbow Sandals Factory Tour.” Footwear News, Footwear News, 28 Apr. 2015, footwearnews.com/2015/focus/athletic-outdoor/american-made-rainbow-sandals-factory-tour-26084/.

“How Is Leather Made?” MAHI Leather, mahileather.com/blogs/news/how-is-leather-made.

Lennon, Caroline. “Leather Is More Than ‘a By-Product of the Meat Industry.’” One Green Planet, One Green Planet, 2 Jan. 2014, www.onegreenplanet.org/animalsandnature/leather-is-more-than-a-by-product-of-the-meat-industry/.

“Manufacturing Process.” The Shoe Industry, theshoeindustry.weebly.com/manufacturing-process.html.

“Memory Foam: Curious What It Is and How It Is Made?” ReviewsWorthy!, 7 Jan. 2019, www.reviewsworthy.net/memory-foam-mattress/what-how-memory-foam-made.

Ng, Ee Ling, et al. “Nitrogen Pollution: the Forgotten Element of Climate Change.” The Conversation, 28 Aug. 2019, theconversation.com/nitrogen-pollution-the-forgotten-element-of-climate-change-69348.

“Nylon - The Science of Synthetic Textiles.” Explain That Stuff, 31 Jan. 2019, www.explainthatstuff.com/nylon.html.

“Reducing the Environmental Impact of Cows' Waste.” Reducing the Environmental Impact of Cows' Waste, cfaes.osu.edu/news/articles/reducing-the-environmental-impact-cows-waste.

“Regulations for Greenhouse Gas Emissions from Commercial Trucks & Buses.” EPA, Environmental Protection Agency, 12 Sept. 2019, www.epa.gov/regulations-emissions-vehicles-and-engines/regulations-greenhouse-gas-emissions-commercial-trucks.

“Repair-Reuse-Recycle: Rainbow Sandals.” Repair-Reuse-Recycle | Rainbow Sandals, www.rainbowsandals.com/rainbow-story/repair-reuse-recycle.

“A Sustainable Approach to the Supply of Nitrogen”. Parker Hannifin, Filtration and Separation Division. Retrieved 5 March 2015.

“US4347637A - Manufacturing Process of Sandals and Clogs with Plastic Soles and Shoes Manufactured through This Process.” Google Patents, Google, patents.google.com/patent/US4347637A/en.

Volatile Organic Compounds www.adhesives.org/resources/volatile-organic-compounds-(voc)-regulations.