Design Life-Cycle

assess.design.(don't)consume

Shruti Wakharkar

DES 40A

Professor Cogdell

Embodied Energy in the Glow Stick Life Cycle

Glow sticks are a popular light-up accessory used to bring a little bit of color and energy to a party environment. They are often seen at concerts, or parties, where people wave them around in the air to create an electric atmosphere, as they sing along to their favorite artist’s songs. Children often use them as bracelets on Halloween night, as they go trick or treating through the neighborhoods, as a way to locate each other, and even as an accessory to their costumes. Glow sticks are also used in military activity, as a way for troops to locate each other in dense forest regions, or to send each other non verbal signals while on a mission. Glow sticks are rather versatile in their use, and are a convenient source of light in many different settings. Since they are known to be waterproof, and don’t require external power like a plug or batteries, they are considered to be energy efficient means of portable lighting. However, there is much more to them than the surface level luminescence they create, in terms of the energy it takes to process, deliver, and eventually, dispose of them at the end of their life cycle. As glow sticks are used in a wide variety of areas and for various different reasons, it is important to consider the environmental impact of these rather simple looking instruments. The manufacturing, transportation and waste disposal processes in glow stick production use a very high amount of energy in its overall life cycle compared to during its utility, indicating that it causes a significant impact to the environment.

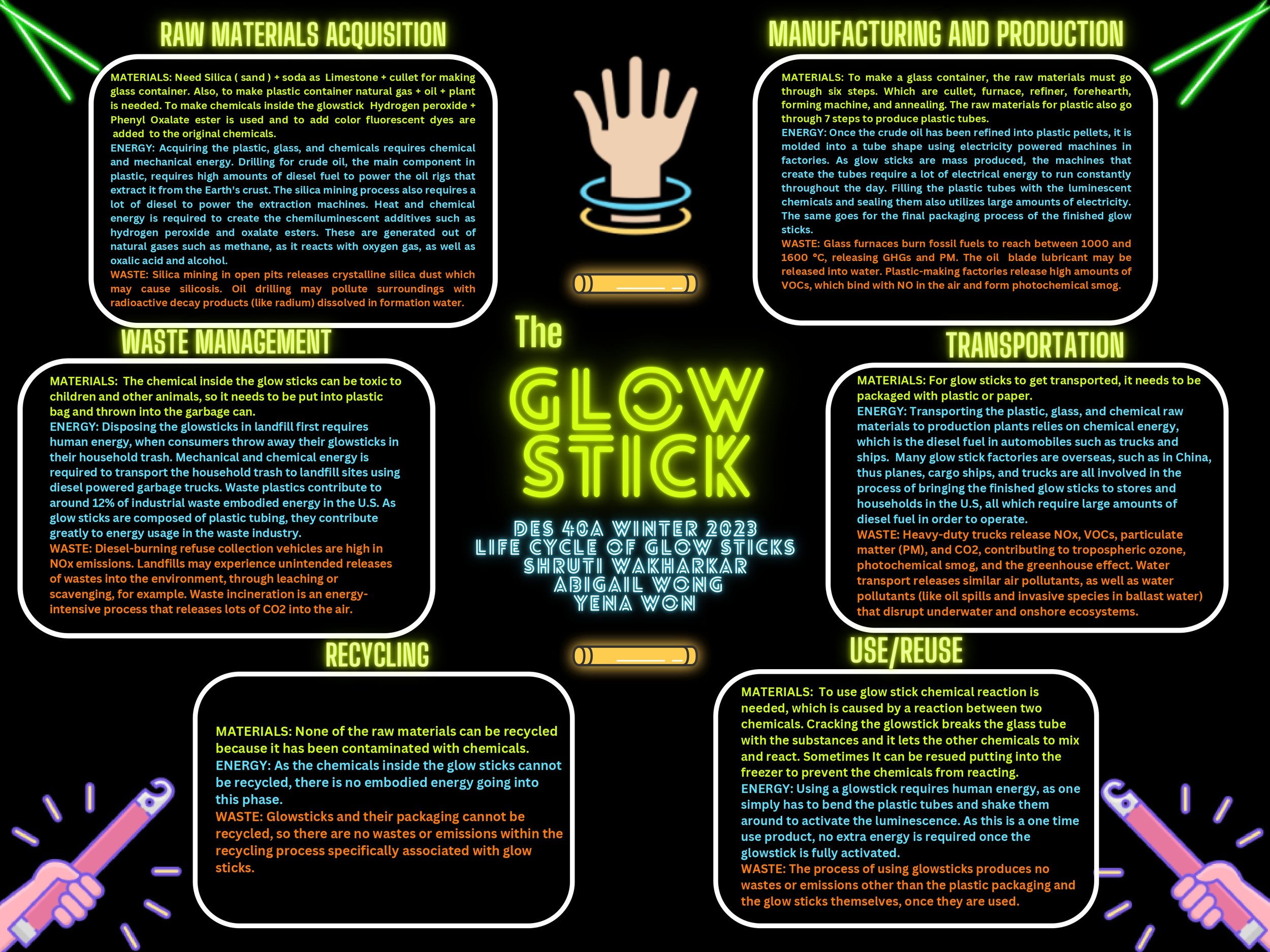

The first phase in the life cycle of a glow stick is the raw materials phase, which consists of a rather environmentally taxing use of energy. To start off, the key component in keeping the luminescent fluid of a glow stick intact is plastic, which is what the tubing is made up of. According to This Is Plastics, a website dedicated to providing statistics about plastic usage, safety, and environmental impact, the main raw material that turns into synthetic plastics is oil, which is later refined into ethane and propane. This oil is known as crude oil, which requires a considerable amount of energy to extract. Harvesting crude oil uses a lot of mechanical and chemical energy, due to the automobiles that drill it out, as well as the fuel that powers them. Crude oil is extracted using drilling rigs, which run on diesel, the world’s primary fuel source for transportation. The Ipieca, a global nonprofit oil and gas industry association, states that “...these engines use 20–30m3 diesel fuel per day, depending on the operations performed” (“Offshore Drilling Rigs (2013)”). Crude oil is harvested in large amounts due to the high demand for plastics in the industry overall, which suggests that the drilling rigs require refilling quite often. Diesel is considered to be a dirty fuel, due to its significantly large carbon footprint. Environmental survey technician Grace Smoot states that “One gallon of diesel weighs approximately 7 pounds, but when combusted it produces 22.38 pounds of CO2” (Smoot, 1). Each drilling rig, excavation machine, and truck or trailer involved in the process of drilling crude oil uses vast amounts of diesel, which takes a toll on the environment as a whole. The same goes for the automobiles that mine silica, which is needed to produce the glass which is also a part of the glow stick tubes. Some of the chemicals that create the luminescence of glow sticks are hydrogen peroxide and oxalate esters. The raw material required to produce hydrogen peroxide are natural gases such as methane as well as oxygen. According to MIT News Office correspondent David Chandler, processing hydrogen peroxide takes place in “...large chemical plants, where methane, or natural gas, is used to provide a source of hydrogen, which is then reacted with oxygen in a catalytic process under high heat”. The process utilizes a lot of chemical and heat energy, as peroxide is produced in large amounts at these plants. Oxalate esters, which make the chemiluminescence, are key in the creation of glow sticks, and are also formulated using chemical energy. In an academic paper by a team of researchers from Soochow University, it is noted that oxalate esters are derived from the “...coupling reactions of oxalic acid [C2H2O4] or oxalic acid derivatives with alcohol” (Ma et al.). The process is likely done in laboratories using human energy to pour and combine the chemicals, which doesn’t require as much energy as previous items such as crude oil. However, overall, obtaining all the raw materials requires vast amounts of energy in total, which is significantly harmful to the environment. After looking at the energy required in raw material acquisition, the next step is to observe the manufacturing process of glow sticks, and how much energy goes into the actual production phase in their life cycle.

From the raw materials phase, we move into the manufacturing process of glow sticks, which also has a significantly high embodied energy. This phase includes the processing of the plastic, creating the glow stick tubes, mixing the chemiluminescent materials, and lastly, filling, sealing, and packaging the finished glow sticks. To begin the plastic tubing process, the crude oil, alongside natural gases, are transformed into “...hydrocarbon monomers that are then linked together into long chains known as polymer plastics (such as PVC or HDPE)” (Saxena). This is done in large scale factories, using electrical energy to power the machinery. Once the plastic polymers have formed, they are stored in pellet form while they are shipped to glow stick factories, in which they are fed into an injection molding machine in order to gain their tube shape. These machines “...mold the pellets into the correct shape and add additives to give them the correct color and texture” (Saxena), a process which requires a considerable amount of electricity to do so at the mass production level. Once the tubes are ready, the chemicals that create the glow must be mixed together and filled into the tubes. This process requires chemical and electrical energy, as there are special machines designed to pour the correct quantities of chemicals into each tube. Once this is complete, the tubes are then vacuum sealed to prevent the chemicals from leaking out, after which they are packed into plastic packaging, and ready for shipment to stores all over the world. The entire manufacturing process utilizes a lot of energy, as glow sticks are produced in large factories, which rely on electricity to power their machinery throughout the day. These are some of the energy processes that go into the creation of glow sticks, and it is evident that they utilize a great amount of power to undergo the transformation from raw material to product. Next, it is important to look at the energy required in the transportation of raw materials to factories, as well as the finished glow sticks to stores and households for use.

The transportation process of raw materials to factories, and later the finished glow sticks to markets and households is a significant step in the product’s life cycle which requires a high amount of mechanical and chemical energy. When the crude oil is refined into ethane and propane, it is transported to the petrochemical plants via truck or railway, where it is molded into the polymer pellets, as seen in the manufacturing process. Once this is done, the plastics are ‘containerized’-- “they can be shipped domestically or can travel to a port, transferred to an ocean carrier, and shipped overseas” (Transportation: Delivering the Plastic Products You Can’t Live Without). It is at this point when the pellets are sent to the glow stick manufacturing factories located worldwide. The trucks, trains, and cargo ships that transport the plastic use very large amounts of chemical energy, once again, in the form of diesel fuel. These automobiles are also responsible for sending the chemiluminescent materials such as oxalate esters to glow stick manufacturers as well. Once the manufacturing process is complete, packages of glow sticks are then taken to stores in trucks, where they will be purchased and taken home by consumers. The reliance on diesel fuel throughout this stage of the glow stick life cycle is very prominent, and can have adverse effects on the Earth’s environment. According to an article from the Harvard T.H. Chan School of Public Health, the over combustion of fossil fuels “creates air pollution that harms our health and generates toxic emissions that drive climate change” (“Fossil Fuels and Health”). Additionally, as many glow stick factories are located overseas, for example, the Nanjing based company China Bessen Glow Technology Ltd, the overall amount of fuel energy it takes to import the packaged glow sticks to stores in the United States is significantly high. After looking at the energy used in the transportation processes of the glow stick’s life cycle, it is important to consider the energy used in the next step, the usage of glow sticks by the consumers.

As glow sticks are single use products, their utility ends as soon as they’ve been activated by the consumer, and this activation process requires the least amount of embodied energy, after which their glow only lasts for a limited amount of time. Glow sticks become activated when a user bends the little tubes to trigger the luminescent chemicals. This process utilizes a very small amount of human energy, as it takes little effort to bend and shake the glowsticks and activate the chemicals (Everything There Is to Know About Glowsticks...). Upon activation, the sticks have a very limited lifetime, and they are discarded as soon as the luminescence runs out. Glow sticks spend the least amount of time in this phase, hence require the least amount of energy in it. The overall utility of glowsticks is rather limited due to their single use nature, and thus do not require a lot of energy compared to the previous phases. Once the luminescence of the product fades away, the consumers will discard it, after which it enters the last phase of its life cycle–waste disposal. Glow sticks do not have a recycle phase in their life cycle, as the chemicals inside of the plastic tube are toxic, so they are sent directly to landfills upon disposal.

As these glow sticks contain high amounts of plastic and chemicals, disposing them requires a high amount of embodied energy. The first step in the disposal process requires human energy, as consumers will discard the used glow sticks in their household garbage. This garbage is later collected by garbage trucks, and sent to landfills for storage. Disposing of plastics is severely detrimental to the environment in terms of how much embodied energy it takes to do so. As glow stick tubes are composed almost entirely of plastic, it is important to note just how much of an impact this has. Glow sticks are likely being disposed of frequently due to their popularity among consumers and their single use mechanism, and the weekly garbage truck transports the plastic remains of the products to landfills all over the country. As a result, the amount of plastic that accumulates in these landfills increases significantly, which takes a toll on energy usage in the waste industry. According to Sci Tech Daily, the embodied energy of waste plastics “equates to about 12% of the country’s energy consumption by the industrial sector” (SciTechDaily). Though glow sticks are a rather small plastic product compared to some of the larger ones, the fact that they are frequently disposed of in this manner will greatly contribute to the amount of plastics in landfill sites. This greatly increases the amount of energy utilized in this step of their life cycle. From the manufacturing, to the transportation, and finally waste disposal processes involved in the life cycle of a glow stick, it can be seen that this form of lighting requires quite a lot of energy compared to how much it is used. Finally, it is important to note whether glow sticks are overall sustainable options for a portable light source.

Although glow sticks are considered as energy efficient portable light sources, the impact they have on the planet is rather large. Considering the amount of energy that goes into the manufacturing, transporting and disposing processes of this rather small object is necessary in order to evaluate whether it really is as sustainable of a design as it is seen to be. The consumer usage stage of the glow stick life cycle requires the least amount of energy due to its easy crack-and-shake activation mechanism, and thus is viewed as easy to use, and helpful in low lit environments. As a result, they are a very popular choice of lighting accessory, and can usually be bought in bulk at an affordable value. However, the production, transportation, and disposal processes of these glow sticks utilize high amounts of electrical, mechanical, and chemical energy overall, which renders this light source unsustainable in the long run.

Bibliography

Chandler, David. “New Process Could Make Hydrogen Peroxide Available in Remote Places.” MIT News | Massachusetts Institute of Technology, 23 Oct. 2019, news.mit.edu/2019/mit-process-could-make-hydrogen-peroxide-available-remote-places-1023.

Collins, Colin. “Scientists Estimate That the Embodied Energy of Waste Plastics Equates to 12% of U.S. Industrial Energy Use.” SciTechDaily, 14 May 2022, scitechdaily.com/scientists-estimate-that-the-embodied-energy-of-waste-plastics-equates-to-12-of-u-s-industrial-energy-use.

“Energy Consumption.” cefic.org, 22 Feb. 2023, cefic.org/a-pillar-of-the-european-economy/facts-and-figures-of-the-european-chemical-industry/energy-consumption.

Everything There Is to Know About Glowsticks... www.glowsticks.co.uk/everything-about-glowsticks.html.

Glow Stick, China Glowsticks Wholesale, Light Sticks, Glow Necklace, Glow Bracelets, Glow Fishing Float Manufacturer. www.sino-glow.com.

Greenberg, Julia. “What Makes Glow Sticks Shine?” WIRED, 16 Oct. 2014, www.wired.com/2014/10/makes-glow-sticks-shine.

“How Are Plastics Made?” This Is Plastics, 16 June 2021, thisisplastics.com/plastics-101/how-are-plastics-made.

Ma, Meihua, et al. “Interception of Radicals by Molecular Oxygen and Diazo Compounds: Direct Synthesis of Oxalate Esters Using Visible-Light Catalysis.” Organic Letters, vol. 20, no. 18, American Chemical Society, Aug. 2018, pp. 5799–802, doi:10.1021/acs.orglett.8b02487.

McDonald, Mary. “The Problems With Glow Sticks.” Earth911, 18 Apr. 2022, earth911.com/how-and-buy/the-problem-with-glow-sticks.

O’Connor, Aisling. “Are Glow Sticks Bad for the Environment? 6 Crucial Facts.” Citizen Sustainable, 16 Oct. 2022, citizensustainable.com/glow-sticks.

“Saving Energy in the Plastics Industry.” Electrex - the Energy Saving Technology, 30 Aug. 2000, www.electrex.it/en/company/about-us/saving-energy-in-the-plastics-industry.html.

The Chemistry of Glow Sticks. www.chemie.de/infografiken/180/the-chemistry-of-glow-sticks.html.

Transportation: Delivering the Plastic Products You Can’t Live Without. www.up.com/customers/track-record/tr020420-transportation-and-plastics.htm.

Wey, Laura. “Is It Possible? How to Dispose of Glow Sticks Properly and Efficiently.” Puratium, 16 May 2021, puratium.com/how-to-dispose-of-glow-sticks.

Smoot, Grace. “What Is the Carbon Footprint of Diesel Fuel? A Life-Cycle Assessment.” Impactful Ninja, impactful.ninja/the-carbon-footprint-of-diesel-fuel.

Saxena, V. “What Is the Plastic Manufacturing Process?” About Mechanics, 30 Dec. 2022, www.aboutmechanics.com/what-is-the-plastic-manufacturing-process.htm.

Abigail Wong

Professor Cogdell

DES 40A A03

Wastes and Emissions along the Glow Stick Life Cycle

Glow sticks have a very simple and user-friendly design: bend them, hear them snap, and watch them glow. This seemingly magical, no-electricity illumination is made possible by a chemical reaction. Each glow stick is composed of two tubes: a thin glass tube containing a hydrogen peroxide solution, enclosed within a flexible plastic tube that contains a mix of phenyl oxalate ester and dyes. When the glow stick is bent, the inner glass tube breaks and the two chemical mixtures come in contact with each other, facilitating the reaction: a form of chemiluminescence which emits the light that gives glow sticks their glow. Since glow sticks produce light with no obvious energy inputs involved (no fossil fuel combustion, no electricity power) their use involves no direct emissions and wastes. This may give them the guise of being environmentally friendly lighting options, making them an interesting product to study. However, a look into the life cycle analysis of glow sticks reveals that emissions from the manufacturing and transportation of materials crucial to the design (like glass and plastic), along with the high amount of waste produced from this entirely non-recyclable product render it a product with high environmental burdens.

The processes of acquiring the raw materials in glow sticks involve large quantities of emissions and wastes. Glow sticks contain three main materials: glass, plastic, and the chemicals that produce the reaction. In order to truly explore the entire LCA, we must dig deeper into the extraction of primary raw materials that make up these materials. Silica, a form of industrial sand, is the primary component of glass. It is mined through open pit or dredging methods. Many mining companies are quick to defend this process as having a “limited environmental impact,” because it does not “require extractive methods or tunnels” unlike ore or oil extraction (AngloAmerican). However, this does not make it environmentally friendly. Open pit silica mines, along with crushing and screening plants, release dust which can harm the health of surrounding flora, fauna, and humans. If inhaled, crystalline silica dust can cause silicosis, a “debilitating and potentially deadly lung disease” (CDC). Silica mines also deposit tailings (waste) into tailings ponds and dams. This waste, which takes the form of a slurry, may contain unextracted minerals that render it toxic to the environment. Petroleum, the primary raw material in making plastic, is extracted from the earth via oil drilling and fracking. During the drilling process, a solution called formation water is pumped to the surface alongside the oil. Formation water may contain dissolved radioactive elements such as radium, a decay product of naturally occurring uranium and thorium in the oil reservoirs. This radioactive waste often accumulates in waste pits or drilling equipment in high concentrations, and can cause biological damage to surrounding life that is exposed to it. Lastly, the chemicals present in glow sticks such as hydrogen peroxide are synthesized from many other chemicals, which in turn may be synthesized themselves with the help of certain oxidizing agents like hexavalent chromium. Mined ores such as chromium ore are the primary raw materials in these agents, and they are extracted through similar open-pit mining techniques as silica and involve similar wastes (dust and toxic tailings). These ores may also be extracted via underground mining, which relies on diesel-powered mining equipment that is high in NOx emissions. All in all, the methods used to extract the raw materials for glow sticks have numerous, various emissions—yet they are still only a fraction of the complete picture.

The next step to consider along the LCA is the processing that transforms these primary raw materials into the glass, plastic, and chemicals central to the glow stick. These operations are highly industrial and come with a host of wastes and emissions. In transforming silica, lime, and soda into glass, the majority of these emissions come from burning the fuel source used to power the furnaces. These furnaces melt batches of prepared raw material at temperatures between 1000 and 1600 °C, and to reach such heights they commonly rely on energy-dense fossil fuels like natural gas. Burning natural gas releases high amounts of pollutants like NOx, CO2, CO, CH4, and particulate matter into the air. Glassmaking factories also release water pollutants, including emulsified oil used to lubricate the blades, via their water outflow stream. Some factories have implemented processing methods to mitigate this issue, however their waterborne waste contribution is still significant. Within the plastic manufacturing sector, the most significant kind of pollutant emitted is volatile organic compounds (VOCs), which arise from “leakage, venting, and the evaporation of raw materials and finished products” (Cherimisinoff and Rosenfeld). VOCs in the air bind with NO (which occurs when sunlight breaks down NO2 emitted into the air) to form photochemical oxidants. The resulting compound binds with ozone (whose formation is also accelerated by NO2 emissions) and forms photochemical smog, a harmful pollutant that can cause respiratory irritation in humans and animals and can block sunlight from reaching plants and crops. Regarding VOCs alone, high concentrations can cause “irritations, nausea, dizziness, and headaches” and can be “carcinogenic for both humans and animals” (Kamal et al.). For the last main component of glow sticks—the chemicals (such as hydrogen peroxide)—processes including oxidation with compressed air, catalytic hydrogenation, and fractional distillation are required. In industrial settings these procedures are carried out with air compressors, tubular plug-flow reactors, and fractional distillation columns. While I encountered some limitations to my research regarding the total emissions of these technologies and what powers them, one thing is certain: they are all large-scale, heavy-duty forms of equipment and are extremely energy-intensive. This means they likely rely on high amounts of electricity or fuel to operate, and must release emissions as power is generated or used. Additionally, the manufacturing of the glow sticks themselves relies on similarly energy-consuming factory equipment such as ultrasonic welders; they are powered by electricity, a secondary power source that burns greenhouse gas-releasing fossil fuels for its initial generation. Eventually, after all this industrial processing and manufacturing is complete, the packaged final products must be shipped in order to be sold.

Glow stick companies rely on land and water transportation to get their product from manufacturers to wholesalers, and from wholesalers to retailers to channel them into the market. Transportation is a large contributor to global greenhouse gas emissions, as most trucks and ships are powered by fossil-fuel burning internal combustion engines. According to the Environmental Protection Agency, the transportation sector is responsible for “over 50% of NOx total emissions inventory in the U.S., over 30% of VOCs emissions in the U.S., [and] over 20% of PM [particulate matter] emissions in the U.S.”, and that “within transportation, heavy-duty trucks are the fastest-growing contributor to emissions” (EPA). As mentioned earlier in this paper, these pollutants accelerate the formation of tropospheric ozone and photochemical smog; land transport emissions consequently contribute up to 18% of ground-level ozone in source regions of North America and Southern Europe. Water transport, in comparison, contributes up to 52% of the net ozone production in the North Pacific Ocean due to the gases cargo ships release, and in 2012 “accounted for 961 million tonnes of CO2 (up from 816 million tonnes of CO2 in 2007)” giving it a significant role in the greenhouse effect and thus climate change (Styhre et al.). Cargo ships also release several direct wastes into the water. This may include ballast water (containing invasive aquatic species), antifoulants, oil and chemical spills, garbage, sediment contamination, and underwater noise pollution disruptive to aquatic fauna. All of these wastes damage underwater environments, and pollution from oil spills and garbage can harm on-shore environments as well. Much of this is overlooked when considering the environmental impact of glow sticks, since it is not directly tied to using the glow stick itself. However, this is what makes the LCA so important; it unearths surprisingly significant emissions that lie behind the rather unassuming process of using a glow stick.

The process of using glow sticks—essentially just unwrapping them, bending them, and watching them glow—releases no direct emissions or wastes other than the discarded plastic packaging and any potential leakage of the interior chemicals (if the glow stick happens to break). The light-emitting reaction is contained within the plastic ampoule, so there is no channel for any physical emissions to escape. It is not powered by electricity or the combustion of fossil fuels (simply a reaction between hydrogen peroxide and phenyl oxalate ester), so the process inherently does not release any greenhouse gases. If any of these chemicals were to escape via a puncture in the plastic casing, they are not present in high concentrations given the size of each glow stick and do not present a large environmental threat. However, the chemical reaction inside the glow stick only lasts for about 8-12 hours, leaving a significant form of waste behind: the glow sticks themselves. Glow sticks cannot be reused. There are some strategies to prolong the reaction, but none can make its glow last for more than a day or two. Beyond this time frame, spent glow sticks have little reuse value, as their primary asset is their glowing power. So, given that there is little left to do with it now, the glow stick must be thrown out.

Considering that glow sticks are single-use, recycling would be a good way to reduce the wastes they produce. However, glow sticks cannot be recycled. The liquid chemicals they contain would leak out during the recycling process and contaminate other materials such as paper or cardboard, mixing with the fibers and thus interfering with the process of pulping. So, since they cannot be recycled, there are no emissions or wastes involved with glow sticks in this step of the LCA.

This brings us to waste management. There are emissions involved in each step of waste management. Waste collection often relies on diesel-burning vehicles for transport, which in affluent countries may take the form of energy-demanding “state-of-the-art refuse collection vehicles (RCVs) equipped with hydraulic bin-lifting gear” (McLeod et al.). In the United States, “almost all of the more than 136,000 refuse collection trucks in the United States are powered by heavy-duty diesel engines” (Mohamadreza, et al.). These vehicles are high in emissions of NOx and diesel particulate matter (DPM), which contains several cancer-causing substances and can cause other health dangers. These emissions are heightened by the stop-and-start nature of waste collection, as the frequent stops made by refuse vehicles to service each household prolong the time fuel is being burned. According to a 2009 paper, “these characteristics of refuse trucking activity make it one of the major contributors to the pollutant emissions in urban areas across the country” (Mohamadreza, et al.). Landfills also have a heavy environmental impact. They contain many materials that can take decades to degrade—such as plastic waste, whose presence in landfills amounts to over “4,000 × 10^6 tons worldwide, [or] over 50% of all the plastics ever made” (Lu et al. 367). This plastic is, according to a 2022 journal, “prone to unintended releases to the environment” via erosion, surface runoff, leaching, scavenging, and slope failures (Lu et al. 376). Many plastic LCA studies fail to recognize this and consider a landfill the endpoint of their analysis, as a “permanent sink” rather than an “intermediate reservoir” (Lu et al. 376). It is crucial to account for environmental releases, especially in less affluent areas whose landfill containment measures are less developed. Disposed glow sticks may also end up in waste that is incinerated, another highly harmful process in terms of emissions. According to Eurostat, each ton of municipal solid waste incinerated releases between 0.7 and 1.7 tons of CO2 (EPA). The process is also driven by high amounts of electricity, whose generation releases lots of CO2 in addition. In sum, the wastes and emissions along a glow stick’s LCA are continually high even after it is thrown in the trash.

Glow sticks, although electricity and fossil fuel-free during use, involve considerable amounts of wastes and emissions along the process of creating them and disposing of them. Performing a life cycle analysis of the product brings these areas to light. Some of the key emissions to remember are NOx and VOCs (released especially during processing, transportation, and waste management steps of the LCA), which contribute to tropospheric ozone and photochemical smog; along with CO2, which is a greenhouse gas that plays a large part in climate change. Both polar ends of the LCA produce waste—from airborne crystalline silica particles during mining to plastic waste that leaches out from landfills into the environment—all of which can have adverse effects on surrounding flora, fauna, and communities. It is important to remember that for each product, even one as simple as glow sticks, its journey from cradle to grave may involve many intense industrial processes whose emissions all contribute to its environmental footprint.

Bibliography

Halford, Bethany. “What Are Glow Sticks, and What’s the Chemical Reaction That Makes Them Light up?” Cen.acs.org, 19 Oct. 2021, https://cen.acs.org/business/consumer-products/glow-sticks-s-chemical-reaction/99/i39.

“Open-Pit Mining Definition.” Anglo American, 18 Apr. 2022, https://www.angloamerican.com/futuresmart/stories/our-industry/mining-explained/mining-terms -explained-a-to-z/open-pit-mining-definition.

“Exposure to Silica Dust on Continuous Mining Operations.” Centers for Disease Control and Prevention, Centers for Disease Control and Prevention, 6 June 2014, https://www.cdc.gov/niosh/docs/97-147/default.html.

Cheremisinoff, Nicholas P., and Paul Rosenfield. “The Petroleum Industry.” Handbook of Pollution Prevention and Cleaner Production - Best Practices in The Petroleum Industry, William Andrew Publishing, 22 Oct. 2009, https://www.sciencedirect.com/science/article/pii/B9780815520351100016.

Muhammad Shahzad Kamal b, et al. “Catalytic Oxidation of Volatile Organic Compounds (Vocs) – A Review.” Atmospheric Environment, Pergamon, 18 May 2016, https://www.sciencedirect.com/science/article/pii/S1352231016303727.

“Anthraquinone Process.” Wikipedia, Wikimedia Foundation, 3 May 2022, https://en.wikipedia.org/wiki/Anthraquinone_process.

“Why Freight Matters to Supply Chain Sustainability.” EPA, Environmental Protection Agency, https://www.epa.gov/smartway/why-freight-matters-supply-chain-sustainability.

Wong 9 Mertens, Mariano, et al. “Revisiting the Contribution of Land Transport and Shipping Emissions

to Tropospheric Ozone.” Atmospheric Chemistry and Physics, Copernicus GmbH, 24 Apr. 2018, https://acp.copernicus.org/articles/18/5567/2018/.

Styhre, Linda, et al. “Greenhouse Gas Emissions from Ships in Ports – Case Studies in Four Continents.” Transportation Research Part D: Transport and Environment, Pergamon, 27 May 2017, https://www.sciencedirect.com/science/article/pii/S1361920916306216.

McLeod, Fraser, and Tom Cherrett. “Waste Collection.” Waste, Academic Press, 27 Jan. 2011, https://www.sciencedirect.com/science/article/pii/B978012381475310004X.

Farzaneh, Mohamadreza, et al. “Evaluation of in-Use Emissions from Refuse Trucks.” Transportation Research Record: Journal of the Transportation Research Board, vol. 2123, no. 1, 2009, pp. 38–45., https://doi.org/10.3141/2123-05.

Lu, Xuhong, et al. “The Distribution, Behavior, and Release of Macro- and Micro-Size Plastic Wastes in Solid Waste Disposal Sites.” Taylor & Francis, 23 Mar. 2022, https://www.tandfonline.com/doi/full/10.1080/10643389.2022.2054649.

Yena Won

Des 40A

Professor Cogdell

Raw Materials in Glow Sticks

The glow sticks are light sources easily seen in any market and used for entertaining with color and glow in the dark. Not only are glow sticks used for entertaining purposes, like in the party and concerts for adults and also children, but for other than entertainment purposes, they are often used as safety sources in the dark to light up and gain visibility in dark and dangerous places because glow sticks are light weighted and small size. Hence, it is portable in the wild without electricity. When Glow sticks are used for safety, it gives them a light and a Save Our Ship sign to be easily seen and rescued. For people to use these good resources, raw materials must be found and go through the life cycle steps to be produced as finalized product glow sticks. For glow sticks, the central part of raw materials is glass and plastic container and two main chemicals that makes a glowing liquid. The chemicals are not environmentally sustainable because they mostly do not get recycled and end up in a landfill.

According to glowsticks.co.uk, glow sticks are plastic tubes that hold two chemicals. One of the chemicals goes into a glass tube that is inside the plastic tube. When the glass tubes break, the chemical mixes with other chemicals that are around it. Then it causes a chemical reaction which causes heat; the term that describes the reaction is chemiluminescence.

To produce glow sticks, raw materials need to be found and go through the procedure to become the materials of glow sticks which are glass containers, plastic containers, and several liquid chemicals that light up the sticks. The other liquid chemicals must be added to the original chemicals to add colors. The raw materials for glass containers are silica ( sand ), soda as limestone, and cullet ( furnace-ready, recycled glass ). These materials go through various steps to be finalized as a glass tube, which goes into the plastic pallet. To produce plastic tubes called plastic pellets, according to plastic 101, plastics are made from raw materials, natural gas, oil, or plants and processed into ethane and propane. The two main chemicals used to make glowing liquid is Hydrogen Peroxide and Phenyl Oxalate ester. Water is needed for Hydrogen Peroxide, and CO2 is required for Phenyl Oxalate ester. To add colors to the glowing light Fluorescent dyes are added to the original hydrogen Peroxide and Phenyl Oxalate ester.

When the glow sticks are made, it is made out of two containers to hold the liquid. One of them is a glass container called a glass vial which is placed on the inner side of the glow stick that goes into the plastic pellets. According to Oi, making a glass container goes through 6 significant steps. In the first step of making glass which is called cullet, raw materials are needed: silica ( sand ), soda as limestone, and cullet ( furnace-ready, recycled glass ). These materials are put together to make a mixture of batches. The second step, the furnace, uses 1550 degrees celsius to create molten glass. The next step is the refiner, which cools down the heated molten glass mixture inside the big container. Forth step is called forehearth, which cools down the temperature and cuts the shape of the molten glass to become a “gods,” and it will become a glass container. The second to last step is called forming machine, in which compressed air shapes and expands “gods” into a glass container. The final step is called Annealing, which cools down the inside and outside of the glass bottle simultaneously at different temperatures so it can get cool down gradually with the proper temperatures and is ready to be finalized with coating. According to O.Berk, after a glass container gets produced, it gets coated with Oleic Acid Vapor, a standard glass coating often used for glass bottle protection with minimum label adhesion problems. Also, Polyethylene Spray is used when the container needs more strength to prevent it from cracking. However, this way is the most permanent form of coating. The outer container is a plastic tube; the plastic container holds the rest of the chemicals that do not go into the glass container. This plastic tube is called a plastic pellet. The raw materials for the plastic need to go through a process called cracking which converts the materials into monomers like ethylene and propylene. Next, the monomer is combined with a catalyst to create polymer “fluff,” which looks like a powder. Then, the polymers go into the long tube to cool them. When it gets cooled down, the tube is cut into small pallets. Lastly, pellets are shifted to factories to be melted and molded into plastic tubes, and it is ready to be transported. After making glass and plastic containers, it is time for chemicals to be mixed.

According to Gol Bio, an inner glass vial holds hydrogen peroxide. When it gets mixed with the phenyl oxalate ester, which is pace around the glass tube, phenol, and peroxy acid ester are produced. Peroxy acid decomposes to activate the fluorescent glow stick dye with its energy. The pigment is then responsible for releasing photons when its electrons are excited. To make it more colorful fluorescent dyes need to be added around the glass tube with the rest of the chemicals. There are several different kinds of chemicals that produce different colors. For example, Rhodamine B makes radiant red, 9,10-bis anthracene gives green, and 9,10-diphenyl anthracene glows up with a blue hue.

When it is time for glowsticks to be transported from the factory, they must be packaged with plastic or paper. Plastic or paper is used for containers to hold the glow sticks to be shifted out. The finalized glow sticks need to go into the plastic bag or paper box, and it is ready to be shifted. Then, it gets transported to different places to be prepared to be sold.

To use a glow stick, a chemical reaction needs to occur between two chemicals and it causes by cracking the glow stick. Cracking the tube breaks the glass and lets the chemicals mix and react.

Only some of the time, glow sticks can be reused because it is made for one-time use product but according to WikiHow, reusing the glow stick, several ways can help in several ways. First, put used glowsticks into freezers to freeze the liquid inside, and it prevents the chemicals from reacting. After an hour, check on the glow stick and try shaking and cracking it. If it doesn’t work, put it back into the freezer and try again the next day or a few hours later. Putting glow sticks into the freezer will give an extra glowing time when the chemicals inside melt and combines again. Another way is to use boiling water to speed up the chemical reaction that causes the glowing between the chemical. Pour the hot water into the glass jar, let it cool down a little, and put the glow stick inside the water for thirty seconds and it will likely glow up again. Other than these two ways, there is an easy way to reuse the glow stick. After the glow stick is used, there can be a space where it is not yet been cracked, so find an area where it has not been cracked and do not leave any space.

The chemicals inside the glow sticks can be toxic to children and other animals, so it needs to e put into a plastic bag and thrown into the garbage can. Also, none of the raw materials used to make glow stick can’t be recycled because it has been contaminated with chemicals.

Even though glow sticks seem a very simple product, they go through complicated life cycle steps to be produced. The first step of the life cycle, finding a raw material, is significant. It determines whether or not the product needs a toxic chemical or other raw materials that can be recycled or placed in a landfill. Unfortunately, glow sticks are made up of raw materials that can not be recycled because they contain a chemical that can harm children and animals.

Bibliography

Alexander, Gemma. “How to Dispose of Glow Sticks - 3 Effective Methods.” Dispose It Well, 15 Feb. 2023, https://disposeitwell.com/how-to-dispose-of-glow-sticks/.

Everything There Is to Know about Glowsticks... https://www.glowsticks.co.uk/everything-about-glowsticks.html.

“Glow Stick.” Wikipedia, Wikimedia Foundation, 3 Dec. 2022, https://en.m.wikipedia.org/wiki/Glow_stick.

Halford , Bethany. “What Are Glow Sticks, and What’s the Chemical Reaction That Makes Them Light up?” Cen.acs.org, 19 Oct. 2021, https://cen.acs.org/business/consumer-products/glow-sticks-s-chemical-reaction/99/i39#:~:text=Glow%20sticks%20light%20up%20when,releases%20light%20as%20it%20relaxes.

Hardie, Megan. “The Science and History of Glow Sticks.” GoldBio, https://goldbio.com/articles/article/the-science-and-history-of-glow-sticks#:~:text=An%20inner%20glass%20vial%20holds,when%20its%20electrons%20are%20excited.

Helmenstine, Anne Marie. “Here's How Glow Sticks Get Their Colors.” ThoughtCo, ThoughtCo, 1 Feb. 2020, https://www.thoughtco.com/how-glow-stick-colors-work-4064535.

“How Glass Bottles and Jars Are Made.” OI, 17 Sept. 2020, https://www.o-i.com/our-story/how-glass-bottles-and-jars-are-made/.

“Quick Question Monday : What Are Cold End Glass Coatings for?” Glass, Plastic, Metal Bottles and Caps Wholesale - O.Berk®, O.Berk Leaders in Packaging Solutions , 7 Nov. 2016, https://www.oberk.com/packaging-crash-course/cold-end-glass-bottle-coatings#:~:text=Oleic%20Acid%20Vapor%3A%20This%20is,manufacturing%20and%20filling%20of%20containers.

Sarah. “How Glow Sticks Work: The Science behind Glow Sticks.” Glowtopia, 16 Mar. 2017, https://www.glowtopia.co.uk/news/how-glow-sticks-work/.

“The Chemistry of Glow Sticks.” Compound Interest, 9 Nov. 2016, https://www.compoundchem.com/2014/10/14/glowsticks/.

Wey, Laura. “How to Dispose of Glow Sticks Properly & Efficiently.” Puratium, 16 May 2021, https://puratium.com/how-to-dispose-of-glow-sticks/.

wikiHow. “How to Make Glow Sticks Glow Again: 8 Steps (with Pictures).” WikiHow, WikiHow, 23 Dec. 2022, https://www.wikihow.com/Make-Glow-Sticks-Glow-Again.