Design Life-Cycle

assess.design.(don't)consume

Sara Besson

Professor C. Cogdell

Design 40A

1 December 2016

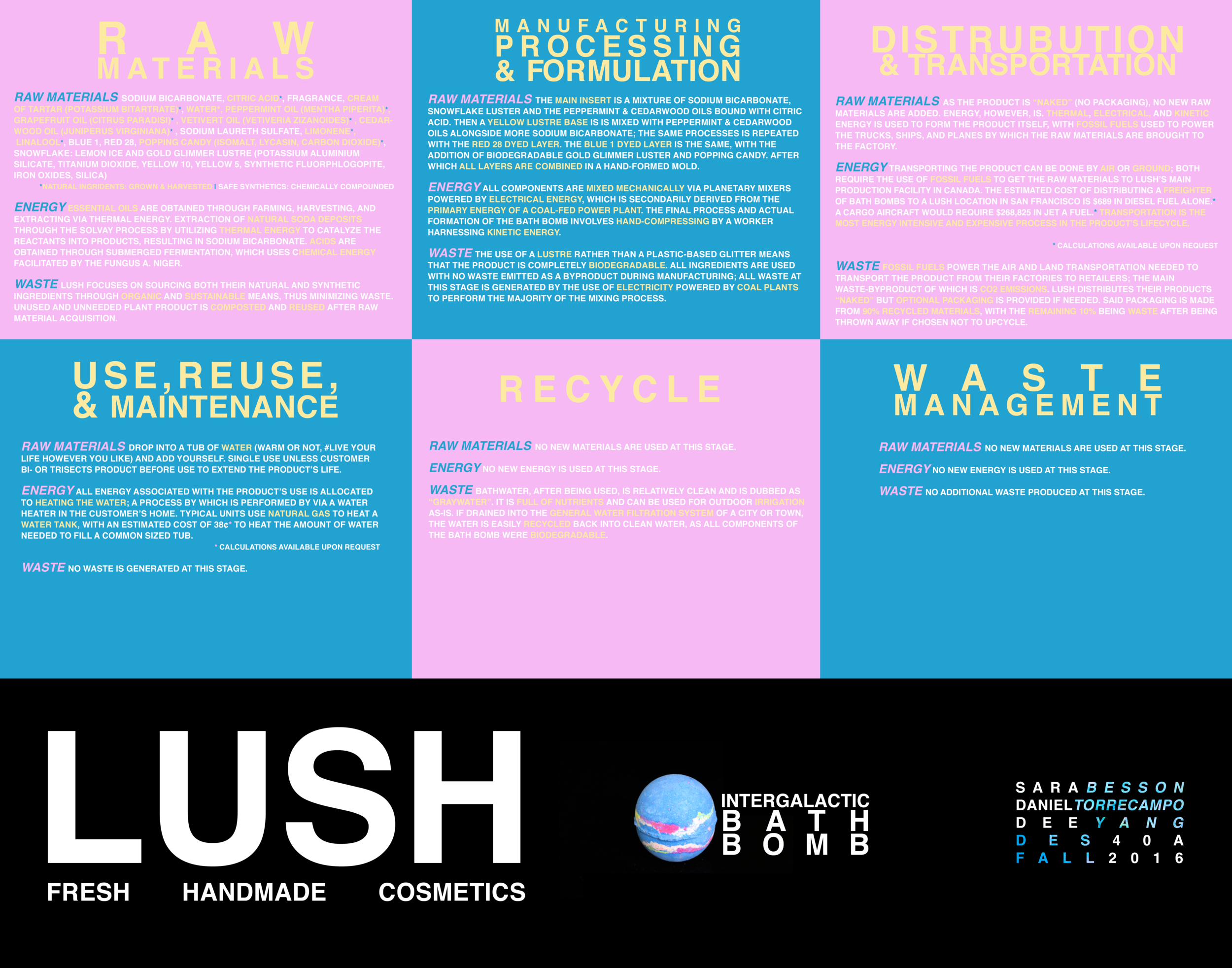

Lush Intergalactic Bath Bomb: Raw Materials

One of the more popular ongoing trends in the beauty and cosmetic industries is the reduction of ingredient lists to their most essential parts, with a particularly stressed importance being placed on the quality of the the ingredients that remain. Of all the brands cashing-in on this more ethical, ‘natural’ movement, Lush makes a point of centering its identity around products that are sourced responsibly and that have minimal impact. This concept is especially evident in how they take care to ensure that the base raw materials in every product are as natural and minimalist as possible. As a company that claims that “‘fresh’ and ‘organic’ have honest meaning beyond marketing” (“We Believe”), the Intergalactic Bath Bomb — one of the top sellers in their most iconic and near brand-synonymous bath bomb product line — provides a perfect opportunity to track Lush’s materials and see if they indeed are a company that practices what they preach when it comes to the product’s comprehensive life-cycle.

Given the advent and popularization of showers, baths can seem like the relic of the past. This sentiment is doubled when viewed through the context of a world plagued by drought and with a finite fresh water supply. With the caveat that it doesn’t last longer than 10 minutes, showers typically save more water than letting the tub fill up (Jen). Similarly, bath bombs don’t do much to clean one’s body in and of itself — although the essential oils contained within can be moisturizing and beneficial to skin (Lawless). So why then is it that humans are so drawn to sit-down bathing? The intuitive answer is for the sensory experience, and that’s what a bath bomb’s spectacle adds on to. The question then becomes: how can Lush go about enhancing an already lavish and not-so-ecologically friendly activity in a way that avoids making a wasteful product whose downsides weigh heavier than its benefits?

Lush views the ethical sourcing of their raw materials as the the backbone of their products, and their buying policy reflects that. They do not limit this sentiment to being an entirely cruelty-free, vegetarian company — with many products going so far as to be vegan; the main manifestation of this ethos reveals itself in Lush prioritizing its buying from first-party growers themselves so that Lush can ensure the workers are treated fairly and that the negative impact on the environment and surrounding societies is minimal (“Ethical Buying Policy”). It is through their buying policy that Lush aims to help foster those locales while also reaping the benefits of having that same sense of ‘community’ transferring to their brand, associating it with the idea that items grown there, rather than in large farming outfits, are more ‘pure’ and ‘beautiful’ than their mass produced counterparts, as reflected by the language used throughout their Ethical Buying Policy. This focus on where it is that they’re buying from provides Lush the ability to have raw materials that stand on their own in the eyes of consumers and comprise the majority of said product’s ingredient listing as a result.

Of the sixteen raw material ingredients that make up the Intergalactic Bath Bomb, ten are ‘natural’ (“Intergalactic Bath Bomb”). They are: citric acid, ‘popping candy’, cream of tartar (potassium bitartrate), water, peppermint oil (mentha piperita), grapefruit oil (citrus paradisi), vetivers oil (vetiveria zizanoides), cedarwood oil (juniperus virginiana), limonene, and linalool.

Essential oils are some of the oldest additives used for bathing, not just for their lovely stimulating fragrances but for the benefits they afford to skin and the mind as well (Tisserand 17). Regardless of where they derive, the process of extracting essential oils is generally similar across the board. Peppermint, grapefruit, vetivers, and cedarwood oils are derived from leaves, fruit rinds, grass, and berries, respectively. The respective plants and fruits are grown and then harvested during their most ripe and/or respective blooming seasons (Cassel et al). The longstanding process of hydrodistillation (HD) is the industry standard for essential oil extraction, This process, however, can be time consuming, leading to an overall trend towards microwave-assisted hydrodistillation(MAHD) extraction, which has been shown to produce quantitatively and qualitatively comparable amounts of essential oil in 30 minutes where it would typically 4.5 hours via HD (Golmakani and Rezaei). In both methods, as outlined by Golmakani and Rezaei, the intended plant material is placed into a container filled with water and then heated. With MAHD the heat is administered via microwave, as the name suggests, while HD utilizes an electromantle. With the former the oils can be collected and decanted in 15 minute intervals while the latter requires 60 minutes.

The remaining ‘natural’ ingredients are somewhat easier to explain. Limonene is a liquid hydrocarbon that naturally occurs in citric acids. It carries the main fragrance of the fruits and also has cleansing and solvent properties (“Limonene”). The mold Aspergillus niger is be fed sugar to produce critic acid itself (Berovic, Marin, and Legisa). Linalool is a serpentine alcohol that occurs naturally in essential oils and also carries the majority of the scent properties of said oils (“Linalool”). Cream of tartar is a byproduct of winemaking, a crystallization that forms along the inside of casks from “the reaction between the bitartrate ion (HTa-), from tartaric acid (H2Ta), and the potassium ion (K+) found in grapes, especially grape skins” (“Potassium Bitartrate”) and is used as to activate baking power and stabilize certain compounds. ‘Popping Candy’ is Lush’s term for a blend of isomalt, which is manufactured in the two-stage process of enzymatically transforming sucrose into isomaltulose —producing a yield of about 80-85% — and is then hydrogenated to make isomalt (Rose, Thomas, and Kunz); Lycasin, which is Roquette’s trade name brand for hydrogenated glucose syrup that is produced by the hydrolysis of starch that then undergoes hydrogenation to turn the subsequent dextrin into sugar alcohols (Kearsley and Birch); and carbon dioxide (“Fizzing Candy”).

The remaining six ingredients are what Lush deems ‘safe synthetics’ (“Intergalactic Bath Bomb”): sodium bicarbonate, fragrance, sodium laureth sulfate, ‘Snowflake’ (lemon ice and gold glimmer luster), Blue 1, and Red 28.

Sodium bicarbonate is produced by first mining trona ore and bringing it to the surface. It is refined until it becomes what is known as soda ash, which is then put into a centrifuge and separated from liquid into crystals. Those crystals are then dissolved into a solution that is filtered, has carbon dioxide introduced into it, and then undergoes pressure. After that cools, the newly formed crystals are washed in a bicarbonate solution and are made into a cake-like shape where they then can be flash dried and be crumbled into granules (John).

Sodium laureate sulfate is used as a surfactant, emulsifier, and cleansing agent that is derived from ethoxylated laurel alcohol (Charbonnier et al). Yellows 10 & 6, Blue 1, and Red 28 are dyes. Two are food-grade — Blue 1 is food grade and made from an oil base (Borrell) and Yellow 6 is made via a “coupling of diazotized sulfanilic acid with 2-naphthol-6-sulfonic acid” (FD&C). Yellow 10 and Red 28 are regulated by the FDA as to be used for external cosmetics and drugs use only (“Color Additive Status List”), which contrasts Lush’s claim of all their dyes being “food grade” (“Lush How It’s Made”). The Snowflake and Gold Glimmer Lustre are just that — mineral mixtures of potassium aluminum silicate, titanium dioxide, the Yellow 10 & 6 dyes, synthetic fluorphlogopite, iron oxides, and silica (“Snowflake”) that are biodegradable, unlike plastics that make up traditional glitters (“Lush How It’s Made”).

Lush’s ‘fragrances’ are a well-kept secrets containing unknown ingredients that are dermal allergens for some, just as essential oils are also known to be (Tisserand and Young 80). It is important to delineate that “natural” products are not synonymous with being suited to all skin types; in fact, a common complaint against Lush products pertains to their instance on using certain natural ingredients that are known dermal allergens over safe synthetics and/or other alternatives that have similar properties without the irritant — or, in the case of their ‘fragrance’, not detailing its component parts so that potential irritants can be identified before exposure.

After all these ingredients are gathered, the manufacturing process can begin. Even at such a high production level as what Lush’s Canadian manufacturing headquarters (Weller) needs to output, the actual process of creating a bath bomb isn’t much different than what a person might create in their own home (Cox and Cox 132). The Intergalactic Bath Bomb is made in relatively small batches, the first step of which requires the creation an ‘insert’ comprised of the sodium bicarbonate, snowflake luster, peppermint and cedarwood oil, and Lush's ‘bubble mix’ all combined via planetary mixers (“Lush How It’s Made”). The composition of the ‘bubble mix’ is never revealed, but based on the ingredients list it would appear to be the combination of the sodium laureth sulfate and cream of tartar. Then the colored layers are produced: the yellow layer is made with sodium bicarbonate colored with the yellow luster and peppermint & cedarwood oils. The process is repeated with the Red 28 for the red layer, and then again with Blue 1, noting the addition of the biodegradable gold glimmer and popping candy inside the blue layer (“Lush How It’s Made”). The final aspect of manufacturing is for all four compounds to be hand-pressed into bisected circular molds by workers (“Handmade”). From this point the bath bomb is ready to be shipped out to Lush locations around the world.

When it comes to distribution and transportation, Lush is in a slight hell of their own creation. Harvesting things like Orange Flower from Tunisia (“Ethical Buying Policy”) is all ecologically well and good until it needs to be shipped to Canada for processing. While said Buying Policy says that they do actively address “minimum air freight [and] packaging material used”, Lush never discloses what it is they do to lessen fossil-fuel emission impacts of the air, sea, and land freighters used to ship their raw materials and finished products. Granted, same policy notes that Lush sources the flowers, fruits, and vegetables used in their products locally, weather permitting. That aside, however, Lush does sell its bath bombs ‘naked’ — that is, without any packaging or wrapping. The reasons for this are two-fold. First and most obvious is to cut down on the use of plastics and other waste materials. Second is to “increase awareness surrounding the overuse of disposable packaging and challenge other retailers to reduce their packaging too” (“Naked”). The main effect of this choice entails that once the product has been shipped to the retail location or the customer’s home, the most wasteful part of its entire existence has ended.

Use of the bath bomb is fairly straightforward: fill any other desired bathing area with water — hot, warm, or cold at the bather’s discretion — and then drop the bath bomb in, letting chemistry work its magic. Lush intends the product to be single use, but it isn’t uncommon for a customer to bisect (or even trisect) the product so that the unused portion can be stretched into another bath despite the lessened potency of said bath bomb. Then you sit, soak, and enjoy life.

Thanks to Lush’s focus on using mostly natural and otherwise biodegradable products, the end-result of a bath taken with the Intergalactic Bath Bomb is the same as if it had been taken without it. The water is completely recyclable. Once drained it can go through a city’s water filtration system without any issues (“Intergalactic Bath Bomb”), but that is far from sole avenue of its recyclability. Water that is relatively clean, such as that from baths or showers, is known as ‘greywater’ (Al-Jayyousi). It is full of nutrients and can be used for outdoor irrigation, especially when used within 24 hours (“Greywater Reuse”). With more cities allowing this practice — such as in Davis, CA (“Grey Water”) — baths suddenly become more conscientious than they had been previously, as they present an opportunity to save fresh, clean water from being wasted in instances where greywater can instead be used.

As a whole, the Intergalactic Bath Bomb is a solid embodiment of what Lush sets out to achieve with their products — successfully leaving the water no worse than before the product was introduced. Lush as a company does indeed have a few drawbacks, namely using common allergens and its implicit cost in transportation & distribution, but it does fulfill one of their overarching objectives of increasing awareness of one’s lifestyle habits in general. Many people use Lush as their ‘gateway’ into the natural and minimalist beauty sector, oftentimes leading to the support of smaller, local brands that source closer to where the customer resides (addressing the transport issue), with some people even going as far as to make products completely on their own — which, combined with greywater reuse, is a step towards the ultimate end of a lessened ecological-footprint overall while still being able to enjoy in life’s small pleasures.

Bibliography

Al-Jayyousi, Odeh R. "Greywater reuse: towards sustainable water management." Desalination

156.1 (2003): 181-192.

Aronczyk, Melissa. "Market (ing) activism: Lush Cosmetics, Ethical Oil, and the self-mediation

of protest." JOMEC Journal 4 (2016).

Berovic, Marin, and Matic Legisa. "Citric acid production." Biotechnology annual review 13

(2007): 303-343.

Borrell, Brendan. "Where Does Blue Food Dye Come From?" Scientific American. Scientific

American, 30 Jan. 2009. Web. 30 Nov. 2016. <https://www.scientificamerican.com/

article/where-does-blue-food-dye/>.

Charbonnier, V., et al. "Subclinical, non-erythematous irritation with an open assay model

(washing): sodium lauryl sulfate (SLS) versus sodium laureth sulfate (SLES)." Food and

chemical toxicology 39.3 (2001): 279-286.

Cassel, E., et al. "Steam distillation modeling for essential oil extraction process." Industrial

crops and products 29.1 (2009): 171-176.

Cox, Lauren, and Janice Cox. EcoBeauty: Scrubs, Rubs, Masks, Rinses, and Bath Bombs for You

and Your Friends. Ten Speed Press, 2011.

Golmakani, Mohammad-Taghi, and Karamatollah Rezaei. "Comparison of microwave-assisted

hydrodistillation withthe traditional hydrodistillation method in the extractionof essential

oils from Thymus vulgaris L." Food Chemistry 109.4 (2008): 925-930.

Jen, Tessaly. "Shower or Bath?: Essential Answer." Stanford Magazine. Stanford University,

Mar.-Apr. 2011. Web. 30 Nov. 2016. <https://alumni.stanford.edu/get/page/magazine/

article/?article_id=28853>.

John, Ross Taylor. "Sodium bicarbonate production." U.S. Patent No. 2,527,340. 24 Oct. 1950.

Kearsley, M. W., and G. G. Birch. "Production and physicochemical properties of hydrogenated

glucose syrups." Starch‐Stärke 29.12 (1977): 425-429.

Lawless, Julia. The Encyclopedia of essential oils: the complete guide to the use of aromatic oils

in aromatherapy, herbalism, health, and well being. Conari Press, 2013.

Levitan, Herbert. "Food, drug, and cosmetic dyes: biological effects related to lipid solubility."

Proceedings of the National Academy of Sciences 74.7 (1977): 2914-2918.

Rose, Thomas, and Markwart Kunz. "Production of isomalt." Practical aspects of encapsulation

technologies. Bundesforschungsanstalt für Landwirtschaft. Braunschweig. Landbauforsch

Völkenrode Sonderh 241 (2002): 75-80.

Tisserand, Robert. The art of aromatherapy: The healing and beautifying properties of the

essential oils of flowers and herbs. Inner Traditions/Bear & Co, 1978.

Tisserand, Robert, and Rodney Young. Essential oil safety: a guide for health care professionals.

Elsevier Health Sciences, 2013.

Weller, Chris. "Inside the Surreal LUSH Factories, Where the Willy Wonka of Soap Is

Reinventing Cosmetics." Business Insider. Business Insider, 30 Sept. 2016. Web. 01 Nov.

2016. <http://www.businessinsider.com/lush-factory-photo-tour-inside-the-willy-wonka-

factory-of-soap-2016-9>.

"Color Additive Status List." U.S. Food & Drug Administration. FDA, Dec. 2015. Web. 30 Nov.

2016. <http://www.fda.gov/ForIndustry/ColorAdditives/ColorAdditiveInventories/ ucm106626.htm>.

"Ethical Buying Policy." Lush Fresh Handmade Cosmetics. Lush Retail Ltd, 11 Feb. 2015. Web.

24 Oct. 2016. <https://uk.lush.com/article/ethical-buying-policy>.

"FD&C Yellow No. 6: Sunset Yellow Food Dye." CulinaryLore.com. CulinaryLore, 4 Aug. 2015.

Web. 30 Nov. 2016. <http://www.culinarylore.com/ingredients:fdc-yellow-no-6-sunset-

yellow-food-dye>.

“Fizzy Candy (Isomalt, Lycasin, Carbon Dioxide)” LUSHopedia Ingredient Finder, Lush North

America, n.d. Web. 21 Oct. 2016. <http://www.lushusa.com/on/demandware.store/Sites-

Lush-Site/en_US/Lushopedia-Start?iid=10647>.

"Grey Water." Davis, California. City of Davis, n.d. Web. 30 Nov. 2016. <http://cityofdavis.org/

city-hall/public-works/water/water-conservation/saving-water-indoors/grey-water>.

"Greywater Reuse" Greywater Action For A Sustainable Water Culture. Greywater Action, n.d.

Web. 22 Nov. 2016. <http://greywateraction.org/contentabout-greywater-reuse/>.

"Handmade." Our Values. Lush North America, n.d. Web. 30 Nov. 2016. <http://

www.lushusa.com/on/demandware.store/Sites-Lush-Site/en_US/Page-View?cid=our-

values-handmade>.

"Intergalactic Bath Bomb." LUSH, Lush North America, n.d. Web. 21 Oct. 2016.

<http://www.lushusa.com/bath/bath-bombs/intergalactic/04031.html>.

"Limonene" Limonene. Cosmetics Info, n.d. Web. 30 Nov. 2016. <http://

www.cosmeticsinfo.org/ingredient/limonene>.

"Linalool" Linalool. Cosmetics Info, n.d. Web. 30 Nov. 2016. <http://www.cosmeticsinfo.org/

ingredient/linalool>.

Lush How It's Made: Intergalactic Bath Bomb. Youtube. Lush Cosmetics North America, 3 Oct.

2016. Web. 30 Nov. 2016. <https://www.youtube.com/watch?v=5m5LR-yzoNo>.

"Potassium Bitartrate" Potassium Bitartrate. Monash Scientific Glass Blowing Services, n.d.

Web. 30 Nov. 2016. <http://www.monashscientific.com.au/

PotassiumBitartrate.htm>.

"Naked" Our Values. Lush North America, n.d. Web. 30 Nov. 2016. <http://www.lushusa.com/

our-values-naked.html>.

“Snowflake; Lemon Ice and Gold Glimmer Lustre (Potassium Aluminium Silicate, Titanium

Dioxide, Yellow 10, Yellow 5, Synthetic Fluorphlogopite, Iron Oxides, Silica)”

LUSHopedia Ingredient Finder, Lush North America, n.d. Web. 21 Oct. 2016.

<http://www.lushusa.com/on/demandware.store/Sites-Lush-Site/en_US/Lushopedia-

Start?iid=11456>.

“We Believe” A Lush Life, Lush North America, n.d. Web 11. Nov. 2016.

< http://www.lushusa.com/about-us.html>.

Daniel Torrecampo

Professor Cogdell

Design 40A

30 November 2016

Lush Intergalactic Bath Bomb: Embodied Energy

Introduction

A bath bomb is an item designed to enhance one’s bathing experience. When placed in the tub full of water, a bath bomb will effervesce, spreading essential oils, fragrance, and color. Bath bombs were invented in 1989 by the cosmetics retailer LUSH. The company prides themselves in producing beauty products that have a positive impact on the planet by reducing waste, energy use, and conserving water with their Green Policy. (“Green Policy”). LUSH produces many variations of its bath bombs by adding various colors and scents. The Intergalactic bath bomb will be the topic of this research paper. The Intergalactic Bath Bomb features peppermint oil and three layers of coloring being blue, red and yellow. This research paper addresses the embodied energy required to produce LUSH’s Intergalactic Bath bomb through its entire lifecycle. From raw material acquisition to waste management, this lifecycle assessment will ultimately determine whether company is consistent with its values in terms of reducing energy use for their processes.

Before analyzing the embodied energy for the Intergalactic bath bomb, it is critical to review the definition of a life cycle and concepts pertaining to energy. A life cycle consists of stages that a product undergoes in its lifetime. These stages include raw materials acquisition, manufacturing, distribution, use, recycle, and waste management. Energy is an integral component at almost each of these stages and analysis will be conducted for these sections. Energy can be categorized as either renewable or non-renewable. Renewable means that the resource is not depleted when used and can be replaced on a relatively short timescale (GCSE Chemistry). Wind power for example is a renewable source of energy because there will always be wind. Fossil fuels on the other hand take more than 300 million years to replenish and are thus non-renewable. Employing energy for useful work requires a prime mover. Prime movers can be classified as animate or inanimate. An animate prime mover is one that is living such as a horse pulling a plow or a donkey moving cargo. An inanimate prime mover is one that is not living such as internal combustion engine. With these concepts in mind, one can fully analyze the embodied energy in a lifecycle.

Processing of Raw Materials

LUSH’s Intergalactic bath bomb is composed of three main ingredients – peppermint oil, sodium bicarbonate, and citric acid. Acquiring these raw materials involves many different processes each demanding its own type of energy source. As a side note, the suppliers that provide the raw materials to LUSH could not be identified. Consequently, the research in for this stage in the lifecycle was limited to analyzing the generic processes required for raw material acquisition.

Peppermint oil is made from peppermint leaves. Under the right conditions, a typical acre of can yield 22,258 – 27,362 peppermint plants ( Republic of South Africa Agriculture, Forestry, and Fisheries Dept.). The leaves are then cut with conventional hay mowers and sent to a distillation facility. Peppermint oil is extracted from peppermint leaves through a process called steam distillation. The energy embodied in converting water to steam requires energy in the form of heat. The steam distillation process is dependent on inanimate prime mover in this case a heater which can be powered by either electricity or gas (The Essential Oil Company).

The peppermint leaves are then subjected to the steam under pressure (Mulvaney, Jill). As the steam passes through the peppermint material, it captures the essential oils from the plant. It then passes through a condenser where the gas turns back to a liquid. The liquid that results from this phase change is called a hydrosol. Hydrosol is the resulting water mixed with extracted essential oils from the peppermint leaves (Mountain Rose Herbs). The distillation process varies between the companies processing these materials. Steaming the peppermint leaves at higher temperatures yields higher levels of menthol in the oil at the expense of prolonged energy use (Isensee, Robert). From Robert’s experiment, peppermint leaves treated between 210-214 degrees Celsius yielded a final menthol content of 69 percent (“The Extraction of Menthol From Peppermint Oil”). However at temperatures ranging below 190 degrees Celsius, the final menthol content was 15.6 percent by weight. The quality of peppermint oil is predicated on several factors. The most immediate factors are odor and taste followed by a correct balance of chemical components. In general, higher levels of menthol is often regarded as higher quality material (Souza and Lemos). The main chemical components that determine these characteristics is the concentration of menthol in the oil. Typical menthol concentration in peppermint oil range from 50-70 percent. Japanese oil is known to have up to 85 percent concentration in their peppermint oil.

To summarize, the embodied energy required to extract peppermint oil is the following sequence. Solar energy provides the energy to the peppermint plants facilitating their growth. Chemical energy in the form of fossil fuel powers the tractors that converts the chemical energy of the fuel into mechanical energy to cut and collect the plant matter. Heat energy is then used to extract the oils from the peppermint leaves. The primary form of energy involved in this entire process are fossil fuels because they provide the energy necessary to extract the peppermint matter and provide the heat energy for the steam distillation procedure. Although the peppermint is a renewable resource, the processes required to convert it to peppermint oil is dependent on non-renewable energy sources.

The most prominent feature of LUSH’s bath bomb is its bubbling and fizzing reactions when placed in the tub. LUSH’s bath bombs bubble and fizz because its contents chemically react with the water. The two main ingredients responsible for this action are sodium bicarbonate and citric acid. Extracting these raw materials requires chemical and heat energy.

Sodium bicarbonate is a chemical compound that is commonly referred to as baking soda. It is used for cooking, pest control, and medical applications such as antacid for heartburn. Sodium carbonate is created by utilizing the Solvay process. The the most crucial source of energy used in the Solvay process is the heat energy because it forces a reaction and decomposes the reactants to the products. For example, sodium bicarbonate is heated to 300 degrees Celsius to produce sodium carbonate. Sodium bicarbonate and sodium carbonate are often produced together in the Solvay process for economical reasons. Additionally, mechanical energy is embodied in this process because centrifuges are required for separating the sodium bicarbonate from the remaining byproducts.

Citric acid is the last raw material that will be analyzed in terms of energy. Citric acid has a number of applications. It is commonly used in the food industry because it is highly soluble in water and acidic in taste. Citric acid is used in the Lush’s Intergalactic bath bomb because it reacts with the sodium bicarbonate when exposed to water. The citric acid chemically reacts with sodium bicarbonate and produces carbon dioxide gas and sodium citrate which is another form of salt. This helps disperse the bath bomb’s ingredients throughout the tub.

Citric acid is produced through a process called submerged fermentation. The energy driving this process is chemical energy. Fermentation occurs when microorganisms chemically breakdown a substance. With submerged fermentation, the microorganisms are submerged in a nutrient rich liquid where they breakdown the nutrient substance (Ravichandran and Vimala). The process is contained in large cylindrical containers that mechanically stir the microorganisms and nutrients. The fungus A. niger is a common microorganism used in commercial production (“Microbial Production of Citric Acid”). A. niger is often submerged in a starch or sucrose based media. These materials are relatively inexpensive compared to other nutrients such as molasses and heavy starches which require additional sterilization and thus more energy (“Microbial Production of Citric Acid. The submerged fermentation process takes approximately 5 – 10 days to complete.

Citric acid is extracted from the resulting mixture in three steps – precipitation, extraction, and adsorption. Precipitation is performed by adding calcium oxide hydrate to the fermented product. The resultant material is then filtered and treated with sulphuric acid. Further treatment with cation and anion exchangers yields a substance which is then concentrated in vacuum crystallizers at 20-25 degrees Celsius (“Microbial Production of Citric Acid). The vacuum crystallizers require electrical energy to power the compressor motor that creates the vacuum environment. This forms the final product which is citric acid monohydrate. The A. niger fungus uses chemical energy to break down the nutrient mixture which results in a material that can be further processed to produce citric acid. The prime mover in this case would be animate since the fungus is a living organism providing the work. This process can be identified as renewable because the resource is not depleted when used. To reiterate, renewable simply means that the resource can be replaced in a relatively short time scale. For example, the A. niger fungus can be readily grown and cultivated in a matter of weeks rather than millions of years for fossil fuels (GCSE Chemistry). The process of extracting citric acid from the fermented product also requires electrical and mechanical energy. The A. niger and nutrient mixture must be mechanically mixed and aerated to insure proper fermentation. Electrical energy is consequently required to power the motors that stir and aerate the fermentation mixture. Electrical energy is often provided through means of fossil fuels which makes the fermentation process dependent on a non-renewable process.

Manufacturing, processing, and formation of the Intergalactic Bath Bomb

Lush’s Intergalactic bath bombs are formed through a series of processes. The ingredients are mechanically mixed and three layers are formed. Each layer contains the same ingredients but their colors vary. The Intergalactic bath bomb is composed of a yellow layer, red layer and blue layer. When these three layers are formed, they are hand-compressed into a mold.

The energy embodied in this process is primarily mechanical and electrical. From LUSH’s YouTube video, they produce their Intergalactic bath bombs with planetary mixers which blend all the ingredients together. With this knowledge, we can calculate the amount of energy that the mixing process requires. The planetary mixer that was selected for analysis is the Hobart Legacy HL400-1 40 Quart Commercial Planetary Mixer (Webstaurant Store). This machine is rated at 1344 Watts meaning it uses 1344 Joules of per second. Various sources online note that a typical bath bomb requires approximately 11 tbsp material consisting of baking soda, citric acid, oils, and other miscellaneous ingredients (Science Buddies). Assuming that the planetary mixer mixes the material for 20 minutes, the energy required would be the following.

20min * (60sec/1min) = 1200 seconds

1200 seconds * (1344 Joules/ second) = 1.6128E6 Joules of energy required to make 40 quarts of bath bomb material

11 tbsp = 0.171875 qt

0.171875 qt * (1.6128E6 Joules/ 40 quarts) = 277,200 Joules of energy/ Bath bomb

In this case, electrical energy is used to power the inanimate planetary mixing machines which converts the electrical energy to mechanical energy. The animate workers then assemble the bath bomb by mechanically compressing the material into plastic molds by hand.

Distribution and Transportation

Because Lush sells their products internationally, the energy required to transport the products will vary depending on location. The company notes that they have over 210 retail shops in North America (Lush, “Our Fresh Handmade Story”). All these shops are supplied by two factories in Canada. For this report, we will assume that the products will be sent from the Lush factory in Toronto, Canada to the Lush retail shop in San Francisco, a total distance of 2,634 miles. Fossil fuels are the dominate form of energy in this part of the lifecycle because they are required to power both modes of transportation. The energy embodied in the transportation process can be placed into two categories – air and ground travel.

Lush ships their products through UPS. In the case of air travel, one must consider the vehicle in and its efficiency in question. UPS uses a variety of aircraft to transport their cargo. Their current fleet of aircraft include: the 747, 757, 767, A300-600, and MD-11 (UPS Air Cargo Aircraft). To simplify matters, we will consider the case of the Boeing 747 aircraft.

Determining the fuel efficiency of the Boeing 747 for a specific flight is inherently complicated. It is said that “over 150 assumptions and parameter definitions required to fully define a mission for a simulation tool” (Yutko and Hansman). For example, one must account for temperature, pressure, viscosity, and density because these variables are constantly changing and directly affect the performance of an aircraft in flight. The standard for measuring efficiency for US automobiles is the Corporate Average Fuel Efficiency (CAFE). It measures the fuel burned over the course of a mission which is usually represented as a distance. Unlike automobiles, commercial airlines utilize a different process to measure efficiency. One way the aerospace industry measures efficiency is through measuring Specific Air Range or SAR. The mathematical relationship is represented as the following:

SAR = distance / unit fuel of mass.

This metric is similar to the CAFÉ standard (“miles per gallon”) however the SAR is taken at a single instant in time with constant parameters. An example of a SAR value is the following:

“The nautical miles per pound of fuel at an A320 Aircraft gross weight of 145,000 lb at pressure altitude of 37,000 ft in ISA+ 10 (degree) C conditions at a true Mach number of 0.78 will be not less than a guaranteed value of 0.0839 nm/lb.”

SAR values are often regarded as over-simplifications of an aircrafts fuel economy and thus software is almost always utilized to perform simulations to determine the amount of fuel required per flight. As listed in Boeings spec sheet, the 747-400 series can carry 878,000 lbs of payload with a range of approximately 4,455 nautical miles (5,126 miles) when configured with General Electric’s turbofan engines (Boeing). With this information we can approximate the expended energy in terms of cost. The distance between the Lush facility in Toronto Canada to San Francisco is 2634 miles, approximately half the maximum range of the Boeing 747. From Boeing’s spec sheet, the maximum fuel capacity for the 747-400 is 53,765 gal. Using the average cost of Jet A fuel from August 2015 ($5.00/gal), the total cost of fuel for shipping 878,000 lbs of bath bombs from Toronto Canada to San Francisco would be $ 134,412 (Aviation Week)! LUSH would be smart to not ship all their bath bombs via air.

Considering the case of ground travel, a typical freightliner or Class 8 Truck has a fuel efficiency is 7.4 mpg (“Actual MPG from 50 Freighter Cascandia Owners”). As listed in the spec sheet, freighter carrying 80,000 lbs of payload can travel 1,363 miles at an average speed of 65 mi/hr mpg. Again, the distance between the Lush facility in Toronto Canada to San Francisco is 2634 miles. If the truck traveled from Toronto to San Francisco, it would have to refuel at least one time, meaning it would consume a total of 344.6 gal of fuel (172.3 gal *2). The average price of diesel fuel in the United States is $2.15/ gal meaning the total cost for fuel would be $689.20!

Shipping a plane full of bath bombs seems significantly more expensive than shipping a truck full of bath bombs. Such is the case only because the mass proportions are not the same. A typical freightliner can carry 80,000lbs while the Boeing 747-400 can carry 878,000lbs of payload, an order of magnitude larger. Based on previous calculations, shipping via ground costs $0.0086 per lb while shipping via air cost $0.15 per lb.

Use/Re-use/Maintenance/ Recycle and Waste Management

Bath bombs are used by placing them in a tub full of water. When placed in the water, it effervesces and mixes with the tub water. There is no reuse unless a second person wants to use the tub after the first. Additionally, there is no maintenance involved since the water goes down the drain and into the sewage system. One could add that the there is energy embodied in the sewage system. While this is true, the sewage system is beyond the scope of this research paper and therefore only the energy required for heating the bathtub water will be considered.

Water is heated with a water-heater. Conventional storage water heaters warm water with a gas burner fueled by natural gas. A typical residential water heater stores around 20-80 gallons of water (US Department of Energy). For natural gas water heaters, the energy factor is approximately 0.67 (Consumer Energy Center). The energy factor is the standard for measuring the efficiency of water heaters. The higher the number, the more efficient the machine. In comparison, electrical resistance water heaters have an energy factor of 0.97. Oil-fired storage have an efficiency factor of 0.59 and gas-fired instantaneous has an efficiency factor of 0.62 (Consumer Energy Center). To determine the annual cost of using a gas water heater, utilize the following equation:

365 X 41045 ÷ EF X Fuel Cost (Btu) = estimated annual cost of operation

Since the average cost of natural gas per BTU is $0.00000619, the following applies (Energy Saver).

365 X 41045/.67 X $0.00000619 = $138 /year

One day of using the water will cost approximately 38 cents assuming the water heater tank is depleted only once a day. A typical tub of water can hold from 60-80 gallons of water. Filling a bathtub full of hot water will deplete a typical water heater tank. Therefore, at most, the cost of heating a tub of water will cost at most 38 cents assuming the water heater has an efficiency of 0.67 and the price per BTU of natural gas fuel is $0.00000619.

Conclusion

The embodied energy for the Intergalactic bath bomb is much greater than expected. In the raw materials acquisition stage of the lifecycle, the most notable energy processes were steam distillation, the Solvay process, and submerged fermentation. On the surface, the energy embodied in these processes seemed obvious. Steam distillation and the Solvay process requires heat energy and submerged fermentation uses chemical energy. However, all these processes require a secondary form of energy such as electricity and natural gas to run the machines that make these processes possible. The manufacturing and processing stage of the Intergalactic bath bomb showed that only mechanical mixing and compression was needed to make the product. The calculations made in the transportation and distribution section showed that energy is expended at the highest rates in this part of the lifecycle. Furthermore, using the Intergalactic bath bomb was found to cost 38 cents.

Analysis of the Intergalactic bath bomb lifecycle shows preliminary evidence that Lush is environmentally friendly by reducing its energy use. Manufacturing the Intergalactic bath bomb only requires mixing its ingredients and hand compressing them into molds. By employing animate prime movers in the processing stage, Lush uses less machines thus reducing electricity use. From an industrial standpoint, adding human labor to the production phase is a frivolous move because human labor cannot nearly match the output of automated machines. With the currently technology available, Lush could have easily automated their entire bath bomb making process at little cost, but they don’t. While Lush’s manufacturing process is environmentally friendly, the embodied energy is highly dependent on non-renewable sources. These sources are the fossil fuels necessary to power the tractors, mowers, gas burners, and engines for transportation.

Bibliography

Admin, Scienceopen. "SciELO Brazil." Microbial Production of Citric Acid (1999): 1-14. SciELO. Web. 10 Nov. 2016.

Antigerminative Activity." American Journal of Plant Sciences (2014): 1-9. Scientific Research. Web. 10 Nov. 2016.

"Bath Bomb Science." Science Buddies. N.p., n.d. Web. 14 Nov. 2016.

"Energy Basics." Department of Energy. N.p., n.d. Web. 11 Nov. 2016.

"Estimating Costs and Efficiency." Energy Saver. N.p., n.d. Web. 17 Nov. 2016.

"GCSE CHEMISTRY - What Is Fermentation? - How Is Ethanol Made on a Large Scale? - GCSE SCIENCE." GCSE CHEMISTRY - What Is Fermentation? - How Is Ethanol Made on a Large Scale? - GCSE SCIENCE. N.p., n.d. Web. 29 Nov. 2016.

"Hobart Legacy HL400-1 40 Qt. Commercial Planetary Floor Mixer with Standard Accessories - 240V/3 Phase, 1 1/2 Hp." WebstaurantStore. N.p., n.d. Web. 15 Nov. 2016.

"Hydrosols?" What Is A Hydrosol? – Mountain Rose Herbs. N.p., n.d. Web. 20 Nov. 2016.

"Home." Actual MPG from 50 Freightliner Cascadia Owners. N.p., n.d. Web. 29 Nov. 2016.

Isensee, Robert WIlliam, Dr. The Extraction of Menthol From Peppermint Oil. Diss. Oregon State College, 1943. N.p.: n.p., n.d. Print.

"Inventing the Bath Bomb." Lush Fresh Handmade Cosmetics. Lush, 17 Feb. 2015. Web. 28 Nov. 2016.

"Jet-A and Avgas Fuel Prices: August 2015." Aviation Week. N.p., n.d. Web. 22 Nov. 2016.

Mulvaney, Jill. Essential Oils and Steam Distillation (n.d.): n. pag. Natural Ingredient Resource Center. Web. 11 Nov. 2016.

"Our Fresh Handmade Story." LUSH. N.p., n.d. Web. 10 Nov. 2016.

"Our Green Policy." Our Green Policy. N.p., n.d. Web. 28 Nov. 2016.

Ravichandran, Subramaniyam Ravichandran, and Vimala R. "Solid State and Submerged Fermentation for the Production of Bioactive Substances: A Comparative Study." Research Gate. N.p., Mar. 2012. Web. 10 Nov. 2016.

Republic of South Africa. Agriculture, Forestry, and Fisheries. Directorate Plant Production. Peppermint Production. Agriculture, Forestry, and Fisheries Department, n.d. Web. 8 Nov. 2016.

Souza, Marco A., Marcel J. Lemos, Diego Brito, Manlio Fernandz, Rosane Castro, and Sonia Souza. "Production and Quality of Menthol Mint Essential Oil and Antifungal and

"Shipping Info." Lush. N.p., n.d. Web. 10 Nov. 2016.

Shakhashiri. "Sodium Bicarbonate and Sodium Carbonate." Sodium Bicarbonate and Sodium Carbonate. N.p., n.d. Web. 20 Nov. 2016.

"UPS Air Cargo Aircraft." UPS Air Cargo Aircraft. UPS, n.d. Web. 19 Nov. 2016.

"Water Heaters." Consumer Energy Center - Water Heaters. N.p., n.d. Web. 29 Nov. 2016.

Yutko, Brian, and John Hansman. APPROACHES TO REPRESENTING AIRCRAFT FUEL EFFICIENCY PERFORMANCE FOR THE PURPOSE OF A COMMERCIAL AIRCRAFT CERTIFICATION STANDARD (n.d.): n. pag. DSpace@MIT. May 2011. Web. 13 Nov. 2016.

"15 Gallon Copper Distiller With Glass Essencier." The Essential Oil Company. N.p., n.d. Web. 15 Nov. 2016.

"747-400 Freighter." Aircraft Engineering and Aerospace Technology 72.1 (2000): n.pag. Boeing. Web. 11 Nov. 2016.

Dee Yang

Christina Cogdell

Des 40A

1 December 2016

LUSH: Intergalactic Bath Bomb

LUSH Fresh Handmade Cosmetics is a business started by Mark Constantine and Liz Weir in 1996 in Poole, UK. It began as a small store with the support of the community and then turned into global enterprise well known for their beautiful bath bombs (“Our History”). Lush takes great pride in their green policy. They spend as little energy as they can and use ingredients that biodegrade and do not harm the environment. Their raw materials are sustainable ingredients and bought and transported to factories with minimal energy. All their bath bombs are made of natural ingredients and safe synthetics. They are also 100% biodegradable so they should not leave behind any waste at all. (“Green Policy”) Lush products claim to be environmentally friendly and so we challenge this proclamation by examining the life cycle of the intergalactic bath bomb to determine if all aspects of the bath bomb, from the material gathering to when it enters the ocean, generates any harmful waste that pollutes our environment.

The beginning of the bath bomb’s life cycle begins at the raw materials acquisition. Lush is confident about their ethical buying policy. They send their teams around the world to buy raw materials from farmers, growers, and processors. They only use organic and sustainable ingredients that will not threaten the environment or animals. Palm oil is commonly used in cosmetics but Lush stopped acquiring Palm oil in an effort to discontinue the deforestation of Indonesia’s rainforests. Deforestation has caused orangutans to lose their homes. On another note, Lush prefers to use almond oil and olive oil in their products instead of mineral oil because it is more environmentally friendly to have a field of trees instead of a field of oil (“Environmental policy”). As for how much of the raw materials that Lush uses, we are not sure. Lush has factory tours but they do not reveal where their ingredients are stored or if there is any wasted product in the acquisition of any materials.

Once the materials have been gathered, they must be processed and manufactured. All Lush products are handmade in factories. The materials and ingredients are all fresh except for some synthetic materials. Most of the bath bombs are composed of a basic mix of sodium bicarbonate, citric, acid, and fragrance. The intergalactic bath bomb is made of oils and different lusters. Lush uses luster instead of glitter in their products because glitter is plastic based and does not biodegrade in the ocean. Instead, lusters provide the same shine and glitter looks while being vegetable based. Since all the products are handmade, there is a minimal waste emission from the use of machines (“How it’s Made”).

Now, the product is made. How does Lush distribute their products? Lush uses as little packaging as they can, both for transportation and for retail. They usually sell their products without packaging. When it is unavoidable they use recycled materials that are compostable and recyclable. Lush sells their shampoo products in the form of shampoo bars to avoid plastic bottle packaging. Their facial cleansers that need a packaging, comes in black pots that have their own way to be recycled. Most of the packaging products used are 90% made from recycled products while the remaining 10% is not. The intergalactic bath bomb, like the other bath bombs, are displayed in the stores with no package and the customers buy them as is. However, the shops do offer gift wrapping and carrier bags in which to wrap the bath bomb and/or carry it. The bags are 100% recycled paper while the wrapping paper is made from potato starch which is 100% biodegradable (“Green Policy”). So, meanwhile they can’t eliminate waste that comes from packaging, they make it so it is easily recyclable.

As for the recycling process, Lush does have a recycling process for the black pots that they sell. Consumers are encouraged to bring them back to the shop with their five pot program where if a consumer brings back five empty Lush pots, they get a free face mask. This saves about 65 tons of Carbon Dioxide and 800 barrels of oil each year (“Green Policy”). However, we are focusing on the intergalactic bath bomb and since it dissolves into the consumer’s bath water and the packaging is thrown away or recycled, there is nothing that can be brought back to the shop to be recycled.

Say, you’ve bought an intergalactic bath bomb and you take it home to use it. The bath bomb will react with your bath water and fizzy up and leaves beautiful blue and pink hues in your bath water. When you let the water drain, the water disappears and will probably end up in the ocean. You as a consumer have nothing of the product left. However, what happens to all the ingredients in the bath bomb? Physically, there is no waste left behind as seen from the consumer, but on a deeper level we can analyze the contents of the bath bomb to see if any stick around in the ecosystem or are harmful to the environment.

The intergalactic bath bomb is made up of both natural ingredients and synthetics. The main natural ingredients are sodium bicarbonate, potassium bitartrate, and peppermint oil. The synthetics will be evaluated as a whole because there are very many of them. One thing that comes across as unusual is that not all the ingredients have a proper name to them so you can’t find what they are. For example, one of the ingredients in the bath bomb is Fragrance. We have no idea what that ingredient is made up of and therefore no way to find out how it affects the environment. Despite Lush’s prideful behavior of creating animal friendly and environmental friendly products, it is suspicious that they hide some of the ingredients. On the Lush website you can look at the ingredient list and each ingredient will have a link that takes you to the Lushopedia and gives a short explanation of what the ingredient is. However, they cleverly hide any information that might hint that the ingredient they are using is not fresh or good for you. Meanwhile some ingredients in the list do not even have an explanation, but a picture of a fresh fruit or vegetable that probably does not have anything to do with the ingredient. The takeaway note here is: Lush, like every company, is withholding information on their products.

Sodium Carbonate is usually used in products like soap or cleaners. It is generally safe. It may cause skin and eye irritation. However, at the same time it can be soothing and used for eczema, sunburn, or bug bites. At very high doses or constant exposure, sodium carbonate can be toxic. However, the normal public will not get so much exposure as to feel its toxic effects. Sodium Bicarbonate is a natural mineral. Studies conducted on its toxicity suggest that there is no harmful effect to both plant life and aquatic life under normal exposure levels (“Product Safety”).

Potassium Bitrate, also a main ingredient of the bath bomb, is used in the bath bomb to form a paste in which the bath bomb’s shape can be formed. It is also soluble in water and will degrade in water. It may be toxic to humans or an irritant but the product itself is not hazardous (“Material Safety”).

Citric acid naturally occurs in lemons and limes and is responsible for what causes the bath bomb to fizzle when it encounters water. It is a natural fruit acid. However, studies say that citric acid production actually contains hazardous chemicals such as sodium hydroxide, ammonium nitrate, and hydrogen chloride. But then, when introduced to water and turned into wastewater, there are no wastes produced because the water dominates (NICA, Anca, and Woinarschy).

As for the grapefruit, peppermint, and cedarwood oils, the environmental impact they have in not clear. However, essential oils in general, have received many warnings for being dangerous to consume and hazardous if spilled into a waterway. Depending on the oil, many oils have to potential to be toxic to aquatic organisms, flora, and fauna. Mountain Rose Herbs says to not toss oils into any waterway because they have proven to be dangerous and can cause long term problems to environments.

The Lush bath bomb contains many synthetic ingredients such as sodium sulfate and color additives. The color additives are FDA approved for use in food, drugs, and cosmetics (“Yellow No. 10”). The sodium sulfate is also proven to have low toxicity to fish and algae. Even microorganisms face a similar level of toxicity. It is generally safe enough that it does not raise any safety concerns for the environment (Hera, 6-8).

After analyzing the life cycle of the Intergalactic bath bomb, all the ingredients I was able to find information on were biodegradable and showed no harm to the environment. The only thing that worries me is the lack of information on the ingredients and how there are some omitted, like the “fragrance” ingredient. There’s no telling what the fragrance is made from. Other than that, Lush really lives up to their green policy. They have a mind mindset and motivation to be kind to the environment and it shows in their products.

Work Cited

"D&C Yellow No. 10 (Inactive Ingredient) - Drugs.com." (Inactive Ingredient). Drugs, n.d. Web.

20 Nov. 2016.

Hera – Cover Note Of Sodium Sulfate 7757-82-6. Page 1 Of. "Human and Environmental Risk

Assessment on Ingredients of Household Cleaning Products." HERA – Cover Note of Sodium Sulfate 7757-82-6. Page 1 of 50 Human and Environmental Risk Assessment on Ingredients of Household Cleaning Products Substance: Sodium Sulfate (CAS# 7757-82-6) (n.d.): 6-8. Heraproject. Jan. 2006. Web. 23 Nov. 2016.

Lush How It's Made: Intergalactic Bath Bomb. Perf. Dan and Gladice. Youtube. Lush Cosmetics

North America, 3 Oct. 2016. Web. 30 Nov. 2016.

"Material Safety Data Sheet Potassium Bitrate MSDS." Sciencelab. N.p., 11 Oct. 2005. Web. 18

Nov. 2016.

NICA, Anca, and Alexandru WOINAROSCHY. "ENVIRONMENTAL ASSESSMENT OF CITRIC ACID

PRODUCTION."

"Our Environmental Policy." Lush Fresh Handmade Cosmetics. Lush, 18 Aug. 2016. Web. 30

Nov. 2016.

"Our Green Policy." Our Green Policy. Lush, n.d. Web. 30 Nov. 2016.

"Our History." Our History. Lush, n.d. Web. 30 Nov. 2016.