Design Life-Cycle

assess.design.(don't)consume

William Chen

Brandy Fabian & Kristen Shih

DES 40A

Professor Cogdell

4 December 2019

Acrylic Keychains and The Materials to Make Them

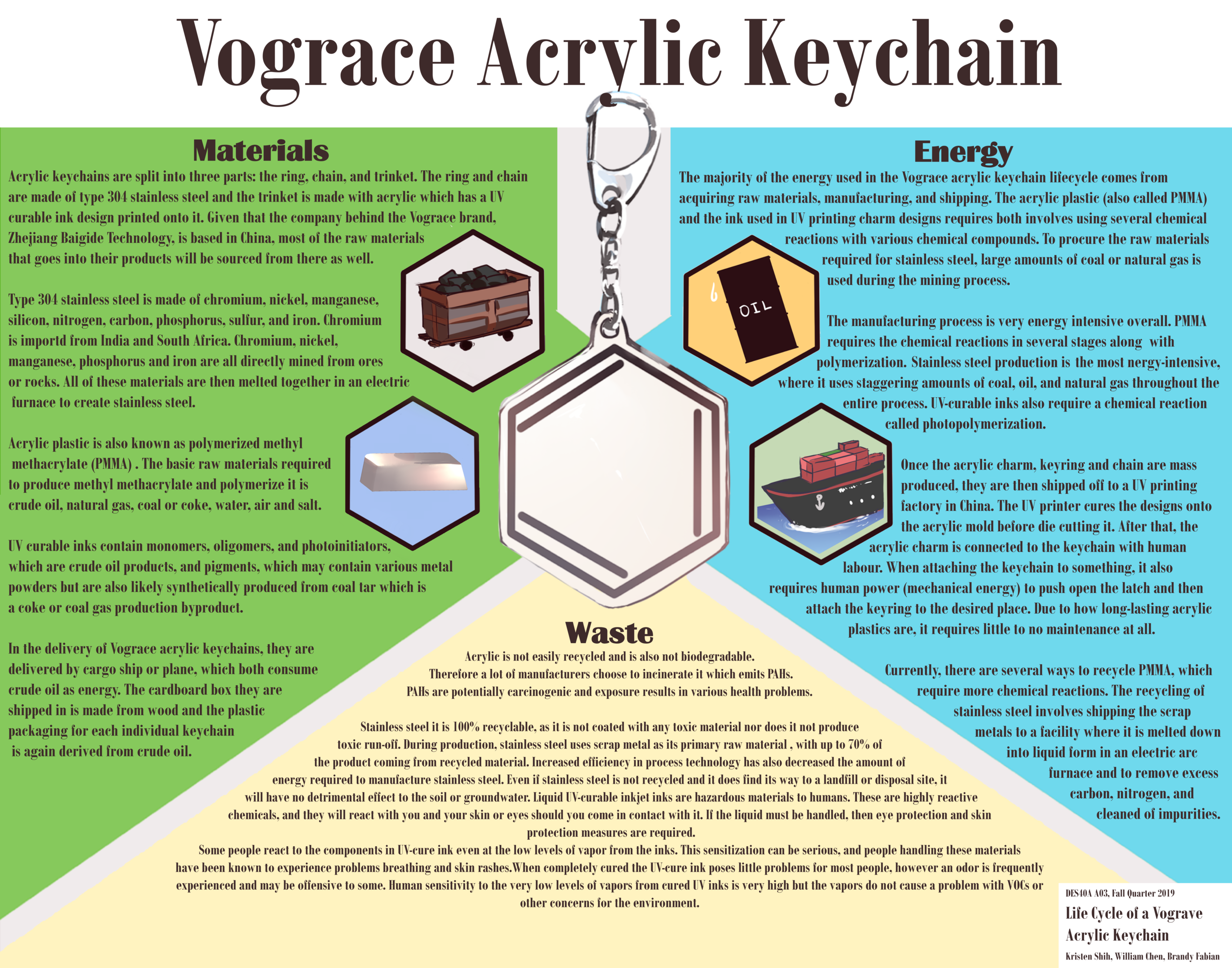

Acrylic keychains are a popular type of accessory used by many to display various graphics. Due to its light and durable nature, acrylic plastic makes for a good material to print images on. And since its main components stainless steel and acrylic plastic are both cheap, they make the keychains very easy to mass produce. However, many various forms of secondary raw materials go into the creation of acrylic keychains and unfortunately many of them originate from crude oil or coal.

Acrylic keychains are generally made of three different parts: the loop, chain, and trinket. For the purposes of research, the components of the acrylic keychain and its manufacturing processes are based up on Vograce brand acrylic keychains. The company behind the Vograce brand, Zhejiang Baigedi Technology, is a based in China and mass produces these keychains having sold 20 million keychains in just 2018 (Zhejiang Baigedi Technology). Vograce brand keychains are custom keychains in which the customer submits the design to be put onto the keychain and many of the examples the website has are of Japanese cartoon characters. While the company does not specify what specific materials and processes are involved in the process of producing their keychains, in the factory’s production equipment list includes a slotting machine and a UV printing machine (Zhejiang Baigedi Technology). This means that they only cut and print the designs and so the components should all be standard mass-produced industrial materials: cast acrylic plastic sheets, type 304 stainless steel chains and loops, and UV curable ink.

There are many intermediary steps in the processing and creation of acrylic plastic, but its raw materials come down to: crude oil, natural gas, coal/coke, salt, water and air. For stainless steel, specifically type 304, its raw materials are: crude oil, natural gas, coal/coke, quartzite, iron, chromium, nickel, manganese, and phosphorus. The specific ingredients for the coloration of UV curable inks may vary depending on brand and color, but its main raw materials are crude oil and coal tar. China produces nearly all the raw materials required, but it sometimes still needs to import more resources from other countries to meet its supply demands. For example, with crude oil and natural gas, China is the world’s fourth and sixth largest producer for the two raw materials respectively (Fontinelle and Natural Gas - Production). However, at the same time China is the worlds greatest oil importer and the second most for natural gas (China - Oil and Gas). Unless specified otherwise, China procures the raw materials and may import more from other countries. Crude oil and natural gas are both collected by drilling into the ground. Coal is mined from mines and coke is coal superheated without the presence of oxygen and coal tar is a byproduct of this. Salt is collected from sea water. Water is pumped from rivers. Air is collected from the air. Quartzite, iron, chromium, nickel, manganese and phosphorus are all mined from the ground. China does not produce a significant amount of chromium and most of the world’s supply comes from South Africa (Schulte). At the same time, China was the world’s greatest chromium importer for the purposes of producing stainless steel and other chromium metals. Due to the wide variety of raw materials that are needed to be collected, it can be expected that even more oil and natural gas is used as fuel for harvesting and transporting the materials for processing.

Before all the components can be brought together to create an acrylic keychain, the raw materials need to be processed into their respective parts. For the loop and chain, they are made from type 304 stainless steel. This grade of stainless steel is used in a lot of products due to its corrosion resistance, heat resistance, and clean appearance. Type 304 stainless steel’s element composition is made of 18-20% chromium, 8-10.5% nickel, 2% manganese, 0.75% silicon, 0.10% nitrogen, 0.08% carbon, 0.045% phosphorus, 0.030% sulfur, and the remaining composition with iron (Stainless Steel Alloy 304, A2). Chromium, nickel, manganese, phosphorus, and iron are all either ores or rocks that just need to be melted or broken down to gather the element need. Coal or coke is used as the source for carbon. While sulfur ores exist, most industrial sulfur is processed from crude oil or natural gas (Apodaca). Nitrogen is gathered from ammonia which is processed from air. And silicon is processed from quartzite. All these materials are then put into an electric furnace for around 8 to 12 hours at high heats to melt them together into stainless steel (Stainless Steel). When the stainless steel comes out of the furnace, it is first formed into large blocks called blooms or smaller ones called billets before being formed into a wire thickness. Usually after this, most stainless steels would need to be heat treated again, type 304 steel does not need to (Bell). The wire is then polished before being shipped to another factory that will cut and shape the stainless-steel wires into chains and loops before finally being delivered for keychain assembly.

Acrylic plastic requires a much more complicated process than stainless steel to be produced from its raw materials. While many plastics can be called acrylic plastic, the main form of acrylic plastic is usually known as PMMA or polymerized methyl methacrylate (Acrylic Plastic). In order to create PMMA, you need to polymerize MMA or methyl methacrylate, and this is done with the help of an organic peroxide catalyst. A common industrial organic peroxide that is usually used for this is BPO or benzoyl peroxide (GPS Safety Summary). For acrylic plastic sheets for keychains use an acrylic cast method in which MMA is put in a mold between two sheets of glass before being submerged in water and polymerized with the catalyst (Difference between CAST Acrylic & EXTRUDED). Cast acrylic plastics have cleaner edges when cut with something like the slotting machine our example acrylic keychain brand uses. MMA has the chemical composition C5H8O2 and BPO has a chemical composition of C14H10O4 and the classic carbon ring molecular structure which is naturally found in crude oil products. MMA is created from a reaction between acetone cyanohydrin and methyl alcohol. Methyl alcohol is currently industrially synthesized from the methane in natural gas (Methanol). Acetone cyanohydrin is industrially created by reacting acetone with hydrogen cyanide in an alkaline solution before being treated with sulfuric acid (Yamagishi). The alkaline solution in question is most likely sodium hydroxide due to how easy it is to produce with electrolysis of salt and water. Acetone is produced along with phenol in a reaction with propylene and benzene which are both crude oil products (Acetone). Hydrogen cyanide is produced combining methane, ammonia, and air at high temperatures and the gas is then washed with water to be collected in a liquid solution (Hydrogen Cyanide). Finally, sulfuric acid is produced by burning sulfur and producing sulfur dioxide gas before it is heated at high temperatures and mixed with water (Sulfuric Acid). BPO is created in a reaction between benzoyl chloride, sodium hydroxide, and hydrogen peroxide (El-Samragy). Benzoyl chloride is created in a reaction between chlorine and toluene (Seper). Chlorine is derived from the electrolysis of salt and water and toluene is a component of crude oil (Toluene). Hydrogen peroxide is produced through oxidation and reduction of anthraquinone with oxygen (Hydrogen Peroxide). Anthraquinone is created in the reaction between phthalic anhydride and benzene (ANTHRAQUINONE). Phthalic anhydride is then created from the oxidization of naphthalene which is in turn derived from coal tar (Naphthalene). All these various reactions and different processes to produce different chemical compounds are all then combine to finally create a sheet of PMMA. Many of the components can be traced back to either coal, natural gas or crude oil and even more is burned to power some of the high temperature reactions as well as electrolysis processes.

UV curable inks are composed of monomers, oligomers, photo initiators, and pigments (How UV-Curable Ink Works). However, the exact said chemicals and the processes undergone are not available as public knowledge nor are the pigments specifically used to make specific colors. The composition of the ink may also differ based up on the pigments used. The monomers and oligomers whatever they are by chemical composition going to be derived from crude oil and will likely undergo a few chemical reactions. Photo initiators are also produced from crude oils, but the chemical structure of the initiator used varies differently based upon the chosen pigment (Wei). And pigments themselves are generally synthesized from coal tar.

After the acrylic keychain is finally cut from the delivered acrylic plastic sheets, had the designated designs printed onto it with the UV printer, and the chain and loop attached to the trinket, it can finally be packaged and shipped to its destination. Vograce acrylic keychains uses a plastic packaging for its keychains and has its deliveries shipped in carboard boxes. The plastic again comes from crude oil and the cardboard is made from processed wood. 45% of Zhejiang Baigedi Technology’s products are sold in North America and 15% to Western Europe. It also uses FedEx as one of its main shipping sources. The product is either transported by freight ships or airplane both of which use fuels derived from crude oil, before it reaches a port near its destination in which it is delivered by truck which requires more fuel. While it takes a lot of crude oil and energy in the production of a single acrylic keychain, once it is delivered, the keychain will last until the chain breaks or the printed graphic is all scratched off. Due to how durable stainless steel is and the material of acrylic plastic, if the keychain is treated will it could easily outlive its owner.

Acrylic keychains are generally only disposed of when either lost, due to falling off where it was hung on or thrown away when no longer wanted. For this reason, most acrylic keychains will make their way to land fills in which the acrylic plastic will not break down for hundreds of years. However, even if the keychain is recycled, there will likely still be waste that needs to be thrown away. The stainless-steel loop and chain are completely recyclable. Stainless steel scrap metal can be melted down to be reused for other stainless-steel products, primarily for its chromium, nickel and iron content (Johnson). Acrylic plastic on the other hand is much harder to recycle. Because conventional burning or melting of acrylic plastic often releases toxic fumes, it is difficult to safely recycle it. It is possible to decompose of acrylic plastic by melting it at high temperatures without air to prevent toxic reactions, but very little facilities are designed to be able to do this (PMMA Recycling). With the addition of the UV curable ink graphic printed onto the acrylic plastic which may impact any recycling attempt, it is often much simpler to dump the keychain trinket into the landfill with all the other unrecyclable plastics.

Acrylic keychains are a simple, durable and cheap graphic display item that many people hang on their backpacks or on their keyrings, however the production of it is much more complicated. There are many different industrial producers to streamline the creation of acrylic plastic and stainless steel, but that requires all the more resources and energy. The amount of crude oil related chemical processes utilized to create such a small trinket should make you rethink really how much it cost to display a little graphic for a little fun.

Bibliography

Apodaca, Lori E. “Sulfur.” Mineral Commodity Summaries 2019, U.S. Geological Survey, 2019, pp. 160–161.

Wei, Jie, et al. Research on Photoinitiator for UV Curable Jet Ink . Research on Photoinitiator for UV Curable Jet Ink .

“Acetone.” The Chemical Company, The Chemical Company, https://thechemco.com/chemical/acetone/.

“Acrylic Plastic.” How Products Are Made, Advameg, Inc., http://www.madehow.com/Volume-2/Acrylic-Plastic.html.

“ANTHRAQUINONE.” Some Chemicals Present in Industrial and Consumer Products, Food and Drinking-Water., U.S. National Library of Medicine, 1 Jan. 1970, https://www.ncbi.nlm.nih.gov/books/NBK373184/.

Bell, Terence. “Learn About the Difference Between Types 304 and 304L Stainless Steel.” The Balance, The Balance, 25 Jan. 2019, https://www.thebalance.com/type-304-and-304l-stainless-steel-2340261.

“China - Oil and Gas.” China - Oil and Gas, International Trade Administration, https://www.export.gov/article?id=China-Oil-and-Gas.

“Company Overview - Zhejiang Baigedi Technology Co., Ltd.” Alibaba.com, https://bgd.en.alibaba.com/company_profile/trustpass_profile.html?spm=a2700.icbuShop.81.7.51e25f2fVHLW08&certification_type=intl_assessment.

“COUNTRY COMPARISON :: NATURAL GAS - PRODUCTION.” Central Intelligence Agency, Central Intelligence Agency, https://www.cia.gov/library/publications/the-world-factbook/rankorder/2249rank.html.

“Difference between CAST Acrylic & EXTRUDED Acrylic Sheets?” Access Plastics, Access Plastics Limited, https://www.accessplastics.com/cast-vsextruded-acrylic/.

El-Samragy , Yehia. Benzoyl Peroxide Chemical and Technical Assessment. Food & Agriculture Organization of United Nations, Benzoyl Peroxide Chemical and Technical Assessment, http://www.fao.org/fileadmin/templates/agns/pdf/jecfa/cta/63/Benzoylperoxide.pdf.

“FedEx Trade Networks.” FedEx Trade Networks - International Ocean Freight Forwarding, http://ftn.fedex.com/us/services/transportation/oceanfreightforwarding.shtml.

Fontinelle, Eric. “Top 5 Oil-Producing Countries In 2011.” Investopedia, Investopedia, 18 Nov. 2019, https://www.investopedia.com/financial-edge/0311/top-5-oil-producing-countries-in-2011.aspx.

GPS Safety Summary Substance Name: Dibenzoyl Peroxide. Arkema, GPS Safety Summary Substance Name: Dibenzoyl Peroxide, https://www.arkema.com/export/shared/.content/media/downloads/socialresponsability/safety-summuries/Functional-Additives-Luperox-A75-Dibenzoyl-peroxide-GPS-2013-03-11-V0.pdf.

“Hot Sale Vograce Cheap Customized Cartoon Anime Acrylic Keychain,Printed Plastic Clear Key Ring,Transparent Hologram Charms - Buy Acrylic Keychain,Custom Keychain,Hologram Charms Product on Alibaba.com.” Www.alibaba.com, https://www.alibaba.com/product-detail/Hot-sale-VOGRACE-cheap-customized-cartoon_62256874210.html?spm=a2700.icbuShop.41413.21.6bcc15c0ftF4D7.

“How UV-Curable Ink Works.” Printing Impressions, NAPCO Media, 11 Sept. 2017, https://www.piworld.com/article/uv-curable-ink-works/.

“Hydrogen Cyanide – HCN – Manufacturing Process for Hydrogen Cyanide.” Guichon Valves, Guichon Valves, https://guichon-valves.com/faqs/hydrogen-cyanide-hcn-manufacturing-process-for-hydrogen-cyanide/.

“Hydrogen Peroxide.” BASF Catalysts, BASF Catalysts, https://catalysts.basf.com/literature-library/adsorbents/adsorbents-for-peroxide.

Johnson, Jeremiah, et al. The Energy Benefit of Stainless Steel Recycling. 2007, The Energy Benefit of Stainless Steel Recycling.

Methanol. The Chemical Company, https://thechemco.com/chemical/methanol/.

“Naphthalene.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/Naphthalene.

“PMMA Recycling: Acrylic Recycling.” Plastic Expert, Plastic Expert, https://www.plasticexpert.co.uk/plastic-recycling/pmma-acrylic-recycling/.

Schulte, Ruth F. “CHROMIUM.” Mineral Commodity Summaries 2019, U.S. Geological Survey, 2019, pp. 46–47.

Seper, Karl W. “Benzyl Chloride, Benzal Chloride, and Benzotrichloride.” Wiley Online Library, American Cancer Society, 16 Apr. 2001, https://onlinelibrary.wiley.com/doi/10.1002/0471238961.02051426120914.a01.pub2.

“Stainless Steel.” How Products Are Made, Advameg, Inc., http://www.madehow.com/Volume-1/Stainless-Steel.html.

“Stainless Steel Alloy 304, A2.” Continental Steel & Tube Company, Continental Steel & Tube Company, https://continentalsteel.com/stainless-steel/grades/alloy-304-a2/.

“Sulfuric Acid – Manufacturing Process of Sulfuric Acid.” Guichon Valves, Guichon Valves, https://guichon-valves.com/faqs/sulfuric-acid-manufacturing-process-of-sulfuric-acid/.

“Toluene.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/Toluene.

Yamagishi, Akio, et al.

Kristen Shih

DES40A

Professor Cogdell

4 December 2019

Life Cycle of a Vograce Acrylic Key Chain: Energy

The Vograce acrylic key chain, a type of souvenir with a growing popularity, is often made with a personal design and used as decorations for everyday things such as bags. All it is is simply an acrylic charm with a colorful drawing printed onto it and is then attached to a metal chain and key ring. Yet, each part of the key chain requires various types of energy to produce, transport, and recycling of the product. By examining the energy required in the life cycle of an acrylic key chain, we see how something so small is more complicated than it may appear.

As stated earlier, the usual acrylic key chain is made up of three main materials: acrylic plastic, stainless steel key chain and key ring, and the ink printed onto the charm part. The most commonly used acrylic type is polymethyl methacrylate (PMMA), which begins with the use of a lot of chemical energy with various chemical compounds in several stages before ending with the final product. The ink used in UV printing charm designs requires esterification, a type of chemical reaction in order to obtain the monomers and oligomers needed to make the ink. The stainless steel first begins in the mines, where it requires a lot of physical force to be removed from the earth. Stainless steel is the combination of many various elements found under the Earth’s surface, including: iron ore, chromium, silicon, nickel, and manganese. In order to procure these raw materials, large amounts of coal is used during the mining process, which changes from chemical energy to thermal energy when burning in the presence of oxygen. This thermal energy is then used to power up a machine that uses mechanical energy in the form of kinetic energy to excavate and mine the ores.

PMMA, is a synthetic plastic made from a combination of various chemicals plus acrylic acid, a product of propene that undergoes oxidation. It begins with a basic monomer, methyl methacrylate. One of the ways to create this monomer is to chemically react acetone with sodium cyanide and produce acetone cyanhydrin. This then chemically reacts with methyl alcohol to create methyl methacrylate, which undergoes polymerization, the act of making monomers to again chemically react with each other and create a chain or extended 3D networks, to make PMMA (How Products are Made). The PMMA is then put into molds fitting the charm design and die-cut by machine.

The ink used in UV printing coloured designs onto the acrylic charms is cured rather than dried, which means that it requires chemical reactions. The molecules in the “ink” rely on photo initiators that produce free radicals when exposed to UV light energy. The major components of UV-curable inks are monomers (mostly acrylic monomers) and oligomers, which are forced to cross-link together in a process known as photopolymerization. (FESPA) Monomers are made when a polyol or alcohol chemically reacts with acid, creating ester and water. Oligomers are basically made out of a few units of the same monomers. When these two components are cured onto an acrylic piece, they become bonded to the surface.

Stainless steel production is very energy intensive despite the changes made to try and reduce the energy cost, as there are several stages to the process. The raw materials are first prepared, requiring coal in the blast furnace for thermal energy to smelt the ores into iron, also known as hot metal. The iron is then converted into steel in the basic oxygen furnace, which is powered by natural gas, oil, or more coal (Worldsteel Association). This molten steel is then cast into small rod shaped forms, which are the basis for the miniature chain and the key ring. Due to the small size of the key ring and chain part, the twisting of the rods steel is often done with the combination of thermal energy and human labour.

Once the acrylic charm, key ring and chain are mass produced, they are then shipped off to a UV printing factory in China, where the designs are printed onto the charm. However, due to the difficulty of obtaining information from China, it is hard to find any information regarding the specific machines used in the process besides the die-cutting machine and the UV printer. The UV printer takes the UV-curable ink and cures the designs onto the acrylic mold before die cutting it. After that, the acrylic charm is connected to the key chain with human labour.

Raw materials are shipped or sent to corresponding facilities for manufacturing. Once the acrylic key chains are assembled, they are shipped off to various locations via cargo ship or airplane, and then by automobile, specifically the FedEx delivery service. This uses a large amount of fossil fuel overall, which becomes chemical energy during the transportation process. Any time during the transportation process to the buyer, mechanical energy via machines or human labour may also be included when moving the key chains between two transportation vehicles.

Key chains are simply hung onto various things such as bags, car keys, or even on the wall by a push pin. Because these items are often gifts or hand-picked souvenirs, reusing these products are not applicable. When attaching the key chain to something, it requires human power (mechanical energy) to push open the latch and then attach the key ring to the desired place. As the key chain is hung on the bag, it exerts gravitational potential energy that turns into kinetic energy when swung around by the keyring. Due to how long-lasting acrylic plastics are, it requires little to no maintenance at all. The metal chain however could possibly break or come loose, allowing the acrylic charm to possibly fall off the key chain. If this happens, the owner could choose to either fix it by manual labour or throw it away. On top of that, key chains are easily replaceable with other key chains and can simply be removed and/or swapped out by using human force (mechanical energy) again to remove the key chain.

When thrown away, acrylic key chains are often sent into the trash instead of the recycling bin due to the fact that it is not easy to recycle it and is classified as a Group 7 plastic (AZO). The stainless steel key chain is also often thrown away with its acrylic part due to the difficulty in twisting the metal far enough to remove the acrylic charm, thus separating the two components and allowing the owner to recycle the metal.

Although the recycling of acrylic plastic is not very widely done, it is still possible. Currently, there are several ways to recycle PMMA. One way is to use pyrolysis, which involves chemically reacting the material with heat but without the presence of oxygen. Due to some acrylics being highly combustible, pyrolysis is used to prevent it from exploding during the recycling process. It is also possible to recover PMMA by making it come into contact with molten lead, depolymerizing it and turning it back into its monomer form, methyl methacrylate. However, from an environmental point of view, this is not a desirable use for lead since it becomes very difficult to remove and thus unusable (AZO). The recycling of stainless steel involves shipping the scrap metals to a facility where it is melted down into liquid form in an electric arc furnace and to remove excess carbon, nitrogen, and cleaned of impurities. After that, it is remodeled into whatever is needed. That said, people who buy these types of key chains often have a personal connection with the charm designs and would probably not be willing to throw it away, even if it was broken somehow.

Vograce acrylic key chains are made to be long-lasting, scratch resistant gifts with the goal of having no need for a replacement. However, once broken, they are un-reusable and biodegradable, and can only be thrown away or recycled. Through either process, more energy will be used, which will then cause further harm to the environment.

Through the analysis of the life cycle of every part of the acrylic key chain, we find that every step requires some sort of energy form. The majority of the energy involved happens during the manufacturing and processing and material acquisition, mainly because of how energy-intensive steel production is. It is also important to note how much fossil fuel is burned during transportation. Since key chains are so popular as small gifts, they are being shipped to places all around the world and in mass-produced quantities. In the end, even for something so small and resistant, the ratio comparing the size and the amount of energy it takes to create a Vograce acrylic key chain really is staggering.

Bibliography

(For reference of the item being researched). Alibaba website. Zhejiang Baigedi Technology Co. LTD, An Acrylic Keychain producer. October 24, 2019.https://bgd.en.alibaba.com/

Anonymous Blog Post. Quality Logo Products Blog. How Are Keychains Made?. Published April 19, 2019. October 20, 2019. https://www.qualitylogoproducts.com/blog/how-are-keychains-made/

Anonymous Post. How Products Are Made. Acrylic Plastic. No published date. October 20, 2019. http://www.madehow.com/Volume-2/Acrylic-Plastic.html

Anonymous Post. McMaster-Carr. Hairpin Clips. No Published date. October 19, 2019. https://www.mcmaster.com/hairpin-clips

AZoM. AZO Materials. How do you Recycle Acrylic Resin? Published Dec. 10, 2012. October 20, 2019. https://www.azom.com/article.aspx?ArticleID=7945

Anonymous Post. How Products Are Made. Stainless Steel. No published date. October 19, 2019. http://www.madehow.com/Volume-1/Stainless-Steel.html

Company website. RecPlas Limited. Acrylic / PMMA (Polymethyl Methacrylate). No published date. October 25, 2019. http://www.recplas.co.uk/acrylic-pmma-recycling.html

Company website. Outokumpu. Stainless Steel Life Cycle. Published April 02, 2019. October 25, 2019. https://www.outokumpu.com/en/sustainability/product-stewardship/stainless-steel-life-cycle

Glaban, Lauren. Prezi. Life Cycle of Acrylic Plastic. Published October 14, 2015. October 24, 2019. https://prezi.com/j0525_5cvrp2/life-cycle-of-acrylic-plastic/

Company website. Worldsteel association. Life Cycle Thinking. Copyright 2019. October 25, 2019. https://www.worldsteel.org/steel-by-topic/life-cycle-thinking.html

Company website. Worldsteel association. Energy Use in the Steel Industry. Updated April 2019. November 29, 2019. https://www.worldsteel.org/en/dam/jcr:f07b864c-908e-4229-9f92-669f1c3abf4c/fact_energy_2016.pdf

Company website. Montanstahl. Recycling of Steel and Stainless Steel. Updated November 7, 2017. November 29, 2019. https://www.montanstahl.com/blog/recycling-stainless-steel/

Waste and Pollution (to be added)

Brandy Fabian

William Chen, Kristen Shih

DES 40A

Professor Cogdell

11/13/2019

Acrylic Keychain: Material Emissions

When traveling around places, it is very common to visit a gift shop and find various items that one can purchase to giveaway as souvenirs. Common items that one can find are acrylic keychains which people make use of by attaching them to car keys, backpacks or purses. These items have become so popular amongst its users that now the amount of keychain material varies from different components like wood, rubber, fabric, acrylic, paper, and sheet metal. By analyzing acrylic keychains life-cycle through the use of: materials, energy and waste/emissions, we are able to understand how they are produced and how they impact our world in the long-run. Due to their minute and effortless making process, Acrylic keychains are seen as the world’s main item to purchase when traveling, but many do not realize how the manufacturing of materials affects our environment. The materials that are used in keychain production are not harmful to our environment until they reach the ending cycle in which improper disposal of substances like acrylic, and UV curable-ink can lead to serious environmental problems through emissions.

Keychain production involves different methods of manufacturing. There are various ways of making keychains such as: die cutting, stamping press and injection molding. The first method involves a die cut machine that is pressed with low-strength on materials such as plastic and paper however, this method also works for other sources such as wood, rubber, fabric, and sheet metal. In this process, the material for the keychain is fed through a machine via mechanized rollers. The custom die is properly aligned with the materials so it forms the intended shape of the keychain. Once it is aligned, the die has a cutting blade that presses down and it is strong enough to cut through the materials. If there is any excess, it is trimmed off, but it is rare since the machine is very precise. With stamping press, metal is pressed between a die and a heavy machine called punch to get the desired shape. The machine requires approximately 71 tons of pressure to cut a 10-inch circle from the metal. After the metal is pressed, the form it takes is good enough to be recognized as a keychain trinket. Similar to the die cutting, once the trinket is ready, if there is excess material, a technician uses heavier tools to cut from the metal (source). Through this research we found that production of keychains does not cause too much waste or emissions. One thing we did notice is that certain methods involve more energy than others as seen in the amount of pressure that is put to create various shapes and pieces with stamping press. Our group tried to find a specific company that followed either one of the steps that we mentioned, however we could not confirm which manufactures follow these methods.

There are various elements that go into creating acrylic keychains, but the most common type of keychain involves three parts: trinket, chain and clasp/ring. These parts are composed of different elements which often vary depending on what materials manufacturers decide to use. This report however, will focus on three specific materials: acrylic, stainless steel and UV curable inks. Acrylic is a type of plastic that contains derivatives of acrylic acid which is also known as polymethyl methacrylate (PMMA). Acrylic plastic manufacturing involves highly toxic substances such as cadmium, cobalt, manganese, chromium and lead (source). Since acrylic has toxic substances it requires careful handling, storage and disposal. Acrylic is made from a polymerization process which if not done properly, can result in explosions which can produce toxic fumes. In the polymerization process, a polymer is produced by adding a catalyst like organic peroxide to a monomer like methyl methacrylate. The catalyst is not produced in the reaction but will cause the polymers to form much more quickly making the process more efficient. Acrylic is not easily recycled and as a group 7 Plastic, it is not collected for recycling in most communities. As many of us are aware, plastic often ends up being considered waste and becomes a main polluter of our oceans. Large pieces can be collected to be reformed into other objects, but only if they do not have crazing or cracking, furthermore this process only accounts for a small portion of acrylic waste. Like many other plastics, acrylic is not biodegradable and in fact, can produce polycyclic aromatic hydrocarbon emissions (PAHs) when it is incinerated which is often a common method of getting rid of acrylic that is wasted. Incineration is an engineered process that employs thermal decomposition through thermal oxidation at very high temperatures to destroy certain waste. After doing some research on this topic, we found an article that conducted a study and found that burning acrylic produces PAHs which are of great concern due to their potential carcinogenicity (Singh, S.,& Prakash, V. 2007). Those who are exposed to these emissions are susceptible to health problems such as lung, bladder, skin and gastrointestinal cancer.

The other component that is used in acrylic keychain production is stainless steel. This material is made out of basic elements that are found on earth: iron ore, chromium, silicon, nickel, carbon, nitrogen and manganese. All of these materials are melted together in a furnace and create steel which is then heat treated, cleaned, and polished. Once it is ready, the steel is packaged and sent to manufacturers who weld and join it to produce the desired shape (How Products are Made). Out of all the three materials that we have mentioned, stainless steel is the most eco-friendly in fact, it is 100% recyclable as it is not coated with toxic material and does not produce toxic-run off. According to the Southern Africa stainless steel development association (SASSDA), many companies would make a huge difference by choosing stainless steel instead of materials that are non-recyclable.

UV curable inks consists of four components monomers, oligomers, pigments and photoinitiators. All of these materials are considered crude oil products. The pigments that produce the color of the ink may contain various metal powders but are also likely synthetically produced from coal tar which is a coke or coal gas production byproduct (How Products are Made). Although UV curable inks are not as harmful to the environment as acrylic, it can be very harmful to humans, especially those who work with this substance. Liquid UV curable inks contain materials that are hazardous to humans. These contain highly reactive chemicals that can damage the skin and eyes when they come into contact. Some people have reactions from the components of UV curable-ink even at the low levels of vapor

Waste Management and emissions

The waste that is created from acrylic keychain manufacturing is very small and rare since the machines are accurate enough to ensure that no pieces are left out. However, the waste and emissions are seen through how this item, specifically acrylic is disposed. Since acrylic is a type of plastic, it often ends up as a main source of pollution to our environment. Because acrylic is often not recyclable, certain manufacturers choose incineration as a way to dispose of this material. This process then creates problems for our atmosphere since it creates and emits PAHs.

During the delivery process, cargo ships or airplanes are used which use crude oil product as energy for transportation. Most forms of aviation release carbon dioxide (Co2) and other greenhouse gases into the Earth’s atmosphere which contributes to global warming and ocean acidification. As for ships they release air pollution by burning fuels which also contributes to carbon dioxide emissions.

Conclusion

As buyers and consumers, we rarely wonder about the kind of materials certain products are made of. Because the production of keychains has become so popular, a lot of manufacturers have expanded their ideas on what kind of materials can be used as a decoration for a keychain trinkets. While the process of creating a keychain has little to no impact in terms of waste and emissions, the way that certain manufacturers decide to get rid of acrylic waste affects our world by creating carcinogenic emissions. It is important to understand how our product’s materials affect our environment since only then, we are able to put an end to a life-cycle that contributes with pollution and environmental issues.

Works cited

2012, Written by AZoMDec 10. “How Do You Recycle Acrylic Resin?” AZoM.com, 13 May 2019, www.azom.com/article.aspx?ArticleID=7945.

“Acrylic Plastic.” How Products Are Made, www.madehow.com/Volume-2/Acrylic-Plastic.html.

“Custom Enamel Pins - Make Your Own Enamel Pins.” The/Studio, www.thestudio.com/pins/enamel-pins/.

“Difference between CAST Acrylic & EXTRUDED Acrylic Sheets?” Access Plastics, Access Plastics Limited, www.accessplastics.com/cast-vsextruded-acrylic/.

Herbst, Richard. "Apparatus for injection-molding plastic material items." U.S. Patent No. 6,027,328. 22 Feb. 2000.

“Life Cycle Thinking.” Worldsteel, www.worldsteel.org/steel-by-topic/life-cycle-thinking.html.

Galban, Lauren. “Life Cycle of Acrylic Plastic.” Prezi.com, 14 Oct. 2015, prezi.com/j0525_5cvrp2/life-cycle-of-acrylic-plastic/.

Mertes, Alyssa. “How Keychains Are Made: Quality Logo Products, Inc.” Quality Logo Products Digest | A Promo Products Blog, Quality Logo Products, 29 July 2019, www.qualitylogoproducts.com/blog/how-are-keychains-made/.

“Stainless Steel Life Cycle.” Outokumpu, www.outokumpu.com/en/sustainability/product-stewardship/stainless-steel-life-cycle.

Singh, Satnam, and Vinit Prakash. "The effect of temperature on PAHs emission from incineration of acrylic waste." Environmental monitoring and assessment 127.1-3 (2007): 73-77.

“Stainless Steel.” How Products Are Made, www.madehow.com/Volume-1/Stainless-Steel.html.

“Zhejiang Baigedi Technology Co., Ltd. - Keychain, Badge.” Alibaba.com, bgd.en.alibaba.com/.