Design Life-Cycle

assess.design.(don't)consume

Gabby Escobar

Professor Christina Cogdell

DES 040A, Section 4 Lauren, FQ 2021

25 November 2021

Materials of the Ukulele

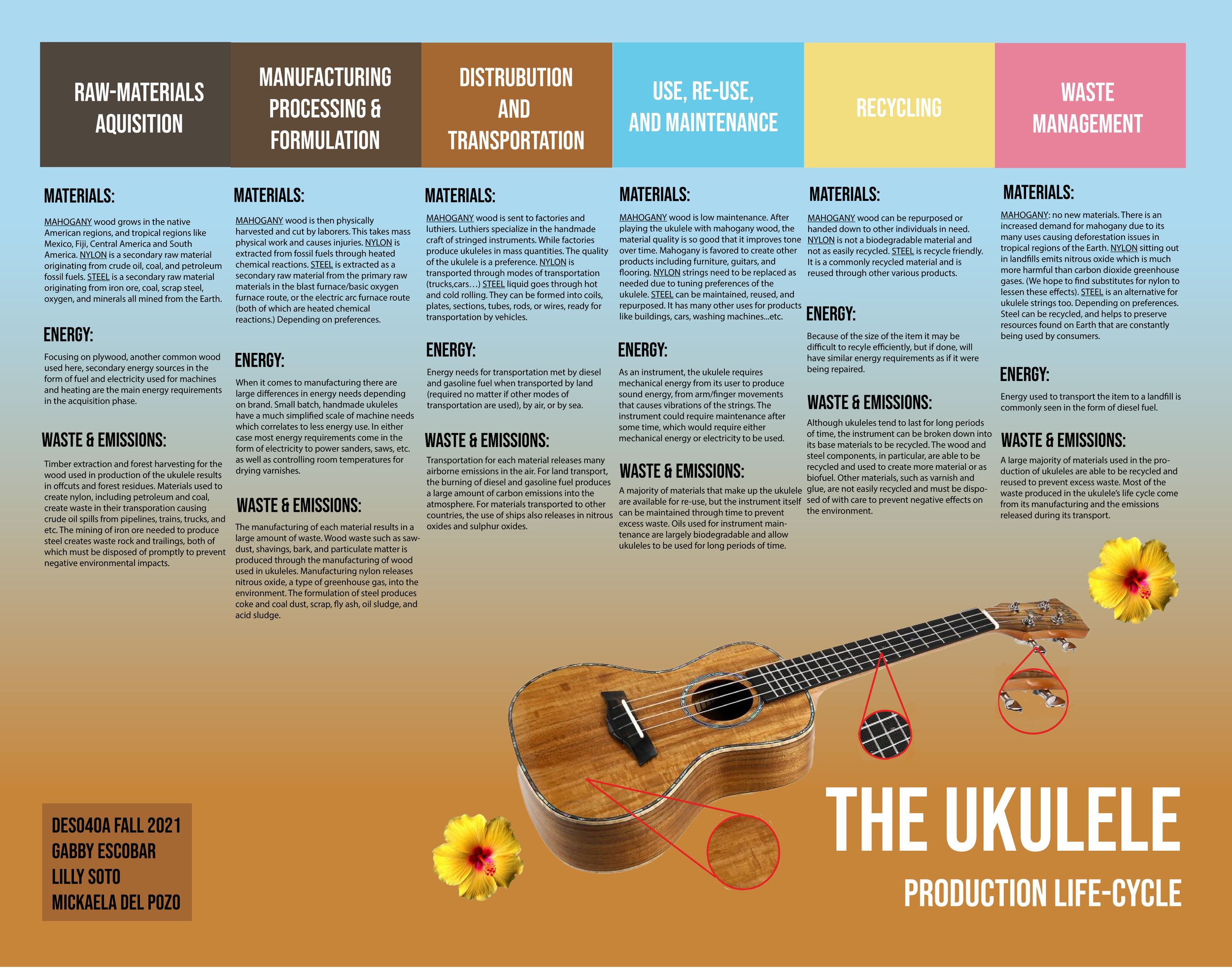

The Ukulele is a stringed instrument that produces music enjoyed by many people. The body of the instrument is made to resonate with sound as each of the four strings attached to it are strummed by their player. It would be fascinating to discover where the specific materials come from to help put together this musical instrument. Specifically, I will be focusing on the raw materials that are used to build up a ukulele. It would be good to research the materials sustainability that create and form this instrument. Being able to study a life cycle perspective demonstrates exactly where the raw materials come from, how they are manufactured, transported, maintained, and how they are recycled or wasted. The materials are most important to examine, because we want to discover the environmental impacts from it.

Discovering more about the raw materials of the ukulele is only one step out of the whole process of the product’s life cycle. It is important to know that there is more to this, including the energy and waste life cycles too. For this paper, we will have a closer focus on the materials of the ukulele.

Most ukuleles are made from mahogany wood, maple, walnut, rosewood elm, Hawaiian koa wood, or plastics to list a few. Plastics are more common in cheaper quality ukuleles. These materials are used to make up the body of the ukulele, but we will focus on mahogany wood for now. Mahogany originates in the native American regions and grows across Central America, and South America. “The global and material life of mahogany begins in the Americas. Honduran mahogany (Swietenia macrophylla), is considered to be the wood from trees of the botanical genus Swietenia, which is native to the Americas. Honduran mahogany grows naturally from the lowlands of the Yucatan peninsula, across Central America, to the north-eastern Amazon rainforest in South America.” (Martinez-Reyes, journals.sagepub.com). Being able to grow and harvest the mahogany wood from regions like Mexico and Fiji are another laboring process, because it takes a lot of effort and is a dangerous task. Workers get hurt harvesting the trees from these regions of Mexico and Fiji. “The amount of physical labor and the risk of serious injuries became evident while doing fieldwork... Once in the base camp there were mahogany logs that had to be prepared to be loaded in the truck the following day. They cut them..measured the length...Once finished with the pile of mahogany, we jumped in the truck and went to another gathering area. The crew followed the same process. There were people with visible scars on their bodies, others with missing fingers from their exposure to dangerous tools and big trees...” (Martinez-Reyes, journals.sagepub.com). After being cut and measured, the wood is sent to luthiers and factories. Luthiers specialize in the handmade craft of stringed instruments, and factories form the materials for a ukulele with specialized machinery. Most ukuleles are made by hand, but some materials are sent towards the factories too depending on preference. Mahogany’s wood also has easy building properties that are good for other uses like furniture, guitars, and flooring. “Unlike traditional luthiery, in which the instrument maker works on every aspect of the production of the instrument from beginning to end...mass produced in a factory facilitated by special machinery and a division of labor between the different stages of production in an assembly line. The cutting of the bodies and necks, gluing, applying binding and inlays, installing and levelling frets, sanding, applying color and finish, installing electronics, stringing the instrument, and setting up for optimum playability by adjusting neck and intonation are all done by different work groups.” (Martinez-Reyes, journals.sagepub.com). This type of wood is low maintenance. The mahogany seen in the creation of ukuleles do not need to be wasted, but can be reused by selling the instrument to other musicians, or handing the instrument down to another person who would be more interested in playing. On the other hand, mahogany trees are in high demand for their many uses, and are unfortunately causing deforestation in tropical regions of the world. Because of this, mahogany material is limited and continues to slowly run out. “Logging of American (bigleaf ) mahogany (Swietenia spp.) initiates a series of events that leads to degradation and later destruction of tropical forests in the New World. It also is a spear-point for penetration of indigenous areas by loggers, who inflict both social and environmental impacts on the tribes. Mahogany populations are declining and are not being replenished by natural regener-ation; the situation of the species continues to worsen in the field.” (Fearnside, Protection of Mahogany, cambridge.org).

Nylon is a main material found in ukulele strings. It is popular for uses with clothing materials and everyday objects like umbrellas and toothbrushes. It originates from crude oil, which is a fossil fuel found in the depths of the Earth. That being said, nylon is a secondary raw-material because it needs to be extracted and processed from crude oil through chemical reactions. “More specifically, nylons are a family of materials called polyamides, made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure, heated environment. This chemical reaction, known as condensation polymerization, forms a large polymer—in the form of a sheet of nylon. To make nylon fabric for apparel, this nylon sheet is then broken into chips, melted, and drawn through a mechanical spinneret to produce individual fibres that are woven into fabric.” (goodonyou.eco) Nylon materials are transported through modes of transportation, like trucks and cars. As for maintenance, the strings can last a while before they need to be replaced. This is due to tuning preferences with the stringed instrument. The unfortunate side to nylon is that it is not biodegradable, so it takes hundreds of years to decompose. With every string that needs to be replaced in a ukulele, it can be wasteful and have harmful effects on the environment. When nylon is wasted out in landfills, it emits a greenhouse gas known as nitrous oxide. This type of gas is much more harmful than carbon dioxide, and they are both gases that contribute to the warming of the climate. Here are some facts about nylon waste: “Greenhouse gases: producing nylon creates nitrous oxide, a greenhouse gas that is 300 times more potent than carbon dioxide. Water: manufacturing nylon is a very thirsty process; large amounts of water are used for cooling the fibres, which can be a source of environmental contamination and pollution. Energy: manufacturing nylon is a very energy-hungry process, which contributes to environmental degradation and global warming.” (goodonyou.eco)

Steel is another type of material commonly used for strings, and also found in the tuning pegs of the ukulele. It is a combination of iron ore, coal, scrap steel, and oxygen elements including additional minerals that are all mined from the ground as first raw materials. Again, steel is a secondary raw material because it goes through heat and electricity to extract and process steel from chemical reactions. “The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic oxygen furnace route, and the electric arc furnace route.” (corporate.arcelormittal.com) The raw materials are heated and formed into a liquid iron from the blast furnace process or the electric arc furnace. Then the liquid is shaped from hot and cold rolling. They can be formed into coils, plates, sections, tubes, rods, or wires, ready for transportation by vehicles. Steel does not have to be limited to uses for the ukulele strings and tuning pegs but has many uses for products on Earth. For example; buildings, cars, washing machines… Steel can be maintained, reused and repurposed. It is also very good because it can be easily recycled and formed for other uses again. “Steel tops the list of North America’s most recycled materials, with over 60 percent of steel being recycled annually since 1970. Steel’s production by-products also has a high rate of recycling, with 90 percent of the co-products used in steel production—including slag, water, gas, and dust—also being reused or recycled.” (Bennett, Steel Recycling, rubicon.com) This is good news because steel helps to preserve resources found on Earth that are constantly being used by consumers.

The materials of mahogany wood for the body, nylon for the strings, and steel for the tuning pegs (and string alternatives) are all the resources from the Earth that help build up the ukulele instrument. The need for mahogany wood by consumers is steadily growing, and causes deforestation damages in the tropical regions of Earth. Since there are other types of woods used for ukulele bodies, they could be better alternatives to lessen deforestation. Nylon is used for the strings of the ukulele but is a material that has harmful, wasteful and toxic effects on the Earth. It would be good to find a substitute for the strings. Another form of material used for the strings is steel. Steel is also a common material that is great for the tuning pegs of the ukulele. It is a recycled material and is great for preserving resources. Steel strings are a better alternative for ukuleles. These main materials of the mahogany wood, nylon, and steel are good to examine so people are more informed about their environmental impacts.

Bibliography

Dubois, Laurent. “8. Sounding America.” 8. Sounding America, Harvard University Press, 2016, pp. 271–304. www.degruyter.com, https://doi.org/10.4159/9780674968813-009.

Fearnside, Philip M. “Protection of Mahogany: A Catalytic Species in the Destruction of Rain Forests in the American Tropics.” Environmental Conservation, vol. 24, no. 4, Cambridge University Press, Dec. 1997, pp. 303–06. Cambridge University Press, https://doi.org/10.1017/S0376892997000404.

Gala, Selfina, et al. “COMPARISON OF MICROWAVE AND CONVENTIONAL EXTRACTION METHODS FOR NATURAL DYES IN WOOD WASTE OF MAHOGANY

(SWIETENIA MAHAGONI).” Journal of Applied Engineering Science, vol. 18, no. 4, 4, Nov. 2020, pp. 618–23. aseestant.ceon.rs, https://doi.org/10.5937/jaes0-23695.

How Ukulele Is Made - Production Process, Manufacture, Making, History, Used, Parts, Product, Machine, History. http://www.madehow.com/Volume-6/Ukulele.html. Accessed 25 Nov. 2021.

Kitto, Kathleen. The Sound Of Materials: Creating Excitement For Materials Engineering And Science In Engineering Technology Programs. 2007, p. 12.1469.1-12.1469.20. peer.asee.org, https://peer.asee.org/the-sound-of-materials-creating-excitement-for-materials-engineering-and-s cience-in-engineering-technology-programs.

Lowell, Eini C., et al. “A Photographic Guide to Acacia Koa Defects.” Gen. Tech. Rep. PNW-GTR-871. Portland, OR: U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station. 100 p., vol. 871, 2013. www.fs.usda.gov, https://doi.org/10.2737/PNW-GTR-871.

Mahogany Intertwined: Enviromateriality between Mexico, Fiji, and the Gibson Les Paul - Jose Martinez-Reyes, 2015.

https://journals.sagepub.com/doi/abs/10.1177/1359183515594644?journalCode=mcua. Accessed 25 Nov. 2021.

Making Steel | ArcelorMittal. https://corporate.arcelormittal.com/about-us/making-steel. Accessed 25 Nov. 2021.

Martinez-Reyes, Jose. “Mahogany Intertwined: Enviromateriality between Mexico, Fiji, and the Gibson Les Paul.” Journal of Material Culture, vol. 20, no. 3, SAGE Publications Ltd, Sept.

2015, pp. 313–29. SAGE Journals, https://doi.org/10.1177/1359183515594644. “Material Guide: How Sustainable Is Nylon?” Good On You, 30 Aug. 2020, https://goodonyou.eco/material-guide-nylon/.

Maz, +Barry. “Ukulele Beginners Tips - Different Uke Finishes.” GOT A UKULELE - Ukulele Reviews and Beginners Tips,

https://www.gotaukulele.com/2011/02/ukulele-beginners-tips-different-uke.html. Accessed 25

Nov. 2021.

Phillips, Steven. Bio-composite material applications to musical instruments. McGill University, https://escholarship.mcgill.ca/concern/theses/1544bq27t. Accessed 25 Nov. 2021.

Phillips, Steven, and Larry Lessard. “Application of Natural Fiber Composites to Musical Instrument Top Plates.” Journal of Composite Materials, vol. 46, no. 2, SAGE Publications Ltd STM, Jan. 2012, pp. 145–54. SAGE Journals, https://doi.org/10.1177/0021998311410497.

Steel Recycling: Processes, Benefits, and Business Solutions | Rubicon. https://www.rubicon.com/blog/steel-recycling/. Accessed 25 Nov. 2021. “Ukulele Anatomy Guide: 10 Parts of a Standard Ukulele - 2021.” MasterClass,

https://www.masterclass.com/articles/ukulele-anatomy-guide. Accessed 25 Nov. 2021.

“What Is A Guitar Luthier And How Can You Become One?” Musicians Institute Hollywood, 8 Jan. 2019, https://www.mi.edu/education/guitar-luthier-can-become-one/.

Where Does Crude Oil Come From? | Blog | Howden.

https://www.howden.com/en-us/articles/pcog/where-does-crude-oil-come-from. Accessed 25

Nov. 2021.

Wiedenbeck, Janice K., and Eini Lowell. “Wood Quality of Old-Growth Koa Logs and Lumber.” Forest Products Journal, vol. 67, no. 7–8, Oct. 2017, pp. 416–26. Silverchair, https://doi.org/10.13073/FPJ-D-16-00067.

Lilly Soto

DES 40A

Professor Cogdell

Dec 2, 2021

Embodied Energy of the Ukulele

The ukulele is an instrument that has kept itself relevant since its beginning as a creation inspired by the lute when it was brought to Hawaii from Portugal in the early 20th century(Gillespie). In this paper I will focus on three main materials of the ukulele, wood, making up the base, nylon, making up the strings, and steel used for the tuning knobs. Energy is required at every stage of life for any object, but here I will not include transportation between each step of the life cycle assessment, or LCA, unless explicitly relevant. I will focus on the acquisition and production phase where most of the energy for the ukulele is consumed. The energy used makes up the embodied energy. Embodied energy is the cumulative energy inputs associated with the entire life cycle of any object within a defined system boundary(Cogdell, Trends in Design, Energy, & Materials). Boundaries must be drawn because the inputs can go on forever if each and every object or process involved was analyzed. I attempt to continue to note these throughout.

As a wood instrument, the ukulele’s energy analysis can be useful when looking at similar objects, such as a violin or guitar, taking size differences into account. Considering the brand is important as well. Small batch, handmade ukuleles have scaled down machine needs which correlates to less energy use compared to that of a large factory. In either case most energy requirements are seen in the form of electricity to power sanders, saws, etc. as well as controlling room temperature for drying varnishes. Fossil fuels are the other main sources of energy in this process. Fossil fuels being a primary, chemical energy source whereas electricity is a secondary source of energy. It is commonly, “fossil-fuel-derived electricity,” which converts chemical energy into transferable, electrical energy(Cogdell, Trends in Design, Energy, & Materials; Cogdell,Electricity and Renewable Energy). This is important to note as it is involved at nearly every step.

Beginning with the base material, wood, we can start assessing energy required for each piece of the product. Ukuleles are not exclusively made from plywood, other common materials include mahogany and spruce, but plywood acts as a ubiquitous starting place. It is a cheap and easily accessible material. One study, “Gate-to-Gate Life-Cycle Inventory of Softwood Plywood Production,” looked at some prominent plywood producers in the Pacific Northwest and Southeast of the US going through inputs at each stage of production.

Plywood goes through a much more vigorous “acquisition” than solid wood, as an extra layer of manufacturing is undergone to create the “raw” material. All lumber requires initial extraction, but for my purposes I will begin at the creation of the plywood. First, the lumber must be debarked which requires electricity, then the wood is conditioned, or treated with steam(Wilson). Next electricity is used to power the lathe and conveyor belts used for, “peeling logs into veneer sheets and drying”(Wilson, p.58). The veneer drying process is the most energy intensive step requiring various heating sources. After being pressure and heat cured, the product is trimmed which uses electricity powered saws. In the steam and heat phases hogged fuel, which is created by burning, usually wood bark, is used and makes up a majority of total energy on site. There are many steps to this process, but plywood has advantages to solid wood as it is not limited in size by length or width of trees. This is relevant to changes in production materials of many items over time. Similarly we see changes in string material over time.

In the beginning gut strings were the prominent material used in instrument strings, but as we have seen with countless products, they were pushed out by synthetic alternatives, in this case nylon(Nylon Strings). Gut strings were temperature and humidity sensitive. Some prefer the sound made by gut strings more, but synthetics are more durable, and eventually cheaper to make on a large scale(The Ultimate Guide to Classical Guitar Strings - Inside Guitar). There are many types of nylon used for strings, a common type being nylon-6 and nylon 6,6. I will be defining acquisition here by the production of nylon not extraction of the adipic acid and hexamethylenediamine used for its creation(The Red Nile). As a professor at Carleton University shows in a demonstration, a small amount of these chemical inputs can create a large amount of nylon, as it gets stretched and pulled from the solution(Ottawa). In an industrial setting the solutions are combined first forming a salt that is then heated. This heating process takes a significant length of time and high temperatures(The Red Nile). This most likely uses electrical sources to produce this type of consistent heat. Water and nylon 6,6 are byproducts of the reaction; a spindle of sorts, most likely powered by electricity, is used to collect the seemingly endless formation of string. It must then be treated and dried due to the acidity, which would require more energy inputs.

Finally, the last major material we will look at, steel. Steel hasn’t been replaced by a new material with time, but its production process and energy requirements have changed. Steel used to be exclusively created through the process of smelting. Smelting requires very high heat to extract the metal from ore, but today a blast furnace is used to heat powdered iron ore that is combined with coke(Binggeli, p.154). The blast furnaces, or electric arc furnace, powered by electricity, “requires more energy… than any other process to produce steel”(Fruehan, p.4). The use of scrap metal decreases energy needs, but one must consider that the scrap metal is a form of “invested energy” referring to its initial production. Once completed the steel will still then have to be reheated and cast into the desired shape for the tuner.

After each of the individual materials has been created they make their way to the site of ukulele production. At this stage the main energy needs will come from electricity to run saws, conveyor belts, etc. First, the wood must be cut into the desired shapes for the base, sides, and neck will, on large production sites, require a laser cutter. On small scale sites a bandsaw may be the only saw needed to create these organic shapes(Imua Ukulele, Cort Guitar Co). Moisture and clamps are used to form the curves and bends, likely only requiring mechanical, human energy. Electricity will feed the CNC cutters for branding or logos. Each wood section is glued together before sanders are used to create a smooth, continuous surface. It will be finished with an application of sealers and varnishes, which on a large scale will utilize machines to dispense the substances and a conveyor belt to keep the line moving. When applied by hand mechanical energy of a human is needed.

This is where differences are seen in energy requirements where small scale producers, such as Imua Ukulele, may use a standing fan to dry their varnishes or hand apply a finish, a company such as Cort uses machines to spray varnishes and temperature controlled rooms to accommodate their large number of guitars(as guitar production is very close in comparison to the ukulele)(Imua Ukulele, Cort Guitar Co).

After the production phase it will need to be transported to distributors. This requires fossil fuels no matter if transported by road, air, or sea. Once the consumer has their ukulele, mechanical energy is required to create the sound energy the instrument is intended for. Longevity of an item like this is dependent on the care taken by the user to preserve it. If maintenance is ever required it will likely be mechanical energy from an individual working on the ukulele.

Once its use is through, the ukulele potentially can be recycled, but because of its small size it may be difficult to find a new purpose for any of the materials, even the wood. Most likely ending up being re-used or as waste. The only extra energy used for waste are more fossil fuels for transportation.

These are the main sources of energy inputs associated with this product. There are many rabbit holes that can be explored including those associated with glues, varnishes, or even discrepancies between different types of steel. It was difficult finding information, especially for nylon strings, that was not extremely surface or was not incomprehensible numbers, but what has been compiled here can give a sense of just how intensive creating a product is at every single level, even for the tiny tuners on a ukulele.

References

Gillespie, Kirsty, et al. A Distinctive Voice in the Antipodes: Essays in Honour of Stephen A. Wild. ANU Press, 2017.

Christina Cogdell, “Lecture 2: Trends in Design, Energy, & Materials” (presentation, Cruess Hall, Davis, CA, September 28, 2021).

Christina Cogdell, “Lecture 13: Electricity and Renewable Energy”(presentation, Cruess Hall, Davis, CA, November 16, 2021).

Wilson, James B., and Eric T. Sakimoto. “Gate-to-Gate Life-Cycle Inventory of Softwood Plywood Production.” Wood and Fiber Science, 2005, pp. 58–73.

Nylon Strings | Guitar Center. https://www.guitarcenter.com/Nylon-Strings.gc. Accessed 12 Nov. 2021.

The Ultimate Guide to Classical Guitar Strings - Inside Guitar. https://inside-guitar.com/the-ultimate-guide-to-classical-guitar-strings/. Accessed 17 Nov. 2021

The Red Nile, director. Making Nylon . YouTube, YouTube, 22 Apr. 2017, https://www.youtube.com/watch?v=HTh_5CWMSoQ. Accessed 30 Nov. 2021.

Robert Burke Ottawa, director. Making Nylon . YouTube, YouTube, 29 Jan. 2007, https://www.youtube.com/watch?v=y479OXBzCBQ. Accessed 30 Nov. 2021.

Binggeli, Corky. Materials for Interior Environments. Wiley, 2014.

Fruehan, R.J., et al. “Theoretical Minimum Energies to Produce Steel for Selected Conditions.” Energies, Inc. Columbia, MD, 2000, https://doi.org/10.2172/769470.

Imua Ukulele, director. Imua Ukulele Honolulu Factory. YouTube, YouTube, 23 Oct. 2015, https://www.youtube.com/watch?v=DYNPRF5mk_s. Accessed 30 Nov. 2021.

Cort Guitar Co, director. Cort Acoustic Guitar Factory Tour . YouTube, YouTube, 4 Jan. 2011, https://www.youtube.com/watch?v=Cylr2aG6zAw. Accessed 30 Nov. 2021.

Mickaela Del Pozo

Professor Cogdell

DES 40A 004

02 December 2021

Waste and Emissions in the Life Cycle of the Ukulele

Ukuleles carry a deep history in both their rise to popularity and creation as a beloved musical instrument for a variety of ages today. The wooden instrument, though small in size, contains materials found in numerous musical instruments with varying life cycles. The materials used to produce ukuleles include wood, nylon, steel, glue, and varnish similar to those found in guitars and violins. Although the process of making a ukulele varies from traditional instrument makers to those produced in factories, the materials used undergo similar processes from their acquisition to disposal. Wood waste and airborne emissions produced through the life cycle of the ukulele lie primarily in its manufacturing and depend on the instrument, as recent instruments are maintained and reused through time.

Wood serves as the primary material in the production of a ukulele as it makes up the main body of the instrument. The wood types used in this process are softwood, hardwood, composite wood, and monocots (Waltham). Each wood type is utilized depending on the availability of the material and the desired sound quality of the ukulele. Plywood, a type of composite wood, is commonly used in musical instruments as a more inexpensive option compared to other types of wood that are not as heavily harvested. With the extraction of this wood from forests comes a large amount of wood waste. Acquisition of this resource results in offcuts and forest residues left behind after forests are harvested, leading to deforestation in areas where natural processes cannot keep up with. Manufacturing wood used to create a variety of products also results in much waste including sawdust, wood shavings, bark, chips, and particulate matter. In previous years, timber production companies did not know how to deal with the wood waste they produced which led to much of the waste ending up in landfills. However, as the world’s needs for sustainable resources and processes continue to increase, wood waste is now utilized for a variety of purposes. A majority of sawdust and shavings are now made into wood pellets and wood chips described as “[...] the predominant solid biofuel commodity on the international market” (Belyakov). These global transactions result in a larger use of energy and fuel from the transportation of this waste between countries, but the development of sustainable fuel resources including wood biofuel continues to be in development. Wood chips are also used for pulp to produce paper, another more sustainable option that makes use of the waste produced by wood extraction. The wood used to produce ukuleles is largely biodegradable, but the materials used to make the strings of the instrument are not.

Ukulele strings, a major component of the instrument, are made of nylon. Nylon is a material made from polyamide monomers that are extracted from petroleum and coal along with the addition of air and water (Theimens). Petroleum, also known as crude oil, is largely known as a nonrenewable resource whose waste results in various contamination of land and water sources. A part of this waste can be attributed to the transportation of the material as spilled and unrefined crude oil enters the environment from pipelines, trains, trucks, tanks, and other forms of transport (Minnesota Pollution Control Agency). The manufacturing of nylon produces another kind of harmful waste into the environment, nitrous oxide. This gas contributed to stratospheric ozone destruction and is stated to be a more potent greenhouse gas in comparison to carbon dioxide. The material itself, unlike the wood used in producing the instrument, is non-biodegradable and not heavily recycled. Certain types of nylon can be recycled, such as those found in bags and clothing, but a majority of the material is disposed of in landfills. Unlike the wooden body of a ukulele, nylon strings need to be replaced over time ranging from every eight months to years at a time. A sustainable alternative for nylon is yet to be developed, resulting in a large amount of nitrous oxide being emitted into the atmosphere as its primary waste. Another component of the instrument, the tuners, is another heavily used material with more environmentally-friendly waste.

The tuners of a ukulele are often made from steel, a material found in numerous aspects of people’s everyday lives. Steel is produced from iron ore that is mined and excavated from many parts of the world. The acquisition of this iron ore results in waste rock and tailings. Waste rock comes from the excavation of the ore and is often taken to a waste-rock dump to occupy land for long periods of time. The mineral beneficiation part of the mining process produces tailings, which must be promptly disposed of after its production to prevent pollution of nearby land and negative effects on communities in close proximity to the mining site. A large amount of waste comes from the manufacture of steel. This includes coke and coal dust, scrap, ash, oil, and acid sludge (Sarkar). Unlike nylon, steel is a largely recycled material whose byproducts can be used for a variety of purposes. After steel is used to produce different products, the iron and steel byproducts are recycled to be used in the production of new steel products. Using these scraps takes a lesser amount of energy compared to making steel from iron ore, also saving on the fuel used by machines in mining the unrefined ore. The coke and coal dust produced during the manufacture can be used as a source of lime and phosphorus for various fertilizers. In addition, the ash created in the same process is available to be used in the production of cement and certain types of brick. Although the amount of steel used in the production of a ukulele is relatively small, the byproducts used in its manufacturing can be used for many purposes. Other small components of the ukulele include the glue and varnish used to finish the ukulele’s production.

Many wooden musical instruments utilize glue and varnish to finish their production and ensure the quality of the instrument. To assemble a ukulele, glue is a necessary component that affects the durability of the wooden body. Hide glue, made from the collagen of cattle, is considered a traditional standard for instrument makers worldwide (Waltham). Modern chemical adhesives may be used as an alternative, especially for ukuleles manufactured in factories. A majority of instrument makers prefer to use hide glue because it aids in a longer life cycle for each instrument. The material itself is non-toxic, biodegradable, and recyclable in comparison to chemical alternatives. Varnish, on the other hand, is not as sustainable of a material. This material is made of resin, drying oil, and volatile solvent and is used to create a shiny finish for the instrument. Improper disposal of varnish can result in water and airborne pollutants and must be disposed of as hazardous waste.

The life cycle of a ukulele includes the production of numerous byproducts taking form as wood waste, scrap, and airborne emissions. Many of these byproducts can be recycled and reused to create more material or other products, serving as sustainable alternatives to the waste that occupies landfills. This proves true for both the wood and steel used in ukuleles, whose waste can be used as fuel or material. Some materials used in the instrument’s production are less sustainable and require careful disposal to prevent harmful effects on the environment. The ukulele itself, similar to many instruments, is able to last for long periods of time depending on the materials used to produce it. Through regular maintenance, the instrument can survive generations before it is rendered unusable. Ukuleles that use more sustainable materials can then be recycled and used to produce other products. Care and maintenance of the ukulele ensure that the instrument can be used for decades with less production of unneeded waste.

Bibliography

Asamoah, Obed et al. “Assessing Wood Waste by Timber Industry as a Contributing Factor to

Deforestation in Ghana.” Forests, vol. 11, no. 9, 2020.

Belyakov, Nikolay. Sustainable Power Generation Current Status, Future Challenges, and

Perspectives. Academic Press, Is an Imprint of Elsevier, 2019.

“Crude Oil and Unrefined Petroleum Wastes.” Minnesota Pollution Control Agency,

https://www.pca.state.mn.us/sites/default/files/w-hw4-11.pdf.

Hajam, M. El, et al. “Adsorption of Methylene Blue on Industrial Softwood Waste ‘Cedar’ and

Hardwood Waste ‘Mahogany’: Comparative Study.” Materials Today: Proceedings, Elsevier, 2019, https://www.sciencedirect.com/science/article/pii/S2214785319306364.

“How Is Nylon Made?” OpenLearn, The Open University, 1 Mar. 2019,

https://www.open.edu/openlearn/science-maths-technology/science/chemistry/how-nylon-made.

Issi. “Environmental Impacts.” Green Choices, Green Choices, 19 Apr. 2018,

https://www.greenchoices.org/green-living/clothes/environmental-impacts.

Lu, Zengxiang and Meifeng Cai. “Disposal Methods on Solid Wastes from Mines in Transition

from Open-Pit to Underground Mining.” Procedia Environmental Sciences, vol. 16, 2012, pp. 715-721.

Sarkar, Sushovan and Debabrata Mazumder. “Solid Waste Management in Steel Industry -

Challenges and Opportunities.” International Journal of Social, Behavioral, Educational, Economic, Business and Industrial Engineering, vol. 9, no. 3, 2015.

Thiemens, Mark and William Trogler. “Nylon Production: An Unknown Source of Atmospheric

Nitrous Oxide.” Science, vol. 251, no. 4996, 1991.

Tiede, Clayton. “Avoid Major Repairs Through Preventive Maintenance.” Music Educators

Journal, vol. 62, no. 2, 1975.

Waltham, Chris and Shigeru Yoshikawa. “Construction of Wooden Musical Instruments.” Springer Handbook of Systematic Musicology. Springer Handbooks. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-55004-5_4, pp. 63-79.

Wilson, James and Eric Sakimoto. “Gate-to-Gate Life-Cycle Inventory of Softwood Plywood

Production.” Wood and Fiber Science, vol. 37, 2005.