Design Life-Cycle

assess.design.(don't)consume

Giang Ta

DES040A

Riddhi, Professor Cogdell

3/13/23

Life Cycle of IKEA FRAKTA Bag Throught The Lens of Raw Materials

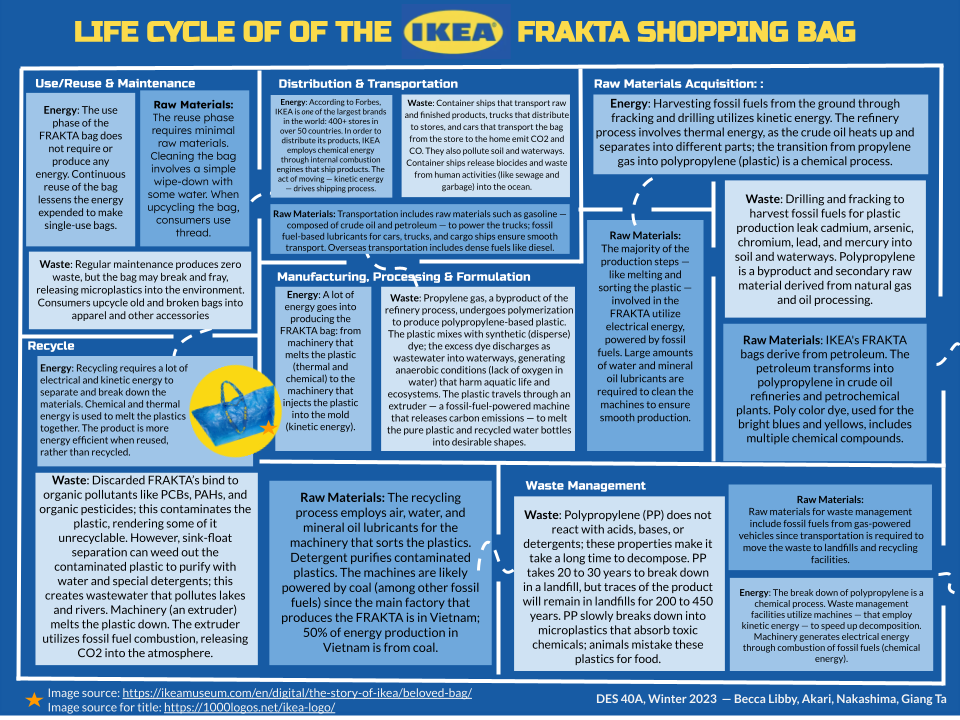

IKEA FRAKTA bags are the most authentic bags with a simple design appearance. The company is passionate about the production of recycling materials and idea of reuse/reduce the amount of contaminable waste being produced. IKEA exist widely across the world accepting IKEA’s design and concept of sustanability. With IKEA’s simple design it is noticeable that IKEA limits the amount of material used in the bag to make the recycling process easier. The FRAKTA bag is also known for 60% of its materials recycled and reused into different materials. In detail, the bag is composed of Polypropylene also known as olefin, a common type of plastic. With IKEA’s acquirable pricing it is hard to believe the company is selling sustainable goods at a reasonable pricing. But are the bags truly sustainable? In this paper I will examine if the IKEA bag is truly contributing to sustainability through the lens of raw materials and the life cycle of IKEA FRAKA bag.

To better understand sustainability of the FRAKTA bag, we jump right into Raw material accusations of the bag. Bag is mainly consisted of olefin, inorganic dye, Oil lubricants, water. which is composed from ethylene and propylene. Plastic (propylene & ethylene) main raw material is crude oil & natural gas. Depending on the temperature level, different types of plastics are created temperature affecting plastic in its strength/toughness, flexibility, etc. Nylon strings used in the handles are plastic which has raw material of Crude Oil. Olefins are produced at crude oil refineries and petrochemical plants and are not naturally occurring constituents of oil and natural gas The olefin fiber is created from previously mentioned plastic pellets which are melted and put through a spinneret which allows the melted pellets to create fibers. Handle of the bag is made out of Yellow polyester thread. The die to make the yellow along with the blue to dye the elastic fibers a vivid blue. There are 2 types of dyes, Inorganic dye and Organic dye. Approximately 84% of the industry is said to use Inorganic dye, leaving 16% or Organic dyes. Because we were not able to research in details about types of dye FRAKTA bag uses, Assuming IKEA uses inorganic dyes thinking the price of the IKEA bags are sold around per 2.99, despite its affordable price, and how strong the dye imparts to the plastic material is also a factor that it is convincing to think the dye are made inorganic dye. Inorganic dyes include raw materials such as Direct, Acid, Basic, reactive dye, Mordant, Metal complex, Vat, Sulphur, Disperse dye, etc, which creates the strong glow on plastic fibers. Additionally water gets consumed in the manufacturing process, consuming 22 gallons of water to make one pound of plastic.

Moving on to the manufacturing process, Raw materials used in the manufacturing process are mainly crude oil, natural oil, water, oil lubricants. Unfortunately we do not know in detail how specifically IKEA FRAKTA bags are created but manufacturing wise the machinery has common raw materials uses.Moving on to manufacturing. Crude oil is first extracted from the earth using an oil rig composed of iron/steel. Additionally, Fossil fuels are used throughout the whole process of extracting crude oil from the ground to transform into olefin which are plastic fibers, the whole process until the end product. In huge industrial companies such as IKEA, the process of cutting, stitching, shaping color, dye is done all mechanically using Water Mineral Oil Lubricants (Oil for machine maintenance) The US uses 669 million oil lubricants per day in the manufacturing process. Within the manufacturing process, the industry uses up to 12% of public water for mainly fabricating, cooling, washing, and diluting. Polypropylene is created by Crude Oil which is extracted from underground using oil rigs. After being transported to oil refineries crude oil is placed to a heating machine where energy run powered again by fossil fuels to construct plastic at different temperatures. Once plastic fiber is created, polyester fiber is brought to a factory to dye to coordinated colors thought the process of Disperse dye where multiple chemicals and pigments FRAKTA bag consists of Sweedish blue Hex: #ffcc00 RGB: 255, 204, 0 and Yellow Hex: #003399 RGB: 0, 51, 153 which create the color of the IKEA bag.

After the manufacture aspect of the bag is completed there is still amount of raw materials involved in the life cycle. The transportation process occurs between mining of oil to oil refineries, oil refineries to production of poly fiber, production of poly fiber to IKEA manufacture, manufacture to IKEA shops, and so on to recycling transportations. Four most common types of transportation of industries are air, road, sea and rail. Out of all, trucks are the most common, moving 50 million tons everyday within the US. Railroads are also a common form of transportation along with road transportation, and over sea transportation which three are all primarily powered by petroleum or crude oil. Air transportation of goods are the least common 0.5 percent out of all volumes fueled by Aviation kerosene, also known as QAV. 29% of fossil fuel materials are used for transportation. IKEA FRAKTA bags are majority created in Vietnam which their production uses 50% coal and other 50% consistinig crude oil, natural gas, etc. The transporation root that IKEA has from production in Vietnam to America first through cargo ships to trucks and rail road sending products to different matr of countries. Inorder to reduce greenhouse emissions, IKEA started a movement in poland joining with Volvo trucks and Raben group to reduce 70 percent of greenhouse emissions in transportation by electrifying heavy duty trucks. Trucks will be charged at the IKEA industry using reusable energy sources. The transportation process additionally use raw materials such as water and soap to clean craft from time to time along with oil lubricants to maintain the inner mechanics. The IKEA FRAKTA bag is very popular as a diy's and repurposing as a bag for daily usage. In the hands of a craft professional, IKEA FRAKTA bag have repurposed themselves into clothing, accessories, masks, etc. This process of diy’s limit the amount of new raw materials that are consumed in the process such as water to clean and thread to reform the bag.

FRAKTA bag made 60% recyclable material, FRAKTA bag will end up in material recycling facilities. There, the bag goes through the sorting process. There are multiple sorting processes the waste needs to go though such as, sorting with human eye, laser sensors, magnets and shots of air. After material is sorted the FRAKTA bag goes through a decomposition process, where recyclable polypropylene is sorted out at recycling facilities. Dye detergents are used to get rid of the colo dye’s in plastic. Once polypropylene is sorted out, high temperature to coincidencing or metlptingplastic pellets into one whole plastic cube ready to be shaped into a new product. Another recycling method of Polypropylene is to placsiting the process places polypropylene in a reactor filled with water, and heat it up to extremely high temperatures ranging from 380-500 degrees Celsius. This continues for up to five hours at high pressure. At this high heat and pressure, water breaks down the plastic and converts it into oil. This process is known as the The Polypropylene Recycling Process. This process converts polypropylene in to may products such as plastic boxes to reproduce a plastic material or into fossil fuels for energy usage. The recycling process is machine heavy similar the manufacturing process heavenly reliant on energy fossil fuels such as crude oil and coal. And continuing on to waste management, wastes goes through recycling to land fills. Raw materials that get involved in this process composed of crude oil and petroleum for short transportation.

Although the IKEA’s FRAKT bag appeals that FRKTA is minimalized with its simple color and simple design, even with with less materials, leading to more materials through the whole life cycle of FRAKTA bag. As a consumer it is very important to understand the process each product goes through along with the amount of raw materials such as fossil fuels and water that are being used. Even if the material is known to be recyclable, it is not easy to imply eco-friendly considering the amount of raw material it takes to create one IKEA FRAKTA bag. Although there is excess amount of fossil fuels involved in the process, still want to acknowledge the choices IKEA is making their products to better improve to their future goal of zero waste 2025, IKEA just started its sustainable journey towards zero waste and continuous support for the company running towards zero waste/emmitions is crucial from us consumers for the future we are walking towards.

Bibliography

Arrigo, Elisa. “Corporate Responsibility and Hypercompetition:the IKEA Case.” SSRN,

RELX, 8 Feb. 2013, pp.46-48 https://deliverypdf.ssrn.com/delivery.php?ID=223117004126125093065065113089014018056013034051087067098002113113091069068013002006012058017121015012035003006080098112124114039069054051084086083113124102105088070061093042100068121119087094119074113088109083018094023087106116106019097079021000068124&EXT=pdf&INDEX=TRUE.

Austrom, Mangus. “IKEA and the Responsible Governance of Supply Chains.” Diva

Portal, Sodetorn University, 2013 pp.5

https://www.diva-portal.org/smash/.

Gibbons, James. “What Is Polypropylene Fabric?” Revolution Fabrics, Revolution

Fabrics, 20 Jan. 2020, pp.1 https://revolutionfabrics.com/blogs/gotcha-covered/what-is-polypropylene-fabric#:~:text=What%20is%20Polypropylene%20made%20of,oil%20and%20natural%20gas%20facilities.

Ivarsson, Inge, and Claes Goran Alvstam. “Supplier Upgrading in the Home-Furnishing

Value Chain: An Empirical Study of IKEA's Sourcing in China and South East Asia.” World Development, Pergamon, 24 July 2010, pp.1577- 1579 https://www.sciencedirect.com/science/article/pii/S0305750X10001154.

“IWAY – the IKEA Supplier Code of Conduct.” IWAY – IKEA Supplier Requirements,

IKEA, pp.1 https://about.ikea.com/en/work-with-us/for-suppliers/iway-our-supplier-code--of-conduct.

Kilgore, Georgette. “Air Freight vs Sea Freight Carbon Footprint (the Real Numbers in

2023).” 8 Billion Trees: Carbon Offset Projects & Ecological Footprint Calculators, 8 Billion Trees.com, 20 Jan. 2023, pp.4 par.32 https://8billiontrees.com/carbon-offsets-credits/carbon-ecological-footprint-calculators/air-freight-vs-sea-freight-carbon-footprint/.

Lipponen, Kaisa. “IKEA and Neste Take a Significant Step towards a Fossil-Free

Future.” Neste in North America, Neste Corporation, 5 Mar. 2021, pp.35-40 https://www.neste.us/releases-and-news/renewable-solutions/ikea-and-neste-take-significant-step-towards-fossil-free-future.

“Polypropylene+Eulithe100+Polypropylene” Data Base Material Connection, UC Davis,

pp.1

https://www.materialconnexion.online/database/689004.html.

Rocha, Joseph R. “PLASTIC BAG NEWS ARTICLES.” Lacounty.org, 18 Apr. 2008, pp.3

http://dpw.lacounty.gov/epd/plasticbags/PDF/04-16-08/Item2.pdf

Royer, Sarah-Jeanne, et al. “Production of Methane and Ethylene from Plastic in the

Environment.” PLOS ONE, Public Library of Science, 1 Aug. 2018, pp.16-20 https://journals.plos.org/plosone/article?id=10.1371%2Fjournal.pone.0200574.

Sen, Mayukh. “How to Repurpose Your Bright, Blue Ikea Bag.” Food52, Food52, 3 Jan.

2022, pp.1-3

https://food52.com/blog/19685-how-to-repurpose-your-bright-blue-ikea-bag

Shaver, Michel P. “Mechanical Recycling of Packaging Plastics: A ReviewMichel.” Wiley

Online Library, The UC Davis Library, 30 Sept. 2020, pp.3-10 https://onlinelibrary.wiley.com/doi/full/10.1002/marc.202000415.

Slav, Irina. “How Much Crude Oil Does Plastic Production Really Consume?”

OilPrice.com, 10 Oct. 2019, pp.1 par.3 https://oilprice.com/Energy/Energy-General/How-Much-Crude-Oil-Does-Plastic-Production-Really-Consume.html.

Sporrer, Alyssa. “Environmental Group Targets Retailers' 'Shady' Shipping Routes.”

FreightWaves, 30 Nov. 2021, pp.1-2 https://www.freightwaves.com/news/environmental-group-targets-retailers-shady-shipping-routes.

“The Story of a Beloved Ikea Bag.” IKEA Museum, 11 Nov. 2022, pp.1-9

https://ikeamuseum.com/en/digital/the-story-of-ikea/beloved-bag/.

Tim, Tim. “How to Make DIY IKEA Frakta Grow Bags.” Clever Creations, Clever

Creations, 1 Jan. 2023, pp.10-17 https://clevercreations.org/how-to-make-diy-ikea-frakta-grow-bags/.

“Towards Zero Waste.” This Is IKEA, IKEA, pp.1-5

https://www.ikea.com/us/en/this-is-ikea/about-us/towards-zero-waste-towards-a-better-tomorrow-pub37a63340.

Ideas Behind Energy Use of IKEA’s FRAKTA Bag

IKEA’s idea to create a fully reusable bag has pioneered the movement of creating reusable bags among so many stores and businesses we see today. It has taken the world by storm as it is an innovative idea done right, with a durable build, classic look, and general practicality, the FRAKTA bag has become a household staple within the living spaces of many of IKEA’s loyal customers. Furthermore, as many of IKEA’s products have been made with plastics, both recycled and consumer solutions, the choice to make a packaging system from a plastic byproduct only goes to reduce their plastic footprint within their market. As it stands, the FRAKTA bag might be the most energy efficient choice for IKEA as a company, and it’s become one of the most energy efficient bags on the market today as it’s mostly safe, affordable, mainly made from byproduct, reusable, and trendy.

In order to talk about ideas on energy within the making of the IKEA FRAKTA bag, we must dwell into the ideas of IKEA as a whole as the bag is simply just another part of the entire business, a business that stands to produce goods in an almost universal way. IKEA is able to keep the cost of manufacturing and transportation very low due to their marketing strategies and general beliefs. IKEA mostly uses recycled and sustainable goods to produce their products, which means that they are not expanding as much of their expenses in order to purchase new plastics and have them shipped. By having the customers assemble the furniture themselves, they are able to ship their products out in pieces which makes for a smaller overall package. Such is the reason why most of the furniture you buy at IKEA normally comes in a flat box. With this, they are able to load more products in their shipments and lower the overall cost for customers as the convenience of assembling it is not there. IKEA also has contracts with a lot of their manufacturers, a lot of which abide towards IKEA’s regulations of sourcing from ethical and recycled goods. At the warehouses, IKEA sorts their products by presenting their best sellers more and having their slow movers in the back and in other storage facilities. By doing this, they are able to reduce storage and handling costs of items that don’t sell as well – it also provides for a very fast moving product line in their main stores, which makes for very efficient marketing.

All of this ties towards the ideas behind the FRAKTA bag as the iconic bag has become such a staple within IKEA and what the company itself stands for. Everyone knows of the bag, that big, blue and boxy design, the texture of it, the yellow lettering on the handle with the zipper in the middle. The bag itself has become a part of the shopping experience within all IKEA stores. That being such, the FRAKTA bag itself reflects a lot of the company’s ideals. Being that IKEA works with a lot of plastic products, be it recycled, the production of their products expands a lot of heat energy, turning a good amount of their materials into gas and byproducts. Gas propylene is apparent within the production of their products, that of which gets turned into polypropylene fiber, also known as olefin. Today, olefin makes up for 16% of all fabric production in the world. With the amount of products IKEA makes, using a byproduct material to produce their bags is a very good strategy as it cuts their total waste down while eliminating the need to source their bags in any other way.

Olefin itself is actually a very green product. It comes from byproduct, which already reduces a wasteful footprint. Not only that, it takes a lot less energy to produce compared to other fabric materials like cotton, linen, and wool. Within the production of olefin, there is no need to water and grow anything, and this also takes a lot less space and labor. Olefin is manufactured by melting two chemicals (ethylene and propylene) and feeding that mixture through a spinneret in order to make the strands. This production is very eco-friendly and barely has any byproduct which in turn means there is very little waste left over. Olefin is a very durable fabric material as it is mostly weatherproof, harder to tear as it is oil based, and its colors do not fade as easily. If anything, IKEA’s choice to make a bag from olefin has helped reinforce its quality standards to a very high point. Because of everything mentioned above, olefin is one of the most affordable fabrics to produce, which goes to show IKEA’s ideals of cutting overall costs and expenses with energy. The FRAKTA bag itself is as foldable as it is expandable, as many customers have been able to tell. With this idea, IKEA is able to ship out many more bags within a single trip. It is also very convenient in the customer’s house, as it is very easy to pack away and store.

That being said, IKEA’s production of their FRAKTA bags do come at an expense, be it almost as minimal as can be. There are many details behind the production of a bag, from the production of the fabric itself to the sewing and building of the bag to the transportation of it and even more.

The production of polypropylene itself is a bit of a complicated process. As stated, the fibers are made from melting chemicals and feeding them through machines. This process takes a lot of electricity as well as some fossil fuels depending on the method used to make it. The binding and making of the chemical oil based fabric itself is a chemical process. The extraction of crude oil from recycled products and byproducts in order to make such a fabric also takes a lot of chemical and electrical energy. Being that it is an oil based product, the fabric itself is very difficult to dye once it forms; because of this, solution based dyes are needed within the production process, that of which also takes a good amount of chemical, thermal and electrical energy to produce. Surely IKEA tries to find a fairly sourced and ethical way to obtain these chemical dye solutions through a contract, but that information is yet to be released to the public.

Moving forward from that, the assembling of the bags themselves takes a very hefty amount of energy to produce at the level that they have been at. From the manual labor in cutting the fabric to using industrial sewing machines to sew them together to screen printing the logos onto the bags, this process takes a significant amount of electrical energy in order to finish the production of the FRAKTA bag. The machines themselves also take a good amount of oil as well as electricity in order to run smoothly.

Other parts of the manufacturing process also need to be considered, such as the packaging and transportation of the FRAKTA bags from the factories into the warehouse stores and eventually into the customer’s hands. Producing the cardboard itself to package everything also takes a lot of mechanical and electrical energy as well as a good amount of labor. IKEA probably has a contractor to handle the production of cardboard boxes for them, but that company in itself is probably using a lot of energy, and IKEA by extension. With IKEA being one of the top fifty brands in the world, owning over four hundred stores in fifty countries, IKEA’s manufacturing progress should take a very hefty portion of their total energy usage, be it that they are making great efforts in order to keep these costs and expenses at a minimum.

That being said, with all of IKEA’s efforts to practice sustainability and cutting down energy usage, they are doing a great job at what they do. IKEA has been able to reduce their overall carbon footprint by a monumental amount by implementing the use of the FRAKTA bag within stores. They had been projected to reduce the use of plastic bags within their stores by fifty percent within the first year of the new implementation, and have since stomped over that amount by a very considerable margin, being able to reduce about ninety-five percent of their total usage of plastic bags to this day.

Upon further research, IKEA is currently making a plan to phase out their use of plastic consumer packaging and are looking into viable alternatives like using paper to package most of their merchandise. Of course, they will still be using plastics for their food packaging for safety reasons, but this step towards reducing their plastic waste seems to be very significant for their ideals as a brand and company. To hold up this promise, however, would take a lot of mechanical and chemical energy in order to produce as much paper as they should be.

In any case, a good point can be made to say that IKEA’s efforts on reducing plastic and energy waste makes it so they can produce almost double the amount of any other brand as big as them and use about the same amount of energy and resources. With a brand as big as IKEA, most loyal customers would be happy to say that they are avid supporters of the company’s causes and would not rather buy from any other brand.

In conclusion, IKEA’s FRAKTA bag could quite possibly be one of the most energy efficient products along with much of IKEA’s market. The bag is durable, trendy, affordable, and sustainable. Though the FRAKTA bag does come with its own hefty cost of energy use from the extraction of crude oil to make the material, to the production, manufacturing, and transportation of the product, it still stands to be a very optimal decision by IKEA. Situations could be much worse here but simply are not, and that is what makes the FRAKTA bag one of the most energy efficient bags on the market today.

Sources:

“Frakta Shopping Bag, Large, Blue, 19 Gallon.” IKEA, https://www.ikea.com/us/en/p/frakta-shopping-bag-large-blue-17228340/

Staff, Creative Mechanisms. “Everything You Need to Know about Polypropylene (Pp) Plastic.” Everything You Need To Know About Polypropylene (PP) Plastic, https://www.creativemechanisms.com/blog/all-about-polypropylene-pp-plastic#:~:text=Polypropylene%20(PP)%20is%20a%20thermoplastic,like%20living%20hinges%2C%20and%20textiles.

“Frakta Shopping Bag, Large, Blue, 19 Gallon.” IKEA, https://www.ikea.com/us/en/p/frakta-shopping-bag-large-blue-17228340/.

“Polyethylene Terephthalate.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/science/polyethylene-terephthalate

Gibbons, James. “What Is Polypropylene Fabric?” Revolution Fabrics, Revolution Fabrics, 20 Jan. 2020, https://revolutionfabrics.com/blogs/gotcha-covered/what-is-polypropylene-fabric#:~:text=What%20is%20Polypropylene%20made%20of,oil%20and%20natural%20gas%20facilities

Water, Path. “What Exactly Is Pet Plastic?” PathWater, PathWater, 20 Mar. 2019, https://drinkpathwater.com/blogs/news/what-exactly-is-pet-plastic

“Polyethylene Terephthalate.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/science/polyethylene-terephthalate

Sewport. “What Is Polyester Fabric: Properties, How Its Made and Where.” Sewport, Sewport, https://sewport.com/fabrics-directory/polyester-fabric#:~:text=Polyester%20is%20a%20synthetic%20fabric,within%20the%20ester%20functional%20group

“Supplier Upgrading in the Home-Furnishing Value Chain: An Empirical Study of IKEA's Sourcing in China and South East Asia.” World Development, Pergamon, 24 July 2010, https://www.sciencedirect.com/science/article/pii/S0305750X10001154

Arrigo, Elisa. “Corporate Responsibility and Hypercompetition:the IKEA Case.” SSRN, 8 Feb. 2013, https://deliverypdf.ssrn.com/delivery.php?ID=223117004126125093065065113089014018056013034051087067098002113113091069068013002006012058017121015012035003006080098112124114039069054051084086083113124102105088070061093042100068121119087094119074113088109083018094023087106116106019097079021000068124&EXT=pdf&INDEX=TRUE

“Material Connexion.” Material ConneXion, 24 Nov. 2021, https://materialconnexion.com/

Adam ShrumAdam is the Assistant Director of Operations at Dynamic Inventory. He has experience working with retailers in various industries including sporting goods. “Inside IKEA's Supply Chain & Inventory Management.” Dynamic Inventory, 3 Jan. 2019, https://www.dynamicinventory.net/ikea-supply-chain-management/.

“[Node:Title].” CSRWire, https://www.csrwire.com/press_releases/16622-ikea-u-s-bag-the-plastic-bag-initiative-asks-customers-to-stop-plastic-bag-waste.

“IKEA to Phase out Plastic from Consumer Packaging by 2028.” About IKEA, 23 Nov. 2021,https://about.ikea.com/en/newsroom/2021/11/17/ikea-to-phase-out-plastic-from-consumer-packaging-by-2028.

Becca Libby

Professor Cogdell

DES40A

15 March 2023

Life Cycle of an Ikea Frakta Shopping Bag: Waste and Emissions

Ikea, the Swedish multinational conglomerate, takes pride in its classic, blue Frakta shopping bag composed of 60% recycled plastic: a nod to sustainability present throughout Ikea’s mission statement. However, plastic is inherently detrimental to the environment, as production and decomposition produce toxic wastes and byproducts. A closer look at the Frakta life cycle reveals the inefficiencies in manufacturing and recycling processes that contribute to waste and pollution. Regardless, its favorable properties — like durability and relatively low price — explain why the material is popular among manufacturers and consumers. The Frakta bag exposes the shared blame between the pitfalls of plastic as a material and the faulty systems that process it, as both components heighten environmental issues. Even though the Frakta incorporates recycled material, the bag still contributes to global pollution by degrading into toxic microplastics; the manufacturing and shipping process releases carbon emissions and creates harmful byproducts.

Despite marketing tactics and public perception, post-consumer-based products are still guilty of environmentally degrading raw material acquisition process that produces the secondary raw material — as with Ikea’s Frakta shopping bag, partially composed of recycled plastic bottles. Some may argue that products incorporating recycled plastic skew the global perception of plastic as a semi-sustainable material due to its capacity for recycling. The harsh reality is that plastic is unsustainable in every sense. For starters, the raw material acquisition to create pure plastic produces harmful wastes and byproducts. The main constituent for the Frakta is the thermoplastic called Polypropylene (PP), a waste product of natural gas and oil processing (1). The sequestration of natural gas and oil entails environmentally damaging practices such as fracking and drilling, which leak cadmium, arsenic, chromium, lead, and mercury into soil and waterways; also, the fracking fluid itself pollutes drinking water. Next, the crude oil and natural gas travel to a refinery and undergo processing that releases toxic flue gas into the atmosphere. Although the flue gas passes through scrubbers — waste treatment installations — that remove major pollutants like ammonia and chloride, it still releases carcinogenic BTEX compounds that pollute the air. Like virgin plastic, the post-consumer plastic present in the Frakta derives from petroleum. Oil sequestration is still a central component of both pure and recycled plastics, even if the dominant primary material in the bag stems from recycled polypropylene-based plastic water bottles.

Converting fossil fuels into plastic is a very energy-intensive process; once the material transforms, high melting points and inefficient fuel sources for machinery contribute to large amounts of waste and harmful outputs. Once propylene gas, a byproduct of the refinery process, is produced through catalytic cracking of gas oils (2), it undergoes polymerization to produce polypropylene-based plastic: the sole component of the Frakta shopping bag (3). First, the polymer is fed through an extruder and takes the shape of small pellets, which later undergo injection molding. Some polypropylene spins when melting to produce the thread that lines the top of the bag and handles. It is difficult to determine the precise fuel source for the extruder since Frakta production occurs across multiple countries with different natural resources. That said, Ikea cites its Vietnam factory as the largest producer of the Frakta. About half of the energy in Vietnam comes from coal, which powers energy-intensive plastic extruders to 400F: the approximate lowest temperature to melt polypropylene. Coal is an inefficient fuel source, as 56% of the energy from coal is lost through heat when burned to generate power. The combustion of fossil fuels for energy releases carbon dioxide, water vapor, sulfur oxides, and nitrogen oxides into the atmosphere. Before the pure or recycled polypropylene melts through an extruder, the plastic mixes with pigments and dyes that produce the vibrant blues in yellows in the bag. Excess disperse dye (the type that binds to plastics) discharges as wastewater into lakes and rivers bordering factories, leading to anaerobic conditions characterized by disturbances in dissolved oxygen levels as a byproduct of reduced photosynthesis from aquatic plants. The dye in the water blocks UV radiation, hindering photosynthesis and disrupting entire ecological cycles and even water purification due to the lack of oxygen in the water. The final consumer version of the Frakta Bag does not release any waste in its use phase. Regular maintenance does not produce waste either; cleaning the bag is a simple wipe-down with a damp cloth. That said, old and heavily-used bags may break, releasing bits of microplastics into the environment as the synthetic fabric frays. Designers and regular consumers alike repurpose old and broken Frakta bags into accessories like bucket hats, apparel, and even face masks: transforming waste that would otherwise end up in landfills into a usable product.

Although the use of post-consumer plastic reduces the demand for virgin plastic, shipping the plastic bottles to and away from recycling centers adds additional steps to the transportation phase, thus increasing the carbon footprint of the Frakta bag from transportation. Additionally, transforming crude oil into polypropylene requires multiple different modes of transportation. The raw fossil fuels that compose the pure plastic in the bag — made from the polymerization of petroleum — travel through underground pipelines to reach the refinery. Due to natural erosion, they occasionally leak, seeping crude oil and natural gas into the environment. Crude oil, in particular, sticks to most objects, harming wildlife and contaminating water sources. In rare cases, the pipeline ruptures, triggering an explosion that releases methane into the atmosphere: a greenhouse gas perpetuating climate change (4). Once the fossil fuels are processed in the refinery and undergo polymerization, the secondary raw material — plastic pellets — travel to Ikea factories for further production. I could not find specific information about how Ikea transports its plastic pellets. However, plastic pellets commonly source from China, and most Frakta bags derive from Vietnam — given the distance the pellets most likely travel by truck or train (5). These modes of transportation involve fossil fuel-based vehicles that emit greenhouse gasses — like carbon dioxide and carbon monoxide — into the atmosphere. Once assembled, the bag travels on container ships to store locations in 63 countries. Besides gas emissions, container ships release biocides and waste from human activities (like sewage and garbage) into the ocean (6). The transportation phase continues once the consumer reaches the product. The Frakta bag is purchased in-store or ordered online. Usually, the bag progresses to the consumer via truck or car: releasing more greenhouse gasses through gas-powered vehicles, which vastly outnumber electric vehicles. Once the consumer disregards the product, the Frakta bag travels to a landfill (or sometimes a recycling facility) by garbage truck — yet another CO2-emitting vehicle. As demonstrated in the next paragraph, once the bag reaches the landfill, the life cycle continues as the product degrades into harmful microplastics.

Polypropylene (PP) plastic does not react with acids, bases, or detergents; because of these properties, it takes a long time to decompose. PP takes around 20 to 30 years to break down in a landfill, but some sources suggest that traces of the material will remain intact in landfills for 200 to 450 years (7). The decomposition process breaks down the Frakta bag into tiny microplastics that sea animals may ingest, as microplastics from landfills typically end up in or around the ocean. The National Institute of Health outlines the presence of “persistent organic pollutants such as polychlorinated biphenyls (PCBs), polycyclic aromatic hydrocarbons (PAHs), and organochlorine pesticides” that bind to polypropylene, thus contaminating the plastic (8). The contamination alters the molecular structure of the plastic, producing stiff and brittle polypropylene as a byproduct of the weathering process (9). Contamination from weathering in the natural environment contributes to the difficulties associated with the recycling process. Contamination prevents manufacturers from recycling PP into usable plastic for new products. Therefore, even though the plastic in the Frakta is technically recyclable, weathering and contamination produce undesirable plastic that contributes to global pollution; some deteriorated plastic is in too bad of a state to be economical to recycle. However, there are processes to sort through contaminated plastic, like sink-float separation. Through this process, discrepancies in densities separate large amounts of PP plastics from other mixtures of plastics and contaminants (10). The polypropylene is then washed with specialized detergents and shredded to prepare for the extruder. I could not find any specified information as to the chemical composition of these detergents, but I can infer that these chemicals create wastewater that exacerbates the pollution of waterways. As mentioned in the manufacturing stage, the extruder (and accompanying processing steps) melt the recycled water bottles into usable plastic and utilizes fossil fuels that release carbon dioxide and other pollutants into the atmosphere.

Even though the previous points suggest otherwise, Ikea as a company attempts to monitor its waste and enact sustainable measures whenever possible. The environmental impact of the Frakta speaks more to the downsides of plastic than Ikea as a company. That said, the future of sustainable product design lies in alternative materials — like bacteria and fungi — that can step in as an alternative to plastic. Ikea and manufacturers as a whole have a shared responsibility for the environmental impact of plastic and should invest time and money into exploring alternative sustainable materials.

Sources:

(1) Gibbons, James. “What Is Polypropylene Fabric?” Revolution Fabrics, Revolution Fabrics, 20 Jan. 2020, https://revolutionfabrics.com/blogs/gotcha-covered/what-is-polypropylene-fabric#:~:text=What%20is%20Polypropylene%20made%20of,oil%20and%20natural%20gas%20facilities.

(2) “IARC Monographs on the Evaluation of Carcinogenic Risks to Humans.” Analytica Chimica Acta, vol. 336, no. 1-3, 1996, pp. 229–230., https://doi.org/10.1016/s0003-2670(97)89591-8.

(3) Nikolovska, Gracija. “All about Polypropylene: How It's Made and Used.” Xometrys RSS, Xometry, 24 June 2022, https://www.xometry.com/resources/materials/polypropylene/.

(4) Krosofsky, Andrew. “Here's How Pipelines Directly Affect the Environment, Wildlife, and Human Beings.” Green Matters, Green Matters, 8 Feb. 2021, https://www.greenmatters.com/p/why-are-pipelines-bad.

(5) The Story of a Beloved Ikea Bag.” IKEA Museum, Inter IKEA Systems, 11 Nov. 2022, https://ikeamuseum.com/en/digital/the-story-of-ikea/beloved-bag/.

(6) mcraft2016. “Cargo Ships Are Cleaning up Smog - by Dumping Pollution into the Seas.” Grist, 25 May 2021, https://grist.org/transportation/cargo-ships-are-cleaning-up-smog-by-dumping-pollution-into-the-seas/.

(7) Admin. “Does Plastic Decompose? How Long Does It Take?” Maesindo Paper Packaging, 24 Sept. 2020, https://maesindopaperpackaging.com/does-plastic-decompose-how-long-does-it-take/.

(8) Smith, Madeleine, et al. “Microplastics in Seafood and the Implications for Human Health.” Current Environmental Health Reports, U.S. National Library of Medicine, Sept. 2018, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6132564/#:~:text=In%20addition%20to%20additive%20chemicals,pesticides%20like%20dichlorodiphynyltrichloroethane%20(DDT)%20or.

(9) Karaagac, Erdal, et al. “Polypropylene Contamination in Post-Consumer Polyolefin Waste: Characterisation, Consequences and Compatibilisation.” MDPI, Multidisciplinary Digital Publishing Institute, 6 Aug. 2021, https://www.mdpi.com/2073-4360/13/16/2618.

(10) Basham, Kevin. “How Is PP Plastic Recycled?: Plastic Recycling.” Plastic Expert, 27 Jan. 2023, https://www.plasticexpert.co.uk/how-is-pp-plastic-recycled/#:~:text=One%20of%20the%20problems%20with,the%20quality%20of%20the%20material.

IWAY – IKEA Supplier Requirements, Inter IKEA Systems B.V. , https://about.ikea.com/en/work-with-us/for-suppliers/iway-our-supplier-code--of-conduct.

Mannheim, Viktoria, and Zoltan Simenfalvi. “Total Life Cycle of Polypropylene Products: Reducing Environmental Impacts in the Manufacturing Phase.” Polymers, U.S. National Library of Medicine, 24 Aug. 2020, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7563104/.

Staff, Creative Mechanisms. “Everything You Need to Know about Polypropylene (Pp) Plastic.” Everything You Need To Know About Polypropylene (PP) Plastic, Creative Mechanisms, 6 May 2016, https://www.creativemechanisms.com/blog/all-about-polypropylene-pp-plastic#:~:text=Polypropylene%20(PP)%20is%20a%20thermoplastic,like%20living%20hinges%2C%20and%20textiles.