Design Life-Cycle

assess.design.(don't)consume

Zavala 1

Chiara, Zavala

Eunice Fulgueras, Jennifer De Jesus

DES 40A

Professor Cogdell

YETI Rambler Bottle - Raw Materials

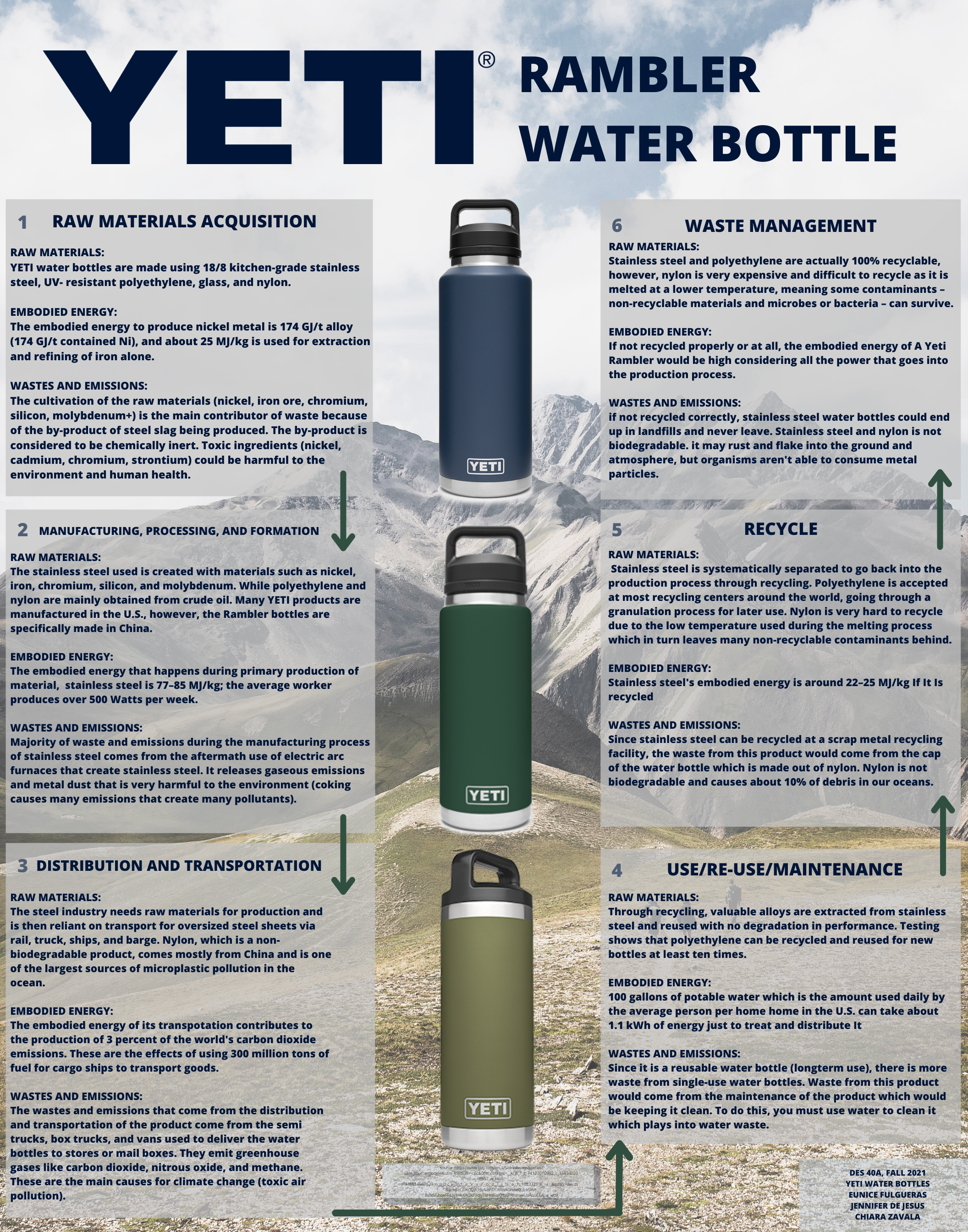

Through this research paper focusing on the life-cycle of designs, I decided to focus on the raw materials that go into producing the YETI Rambler water bottle. These bottles are made from materials such as 18/8 kitchen-grade stainless steel, UV-resistant polyethylene, and nylon. This brand is highly revered by the public as they are known for producing high-quality reusable water bottles and cooler products that offer long-lasting temperature protection for any kind of food and beverage while also ensuring a more sustainable alternative to single-use plastic bottles. The YETI brand is one that has gained a lot of popularity and cult followings over the last couple of years since its initial release in 2006. I myself own multiple YETI products and prefer them over competing brands such as Hydro Flask due to its proven quality and durability. All YETI bottles are manufactured to be dishwasher safe, featuring double-walled vacuum insulated technology which ensures that whatever beverage is placed in the bottle, will remain at your desired temperature. But as many people wonder before purchasing their first YETI product, what makes this 50 dollar water bottle better than other cheaper alternatives? And the answer is the quality of materials used during production. Throughout this essay, I will be arguing that although the YETI Rambler is a great sustainable alternative in comparison to plastic bottles, the raw materials that go into producing them can still cause long-lasting negative effects on the environment.

Zavala 2

The YETI Rambler water bottle is built using 18/8 food-grade stainless steel, which when broken down, is made up of iron ore, chromium, nickel, carbon, silicon, nitrogen, molybdenum, zirconium, and titanium. When these basic elements are fused together under extreme heat, they create a powerful and versatile alloy such as stainless steel. 18/8 stainless steel, also known as Type 304 stainless steel, is one of the most commonly used grades of steel used for food preparation and serving. The first number, 18, is representative of the amount of chromium that can be found within the stainless steel, while the second number, in this case, 8, represents the amount of nickel. This makes the stainless steel used in the production of the YETI Rambler, 18% chromium and 8% nickel. This type of stainless steel is mostly made up of at least 50% iron ore and no more than 0.8% carbon. The percentage of chromium found within the steel is what binds oxygen to the surface of the product in order to protect the iron ore from any oxidation. The nickel present also works to enhance the corrosion resistance of the stainless steel, therefore, the higher the nickel content, the more resistant the steel from corrosion. The outside of the YETI Rambler is made using UV-resistant polyethylene, which is a type of hard plastic. This plastic is made up of hydrocarbon chains that exhibit both of their most basic components to be the ethylene molecule, which consists of two carbon and four hydrogen atoms. When these ethylene molecules are combined, they create polyethylene. Polyethylene is a weather-resistant and BPA-free material, however, it can easily become brittle when exposed to sunlight and heat for extended periods of time, which defeats the entire purpose of the YETI Rambler. To combat this and make their products extremely resistant to extreme weather conditions, YETI uses the addition of UV stabilizers. In terms of aesthetics, polyethylene has a naturally white color to it, making it easy to add colors and therefore create the broad range of shades that YETI offers. Lastly, YETI lids are made using nylon and glass. Nylon is a stiff and strong plastic that can

Zavala 3

typically be found within engineering applications to replace metal bearings, eliminating the need for any external lubrication. There are different types of nylons that belong to a family of materials called polyamides, which are made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure and heated environment. This chemical reaction, known as condensation polymerization, forms a large polymer in the form of a large sheet of nylon. Despite nylon being a very durable material, it is a plastic derived from crude oil, which is a non-renewable resource.

The ability to recycle a product after you are through using it is a very important feature that can often be overlooked due to mass production and consumption. For the most part, the individual parts that are used to create YETI Rambler bottles can be recycled, this includes stainless steel and polyethylene. However, it is extremely difficult and expensive to recycle the YETI bottle once the final product has been produced. This is due to the fact that traditional recycling programs will not recycle them for you, taking away the aspect of accessibility. Common recycling programs will not recycle the final product as they typically crush and bale all leftover materials for easy transportation, however, YETI bottles are meant to withstand the impact of a moving car, so, therefore, are extremely difficult to crush down. The raw materials themselves, however, are recyclable. For example, when stainless steel is recycled there are valuable alloys extracted that can be reused multiple times with no degradation within the performance of the product. Likewise, following the granulation process of recycled polyethylene, it can be reused to make new water bottles at least ten separate times. Alternatively, nylon, which is the material used to make the lids, is very difficult to recycle due to the fact that it is melted down at a very low temperature to avoid burning, which in turn does not kill or remove many of the non-recyclable contaminants within the material. Many YETI

Zavala 4

products, such as their coolers, are manufactured inside the United States, however, the Rambler bottles are specifically made in their Chinese manufacturing companies overseas. The largest manufacturer of these products in China is Shenzhen Zhizhen Technology Co., Ltd. China also dominates the world production of nylon filament which is later used in the process of making nylon plastics for the bottle caps. Nylon, a non-biodegradable product that comes mostly from China, is also, unfortunately, one of the largest sources of microplastic pollution found in the ocean as it continues to break down but never fully disappears. Because China is the main manufacturer of our product, we must also consider the materials that go into transporting it to large suppliers within the United States. Coming all the way from China, the quickest and most efficient way to transport the YETI Rambler is through aircraft. Large cargo planes rely on jet fuel to get them from one place to another. Jet fuel is based on either unleaded kerosene or a naphtha-kerosene blend, naphtha being a flammable liquid from distilling petroleum. It is created by distilling petroleum, and it's a common component of both gasoline and kerosene. After arriving in the United States, the YETI rambler must then be shipped to retailers around the country, predominantly by cargo planes and trucks. The majority of trucks that are currently in use are still powered by diesel engines. Diesel fuel is made from crude petroleum and small amounts of sulfur, nitrogen, and oxygen, which are called heteroatoms, are often present in this fuel. Besides the raw materials that are used to make the YETI Rambler, there are many other raw materials that go into other factors such as manufacturing and transporting the product.

In terms of use, re-use, and maintenance, the YETI Rambler holds up in terms of its quality and durability. Because of its size, the YETI Rambler is most commonly used for water, although you can definitely fill it up with any beverage of your choice. The YETI brand makes so many options in terms of drinkware that are specifically marketed towards one beverage, such

Zavala 5

as coffee, tea, wine, and even beer and seltzers. In my personal experience, once you buy one YETI product you want to buy them all because of how well they perform under any sort of condition. YETI is constantly coming out with new collections and colors that entice YETI users to continue to buy more and more of their products. Despite already owning two Rambler water bottles myself, I jumped to repurchase once I saw the limited edition launch of their new color ‘Prickly Pear Pink,’ an over-the-top hot pink shade. The quality of this product stands up against my own personal test of filling it up with ice water in the morning and leaving it on my dorm room desk, only to return at night and find it full of just as many ice cubes. All in all, this is a very reliable product and I would highly recommend it if you are looking for a high-quality sustainable alternative to single-use plastic water bottles. In terms of sustainability, YETI water bottles are definitely a step in the right direction, as it drastically reduces the amount of plastic waste going back into the environment. While the product itself is a great alternative, the raw materials that go into making it could definitely be more environmentally friendly, such as nylon. Nylon is extremely difficult to recycle, meaning that YETI caps will continue to float around our landfills and oceans as it is difficult to repurpose them and easy to simply throw away. Stainless steel and polyethylene, while easy to recycle in their respective parts, become very difficult to separate and recycle once in the final product. We are a long way from creating an even more sustainable and semi-affordable product, however, the YETI brand has been doing a really good job at bringing awareness to environmental causes. As a whole, this water bottle is a great option as a product, however, its remnants can and will continue to cause harm to our environment.

Through my research of the raw materials that go into creating the YETI Rambler, I have been able to garner a stronger understanding of what exactly goes into harvesting, producing, and transporting the materials for this product. I have learned that while many parts of the YETI

Zavala 6

Rambler offer a sustainable alternative, there are still many pieces to the equation that will negatively affect our environment. I believe that the brand itself is doing a really good job at raising awareness towards larger causes such as climate change, however, many parts of the process are still adding to the overall issue.

Zavala 7

Resources

Alexandru, Moisă Bogdan. “Stainless Steel the Environment-Friendly Choice .” Advances in Control, Chemical Engineering, Civil Engineering and Mechanical Engineering ISBN: 978-960-474-251-6 159.

Bach, Cristina, et al. “Chemical Compounds and Toxicological Assessments of Drinking Water Stored in Polyethylene Terephthalate (PET) Bottles: A Source of Controversy Reviewed.” Water Research, Pergamon, 6 Dec. 2011,

https://www.sciencedirect.com/science/article/pii/S0043135411007548.

“Discover Research from Ryerson University.” Ryerson University,

https://rshare.library.ryerson.ca/.

Broadbent, Clare. “Steel’s Recyclability: Demonstrating the Benefits of Recycling Steel to Achieve a Circular Economy.” The International Journal of Life Cycle Assessment, vol. 21, no. 11, 2016, pp. 1658–1665., https://doi.org/10.1007/s11367-016-1081-1.

De la Puente, G. “Conversion of Waste Plastics into Fuels Recycling Polyethylene in FCC.” Applied Catalysis B: Environmental, vol. 36, no. 4, 2002, pp. 279–285., https://doi.org/10.1016/s0926-3373(01)00287-9.

Fan, Ying-Ying, et al. “Effects of Storage Temperature and Duration on Release of Antimony and Bisphenol A from Polyethylene Terephthalate Drinking Water Bottles of China.” Environmental Pollution, Elsevier, 6 June 2014,

https://www.sciencedirect.com/science/article/pii/S0269749114002000.

Johnson, Jeremiah, et al. “The Energy Benefit of Stainless Steel Recycling.” Energy Policy, Elsevier, 18 Oct. 2007,

https://www.sciencedirect.com/science/article/pii/S0301421507003655.

Lloyd, Alan C., and Thomas A. Cackette. “Diesel Engines: Environmental Impact and Control.” Journal of the Air & Waste Management Association, vol. 51, no. 6, 2001, pp. 809–847., https://doi.org/10.1080/10473289.2001.10464315.

Marchi, Elisa De, et al. “Plastic Packaging Goes Sustainable: An Analysis of Consumer Preferences for Plastic Water Bottles.” Environmental Science & Policy, Elsevier, 12 Sept. 2020, https://www.sciencedirect.com/science/article/pii/S1462901120303300.

“Migration of Bisphenol A from Polycarbonate Baby and Water Bottles into Water under Severe Conditions.” ACS Publications, https://pubs.acs.org/doi/10.1021/jf800870b.

Palmer, Robert J., and Updated by Staff. “Polyamides, Plastics.” Kirk-Othmer Encyclopedia of Chemical Technology, 2005,

https://doi.org/10.1002/0471238961.1612011916011213.a01.pub2.

Zavala 8

Song, Chunshan. “An Overview of New Approaches to Deep Desulfurization for Ultra-Clean Gasoline, Diesel Fuel and Jet Fuel.” Catalysis Today, vol. 86, no. 1-4, 2003, pp. 211–263., https://doi.org/10.1016/s0920-5861(03)00412-7.

Song, Ke, et al. “Microparticles and Microplastics Released from Daily Use of Plastic Feeding and Water Bottles and Plastic Injectors: Potential Risks to Infants and Children in China.” Environmental Science and Pollution Research, Springer Berlin Heidelberg, 19 June 2021, https://link.springer.com/article/10.1007/s11356-021-14939-7.

De Jesus 1

Jennifer De Jesus

Chiara Zavala, Eunice Fulgueras

DES 40A

Professor Cogdell

Life Cycle of Yeti Rambler: Energy

The need for sustainable measures are urgently being pursued in consequence of the environmental crisis that has been brought upon us as a direct result of capitalistic ventures. Because of this, consumers have found an ethical urge to purchase environmentally friendly water bottles as a way to alleviate this environmental distress. This is not to say consumers are at fault, but rather to point out that most of the population is becoming aware of the climate crisis and planning to fight it somehow whether their contribution be big or small. For some consumers, that choice is the Yeti Rambler Waterbottle. Yeti is an American company first founded in 2006 to promote coolers but then eventually leading itself into the water bottle market. Yeti is built on a model of focusing on the needs of consumers rather than the need to produce. This would make a fan of this product feel good of course, but is the user fully aware of how labor intensive it is to make a Yeti Rambler and the effects its production process has on the environment? Through the understanding of the embodied energy a Yeti Rambler Waterbottle produces, we are able to determine the negative effects it causes throughout the different stages of its life-cycle from when it is first in production, to observing the long term effects of its energy of use and materials as well as waste management.

The energy input that goes into the life-cycle of a Yeti Rambler is significantly important, especially now in a time where we have to be fully aware of the environmental consequences producing a product may bring. Obviously most of the population does not have the time to be

De Jesus 2

conducting extensive research on a product they just purchased. For this reason, it is important we step back in this paper and truly evaluate the quantities of embodied energy that go into all aspects of production. It is critical to have a conversation about the effects as most companies are not fully transparent with their life-cycle process or make the information available to the public. How can consumers make sure they are purchasing ethically when buying a Yeti Rambler water bottle? Although disappointing, it is no surprise that the life-cycle of a Yeti Rambler or any research in regards to it has not been conducted, giving more reason to why this information is of value.

When discussing the life-cycle of the Yeti Rambler Waterbottle, discussing its raw materials acquisition is crucial to the understanding of its embodied energy. Yeti Ramblers are manufactured from 18/8 stainless steel, also known as kitchen grade stainless steel. Like most bottles made from stainless steel, this is one of the main materials used in its manufacturing process. Therefore, it's important to discuss that grade 18/8 steel is made up of 18% chromium and 8% nickel; then it is added to about 0.8% of carbon and about 50% iron according to Grades of Stainless Steel & What They Mean for Your Foodservice Operation. 1 According to the article, Alternative routes to stainless steel-a life cycle approach, the total energy consumption produced by stainless steel production is about 50% higher than when nickel is obtained as the nickel source. This is about 75 MJ/kg cf. 49 MJ/kg.2 The embodied energy of steel production during its primary production comes to 77–85 MJ/kg.3The article also states that perhaps if some things were altered during some of the smelting stages of steel production, then it would be possible to

1 Marketing, G.E.T. Grades of Stainless Steel & What They Mean for Your Foodservice Operation,

https://blog.get-melamine.com/stainless-steel-grades-what-they-mean-for-your-restaurant.2 Norgate, Terry & Jahanshahi, Sharif & Rankin, William. (2004). Alternative routes to stainless steel-a life cycle approach.

3 Ahmad, Nabeel, and Emmanuel Ugo Enemuoh. “Energy modeling and eco impact evaluation in direct metal laser sintering hybrid milling.” Heliyon vol. 6,1 e03168. 16 Jan. 2020

De Jesus 3

reduce the total energy of steel production. The energy required to produce nickel metal alone already comes to 174GJ/t alloy (174 GJ/t contained Ni).4 For iron about 25 MJ/kg of energy is used; this accounts for both the extraction and refinement of the metal.5 Studies show that over 52 million tons of steel are produced globally in any given year.6 After the raw materials are acquired, the use of electric energy is needed in order to power the gas-powered furnaces that are needed in the steel production process. The need for good quality stainless steel required the elimination of any excess carbon that could be on it. This requires the use of a vacuum chamber where only the power from the vacuum pumps comes to a power consumption of 50-100W.7,8

Not much information is stated about the materials used for the caps on the Yeti Rambler also known as “chug caps” on their website. However, based on research we were able to determine that their chug caps are made out of nylon. Most information focuses on the embodied energy that comes from the production of nylon fibers which is 250 MJ per KG of fiber.9 Though this process was already intensive, it is just the beginning of an energy intensive process.

After we take a look at the damage that is done with just acquiring the raw materials alone, we can now discuss the energy input that must go into the manufacturing, processing and formulation of the Yeti Rambler water bottle. Though the design of the Rambler bottle is not too intricate, the manufacturing process is highly labor intensive. All Yeti Ramblers are

4 Wei, Wenjing, et al. “Energy Consumption and Greenhouse Gas Emissions of Nickel Products.” Energies, vol. 13, no. 21, 2020, p. 5664., doi:10.3390/en13215664.

5 Haque, N., and T. Norgate. “Life Cycle Assessment of Iron Ore Mining and Processing.” Iron Ore, 2015, pp. 615–630., doi:10.1016/b978-1-78242-156-6.00020-4.

6 An Introduction to Stainless Steel and How It's Made.” Monroe Engineering, 22 Feb. 2021, https://monroeengineering.com/blog/an-introduction-to-stainless-steel-and-how-its-made/ 7 “An Introduction to Stainless Steel and How It's Made.” Monroe Engineering, 22 Feb. 2021, https://monroeengineering.com/blog/an-introduction-to-stainless-steel-and-how-its-made/. 8 Sakamoto, K. “Vacuum Chamber.” Encyclopedia of Analytical Science, Second, 2005. 9 O Ecotextiles (and Two Sisters Ecotextiles). “Estimating the Carbon Footprint of a Fabric.” OEcotextiles, 31 Jan. 2012,

oecotextiles.blog/2011/01/19/estimating-the-carbon-footprint-of-a-fabric/.

De Jesus 4

manufactured in China, however it was not specified who their exact manufacturer is. Not only is it machine-heavy but it also requires the labor of humans to operate the machines. There are several manufacturers in China who focus on the production of stainless steel water bottles. Employee count in these companies range from 100-500+. For example, one manufacturer, Kingstar, has over 500+employees working during this process. Kingstar, is specifically in charge of the manufacturing process, testing, and transporting.10 With that being said,it is clear the embodied energy as a result would consist of the food the workers would have to intake in order to perform (thermal chemical energy). Assuming all the workers are also able to put out the average power of 100 Watts for the typical 8-hour work day then that would total to over 500 Watts per week per worker.11 That is also assuming they are putting in the average power only meaning that there would still be those workers with a higher power of Watts per week which is likely considering the importance of producing more and faster for most companies. Specific mechanical equipment is needed to initiate the process. Hydraulic press machines, Argon Arc Welding Machines and vacuum machines with tails are the major equipment needed to create a well-insulated stainless steel water bottle all of which also use electrical energy.12 Hydraulic Press Machines alone are very high in embodied energy. According to A Review on Energy Consumption, Energy Efficiency and Energy Saving of Metal Forming Processes from Different Hierarchies, more energy could be saved if more planning was done during the process not only

10 Agent, Numeriklire Sourcing. “Top 5 Stainless Steel Water Bottle Manufacturer in China.” Numeriklire China Product Sourcing Agent, 26 Jan. 2021,

www.numeriklire.net/top-5-stainless-steel-water-bottle-manufacturer-in-china/.11 LaBonta, Lo'eau. “Human Energy Converted to Electricity.” Stanford University, 6 Dec. 2014. 12 “The Main Mechanical Equipment for the Production of Vacuum Flasks.” Insulated Stainless Steel Water Bottle Manufacturer, 27 Oct. 2021,

https://www.waterbottle.tech/the-main-mechanical-equipment-for-the-production-of-vacuum-flas ks/.

De Jesus 5

for the sake of energy efficiency but also for better production outcomes.13It is clear this process could be handled more efficiently, instead the process could be more harmful for the environment than beneficial.

After the manufacturing, processing, and formulation of the product, it must be transported to its final destination in international stores. Transporting the finished Yeti Ramblers for them to be shipped off internationally. Clear and specific information on who exactly transports Yeti Rambler water bottles could not be found. However, we can assume they are transported in two ways: through cargo shipments or through airplanes. Most goods are transported through cargo ships, however, this uses about 300 million tons of fuel contributing to “3% of the world’s carbon dioxide emissions”.14 American Fuel states that “nearly two-thirds of U.S. oil consumption goes to road transportation, with more than two-thirds of that for gasoline and one-fourth for diesel fuel.”15 This is significant because in order for Yeti Ramblers to get to stores and people’s homes is through the use of transportation trucks which contribute to these negative effects.

Once the product is made and transported for sale, more energy is required not just to use it every single day but also to reuse and to maintain it. According to The Embodied Energy of Tap Water about 100 gallons of potable water can take about 1.1 kWh of energy just to treat and distribute it. It is important to keep in mind that potable water is the amount of water used daily

13 Gao, Mengdi, et al. “A Review on Energy Consumption, Energy Efficiency and Energy Saving of Metal Forming Processes from Different Hierarchies.” Processes, vol. 7, no. 6, 2019, p. 357., https://doi.org/10.3390/pr7060357.

14 Cowing, Henrik Selin And Rebecca. “Cargo Ships Are Emitting Boatloads of Carbon, and Nobody Wants to Take the Blame.” Phys.org, Phys.org, 18 Dec. 2018,

phys.org/news/2018-12-cargo-ships-emitting-boatloads-carbon.html.

15 Director, Sam Hananel Associate, et al. “American Fuel.” Center for American Progress, 5 Apr. 2007, www.americanprogress.org/article/american-fuel/.

De Jesus 6

at home in the U.S by the average person.16 The article also states that from drinking-water plants alone the following data contributes to the high embodied energy of water: “Raw water collection: 11%, In-plant pumping: 9%, Water treatment: 11%, Building operations: 2%, Water distribution: 67%.”17 This is significant as it contributes to the maintenance of the Yeti Rambler water bottle.

When the recycling process and energy that goes into the waste management process is reached in the life-cycle we begin to see the permanent consequences of producing Yeti Rambler water bottles could have on the planet. If not recycled properly or at all, the embodying energy of the water bottle would be high considering all the power that goes into the production process.18 However, if the stainless steel is recycled, then the embodying energy from recycling it would be around 22–25 MJ/kg.19If the nylon parts of the water bottle caps end up in the landfill it could have a serious negative impact on the environment. Plastics that end up in the landfills can release harmful chemicals that could spread into groundwater. It is also important to note that 4% of the world’s oil production is used in the process of making plastics harming the environment further.20

Having discussed the embodied energy a Yeti Rambler Waterbottle produces, we are able to determine how these negative effects to the environment are first introduced through the acquisition of its raw materials all the way to the end of its life cycle, recycling and waste

16 Melton, P. (2015, September 8). The Embodied Energy of Tap Water. Retrieved from https://www.buildinggreen.com/primer/embodied-energy-tap-water

17 Melton, P. (2015, September 8). The Embodied Energy of Tap Water. Retrieved from https://www.buildinggreen.com/primer/embodied-energy-tap-water

18 Johnson, Alissa (2015) "Recycling Energy: An Exploration of Recycling and Embodied Energy," Penn Sustainability Review: Vol. 1 : Iss. 6 , Article

19 Ahmad, Nabeel, and Emmanuel Ugo Enemuoh. “Energy modeling and eco impact evaluation in direct metal laser sintering hybrid milling.” Heliyon vol. 6,1 e03168. 16 Jan. 2020 20 Knoblauch, Jessica A. “The Environmental Toll of Plastics.” EHN, EHN, 29 Sept. 2021, www.ehn.org/plastic-environmental-impact-2501923191/particle-7.

De Jesus 7

management. I found it important to learn more about the life-cycle of the Yeti Rambler water bottle because although sometimes we may think we are doing something good for the environment, the long term effects of its production could still be harmful to the environment. This is also of significance because stainless steel water bottles continue to be made, distributed and sold all throughout the world. Our main focus should be the recycling of/reusing of stainless steel water bottles to decrease their production and therefore the high embodied energy they emit.

De Jesus 8

Works Cited

Agent, Numeriklire Sourcing. “Top 5 Stainless Steel Water Bottle Manufacturer in China.” Numeriklire China Product Sourcing Agent, 26 Jan. 2021,

www.numeriklire.net/top-5-stainless-steel-water-bottle-manufacturer-in-china/. Ahmad, Nabeel, and Emmanuel Ugo Enemuoh. “Energy modeling and eco impact evaluation in direct metal laser sintering hybrid milling.” Heliyon vol. 6,1 e03168. 16 Jan. 2020 An Introduction to Stainless Steel and How It's Made.” Monroe Engineering, 22 Feb. 2021, https://monroeengineering.com/blog/an-introduction-to-stainless-steel-and-how-its-made/ Cowing, Henrik Selin And Rebecca. “Cargo Ships Are Emitting Boatloads of Carbon, and Nobody Wants to Take the Blame.” Phys.org, Phys.org, 18 Dec. 2018, phys.org/news/2018-12-cargo-ships-emitting-boatloads-carbon.html.

Director, Sam Hananel Associate, et al. “American Fuel.” Center for American Progress, 5 Apr. 2007, www.americanprogress.org/article/american-fuel/.

Gao, Mengdi, et al. “A Review on Energy Consumption, Energy Efficiency and Energy Saving of Metal Forming Processes from Different Hierarchies.” Processes, vol. 7, no. 6, 2019, p. 357., https://doi.org/10.3390/pr7060357.

Haque, N., and T. Norgate. “Life Cycle Assessment of Iron Ore Mining and Processing.” Iron Ore, 2015, pp. 615–630., doi:10.1016/b978-1-78242-156-6.00020-4. Johnson, Alissa (2015) "Recycling Energy: An Exploration of Recycling and Embodied Energy," Penn Sustainability Review: Vol. 1 : Iss. 6 , Article

Knoblauch, Jessica A. “The Environmental Toll of Plastics.” EHN, EHN, 29 Sept. 2021, www.ehn.org/plastic-environmental-impact-2501923191/particle-7.

De Jesus 9

LaBonta, Lo'eau. “Human Energy Converted to Electricity.” Stanford University, 6 Dec. 2014.

Marketing, G.E.T. Grades of Stainless Steel & What They Mean for Your Foodservice Operation,

https://blog.get-melamine.com/stainless-steel-grades-what-they-mean-for-your-restaurant. Melton, P. (2015, September 8). The Embodied Energy of Tap Water. Retrieved from https://www.buildinggreen.com/primer/embodied-energy-tap-water

Norgate, Terry & Jahanshahi, Sharif & Rankin, William. (2004). Alternative routes to stainless steel-a life cycle approach.

O Ecotextiles (and Two Sisters Ecotextiles). “Estimating the Carbon Footprint of a Fabric.” OEcotextiles, 31 Jan. 2012,

oecotextiles.blog/2011/01/19/estimating-the-carbon-footprint-of-a-fabric/. Sakamoto, K. “Vacuum Chamber.” Encyclopedia of Analytical Science, Second, 2005. “The Main Mechanical Equipment for the Production of Vacuum Flasks.” Insulated Stainless Steel Water Bottle Manufacturer, 27 Oct. 2021,

https://www.waterbottle.tech/the-main-mechanical-equipment-for-the-production-of-vacuum-flas ks/.

Wei, Wenjing, et al. “Energy Consumption and Greenhouse Gas Emissions of Nickel Products.” Energies, vol. 13, no. 21, 2020, p. 5664., doi:10.3390/en13215664.

Eunice Fulgueras

Jennifer De Jesus, Chiara Zavala

DES 40A

Professor Cogdell

YETI Water Bottle Life Cycle Analysis: Wastes and Emissions

In our day to day lives, we encounter and use many objects on the daily. Some of them have even become a part of our everyday routines. Have you ever taken a second to consider the deeper importances of these objects? The effect they have on our world, in our environment? Let’s take water bottles as an example. More specifically, reusable water bottles. Water is an essential for human life, but have you ever considered the object that holds the water to be important as well? Water bottles come in different containers and different materials. For example, YETI rambler water bottles are made of stainless steel and nylon to withstand outdoor conditions and be of long term use. YETI Coolers was founded in 2006 with a mission to “build the cooler you’d use every day if it existed” (YETI). The main concept of the company was to create outdoor products that could withstand outdoor conditions. Although a reusable water bottle is a better alternative to plastic, outputs of wastes and emissions from the production of YETI rambler water bottles signifies the six steps of an object’s life cycle stage by highlighting the negative effects it has towards our world’s environment.

In the two life cycle stages of raw material acquisition and manufacturing, processing, and formulation, wastes and emissions from a YETI rambler water bottle is highlighted through the preparation of stainless steel used for the base of the water bottle. The cultivation of the raw materials like nickel, iron ore, chromium, silicon, and molybdenum is the main contributor of waste because of the by-product of steel slag being produced by the steel. Steel slag is the by-product created during the production of stainless steel by an electric arc furnace. Even though stainless steel is seen to be a suitable material for our environment because of its ability to be recycled, it develops a significant amount of steel-slag at a value of approximately 78%. This by-product contains a number of different elements that are toxic to the environment. This toxicity creates outputs like waterborne wastes and solid wastes that leach out into soil or water and cause degradation. Toxic metals that come from this process include chromium, nickel, manganese, vanadium and molybdenum. Ultimately, the exposure of this by-product not only affects the environment, but human health as well. Along the same lines, the majority of waste and emissions during the manufacturing process of stainless steel comes from the aftermath of the use of electric arc furnaces that create stainless steel. Outputs from this production include airborne and waterborne wastes. To fuel these electric arc furnaces, coke, a porous fuel, was used to power the furnace. The air emissions from the production of steel include coke oven gas, naphthalene, ammonium compounds, crude light oil, sulfur and coke dust are released from the electric arc furnaces. This causes major pollution in our world. The waterborne emissions from the production of steel comes from the water used to cool the coke after production. This water gets polluted with compounds from the coke. Already, the first two lifecycle steps of YETI rambler water bottles already produce an excessive amount of waste and emissions, but there is still more to look at in the next two life cycle steps of distribution and transportation as well as use/re-use/maintenance.

In the next two life cycle stages of distribution and transportation and use/re-use/maintenance, wastes and emissions of the YETI rambler water bottle is signified through the immediate harsh effects it has on the environment. Emission of greenhouse gases is extensive due to the distribution and transportation of this product. Outputs from this process are gases like carbon dioxide, nitrous oxide, and methane are emitted, causing climate change and toxic air pollution, falling into the categories of airborne wastes and environmental releases. The average U.S. delivery truck contributes 29% of greenhouse gas among six different sectors. These sectors include electricity, industry, agriculture, commercial, and residential. From the transportation that is specifically delivery trucks, it contributes approximately 24% of greenhouse gases among six different transportation sectors. This shows that from just delivery trucks alone, it takes up a little more than a quarter of greenhouse gas emissions from the different sectors of our world. A failure that came up during the acquisition of research for the life cycle stage of distribution and transportation was not being able to find specific details about greenhouse gas emissions from the companies who do deliver. It was difficult to find information about the specific vehicles used during the distribution and transportation process and the fact of these vehicles being detrimental to the environment was not easy to discover. I decided to focus on the distribution and transportation of solely ground vehicle trucks because in the YETI website section of frequently asked questions, it is stated that they distribute their products with ground shipping. If I were able to find the information specific to ground delivery trucks of the amount of greenhouse gases emitted, it would have furthered the explanation of how detrimental the emissions from delivery vehicles are. On the other hand, with the life cycle stage of use/re-use/maintenance, wastes and emissions of the YETI rambler water bottle is seen through water usage. Since it is a reusable water bottle made for long term use, there is more immediate waste from single-use water bottles. Waste from this product would come from the maintenance of the product which would be keeping it clean. To do this, you must use water to clean it which plays into water waste.A failure that came up was not being able to find the exact numerical value of how much water is used to maintain reusable water bottles of any material. Outputs from this process is the ability to have a usable product. Without the use of water to clean the YETI rambler water bottle, it would decrease the time of usage. Waste in terms of usage comes from the maintenance of the product. It is transparent that through life cycle steps number three and four, the actual commodity of production continues to put our wastes and emissions into our environment. Knowing this, the last two steps of the life cycle of a YETI rambler water bottle display the wastes and emissions of the physical product’s being after it is produced and distributed out into the world.

In the last two life cycle stages of recycle and waste management, wastes and emissions of the YETI rambler water bottle denote the physical cons to the actual product itself to the world around us. Since stainless steel can be recycled at a scrap metal recycling facility, the waste from this product would come from the cap of the water bottle which is made out of nylon. Nylon is not biodegradable and causes about 10% of debris in our oceans. Leaving nylon in landfills allows the material to naturally create a greenhouse gas three hundred times stronger than carbon dioxide which makes it very detrimental to our environment. Repurposing this material is very difficult and simply throwing the product out would be the easiest way to not deal with it longer. Similarly, a problem that arises with the terms to recycle a stainless steel water bottle is it can not be recycled at a typical recycling center. Stainless steel water bottles would be too dense in consistency to be broken down by machines used to recycle materials like plastic, aluminum, and glass. To properly recycle a stainless steel water bottle, an individual would need to go to a scrap metal recycling facility. If an individual is unable to properly recycle a stainless steel water bottle, the best way to help out the environment is to repurpose the object. If not, stainless steel is not biodegradable. As time takes its course, stainless steel will rust and leave particles in the ground or atmosphere that organisms are not able to break down. The object would continue to stay in our world’s landfill for years on end. On a similar note, nylon is the material used to make the cap of the YETI rambler water bottle. It is a material that is not cheap or easy to recycle. It is also not easy to find a recycling center that accepts nylon. So, when disposed of, nylon will sit in the dump and spread debris. These outputs are considered to fall under the category of solid, waterborne, and airborne wastes. If not recycled correctly, a stainless steel water bottle would sit in the landfill for years and still be a solid waste because it is not a biodegradable material. The same terms would apply to nylon material because it also is not biodegradable and just emits debris into the ocean. Together, this demonstrates how effective a product’s being could easily have negative impacts on the environment solely based on how they interact with the environment after its usage by humans comes to an end.

To look and focus on the category of wastes and emissions through a microscope when researching the life cycle on an object puts a lot into perspective. As an individual in this world we live in, every human has an input to how our world is treated and what gets put out there. Knowing that an immense amount of the world’s wastes and emissions comes from object’s we see as “essentials” makes an individual think about how much more wastes and emissions comes from the quick timely production of other objects that may or not be essential in our world. Going from step to step of the life cycle process of a YETI rambler water bottle displays in detail how each and every step of the object’s life cycle has some sort of negative impact on the environment. Before knowing about an object’s “life cycle,” it was always quick to assume that the most harmful waste and emissions comes solely from the product being thrown out incorrectly. Instead, I was exposed to the main picture of how our world works alongside the objects that take a space and place in every individual’s life. From the production, to distribution, to the disposal of a product, there is so much information in between the fine lines of companies and object’s that most are not aware of. Not being able to understand this information just leads to a shorter and shorter life in our world because there are a lot of negative effects occurring that are not being addressed. The consequences of owning a product we see as an essential without knowing it’s life cycle is slowly killing our planet. It makes you question “is this object even worth it?”

Works Cited

Bottles, Elemental. “What to Do with Old Stainless Steel Water Bottles.” Elemental Bottles, 1 Oct. 2018, https://www.elementalbottles.com/blogs/news/what-to-do-with-old-stainless-steel-water-bottles.

Burnett, Chris, et al. “What Is Stainless Steel? Part I.” Analyzing Metals, 21 July 2016, https://www.thermofisher.com/blog/metals/what-is-stainless-steel-part-i/.

Coolers, YETI. “Our Story.” YETI, https://stories.yeti.com/story/our-story.

Jin, Peng, et al. “The Energy Consumption and Carbon Emission of the Integrated Steel Mill with Oxygen Blast Furnace.” Resources, Conservation and Recycling, Elsevier, 20 Aug. 2015, https://www.sciencedirect.com/science/article/pii/S0921344915300410?casa_token=M2bzIcan5u8AAAAA%3AQQqTWvGUxQUw0GbcL2jeYfKi9LNWjzBO9N413QWHDrjSQXEfp4tRCVhQP6ZYuotuCqWcUCgA.

Jing, Ran, et al. “Assessments of Greenhouse Gas (GHG) Emissions from Stainless Steel Production in China Using Two Evaluation Approaches.” American Institute of Chemical Engineers, John Wiley & Sons, Ltd, 12 Jan. 2019, https://aiche.onlinelibrary.wiley.com/doi/abs/10.1002/ep.13125?casa_token=6FOmsyPgWFEAAAAA%3Ar8nimU0Op-CNEXRCuCCRpbZDeC8BS2erRFRfv4ZRQpyIbLSqf80SWEMXlyM-hyU_TkYoiErAkLzSnQ.

Ma, Guang-yu, et al. “Analytical Research on Waste Heat Recovery and Utilization of China's Iron & Steel Industry.” Energy Procedia, Elsevier, 8 Mar. 2012, http://www.sciencedirect.com/science/article/pii/S1876610211044699.

Mao, Sherry. “What to Do with Your Old Stainless Steel Water Bottle.” NAYAD, NAYAD, 11 Jan. 2021, https://nayad.com/blogs/nayad-drinkware/what-to-do-with-your-old-stainless-steel-water-bottle.

Mini, CAPGE. “Sustainability Transformation.” Capgemini US, 26 Oct. 2021, https://www.capgemini.com/us-en/service/sustainability-transformation/?gclid=Cj0KCQiA-qGNBhD3ARIsAO_o7ykoxwpVBMy0QJTSWZKK81-evFYzz4dIa4hvdG8R0qYaksCF5rumNckaAiz8EALw_wcB&gclsrc=aw.ds.

Rosales, Julia, et al. “Potential of Stainless Steel Slag Waste in Manufacturing Self-Compacting Concrete.” EPA, Environmental Protection Agency, 28 Apr. 2020, https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions.

Shi, Caijun. “Steel Slag-Its Production, Processing, Characteristics, and Cementitious Properties: Journal of Materials in Civil Engineering: Vol 16, No 3.” Journal of Materials in Civil Engineering, American Society of Civil Engineers, 14 May 2004, https://ascelibrary.org/doi/abs/10.1061/(ASCE)0899-1561(2004)16:3(230)?casa_token=7TtIJEtv7lkAAAAA%3AwXLWx_n9rMgGuuJtzsVx0M44b4Q97pNKcUj4tliJHV7IlQbQqMdySERoDoln6jQxyIICUrTu.

Silks, Unati. “Recycling Nylon Is Good for the Planet – More Needs to Be Done.” Swadesh | Official Blog of Unnati Silks, 14 Aug. 2019, https://www.unnatisilks.com/blog/recycling-nylon-is-good-for-the-planet-more-needs-to-be-done/#:~:text=Since%20Nylon%20is%20made%20of,every%20year%2C%20including%20nylon%20nets.

“Steel Production & Environmental Impact.” Greenspec, https://www.greenspec.co.uk/building-design/steel-products-and-environmental-impact/.

Steel, Marlin. “How Is Stainless Steel Made?” Custom Wire Products and Metal Fabrication, https://www.marlinwire.com/blog/how-is-stainless-steel-made.

“User Guidelines for Waste and Byproduct Materials in Pavement Construction.” U.S. Department of Transportation/Federal Highway Administration, https://www.fhwa.dot.gov/publications/research/infrastructure/structures/97148/ssa1.cfm.