Design Life-Cycle

assess.design.(don't)consume

Madison Wong

Kelly Tan, Jessica Alvarado

DES 40A

Professor Cogdell

First Generation Apple Pencil Materials

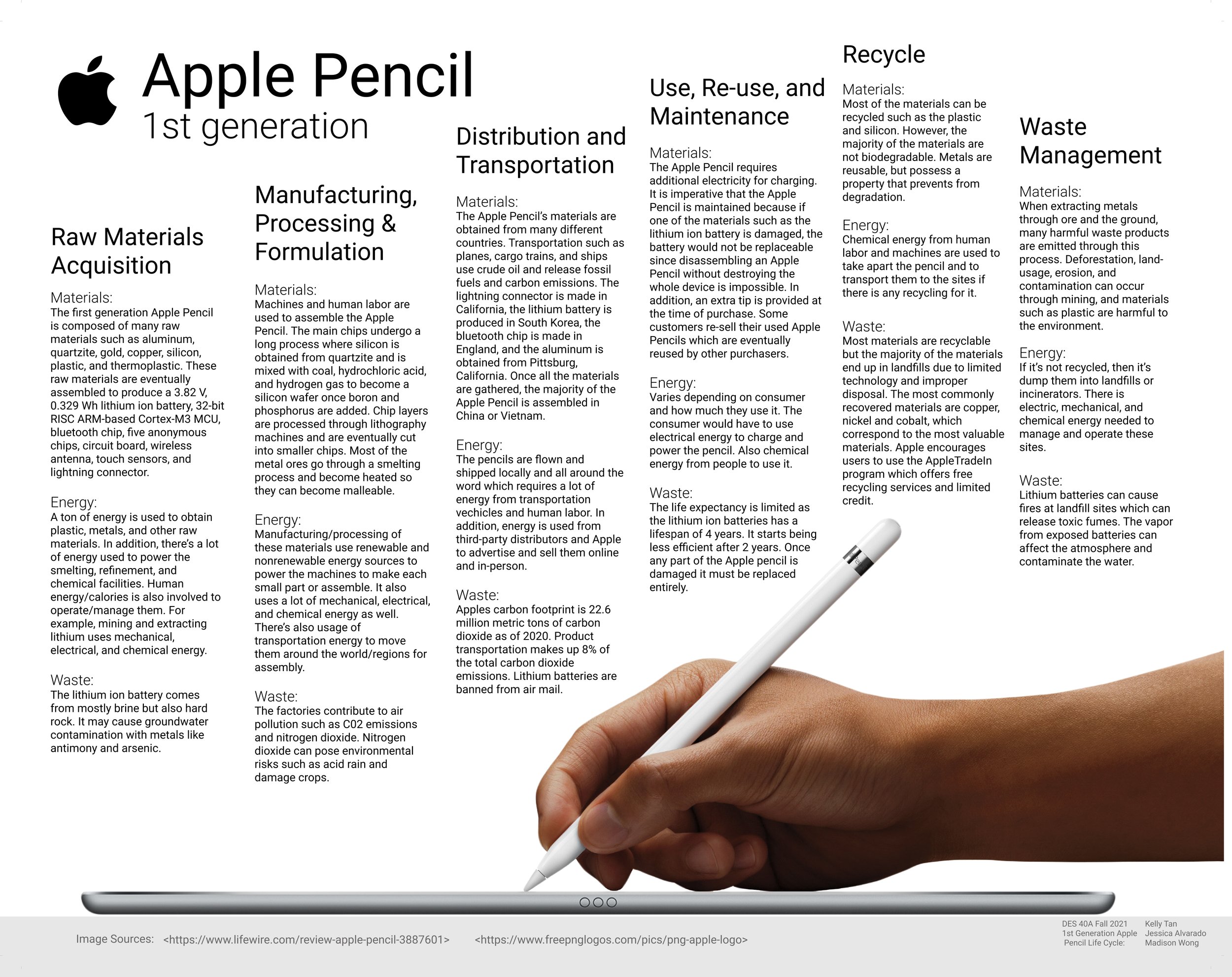

Over time, society has become more dependent on technology, and consumers have become largely attracted to new electronic products such as electric cars, smartphones, tablets, and virtual reality. Apple, one of the most recognized companies in the world, has contributed immensely in the information technology industry and has been innovating their products for better efficiency. One popular Apple product, the first generation Apple Pencil, has been utilized by many consumers, especially students. So far, the Apple Pencil has two versions, a first and second generation. The Apple Pencil is an advanced stylus that can be used on certain Apple products. The popularity of this product has grown due to its bluetooth and pressure sensors, along with its overall ability to facilitate handwriting on electronic devices. Unfortunately, consumers are unaware of what goes into the production of the popular writing tool and how it could potentially be damaging to the environment. More specifically, the Apple Pencil utilizes materials that are mostly non-recyclable and/or not biodegradable. They end up as waste products that are difficult to dispose of. The first generation Apple Pencil is made of common tech materials — plastic, metals, batteries, bluetooth chips, silicon — and Apple hopes to reduce environmental damage (as the majority of the non-recyclable secondary materials in the Apple Pencil tend to be environmentally harmful during manufacturing and after disposal) by producing high quality, recyclable products in renewable energy facilities that meet consumer demand and sustainability in the future (Athwal, 2020).

There are many materials used to create the first generation Apple Pencil which was released in 2015. When analyzing each material individually, it appears that Apple’s goal of sustainability has been difficult to meet due to the majority of the Apple Pencil’s materials being non-environmentally friendly. For instance, in terms of the materials on the exterior of the Apple Pencil, it is made of plastic which is generally recyclable but not biodegradable (Detwiler, 2015). To produce the plastic, raw materials such as coal, crude oil, and natural gas are refined in a production process to obtain ethane and propane which are the main plastic building blocks (“How is Plastic Made?” 2020). The ethane and propane are then converted into ethylene and propylene through a high heating process called “cracking” and are combined to create polymers which eventually form into plastic (“How are Plastics Made?” n.d). On the other hand, the writing tip is composed of capacitive polypropylene, a type of thermoplastic that is recyclable and easily remolded and reheated for other purposes (“Apple Pencil (Tips),” 2021). Thermoplastic goes through a similar production process as regular plastic, where a group of polymers are melted through heat to be processed in a heat-softened state or liquid state (i.e. molding) (Mallick, 2021). Yet, these materials are difficult to decompose and are essentially harmful to the environment. Since thermoplastic is similar to plastic, it is essentially difficult to dispose of and can take years to decompose.

Additionally, many primary and secondary materials are assembled to form the advanced stylus technology. These include a 3.82 V, 0.329 Wh lithium ion battery, 32-bit RISC ARM-based Cortex-M3 MCU, aluminum, gold, bluetooth chip, five anonymous chips, circuit board, wireless antenna, touch sensors, and lightning connector (inside the magnetic cap) (Detwiler, 2015). When researching the lithium ion battery, the lithium ore is mined in China or Argentina and is eventually produced into a battery in South Korea (Athwal, 2020). In addition to the lithium ore, the battery is made up of polymer binders, conductive additives, and solvents (N-methylpyrrolidone (NMP)) which are coated with collector foil to create electrode coating (Daniel, 2015). The lithium ion battery goes through a long production process as time is needed to extract the ore, and the assembling of the battery requires transportation since the manufacturing is in South Korea. This ultimately uses up fuel and releases waste into the atmosphere. In terms of the antenna, it is attached to a silicon circuit board through a copper wire and picks up amplitude modulation signals (Woodford, 2021). Moreover, many elemental ores are utilized in the Apple Pencil’s production process. The aluminum for the tech inside the Apple Pencil is recycled and obtained from Pittsburg, California (Athwal, 2020). Aluminum undergoes the Hall-Heroult process where metallic aluminum is created by the smelting of alumina in a reduction pot (“How aluminum is made,” n.d). Carbon helps act as an electrode conductor in the reduction pot, and alumina crystals are dissolved in high temperatures of 1760-1780 degrees Fahrenheit where the resulting molten aluminum is eventually molded (“How aluminum is made,” n.d). The gold ore surrounding the antenna is non-renewable and mined in Columbia which is eventually attached to the antenna through oxidation production processes in China or Vietnam (Athwal, 2020). In addition, a magnetic material is used to attach the cap onto the Apple Pencil. Not much research is available on the magnetic material; however, it is reasonable to infer that this type of metal is mined from ore as well.

The Apple Pencil is also composed of a bluetooth chip, five anonymous chips, and circuit board. Unfortunately, not much information was accessible particularly for the bluetooth chip. However, research based on standard computer chips implies that bluetooth chips are made of silicon which is an ideal semiconductor material for circuits within the chip (“Learn the Microchip Basics,'' 2019). Mining quartzite provides the chip’s polysilicon which is mixed with coal, hydrochloric acid, and hydrogen gas, and the silicon wafer is produced once boron and phosphorus are added (Cplai, 2008). Circuits and transistors are eventually placed on top of the silicon wafer to create a chip. In the production process for printing chip layers, the chip goes through a lithography machine to be coated with a light-sensitive layer, and the machine shines a light to print a pattern based on a blueprint (“How Microchips are Made,” 2019). The chip wafer could have hundreds of silicon and metal layers to create a final circuit until the chip wafer is ready for splitting into smaller chips.

For the Apple Pencil’s processor, the 32-bit RISC ARM-based Cortex-M3 MCU is an essential part of the Apple Pencil. The MCU is a microcontroller that is also made of pure silicon and goes through a similar production process as a typical computer chip. The microcontroller is vital for interpreting inputs and controlling the Apple Pencil by sending output signals based on what it detects (“How Microcontrollers Work,'' 2021). The microcontroller detects the touch of the Apple Pencil’s tip onto a surface and is able to recognize shapes and words. In addition to the previously mentioned materials, there are pressure sensors that also use resistors and conductive materials. More specifically, the multiaxial force sensor consists of transistors, copper coils, and sensor films (Noh, Yohan, et. al, 2016). The copper coils are assembled using copper ore which is non-renewable. The copper goes through a series of extrusion where bricks of copper are shaped into thin, long strands and eventually become malleable through an “annealing” process where temperatures range from 1000-1200 degrees Fahrenheit. (“How Cables are Made,” n.d). Once the copper cools, it is shaped into wires. The transistors are also made from silicon, and the sensor films are made of polystyrene microsphere film and carbon nanotube films (Chen, Wufan, et. al, 2019). Once pressure is applied, a current runs through the sensor films. The pressure sensors are used in the Apple Pencil to detect how hard the tip is being pressed onto a surface which helps to determine the thickness of the writing stroke. In order to charge the Apple Pencil, the lightning connector is attached to the end of the Apple Pencil underneath a magnetic cap. The lightning connector is made of a conductive metal and chips that charge the Apple Pencil when inserted into an Apple product’s charge port (i.e. iPad Pro). Unfortunately, not much research was found on the lightning connector’s production process nor the particular type of metal; however, the metal and parts of the chips are non-renewable which is again, detrimental to the environment.

In order to assemble these materials, many methods of transportation are needed to move these materials for assembly in particular facilities. The components are transported to a variety of different countries before becoming the final product. However, the transportation and manufacturing does emit harmful waste. To reiterate the manufacturing locations for some of the materials, the lightning connector is produced in California, the bluetooth chip is created in Cambridge, England, and the lithium ion battery is produced in South Korea (Athwal, 2020). Once all the raw materials are assembled and produced into secondary raw materials, they are constructed into the Apple Pencil in either China or Vietnam (Athwal, 2020). Clearly, the raw materials are extracted from all over the world and transported to various countries for assembly. Eventually, the final product is produced in China or Vietnam, then shipped to stores all around the world. An abundant amount of energy is required to transport every individual material across several countries to assemble one Apple Pencil. Transportation systems such as planes and cargo trains are most likely the modes of transportation for some of the materials. Other additional materials used during manufacturing are human labor, oil, and fossil fuels.

In terms of using and maintaining the Apple Pencil, more power is needed for charging it occasionally. The lightning connector’s main job is to transfer electricity to the Apple Pencil. By connecting the Apple Pencil’s lightning connector to the port of the iPad, an electric current travels through which is a process that consumes and transfers energy and electricity. A USB cable could also be used as a charger by connecting the Apple Pencil to a computer. Yet, charging the Apple Pencil through a computer is much slower because only five volts of electricity are transferred with a maximum current of 0.5 amps (“Connecting Power,” n.d). Maintaining the Apple Pencil is imperative and must be kept in good condition. Many of the materials inside are a challenge to replace, and if damaged, most consumers would have to purchase another one. For example, if one of the materials such as the lithium ion battery is damaged, the battery would not be replaceable since disassembling an Apple Pencil without destroying the whole device is impossible (Rossignol, 2015). As for the tip of the Apple Pencil, it could be replaced with another tip which is provided at the time of purchase. On the other hand, some people resell their used Apple Pencil for a lower price which is then reused by other customers. Once the Apple Pencil is no longer usable, parts of the Apple Pencil are broken down and transported to be either recycled or placed in a landfill.

Unfortunately, some of the materials such as plastic or the metals mined from ore are not biodegradable and take hundreds of years to break down or regenerate (Parker, 2021). Even so, many of the metals within the chips, circuit boards, cap, etc., are not renewable but can be recycled since metals have a property that does not lead to degradation (LeBlanc, 2021). Metals can be shredded, melted, and separated through a recycling process. Overall, the majority of the materials may be recycled since the Apple Pencil is mainly composed of metals on the inside and plastic on the outside. Sadly, only about nine percent of plastic is actually recycled (Krosofsky, 2021). Furthermore, it appears that the majority of Apple’s products are difficult to break down due to their consistent utilization of materials that are not biodegradable such as silicon and plastic. Their goal of reaching sustainability has been difficult to meet, but Apple is hoping to use renewable energy sources for their facilities since it has been shown that 77% of their emissions come from transportation (Athwal, 2020).

When extracting metals through ore and the ground, there are many harmful waste products that are emitted through this process. Deforestation, land-usage, erosion, and contamination can occur through mining, and manufacturing the materials releases harmful chemicals into the atmosphere (Haddaway, Cooke, et. al, 2019). The transportation of materials to various countries or landfills also requires energy, fossil fuels, and natural gas. Therefore, the production of one Apple Pencil leads to an abundant amount of pollution and waste. The Apple Pencil itself will eventually become waste that would be nearly impossible to break down due to the plastic and silicon on the outside with the metals sealed inside. On the bright side, Apple has been working on facilities where 93% of the manufacturing facilities rely on renewable energy and robots which are definitely major upgrades to their previous methods of production (Athwal, 2020). This ultimately reaches some aspects of Apple’s sustainability goal.

To conclude, the Apple Pencil is made up of an abundant amount of materials that are either recyclable or difficult to decompose. The majority of the Apple Pencil’s assembly takes the most time during the manufacturing process due to the detailed processes of producing the internal components such as the bluetooth chip and circuit boards. Nonetheless, the Apple Pencil’s life cycle eventually leads to an abundant amount of pollution that is detrimental to the environment. Greenhouse gases will continuously be emitted through the production, manufacturing, and transportation of the device; however, the use of renewable energy facilities will help reduce the emissions by a large factor. Apple is aiming to reduce the amount of waste and still has yet to innovate its current production and material processes for their products. In the future, Apple hopes to become environmentally friendly and sustainable for the benefit of the environment.

Bibliography

“14 Questions about Apple Pencil (Tips).” Pen Tips, Shopify, 2021, https://pen.tips/blogs/news/the-ultimate-2020-apple-pencil-tips-guide.

“Apple Trade In.” Apple, Apple, https://www.apple.com/shop/trade-in.

Athwal, Gursakhi. “Journey of the Apple Pencil.” ArcGIS StoryMaps, Esri, 4 Feb. 2020, https://storymaps.arcgis.com/stories/624115e5ba264d199a319315fa800c5d.

“Buy Apple Pencil (2nd Generation).” Apple, Apple, https://www.apple.com/shop/product/MU8F2AM/A/apple-pencil-2nd-generation.

Chen, Wufan, et al. "Flexible pressure sensors with a wide detection range based on self-assembled polystyrene microspheres." Sensors 19.23 (2019): 5194. https://www.mdpi.com/1424-8220/19/23/5194/pdf.

Chris Woodford. Last updated: October 6. “How Do Antennas and Transmitters Work?” Explain That Stuff, 6 Oct. 2021, https://www.explainthatstuff.com/antennas.html.

Clover, Juli. “Everything You Need to Know about the Apple Pencil.” MacRumors, MacRumors, 4 Mar. 2020, https://www.macrumors.com/guide/apple-pencil/.

“Connecting Power, People and Organisations.” CMD Ltd, https://www.cmd-ltd.com/advice-centre/usb-chargers-and-power-modules/usb-and-po wer-module-product-help/usb-charger-faqs/#usbchargerfaqs2.

Cplai. How Do They Make Silicon Wafers and Computer Chips? YouTube, YouTube, 5 Mar. 2008, http://www.youtube.com/watch?v=aWVywhzuHnQ.

“Cracking Open - Apple Pencil.” Youtube, uploaded by CNET, 24 Nov. 2015, https://www.youtube.com/watchv=cX9d-6OPSDs.

Daniel, Claus. "Lithium ion batteries and their manufacturing challenges." The Bridge (Washington, DC) 45.1 (2015). https://www.osti.gov/servlets/purl/1265419/.

Detwiler, Bill. “We Cracked Open an Apple Pencil so You Don't Have To.” CNET, CNET, 25 Nov. 2015, https://www.cnet.com/tech/computing/apple-pencil-powered-by-amazingly-tiny-tech/.

Haddaway, Neal R., et al. "Evidence of the impacts of metal mining and the effectiveness of mining mitigation measures on social–ecological systems in Arctic and boreal regions: a systematic map protocol." Environmental Evidence 8.1 (2019): 1-11. https://environmentalevidencejournal.biomedcentral.com/articles/10.1186/s13750-019 -0152-8.

“How aluminum is made - material, manufacture, making, used, processing, aluminium, composition, product.” How Products Are Made, Advameg, http://www.madehow.com/Volume-5/Aluminum.html.

“How Are Plastics Made?” This Is Plastics, Plastics Industry Association, https://thisisplastics.com/plastics-101/how-are-plastics-made/.

“How Cables are Made - Start to Finish.” CableWholesale, CableWholesale, https://www.cablewholesale.com/support/technical_articles/how_cables_are_construct ed.php.

“How is Plastic Made? Plastic Production Process Simplified.” Plastic Collectors, Logicsofts, 7 May 2020, https://www.plasticcollectors.com/blog/how-is-plastic-made/.

“How Microchips Are Made.” ASML, 2019, https://www.asml.com/en/technology/all-about-microchips/how-microchips-are-made.

“How Microcontrollers Work.” IntervalZero, 25 June 2021, https://www.intervalzero.com/how-microcontrollers-work/.

Kingsley-Hughes, Adrian. “Apple Pencil: Crammed Full of Tech You're Never Meant to See.” ZDNet, ZDNet, 19 Nov. 2015, https://www.zdnet.com/article/apple-pencil-crammed-full-of-tech-youre-never-meant to-see/.

Krosofsky, Andrew. “What Percentage of Recycling Actually Gets Recycled?” Green Matters, 16 March 2021, https://www.greenmatters.com/p/what-percent-recycling-actually-gets-recycled.

“Learn the Microchip Basics.” ASML, 2019, https://www.asml.com/en/technology/all-about-microchips/microchip-basics.

LeBlanc, Rick. “Get an Introduction to Metal Recycling.” The Balance Small Business, The Balance Small Business, 5 Mar. 2021, https://www.thebalancesmb.com/an-introduction-to-metal-recycling-4057469.

Mallick, P. K. "Thermoplastics and thermoplastic–matrix composites for lightweight automotive structures." Materials, design and manufacturing for lightweight vehicles. Woodhead Publishing, 2021. 187-228. https://www.sciencedirect.com/science/article/pii/B9781845694630500055.

Noh, Yohan, et al. “Multi-Axis Force/Torque Sensor Based on Simply-Supported Beam and Optoelectronics.” MDPI, Multidisciplinary Digital Publishing Institute, 17 Nov. 2016, https://www.mdpi.com/1424-8220/16/11/1936/htm.

Norgate, Terry E., Sharf Jahanshahi, and William J. Rankin. "Assessing the environmental impact of metal production processes." Journal of Cleaner Production 15.8-9 (2007): 838-848. https://www.sciencedirect.com/science/article/pii/S0959652606002320.

O'Donoughue, Patrick R., et al. "Life cycle greenhouse gas emissions of electricity generated from conventionally produced natural gas: systematic review and harmonization." Journal of Industrial Ecology 18.1 (2014): 125-144. https://onlinelibrary.wiley.com/doi/pdf/10.1111/jiec.12084.

Parker, Laura. “Plastic Pollution Facts and Information.” Environment, National Geographic, 3 May 2021, https://www.nationalgeographic.com/environment/article/plastic-pollution.

Purcher, Jack. “The Invention behind Apple's Force-Sensing Pencil Surfaces.” Patently Apple, 30 June 2016, https://www.patentlyapple.com/patently-apple/2016/06/the-invention-behind-apples-f orce-sensing-pencil-surfaces.html.

Rossignol, Joe. “Apple Pencil Teardown Reveals Antenna, Battery and Tiny Folded Logic Board.” MacRumors, MacRumors, 19 Nov. 2015, https://www.macrumors.com/2015/11/19/apple-pencil-teardown-ifixit/.

Segan, Sascha. “Apple Pencil (2nd Generation) Review.” PCMAG, Ziff Davis, 26 July 2021, https://www.pcmag.com/reviews/apple-pencil-2nd-generation.

“Why the Apple Pencil Is So Expensive.” Youtube, uploaded by Apple Explained, 10 Sept. 2021, https://www.youtube.com/watch?v=wlRfHlMhMRU.

Kelly Tan

Jessica Alvarado and Madison Wong

DES 40A

Professor Cogdell

Apple Pencil Generation 1 Embodied Energy

Apple is known for its iPhones these days but they also produce other products many students, designers, and/or consumers use, the Apple Pencil. The Apple Pencil isn’t as widely bought as the iPhone and it’s usually paired with their iPads. Furthermore, the pencils can only be used on iPads and only certain generations are compatible with specific iPads, like gen 1 pencil with iPad 9th Generation. Apple Pencil generation 1 has the most compatibility compared to the 2nd generation, but even with that, Apple uses a lot of energy to produce a pencil that is limited to just iPads and compatible with specific ones too. In addition, there seems to be limited information on Apple Pencils in general, especially their embodied energies, since it’s one of the lesser marketed and known products in Apple. With that being said, this paper will bring in more information on the Apple Pencil gen 1 and specifically the embodied energy used to produce it. Understanding all the embodied energy used in the life cycle of an Apple Pencil gen 1 will help reveal that obtaining raw materials, manufacturing, distributing, and recycling/waste management produces way more energy than Apple says they are producing in their yearly environmental reports because they don’t account for the entire life cycle of the pencil.

This is an important topic because Apple produces a ton of e-waste and energy to make them yearly. The Apple Pencil, specifically the first generation, is one of those wastes and can be overlooked in their annual reports since their iPhones are more popularly associated with them. Many sources either focus on iPhones or iPads but not much on the pencils since it’s one of the items paired with the iPad. However, there is only one source that did a partial/incomplete life cycle on the first generation of the Apple Pencil in a story map format called “Journey of the Apple Pencil” [3]. However, it doesn’t really focus on the different energies used in each step and barely any details on the energy used in the recycling and waste management levels Apple is doing nowadays. This paper will be addressing all 7 steps of its life cycle and mainly focuses on contributing the energies an Apple Pencil gen 1 produces throughout all 7 steps.

First, getting their raw materials from suppliers all over the world takes a ton of energy. An Apple Pencil gen 1 has mainly a lithium-ion battery, a microcontroller, lightning connector (only Gen 1 has this feature), wireless antenna, Bluetooth chip, circuit board, magnetic cap, driver IC, metals like gold and aluminum, and others like plastic and silicon. Since there are many parts, it’s difficult to find specific information for each item, but synthesizing together many sources offers a feasible understanding of the energy needed to get these materials. On the other hand, this section will only go over a few of these parts to keep it digestible and short. Starting with the plastic shell, Apple states they are transitioning from “fossil fuel-based plastics” to renewable or recycled ones, by putting an undisclosed amount of energy into getting plastic from their recycled materials instead of using more energy to make more plastic [12, 3]. However, this source is talking about the iPad 9th gen and it seems like Apple might still be in transition. So there might still be some energy in producing more plastic to meet demands and a source mentions that embodied energy of plastics is 22kWh per kg of plastic [17]. The next important part is the lithium-ion battery, which can be extracted and mined [3]. In Apple’s yearly list of smelters and refiners, there’s lithium, meaning they have people getting lithium for them [21]. There are several companies all located in Mainland China, where most would mine or extract lithium. Mining and extracting lithium use mechanical, electrical, and chemical energy because we would assume they are using machines and electricity to do that for them. As for chemical energy, one of the suppliers, Tianqi Lithium (Shehong) Co., Ltd., produces battery-grade lithium carbonate and lithium hydroxide [14]. According to Bisley International, lithium carbonate is a lithium compound that carbonates to become a salt, which is a chemical process that uses chemical energy [5]. Finally, there’s a bit of gold used in the wireless antenna and in the lightning connector. To obtain gold, it is extracted from the ground by mining using machines which takes energy to do [3]. In addition, the gold would then be transported from the mining sites to chemical facilities, which takes energy to move and energy to power the facilities to do smelting or refinement to the minerals. These companies use electricity which is a form of secondary energy to power their machines and facilities, and human energy/calories (an average of 100 watts over workday) to operate/manage each step. Overall, the specific amount of energy they produce is an estimate because we don’t actually know the specific machines they operate with and they don’t post any of this information either. So we can only assume that each of these materials requires a lot of energy to obtain and to prepare before heading over to manufacturing.

Next, manufacturing and processing of these materials to get each piece assembled use renewable and nonrenewable energy sources, in addition to primary and secondary. Apple has stated that they are using renewable energy to power their facilities, like solar, wind farms, and biogas fuels [9]. According to Vikram Aggarwal, most solar panels would make between 250-400 watts of power depending on where it is and how much sun it’s capturing per hour [2]. Apple also states that some of their facilities are moving to renewable energy, so the pencil might be using some of that renewable energy [9]. First, let’s start with the microcontroller (MCU), which is a microcomputer chip that is usually made through VLSI fabrication [23]. The cycle of fabrication consists of “crystal growth and wafer preparation, epitaxy, dielectric and polysilicon film deposition, oxidation, lithography, and dry etching” and during it, devices are made on the chip [20]. The person has to also follow proper functions to create the circuit and ultimately the chip, which is a ton of work to create [20]. This process sounds time and energy consuming to make and it has to be small enough to fit inside a pencil so we would assume there are powerful machines involved to facilitate the process. Next, they would take the microcontroller and house it with a Bluetooth chip and 3 other parts in a 1 gram folded logic board [19]. And that is one of the parts assembled together, which is really minuscule in the pencil. Another part that needs to be manufactured is the lightning connector, which according to Apple is designed in California and assembled either in China and Vietnam, or Brazil [11]. We can use this to infer that once the design is completed in CA, that information would be sent off to manufacturers in China or Vietnam, which uses electrical energy, and they would make it there, which also uses energy to assemble. The lightning connector also has laser etchings to help with identification, which is also energy produced for extra details [11]. Then there’s the lithium which is extracted and made into lithium-ion batteries. To manufacture the batteries, it is done in sets of electrodes and assembled into cells [6, 47]. Then it’s mixed with active materials, which uses mechanical, electrical, and chemical energy to perform and has to be done carefully because these materials are highly toxic [6, 47]. With all of these parts finally made, it’s time to transport them, which uses energy because of the usage of petroleum and electricity. There isn’t any information as to where any of these are finally assembled but we would assume there are many places and they would all be sent to the nearest one. However, I have to emphasize that there’s a lot of energy being used to ship and transport each of these materials and parts around the world or in their own regions multiple times. To put all the pieces together, there is a small cable that connects the battery with the connector, which takes energy to perform [19]. Then they also use glue and 6 screws to attach all of its insides before covering it up with two layers of protection, a metal internal shell and the outer plastic shell [8]. There is also energy used to put these parts together and to make sure they all function properly. Unfortunately, there’s even less information on how much energy this step takes, and we can only guess based on how extensive it takes to get here because this step for the making of the Apple Pencil can occur anywhere and be transported all over the world, which uses transportation energy to move. To create each part, we would assume that it would be assembled in some places, which also takes energy to put together. Especially with the plastic shell and internal metal shell which is impossible to take apart without a rotary cutter [8]. And all of this using renewable energy? That’s not possible, they would have to use some carbon-based sources of energy to produce this pencil, especially as we mentioned earlier that Apple isn’t only producing pencils and their focus is on iPhones.

The next step would be the distribution of the finished Apple Pencils. Earlier, Apple mentions that they are using renewable energy for manufacturing their products like the pencil, but for the distribution and transportation at this level, I assume they rely on jets, airplanes, and trucks mainly. In addition, they also rely on third-party partnerships with Amazon and eBay to distribute these pencils to even more places globally [15]. This means that people can buy from third-party sellers and carriers and Apple would have to ship/fly more products to their warehouses, using even more energy than just delivering to their own warehouses or stores around the world [15]. So if we include Apple and two third-party sellers, that triples the amount of transportation energy needed. However, recently, Apple has shifted to a more “efficient” and faster way to ship their products and pencils out to their consumers. Instead of shipping directly from China or local warehouses, they will ship from their Apple stores to consumers’ front doors [10]. That is good in the sense of time-saving, however not energy efficient because the Apple stores become the middleman and you’ll need even more fuel to deliver to them first before it arrives to the consumer.

Once the consumer gets the Apple Pencil, they would use it and the energy produced here would vary depending on the consumer, which uses chemical energy. The consumer would also have to use electrical energy to charge and power the pencil depending on how often they use it. Finally, the nib of the Apple Pencil is replaceable and the consumer gets an extra spare with their new Apple Pencil. However, it’s impossible to repair the pencil if something breaks inside resulting in replacement or throwing it out [8].

The sixth step is recycling for the Apple Pencil. Apple has put out a program called “Apple Trade In” where you can trade your products in for cash credit or a replacement [4]. If the Apple Pencil is replaced, then more energy is produced to create a new one and to recycle it. Furthermore, they state to mail in the product or bring it into their stores, which produces energy because of the transportation [4]. As for recycling according to Santiago Perez, Apple is dismantling their phones and recycling the materials from them using a Robot named Daisy [16]. However, it mentions that only certain phones are extracted from and pencils might not even be one of the items Daisy would be able to extract from. Finally, recycling the pencil is difficult because of the outer plastic shell and it doesn’t have as many materials compared to other products they have. So that would lead us to other options in the next step.

Finally, waste management. Apple mentions that they have a trade in program to help recycle the products, however, that requires energy to manage and to send off to their partners that deal with the recycling [18]. But who are those partners? There is no information on them and how much energy they use to manage billions of products and the Apple pencils. According to Sandra Laville, it seems like their partners aren’t managing the wastes properly because they found out that a lot of it goes to “landfill, incineration or is dumped overseas” which takes energy to operate [13]. So the Apple Pencil is being transported and dumped into landfills or incinerators which utilizes mechanical, chemical, and electrical energy to operate. This might be the case because trying to recycle all those billions of products and pencils is overwhelming and they would have to somehow put in even more energy to create a better system to manage it all than what they have up to now.

In conclusion, the Apple Pencil uses a ton of energy to manufacture, distribute, and manage. What Apple claims they are doing with reducing carbon emissions and wastes don’t add up with what just the Apple Pencil produces in terms of energy. They have multiple suppliers for one raw material and multiple locations to manufacture and produce each part of the pencil which ultimately results in an unimaginable amount of energy embodied in the life cycle of an Apple Pencil. Even with renewable energy that they are trying to implement, the pencil still uses a lot of energy because of the transportation of those pieces or pencils and to manufacture them to fit in the skinny pencil. With this information, we have a better understanding of how a small and specific product like the Apple pencil can produce a lot of energy when you look at the entire life cycle. However, this only mentions a few of the materials and there aren’t specific numbers of the energy produced, so this would need further research and studies.

Bibliography

“2021 Apple Supplier List.” Apple, Apple Inc., https://www.apple.com/supplier-responsibility/pdf/Apple-Supplier-List.pdf.

Aggarwal, Vikram. “How Much Energy Does a Solar Panel Produce? Solar Panel Output Explained.” Energy Sage, EnergySage, Inc, 18 Sept. 2021, https://news.energysage.com/what-is-the-power-output-of-a-solar-panel/.

Athwal, Gursakhi K. “Journey of the Apple Pencil.” ArcGIS StoryMaps, 3 Feb. 2020, https://storymaps.arcgis.com/stories/624115e5ba264d199a319315fa800c5d.

“Apple Trade In.” Apple, Apple Inc., https://www.apple.com/shop/trade-in#:~:text=It%27s%20our%20trade%2Din%20and,can%20recycle%20it%20for%20free.

Bisley International. “What Is the Difference Between Lithium Carbonate & Lithium Hydroxide.” Bisley International LLC, Bisley International, 14 Feb. 2021, https://bisleyinternational.com/what-is-the-difference-between-lithium-carbonate-lithium-hydroxide/.

Daniel, Claus. "Lithium ion batteries and their manufacturing challenges." The Bridge (Washington, DC) 45.1 (2015).

Dempsey, Paul. “The Teardown: Apple Pencil.” Engineering & Technology, vol. 11, no. 2, 2016, pp. 82–83., https://doi.org/10.1049/et.2016.0230.

Detwiler, Bill. “Cracking Open: Apple Pencil Is Powered by Amazingly Tiny Tech.” CNET, CNET, 24 Nov. 2015, https://www.cnet.com/tech/computing/apple-pencil-powered-by-amazingly-tiny-tech/#:~:text=Video%3A%20Cracking%20Open%3A%20Apple%20Pencil,with%20pixie%20dust%20and%20unicorns.

Fulton, Sam. “Apple Now Globally Powered by 100 Percent Renewable Energy.” Apple Newsroom (United Kingdom), Apple Inc, 9 Apr. 2018, https://www.apple.com/uk/newsroom/2018/04/apple-now-globally-powered-by-100-percent-renewable-energy/.

Gartenberg, Chaim. “Apple Is Starting to Ship Devices Directly from Its Stores.” The Verge, Vox Media, LLC, 9 Oct. 2020, https://www.theverge.com/2020/10/9/21509992/apple-store-ship-devices-directly-faster-iphone.

“Identify Counterfeit or Uncertified Lightning Connector Accessories.” Apple Support, Apple Inc., 27 Aug. 2021, https://support.apple.com/en-us/HT204566.

“IPad (9th Generation) - Apple.com.” Apple, Apple Inc., 14 Sept. 2021, https://www.apple.com/in/environment/pdf/products/ipad/iPad_PER_Sept2021.pdf.

Laville, Sandra. “Amazon and Apple 'Not Playing Their Part' in Tackling Electronic Waste.” The Guardian, Guardian News and Media, 26 Nov. 2020, https://www.theguardian.com/technology/2020/nov/26/amazon-and-apple-not-playing-their-part-in-tackling-electronic-waste.

“Our Business - Operations.” Tianqi Lithium, Tianqi Lithium Industry Co., Ltd, http://en.tianqilithium.com/business/produce.html.

Parisa, and Maarten. “Apple’s Global Distribution Channels.” Global Marketing Professor, Global Marketing Professor, 3 May 2021, https://globalmarketingprofessor.com/apples-global-distribution-channels/.

Perez, Santiago. “Is Apple Delivering on Its Environmental Claims?” EWaste World Conference Expo, 12 Feb. 2020, https://www.ewaste-expo.com/is-apple-delivering-on-its-environmental-claims/.

“Plastics.” Learn OpenEnergyMonitor, https://learn.openenergymonitor.org/sustainable-energy/energy/industry-plastic.

“Recycling.” Apple (Saudi Arabia), Apple Inc., https://www.apple.com/sa/recycling/.

Rossignol, Joe. “Apple Pencil Teardown Reveals Antenna, Battery and Tiny Folded Logic Board.” MacRumors, MacRumors, 19 Nov. 2015, https://www.macrumors.com/2015/11/19/apple-pencil-teardown-ifixit/.

Sherwani, Naveed. "Design and fabrication of VLSI devices." Algorithms for VLSI Physical Design Automation. Springer, Boston, MA, 1995. 37-79.

“Smelter and Refiner List - Apple.” Apple, Apple Inc., 31 Dec. 2020, https://www.apple.com/supplier-responsibility/pdf/Apple-Smelter-and-Refiner-List.pdf.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” EIA, 17 May 2021, https://www.eia.gov/energyexplained/use-of-energy/transportation.php.

Vysakh. “Basics of Microcontrollers.” Circuits Today, CircuitsToday, https://www.circuitstoday.com/basics-of-microcontrollers.

Jessica Alvarado

Madison Wong, Kelly Tan

DES 40A

Professor Cogdell

02 December 2021

Following the Apple Pencil Waste Life Cycle:

Environmental and Human Health Impacts

Apple denies planned obsolescence claims despite criticisms and numerous lawsuits (investopedia.com). Many apple products are considered vintage after 7 years and are often not compatible with the latest update or devices. Although the first generation apple pencil does not require a software update, it is incompatible with some of the latest iPad models. Apple released the first generation digital stylus, the Apple Pencil, in 2015. It features precision, tilt/pressure sensitivity, and pairing via the lightning connector. The pencil is made up of a thermoplastic outer shell, a ST Microelectronics low-power 32-bit ARM-based Cortex-M3 microcontroller, a Qualcomm Bluetooth 4.1 chip from Cambridge Silicon Radio and a lithium ion battery. The lithium ion battery is the main component of the apple pencil and it takes up the most space. The lithium ion battery waste in the first generation Apple pencil materials contribute to the harm of the environment and human health

The apple pencil lithium ion battery has harmful byproducts from the mining process that pose a threat to human health and the environment. The demand for the battery is expected to increase, “estimates have pegged the demand for lithium-ion batteries to reach 2.2 million tonnes by 2030” (Kaunda). Lithium is extracted by hard rock mines (such as those in Australia) or from brine by evaporating it from huge salt flats in countries including Argentina and Chile. This process takes up a lot of water supply and harmful chemicals are used in the process. Lithium comes from brine in “South America’s Lithium Triangle, which covers parts of Argentina, Bolivia and Chile, holds more than half the world’s supply of the metal beneath its salt flats” (instituteforenergyresearch.org). The mines took up 65% of the water and these areas are already dry with limited water stores. These communities were forced to look for other sources of water or relocate. The mining of the lithium battery and lithium waste contaminates the water supply and soil. Residents in Argentina deem the lithium mining to be responsible for the contamination of streams that affect humans and livestock. The mining of the lithium battery and lithium waste contaminates the water supply and soil. Lithium ion contamination does not only occur during the extraction of raw materials.

There is contamination of waste waters released at industrial sites, incineration systems, and illegal landfills or storage of old batteries (Rueters.com). Yet, there is still uncertainty around the exact source of lithium contamination. Although small amounts of lithium are found naturally in water, higher amounts of lithium are expected to increase particularly in urban areas. The wastewater treatment plants are not as effective at removing lithium. There is hope and steps are being taken to help with the removal of lithium in contaminated water. A research team from University of Texas at Austin and University of California, Santa Barbara are developing a way to extract lithium from contaminated water (news.utexas.edu). The researchers claimed that a week’s worth of water from hydraulic fracturing in Texas’ Eagle Ford Shale may produce enough lithium for 300 electric vehicle batteries or 1.7 million smartphones. The lithium battery in the apple pencil is small, so it is for certain that they may be able to extract enough lithium for it from the contaminated water. This potential solution is for groundwater contamination, but not for air pollution.

The lithium ion battery in the apple pencil compromises people’s health and the environment because it contributes to air pollution. According to Apple’s 2021 Environmental Progress Report, Apple's carbon footprint is 22.6 million metric tons of carbon dioxide as of 2020. Product transportation makes up 8% of the total carbon dioxide emissions. Product manufacturing releases the largest emissions at 71%. Carbon dioxide is one of the most common pollutants and can impact human health causing respiratory problems. Although Apple plans on becoming a Carbon Neutral company, carbon emissions are not the only pollutant that is of concern. Apple’s factories contribute to air pollution such as carbon dioxide emissions and nitrogen dioxide. This air pollutant is a cause for concern in one Apple factory in particular in ‘IPhone City’ or Zhengzhou, China (9to5Mac.com). Nitrogen dioxide can pose environmental risks such as acid rain and damage crops. It may also impact human health and cause airway inflammation and asthma. There is a new way to capture nitrogen dioxide gases from the air. A research team from The University of Manchester figured out how to turn nitrogen dioxide with nitric acid for industrial use (labroots.com). The system uses a metal-organic framework (MOF) material with 3D porous structures that are able to capture nitrogen dioxide gases. These structures are small but have a large surface area. The goal for this invention is that it will lead to improvements in controlling the polluting effects of nitrogen dioxide for the environment and air pollution control. Hopefully, places like China can implement some of these technologies in the future. For now, there is a growing problem of waste that occurs even before the recycling process.

The Apple pencil has recyclable parts but they are difficult to recycle because of limited services and technology. This shortens the life cycle because most materials are gathered from raw materials through mining rather than recycling. Apple TradeIn program allows users to get credit towards eligible devices and free recycling services (Apple.com). The first generation apple pencil is currently not eligible for credit and can be taken in for recycling. If the product is in good condition it can be reused and if not then recycled. Since the lithium ion battery efficiency degrades overtime (even if you're not using it), there is no telling the lifespan of the lithium battery which may compromise it’s long term usability (popularmechanics.com). Most local E-waste facilities will take the product if one chooses to not use the TradeIn program. Only about 5% of lithium ion batteries are recyclable. Only two percent of Australia's 3,300 metric tons of lithium-ion waste is recycled (instituteforenergyresearch.org). Most of the items recovered are metals like copper, nickel and cobalt, which correspond to the most valuable materials and tend to be expensive (cen.acs.org). Lithium contains a variety of materials that are changing and are not made for disassembly. This makes the recycling process challenging. Brett Robinson, a professor of environmental chemistry at the University of Canterbury in New Zealand, mentioned that “The batteries can be recycled, but most are not,” (Reuters.com). The problem with recycling metals is that their value tends to fluctuate, therefore, recycling is not economically certain. If not recycled, the majority of the batteries end up in landfill and are a fire hazard. The recycled materials are not enough output and more mining is required. Recycling cannot keep up with the increase of waste from obsolete apple products.

The first generation Apple pencil’s short lifespan may have been intentional to encourage consumers to purchase the latest products. The Apple pencil is irreparable and can be replaced within the limited 1 year warranty period. This contributes to waste and has a limited lifespan. The pencil is hard to disassemble which hints that it was not designed to be repaired. The only part of the pencil that is replaceable is the tip. Once the pencil is in need of repair or replacement of batteries, it must be tossed away. The lithium-ion batteries last for 2,000-3,000 cycles around 2 years and begin losing their efficiency (fluxpower.com). The apple pencil is compatible with earlier iPad models. Once these products become obsolete around 7 years, so will the apple pencil (given the lithium battery won’t die out within a few years)(apple.com). I wonder if there is a possibility to explore other ways to lengthen the life cycle of the Apple pencil for the sake of health and the environment. Perhaps Apple can investigate the manufacturing process since it has the highest carbon footprint? I can imagine this may be a challenge as these changes tend to be costly. The use of lithium batteries has a high cost in disrupting the livelihood and health of people’s lives and our environment. I question the idea of lithium batteries as the “green” solution in the car industry as electric cars become more available. In the words of University of Chile lithium expert Guillermo Gonzalez, “This isn’t a green solution – it’s not a solution at all”(instituteforenergyresearch.org).

Works Cited

Air pollution in China’s “iPhone city” blamed on iPhone 12 - 9to5Mac. (n.d.). Retrieved November 30, 2021, from https://9to5mac.com/2020/10/29/air-pollution-in-china/

Antti Porvali, Miamari Aaltonen, Severi Ojanen, Omar Velazquez-Martinez, Emmi Eronen, Fupeng Liu, Benjamin P. Wilson, Rodrigo Serna-Guerrero, Mari Lundström, Mechanical and hydrometallurgical processes in HCl media for the recycling of valuable metals from Li-ion battery waste,Resources, Conservation and Recycling, Volume 142, 2019, Pages 257-266, ISSN 0921-3449, https://doi.org/10.1016/j.resconrec.2018.11.023 (https://www.sciencedirect.com/science/article/pii/S092134491830449X)

Apple Pencil warranty - Apple Community. (n.d.). Retrieved November 30, 2021, from https://discussions.apple.com/thread/250497420

Apple Trade In - Apple. (n.d.). Retrieved November 28, 2021, from https://www.apple.com/shop/trade-in

“Apple Wins Patent for next-Gen Apple Pencil with Advanced Haptics for IPads and IPhones.” Patently Apple, https://www.patentlyapple.com/patently-apple/2020/07/apple-wins-patent-for-next-gen-apple-pencil-with-advanced-haptics-for-ipads-and-iphones.html.

Editor. “Apple Pencil Almost Impossible to Repair, Finds IFixit Teardown.” TECHPHLIE, https://www.techphlie.com/2015/11/apple-pencil-almost-impossible-to.html.

It’s time to get serious about recycling lithium-ion batteries. (n.d.). Retrieved November 30, 2021, from https://cen.acs.org/materials/energy-storage/time-serious-recycling-lithium/97/i28

Kaunda, R. B. (2020). Potential environmental impacts of lithium mining. Https://Doi.Org/10.1080/02646811.2020.1754596, 38(3), 237–244. https://doi.org/10.1080/02646811.2020.1754596

Kevin M. Winslow, Steven J. Laux, Timothy G. Townsend, A review on the growing concern and potential management strategies of waste lithium-ion batteries, Resources, Conservation and Recycling, Volume 129, 2018, Pages 263-277, ISSN 0921-3449, https://doi.org/10.1016/j.resconrec.2017.11.001.(https://www.sciencedirect.com/science/article/pii/S0921344917303774)

Lithium from electronic waste can contaminate water supply | Reuters. (n.d.). Retrieved November 30, 2021, from https://www.reuters.com/article/us-health-water-lithium/lithium-from-electronic-waste-can-contaminate-water-supply-idUSKBN1YM2JW

Luisa Canopoli, Frédéric Coulon, Stuart T. Wagland, Degradation of excavated polyethylene and polypropylene waste from landfill, Science of The Total Environment, Volume 698, 2020, 134125, ISSN 0048-9697, https://doi.org/10.1016/j.scitotenv.2019.134125.(https://www.sciencedirect.com/science/article/pii/S0048969719341026)

M Contestabile, S Panero, B Scrosati, A laboratory-scale lithium battery recycling process This work has been presented as an invited talk at the 4th International Battery Recycling Congress, Hamburg, Germany, 1–3 July, 1998.1, Journal of Power Sources, Volume 83, Issues 1–2,1999,Pages 75-78, ISSN 0378-7753, https://doi.org/10.1016/S0378-7753(99)00261-X.(https://www.sciencedirect.com/science/article/pii/S037877539900261X)

Murodjon, S., Yu, X., Li, M., Duo, J., & Deng, T. (2020). Lithium Recovery from Brines Including Seawater, Salt Lake Brine, Underground Water and Geothermal Water. Thermodynamics and Energy Engineering. https://doi.org/10.5772/INTECHOPEN.90371

New Way to Pull Lithium from Water Could Increase Supply, Efficiency - UT News. (n.d.). Retrieved December 1, 2021, from https://news.utexas.edu/2021/09/08/new-way-to-pull-lithium-from-water-could-increase-supply-efficiency/

Obtaining service for your Apple product after an expired warranty - Apple Support. (n.d.). Retrieved November 30, 2021, from https://support.apple.com/en-us/HT201624

“Our Environmental Initiatives.” Qualcomm, 22 Oct. 2021, https://www.qualcomm.com/company/corporate-responsibility/responsible-business/sustainable-product-design/environment.

P. A. D. Legaspi et al., "Porting an Operating System on an ARM-based sensor platform," TENCON 2015 - 2015 IEEE Region 10 Conference, 2015, pp. 1-3, doi: 10.1109/TENCON.2015.7372829.

Planned Obsolescence Definition. (n.d.). Retrieved November 30, 2021, from https://www.investopedia.com/terms/p/planned_obsolescence.asp

Rahman, A., AFROZ, R., & SAFRIN, M. (2017). Recycling and Disposal of Lithium Battery: Economic and Environmental Approach. IIUM Engineering Journal, 18(2), 238–252. https://doi.org/10.31436/iiumej.v18i2.773

The Environmental Impact of Lithium Batteries - IER. (n.d.). Retrieved November 30, 2021, From https://www.instituteforenergyresearch.org/renewable/the-environmental-impact-of-lithium-batteries/

Top 5 Factors That Affect Industrial Battery Efficiency. (n.d.). Retrieved November 30, 2021, from https://www.fluxpower.com/blog/top-5-factors-that-affect-industrial-battery-efficiency

Why Your Gadgets’ Batteries Degrade Over Time. (n.d.). Retrieved November 30, 2021, from https://www.popularmechanics.com/technology/gadgets/how-to/a7432/why-your-gadgets-batteries-degrade-over-time-6705747/

Wojciech Mrozik, et al. “Environmental Impacts, Pollution Sources and Pathways of Spent Lithium-Ion Batteries.” Energy & Environmental Science, Royal Society of Chemistry, 13 Oct. 2021, https://pubs.rsc.org/en/content/articlehtml/2021/ee/d1ee00691f.