Design Life-Cycle

assess.design.(don't)consume

Anabela Stewart

Chantal Lau, EJ Balingit

DES 40A

Professor Cogdell

Piano Raw Materials

A true tale as old as time, the piano is an instrument that has been present through centuries of history. Originally created in the year 1700, this beautifully crafted piece is mainly structured of high quality wood, like mahogany or maple, and intricately crafted with copper or high carbon steel strings that ring by the playing of early ivory keys all the way to modern plastic keys. When built well, pianos have the potential to have a usable life span of up to 100 years. Early methods of material harvesting for pianos were not the most sustainable, in practice. Deforestation and a high demand for ivory trade became dangerous methods for attaining these materials, but over time, more sustainable alternatives to these extreme harvesting techniques have been executed. Aside from production materials, a piano is almost fully recyclable or reusable at the end of its life. This opportunity for repurposing materials brings balance to any wasteful emissions that may come with the territory of material acquisition. With the continuation of responsible harvesting techniques paired with the reliable manufacturing of long lasting pianos, these instruments can continue to serve consumers without a significantly harsh ecological footprint following its path.

The high demand of luxury timber products, such as mahogany, pose a threat to major wildlife ecosystems in Central and South America. The 20th century saw a major boom in the harvest of mahogany in South America. The discovery of an abundance of this luxury product drew in enough consumers to create a massive mahogany industry in the Americas. Nearly 6 million sawn mahogany were produced and exported from Brazil between 1971 and 1992 (Conservation Letters, 2010) leaving a trail of corruption in the industry by those over exploiting what was left to harvest. Selective logging, the process of harvesting only the highest value trees, that is used in mahogany farming does not allow for the sustainable regeneration of these trees. By taking the strongest and largest trees, harvesters are also taking a majority of seed producing trees as well as altering the environment that no longer encourages new growth. This fall was a turning point towards environmental protections and an overall shift in harvesting practices.

The world is currently in a universal shift of transforming overharvesting practices into sustainable systems of production. The conversation surrounding the conservation of mahogany is one that started in the 1990’s and continues to be a complicated ongoing fight. The tree is currently under protection by United Nation CITES (Convention on International Trade in Endangered Species) requiring any export operation to obtain permits (Global Trees Campaign). It is also common for mahogany producing countries to have their own regulations or laws following the protection of the species. Unfortunately, the bigger problem lies in a lack of infrastructure able to fully enforce these policies. In places like the Amazon Rainforest that are so densely packed, it is nearly impossible to stop all illegal harvesting activity without proper government resources. Taking care of the earth’s natural resources is an evolving process that proves to become successful with time and consistent advocacy and continues to be something nations all over the world are collectively working towards.

Needing a more successful alternative from the mahogany harvest for pianos, maple has quickly become a much more sustainable, and equally reliable wood that is used as the body structure of the instrument. Maple offers an incredibly large growing stock in North America. According to Quynh Nguyen, American forests produce roughly 36 million cubic meters of maple growth annually, while the consumption of the wood is only half the rate of production. Additionally, maple trees are large collectors of carbon dioxide from the atmosphere and also have the ability to act as long term carbon storage when in furniture form, or in this case, piano form. This tree species is a great alternative to more exclusive woods, like mahogany, and gives more opportunity to restructure responsible land management.

Second most abundant to wood harvest for pianos, is the historical ivory trade and its collapse that morphed into plastic being the modern material for piano keys. Ivory was once a prized material in the early 1900’s for many uses, including piano keys. At this time the United States alone was consuming over 200 tons of ivory a year (National Geographic). This period of reckless hunting resulted in a dramatic decrease of the global elephant population. It was not until the 1990’s that CITES moved to stop ivory trade in an attempt to repopulate elephants. In more recent years, there is still believed to have been a 30 percent decline in elephant numbers between 2007 and 2014 (Wang, 2016). While piano manufacturing no longer commonly uses ivory, this nearly irreversible damage is a legacy to learn from. Turning to the manufacturing of synthetic materials has its cons, but it most definitely avoids direct wildlife loss.

The last two major raw materials found in pianos are copper and steel. These metals make up the strings and pedals of the instrument. Copper is extracted through open pit mining. This process involves blasting rock downward to open up a large ‘pit’ shape to pull the metals from the earth. Open pit mining does run a risk of spreading dust with heavy metals or worst case, polluting nearby water sources with toxic waste. While this process can be disruptive, copper alloys and scraps are also able to be recycled by being melted and re purified. In 2010 alone, over 770,000 metric tons of copper were recycled, equivalent to around six billion dollars (University of Arizona, Papp, 2010). Steel is processed slightly differently and is responsible for approximately 11 percent of CO2 emissions, says the World Steel Association. Electric Arc Furnaces are used in over 70 percent of production in modern times and are believed to emit three-quarters less the carbon intensity than traditional steel blast furnaces. While any emissions are potentially harmful to the environment, it is hopeful to see that technology is improving not only in production but also in the ability to recycle and reuse these materials.

After fully built, the standard use of a piano can give an expected lifetime of 30 to 100 years. This wide range is dependent on many factors including the quality of the original assembly, the amount of use the piano gets, and how well the piano can be maintained. Being that pianos have existed for so many years and are intentionally built to last, it is fairly accessible for piano owners to regularly maintain their instruments with the help of knowledgeable professionals and the use of replacement parts from older models. Outside of regular tuning, it is recommended that pianos are serviced once a year. Piano service companies are quite easy to find and encourage people to easily preserve their piece. This type of practice demonstrates responsible ownership that insures a long life expectancy for the piano and avoids any wasteful behaviors.

Once that piano has gone through its expected lifetime, there are several options of disposal. The most wasteful method would be taking a piano to the dump, but luckily there are removal services or donation centers that could take these large instruments away. To avoid any unnecessary waste when parting with a piano, it is best that the instrument be fully disassembled and sorted by material type. It is possible for one to do this on their own, but it is also common for someone to be hired to properly dispose of the piano. Individually, the biggest components of a piano are able to be recycled or repurposed to avoid ending up in a landfill.

The piano is an internationally played instrument. Its intricate design has been with many cultures for hundreds of years. After fully analyzing the historical process of material accumulation, it is true to say that pianos will more than likely continue to exist for hundreds more years to come. The continued use of high quality materials will guarantee a quality build. Ultimately, it is in the hands of large companies and international environmental organizations to continue doing the work of protecting endangered species and making legislation that encourages responsible land management. In turn, accountability, creativity, and ecological protection will be the most important elements of product production, not only for pianos, but for maintaining sustainable practice in industry operations.

Bibliography

Chaiklin, Martha. “Ivory in World History – Early Modern Trade in Context.” Compass.onlinelibrary.wiley.com, History Compass, 4 June 2010, https://onlinelibrary.wiley.com/doi/pdf/10.1111/j.1478-0542.2010.00680.x.

Collaboration . “Big-Leaf Mahogany.” Global Trees, https://globaltrees.org/threatened-trees/trees/big-leaf-mahogany/.

Contributor. “How Pianos Are Made.” GospelChops, 2 May 2022, https://gospelchops.com/how-pianos-are-made/.

“Copper Mining and Processing: Processing Copper Ores.” Superfund.arizona.edu, University of Arizona, 17 Mar. 2021, https://superfund.arizona.edu/resources/learning-modules-english/copper-mining-and-processing/processing-copper-ores.

“FAQ: How Are Copper Conductors Made/Processed?: Eland Cables.” Eland Cables, https://www.elandcables.com/the-cable-lab/faqs/faq-how-are-copper-conductors-made-processed-mine-extraction-to-stranding.

Grogan, James, and Arthur G Blundell. Over‐Harvesting Driven by Consumer Demand Leads to Population Decline ... Society for Conservation Biology, 11 Feb. 2010, https://onlinelibrary.wiley.com/doi/10.1111/j.1755-263X.2009.00082.x.

“The History of the Ivory Trade.” National Geographic Society, https://education.nationalgeographic.org/resource/history-ivory-trade.

“How a Piano Is Made Making the Body.” How a Piano Is Made:Making the Body - Musical Instrument Guide - Yamaha Corporation, Yamaha Corporation, https://www.yamaha.com/en/musical_instrument_guide/piano/manufacturing/.

Nguyen, Quynh. “How Sustainable Is Maple Wood? Here Are the Facts.” Impactful Ninja, https://impactful.ninja/how-sustainable-is-maple-wood/.

Wang, Steffanee. “It’s Almost Impossible to Sustainably Harvest Ivory.” Psmag.com, 3 Oct. 2016, https://psmag.com/news/its-almost-impossible-to-sustainably-harvest-ivory.

EJ Balingit

Chantal Lau, Anabela Stewart

DES 40A

Professor Cogdell

The Embodied Energy of a Piano

The piano is a keyboard musical instrument invented in Italy 1700 by Bartolomeo Cristofori. For more than a century, it has been a dominant force in the music industry (Ehrlich). The first piano, the fortepiano, was used during the time of Mozart. It became a common item during the Victorian era, referred to as “household orchestra and god.” Today, Japanese manufacturers like Yamaha create modern versions of the instrument. There are several types of pianos including grand, electric, upright, and hybrid. Pianos are very complicated instruments, containing more than 7,000 parts, that all support the main functional features: keyboard, strings, soundboard, hammers, bridge, and dampers (Steinway Pianos).

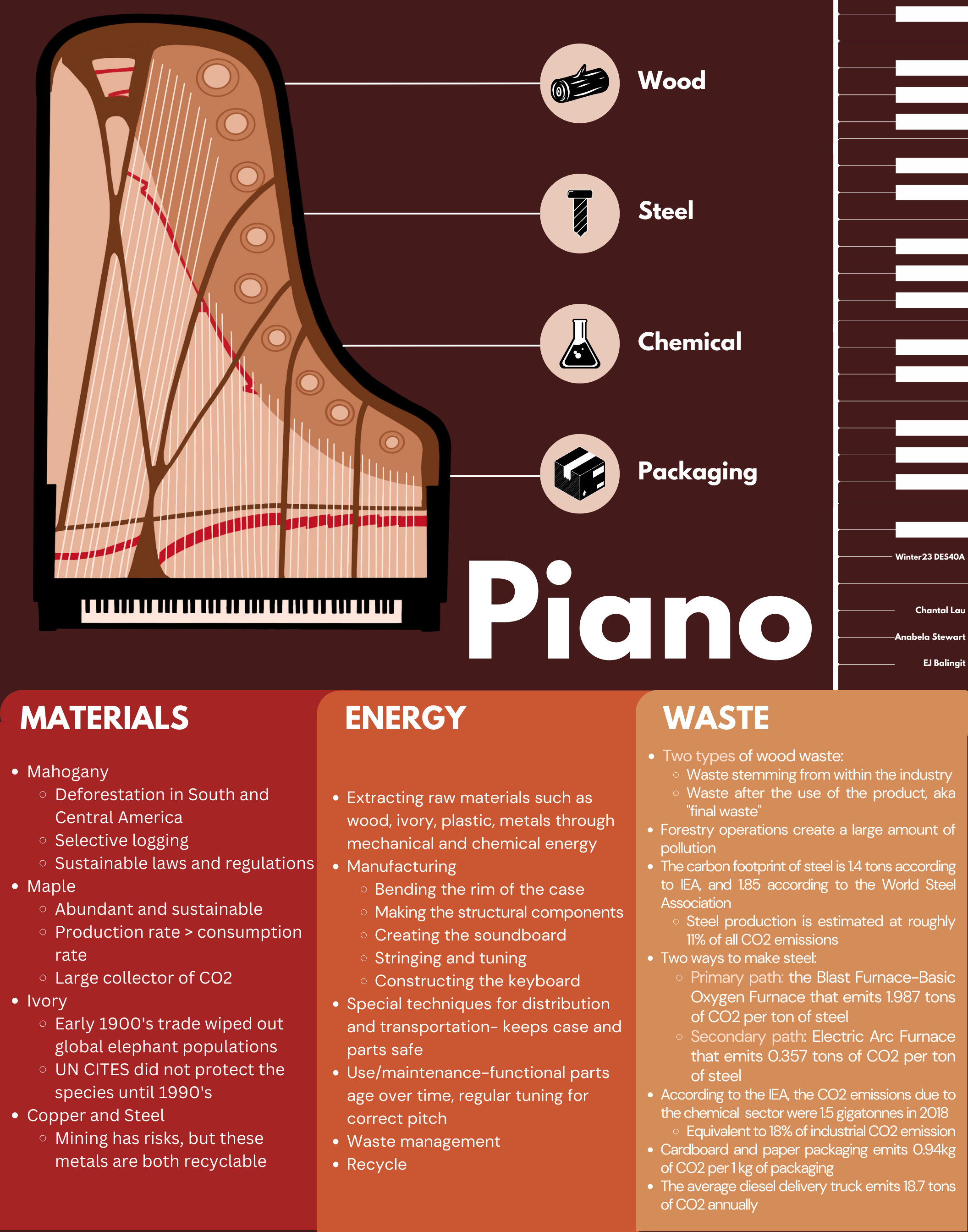

Pianos have several parts made out of different materials. When going into raw materials, pianos are made out of hardwood including maple and spruce. Metal is found as well, for example, cast iron plates (Bielefeldt). Sand is extracted in order to cast molds. The molten iron for casting is made of pig iron with steel and scrap iron. The case is made out of woods like maple, roewood, and mahogany. Its strings are made out of either high carbon steel or copper (Ford). Other woods like spruce make up the soundboard and the bridge and pin block consist of maple. In its early years, the actual playing keys were different from todays’ concepts. The black keys were made of ebony and the white keys consisted of ivory (Dolge). Since endangered animals were being poached for ivory, it became illegal in some countries, and piano makers

Balingit 2

turned to plastic to make the keys. The pedals are tiny functional parts that need brass and other metal alloys to take form.

The manufacturing process is a very complicated one. Steinway & Sons is a prominent piano company that specializes in world-class pianos. Mahogany and maple wood are harvested by selective logging, when only high value trees are extracted from forests. Mechanical energy is needed to extract the wood and then transport it to the factory. Their style is drying the highest quality wood for two years when it arrives. Steinway’s method of rim bending is the first step in creating a grand piano, requiring mechanical labor in every step. Long-fiber maple wood up to 25 feet long is layered, bent together, and then bent in a press to form an inner and outer rim. The molded case would take another few months to dry to ensure shape and texture. They are put under controlled temperature, using thermal energy, in order for the wood to reach the right moisture to hold other wooden components: pinblock, cross braces, and keybed, in which they are all glued together. The cabinet is finished to improve on the piano’s sound properties. The piano string contacts the bridge in order to transfer energy to the soundboard. Parts of the bridge must be removed when they interfere with free vibrations from the string, in a process called “notching.”

In the next step, the craftsmen nail hundreds of nails to every bridge in order to guide the strings. This process makes it certain for transmission of sound to the soundboard to stay at one hundred percent. The pianos are said to be holding 40,000 pounds of tension from its strings made of elastic steel wire. The tension is manually applied with a tuning wrench. A small square with a pre-set weight is used to check the balance of each key in order to guarantee they will return to its original position after being activated when played. The keys are the deciding factors of sound coming out of the piano due to hammers hitting them. With respect, the strings in the

Balingit 3

low range are going to be a lot heavier than the ones in the high range. When the stringers are triggered, they must be sparked vertically to ensure the fullness of the sound. The technicians from Steinway continue to tune the piano until all keys are hit vertically. In order to test the keys’ stability, the piano is taken to “The Pounding Room” where each and every key is played up to 3,200 times.

Casing and finishing up the piano ends the manufacturing process. Each one requires six coats of paint to ensure the right thickness in case sanding and polishing is required later on. Steinway highly believes in quality, to manufacture pianos in a slow and steady manner rather than efficient mass production for increasing profits. The process of manufacturing pianos has remained the same for the most part for over a century. Engineers, however, are seeking new methods including vacuum casting to create cast iron plates with smooth finishes without the process of grinding.

Transporting pianos are very difficult because they are heavy and durable, yet quite delicate. Maintaining a piano requires regular tuning for the correct pitch to be certain. VSW Expeditie is a “global service” that prioritizes transport in furniture home delivery, and even pianos. The process takes place in their warehouse, covering more than 15,000 m2 and requiring climate control and an electronic humidity control system to ensure safety. In this specific distribution example, transport goes through a smooth process due to vehicles with air suspension and hydraulic loading platforms, double loading fibers, customized packaging material, and takes no more than 80 pianos per vehicle. Electrical, mechanical, and thermal energy are all used within the transportation process, especially with climate controlled safety systems. They also require regular maintenance towards key parts in order to function properly. The main functional features age over time and eventually could be reconditioned or even rebuilt

Balingit 4

by rebuilders. Strongs must be replaced over time. Pianists would hire a piano tuner which are technicians in their craft, requiring specialized tools.

Pianos are very large instruments and must require moving services when recycled. They are not small items that you can throw away when you find no longer need in them. They require moving teams or maybe even to be disassembled to move to a different spot. They have a very long life but it is difficult to put up an offer when they reach the end of their lifespan because many people are not looking to buy an old and used instrument (Healy). While some end up in the landfill, many sources recommend eco-friendly recycling and donation options. Many places would accept older pianos including schools, churches, senior centers, and social groups. A few third-party organizations and projects match pianos with nonprofits as well. Goodwill, Piano Finders, The Salvation Army Piano Donation, and The Beethoven Foundation are a few organizations that pick up pianos for free if it meets requirements. Donating pianos to churches, schools, or programs with low incomes will not result in a tax deduction. In order to receive one, one must donate towards a non-exempt, nonprofit organization known as 501 ©(3). Nixxit is one of many junk removal companies that offers piano removal and disposal. It requires disassembling the piano for recycling and eventually safe disposal. Even though it may no longer function as a piano anymore, its several thousand parts are still recycled and used for other items. Removers take the hardwood, metal, and even strings to make new pianos or for other resources that require those parts. While the worn out piano no longer holds any value, it still has wood, steel wire, screws, and cast iron, which is passed down to many other items.

Pianos are a very complicated but delicate piece of musical instrument. They require thousands of parts which run many tasks in order for the whole point to function properly. The gaining of raw materials may take several years from extracting hardwood trees in forests to cast

Balingit 5

iron to hold many cabinets together. The energy needed to create a piano is also a very complicated one. There are several machines from cutting down trees, to cooling the wood, and individuals crafting each specific detail that require thermal, kinetic, and mechanical energy. Some errors include finding the embodied energy of every single part and how much energy is used because it is very relative. There are many types of pianos as well as different parts. There is also a lot of waste used in the making of pianos. Even the energy and CO2 released when gathering and transporting the parts to the factory is waste emissions released to the environment. The process of recycling a piano is also not an easy one, most would require calling a removal team due to its size. Pianos are very complicated instruments that require much care from the beginning of its creation to the end of its life.

Balingit 6

Bibliography

161 Facts about Steinway & Sons and the Pianos They Build,

https://web.archive.org/web/20141116183623/http://www.steinwaypianos.com/159-facts-about-s teinway-and-the-pianos-they-build.

Bielefeldt, Catherine C.; Weil, Alfred R., ed. The Wonders of the Piano: The Anatomy of the Instrument. William Anton Publishing, 2004.

DOLGE, Alfred. Pianos and Their Makers: A Comprehensive History of the Development of the Piano. Dover, 1972.

Ehrlich, Cyril. The Piano: A History. Clarendon Press, 2002.

Ford, Charles Henri. Making Musical Instruments: Strings and Keyboard. Faber & Faber, 1979. Healy, Nick. The Piano. Creative Education, 2006.

“How a Piano Is Made Making the Body.” How a Piano Is Made:Making the Body - Musical Instrument Guide - Yamaha Corporation,

https://www.yamaha.com/en/musical_instrument_guide/piano/manufacturing/. Nave. The Piano, http://hyperphysics.phy-astr.gsu.edu/hbase/Music/pianof.html.

“A Piano Is Made in 6 Steps.” Hollywood Piano, 9 Sept. 2022,

https://www.hollywoodpiano.com/a-piano-is-built-in-6-steps/.

“Piano Transport.” VSW Expeditie B.V., 12 Oct. 2021, https://vsw.nl/en/piano-transport/.

Balingit 7

Chantal Lau

3/15/23

DES40A

Justin Marsh

Research Paper: Piano

The piano is an instrument that has been beloved for centuries, invented by Bartolomeo Cristoforia in Padua, Italy, in the 1700s. The piano has over 12,000 individual parts and has six key features: the keyboard, hammers, dampers, bridge, soundboard, and strings. The outside of the piano is typically made of hardwood, such as hard maple or beech. These parts, along with the screws, of the piano are made from materials that were selected for strength and durability. When you press a key on the piano, a cushioned hammer inside hits the strings in the piano's body. The strings are supported by the bridges, which are also attached to the soundboard. After the hammer hits the string, the vibration moves through the bridge and to the soundboard. This results in a loud sound that is the result of vibrating air. Once the piano is made, all of its parts can be reused and not go to waste. This allows less waste in landfills and less CO2 emitted into the atmosphere. Pianos are very eco-friendly objects that are useful from the cradle to the grave.

Wood is a very in-demand renewable resource that is very important for construction and everyday materials. Since wood does not compete with food, there has been an increase in the consumption of food for energy production, building materials, chemicals, etc. By 2030, there is a chance that the production of wood may become insufficient according to the demand in Europe. Wood waste is typically divided into two categories: waste stemming from

Lau 2

within the industry and waste after the use of the product, also known as final waste. The waste that is generated from within the industry is not legally considered waste. In Europe, the amount of legally defined wood waste was roughly 33.2 million tons in 2007. Wood recycling is usually done by grinding or cutting down wood into chips and fibers.

Forestry operations are able to create a large amount of pollution. When forests are cut down, a large amount of carbon and CO2 is released into the atmosphere. One mature tree is able to take in about 50 pounds of carbon dioxide every year. Deforestation and logging contribute to global warming. Forests are cleared to keep up with the demand for agricultural products and other human needs. Logging and wood processing in America emit much more carbon, roughly five times the amount, as wildfire, bark beetles, wind thrown, land use conservation, and drought combined. However, harvesting trees can create bioenergy that can substitute fossil fuel energy. Wood products can also store carbon and substitute for emission-intensive products such as concrete and steel.

The acoustic piano is a very intricate and complex instrument with thousands of parts that make a piano a piano. A majority of those parts, roughly 85%, are made from wood. The main parts of a piano that are made from wood are the casing and lid, keyboard, legs, wheels, hammers, and soundboard. Because the piano is made from the majority of wood, more wood harvesting must be done to build a piano. This means that there is more CO2 emitted into the atmosphere. Although a piano is made from wood, once it has lived past its due, we are able to recycle the piano’s wooden frame, which saves energy and is more beneficial for our atmosphere.

Lau 3

The carbon footprint of steel is 1.4 tons according to IEA and 1.85 according to the World Steel Association. Steel production is a considerable percentage of global CO2 emissions and is estimated at roughly 11% of all CO2 emissions. However, other sources say it is closer to 7.2%. There are ways to recycle steel, however. There are two ways to make steel: the primary way, known as the Blast Furnace-Basic Oxygen Furnace, and the secondary way, the Electric Arc Furnace. The primary path uses 13.8% of scrap metal and emits 1.987 tons of carbon dioxide per ton of steel produced. The second way uses 105% of scrap metal with an emission rate of 0.357 tons of CO2. Although steel can be recycled with 1.787 tons of CO2 saved, the amount of scrap steel is not enough to fulfill the current demand.

A small percentage of the piano is made from steel or metal: the springs, pedals, and the screws that hold the instrument in place. There are also the tuning and hitch pins that are located in the piano, which are made of steel cylinders. Metal scraps and shavings may form during manufacturing and must be disposed of or recycled. Once the piano is taken apart, the pedals, screws, and strings can be recycled and contribute to the effort of a more CO2-free world.

The manufacturing process of a piano may also include chemical waste, such as the glues, adhesives, and finishes used. Rubber is used underneath the legs of the piano. In order to make rubber, there is a mix between oil or coal, natural gasses, and many additives. Synthetic rubber emits about 2,921kg of CO2 into the atmosphere for every 1 kg of rubber made. Glues are made from collagen from animal by-products like skin and bones. In order to turn collagen into glue, the glue must be cooked at a high temperature and then extracted. According to the

Lau 4

IEA (International Energy Agency), the CO2 emissions in 2018 due to the chemical sector were 1.5 gigatonnes. This is equivalent to 18% of industrial CO2 emissions.

After the piano is completed, they are put up for sale. Once someone buys their new piano, many companies ship it or deliver it to the buyer’s house. Pianos generate packaging waste, and that can be from crates made from wood or cardboard, or plastic packaging such as bubble wrap. This generates waste that must be disposed of. Cardboard and paper packaging emits 0.94kg of carbon dioxide per 1kg of packaging. Plastic, on the other hand, produces 3.50kg of carbon emissions per 1kg of packaging. Sometimes styrofoam is used, and that is 1.16kg of carbon emissions per 1kg of packaging.

After packaging the piano, it must be shipped over via container ship or moving truck. A cargo ship produces 16.14g of CO2 per metric ton of goods shipped per kilometer. Container ships generate an average of 140 million metric tons of CO2 annually, and finally, bulk carriers emit 440 million metric tons of carbon dioxide yearly. After the possible shipment of the piano, it must go onto a moving or freight truck. The average freight truck is roughly 161.8 grams of CO2 per ton-mile, and the average diesel delivery truck emits 18.7 tons of carbon dioxide annually.

Once the piano is done being used and it has reached its expiration date, which can span from 10-30 years, many people end up hiring someone to throw their piano away for them. However, you are also able to recycle your piano and certain parts of it after reviewing if the piano is beyond repair or not. In order to recycle a piano, more often than not, it must be fully disassembled. Since a piano is made by the combination of many small and large components, they are also made of various materials. Many recycling centers do not accept wood, and

Lau 5

sometimes it is left as waste, but sometimes the wood can be recycled to make new products. Most metal parts of the piano are recyclable.

The piano is one of the most popular instruments in the world. In order to make one, there are several different parts that make a piano a piano. The main material that is used to build a piano is wood, which makes up 85% of it. Forestry and logging processes release a large amount of CO2 into the atmosphere, although they can also create bioenergy that replaces fossil fuel energy. Two types of wood waste accumulated during the manufacturing process of wood: waste stemming from within the industry and “final waste.” Pianos are also partially made up of steel, which is a little harder to recycle. In order to recycle the steel parts, they must be melted down by a furnace that is run at an extremely high temperature. There are two ways to make steel: the Blast Furnace-Basic Oxygen Furnace and the Electric Arc Furnace. Unfortunately, the one we need to keep up with the demand for steel releases an enormous amount of CO2. Chemicals such as glues, adhesives, and rubbers are used to keep the piano together, and the chemical sector has been reported to make up 18% of industrial CO2 emissions. Pianos are then packaged with cardboard and plastics, which also require the issue of releasing CO2 into the atmosphere. Finally, the piano is shipped and driven to the purchaser’s house. Although the piano requires an enormous amount of CO2 to be produced for all of its materials, all parts can be recycled and reused in various ways.

Lau 6

Bibliography

Besserer, Arnaud, et al. “Cascading Recycling of Wood Waste: A Review.” Polymers, vol. 13, no. 11, May 2021, p. 1752. Crossref, https://doi.org/10.3390/polym13111752. Cutler, Aurora, et al. “The Wood Product and Carbon Connection.” USDA, 29 July 2021, https://www.usda.gov/media/blog/2019/10/07/wood-product-and-carbon-connection. Doedee, Vincent. “What Is the Carbon Footprint of Steel?” Sustainable Ships, Sustainable Ships, 12 Mar. 2023,

https://www.sustainable-ships.org/stories/2022/carbon-footprint-steel#:~:text=Weighte d%20average%20carbon%20footprint%20of,to%201%20tonne%20steel%20produced.

“How Is Rubber Made?” Coruba, 21 Dec. 2022,

https://www.coruba.co.uk/blog/how-is-rubber-made/.

Kana, Hemal. “What Is the Carbon Footprint of Packaging?” TEORRA, 16 Jan. 2023, https://www.teorra.com/blog/what-is-the-carbon-footprint-of-packaging. Kilgore, Georgette. “Air Freight vs Sea Freight Carbon Footprint (The Real Numbers in 2023).” 8 Billion Trees: Carbon Offset Projects & Ecological Footprint Calculators, 20 Jan. 2023, https://8billiontrees.com/carbon-offsets-credits/carbon-ecological-footprint-calculators/ air-freight-vs-sea-freight-carbon-footprint/#:~:text=A%20cargo%20ship%20produces%20 16.14,metric%20tons%20of%20carbon%20dioxide.

MacLeod, Robert. “How the Petrochemicals Industry Can Reduce Its Carbon Footprint.” World Economic Forum, 21 Oct. 2021,

Lau 7

https://www.weforum.org/agenda/2021/10/how-petrochemicals-industry-can-reduce-it s-carbon-footprint/.

“Nonpoint Source Pollution, NOS Education Offering.” Pollution Tutorial, 1 June 2013, https://oceanservice.noaa.gov/education/tutorial_pollution/08forestry.html#:~:text=For estry%20operations%20such%20as%20logging,increasing%20the%20risk%20of%20erosi on.

Seppälä, Jyri, et al. “Effect of Increased Wood Harvesting and Utilization on Required Greenhouse Gas Displacement Factors of Wood-Based Products and Fuels.” Journal of Environmental Management, Academic Press, 28 June 2019,

https://www.sciencedirect.com/science/article/pii/S0301479719308333?via%3Dihub. “Tropical Deforestation and Global Warming.” Union of Concerned Scientists, 27 July 2008, https://www.ucsusa.org/resources/tropical-deforestation-and-global-warming#:~:text= When%20forests%20are%20cut%20down,degradation%20contribute%20to%20global% 20warming.

Worrell, Ernst, et al. “Energy Efficiency and Carbon Dioxide Emissions Reduction Opportunities in the US Iron and Steel Sector.” Energy, Pergamon, 12 Apr. 2001,

https://www.sciencedirect.com/science/article/pii/S0360544201000172?via=ihub.

Yellishetty, Mohan, et al. “Iron Ore and Steel Production Trends and Material Flows in the World: Is This Really Sustainable?” Resources, Conservation and Recycling, Elsevier, 31 Mar. 2010,

https://www.sciencedirect.com/science/article/pii/S0921344910000674?via%3Dihub.