Design Life-Cycle

assess.design.(don't)consume

Raw Materials

Brandon Gramajo

Gabriel Figueroa, Christina Liu

DES 40A

Professor Cogdell

Sony XM4 Headphones: Raw Materials

Introduction

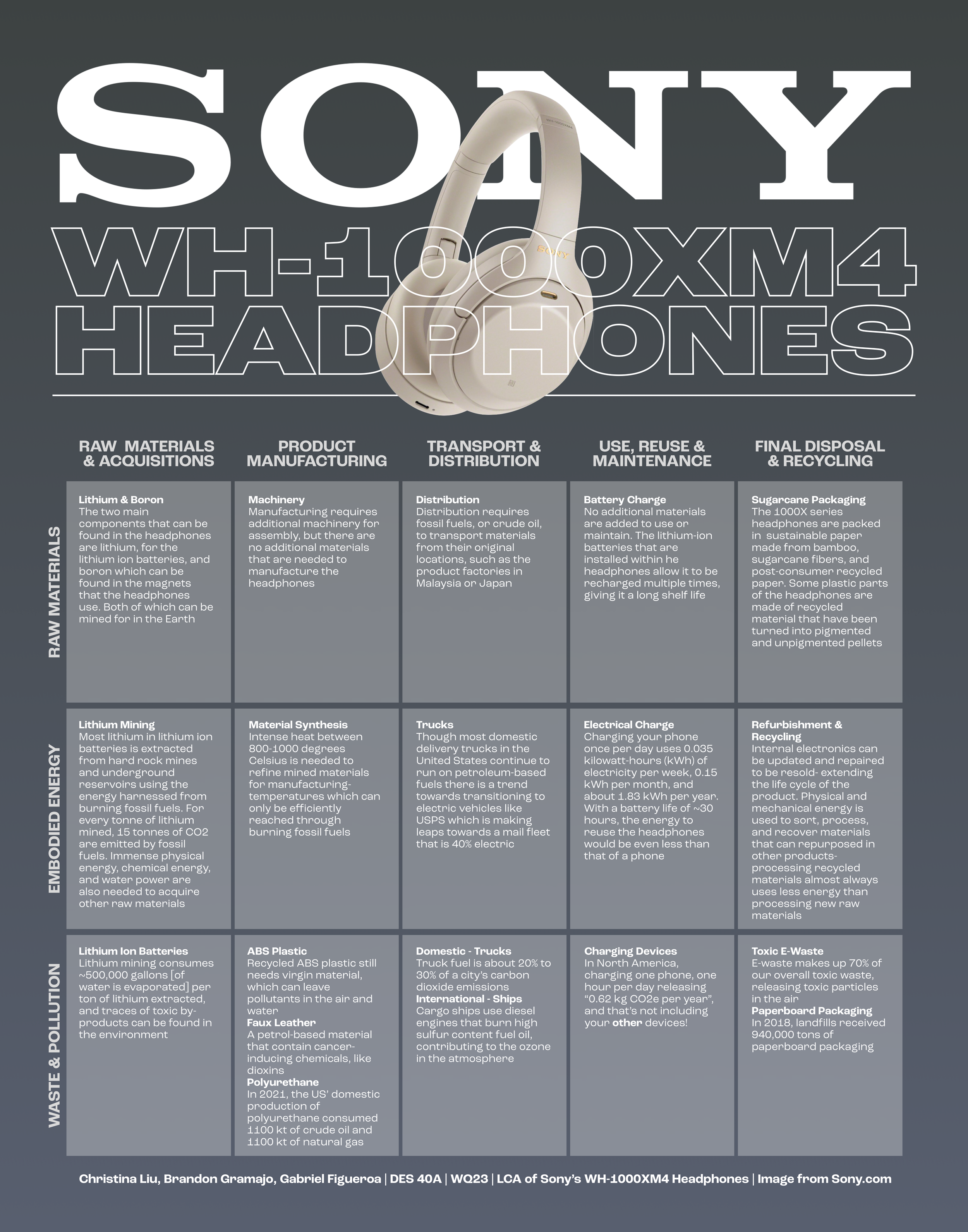

There are a lot of headphones out in the current market that are competing to see who can give out the best quality of sound, while also looking fashionably sleek. The WH-1000XM4 Sony headphones are one of the few brands of quality headphones that are out in the market right now. Ever since noise canceling became a feature, every company since then has been trying to come out as the best noise canceling headphones that gives you the most control in how you listen to your music and gives you the best quality on top of that. The Sony WH-1000XM4 headphones do not only have a noise canceling function, but they even have a speak-to-chat feature added along with the noise canceling. It allows users to stop their music by using the sound of their voice, ideal if your hands are busy doing something else. Once the chat is over, the music starts to play automatically again. Along with the nice simplistic design, who wouldn’t want a pair of Sony headphones. These are just some of the functions that make them a great pair of headphones. However, one of the things that people don’t really put into consideration when they’re thinking about is what the headphones themselves are made of. Sony, along with other major companies, are working to find other alternatives in order to create their products that will have a weaker impact on the Earth’s health so as to not damage it as badly as it is. “Our headphones are engineered for high-quality design and sound, and also with the environment in mind… Sony continues to pursue environmentally conscious development of both products and packaging” (ECO MDR). Even though they are still far from having an eco-friendly product, Sony is well on their way to doing so.

Raw Materials

There are a lot of parts that come together in order to produce a set of Sony XM4 headphones. First, we have the cups of the headphones. The cups on the Sony XM4 are made from faux leather which is a fabric made with a base of polyester and “then given an imitation leather finish and texture with wax, dye, polyvinyl chloride (PVC), or polyurethane” (Media). The faux leather helps to give it that nice finish, while also staying away from using real leather. Then we have the memory foam inside the muffs. Memory foam is usually made with “a polymer (a substance with large molecules, consisting of many small, similar subunits bonded together) called polyurethane” (Noyed). Polyurethane is actually used within a lot of other products as well, such insulators in buildings and refrigerators. With that being said, can really the headphones keep sounds from the outside get into the area enclosing the users ears. Lastly, the lithium ion batteries that allow the headphones to be recharged for users to continue their music experience.

Product Manufacturing

No new materials are introduced in the making of the headphones at this stage. Only manual labor and machinery are used in order to craft the pieces and put them together. The headphones are usually manufactured in one of Sony’s factories overseas, whether in Japan or Malaysia. Though, since the Sony XM4 headphones were made in their Malaysia factory, their XM4 most likely followed suit as well, though not much is said about where they are manufactured.

Transportation and Distribution

Even though I was unable to find any info as to how Sony transports their headphones around, it can be assumed that any form of transportation that is used is going to be using fossil fuels to transport the product. Chances are that their trucks use fossil fuels as well for their gasoline. One form of fossil fuels that can be used for their vehicles to operate would be oil–which is the number one fuel source for transportation (Fossil Fuels). Oil is usually pumped from underground as crude oil, which is later processed to create fuel oil and gasoline.

Use, Reuse, and Maintenance

There are no additional materials added to the headphones in order for the user to use the product. However, when the battery does run out on the Sony XM4 headphones, the only thing that the user has to do is to use the charger cable that is added with their package, and charge their headphones so that they can be functional again. The lithium ion battery that is embedded into the headphones allow for multiple uses of the headphones all until the battery starts to wear out. However, that usually does not happen until a year of using the headphones. Lithium ion batteries start to deteriorate after a year regardless. There are no additional materials added to the headphones for maintenance either. If anything happens the user can take it to the store to get it repaired, but aside from that there isn’t anything else to add to the headphones post production. If the headphones do end up getting damages, with the majority of the headphones being made from recycled plastics and Sony’s plastic pellets, it makes it easier for the damaged parts to be used again for the production of new headphones.

Recycling and Disposal

As stated before, Sony has been introducing these recycled plastic pellets into their headphones. Their unpigmented pellets minimize “the additives required in the coloring process. This enables the use of more than 85% recycled material in our plastics, and up to a remarkable 98% for black materials” (ECO MDR). With their headphones having recycled material, it is easier for the product to be recycled again after its use. For the rest of the product that cannot be recycled, however, it will have to go through the usual process of disposal. For everything else, however, such as the packaging that the headphones come in, the materials are actually made from sustainable paper materials. Their packaging is made from a mixture of bamboo, sugarcane fibers, and post-consumer recycled paper (ECO MDR) making it easier for disposal compared to alternatives such as cardboard.

Conclusion

With there being many competitors in the market right now for high quality headphones that allow for noise cancellation as well, it can be tough for Sony to stand out among the competitors. However, Sony is known to bring its users quality sound through their products. What is helping them stand out even more is the amount of effort that they are putting into creating headphones that are made mostly from recycled materials and even going as far as creating sustainable paper materials made from bamboo and recycled paper for their packaging. These efforts help to reduce the impact that we have on the Earth on a daily basis with our misuse of materials and our quickly disposable products. Sony’s XM4 headphones are made from recycled plastics that are turned into pellets that are used to help create the headphones. They use faux leather for the cups and memory foam which helps to insulate the sound once put on. Even though their headphones are not 100% recyclable, the effort that they are putting and continue to put definitely shows in their products, even in the packaging that they come in. Even with all of these recycled products and faux materials, the headphones are still able to provide quality sound to their users while not increasing the footprint too much after using them.

Bibliography

1. public health statement - agency for toxic substances and disease ... (n.d.). Retrieved February

10, 2023, from https://www.atsdr.cdc.gov/toxprofiles/tp26-c1.pdf

Crabb, G. (2023, January 17). How are neodymium magnets made? - FIRST4MAGNETS: Blog.

FIRST4MAGNETS. Retrieved February 10, 2023, from

https://www.first4magnets.com/us/blog/how-are-neodymium-magnets-made/

ECO MDR: Sustainable headphones. Eco MDR | Sustainable Headphones | Sony QA. (n.d.).

Retrieved February 10, 2023, from

https://www.sony.com/en-qa/electronics/eco/headphones

Environmental and Energy Study Institute (EESI). “Fossil Fuels.” EESI, https://www.eesi.org/topics/fossil-fuels/description.

Media, G. (2020, October 6). What is faux leather made out of? Buffalo Jackson Trading Co.

Retrieved February 10, 2023, from

https://buffalojackson.com/blogs/insight/what-is-faux-leather-made-out-of

Noyed, D. (2023, January 31). What is memory foam? Sleep Foundation. Retrieved February 10,

2023, from https://www.sleepfoundation.org/mattress-information/what-is-memory-foam

Polyvinyl chloride. Chemical Safety Facts. (2022, October 14). Retrieved February 10, 2023,

from https://www.chemicalsafetyfacts.org/chemicals/polyvinyl-chloride/

Pulp products: AF&PA. Pulp Products | AF&PA. (n.d.). Retrieved February 10, 2023, from

https://www.afandpa.org/paper-wood-products/pulp

Sony wh-1000xm4 wireless noise cancelling headphones. Sony. (n.d.). Retrieved February 10,

2023, from

https://www.sony.com/lr/electronics/headband-headphones/wh-1000xm4/specifications#f

eatures

Thermoplastic Pla-LCP Composites: A route toward ... - ACS publications. (n.d.). Retrieved

February 10, 2023, from https://pubs.acs.org/doi/10.1021/acssuschemeng.9b06305

What is polyurethane? Polyurethanes. (2022, August 2). Retrieved February 10, 2023, from

https://www.polyurethanes.org/en/what-is-it/

Embodied Energy

Gabriel Figueroa

Brandon Gramajo, Christina Liu

DES 40A

Professor Cogdell

The Life Cycle of Sony’s Fan-Favorite WH-1000XM4 Headphones

The Sony WH-1000XM4 Headphones are the fourth generation of Sony’s high quality 1000X line of wireless noise canceling headphones. Priced at $349, the Sony WH-1000XM4 have become the market leader for noise-cancellation headsets and their combination of a sleek, minimalistic design and high quality sound technology makes it a popular choice among audiophiles and college students alike. Sony’s WH-1000XM4’s are constructed with a variety of materials including polyurethane, polyvinyl chloride, neodymium, lithium, boron, and ABS plastic and the processes for acquiring such materials and manufacturing them into the final product are outsourced to countries overseas to cut costs and imported back into the United States to be sold. The energy inputs required for acquiring raw materials and the subsequent manufacturing process of Sony’s WH1000-XM4 headphones account for the largest sum of energy use in their life cycle that contribute to its overall environmental impact, however this also presents opportunities for improvements through transitions from conventional fossil fuels to renewable energy.

The process for acquiring the raw materials for the Sony WH-1000XM4’s is one of the most energy intensive steps in the life cycle of the headphones. All of the raw materials either need to be mined, extracted, processed, refined and sent to factories to and from multiple countries around the world. The lithium used to make the headphone’s essential lithium ion batteries is extracted from hard rock mines and underground reservoirs using the energy harnessed from burning fossil fuels. For every tonne of lithium mined, 15 tonnes of CO2 are emitted by fossil fuels. Lithium is found most commonly at a high concentration in reserves in Bolivia, Chile, and Argentina containing 21 million, 17 million, and 9 million tonnes of lithium respectively. Although Sony does not explicitly disclose where they outsource their raw material acquisition, it can be assumed that it’s harvested from where it can be found in abundance and then transported to manufacturing facilities to be transformed into lithium ion batteries. Neodymium is another earth mineral that needs to be acquired for the neodymium magnets housed in the headphone’s internals. Once again Sony does not specify their source for neodymium but since the 1990s China has been the world's primary source for neodymium mined from monazite and bastnaesite mineral deposits using fossil fuels as their main energy source. By outsourcing raw material acquisition across the globe, Sony has to transport all of their raw materials for processing and manufacturing to their industrial factories in Malaysia often using diesel powered cargo ships which consumes even more energy in terms of transportation than we have yet to see.

The raw materials extracted from the earth need to undergo additional refining processes in order to be utilized and other materials are created chemically to be manufactured into the final product. Polyurethane is the main component of the WH-1000XM4’s signature memory foam ear muffs and headband. The production process for creating polyurethane involves heavy use of primary energy from crude oils and natural gasses, using 160kWh of primary energy to produce 1m2 of polyurethane spray foam. Polyvinyl chloride faux leather covers the polyurethane ear muffs that contribute to the lux feeling the WH-1000XM4’s are synonymous with. Derived from petroleum, manufacturing faux leather heavily depends on fossil fuels to deliver the high quality finishings that accompany the headphones. Acrylonitrile Butadiene Styrene (ABS) plastic encases the headphone’s earmuffs and is the main material responsible for the structure of the WH-1000XM4’s lightweight build. Also deriving from petroleum as well as natural gasses, the production of 1kg of ABS plastic uses up an average of 95.34 MJ (26.48 kWh) according to PlasticEurope. Additionally, intense heat between 800-1000 degrees celsius is needed to refine mined metals like neodymium and lithium for manufacturing– temperatures which can only be efficiently reached through burning fossil fuels. The manufacturing processes of the Sony WH-1000XM4 headphones at such a massive scale already accounts for large energy use but the final products still need to be exported from the factories in Malaysia into the United States to be sold to an overeager market of consumers.

Once the final product is ready, the WH-1000XM4’s needs to be transported and delivered from Sony’s facilities in Malaysia to prospective buyers on the other side of the globe. This is most commonly achieved through fossil-fuel-fiending cargo ships and trucks although current trends suggest that there may be a more energy efficient future on the horizon. There are two options for the bulk international transport of goods across the globe: by air or by water, the latter of which appears to be the most common resorted to by companies like Sony. Diesel cargo ships have dominated sea transport for centuries and rely on heavy fuel oils as the fuel of choice to sail. According to Camille Bourgeon from the International Maritime Organization (IMO), “The shipping industry uses more than 300 million tons of fossil fuels every year, roughly 5% of global oil production,” and as such there is a rising trend of proponents of greener fuels like methanol and hydrogen as more energy efficient alternatives to fossil fuels although they have yet to be widely adopted. Once the Sony headphones have made the voyage across the seas, they are delivered to buyers typically by standard delivery trucks. Although Sony does not specify which single postal service it uses to ship its products within the United States, the United States Postal Service (USPS) is the most used shipping method in United States e-commerce. Most delivery trucks in the USPS’s delivery fleet run on petroleum based fuels. 433 delivery vehicles are estimated to consume between 297,000 to 516,000 diesel gallons annually. Though most domestic delivery trucks in the United States continue to run on fossil fuels there is a trend towards transitioning to electric vehicles like USPS which is making leaps towards a mail delivery fleet that is 40% electric.

Overall, the process of acquiring raw materials and manufacturing them into finished products like the Sony WH-1000XM4 headphones require heavy, sustained, and consistent energy use still widely depending on non-renewable fossil fuels. However, shifting trends in the sources of energy used for distributing the headphones from relying on petroleum-based fuels towards new attempts at using electric modes of transportation and alternative, renewable fuels suggest that other stages in the life cycle of Sony’s WH-1000XM4 headphones might be experiencing a shift towards more energy-efficient methods in the future.

Bibliography

Frank, Matthew C. The Recycling of Computer Circuit Boards.

Christina Liu

Group Members: Gabriel Figueroa, Brandon Gramajo

DES 40A W23

Christina Cogdell

March 16, 2023

Sony WH-1000XM4 Headphones: Waste & Pollution

I. Introduction

Sony’s WH-1000XM4 headphones have been at the forefront of the fashionable and trendy boom of headphones. The sleek and minimalist design in black, tan, and grey, have become a popular hit amongst the younger generations, being worn across cities and college campuses as high-end fashion statements. In addition to its aesthetic appeal, these headphones are also powerful and convenient, representing Sony’s technological achievements. Features include instant Bluetooth connectivity across multiple devices, long-lasting battery, advanced noise-canceling technology, and an internal microphone for hands-free calls. They are designed with portability, as they are light-weight and can fold easily into a case, which you can carry wherever you go. They are also made for comfort, padded in soft faux-leather for its ear pads and headband, allowing for long sessions. Furthermore, Sony’s latest sustainable initiative, “Road to Zero”, “aims to reduce our environmental footprint to zero by 2050” (Sony). However, Sony's commitment to reducing its environmental impact by using recycled plastics and plant-based materials for their WH-1000XM4 headphones and packaging, the carbon gas emissions needed to manufacture, distribute, and sustain this product, as well as the lack of sustainable ways to recycle this product, cannot be ignored. Despite the little transparency on how Sony operates and the lack of a detailed record of their by-product waste, it’s clear to see their product’s significant and detrimental impact on the environment through its life cycle assessment.

II. Raw Materials

The raw materials of Sony’s WH-1000XM4 headphones are vital to the product, making up its plastic ear cups, leather headband, and the high-functioning electronic instruments inside. Each component requires different raw materials, all mined from the earth. Raw materials unique to these headphones include lithium and neodymium — and those are just the highlights. These materials are mined deep from the earth, making the local environment toxic and emitting greenhouse gases in the process.

Lithium ion batteries have become a staple in modern day technology due to their ability to “charge faster, last longer, and have a higher power density for…a lighter package” (Apple). This mineral is typically mined in major countries in South America, like Bolivia and Chile, as well as the U.S. and China. Though Sony has not disclosed specific information about their raw materials extraction and refinement process, the current “popular method of extracting lithium…causes the loss of about 95 per cent of…water” that “is critical for human consumption, livestock, crop irrigation and native plant species” (Kaunda 238, 243). Some regions even record “approximately 500,000 gallons [of water is evaporated] per ton of lithium extracted” (Kaunda 242). Furthermore, original habitats and landscapes are deforested to access this earth mineral, and the carbon emissions from the heavy machinery needed only adds to the waste at this stage. Mining lithium has become so prominent that even “trace amounts of lithium can… be found in… processed waters… and transported products”, which can harm local communities and environments (Kaunda 241). The consumption of groundwater and traces of toxic by-products from lithium mining puts both humans, flora and fauna all at risk.

III. Product Manufacturing

After raw materials have been obtained, they are transported in factories to be manufactured into the components needed to make these headphones. One synthetic material that is significant in this process is acrylonitrile–butadiene–styrene (ABS) plastics, which are renown for their durability and moldability, thus, becoming one of the most popular plastics to use for product manufacturing. However, these petroleum-based plastics are reliant on crude oil, which needs to be mined for, and do not degrade quickly, filling landfills. As a result, under their sustainable mission, Sony claims to reuse ABS plastic from used cars, but there are additional, unspoken, factors that produce waste during this product manufacturing stage (Sony). Even if ABS products claim to be recycled, re-using the same plastic is not as simple as it may seem. Due to the intensive treatment of ABS plastics and in combination with other materials, these products must first be stripped down into their original form. Along the way, some of that material may be lost or unusable. The current solution demands that new material, also known as virgin material, must be added to be able to reuse the ABS plastic. The result of manufacturing virgin ABS as tiny pellets can leave pollutants in the air, which can cause asthma, lung cancer, brain and organ damage, and in the water, where marine life can accidentally consume these pellets (Jones).

Other petrol-based materials related to the WH-1000XM4 headphones include faux leather and polyurethane. Like it’s name, faux leather has gone through intensive chemical processing to replicate its real counterpart. Faux leather is “fabric coated with a plastic polymer (polyurethane (PU) or polyvinylchloride (PVC))”, both of which contain damaging chemicals like dioxins, which “infamously linked to cancer and developmental and reproductive issues” (Confer). Despite the idyllic goal of faux leather, it’s still made up of plastic, a product of petroleum, and is most likely created through the same pollutive process as ABS plastics. In addition, polyurethane is the soft, sponge foam that cushions the listener’s ears, but the waste made from producing this material may be uncomfortable for many to hear. Polyurethane is usually “not recycled and are made principally from nonrenewable, fossil-fuel-derived resources” (Chao Liang, et al. 14215). Though not directly related, as a reflection of today’s reliance on polyurethane, the US’ “domestic production of polyurethane consumed 1100 kt of crude oil and 1100 kt of natural gas [in 2021]” (Chao Liang, et al. 14215). Once the product has completed its manufacturing stage, it must be shipped out to Sony’s customers.

IV. Transportation and Distribution

Sony's WH-1000XM4 headphones are manufactured in several countries, including Malaysia and China, thus needing a global-wide system of transportation to send out their hundreds of thousands of orders. As a reflection of this high demand, in “2021, 548 million headphones were shipped worldwide,” and Sony was one of the few major manufacturers (Laricchia). Therefore, a sturdy packaging is needed to keep the product safe from harm and damage during transport. Though Sony claims to use plant pulp, it still takes heat, compression, and the energy — most likely fossil fuels — to operate this manufacturing process. That being said, it’s important to note the waste by-products from vehicles of transporattiaon over land and water on this global scale.

Due to the COVID-19 pandemic and Amazon’s popularization of online shopping, domestic and international shipping has become more prominent than ever. For domestic ground transportation, the waste emerges from the diesel that many trucks use as fuel, have become “20% [to] 30% of a city’s carbon dioxide emissions” (Davies). This number is expected to rise due to the shipping industry growing at “an average of five percent per year” (OCEANA). Although many companies are beginning to shift towards electrical transportation methods, it’s important to remember the harmful mining and manufacturing needed to be done for its parts, especially for its large lithium ion batteries. For international distribution, Sony may use cargo ships to transport their headphones across the globe. The air pollution from these ships have a substaintial environmental impact due to their size, and are powered by its “diesel engines that burn high sulfur content fuel oil, also known as bunker oil” (HandWiki Li). Furthermore, the “EPA recognizes that these emissions… contribute to ozone and carbon monoxide” in the atmosphere (HandWiki Li). Although the product may change hands many times during its distribution phase, but that does not discount the amount of waste it’s producing along the way, even if not being used.

V. Use, Reuse, and Maintenance

Once the product has arrived at the customer’s door, it’s time for customers to use and maintain it. The lifespan of Sony's WH-1000XM4 headphones can vary depending on factors such as the amount of usage and care. With proper maintenance, these headphones can last up to several years. The batteries in the headphones have a lifespan of around 500 charge cycles, which means that they can last for approximately 2-3 years with normal use (Grepow). These batteries also need to be charged, where “annual electricity use of charging one phone [is] equal to 0.01% of the total annual [electric] use of a home”, releasing “0.62 kgCO2e per year” when charging one phone, one hour per day in North America (Enright). Though thes numbers may seem small, individuals nowadays possess multiple devices, each needing their own charge, thus, creating a major number in carbon emissions. Furthermore, extended use can wear out the headphone material, like its cushion and faux leather. Despite the availability of replaceable parts on the market, it’s typical for a user to toss it out and purchase a new one, adding to the overall waste in its use.

VI. Recycling and Disposal

Once these headphones are no longer of use or have broken, many users toss them out, sell them, or turn to a recycling facility, though the latter is less common. Most of the pollution at this stage is falls under the general category of e-waste. The most common method of e-waste disposal contributes to the landfills. There is also extra pollution that involves the emissions from the vehicles transporting the device to the landfill site, and any microparticles from the product released into the air due to intense exposure to heat and UV radiation. Currently, “[e]-waste comprises 70% of our overall toxic waste… 85% of our E-Waste are sent to landfills and incinerators … [releasing] harmful toxins in the air!” (The World Counts). If a user decides to opt for Sony’s recycling program, it displays available locations to drop off their products to be recycled (Sony). However, recycling plastics is still considered pollutive, due to the addition of virgin material needed to create a structurally sound product. As Max Liboiron, an associate professor at Memorial University states, “We can’t recycle our way out of this problem… [instead] acute reduction of plastic products, recycled or not, is the solution” (Justine). Furthermore, the disposal of the product’s packaging can add to the waste footprint of this product. Despite its plant based packaging, it may not be encouraged to be composted due to its chemical composition. Even if the “recycling rate for corrugated boxes was 96.5 percent” in 2018, it does not erase the remaining 4%, which “landfills received 940,000 tons [of paperboard packaging] in 2018” (EPA).

VII. Conclusion

Overall, Sony’s declaration to a zero carbon footprint may be further than 2050, due to its traditional methods of global distribution systems and manufacturing methods that rely heavily on a fossil fuel foundation and infrastructure, resulting in massive amounts of greenhouse gases into the atmosphere and destroying local environments. And this life cycle assesment for a single product out of the long list of products and services Sony provides. That being said, be wary of a company’s sustainable mission, and remember that it does not give buyers a “pass” to purchase these headphones “waste-free” and guilt-free. Although many of these statistics cited are not directly linked to Sony and its WH-1000XM4 headphones, the general mining, manufacturing, maintaining, and recycling process can give us a glimpse into the true waste that is produced from this one product.

Works Cited

Apple. “Batteries - Why Lithium-ion?” Apple, https://www.apple.com/batteries/why-lithium-ion/. Accessed 6 March 2023.

Campbell, Maeve. “South America's 'lithium fields' reveal the dark side of electric cars.” Euronews, 21 November 2022, https://www.euronews.com/green/2022/02/01/south-america-s-lithium-fields-reveal-the-dark-side-of-our-electric-future. Accessed 6 March 2023.

Chao Liang,, et al. “Material Flows of Polyurethane in the United States.” Environmental Science & Technology, vol. 55, no. 20, 2021, pp. 14215-14224. ACS Publications, https://pubs.acs.org/doi/10.1021/acs.est.1c03654.

Confer, Sarah. “The Great Debate: Faux Leather vs Real Leather, Which One is More Sustainable?” Nomomente, 29 October 2021, https://www.nomomente.org/post/faux-leather-vs-real-leather. Accessed 13 March 2023.

Davies, Caleb. “The carbon cost of home delivery and how to avoid it.” European Commission, https://ec.europa.eu/research-and-innovation/en/horizon-magazine/carbon-cost-home-delivery-and-how-avoid-it. Accessed 13 March 2023.

Enright, Rebecca. “The Carbon Footprint of Phone Charging | Compare the Market.” Compare The Market, 29 March 2021, https://www.comparethemarket.com.au/energy/features/carbon-footprint-of-phone-charging/#_+_How_we. Accessed 13 March 2023.

Enright, Rebecca. “The Carbon Footprint of Phone Charging | Compare the Market.” Compare The Market, 29 March 2021, https://www.comparethemarket.com.au/energy/features/carbon-footprint-of-phone-charging/#_+_How_we. Accessed 13 March 2023.

EPA. “Containers and Packaging: Product-Specific Data | US EPA.” EPA, 3 December 2022, https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific#PaperandPaperboardC&P. Accessed 13 March 2023.

Grepow. “How Long Does Bluetooth Headset Battery Last?” Grepow, 20 April 2019, https://www.grepow.com/blog/bluetooth-headset-battery-life.html. Accessed 13 March 2023.

HandWiki Li. “Environmental Impact of Shipping | Encyclopedia MDPI.” Scholarly Community Encyclopedia, 31 October 2022, https://encyclopedia.pub/entry/31959. Accessed 13 March 2023.

Jones, Steve. “The Plastic-Production Problem.” Center for Biological Diversity, https://www.biologicaldiversity.org/campaigns/plastic-production/index.html. Accessed 13 March 2023.

Justine Calma. “Recycled plastic won't solve tech's waste problem.” The Verge, 6 October 2021, https://www.theverge.com/2021/10/6/22712435/recycling-e-waste-tech-plastic-pollution. Accessed 13 March 2023.

Kaunda, Rennie B. “Potential environmental impacts of lithium mining.” Journal of Energy & Natural Resources Law, vol. 38, no. 3, 2020, pp. 237-244. Taylor and Francis Online, https://doi.org/10.1080/02646811.2020.1754596. Accessed 6 3 2023.

Laricchia, Federica. “Global headphone unit shipments 2021.” Statista, 16 February 2023, https://www.statista.com/statistics/236075/revenue-of-headphone-shipments-in-the-united-states/. Accessed 13 March 2023.

OCEANA. “Shipping Pollution.” Oceana Europe, https://europe.oceana.org/shipping-pollution-1/. Accessed 13 March 2023.

Sony. “Eco MDR | Sustainable Headphones.” Sony, https://www.sony.com/en-qa/electronics/eco/headphones. Accessed 6 March 2023.

Sony. “Find a location to recycle your Sony product.” Sony, 22 March 2019, https://www.sony.com/electronics/support/articles/00206411. Accessed 13 March 2023.

The World Counts. “Electronic Waste Facts.” The World Counts, https://www.theworldcounts.com/stories/electronic-waste-facts. Accessed 13 March 2023.