Design Life-Cycle

assess.design.(don't)consume

Alyssa Shum

DES 40A

Professor Cogdell

Patagonia Synchilla Fleece Jacket: A 2021 Analysis of Raw Materials

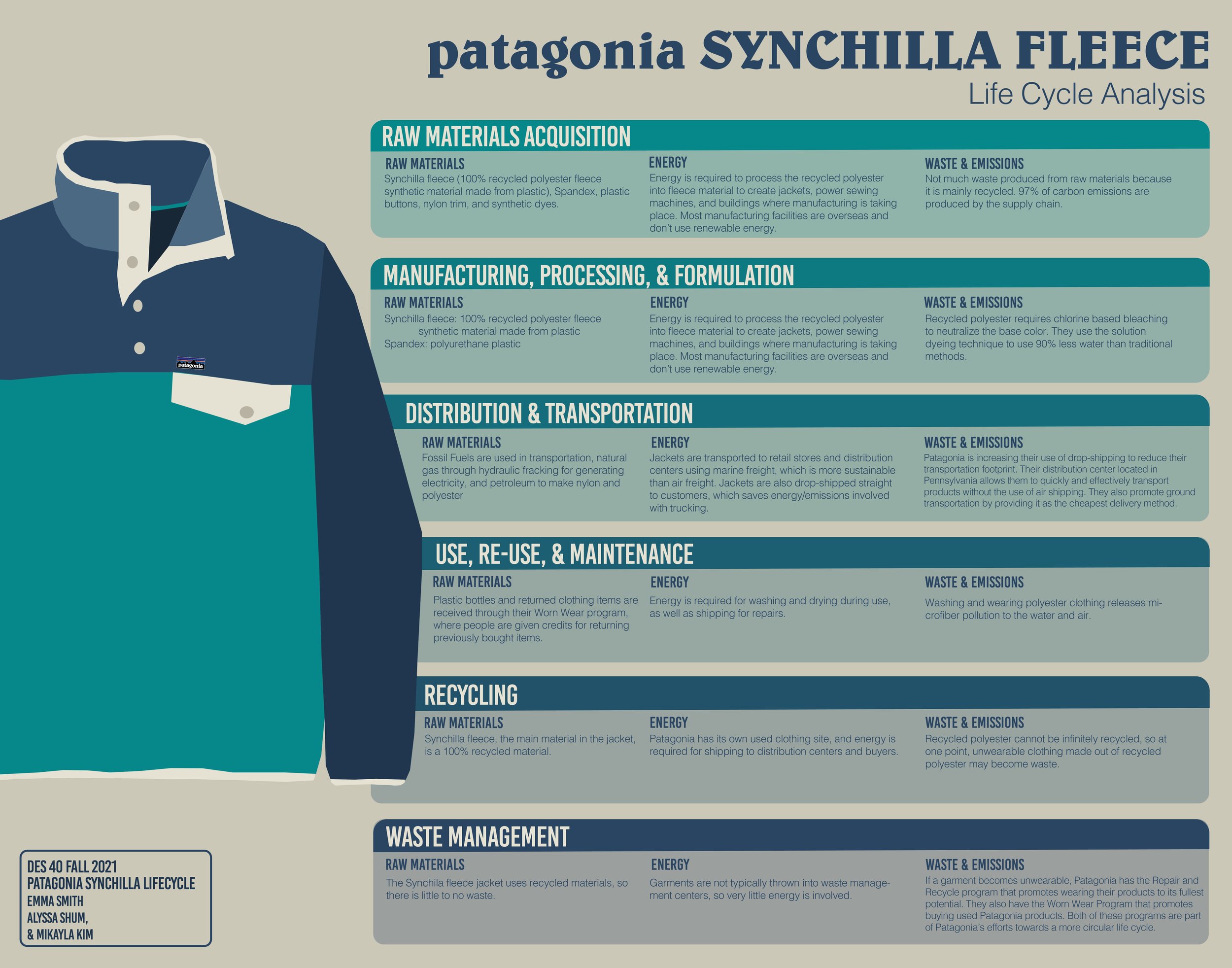

Patagonia, a brand well established as an eco-friendly fashion company has surprisingly lived up to its reputation. One of their featured products is the Patagonia Synchilla fleece jacket which is marketed as warm and durable and is made from 87% recycled materials. Made by Formosa Textil in Managua, Managua, Nicaragua, and by Pettenati Coatepeque, in Santa Ana, El Salvador, this product is produced outside of Northern America, where Patagonia headquarters are located.

The primary materials that comprise Patagonia synchilla fleece are 100% recycled polyester fleece, a synthetic material made from plastic, Spandex, polyurethane plastic, plastic buttons, nylon trim, and the colored dye. Synchilla fleece has a much lower environmental impact than other materials such as cotton or silk, and with Patagonias’ emphasis on recycling, synchilla fleece is a more sustainable material for mass production of clothing. At the moment Patagonia works with 16 different contracted companies across the globe and by working with the FLA Patagonia strives to increase worker benefits and lifestyle quality, no matter the distance. Overall, the Patagonia synchilla fleece jacket is a great alternative to its rivals due to the eco-aware management Patagonia utilizes and the recycled material from which it is made.

Life cycles are the full analysis of the product from the materials used to produce it to the environmental impact it has once its use is no longer needed. Analyzing product lifestyles helps awareness when it comes to the full social, political, and environmental effects of that certain product. In terms of Patagonia’s synchilla fleece jacket, the environmental impact was carefully calculated since one of Patigonias’ main principles is to create clothing that is ethical and sustainable. Overall, around eighty-seven percent of Patagonia's clothing uses recycled materials, so environmentalism is a central component of the company’s policies. They are aware of their usage of cotton, which is a non-eco-friendly material, and therefore chooses to grow their own cotton organically. However, although cotton is a large factor in the pollution through the fashion industry and is used by Patagonia, the synchilla fleece jacket is what I’ll be addressing in this paper.

What I will address in this paper is the full lifecycle of the Patagonia synchilla fleece jacket and the environmental impacts the materials used will produce. The specific materials all have complex methods of production since they are synthetic materials. Synchilla fleece is made from 100% recycled polyester fleece, sourced from plastic bottles or recycled synchilla jackets. The process to make this material requires machinery that can first melt, then squeeze the plastic through tiny holes to make fibers, and then cool the fibers. Once this process is finished, the threads are weaved together to create the fluffy, warm fleece material. For the spandex that makes up the cuffs of the sleeves and the bottom hem of the jacket, spandex is inserted. To create spandex, which is made from polyurethane plastic, it can be made using a couple of processes. For example, melt extrusion, reaction spinning, solution dry spinning, and solution wet spinning are the main ways spandex is produced. These processes leave you with a light and stretchy material that can be used to fit the jacket to the consumer. The plastic buttons are assumed to be made of plastic and are therefore made by melting and molding as well. In addition, there is a large amount of water usage due to the washing, dyeing, and drying process taking place during production. The production of all of these materials relies on the usage of water, fossil fuels, natural gas, and petroleum. These are some of the elements contributing to Patagonia’s environmental impact. However, compared to their rivals, Patagonia’s emissions are significantly lower.

After production of the jacket, the jackets are sent to stores to be sold, and once sold, they are either reused or recycled. Although the primary material that the jacket is made of is plastic and is a non-biodegradable material, Patagonia counteracts the usage of this material through recycling. They use plastic bottles and returned clothing items that they receive through their Worn Wear program, where people are given credits for returning previously bought items. From Reno, where the warehouse stores the recycled material, the plastics are shipped to the processing factories. The processing factories are located all around the world, so it is difficult to track the exact shipping method and factories that are used in producing the Patagonia jacket. For the jacket, the material is shipped generally through marine freight. This requires the use of fossil fuels. The assembly factories are located mostly in the eastern hemisphere, with factories located in countries such as India, Vietnam, Thailand, and the Philippines. The main method used in generating electricity for their factories is through the collection of natural gas through hydraulic fracking. To ship the jackets, they are packaged in polybags, which are made from polyethylene film. This plastic is not easily recycled, but Patagonia has found suppliers that are able to. They have promised to package their products with 100 percent recycled content that is Global Recycle standard approved. However, there are still ways in which not all of these materials end up being reused.

Oftentimes, the products we use no longer serve a purpose to us anymore. Then, we either discard, donate, or return the items we used. In terms of the Patagonia Synchilla jacket, there are three ways it can be dealt with once nearing the end of its life cycle. First, it can be donated. This expands the life of the product, for it can then be worn by another person. Eventually, the product can be unable to use and subsequently discarded. Second, the jacket can be thrown away, essentially sent to another country to be burned. This happens often, where trash is sent to third-world countries to be dealt with, which often pollutes their cities and water, restricting their quality of life. Third, the jacket can be given back to Patagonia, where Patagonia with re-use the material to make new jackets. The first and last options are the most sustainable and should be used by the general public. Patagonia makes sure to actively promote more sustainable methods of waste management so that we can all benefit from the production of its products.

The Patagonia Synchilla jacket is among one of the most sustainable fashion products out there. In addition, it is a warm, durable, and sustainable alternative to the excessive amounts of low-quality products in the market. Fast fashion has reduced the urgency to switch to sustainability and the planet is suffering because of it. Patagonia wants to counteract this effect and is doing so by implementing a strong recycling program. Their reliability for this aspect of their company has branded them as a sustainable fashion company. The materials that they have decided to utilize also have little effect on the planet rather than if they had been producing the Synchilla jackets from scratch.

Studying the Patagonia Synchilla fleece jacket has given me great insight into how a company can actually create sustainable products. By implementing strict recycling programs and emphasizing good working conditions for their workers, they can help create a sustainable company. With the abundance of plastic flooding our oceans and rivers, putting the already made material into good use is a wonderful and innovative solution to our plastic pollution. The less plastic that ends up in the oceans, the less it will enter our food chain. Overall, the general consumption of raw materials is very small since the source of the material comes from secondary materials or materials that were already produced and are given a new purpose. If more companies choose to hold themselves accountable for their impact on Earth we would all benefit from the effects. The Patagonia Synchilla fleece jacket is a great example of sustainability combined with function.

Bibliography/ Works cited

“Spandex.” How Products Are Made, http://www.madehow.com/Volume-4/Spandex.html#ixzz7CXw8wUPK.

“What Is Fleece?: How to Care for Fleece.” Comfort, https://www.comfortworld.co.uk/long-live-clothes/what-is-fleece-material-and-how-to-care-for-it.html.

editor, Enviro. “Patagonia Clothing: Made Where? How? Why?” Patagonia, 18 Nov. 2021, https://www.patagonia.com/stories/patagonia-clothing-made-where-how-why/story-18467.html.

Hepburn, Sharon J. “In Patagonia (Clothing): A Complicated Greenness.” Fashion Theory, vol. 17, no. 5, 2013, pp. 623–645., https://doi.org/10.2752/175174113x13718320331035.

“Patagonia and Petroleum.” Energy API, https://www.api.org/news-policy-and-issues/blog/2019/04/16/patagonia-and-petroleum.

Rattalino, Francesco. “Circular Advantage Anyone? Sustainability-Driven Innovation and Circularity at Patagonia, Inc..” Thunderbird International Business Review, vol. 60, no. 5, 2017, pp. 747–755., https://doi.org/10.1002/tie.21917.

Meyer, Arnt. “What's in It for the Customers? Successfully Marketing Green Clothes.” Business Strategy and the Environment, vol. 10, no. 5, 2001, pp. 317–330., https://doi.org/10.1002/bse.302.

Belz, Frank-Martin. “Marketing in the Age of Sustainable Development: Frank-Martin Belz |.” Taylor & Francis, Taylor & Francis, 8 Sept. 2017, https://www.taylorfrancis.com/chapters/edit/10.4324/9781351280204-14/marketing-age-sustainable-development-frank-martin-belz.

“Reasons to Love the Patagonia Synchilla.” Blondes & Bagels, 15 Sept. 2021, https://blondesandbagels.com/synchilla/.

Patagonia We’re in business to save our home planet. “What We're Doing about Our Plastic Problem.” Patagonia, 18 Nov. 2021, https://www.patagonia.com/stories/what-were-doing-about-our-plastic-problem/story-72799.html.

Emma Smith

DES40A

TA: Lauren

2 December, 2021

Patagonia Synchilla Jacket Embodied Energy

If you live an outdoorsy lifestyle, chances are, you have heard of Patagonia. Patagonia is an American upscale outdoor apparel brand that sells clothing for a variety of outdoor activities (Patagonia, Inc., n.d.). The company prides itself in its sustainability efforts, from using about 87% recycled materials in its products to promoting environmental activism online (Patagonia Men’s Synchilla® Snap-T® Fleece Pullover, n.d.). Perhaps their most iconic product is the synchilla pullover that is made from their trademark synchilla fleece (recycled polyester) and is available in a wide range of colors and patterns, the product that we are going to analyze from the raw materials to the disposal in terms of embodied energy. The Patagonia synchilla jacket is made of recycled materials, which greatly reduces its overall energy involved with raw materials acquisition, meaning that most of the embodied energy is in the manufacturing, distribution to storefronts and customers, and shipping to reuse distribution centers and the company is trying to increase its use of renewable energy sources.

The first step in the life cycle of Patagonia’s synchilla jacket is raw materials acquisition, in which raw materials are collected and brought to the manufacturing site. Patagonia’s trademark synchilla polyester is created by processing plastic bottles (Recycled Polyester - Patagonia., n.d.), meaning that there is energy involved in obtaining the plastic bottles and processing them into a fibrous material that may be sewn into a garment. The company does not share exactly where they obtain the bottles used to create the synchilla or how they are transported, but they have previously stated that they utilize marine freight to transport goods because it is a more sustainable alternative to air freight (Climate Goals - Patagonia, n.d.). Most likely, the company obtains plastic bottles from recycling centers and other discarded polyester garments and has them marine-shipped to their manufacturing centers to be turned into recycled polyester fibers. In terms of embodied energy involved in processing polyester and plastic items into recycled polyester, it is estimated that recycled polyester uses about 66 MJ of energy to create 1 KG of fiber, whereas virgin polyester uses about 125 MJ per KG (T. Today, 2010). This means that creating recycled polyester fibers from plastic uses only about 52% of the energy that creating virgin polyester requires, which is a significant decrease. Using recycled polyester is beneficial not only because it transforms discarded materials into usable material, but also because it uses half the energy that virgin polyester uses. The snaps used to fasten the jacket closed, as well as the elastic in the wristbands and waistband are virgin plastic, meaning that they require more energy and are derived directly from fossil fuels. Luckily, these materials make up a very small portion of the jacket, and are able to be removed to allow the garment to be recycled again. Overall, the energy involved in the raw material acquisition and processing is significantly less for the Patagonia synchilla jacket compared to other jackets, due to the use of recycled polyester as opposed to virgin polyester.

The next step in the lifecycle of the synchilla jacket is manufacturing, where the fleece fiber material is sewn into a garment and the buttons and elastic are added. The jacket is manufactured in Formosa Textil, a factory in Nicaragua, and Pettenati, a textile mill in El Salvador (Men’s Synchilla® Snap-T® Fleece Pullover - Impact., n.d.). Both factories utilize fair trade practices with their employees, which the company takes pride in, however, not much information is released about the amount of energy that goes into manufacturing or the source of that energy. Regardless of material, it is generally understood that garment production processing uses about the same amount of energy (What is the energy profile of the textile industry?, n.d.). Energy, in the form of electricity, is used to power sewing machines in the textile factories. Patagonia has provided on their website that renewable energy is used to power domestic facilities such as retail stores and distribution centers, but has not disclosed what type of energy and energy sources that are used in facilities overseas (Our Footprint - Patagonia, n.d.). Overall, energy is used to power manufacturing processes that occur overseas as well as to provide electricity to the textile factories and other buildings.

A portion of the embodied energy in a Patagonia synchilla fleece jacket goes into its distribution and transportation. Patagonia has factories in over 60 countries, meaning that their garments and gear are shipped long distances from manufacturer to consumer, which requires a lot of energy. The company has disclosed that it uses marine freight to transport goods from the factory to distribution centers and storefronts because it is more energy efficient than air freight which uses exorbitant amounts of jet fuel (Our Footprint - Patagonia., n.d.). This method of transportation uses energy in the form of fuel for freight ships, but the company does not disclose exactly where the energy comes from. Additionally, they implement drop-shipping whenever possible, which is where the goods are shipped directly to the consumer, minimizing shipping back and forth to distribution centers and other stops (“Owned and Operated Facilities - Patagonia.”, n.d.). In terms of how much energy is involved with transportation, Patagonia does not disclose the exact amount, but claims that transportation accounts for “less than 2%” of their products’ carbon footprint (Our Footprint - Patagonia., n.d.). Though this metric does not directly address energy use, it is tied to it because it involves the waste and emissions that come from energy use. Patagonia has also built a new distribution center on the east coast, which can reach “95 % of US customers” in 3 days without using air freight (“Owned and Operated Facilities - Patagonia.”, n.d.). Overall, while Patagonia does not publish their exact energy usage involved with distribution and shipping, they make it clear that they are making efforts to make their shipping methods more energy efficient where possible.

Like all clothing, the Patagonia synchilla fleece requires energy for maintenance and reuse. This is mainly in the form of electricity to power a washer and dryer to clean the jacket after several uses. Patagonia recommends washing the synchilla fleece in cold water, which according to a study done in 2015 in the International Journal of Applied Engineering Research uses about 103 kWh per year (Beemkumar et al., 2015). It is also recommended that users hang-dry the garment to avoid heat damage from a dryer, which saves energy. Patagonia also has a repair program for when garments get damaged, and repaired over 100,000 garments in 2020 (“Our Footprint- Patagonia, n.d.). Though this program uses energy to ship damaged garments to Patagonia and back to the customer, it saves energy that would normally be used to manufacture extra garments to replace the damaged ones. Overall, washing the garments in cold water, hanging them to dry, and sending them back to be repaired saves energy for reuse and maintenance.

The main energy involved with the recycling of the synchilla fleece is for transportation of the goods. Patagonia has a reuse program called Patagonia Worn Wear, which is a reselling platform for used garments. Consumers may trade in items that they no longer want in-store or by sending their items by mail with a prepaid shipping label to the collection facility (Worn Wear - Used Patagonia Clothing & Gear, n.d.). Consumers are compensated for their trade-ins in the form of store credit which they can use towards new items. This garment recycling program is very environmentally-friendly and the energy used in the transportation of the items is likely less than the overall amount of energy needed to create new garments. By recycling garments, Patagonia is creating a more circular life cycle of their jackets.

Another important step in a product’s life cycle is its waste management. As Patagonia’s jackets are costly and high-quality outdoors gear, they are not typically thrown into the landfill or turned directly into waste. This is also facilitated by Patagonia’s Worn Wear and garment repair programs, as previously mentioned. The products’ packaging, however, must be considered in terms of waste management. The garments come with cardboard tags and are packaged in a plastic bag, and energy is required to transport those materials to a recycling facility and landfill, respectively. Overall, this is the only energy associated with waste management for this product.

In conclusion, Patagonia’s synchilla fleece pullover jacket uses less energy than a regular polyester jacket because it uses recycled materials. Additionally, the company is making strides in trying to be more environmentally conscious and part of that means using more energy-efficient means of transportation for its goods such as marine freight and drop shipping. Furthermore, the company even facilitates repair programs and has its own reselling website for used gear, both of which extend the lifetime of the garment. For all of these reasons, compared to regular polyester jackets, Patagonia’s synchilla jacket has significantly less embodied energy.

Works Cited

Beemkumar, N., and Jason Abu Mathews. “Energy and Water Consumption Analysis of Washing Process in a Fully Automatic Washing Machine.” International Journal of Applied Engineering Research, vol. 10, no. 11, 2015. Research India Publications, www.researchgate.net/profile/Beemkumar-N/publication/283096076_Energy_and_water_consumption_analysis_of_washing_process_in_a_fully_automatic_washing_machine/links/5757ae3608ae5c6549042c60/Energy-and-water-consumption-analysis-of-washing-process-in-a-fully-automatic-washing-machine.pdf.

“Climate Goals - Patagonia.” Patagonia, www.patagonia.com/climate-goals. Accessed 1 Dec. 2021.

Leonas, Karen K. “The Use of Recycled Fibers in Fashion and Home Products.” Textile Science and Clothing Technology, 2016, pp. 55–77., https://doi.org/10.1007/978-981-10-2146-6_2.

“Men’s Synchilla® Snap-T® Fleece Pullover - Impact”. (n.d.). Patagonia. Retrieved November 25, 2021, from https://www.patagonia.com/product/mens-synchilla-snap-t-fleece-pullover/25450.html

O'Connor, Mary Catherine, et al. “Patagonia's New Study Finds Fleece Jackets Are a Serious Pollutant.” Outside Online, 30 June 2021, https://www.outsideonline.com/outdoor-gear/gear-news/patagonias-new-study-finds-fleece-jackets-are-serious-pollutant/.

“Our Footprint, Recycled Polyester - Patagonia.” Patagonia, www.patagonia.com/our-footprint/recycled-polyester.html. Accessed 1 Dec. 2021.

“Owned and Operated Facilities - Patagonia.” Patagonia, www.patagonia.com/where-we-do-business/owned-and-operated.html. Accessed 30 Nov. 2021.

“Patagonia, Inc”. (n.d.). Wikipedia. Accessed November 25, 2021, from https://en.wikipedia.org/wiki/Patagonia,_Inc.

“Patagonia Men’s Synchilla® Snap-T® Fleece Pullover”. (n.d.). Patagonia. Accessed November 25, 2021, from https://www.patagonia.com/product/mens-synchilla-snap-t-fleece-pullover/25450.html

Pohjakallio, Maija. “Secondary Plastic Products—Examples and Market Trends.” Plastic Waste and Recycling, 2020, pp. 467–479., https://doi.org/10.1016/b978-0-12-817880-5.00018-9.

“Recycled Polyester.” Patagonia, https://www.patagonia.com/our-footprint/recycled-polyester.html.

Today, T. (2010, January 1). Recycle Polyester: Way to Safe Environment and Energy. Textile News, Apparel News, RMG News, Fashion Trends. Retrieved November 25, 2021, from https://www.textiletoday.com.bd/recycle-polyester-way-to-safe-environment-and-energy/

Vanek, Francis M., and Edward K. Morlok. “Improving the Energy Efficiency of Freight in the United States through Commodity-Based Analysis: Justification and Implementation.” Transportation Research Part D: Transport and Environment, vol. 5, no. 1, 2000, pp. 11–29., https://doi.org/10.1016/s1361-9209(99)00021-8.

“What Is the Energy Profile of the Textile Industry?” OEcotextiles, oecotextiles.blog/2009/06/16/what-is-the-energy-profile-of-the-textile-industry. Accessed 1 Dec. 2021.

“Worn Wear - Used Patagonia Clothing & Gear.” Worn Wear, wornwear.patagonia.com/trade-it-in. Accessed 1 Dec. 2021.

Mikayla Kim

Professor Christina Cogdell

DES 40A

2 December 2021

Patagonia and Their Waste and Emissions

Patagonia is one of the most prominent clothing brands for sustainability. Founded by environmentalist and rock climber Yvon Chouinard, Patagonia remains one of the top outdoor sportswear competing with companies like Nike and Adidas. Due to their transparency, they have gained loyal customers from all around the world. Patagonia provides trendy, yet staple products that appeal to people of all age groups and backgrounds. They were able to stabilize as one of the few companies that put major emphasis on providing earth conscious products.

A long time favorite is the Synchilla Snap-T Fleece Pullover. Since its release in 1985, the synchilla fleece still remains one of the best selling products of all time. It is made out of 100% recycled Synchilla polyester. Although they are a very waste conscious company, Patagonia is not a zero-waste company. Examining its environmental impact from a life cycle perspective shows that recycled polyester (rPET) contributes to water and chemical waste that is released into the environment through the process of textile dyeing. To lower greenhouse gas emissions, Patagonia uses renewable energy in their headquarters, stores, distribution centers, etc. Though they use renewable energy, they emit GHG through acquiring raw materials as well as transportation of their products. Microfibers from the clothing are also polluted into the water and air by wearing and washing of the clothing. In an attempt to reduce waste, Patagonia implemented the Worn Wear program that advocates buying second-hand Patagonia gear as well as repair and reuse the product until it has reached its full potential use.

Polyester (polyethylene terephthalate) is a material made from a chemical reaction between petroleum, air, and water. It is a popular choice of material because of its durability and low maintenance attribute. Polyester “occupies about half the total consumption of global manmade and natural fibers” (Radhakrishan et al.). It is often made in countries that don’t have strict environmental regulations causing inhabitable damages to the natives who reside near the factories that release harmful chemicals. Polyester fabric is non-biodegradable due to its raw material being petroleum. Majority of plastics are made from petroleum. It takes a couple million years to decay naturally (Wolchover).

It is thermoplastic, meaning it can be reformed when in contact with heat (Radhakrishan et al.). This characteristic is how they are able to make recycled polyester. To produce rPET, you have to melt PET and respin it into new polyester fiber. Recycled polyester material for clothing doesn’t only have to be polyester from clothing, it can be almost any polyester material. There are recycled polyester fiber made from plastic bottles. The plastic bottles are first shredded into flakes then they go through the process of depolymerizstion (converting polymers to monomers). The new material will go through polymerization again and it will produce little rPET chips. The chips will then be melted and reformed into filament yarn (Radhakrishan et al). Through this process thousands of yards of rPET yarn is produced and used to create new products. The main difference between virgin polyester and recycled polyester is that the recycled polyester has slightly less strength in the material.

Using plastic bottles to make rPET was first introduced through the synchilla fleece. According to National Geographic, Patagonia and Polartec collaborated “to design and manufacture performance fabric by utilizing plastic water bottles instead of virgin plastic resins, and in 1993 they created the first-ever recycled polyester fleece.” Since then, the use of recycled polyester has increased significantly. Textile Exchange predicts that by 2030, 20 percent of the total polyester produced will be recycled.

The downside of recycled polyester is that it is difficult to get a crispy white color due to the origin of the polyester being from many different sources (Elven). As a solution, chlorine-based bleach is used to neutralize the base color (Radhakrishnan et al.). Bleach is a strong chemical that is used to clean or remove color from a fabric. It is not harmful to the environment but it is not eco friendly. The active ingredient in bleach is a nonhazardous ingredient called sodium hypochlorite, therefore it can be disposed of in wastewater streams (“Using Bleach as a Disinfectant”). However, bleach is still a strong chemical and when you pour it down the drain, it is harmful to aquatic life. Bleach is made from a chlorine and sodium hydroxide reaction. “Chlorine, even in amounts found in tap water, gives marine invertebrates and fish chemical burns. In fish, chlorine burns the gills. At the same time, it absorbs into the bloodstream and causes burns throughout the fish” (Boumis).

The traditional method of dyeing textile involves submerging the material in a solution of water, dye, and mordant (chemical that bonds dye to fabric) (“Fabric Dyeing Process: Dyeing Shrinkage & Sustainability”). Dyeing requires a lot of water. It is one of the most wasteful aspects of the textile industry. To combat that, Patagonia uses the solution dyeing technique to lower water usage (“Solution Dyeing”). Solution dyeing involves adding color in the liquid stage of the material allowing less usage of water and better quality compared to conventional methods. It also uses less energy because it doesn't require multiple washing and drying (“What’s all they hype about solution-dyed fabric?”). According to Universal Fiber, solution dyeing uses 60% less water than traditional methods and emits less carbon dioxide to the air.

Patagonia makes most of their emissions from acquiring raw materials. According to Phys.Org, “extracting and processing materials, fuel and food contributes as much as half of the world’s greenhouse gas emissions.” To reduce their GHG emissions, they plan to solely use renewable or recycled materials by 2025. Patagonia, as a company, uses 100% renewable energy in the US. That includes retail stores, distribution centers, regional and global offices, and headquarters (“How We’re Reducing Our Carbon Footprint”). They also put effort in working with suppliers to convert to renewable energy to further their sustainability goals.

Another major contributor to GHG emissions is the transportation of products. In 2013, the US made a total of 530 million metric tons of carbon dioxide emissions and it’s just going up from there (Valentine). Although it is not caused by Patagonia alone, it is important to highlight the severity of GHG emissions by transportation. The massive trucks that hold large loads of supply run on diesel. “Emissions from diesel engines contribute to the production of ground-level ozone which damages crops, trees and other vegetation” (“Learn About Impacts of Diesel Exhaust and the Diesel Emissions Reduction Act (DERA)”). On the bright side, delivery companies are beginning to replace their gas power vehicles with electric or low-emission vehicles (Domonoske).

Majority of the clothes made today are made out of plastic. Whether they are recyclable or not, it is plastic and it takes millions of years to naturally decompose, hence the reason why it’s labeled as non-biodegradable. Plastic releases microfibers to the environment. Microfibers are very tiny plastic pieces that are not able to easily get filtered. Microfiber pollutants are released into the environment through something as simple as washing and wearing the clothing (Hartline et al.). When you wash your clothes, the excessive pressure and movement sheds little microfibers off the clothing. Microfiber is often so tiny, it doesn’t get filtered well in the wastewater treatment plants. It is harmful for the environment for a number of reasons. Firstly, microfiber harms aquatic organisms that ingest them. Microplastic waste was found in fish and shellfish humans eat. As of now, we don’t have enough information to know the effects of microplastics on humans. It was also found that simply wearing polyester clothing releases microfiber in the air.

Patagonia makes many efforts to enforce sustainability. They have many articles posted on their website that show transparency in their company and their impact on the environment. They implemented the Worn Wear Program that sells second hand Patagonia gear and repairs the products. They provide repair kits and services to extend the lifespan of their products.

One of the reasons Patagonia became so popular to the public was because they provided company gears to major tech and finance companies. This gave the stereotype that “tech bros” and “finance bros” often wear Patagonia fleeces. To promote environmental consciousness, Patagonia is now selective with the companies they collaborate with. They are only providing gear for companies that share the same environmental and social values (Cantor).

The Patagonia synchilla fleece contributes to microfiber pollutants, water waste, and GHG emissions. To counteract that, they put in great efforts to lessen their carbon footprint by using alternative methods to lessen water waste and energy use by solution dyeing, and GHG emissions by using recycled materials and renewable energy. Patagonia is trying to be a carbon-neutral company but it will be impossible as there are so many more aspects that haven’t been covered. They are still a massive corporation that capitalizes off on selling products to consumers. No corporation can be entirely sustainable. How sustainable they appear depends on how well they market themselves.

Works Cited

“2025 Recycled Polyester Challenge.” Textile Exchange, 20 Oct. 2021, https://textileexchange.org/2025-recycled-polyester-challenge/.

“Better than New.” Worn Wear, Patagonia, https://wornwear.patagonia.com/?utm_source=google&utm_medium=cpc&utm_content=text+ad&utm_campaign=Brand+-+Worn+Wear&gclid=Cj0KCQiA-qGNBhD3ARIsAO_o7ynFiD90pOdQzywZYITrcSlvfRK4K8bpvuzfXeMdAoFEYY6iPz43hp8aAsp3EALw_wcB.

Boumis, Robert. “How Does Chlorination Affect Marine Life?” Pets on Mom.com, 19 Nov. 2020, https://animals.mom.com/chlorination-affect-marine-life-5455.html#:~:text=Chlorine%20Burns&text=Chlorine%2C%20even%20in%20amounts%20found,fish%2C%20chlorine%20burns%20the%20gills.&text=It%20has%20a%20similar%20effect,serious%20damage%20to%20marine%20organisms.

Cantor, Matthew. “Patagonia Distances Itself from Tech Bros with New Branded Vest Policy.” The Guardian, Guardian News and Media, 4 Apr. 2019, https://www.theguardian.com/fashion/2019/apr/03/patagonia-fleece-vest-tech-bro-uniform.

Cook, Stacey. “The Evolution of Recycled Fleece.” Science, National Geographic, 3 May 2021, https://www.nationalgeographic.com/science/article/partner-content-evolution-of-recycled-fabrics.

Domonoske, Camila. “From Amazon to Fedex, the Delivery Truck Is Going Electric.” NPR, NPR, 17 Mar. 2021, https://www.npr.org/2021/03/17/976152350/from-amazon-to-fedex-the-delivery-truck-is-going-electric#:~:text=All%20major%20delivery%20companies%20are,for%2010%2C000%20electric%20delivery%20vehicles.

Elven, Marjorie van. “How Sustainable Is Recycled Polyester?” FashionUnited, FashionUnited, 9 Mar. 2021, https://fashionunited.uk/news/fashion/how-sustainable-is-recycled-polyester/2018111540000.

“Fabric Dye Process: Dyeing, Shrinkage & Sustainabilitys.” Indie Source, Johnny Donovan Https://Secure.gravatar.com/Avatar/3e53c959942143517020c2463ce026eb?s=96&d=Mm&r=g, 4 Aug. 2020, https://indiesource.com/fabric-dye-process-dyeing-shrinkage-sustainability/#:~:text=The%20process%20involves%20submerging%20fibers,bonds%20dye%20to%20the%20fabric.&text=Many%20custom%20hoodies%20and%20custom,to%20produce%20as%20many%20units.

Hartline, N.L., Bruce, N.J., Karba S.N., Ruff, E.O., Sonar, S.U., and Holden, P.A. (2016) Microfiber Masses Recovered from Conventional Machine Washing of New or Aged Garments, Environmental Science & Technology, Vol. 50, No.21, pp.11532-11538

Notman, Nina. “Recycling Clothing the Chemical Way.” Chemistry World, Chemistry World, 3 Feb. 2020, https://www.chemistryworld.com/features/recycling-clothing-the-chemical-way/4010988.article.

“Know Your Fibers: The Difference between Polyester and Cotton.” Barnhardt Purified Cotton, 19 Aug. 2019, https://barnhardtcotton.net/blog/know-fibers-difference-between-polyester-and-cotton/.

PatagoniaWe’re in business to save our home planet. “How We're Reducing Our Carbon Footprint.” Patagonia, 18 Nov. 2021, https://www.patagonia.com/stories/how-were-reducing-our-carbon-footprint/story-74099.html.

Radhakrishnan S., Vetrivel P., Vinodkumar A., Palanisamy H. (2020) “Recycled Polyester—Tool for Savings in the Use of Virgin Raw Material.” In: Muthu S. (eds) Environmental Footprints of Recycled Polyester. Textile Science and Clothing Technology. Springer, Singapore. https://doi.org/10.1007/978-981-13-9578-9_3

“Raw Materials behind Half of Global Emissions: Un.” Phys.org, https://phys.org/news/2019-03-raw-materials-global-emissions.html.

“Solution Dyeing.” Patagonia, https://www.patagonia.com/our-footprint/solution-dyeing.html.

“Solution-Dyeing of Yarns Helps Reduce Water and Energy Consumption.” Innovation in Textiles - Technical Textiles & Smart Textiles, https://www.innovationintextiles.com/solutiondyeing-of-yarns-helps-reduce-water-and-energy-consumption/.

“Sustainability.” Home, https://www.universalfibers.com/sustainability.

“Using Bleach as a Disinfectant.” Environmental Health & Safety, 28 June 2021, https://ehs.utoronto.ca/laboratory-hazardous-waste-management-and-disposal-manual/biological-waste-disposal/using-bleach-as-a-disinfectant/.

Valentine, Katie. “Big Trucks Emit Huge Amounts of Carbon Every Year. the EPA Is about to Do Something about It.” ThinkProgress, 2 June 2015, https://archive.thinkprogress.org/big-trucks-emit-huge-amounts-of-carbon-every-year-the-epa-is-about-to-do-something-about-it-5c402732888/.

“What's All the Hype about Solution-Dyed Fabric?” Bimini Tops, https://www.nationalbiminitops.com/a/solution-dyed-fabric.html.

Wolchover, Natalie. “Why Doesn't Plastic Biodegrade?” LiveScience, Purch, 2 Mar. 2011, https://www.livescience.com/33085-petroleum-derived-plastic-non-biodegradable.html#:~:text=Most%20plastic%20is%20manufactured%20from,decay%20of%20once%2Dliving%20organisms.&text=A%20crucial%20manufacturing%20step%20turns,normally%20break%20organic%20matter%20down.