Design Life-Cycle

assess.design.(don't)consume

Lorelei Kriss

Professor Cogdell

DES 040A

Due 16 March, 2023

Squishmallows Life Cycle Analysis: Raw Materials

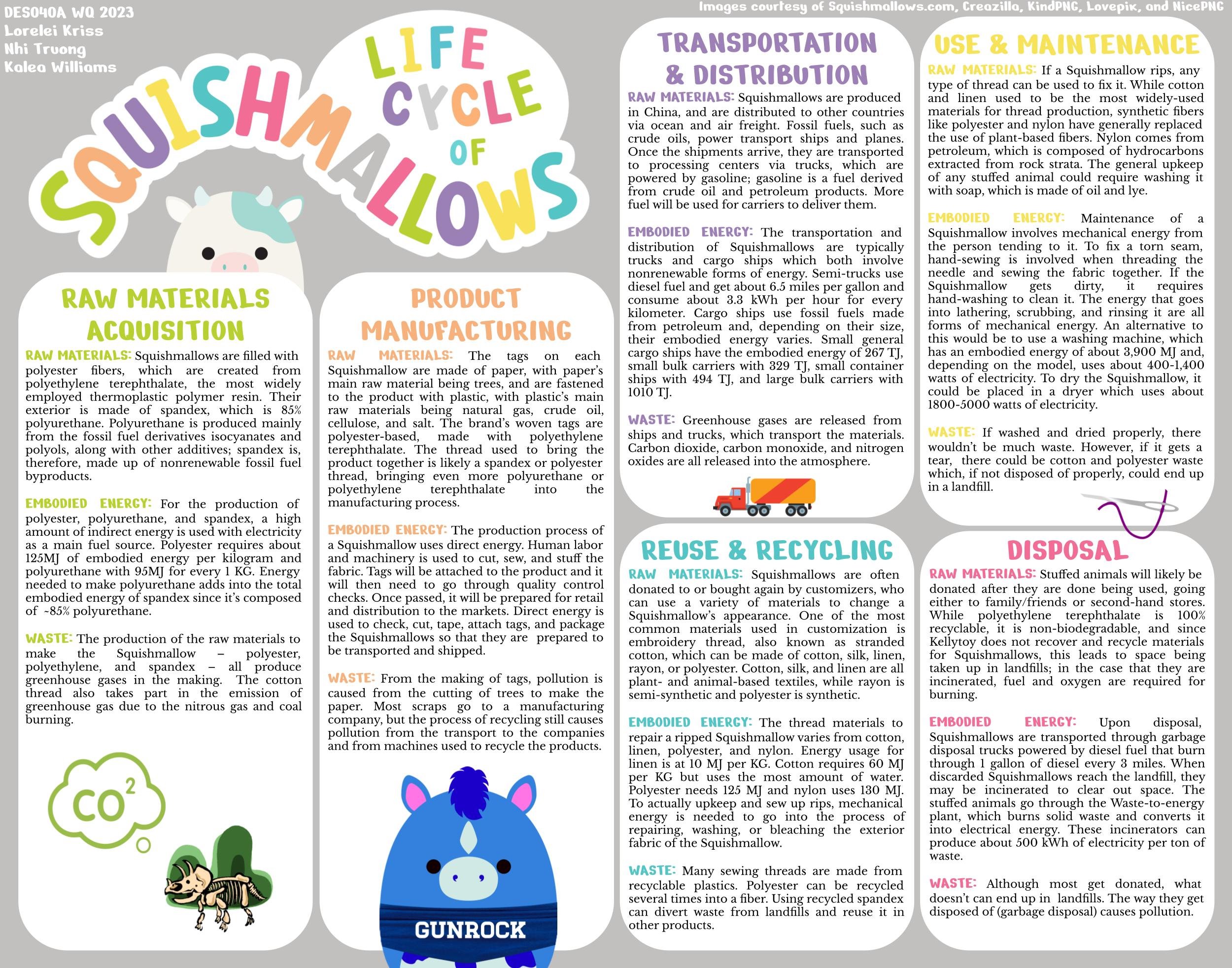

During the early days of the COVID-19 pandemic, Squishmallows took the internet by storm. The stuffed animals come in several different sizes, and are set apart from other plushies by their uniform marshmallow-like shape, black eyes, and unique exterior texture. Due to their boom in popularity during 2020’s lockdown and shelter-in-place orders, more people were on their phones for longer amounts of time, leading to Squishmallow collectors and their collections going viral on sites like Instagram and TikTok. Online shopping allowed consumers to engage in retail therapy while staying safe at home, resulting in purchases that were seen as comforting during a time of great stress. While Squishmallows are cute and cuddly, their mass consumption on a global scale is anything but endearing. As a Squishmallow progresses through its life cycle, more and more nonrenewable and unsustainable materials are used; polyethylene terephthalate and polyurethane, i.e. plastic and fossil fuels, are used to create the stuffed animal itself, while more fossil fuels are used during the transportation and disposal stages.

Since Squishmallows are a more recent craze, not much research has been conducted on their long-term environmental impacts. Our group’s project is preceded by “Polyester” and “Spandex,” both conducted by DES 40A groups in 2013, seeing as polyester and spandex are the main materials used in the production of Squishmallows. While the polyester group concluded that it is non-biodegradable and its waste products are hazardous and harmful, the spandex group mainly focused on its positive properties. Expanding on the research done by both of these groups, conducted a decade prior, we can draw the conclusion that Squishmallows are not a sustainable trend. Many simple substitutions could be made which would create more eco-friendly and sustainable Squishmallows.

The Kellytoy tag attached to all Squishmallows reads “All new material” and “Filling: polyester fibers.” No recycled materials are used, meaning spandex and polyester are constantly being created and used for the stuffed animals with no plan for what will happen after the toy is done being played with or collected. Polyester fibers are created from polyethylene terephthalate, the most widely employed thermoplastic polymer resin (Science Direct). The exterior of a Squishmallow is made of spandex, which is about 85% polyurethane (Britannica). Polyurethane is produced mainly from the fossil fuel derivatives isocyanates and polyols, along with other additives. In 2016, isocyanates and polyols accounted for almost 90% of fossil fuel energy consumption (ACS Publications). Spandex is, therefore, made up of nonrenewable fossil fuel byproducts, and is hard to recycle. Certain companies, such as Patagonia, collect spandex waste throughout their production processes to reintroduce as raw material, but it is unlikely that Squishmallow does this due to the “All new material” disclaimer on their products’ tags (Patagonia).

Aside from polyester and spandex, Squishmallows are not manufactured with many other materials. The individual tags on each product are made of paper, with paper’s main raw material being trees, and are fastened to the product with plastic, with plastic’s main raw materials being natural gas, crude oil, cellulose, and salt (AZo Materials). The brand’s woven tags are polyester-based, made with polyethylene terephthalate (American Law Label). The thread used to bring the product together is likely a spandex or polyester thread, bringing even more polyurethane or polyethylene terephthalate into the manufacturing process. Squishmallows are displayed in stores on shelves or in bins; they are not often sold in boxes or bags, so no other raw materials go into their production once they are transported to retailers.

Fossil fuels are not only used in the manufacturing of Squishmallows, but also in their transportation. Squishmallows are produced in China (MadeFind), and are likely distributed to other countries via ocean and air freight. Fossil fuels, such as crude oils, are utilized to power transport ships and planes. These fuels are a nonrenewable resource with an estimated replacement time of a few million years, making their conservation extremely important yet difficult due to their large-scale consumption. Many products, and likely Squishmallows, are shipped in shipping containers; said containers are predominantly made of steel, which is created by processing iron, carbon, oxygen, and other naturally-occurring minerals and compounds (American Iron and Steel Institute). Once the shipments arrive, they are transported to processing centers via trucks, which are powered by gasoline; gasoline is a fuel derived from crude oil and petroleum products (U.S. Energy Information Administration). Different types of fuels are utilized during different stages of the transportation journey since different types of vehicles are used to deliver the Squishmallows. More fuel will be used for Amazon, UPS, USPS, and other carriers to deliver them, and even more fuel will be used when people drive their vehicles to retail stores and the post office to retrieve their Squishmallows.

Once a Squishmallow has been bought, it does not require much in terms of use and maintenance. If a Squishmallow rips after purchase, any type of thread could be used to fix it. While cotton and linen used to be the most widely-used materials for thread production, synthetic fibers like polyester and nylon have generally replaced the use of plant-based fibers. Nylon comes from petroleum, which is composed of hydrocarbons extracted from rock strata (Xometry). The general upkeep of any stuffed animal could require washing it with water and soap, with soap generally being made of animal- or plant-based oil combined with lye (Healthline). If a Squishmallow gets stained, bleach could be used to return it to its original state; bleach is composed of chlorine, the alkali sodium hydroxide (caustic soda), and water (Vencorex). Any stuffing lost due to fabric ripping could be replaced with more polyester stuffing. It is difficult to report on the materials involved with the “use” of a Squishmallow, since it either sits on a bed or shelf or gets played with by a person.

The reuse and recycling aspects of a Squishmallow’s life cycle are interesting mainly due to their committed and creative fan base. The stuffed animals are often donated to or bought again by customizers, who can use a variety of materials to change a Squishmallow’s appearance. One of the most common materials used in customization is embroidery thread, also known as stranded cotton, which can be made of cotton, silk, linen, rayon, or polyester. Cotton itself is the raw material for the consequent textile, created by spinning the mature fibers of the cotton plant. Silk is made by boiling the cocoons of silkworms and extracting its silk fibers. Linen’s raw material is flax fibers that originate from the stem of the flax plant (World Linen). Rayon is a semi-synthetic material created with cellulose sourced from wood pulp and treated with certain chemicals (Who What Wear). Each type of thread has different strengths and properties that people can use for different types of Squishmallow customization. This reuse of one base product extends its longevity, and “The longer the toy is in use, the smaller its environmental impact becomes” (Robertson and Klimas 7).

The last stage of the Squishmallow life cycle is disposal. Stuffed animals will likely be donated after they are done being used, going either to family/friends or second-hand stores. While polyethylene terephthalate is 100% recyclable, it is non-biodegradable, and since Kellytoy does not recover and recycle materials for Squishmallows, this leads to space being taken up in landfills; in the case that they are incinerated in order to take up less landfill space, fuel and oxygen are required for burning. Mattel has a PlayBack program which allows consumers to receive a prepaid shipping label and send certain products back to Mattel “so they can be reused as recycled content in new products” or “downcycle[d]... into other plastic products or convert[ed]... from waste to energy” (Mattel) – other brands following in Mattel’s footsteps would reduce the amount of waste in landfills and pollutants being released into the environment. The disposal stage of Squishmallows could function as a recycling stage, reintroducing these unsustainable and nonrenewable materials back into the Kellytoy production process and making Squishmallows less harmful.

Squishmallows may not be made of much, with polyester and spandex being the only cited materials that go into the stuffed animals, but this supposed simplicity is non-biodegradable and unsustainable. If Squishmallow production, along with other similar product manufacturing, continues at an exponential rate without change in practices, fossil fuel resources will continue to run out, and will not be replaced in our lifetime or the many lifetimes that will follow ours. Kellytoy could practice sustainability by replacing polyester or spandex with a renewable, plant-based textile; the parent company could also use recycled materials, like recycled polyester. By establishing more production warehouses outside of China, less crude oil would be used in transporting Squishmallows across oceans and countries. Squishmallows may be cute, but knowing the negative environmental impacts consequent of their production life cycle should make one less likely to purchase and collect them in the future.

Full Bibliography

1. Robertson, Madeline R. and Klimas, Christie (2019) “A Playful Life Cycle Assessment of the Environmental Impact of Children’s Toys,” DePaul Discoveries: Vol. 8: Iss. 1, Article 7.

Available at: https://via.library.depaul.edu/depaul-disc/vol8/iss1/7.

2. Peterson, Sara. “What Are Squishmallows Made of? Answered (2023 Updated).” Toynk Toys, Toynk Toys, 29 Dec. 2022, https://www.toynk.com/blogs/news/what-are-squishmallows-made-of.

3. “Polyester Fiber.” Polyester Fiber - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/chemistry/polyester-fiber.

4. “Spandex.” How Products Are Made,

http://www.madehow.com/Volume-4/Spandex.html.

5. Sewport. “What Is Spandex Fabric: Properties, How It’s Made and Where.” Sewport, Sewport, https://sewport.com/fabrics-directory/spandex-fabric.

6. Common Objective. “Fibre Briefing: Polyester.” Common Objective, Common Objective,

22 Oct. 2021, https://www.commonobjective.co/article/fibre-briefing-polyester.

7. “Spandex.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/technology/spandex.

8. “Thread Production - Learn about Thread Manufacturing & Thread Types.” Coats, https://coats.com/en/information-hub/Thread-Production.

9. Material Flows of Polyurethane in the United States. https://pubs.acs.org/doi/10.1021/acs.est.1c03654.

10. Ethan. “Where Are Squishmallows Made 2023.” First, Rarest & More, 31 Dec. 2022, https://madefind.com/where-are-squishmallows-made/.

11. Nunez, Kirsten. “How to Make Soap from Scratch.” Healthline, Healthline Media, 23 Nov. 2021, https://www.healthline.com/health/how-to-make-soap.

12. “Stuffed Toy Labels.” American Law Label INC., 8 Sept. 2022, https://americanlawlabel.com/product/stuffed-toy-labels/.

13. 2022, Akhlaqul Karomah, Mar 10. “What Raw Materials Are Used to Make Plastic?” AZoM.com, 10 Mar. 2022, https://www.azom.com/article.aspx?ArticleID=21427.

14. Xometry, Team. “5 Types of Nylon and Their Differences, Uses, and Properties.” Xometrys RSS, Xometry, 31 Oct. 2022, https://www.xometry.com/resources/materials/types-of-nylon/.

15. “Embroidery Floss – Thread Types, Colors, and Uses.” CreateForLess, https://www.createforless.com/buying-guides/crochet-knitting-and-other-needlework/embroidery-floss-cotton-dmc-six-strand-variegated-more.aspx.

16. Emmanuel, et al. “What Is Linen Made from?” WORLD LINEN, 23 Jan. 2023, https://worldlinen.com/blogs/news/what-is-linen-made-from.

17. Zee, Mandy. “What Is Rayon? Here's What You Should Know.” Who What Wear, Who What Wear, 20 June 2022, https://www.whowhatwear.com/what-is-rayon/slide3.

18. “Mattel Playback and Sustainability: Mattel.” Mattel Shop, https://shop.mattel.com/pages/playback.

19. “U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Gasoline Explained - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/gasoline/.

20. “Chlorine & Caustic Soda Key Raw Materials for Chemicals Intermediates Industry.” Vencorex, https://www.vencorex.com/application/chemicals-intermediates/.

21. “Steel Production.” American Iron and Steel Institute, 16 Nov. 2021, https://www.steel.org/steel-technology/steel-production/.

22. “Recycled Spandex.” Patagonia, https://www.patagonia.com/our-footprint/recycled-spandex.html.

Nhi Truong

Professor Cogdell

DES 40A/SAS 43

16 March 2023

Squishmallows Embodied Energy

An award winning plush toy has taken social media outlets by storm. Known as a “Squishmallow,” the soft, cuddly stuffed toy created by Kelly Toys drastically rose to popularity at the peak of the COVID-19 pandemic in 2020. The different animals and characters that the toy resembles in its iconic round shape constantly circulated through various social media platforms–specifically TikTok. With its rise in popularity, primary consumers started to shift from children to teenagers and adults who now sought out the highly coveted toy. It peaked to a point where Squishmallows were sold out across many retailers as demand consistently soared. As more Squishmallows are purchased, its impact and necessity becomes questionable.

While these cute, huggable toys bring comfort and joy to its consumers, the impact that it has on the environment produces a very harmful and negative effect. The use of direct, indirect, and mechanical energy to manufacture Squishmallows combined with non-renewable fuel sources required for transportation and exports leads to detrimental impacts on the environment with a finished product that is non biodegradable.

To understand the full scope of the life cycle of a Squishmallow’s contribution to the environment, a deep dive into its embodied energy is needed since it can be used to evaluate a product’s sustainability. The term “embodied energy” essentially means the energy involved in the manufacturing of a product from its material acquisition, production, manufacturing, transportation, and distribution. In the early stages of a Squishmallow’s life cycle, it is already clear that it contains high energy consumption which is reflective upon its environmental impact.

The making of a Squishmallow first begins with the materials acquisition. The plush toy is composed of a polyester filling, and a spandex/polyurethane exterior. The production of these materials requires indirect energy at high amounts. Polyester, a manufactured synthetic product, needs a high amount of energy to produce and uses about 125 Megajoules of energy per kilogram. To produce this material, metal machinery is used to convert polyethylene terephthalate (the most widely employed thermoplastic polymer resin) into a polyester fiber through a process called melt spinning. These PET plastic pellets are melted and pushed through tiny holes to form threads that harden into a fiber. The machinery is powered by electrical energy and fossil fuels which produce steam and high levels of heat along with powering the cooling stage towards the end of production (CFDA). Even though polyester is a synthetic fiber, most of its raw material comes from petroleum which has environmental implications.

In contrast, polyurethane is a composite material that takes a little less energy to produce with its embodied energy of 95 MJ for every 1 KG. But composed mainly of fossil fuel derivatives, it is sourced from a non-renewable material. To create polyurethane, layers of polymer resin are combined with urethane links and another textile such as cotton, polyester, nylon, or leather. In this case, the tags on a Squishmallow does not directly list polyurethane as a material used but its exterior spandex fabric is made up of about 85% polyurethane.

Moreover, the production of spandex also known as ‘spandexis’ is, “...made of synthetic polymer called polyurethane which has extraordinary stretch ability. The long chain of polymers is produced by reacting polyester with diisocyanate…” (Fibre2Fashion). Altogether, these materials make up the popular stuffed toy and its notable “squish” and soft outer shell while using high amounts of indirect energy, and electrical energy to power production machinery. While this first step highlights the main usage of indirect energy, the use of fossil fuels and its derivatives have made the process unsustainable.

In addition, the next step in the Squishmallow life cycle is its actual manufacturing. Since the stuffed animals are made up of mainly spandex and polyester, after those materials are produced and acquired, direct energy is used since it involves direct handling of the product. During this process, human labor and machinery are necessary to assemble the toys.

Produced in China, Squishmallows are created in typical factory settings that have workers and machines turn secondary materials into a finished product. Direct energy is needed from employees to operate machinery that involves the action of dyeing and drying the textile so that its colors will correlate with the characters. Workers will either operate a machine that is programmed to cut the fabrics or manually operate one to do it themselves. Depending on which size of Squishmallow is getting produced, the fabric cut guidelines will be set to make smaller or larger shapes. After all the shapes of a Squishmallow are cut, the pieces of fabric will be combined together with a sewing machine. Direct energy goes into using a sewing machine since workers must maneuver the textile through the sewing plate, choose the correct stitch, sew/backstitch the fabric, replace the thread once empty, stuff the toy with a polyester filling, sew on a label, and cut off the remaining thread when done. With a semi-finished product, its corresponding glossy paper tags are attached to the side of the Squishmallow with plastic fasteners. Once the product is finished, the toys go through quality control checks to ensure that it is up to status and once passed, it can be prepared for retail and distribution. Workers use direct energy to directly handle the packaging of the stuffed animals by properly packaging them in cardboard boxes, taping the boxes up, and cutting off excess tape. After the toys are securely packed, they are ready for pick-up and transport.

After a shipment of Squishmallows is picked up by truck, the process of transportation and distribution to stores begin. To carry large loads, semi-trucks are typically used for efficiency. However, standard semi-trucks consume about 3.3 kWh per hour for every kilometer and burn through a gallon of diesel fuel every 6.5 miles (Kaufmann). The diesel fuel that the trucks intake is still a form of nonrenewable energy even if it has the highest energy production to low emissions ratio (Rentar).

From a consumer standpoint, cars are also used as a method of transporting Squishmallows but in the sense that buyers purchased the toy from a retail store by driving there and driving back home. This situation does not necessarily factor into the overall bulk shipment of Squishmallows but it illustrates another potential mode of transportation that plays into the usage of fossil fuels as a form of energy.

Furthermore, to ship Squishmallows globally, a common form of transportation are cargo ships. Similar to trucks, cargo ships also use a nonrenewable source of energy in the form of fossil fuels made from petroleum. But, depending on the size of the ships, their embodied energy varies. Small general cargo ships have the embodied energy of 267 Terajoules. Small bulk carriers come in second at 329 TJ followed by small container ships with 494 TJ and large bulk carriers with a shocking 1010 TJ. Even though cargo ships consume a large amount of energy, it should be noted that different products are often transported together rather than having whole ships dedicated to moving one singular product.

With the distribution stage over, Squishmallows go through a process of maintenance. When a consumer purchases the plush toy, they are now responsible for its maintenance. This stage involves mechanical energy since maintaining a Squishmallow means that a person must physically tend to it if problems arise. The most common issues that consumers will run into is a torn seam, or a dirtied exterior. To fix a torn seam on the stuffed animal, hand sewing is involved when threading the needle, sewing the fabric together, and knotting/cutting off the ends of the thread. If the Squishmallow gets dirty, it requires hand washing to clean it. The energy that goes into lathering, scrubbing, and rinsing it are all forms of mechanical energy. An alternative to this would be to use a washing machine which has an embodied energy of about 3,900 MJ and depending on the model, uses about 400-1,400 watts of electricity (Marsh). To dry the Squishmallow, it could be placed in a dryer which uses about 1800-5000 watts of electricity. It can also be air dried which would not require electricity but would need the owner to manually place it in a desirable place that has sunlight or good ventilation.

As the life cycle progresses after the transportation and distribution stage, energy usage decreases since the finished product does not require regular maintenance and is designed for regular use. At its stage of reuse and recycling, Squishmallow upkeep is similar to its previous maintenance stage. To “reuse” the stuffed animal, it might be repaired with thread materials such as cotton, linen, polyester, or nylon. Linen uses the least amount of energy at 10 MJ per KG. Cotton requires 60 MJ per KG but uses the most amount of water to produce. Polyester needs 125 MJ and nylon uses 130 MJ (Schlesinger). To actually upkeep and sew up rips so that the plush toy can be reused or donated, mechanical energy is needed to go into the process of repairing, washing, or bleaching the exterior fabric of the Squishmallow since a person is needed to carry out these actions.

Lastly, in its last stage of the life cycle Squishmallows are disposed of. Disposal can take the form of donating the stuffed toy or throwing it away but it technically cannot be rid of in a sustainable way since polyethylene terephthalate is non-biodegradable. If a Squishmallow is disposed of in the trash, they are transported by garbage disposal trucks that are powered with diesel fuel. These trucks consume a gallon of diesel fuel every 3 miles while producing lower emissions. When the discarded Squishmallows reach the landfill, they may be incinerated to clear out space. The stuffed animals go through the waste-to-energy plants which burn solid waste and convert it into electrical energy. These incinerators can produce about 500 kWh of electricity per ton of waste. While these waste plants seem to be a good way to extract energy from natural resources, it pollutes the air and the environment in the process (Muznik 4).

In conclusion, the embodied energy that goes through the life cycle of a Squishmallow is increasingly harmful to the environment and its natural resources. Its production, manufacturing, and transportation uses nonrenewable forms of energy which has detrimental and lasting effects. The high amounts of energy usage applied to the stuffed animals far outweigh its cute appearance and overall value that it brings to people. If it continues to increase in popularity, this cycle will only repeat itself at a larger and faster scale with Squishmallows filling up landfills and the air we breathe.

Full Bibliography

Muznik, Sara. “9 Reasons Why We Better Move Away from Waste-to-Energy, and Embrace Zero Waste Instead.” Zero Waste Europe, 30 Aug. 2021, https://zerowasteeurope.eu/2018/02/9-reasons-why-we-better-move-away-from-waste-to-energy-and-embrace-zero-waste-instead/#:~:text=%E2%80%9CWaste%2Dto%2Denergy%E2%80%9D%20is%20often%20described%20as%20a,without%20delivering%20what%20it%20promised.

“Embodied Energy.” Embodied Energy - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/engineering/embodied-energy.

Blesius, Jim. An Overview of Polyurethane Fabric, https://mitchellfauxleathers.com/Default/ViewPoint/Read/faux-leather-viewpoint/2018/03/16/an-overview-of-polyurethane-fabric.

www.fibre2fashion.com. “Significance of Spandex Fibres: Elastane Fabrics.” Fibre2Fashion, https://www.fibre2fashion.com/industry-article/7192/spandex-the-gen-next-fibre#:~:text=Spandexis%20made%20of%20synthetic%20polymer,laboratory%20in%201959%2C%20in%20Virginia.

CFDA, https://cfda.com/resources/materials/detail/polyester#:~:text=To%20make%20polyester%20fibers%2C%20PET,process%20is%20called%20melt%20spinning.

“Diesel, the Best Fossil Fuel.” Fuel Catalyst, 20 Apr. 2018, https://rentar.com/diesel-best-fossil-fuel/#:~:text=Of%20all%20the%20solid%20fossil,gold%20standard%20of%20fossil%20fuels.

“Soft Toy Making Process in Our Factory: Production Process.” Lucky Around, 8 May 2021, https://www.luckyaround.com/soft-toy-making-process/.

Jacobs, Sarah. “Inside a Chinese Factory That Makes Toys for Rest of the World.” Business Insider, 15 August 2017, https://www.businessinsider.com/inside-a-chinese-factory-that-makes-toys-for-rest-of-the-world-2017-8?amp.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Waste-to-Energy (MSW) in Depth - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/biomass/waste-to-energy-in-depth.php.

Peterson, Sara. “What Are Squishmallows Made Of? Answered (2023 Updated).” Toynk Toys, 29 December 2022, https://www.toynk.com/blogs/news/what-are-squishmallows-made-of.

“Can You Recycle Stuffed Animals?” Conserve Energy Future, https://www.conserve-energy-future.com/can-you-recycle-stuffed-animals.php.

Robertson, Madeline R., and Christie Klimas. “A Playful Life Cycle Assessment of the Environmental Impact of Children's Toys.” DePaul Discoveries, vol. 8, no. 1, 2019, p. 15, https://via.library.depaul.edu/cgi/viewcontent.cgi?article=1141&context=depaul-disc.

“Stuffed Toys Production Process.” cuddly plush toy, https://www.cuddlyplushtoy.com/about/Stuffed_Toys_Production_Process.html.

Zhang, Ziqi. Life‐Cycle Energy and Environmental Emissions of Cargo Ships. https://onlinelibrary.wiley.com/doi/full/10.1111/jiec.13293.

“Freight Transportation Energy Use & Environmental Impacts.” Bureau of Transportation Statistics, https://data.bts.gov/stories/s/Freight-Transportation-Energy-Use-Environmental-Im/f7sr-d4s8.

Kaufmann, Johannes. “Electric Trucks like the Tesla Semi Are 'Pointless Both Economically and Ecologically,' According to a Vehicle-Tech Expert.” Business Insider, Business Insider, https://www.businessinsider.com/this-expert-says-tesla-semi-is-economically-and-ecologically-pointless-2019-2.

Marsh, Jacob. “How Many Watts Does a Washing Machine Use?: Energysage.” EnergySage Blog, EnergySage, 29 Nov. 2022, https://news.energysage.com/how-many-watts-does-a-washing-machine-use/#:~:text=On%20average%2C%20washers%20use%20400,to%20run%20for%20a%20year.

Schlesinger, William. “The Fabric for Our Lives.” Translational Ecology, 26 Nov. 2018, https://blogs.nicholas.duke.edu/citizenscientist/the-fabric-for-our-lives/.

Life‐Cycle Energy and Environmental Emissions of Cargo Ships. https://onlinelibrary.wiley.com/doi/10.1111/jiec.13293.

Kalea Williams

Professor Cogdell

DES 40A

March 14, 2023

Squishmallows: Waste

Squishmallows are a plush toy created by Kelly Toys in 2017. They’re known to be soft and cute, popular among children and adults. Though everyone might love stuffed animals, the process of creating stuffed animals actually produces waste through the use of overproduction, heavy machine usage, and lacking the ability to be recycled.

One of the raw materials that makes up squishmallows is polyester. Polyester fabric is described as a smooth, strong and durable man-made synthetic fabric made from petroleum-based synthetic fibers. These types of fibers are non-biodegradable and they end up in landfills and our oceans. Other materials used in the production of polyester are polyethylene terephthalate, resin, fiberglass. Every stage of production releases carbon dioxide, and some acid gasses hydrogen chloride, and unstable compound waste. When polyester is manufactured in factories , the production requires high levels of heat, various chemicals, and dyes.. In the different stages of manufacturing coal, air, water, and petroleum are used. Another raw material used to make squishmallows would be spandex. Spandex fiber is created with prepolymers made through a chemical reaction from polyol (macroglycol) and isocyanate.

When it comes to manufacturing production of Polyester fiber, a certain amount of waste is generated. Drying, melting, spinning, drawing the fiber, and winding are involved in the process of production, mainly requiring a lot of water and coal in order to heat/dry the compounds to create the synthetic fiber. When heated, the emissions of the chemicals are released into the air. Many of the waste emissions are hazardous and can harm us, or our environment with toxins. Processing polyester when resins combined with filler or fiberglass , it can then create a toxic hazard that is harmful when in contact to the skin etc. During the manufacturing process, the majority of waste comes from the burning of fossil fuels to provide electricity to power the high-tech machinery used to mass-produce.Spandex threads are produced in four different ways: melt extrusion, reaction spinning, solution dry spinning, and solution wet spinning. Dyeing the fiber also plays an important factor in waste emissions. The dyes already contain a number of chemicals and compounds in order for it to change the fibers into the color that we want to produce. The ratio of liquid decreases the level of exhaustion of the dye. So, when the amount of liquid dye increases, so does the waste that results from it, because the decreased level of exhaustion causes the dye to not absorb as much into the fiber. Emissions of nitrous oxide- Nitrous oxide is a gas that entraps heat 310 times more efficiently than carbon dioxide, which increases the pollution in the air, the toxins can affect our air and water The distribution and transportation phase contributes a great deal to the overall .Waste and emissions from this would come largely from air travel and boat travel. Carbon dioxide andnitric oxide are emitted from airplane travel, which are greenhouse gasses toxic to the environment.

waste equation. Through the distribution of the squishmallows, from factor to store carbon dioxide is inevitably released. Greenhouse gasses are released from ships and trucks, which transport the materials. Carbon dioxide, carbon monoxide, and nitrogen oxides are all released into the atmosphere. Fossil fuels are used to transport the various materials involved in the creation. A part of the packaging would be tags packaging is made from recycled paper material. Paper comes from tree pulp that has been combined with a mix of binding and whitening agents.

If the squishmallow is taken care of properly there should be little to no waste. However if it gets a tear there could be cotton and polyester waste if not disposed of properly could end up in landfill. For maintenance, soap and water can be used to wipe away any spots. These additional products may need to be taken into consideration when discussing the wastes released during the consumption stage. Products can be used that are more environmentally friendly and that don’t use fluorocarbons to eliminate hazardous wastes going into the air like water repellents.

During the recycling stage, used squishmallows can be recycled at many local retailers, which are then donated to local organizations. Throughout this process of distributing and donating the shoes, modes of transportation are required, thus emitting pollutants, like CO2, into the air. Even though greenhouse gasses are being released into the air, this shouldn’t discredit the recycling process. Many sewing threads are made from recyclable plastics making it easier to recycle, the thread can get reused. The process of doing this wouldn't be very good for the environment but polyester can be recycled several times into a fiber. Using recycled spandex can divert waste from landfills and reuse it in other products, for example be put back in to make another squishmellow. The lifespan of the product honestly depends on how well you take care of it and in a way you play a part on how much waste goes into recycling/ the upkeep of the squishmallows.

The disposal of squishmallows might be the most important part because of the effect it would have on the environment. Simply disposing waste into a landfill, recycling and reusing materials is a more complicated process that includes more steps like sorting, shredding, more sorting, and reprocessing. With this process having more steps, more energy is being used which depending on the energy sources can be even more dangerous to our environment. Polyethylene terephthalate is 100% recyclable, but it is not yet non-biodegradable. Since the materials are not recovered and recycled materials for Squishmallows, this leads to space being taken up in landfills. Although recycling helps to reduce energy usage, reduce the consumption of fresh raw materials, reduce air pollution and water pollution by reducing the need for waste disposal and also reduces greenhouse gas emissions there are some bad parts about it too. The harmful chemicals from these wastes can also be dangerous. Causing massive pollution, the whole recycling process poses health risks for dedicated individuals responsible for recycling these waste products. If such waste products come into contact with water, it results in the formation of leachate that ends up polluting water bodies. Products manufactured from recycled waste may not be at par regarding quality. These kinds of products are almost always made of trashed waste material collected from mountains of other waste materials that have been overly utilized. Recycling tons of garbage will require waste to be transported, sorted, cleaned and processed in separate factories, all of which need energy and may result in by-products that can pollute soil, air or water.Even vehicles that are employed to pick up recyclable products will also increase air pollution by releasing toxins that are all airborne.( Conserve Energy Future 2023)

Through a life cycle which I discovered uses a lot of energy and waste, which has become a concern to our environment. From raw materials, to embodied energy, and waste and emissions The hazards are a huge concern because the structure of the main material, synthetic polyester is non-biodegradable and a small percentage is only recycled. Many of the chemicals and toxins have made their way after manufacturing, into our land, air and water. In conclusion, through the life cycle of synthetic polyester, I was able to reveal the cause and effects of production, transportation, and emitted waste; which has caused many health and environmental concerns due to the huge amounts of energy and toxins being used.

Full Bibliography

Christina Dang, “Spandex is Elastic but the Environment is Not” August 10, 2022 https://www.andher.us/blogs/news/spandex

Alex Assoune, “The Truth About Recycled Polyester Fabric Sustainability” http://www.panaprium.com/blogs/i/recycled-polyester-fabric

Alden Wicker “ Why, Exactly, Is Polyester So Bad for the Environment?” Jan 19, 2021

https://ecocult.com/exactly-polyester-bad-environment

Sewport Support Team, What is Spandex Fabric: Properties, How its Made and Where, February 09, 2023

What is Spandex Fabric: Properties, How its Made and Where | Sewport

Mazharul Islam Kiron,Spandex Fiber: Properties, Manufacturing Process and Uses ,December 12, 2014

Spandex Fiber: Properties, Manufacturing Process and Uses (textilelearner.net)

Cattermole Consulting Inc., Fiber recycling using mechanical and chemical processes , Jun 10, 2019

Fiber recycling using mechanical and chemical processes - Cattermole Consulting Inc.

O ECOTEXTILES (AND TWO SISTERS ECOTEXTILES), WHY IS RECYCLED POLYESTER CONSIDERED A SUSTAINABLE TEXTILE?

Why is recycled polyester considered a sustainable textile? | OEcotextiles

O ECOTEXTILES (AND TWO SISTERS ECOTEXTILES),

TO POLYESTER OR NOT TO POLYESTER

Recycled polyester | OEcotextiles

By Don-Alvin Adegeest Wastewater: fashion's grotesk sustainability problem May 5, 2020

Wastewater: fashion's grotesk sustainability problem (fashionunited.com)

Cotton; waste other than garnetted stock and yarn (including thread) waste exports by country in 2021

Cotton; waste other than garnetted stock and yarn (including thread) waste exports by country |2021 (worldbank.org)