Design Life-Cycle

assess.design.(don't)consume

Annika Mujushi

Professor Cogdell

DES 40A

6 December 2018

Plastic Cutlery Materials

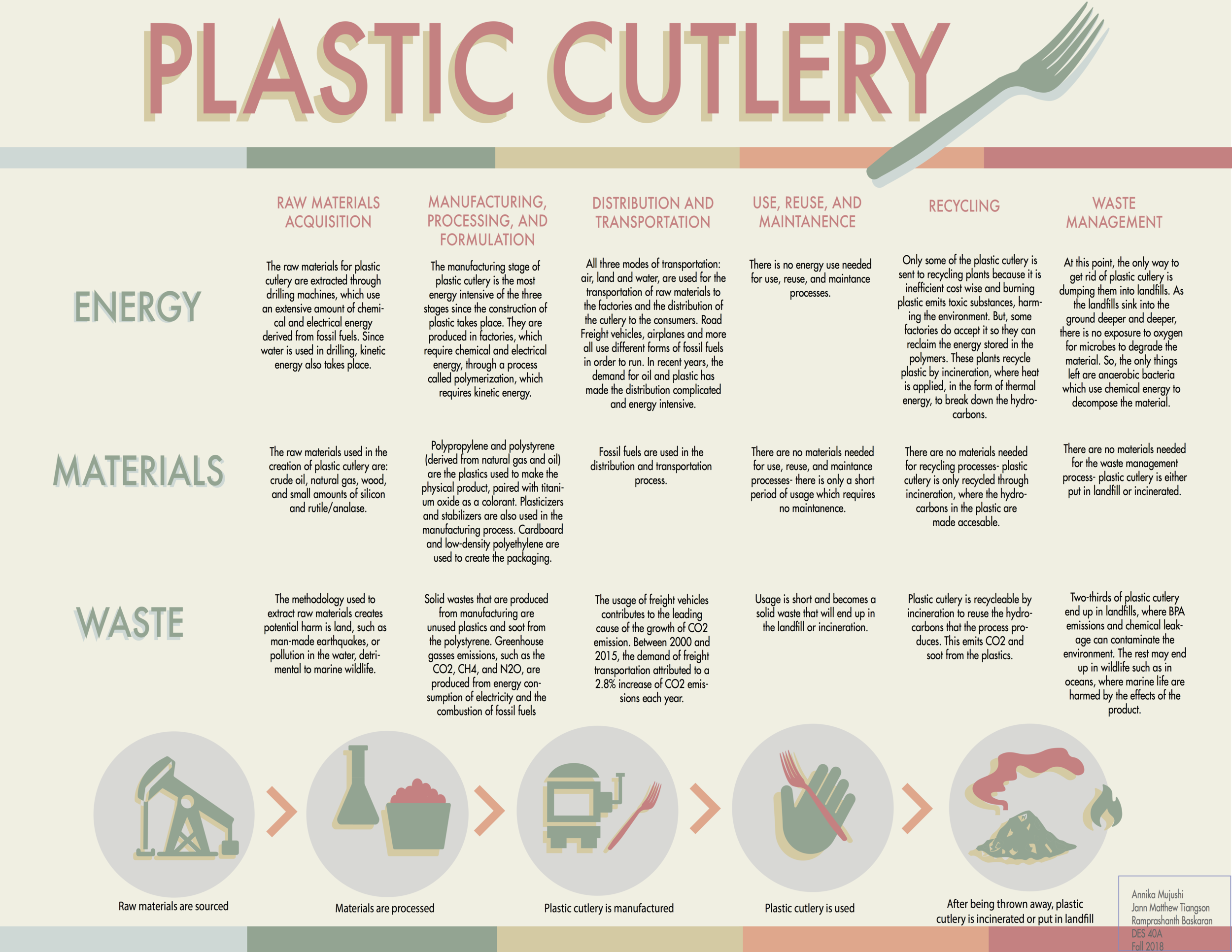

Plastic cutlery has become a staple amongst both the fast food industry and in everyday life, due to its ease of use and accessibility. Due to the fact that plastic cutlery is so easy to use and dispose, the environmental impact of the materials that go into creating the product are rarely thought about. The waste that plastic spoons, forks, and knives produce contributes to the around 300 million annual tons of plastic waste that litters our environment (Li). There are many products on the market that cater towards a more environmentally friendly disposable form of cutlery, some even attempt to disregard the concept of disposability entirely and focus on an easy and portable reusable option. However, plastic cutlery is still a largely used and largely disposed product. While a variety of raw materials go into creating plastic cutlery, a large portion of the primary materials are non-renewable or are being consumed at a rate at which they cannot be renewed quickly enough, meaning that plastic cutlery is ultimately a wasteful and unsustainable product.

Natural gas and oil are the primary materials used to create the polypropylene and polystyrene that is used in the production of plastic cutlery, which are ultimately materials that are being used at an unsustainable rate. The production process of polypropylene begins with natural gas, which is polymerized, meaning the monomers of propylene are strung together to create polypropylene. A very similar process occurs in the process of polystyrene; crude oil is polymerized to create polystyrene plastic. These plastics are brought to factories as pellets, which are then melted with colorants and poured into molds. After this the plastic is cooled and moved on to packaging (HowItsMade). Researchers have found that after 2042, almost all sources of fossil fuels will be depleted (Shafiee). Use of natural gas and oil to create plastics has a lasting effect on the world’s fossil fuel reserves, and when combined with the many other industries that continue to use these resources at fast rates eventually creates a system that is using natural gas an oil at an unsustainable rate. Fossil fuels take millions of years to regenerate, which gives them such a high energy density, but also makes the use of them extremely unsustainable when used at the rate seen today. Plastics like polypropylene and polystyrene that are used to make plastic cutlery aid in this abuse of the earth’s oil reserves, and the following unsustainability of fossil fuels. However, while plastics may make up much of the materials of the physical cutlery, there are many other processes and materials that go into making the end product.

Low-density polyethylene and cardboard are used in different situations to package plastic cutlery. Similarly to the polystyrene and polypropylene, natural gas and oil are the primary materials that make up low-density polyethylene, alongside cardboard derived from wood, which are both, again, unsustainable resources. Low-density polyethylene follows a very similar production process as the aforementioned plastics, crude oil is polymerized to create the thin, transparent plastic (MacNulty). Low-density polyethylene is often used to package singular sets of cutlery, which are often used in restaurants and fast food chains, but is also used in packaging large sets often sold in bulk in stores (Plastic Resins). The same ramifications of the use of polystyrene and polypropylene apply to low-density polyethylene. The use of oil in plastics continues to be unsustainable, especially when being used at such a fast rate. Thin cardboard is also used in the packaging of many bulk sets of cutlery. This cardboard is made of wood that has been pulped to create paper, which is combined with flute, which is scrap recycled paper, and combined to make cardboard. Deforestation is one of the direct causes of global warming, and the use of wood-based products with little effort to ensure recyclability only add to this issue. A Yale study on trees and deforestation concluded that at the current rate of consumption, there are only 300 years until forests will be depleted (Angelson). The carboard used in packaging plastic cutlery is often coated with a shiny or glossy layer, which makes recycling much more difficult. The use in the first place of cardboard, and the absence of recyclability both lead to increasing deforestation and are therefore unsustainable. Low-density polyethylene and cardboard are the physical materials that are seen in the finalized product, however, there are many other unseen pieces that work in the creation of plastic cutlery.

Many other materials are used in the production of plastic cutlery that aren’t necessarily seen obviously in the final product, specifically oil-based materials, are also unsustainable materials. Plasticizers are used in the production process of plastic cutlery to attain a better final product. Paraffinic oils are specifically used- also known as kerosene. Paraffinic oils are made of crude oil that has been processed- meaning that just like the fossil fuels that are used in creating the plastics that the cutlery is made of, it is a limited source that is being consumed at a rate much too high in comparison to the time it takes to be produced. Stabilizers used in the creation of plastic cutlery also are oil based- meaning they too are unsustainable. The removal compounds are made of silicon, which is the most relatively abundant and least finite source used in the creation of plastic cutlery (Kadekar). Asides from the silicon-based removal compound, all of the other production materials are unsustainable, especially at the rate that they are being used. Alongside production material, it is easy to forget the impact of other ‘unseen’ materials that aid in the overall production process.

The transportation of the materials from site to site uses and expends much material, which is mostly comprised of unsustainable fossil fuels. Trucks and freight vehicles ship plastic cutlery in order to distribute the product (Kadekar). These vehicles run on natural gas- fossil fuels that are, again, being consumed at a much faster rate than the earth can produce. Around half of the barrel oil produced goes towards gasoline, which powers these kinds of vehicles (Shafiee). Gasoline is one of the largest uses of fossil fuels and is one of the biggest areas for potential and vital substitution of fossil fuels. The rate at which fossil fuels are consumed is very unsustainable, and the transportation used by both plastic cutlery production and the general industry only aid in this unsustainability. Much of the materials that go into the creation of plastic cutlery are unseen, but even so, remain just as unsustainable as those that are easily visible.

As an overall product, there is not much opportunity for reuse in plastic cutlery, meaning the product often ends up as waste. During production, the molds used to cast the plastic forks are reused, and the plastic used in this process that does not end up as the final product is also melted and reused. However, once the cutlery leaves the factory, there is little more opportunity for reuse at all. After the product is used, normally this is only once as plastic cutlery is designed for single use, it is thrown away. There is no opportunity for recycling, as the product is often spoiled by food remnants. Plastic cutlery commonly ends up in a landfill, where it degrades extremely slowly and releases harmful chemicals into the environment. The other option is incineration, where the plastic cutlery, along with other waste is burned, releasing harmful toxins and emissions into the atmosphere (Kadekar). Plastic cutlery and the industry involved in producing it is heavily reliant on fossil fuels, which is an industry that both destroys natural landscapes and ecosystems, and often results in extremely harmful spills. The fossil fuels burned in transportation and production also end up as emissions that pollute the air and earth’s atmosphere. There is no opportunity for recycling, little opportunity for reuse, and humongous and harmful environmental effect yielded by the life cycle of plastic cutlery (MacNulty). Not only does the product itself yield high amounts of waste, but the processes by which plastic cutlery is produced also yield similarly high amounts of waste, especially as emissions, pollution, and destruction of the earth’s environment. Obvious or not, almost every material that is input into the process of creating plastic cutlery quickly ends up as waste that pollutes our environment- whether in a landfill or as emissions in the earth’s atmosphere.

With continuous use and continuous waste of plastic cutlery, resources will eventually run out, and the product will no longer be sustainable. Many of the materials that are used in the creation process of plastic cutlery end up as waste with little opportunity for reuse. The question is raised of if cheap, easy to use, and easy to throw away plastic cutlery is really worth the destruction of the environment that it yields so blatantly. The entire process of production relies on almost completely unsustainable and nonrenewable materials and will eventually lead to the necessary substitution of these raw primary materials in the future. Plastic cutlery, as both a product and an industry, is reliant on unsustainable materials, which it will eventually see an end to the use of.

Bibliography

Bernier, Andrew. “Living the Life of a Plastic Fork.” Sustainability, Prescott College, 2011,

HowItsMade. “How Its Made: Plastic Cups and Cutlery. YouTube, 2 Mar. 2014,

Kadekar, Aswitha. "Triple Bottom Line Assessment of Single-use Disposable Plastic Cutlery."

(2017).

Li, W. C., H. F. Tse, and L. Fok. "Plastic waste in the marine environment: A review of sources,

MacNulty, Michael. “Plastic Spoon Life Cycle Analysis.” Prezi.com, 22 Mar. 2017,

“Polystyrene.” Wikipedia, Wikimedia Foundation, 17 Oct. 2018,

“PP – Polypropylene – Manufacturing Process of PP (Polypropylene):” Guichon Valves RSS,

guichon-valves.com/faqs/pp-polypropylene-manufacturing-process-of-pp-

Razza, Francesco, et al. "Compostable cutlery and waste management: An LCA

Shafiee, Shahriar, and Erkan Topal. "When will fossil fuel reserves be diminished?" Energy

Staff, Creative Mechanisms. “Creative Mechanisms Blog.” Everything You Need to Know

About Polypropylene (PP) Plastic, 4 May 2016, www.creativemechanisms.com/blog/all-

“The Blunt Truth behind Plastic Cutlery.” Unpackage Me, 11 Oct. 2014,

Ramprashanth Baskaran

Professor Cogdell

SAS 43, Section A04

6 December 2018

Extensive Energy Use for Plastic Cutlery

The last time people went to a fast food restaurant like Panda Express, they probably used plastic forks and knives to eat. After finishing a less than satisfactory meal, they blindly toss all the cutlery in the trash can, not considering about the potential repercussions that it might have. After World War II, most household products transitioned from metal to plastic, including eating utensils. Due to its convenience and low cost, the use of plastics became more pervasive. In the context of utensils, plastic products offered disposability and time-savings that would otherwise go towards washing dishes. Yet through further investigation of the use of plastic cutlery, people are appalled. Many times, the cutlery is not even used and dumped straight into the trash, which then has to be addressed in the recycling and waste process. Though plastic utensils itself seems simple, its production and disposal reflect an overwhelmingly inefficient use of energy; when unaddressed, this poses a significant threat to the environmental sustainability of the modern world.

From its production to its distribution, plastic cutlery calls for attention that the energy required to create it is wasteful. The initial stage of plastic cutlery starts off with the extraction of two important raw material: oil and natural gas, which are fossil fuels. First, the crew has to find a site with plenty of water nearby since it is the primary source of energy (kinetic energy) for drilling. Multiple holes have to be drilled, including one central hole, by using both a small drill truck and the main drilling rig. Rather than using the main rig to drill all the holes, the drilling vehicle is used to be more efficient with its use of energy. In this case, chemical energy is used since the main rig requires an extensive amount of fossil fuels to run. The main rig uses two sources of power: the primary energy source diesel and secondary energy source electricity. The large diesel engines in the rig burn the diesel to use as the primary source of power while the electric generators use the energy from the diesel engines to provide electricity for the drillings equipment. Once the drill reaches the final depth, all the oil is ready to be pumped out by an electric motor, requiring the use of electrical energy. The next step is transporting the oil from the extraction site to the plastic utensil making factories. This occurs in all modes of transportation: air, water, and road. In the US, “the major types of energy used for transportation are petroleum products: gasoline, distillate fuels (mostly diesel fuel), jet fuel, residual fuel oil, and propane, Biofuels: ethanol and biodiesel, Natural gas, and Electricity” (“Energy Use for Transportation”, 2018). It is evident that most modes of transportation run on chemical energy since most of them require some form of fossil fuels to work. Recently, the demand for oil has increased so much that it is being traded to and from other countries. For example, if the oil has to be shipped from the US to China, road-freight vehicles would transport it from the extraction site to the airport or seaport. Then, the oil would be transported by either air or water to China. Once it reaches China, they have to load all the oil into trucks which can then transport it to the factories. Just in the US alone during 2017, “petroleum products accounted for about 92% of the total U.S. transportation sector energy use” (“Energy Use for Transportation”, 2018). When thinking about the amount of fuel used in the world, the total amount of energy used would be overwhelming. Using large amounts of oil is bad for the environment because greenhouse gasses are emitted when fossil fuels are burned. These greenhouse gasses, such as carbon dioxide and methane, become stronger and are in the atmosphere for a longer time if more fossil fuels are burned. As a result, climate change occurs with the global mean temperature constantly rising, affecting the sustainability of the environment. The amount of potential that oil has is above the charts, yet we do not take advantage of it. We turn the blind eye towards its benefits and efficiency compared to plastic, which seems to be a problem that we are yet to solve.

The manufacturing stage requires the construction of plastic, which uses a large amount of energy. Plastic cutlery includes knives, forks, and other utensils. Each of these utensils require different amounts of oil to be made, which may vary the energy use. There are various types of plastics, but the ones used for plastic utensils are polypropylene, polystyrene, and sometimes low-density polyethylene. Plastic is made from monomers through a process called polymerization. The oil and natural gas are heated to high temperatures to convert the atoms of hydrogen and carbon into reactive monomers. These monomers, such as ethylene and propylene, are then chemically linked through polymerization. In polymerization, a “special catalyst is added, frequently a peroxide, that causes one monomer to link to the next and that to the next and so on” (“Plastics”, 2005). Then, the liquid is let to cool in different molds depending on the type and additives added. For example, the factories need various molds for each type of cutlery, like forks and spoons, because they can range from different sizes to colors. For plastic utensil production, polystyrene and polypropylene are used because “it is said to have excellent chemical resistance and is used for many types of packaging. It is ideal for manufacture because it is resistant to degradation by water, salt, and acids, all of which are destructive to metals” (“Spork”, n.d.). Additives are mixed in with the polymers to improve the physical and chemical properties of the cutlery or added towards the end to help with the appearance. Some of the additives include “antioxidants: for plastic processing and outside application where weathering resistance is needed and colorants: for colored plastic parts” (“Plastics”, 2015). According to “A Life Cycle Analysis: A Plastic Fork,” 9.34 kWh of energy and 5.12 gallons of water were used for every 1 lb of polypropylene manufactured back in 2012. Compared to utensils manufactured using polypropylene, those consisting of polystyrene used 11.28 kWh of energy and 20.54 gallons of water. The energy (kWh) used to manufacture 1 lb of polypropylene or polystyrene is equivalent to how much power a baking oven would use for 3 hours. 11.28 kwh may look small, but when considering the number of polymers made throughout the world, the amount of energy used is going to be extremely high. Once the plastic utensils are assorted into packages, they are ready to be shipped to consumers throughout the world. The distribution of cutlery throughout the world has made it more complicated and energy intensive. In most cases, plastic cutlery companies manufacture and distribute within their own countries. Most of the distribution occurs through road freight vehicles since they spread the huge packages from the factories to the retail stores. In the past decade, road freight transport energy consumption has grown by more than 50% from around 23 exajoules (EJ) in 2000 to 36 EJ in 2015 (“The Future of Trucks - Implications For Energy and the Environment”, 2017). With such high demand, the oil use of road freight vehicles has grown by 6 million barrels per day (MB/d) to 17 MB/d since 2000, leading to a staggering increase in chemical energy consumption. These trucks run on diesel fuels and pollute the air through the release of greenhouse gasses, such as carbon monoxide. Once again, increase in greenhouse gasses in the atmosphere affects climate change, impacting the health of the environment. Using plastic cutlery is like a “one and done” effect: once we have used it for our benefit and convenience, we completely disregard its impacts and the tremendous energy used to recycle and decompose our wrongdoings.

An overlooked, yet important factor, to the energy use in throwing away plastic is it takes over 10 decades for plastic to become biodegradable, making it very inefficient. Upon consumer disposal, the utensils need to be transported to landfills or recycling centers. Once again, garbage trucks use gas, mostly diesel fuel, as the energy source. While little data exists regarding energy requirements of trash collection and disposal, it is clear that garbage trucks consume even more energy than road freight vehicles. According to Michael J. Coren, “Garbage trucks are one of the least efficient vehicles on the road. Powered by diesel fuel, they average just 3 miles per gallon, burn about $42,000 of fuel per year, and emit about 20 times the carbon emissions of the average US home” (Coren, 2016). But, it is predicted that by 2025, all of the garbage trucks in the US would be electric, which is much more efficient in energy use and barely will harm the environment. Most of the plastic cutlery is sent to landfills because burning plastic at recycling plants emits toxic substances, harming the environment (Parajuli, 2011). But, some factories do accept it so they can reclaim the energy stored in the polymers. These plants recycle plastic by incineration, where heat is applied, in the form of thermal energy, to break down the hydrocarbons (“Recycling of Plastics”, 2005). Afterward, the ash is transported to a landfill which uses energy once again. According to “Recycling of Plastic,” the embodied energy of recycled polypropylene and polystyrene are about half of that of the virgin material. Since most of the power is lost in recycling plastic cutlery, it is much more efficient to send them to landfills where they are let to decompose. Plastic takes a long time to degrade, and once a substantial pile forms, the plastic pretty much becomes non-biodegradable since there is less exposure to UV lights, microbes, and oxygen. As the landfills sink into the ground more profound and more in-depth, there is no exposure to oxygen for microbes to degrade the material. So, the only things left are anaerobic bacteria which use chemical energy to decompose the material. This would contaminate the soil, harming plants and polluting groundwater. Overall, both processes have some form of consequences for the earth. Landfill temporarily fixes the issue and does not cause harm at the moment, but in the long term, it is going to cause significant damage to the environment. For recycling, incineration has the temporary issue of releasing toxic emissions but provides benefits such as recovering some form of energy from the polymers. Even though it takes less energy to manufacture plastic cutlery compared to stainless steel cutlery and is much more convenient and affordable, there are consequences, especially in the disposal stage, which hurt the environment.

After examining each stage deeply, analyzing the different kinds of energy used, and how much power is used, we can determine that plastic cutlery, used for its convenience and affordability, requires an extensive amount of energy to be manufactured. The life cycle shows the overwhelmingly inefficient use of power from the extraction of raw materials to disposal, which harms the sustainability of the environment. Overall, I found the necessary information needed to complete this assignment, but I could not find the critical facts related to plastic cutlery. Plastic cutlery contains different types of utensils, ranging from knives to modern twists like sporks. Each one of these utensils uses different quantities of oil and energy and the only ones I found were plastic forks and sporks, so I had to use the information and data from that to make my case for all different types of plastic cutlery. Plastic cutlery is made out of mostly three types of polymers, and it was difficult finding data for energy use for each of these polymers. Lastly, I had an issue figuring out what modes of transportation was used for each phase. For example, transportation of raw materials may use all three modes of transportation while transportation of waste might likely only use road vehicles. Different forms of transportation use different amounts of energy, so it was hard to tell which ones are mostly used. With a rapid decline in the number of fossil fuels present, individuals should try to reduce our use of plastic cutlery and use other forms of cutlery to preserve environmental sustainability.

Works Cited

Parajuli, Pramod. “A Life Cycle Analysis: A Plastic Fork - Sustainability.” Google Sites, Fall 2011,

https://sites.google.com/a/pvlearners.net/sustainability/a-life-cycle-analysis-a-plastic-fork.

“The Future of Trucks - Implications For Energy and the Environment.” Edited by Adam Majoe,

IEA, International Energy Agency, Nov. 2017, https://www.iea.org/publications/freepublications/publication/TheFutureofTrucksImplicationsforEnergyandtheEnvironment.pdf.

Khripko, Diana, et al. “Energy Demand and Efficiency Measures in Polymer Processing:

Comparison between Temperate and Mediterranean Operating Plants.” SpringerLink, Springer Berlin Heidelberg, 29 Jan. 2016, https://link.springer.com/article/10.1007/s40095-015-0200-2.

“Energy Use for Transportation.” Energy Use for Transportation - Energy Explained, Your Guide

To Understanding Energy - Energy Information Administration, 23 May 2018, https://www.eia.gov/energyexplained/index.php?page=us_energy_transportation.

“Plastics.” The Basics: Polymer Definition and Properties, American Chemistry Council, 2005,

https://plastics.americanchemistry.com/How-Plastics-Are-Made/.

Cleveland, Cutler J. "Net energy from the extraction of oil and gas in the United States." Energy

30.5 (2005): 769-782.

Hamman, Curtis W. "Energy for Plastic." Energy for Plastic. Stanford University 24 (2010).

“Recycling of Plastics.” The ImpEE Project, University of Cambridge, 2005

http://www-g.eng.cam.ac.uk/impee/topics/RecyclePlastics/files/Recycling%20Plastic%20v3%20PDF.pdf.

“Spork.” How Products Are Made, www.madehow.com/Volume-7/Spork.html.

Kadekar, Aswitha Janardhan. “Triple Bottom Line Assessment of Single-Use Disposable Plastic

Cutlery.” Plastic Pollution Coalition, Pratt Institute, https://commons.pratt.edu/sesresearch/wp-content/uploads/sites/157/2017/12/Aswitha_Kadekar-Capstone_Report.pdf.

“U.S. Energy Facts Explained.” Factors Affecting Gasoline Prices - Energy Explained, Your Guide

To Understanding Energy - Energy Information Administration, U.S. Energy Information Administration, www.eia.gov/energyexplained/?page=us_energy_home.

Freudenrich, Ph.D. Craig, and Jonathan Strickland. “How Oil Drilling Works.” HowStuffWorks

Science, HowStuffWorks, 12 Apr. 2001, https://science.howstuffworks.com/environmental/energy/oil-drilling2.htm

The SOE Team. “The Kilo Watt? Tips for Understanding Your Electricity Usage.” Impact of the

Clean Air Act | SaveOnEnergy.com, 2 Aug. 2018, www.saveonenergy.com/learning-center/post/the-kilo-watt-tips-for-understanding-your-electricity-usage/.

Coren, Michael J. “The Economics of Electric Garbage Trucks Are Awesome.” Quartz, Quartz, 4

Aug. 2016, https://qz.com/749622/the-economics-of-electric-garbage-trucks-are-awesome/.

Jann Matthew Tiangson (915668472)

Professor Cogdell

DES 40A SEC 4

6 December 2018

Plastic Cutlery: Waste and Emissions

Garnering almost nine million views since 2009 is a video of a group of people removing a plastic fork from a sea turtle’s nose. In a progressing society where awareness of the negative impact of plastics have for the environment and the animals in the wild, plastic cutlery has been a product that became a societal norm for its one-time-use before being discarded. Plastic cutlery is known for its usefulness, convenience, and wastefulness as about 40 billion utensils are produced, with the statistics of high usage and low rates of reuses or recycling, according to the Clean Air Council (Trent). The plastic product can be found almost anywhere, such as homes, department stores, and restaurants, and will only have a usability lifespan of one day before being disposed of somewhere, where it may lead to somewhere that can negatively affect something, seen in the viral video of the sea turtle. Not only from the disposal creates waste and emissions, but also the creation of plastic cutlery, the production, and how it is packaged and distributed. Through examining the waste emissions from the life cycle of plastic cutlery, the production, packaging, and distribution of plastic cutlery is detrimental to the environment, with the end stage of the product’s disposal having the most negative effect.

Beginning the process in the creation of waste and emissions in the life cycle of plastic cutlery is the extraction phase. Plastic cutlery has been around since the mid twentieth century, where mass production boomed due to the discovery of polystyrene and polypropylene, which are the two types of plastic used in the production. Before plastics are manufactured in factories, ingredients are first extracted, such as the hydrocarbon that derives from the extraction of crude oil or natural gas, which are considered as some sort of fossil fuels. Many oil extraction companies have created many miles of pipelines to extract crude oil in seas, which creates hazards in the water. With water-based extracts, companies have created potential dangers that can pollute the sea water, creating oil wastes that can affect the underwater wildlife. An example where wasteful hazards have polluted the ocean was from the BP Deep Water Horizon Oil Platform Explosion, in which the platform exploded, leaking the crude oils into the sea and damaging the underwater wildlife. For natural gas extractions, a line is drilled where the gas is found underground, but the consequences leads to human-made earthquakes (Bernier). After extraction of some essential ingredients, the materials are sent to companies that create the plastic cutlery.

The second stage in the life cycle assessment is the production of plastic cutlery, which contributes to the waste and emissions. During the manufacturing process, solid wastes and emissions of greenhouse gases are released into the air. The fossil fuels that have been extracted are sent to companies that produces plastic products. For companies that manufacture plastic cutlery, the ingredients are processed after thorough inspection to create the desired pellets of polymer and in the assembly line, where the pellets are melted and molded into the desired shape of the cutlery, whether it be a spoon, fork, or knife. The a primary waste is unused solid plastic, in which most companies try reusing the unused plastic for other products (“Spork”). Another component creation of solid waste from polystyrene. According to the research from Environmental Science & Technology, polystyrene produces more soot and emits the more polycyclic aromatic hydrocarbons, or PAH, than polypropylene (Wang, Jun, Yiannis A. Levendis, Henning Richter, Jack B. Howard, & Joel Carlson). Detrimental emissions of greenhouse gases created from the manufacturing processes are due to energy consumption from the use of electricity to power the company and the machines and fossil fuels that is needed for incinerators and heating the water in order to melt the plastics to cutlery. From Natural Resources Canada, they have collected and claimed that there are indirect and direct emissions that are generated from production companies. Indirect and direct emissions of greenhouse gases comes from fossil fuel combustion to power the facilities and also during the manufacturing plastic materials, such as plastic cutlery products. The three main greenhouse gases that are discharged into the air is carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), and data collected shows that CO2 produces the most emissions out of all the gases. Measured in grams per cubic meter, emissions of CH4 and N2O generated less than one gram compared to 1880 grams per cubic meter of CO2 (Greenhouse Gas Emissions from the Plastics Processing Industry). The large amount of carbon dioxide emissions derives from the combustion process when polystyrene and polypropylene are in the incineration process (Wang, Jun, Yiannis A. Levendis, Henning Richter, Jack B. Howard, & Joel Carlson). The waste and emission from the manufacturing process contributes to the existing problem of pollution to the environment and increase of greenhouse gases that enables unusual climate change that has been occuring in the past years.

How the product is packaged has a role in affecting the environment. Once the plastic cutlery is manufactured, the products are usually packaged in plastic wraps, made from the same materials. Plastic has been a more favorable application for packaging due to its properties of being light, flexible, and creates a barrier that protects the product. These plastic packaging pose as a potential threat in contributing to unusual climate change because once the packaging ends up in the landfill, carbon dioxide emissions are a result from landfill decomposition (“Impact of Plastics Packaging on Life Cycle Energy Consumption & Greenhouse Gas Emissions in the United States and Canada”, 37).

Transporting plastic cutlery is part of the contribution to the waste and emissions in the the product’s life cycle. Plastic cutlery is then distributed to locations where the product is then promoted and sold to human consumers. Using vehicles that run on petroleum-derived fuels, such as freight trucks, the product is distributed throughout the country. The usage of freight transportation is the leading cause of why the demand for oil has increased by 35% between the years 2000 and 2015. As consumers demand for more oil for the trucks, the result is increase in the waste and emissions that accompanies with the usage of freight transportations for products. Relying on petroleum oil to power freight transportations, such as freight trucks, they become a part of the main contributor for emission for the greenhouse house gas, carbon dioxide.With the demand of oil, freight trucks attributed to a 2.8% increase of CO2 emissions as the usage of petroleum became in demand. In transportation, freight vehicles contributes to the 40% increase in CO2 also. The emissions contribute to a decline of healthy air quality, leading to major health problems to the public. Results from the decline of poorer air quality is correlated to related human problems of high blood pressure and lung complications (“The Future of Trucks: Implications for Energy and the Environment”). Not only are freight vehicles used to transport product, such as plastic cutlery, to its consumer putting a hazard to the environment, but can also be detrimental to human health.

The final stage of the life cycle of plastic cutlery is the stage that causes the most impact to the environment. After the distribution of plastic cutlery, they are used by consumers and are shortly discarded afterwards. Although plastic cutlery are considered to be plastic products, they cannot be recycled as will more likely end up in landfills or incineration. With the complex intermolecular bonds of plastic cutlery, the product degrades slowly and may take about a thousand years to degrade, meaning that the product is a danger for the environment and exceeds the life span of many living things. A detrimental factor that affects the surrounding, specifically environments with humans, as plastic cutlery stays in the landfills is the emission of bisphenol-a, or BPA. BPA has been known for its cancer-causing properties, and is a carcinogen contained in plastic products’ resin such as plastic cutlery. The chemical may leak from the landfills that can contaminate humans, but can also ooze into the environment that damages wildlife (Lewis). Once the plastic utensils somehow breakdown, the chemicals and the additives that creates the product forms a substance (containing BPA) that contaminate the surrounding soils or water. According to the journal Waste Management, it is approximated that two thirds of plastic products would end up in the landfills, but the rest might end end somewhere else such as in the environments that is a potential harm to the animals or its ecosystems (Razza, Francesco, Maurizio Fieschi, Francesco Degli Innocenti, & Catia Bastiolo). Plastic cutlery that end up in the environment plays the role of endangering animals. Since the product is able to float in water, once plastic cutlery ends up in the water, marine life, such as fish may wound up eating the product, causing physical and chemical harm that is attributed to its plastic properties (Kadekar). In the ocean, there is known to be a body of plastic waste that is double the size of Texas and is still growing as of today (Bernier). Where the product after its usage plays the biggest role in the waste and emissions that is created because it is the most destructive. The prior stages in the cycles slowly contributes to greenhouse gases buildup, but when plastic cutlery reaches the stage where the product’s chemicals leaks from the landfills into human populated sites or pollutes habitats of animals, the effects are immediate. The aftermath of the pollution of plastic products, such as plastic cutlery, in the environment take a toll on the wildlife, where many instances have been presented in the mass media of the dangers it places on the lives of the living creatures and the destruction of habitats.

As the waste and emissions problem persists, many companies have been trying to create alternatives to lessen the production and disposal of plastic cutlery. Companies, such as World Centric, have been creating cutlery that is compostable, using plant-based resins rather than the plastic-based resins that is currently used to create plastic cutlery (“Compostable Plastic”). Although green-friendly cutlery that is a form of a substitute for plastic cutlery, can be seen on store shelves, plastic cutlery still dominates for its cheapness, convenience, and easy disposability.

In the life cycle assessment of plastic cutlery, the stages all produces waste and emissions that can bring a negative impact to the environment. Plastic cutlery has become an essential to human consumers, but is also one of the products that creates a huge amount harm to the environment. Although the usage and disposing is still presents, many production companies have been making technologies to lessen the problems. As of now plastic cutlery is still widely used. Each stage, from the extraction, to production, packaging and distribution produces environmental harms, wth the end stage of the product’s disposal having the most detrimental effect to the environment.

Work Cited

Bernier, Andrew. “A Life Cycle Analysis: A Plastic Fork.” Sustainability. CTE, 2011.

<https://sites.google.com/a/pvlearners.net/sustainability/a-life-cycle-analysis-a-plastic-for

k>. Accessed on 30 Nov. 2018.

“Compostable Plastic.” World Centric. World Centric, N.D. <http://www.worldcentric.org/about

-compostables/eco-profiles/plastics>. Accessed on 2 Dec. 2018.

“Greenhouse Gas Emissions from the Plastics Processing Industry.” Natural Resources Canada.

Natural Resources Canada, 27 Feb. 2018. <https://www.nrcan.gc.ca/energy/efficiency

/industry/technical-info/benchmarking/plastics/5211>. Accessed on 1 Dec. 2018

“Impact of Plastics Packaging on Life Cycle Energy Consumption & Greenhouse Gas Emissions

in the United States and Canada.” American Chemistry Council. Franklin Associates Jan. 2014. <https://plastics.americanchemistry.com/Education-Resources/Publications

/Impact-of-Plastics-Packaging.pdf>. Accessed 1 Dec. 2018.

Kadekar, Aswitha Janardhan. “Triple Bottom Line Assessment of Single-Use Disposable Plastic

Cutlery. Plastic Pollution Coalition. Pratt, N.D. <https://commons.pratt.edu/sesresearch/

wp-content/uploads/sites/157/2017/12/Aswitha_Kadekar-Capstone_Report.pdf>.

Accessed on 1 Dec. 2018.

Lewis, Ashleigh. “The Life of a Plastic Fork.” The L Magazine. The L Magazine, 14 Apr. 2010.

<http://www.thelmagazine.com/2010/04/the-life-of-a-plastic-fork/>. Accessed 2 Dec.

2018.

Razza, Francesco, Maurizio Fieschi, Francesco Degli Innocenti, and Catia Bastiolo.

“Compostable cutlery and waste management: An LCA approach.” Waste Management 29.4 (2009): 1424-1433 <10.1016/j.wasman.2008.08.021>. Accessed 1 Dec. 2018.

“Spork.” How Products are Made. Advameg, N.D. <http://www.madehow.com/Volume-7/

Spork.html>. Accessed 30 Nov. 2018.

The Future of Trucks: Implications for Energy and the Environment.” International Energy

Agency. 2nd ed., iea, 2017. <https://www.iea.org/publications/freepublications/

publication/TheFutureofTrucksImplicationsforEnergyandtheEnvironment.pdf>. Accessed

on 1 Dec. 2018.

Trent, Nancy. “Ending Take Out Waste.” Whole Foods Magazine. Whole Foods, 24 Jan. 2011.

<https://wholefoodsmagazine.com/blog/ending-take-out-waste/>. Accessed on 30 Nov.

2018.

Wang, Jun, Yiannis A. Levendis, Henning Richter, Jack B. Howard, and Joel Carlson.

“Polycyclic Aromatic Hydrocarbon and Particulate Emissions from Two-Stage

Combustion of Polystyrene: The Effect of the Primary Furnace Temperature.”

Environmental Science & Technology 35.17 (2001): 3541-3552. <10.1021/es0105109>.

Accessed 1 Dec. 2018.