Design Life-Cycle

assess.design.(don't)consume

Yuqi, Cheng

Group 8

DES 40A

Professor Cogdell

Materials of Coffee sock filter Life Cycle Paper

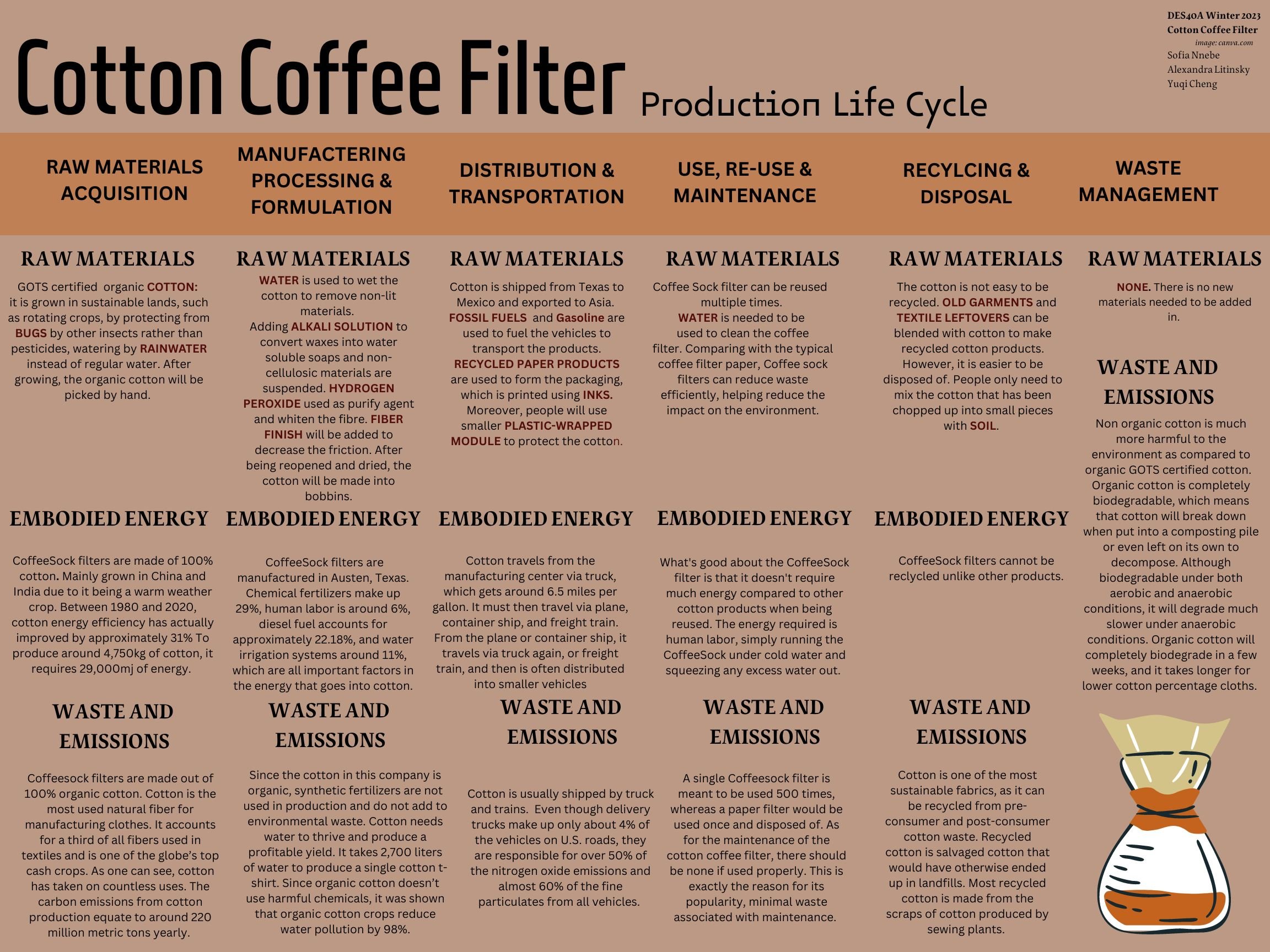

Coffee is a common drink in current people’s daily life and coffee filter paper as a complementary goods of coffee are also familiar with contemporary people. Though people used them daily even used for multiple times in one day, they often ignore how much waste is produced by the coffee filter paper. Even though they realize the coffee filter may cause lots of problems for our environment, they do not know how to improve this situation or have no time to come up with solutions. (12) Under this circumstance, the coffee Sock produces a coffee filter that is make of GOTS certified organic cotton to decrease the pressure of environmental problems, which can be reused for much longer time comparing with common coffee filter papers. The coffee sock filters seem reduce people’s guilty when they use coffee sock filters to brew coffee. At the same time, the GOTS certification raw materials for coffee sock filter make their customers have confidence that they can protect environment. However, it actually harms our surroundings environment a lot. GOTS certification for cotton cannot guarantee the producing process is also meet the standards. Although the raw materials used to produce the coffee sock filter is GOTS certified organic cotton, in the process of producing and manufacturing process, the products still involve lots of chemical materials, which prove the coffee sock filter harm the environment in fact.

GOTS certified raw materials cannot guarantee the whole process of manufacturing and growth also meet the global textile standard, misleading customers think they are protecting the environment through buying the products. When a cotton is considered as organic cotton, they are grown in sustainable lands, such as rotating crops, by protecting from bugs by other insects rather than pesticides, watering by rainwater instead of water. After growing up, the organic cotton will be picked by human hands. In a contrast, typical cotton is grown in either dryland or irrigated, requiring fertilizers, pesticides, and water to grow, picking by machine. (1) However, the organic fibre cultivation does not be directly covered by GOTS and the certification of GOTS only begins from the first stage of textile fibres: people do not know if GOTS certified organic cotton grow in an organic environment or not. (2) Moreover, even though Coffee Sock advertises their products are made by GOTS certified organic cotton, there is not any logo in their website and packages, which only can be used when the final products’ all stages, first processing stages, spinning, weaving and knitting, wet-processing, manufacturing, and trading, meet GOTS criteria. (3) Under this circumstance, before cotton is made into coffee filters, the cotton will be wet by water to remove non-lit materials. After adding alkali solution, waxes in the cotton will be converted into water soluble soaps and non-cellulose materials will be suspended. And then the Hydrogen peroxide will be used as purify agent and whiten the fibre. Finally, fiber finish will be added to decrease the friction between cotton. The cotton will be made into bobbins after being reopened and dried. Workers in Coffee Sock then will use this cotton bobbins to make coffee sock filters by hand. (4) There are lots of chemical materials being added in the process of converting cotton into fabric, proving the organic raw materials cannot ensure the whole process of manufacturing will not harm the environment.

When deciding a product is environmentally friendly or not, customers often focus on the viewable results rather than the unviewable parts. The advantage of Coffee Sock filter is obvious: they can be cleaned by water and reused for multiple times. Comparing with the typical coffee filter paper, Coffee sock filters can reduce the waste efficiently, helping reduce the pressure of environment. Customers often pay attention to this advantage to consider Coffee Sock filter is environmentally friendly and they can help protect environment through purchasing this product. However, they ignore how much chemical materials are used to convert cotton into fabric. Besides the manufacturing process, there are lots of fossil fuels and gasoline when the cotton is shipped from Texas to Mexico or export to Asia. Moreover, people will use smaller plastic-wrapped module to protect cotton in the distribution process. Moreover, after finishing the final products, Coffee Sock will use recycled paper products to form the packaging and inks will also be used to print on it. (5) All materials are used in the process of distribution cannot be considered as organic products to protect the environment and help release the pressure of the environmental problems, but customers often are not willing to pay attention on this unviewable parts.

The cotton is not easy to be recycled while they can be disposed by soil. If people want to recycle the cotton products, such as Coffee Sock filter, they need to chop it up first in order to turn it back into raw materials. However, chopping process is the problem for the recycled cotton products: the strength and softness of cotton threads will be influenced negatively due to the shorten staple length of fibers. It is difficult to use large amount of recycled cotton in products. (6) Though the fashion industry cannot utilize large amount of recycled cotton, people still can attempt to figure out new using approaches of this cotton products. For example, after Coffee Sock filter being reused for multiple times, people can use it for cleaning or planting small plants. If people still try to find new ways to expand the cotton products’ life, the cotton will not create so much pressure for the environment. Comparing with recycled cotton, disposing cotton is much easier: people only need to mix the cotton that has been chopped up into small piece with soil. The cotton will help the water retention because cotton is ultimately biodegradable. (7) Although cotton products seem will harm the environment, it still can help people’s life be easier and help the environment if people still try to come up with new ideas to utilize them and expand their using lives.

Some products seem more environmentally friendly actually harm the environment potentially while some products that seem are more harmful to the environment actually will have less influence. Typical coffee filter paper, whatever blenched or unblenched, is made of coarse long fiber, coming from fast growing trees, which considered as thinner typical paper. After being cut into log, the wood will be cut into smaller chips. And then the smaller chips will enter a process called chemical pulping that breaks down lignin by sodium hydroxide and sodium sulfide into liquid. In this step, cooking liquor is produced as byproduct, which will produce pulp after cellulose fibers being washed. After being meshed, screened, and dried, the pulp is pumped into papermaking machine to be extracted the excess water. The final step is to dry the sheets by over a hundred degree Celsius. (8) Some blenched coffee filter is safe to use, but it may produce dioxin, toxic byproducts, which will harm the environment. (9) Comparing with Coffee Sock filter, the typical coffee filter paper will use fewer chemical materials in the producing process, causing less harm to the environment. However, some people may argue the raw materials of typical coffee filter paper are trees and cutting trees will harm the environment a lot: causing flooding, increasing of carbon dioxide, and loss of soil. In the contrast of planting cotton in dryland or irrigated, the protection for trees have got lots of attention from government: regulating the frequency of cutting trees, encouraging plant trees regularly, and setting laws for cutting trees illegally. (10) Moreover, cutting trees regularly will also encourage people to plant more trees regularly, helping reduce more environmental problems. In the producing process of Coffee Sock filter, they use more chemical materials, causing more environmental problems comparing with typical coffee filter paper. Furthermore, typical coffee filter paper is also biodegradable, which can be deposed very quickly. (11) Although the typical coffee filter paper cannot be recycled. It is still cause lots of pressure for the environment.

When customers are motivated to buy an environmentally friendly products, they should more focus on the process of manufacturing, distribution and recycling, unviewable parts, the products rather than being confused by the merchants’ advertisements and viewable results. GOTS certified raw materials without GOTS logos on merchants’ website and packages cannot guarantee the whole process of manufacturing, distribution, recycling, and disposal is also organic enough that can be certified by GOTS. The merchants still add lots of chemical materials into their products to ensure the quality to meet the customers’ standards and save costs. The more organic products, the more costs in the process of growth and manufacturing. Moreover, in the distribution process, it is hard for manufacturing to avoid using fossil fuels and gasoline that drive the movement of ships and trucks, causing pollution to the environment. Furthermore, the packages for the final products and plastic covers that used to protect raw materials in the shipping process are wastes that will have the environment. The worse thing is that some products advertise that they are environmentally friendly and are considered as organic by customers actually harm the environment while those that are considered to harm the environment reduce the pollution and wastes as large as possible in fact. Through comparing Coffee Sock filter and typical coffee filter paper, coffee filter paper will use fewer chemical materials in the process of manufacturing and encourage more people to plan more trees regularly through cutting trees meanwhile. Though Coffee Sock filter seems help customers reduce waste, the manufacturing process uses lots of chemical materials that will harm the environment. Before considering products are organic enough that will not harm the environment, the customers should attempt to think further to ensure if the products will produce pollution and harm the environment in unviewable parts or not instead of only believing what the merchants say in their advertisements.

Bibliography

(1) “Organic Cotton vs. Conventional Cotton: What's the Difference?”. John-Manuel Andriote. 17 January, 2023. https://www.saatva.com/blog/difference-between-organic-cotton-vs-cotton/?campaign_name=Google_NonBrand_Blog_General&ad_type=dsa&funnel_stage=bofu&campaign_goal=conversion&target_audience=in_market&landing_page=blog&major_sale=evergreen&gclid=Cj0KCQiAjbagBhD3ARIsANRrqEt-ZwuGbEc63hYmd4fN-6BprHdTouGcFz0yMqkOITshO4jPKC0iKGgaAnnXEALw_wcB&gclsrc=aw.ds

(2) “Organic Fibres”. GLOBAL ORGANIC TEXTILE STANDARD. 2021. https://global-standard.org/the-standard/gots-key-features/organic-fibres?highlight=WyJjb3R0b24iLCJjb3R0b24nIiwib3JnYW5pYyIsImZpYnJlIiwiY290dG9uIG9yZ2FuaWMiLCJvcmdhbmljIGZpYnJlIl0=

(3) “WHO NEEDS TO BE CERTIFIED”. GLOBAL ORGANIC TEXTILE STANDARD. 2021. https://global-standard.org/certification-and-labelling/who-needs-to-be-certified

(4) “The Cotton Purification Process for Our Products”. Richmod. 17 December, 2015. https://richmonddental.net/library/the-cotton-purification-process-for-our-products/

(5) Ask Truckload. “The Cotton Supply Chain in Texas”. Truckload shipping, 26 Sep, 2019. https://usatruckloadshipping.com/the-cotton-supply-chain-in-texas/#:~:text=Much%20of%20the%20cotton%20from,the%20border%20crossing%20or%20seaport.

(6) “How to Dispose of Cotton”. Danielle Smyth. 16 September, 2021.

https://homeguides.sfgate.com/dispose-cotton-79249.html

(7) “Why cotton is so difficult to recycle—and how clothing retailers hope to change that”. Marc Bain. 26 August, 2015. https://qz.com/487423/why-cotton-is-so-difficult-to-recycle-and-how-clothing-retailers-hope-to-change-that#:~:text=Unfortunately%2C%20recycling%20cotton%20clothes%20isn,staple%20length%20of%20the%20fibers.

(8) “How paper is made?”. IDAHO forest products commision. 2023.

https://www.idahoforests.org/content-item/how-paper-is-made-2/

(9) “Basics of Paper Manufacturing”. Salim Hiziroglu. July, 2016.

https://extension.okstate.edu/fact-sheets/basics-of-paper-manufacturing.html

(10) “7 Policy Proposals to Restore US Trees: How Do They Compare?”. Jillian Neuberger, Alex Rudee and Haley Leslie-Bole. 20 May, 2021. https://www.wri.org/insights/us-policy-trees-natural-infrastructure

(11) “Is it safe to compost coffee filters? Are coffee filters biodegrable?”. Marie Iannotti. 19 June, 2021.https://www.thespruce.com/is-it-safe-to-compost-coffee-filters-3976346#:~:text=Pros%20and%20Cons%20of%20Filters&text=On%20the%20plus%20side%2C%20coffee,take%20much%20longer%20to%20decompose.

(12) “A value chain analysis of the organic cotton industry: The case of UK retailers and Indian suppliers”. Alison Rieple and Rajbir Singh. 24 July, 2010. https://www.sciencedirect.com/science/article/pii/S0921800910002661

Sofia Nnebe

Group: Alexandra and Yolanda

DES 40A

Professor Cogdell

Embodied Energy in the Production of CoffeeSock

For many of us, coffee is an important factor in life, something that we often depend on to fuel our energy and get us through the day. Each time we brew a cup of coffee, it goes through a filter, whether it be paper, or made of a more sustainable material. When we were first introduced to the life cycle process, I had no idea the steps that went into creating a product, and the amount of time, materials, and waste that was a result of creating products that we use everyday. After some initial research, my group members and I decided we wanted to focus on the coffeesock filter. It felt like something familiar to us, and that many people use every day, so figuring out the steps behind creating it seemed like beneficial information to be made public. Coffeesock filters were created in 2011 by Robert and Corina Guillory and are made from sustainable materials with the goal of creating a richer and cleaner brew and a healthier planet, all at an economic cost. Coffeesock filters remain a useful product, but much of the energy involved is in the manufacturing of the product, which can be environmentally harmful.

When we frequently make use of a product, it is important to understand the different energy sources that go into each step of the life cycle of a particular product. Since we are focusing on the coffeesock, which is made of cotton, we must first understand what forms of energy goes into the raw materials, the manufacturing, distribution and transportation, the maintenance, the recycling process, and finally the waste management of this product. This is all done so that we can eventually determine the quality of this product, and how it impacts the environment. Because it is an everyday product that people use all over the world, I think it is good to understand the process behind it, so we can continue to make conscious decisions about the products we use in our lives. The information found when researching this product is not necessarily to discourage people from continuing to use products they find useful, but to help people understand how it affects the environment, and for them to decide what they want to do going forward.

Coffeesock filters are made of 100% cotton. Cotton is mainly grown in China and India due to it being a warm weather crop, however, the coffeesock company that we are focusing on uses cotton that is mostly grown in Texas and Pakistan, with some of it coming from India as well. Cotton is used in a number of different ways, and between 1980 and 2020, cotton energy efficiency has actually improved by approximately 31%. Cotton growers want to see a continued improvement in this trend going forward. The energy that goes into the raw material of a coffeesock mainly comes from fuel and fertilizer. To produce around 4,750kg of cotton, it requires 29,000mj of energy.

In regards to the production and manufacturing of cotton, chemical fertilizers make up 29%, human labor is around 6%, diesel fuel accounts for approximately 22.18%, and water irrigation systems around 11%, which are all important factors in the energy that goes into cotton. 5.93% of the energy is renewable, while 93.07% of the energy is nonrenewable. Machinery is also another factor in the manufacturing of cotton, and it accounts for around 19%. When it comes to manufacturing cotton, one must separate the fibers from seed cotton. This is known as ginning. This is usually done using machinery; it is more efficient and done at a faster rate., however it is not disclosed what type of machinery is used. Once the product has gone through the raw materials and manufacturing processes, it is then sent to transportation, where we see it go through a new journey that leaves behind its own energy footprint.

The energy used in the transportation of cotton is one of the more harmful steps in the life cycle of coffeesock. This is due to the energy used and the significant carbon footprint that is left behind when transporting goods between locations. The cotton must travel from the manufacturing center via truck, which gets around 6.5 miles per gallon. It must then travel via plane, and since these cotton farms are generally in places such as China and various places in that region, a typical boeing airplane uses 1 gallon of fuel every 4 seconds. Container ships are giant boats that transport goods across our planet via water. These ships often use a large amount of energy, and are harmful for the environment. The average container ship has an hourly energy consumption of approximately 24,000 TEU, and this equates to around 100 tons of energy used. From the plane or container ship, it travels via truck again, or freight train, and then is often distributed into smaller vehicles, with an average consumption of 1.08kg. Freight trains are one of the better forms of transporting goods, and can transport one ton of goods over 480 miles using just one gallon of fuel, which is much better than a container ship or airplane. Cotton generally goes through a number of different locations, shops, transportation vehicles, which all use petroleum gas, before it is eventually recycled or sent to a landfill.

Cotton is one of the most sustainable fabrics out there. It is known as a class A fabric, meaning its ability for reuse is very high. However, this step also tends to be less sustainable because of the energy that goes into reusing a product that requires a machine to wash it, which produces more energy. What's good about the coffeesock filter is that it does require much energy compared to other cotton products when being reused. The energy required is human labor, which is mechanical energy, simply running the coffeesock under cold water and squeezing any excess water out. Every 6-8 weeks, it's important to boil the coffeesock to fully clean it. It takes approximately 2250 kj energy to boil each kilogram of water used. However, every time we use energy to wash the coffeesock, we are wasting water as well. We use approximately 80-120 kj every time we wash a dish, so the coffeesock would be no different. In addition, it also takes energy to recycle the paper used to package the CoffeeSock. However, recycling is much better for the environment, and recycling paper actually saves approximately 4100 kWh.

Through my research, I was able to cover almost every step of the life cycle, starting from raw materials, manufacturing, transportation, reuse and use, and the recycling process and the embodied energy that went into each component. The one step I was unable to find sufficient evidence for was waste management. From my research, there was nothing indicating any energy going into that final step of the life cycle. From what I understand, while CoffeeSock filters are reusable, they cannot be recycled, unlike other products. Specifically, cotton coffee filters can be composted, but they are different from paper filters, which have the ability to be recycled after usage.

To reiterate some of the main points that I was able to find while conducting research, I found that ultimately, the inventors of CoffeeSock did their best at creating a sustainable product when they first introduced their product to the world, but nonetheless, there is still a lot of energy that goes into creating this product. It's clear from their website, the couple that founded this company care tremendously for our planet, so creating a reusable coffee filter made from 100% cotton was their way of contributing an efficient and environmentally conscious product. Along the life cycle journey, I was able to conclude that most steps require sufficient energy and fuel, which is still harmful to our planet. It was interesting to understand the processes behind creating such a product, and then putting it all together in a way that other people can learn from and make their own choices. I think it's important we ask ourselves, what are ways in which we can create products more locally that don't require the same amount of energy consumption? Ways in which we can help reduce that energy footprint and help care for our planet, while still getting access to products we love?

Bibliography

Abbas, Adnan. “Analysis of Energy Input–Output of Farms and Assessment of Greenhouse Gas

Emissions: A Case Study of Cotton Growers.” Frontiers, 20 December 2021, https://www.frontiersin.org/articles/10.3389/fenvs.2021.826838/full#:~:text=The%20production%20of%204%2C750%20kg,%25%20from%20fuel%20and%20fertilizer). Accessed 1 March 2023.

G, Pallvi. “Cotton: Origin, Distribution and Production: Essay: Agronomy.” Essays, Research

Papers and Articles on Agriculture in India, 15 March 2017, https://www.agricultureinindia.net/agronomy/cotton/cotton-origin-distribution-and-production-essay-agronomy/12489#:~:text=Cotton%20is%20the%20most%20important,of%20the%20total%20cotton%20production.. Accessed 1 March 2023.

Guillory, Robert & Corina. “CoffeeSock” CoffeeSock, 2021, https://coffeesock.com/. Accessed

27 February 2023.

Homer, Talon. “How Much Fuel Does an International Plane Use for a Trip?” How Stuff Works.

Science, 20 December 2022, https://science.howstuffworks.com/transport/flight/modern/question192.htm#:~:text=A%20plane%20like%20a%20Boeing,liters%20of%20fuel%20per%20kilometer). Accessed 1 March 2023.

Nguyen, Quynh. “How Sustainable Are Recycled Cotton Fabrics? A Life-Cycle Analysis.”

Impactful Ninja, https://impactful.ninja/how-sustainable-are-recycled-cotton-fabrics/. Accessed 28 February 2023.

(No author). “The shares of energy inputs for cotton production.” Research Gate,

https://www.researchgate.net/figure/The-shares-of-energy-inputs-for-cotton-production_fig1_256091126. Accessed 1 March 2023.

(No author). “Energy consumption in the automotive industry.” Oil and Gas Job Search, 28

September 2022, https://blog.oilandgasjobsearch.com/energy-consumption-in-the-automotive-industry/#:~:text=Recent%20studies%20suggest%20that%20the,consumption%20of%201.08%20MJ%2Fkg. Accessed 1 March 2023.

Rieple, Alison, Signh, Rajbar. “A value chain analysis of the organic cotton industry: The case of

UK retailers and Indian suppliers” Ecological Economies, 24 July 2010. Accessed 12 March 2023. https://www.sciencedirect.com/science/article/abs/pii/S0921800910002661

Yeh, Chin-Ko. “Real-time energy consumption and air pollution emission during the transpacific

crossing of a container ship.” Nature News, 10 September 2022. Accessed 10 March 2023. https://www.nature.com/articles/s41598-022-19605-7#:~:text=Similarly%2C%20the%20hourly%20energy%20consumption,would%20amount%20to%2011.4%20MWh.

(No Author). “How Are Locomotives Getting More Fuel Efficient for the Railroad Industry?”

UP, accessed 10 March 2022. https://www.up.com/customers/track-record/tr040522-locomotive-fuel-efficiency-improvements.htm#:~:text=In%20fact%2C%20trains%20can%20haul,technology%20to%20reduce%20fuel%20consumption.

Munster, Jason. “Energy requirements of disposable cups vs reusable cups.” Jason Munster's

Energy and Environment Blog, 16 December 2016. Accessed 10 March 2023. http://www.jasonmunster.com/disposable_cups-1/#:~:text=The%20same%20source%20indicates%20that,coffee%20to%20a%20warm%20temperature.

Alexandra Litinskiy

Sofia Nnebe

Yuqi Cheng

DES40A

Professor Cogdell

Life Cycle Assessment Research Paper: Waste of Cotton Coffee Filters

The cotton coffee filter is becoming increasingly popular as the replacement for single use paper coffee filters. For every 500 paper filters, one cotton filter is used. Paper filters contain chemicals including bleach, which is harmful to compost. It is also a cause of deforestation, as the filter paper is made from trees and the filters are single use. Cotton coffee filters tend to be less sustainable due to the run-off wastewater from production containing pesticides, toxic dyes, chlorine, and other chemicals. Electricity energy, chemical fertilizers energy, diesel fuel energy, and irrigation water energy are the main energies used in the cotton production process. Contrary to popular belief, the majority of waste that comes from cotton coffee filters comes from the processes of transporting and laundering the recycled cotton, in the form of carbon footprint waste and high energy consumption respectively, however the end of life stage is generally very sustainable.

It is imperative to study the environmental impact of cotton coffee filters because with a cloth filter, you can get hundreds of uses out of a single product, reducing pollution from manufacturing and transport significantly. More than 1 billion people all over the world drink coffee daily. Americans drink 400 million cups of coffee a day. A vast majority of this coffee is made using paper filters. Paper filters disposed in landfills take years to decompose and in effect release harmful toxins into the air and water. Not only is waste volume created, but the bleaching is usually done with oxygen or chlorine. Despite oxygen being more environmentally friendly, it produces waste as a chemical process nevertheless. If paper filters could be replaced with cotton filters, the waste that comes from coffee filters would be reduced significantly. This would mean that there would be a considerably smaller amount of damage to the environment. Therefore it is worthwhile to study the environmental impact of cotton filters as compared to paper filters.

The popular cotton coffee filter company, Coffeesock filter, has filters made out of only organic cotton. Cotton is the most used natural fiber for manufacturing clothes. It accounts for a third of all fibers used in textiles and is one of the globe’s top cash crops. As one can see, cotton has taken on countless uses. The carbon emissions from cotton production equate to around 220 million metric tons yearly. The company this paper will focus on exclusively uses organic cotton, so the synthetic fertilizers do not pose a threat to this company’s waste production. Regular cotton, on the other hand, makes use of toxic chemicals. These chemicals leach into the surrounding ecosystems and wildlife, causing tremendous harm to the farmers and earth. Cotton is a water intensive crop, it needs water to thrive and produce a yield that can be considered profitable. It takes 2,700 liters of water to produce a single cotton t-shirt. This means it takes 20,000 liters of water to produce a kilogram of cotton fiber. However it should be noted that because organic cotton doesn’t use harmful chemicals, it was shown that organic cotton crops reduce water pollution by 98%.

Cotton is usually shipped in square bales compressed according to the needs of the consumer. The bales are then tied firmly with steel straps and mounted onto ships, trucks, or trains. Even though delivery trucks make up only about 4% of the vehicles on U.S. roads, they are responsible for over 50% of the nitrogen oxide emissions and almost 60% of the fine particulates from all vehicles. Although trains and ships account for a far fewer percentage of emissions as compared to trucks, they still produce a considerable amount of waste. Cotton coffee filters can be recycled hundreds of times, and this is why they are growing in popularity. A single Coffeesock coffee filter is meant to be used 500 times, whereas a paper filter would be used once and disposed of. As for the maintenance of the cotton coffee filter, there should be no waste if used properly. The energy used for brewing coffee is electrical energy, which is then transformed into thermal energy. There is nothing associated with waste for the maintenance of the cotton coffee filter.

Cotton is one of the most sustainable fabrics, as it can be recycled from pre-consumer and post-consumer cotton waste. Recycled cotton is salvaged cotton that would have otherwise ended up in landfills. Most recycled cotton is made from the scraps of cotton produced by sewing plants. Pre-consumer waste comes from any excess material arising from the production of textile products. Post-consumer waste comes from discarded textile products. This kind of cotton cannot be recycled ad infinitum, as in this process the cotton fibers are negatively impacted by the recycling. Cotton waste is processed with stripping machines which break the yarns and fabric into smaller pieces. The waste associated with the recycled cotton is much significantly smaller than if it had been virgin cotton. The energy, water, and chemical products levels are reduced greatly for this process. Recycled cotton is less taxing on the environment in terms of cotton farming and textile waste disposed of in landfills. Non organic cotton is much more harmful to the environment as compared to organic GOTS certified cotton. Untreated dye wastewater is often discharged into nearby rivers, which ends up in the sea. There is an increase of diseases associated with these regions because of the incredibly toxic chrome. Organic cotton is completely biodegradable, which means that cotton will break down when put into a composting pile or even left on its own to decompose. Although biodegradable under both aerobic and anaerobic conditions, it will degrade much slower under anaerobic conditions. Organic cotton will completely biodegrade in a few weeks, and it takes longer for lower cotton percentage cloths.

Although organic cotton coffee filters are the best choice in terms of environmental impact and waste, it is still a product that produces waste. The transportation and laundering of the textile cotton produces waste, albeit in much smaller quantities. The end of life stage of organic cotton is quite sustainable. It is extremely biodegradable and compostable, as 100% cotton products will biodegrade in a few weeks.The fact remains that for every one cotton filter, 500 paper ones are used. This one fact will make it so that the filter will only get more popular as people seek ways to become more sustainable in their everyday lives. If used by even a fraction of the one billion daily coffee drinkers, waste from coffee consumption would be severely reduced.

Through my research for this project, I saw all of the steps of the life cycle process. However I struggled the most with finding information for the energy embodiment and waste management. I appreciate that the only material used in the Coffeesock filter is organic cotton. However it was difficult to find specific information about the specific processes involved in the organic cotton life cycle. It was difficult to research the energy embodiment for the waste section of organic cotton. Most of the information is in regards to regular cotton that makes use of synthetic fertilizers. Organic cotton does not use any fertilizers and therefore does not have waste associated in that regard.

Bibliography for Coffee Filter Paper LSA

“History of Paper Coffee Filter” CafeAltura.com March 3, 2021. Accessed February 9, 2023

https://cafealtura.com/paper-coffee-filters/

“How to reduce the environmental impact of your paper filter” AllianceCoffee.com Date Accessed February 9, 2023.

https://www.alliancecoffee.sg/how-to-reduce-the-environmental-impact-of-paper-filter/

“Are Coffee Filters Compostable? (And Ways To Reuse)” ConverseEnergyFuture.com Date Accessed February 4, 2023.

https://www.conserve-energy-future.com/are-coffee-filters-compostable.php

Oden, Garrett “The Differences Between Paper, Cloth, And Metal Coffee Filters” Java Presse.com Date Accessed February 4, 2023.

https://www.javapresse.com/blogs/enjoying-coffee/paper-cloth-metal-coffee-filters

“Exploring The Environmental Impact Of Coffee Filters: Is A Coffee Filter Degradable?” TheCommonsCafe.com January 7, 2023.

Hardman, Ben “Can You Compost Coffee Grounds & Coffee Filters? [Guide to Composting Coffee]” TinyEcoHomeLife.com November 29, 2022.

https://www.tinyecohomelife.com/can-compost-coffee-grounds-filters

Mifflin, Mariette “Difference Between Paper and Permanent Coffee Filters” TheSpruceEats.com August 19, 2022.

https://www.thespruceeats.com/paper-filters-permanents-filters-coffee-makers-1907386

“Eco-Friendly Disposal Of Coffee Grounds From Reusable Filters – Tips For A Greener Coffee Routine” TheCommonsCafe.com January 2, 2023.

Clark, Erica “Save the Planet with Sustainable & Reusable Coffee Filters” PureHQFilters.com June 4, 2020.

https://www.purehqfilters.com/blog/save-the-planet-with-sustainable-reusable-coffee-filters/

“Are Coffee Filters Compostable? What You Need to Know” OurEndangeredWorld.com September 15, 2022.

https://www.ourendangeredworld.com/eco/are-coffee-filters-compostable/

Rieple, Alison. Singh, Rajbir. “A value chain analysis of the organic cotton industry: The case of UK retailers and Indian suppliers” ScienceDirect.com September 15, 2010. Accessed March 15, 2023

https://www.sciencedirect.com/science/article/pii/S0921800910002661