Design Life-Cycle

assess.design.(don't)consume

Pema Sinclair

Des 40A

Professor Cogdell

November 30 2018

Materials of the Ramen Industry:

In Search of a More Sustainable Noodle Product

The manufacturer of the Original Cup Noodles, Nissin, refers to their product as a “3-minute global revolution” (14), and they aren’t far from the truth. Ramen noodles have taken the world by storm. According to the World Instant Noodle Association (WINA), approximately 100 billion servings of instant ramen noodles were consumed globally in 2017 alone, equating to about 270 millions servings per day worldwide (9).

As a massively popular and globally embraced consumer product, it is important to examine the energy consumption, raw materials, and amount of waste produced by ramen noodles in order to estimate their impact on our earth and atmosphere. Through analysis and comparison of the raw materials that go into the processing, ingredients, and packaging of different noodle products, it can be determined whether certain materials are necessary or if they can be replaced or eliminated altogether in order to decrease the environmental footprint of the ramen noodle industry.

The founder of Nissin foods and instant ramen noodles, Momofuku Ando, believed that “peace will come to the world when all it’s people have enough to eat” (Leibowitz, 2011). After World War II, Japan suffered greatly from food shortages. Instant ramen noodles were Ando’s solution. Instant ramen has been a cherished, convenient food, item in many households and dorms since its creation in 1958 (14), and there are legitimate reasons for this.

Ramen noodles were developed with Ando’s five guiding principles in mind; “affordability, convenience, safety and hygiene, long shelf life, and palatability” (9). Instant ramen noodles can last between two to twelve months depending on the product (9) and, at a cost of approximately $0.29 (“Target”) at most food stores, this convenient comfort food is basically irresistible to entire populations.

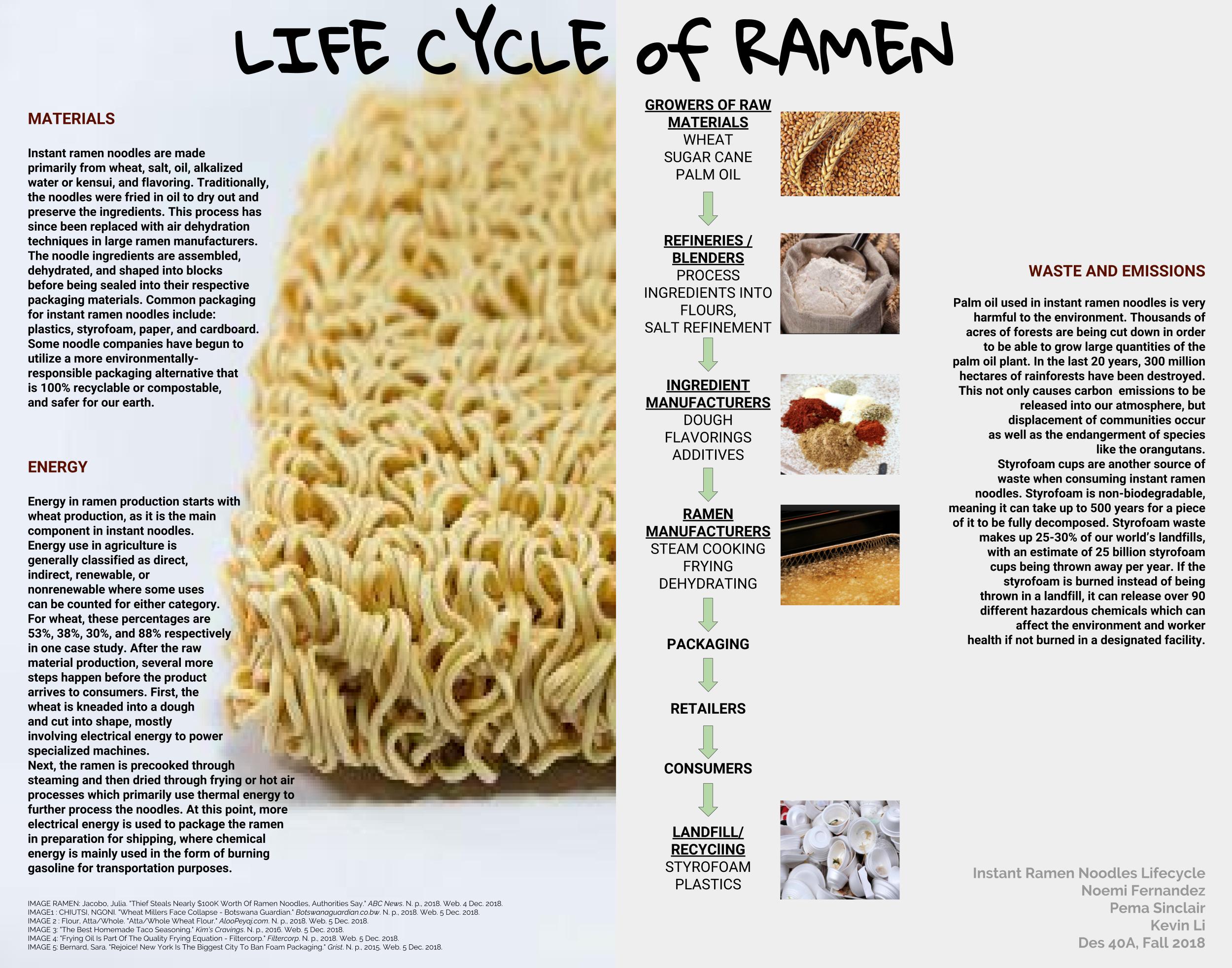

Before reaching the consumer, ramen first goes through an extensive manufacturing process that begins with the initial growers and harvesters of the basic, raw materials - wheat; oil; salt; water (often alkaline water, or kensui); spices; sugar cane; soybeans; eggs; vegetables, and meat, depending on the flavor and product (“Technological” par. 1).

At the next level, the primary materials are stored, transported, and shipped around the world for processing (Lumpur, 2013). Large refineries and blenders then process the raw materials into more manageable, shelf-stable, food substances before the ingredient manufacturers combine all of the ingredients that go into ramen noodles. In this step, wheat flour is fortified and primary raw materials like vegetables, eggs, and meat are transformed into their freeze-dried end product. Traditionally, noodles were fried in hot oil, contributing to both taste and elasticity. This technique has since been replaced with a dehydration process which still preserves the taste and texture of the noodles (Errington 1).

Product manufacturers then assemble the basic noodle ingredients, along with various food additives and antioxidants which are added for stability and shelf-life (14). A powdered flavor mix consisting primarily of oil, salt, sugar, monosodium glutamate, and meat essence is added to the noodles or placed on top in a ‘flavor packet’ (Errington 1). The noodles are then shaped into their infamous cylindrical noodle block and air-dehydrated before being packaged and transported out to retailers worldwide for consumer purchase.

Over 80 percent of communities in the U.S. rely exclusively on trucks to deliver their goods (Schoettle et al., 2016), of which food distribution plays a leading role. In a 2015 study of truck fuel consumption for business purposes, it was estimated that 54 billion gallons of fuel were consumed, “39 billion gallons of diesel fuel and 16 billion gallons of gasoline” (Schoettle et al., 2016). With a percentage of that fuel undoubtedly contributing to the transport of ramen noodles as four billion servings of instant noodles were consumed in the U.S. in 2017 alone (9).

As we delve deeper into the production methods and materials used to make ramen noodles, it becomes questionable how many of the ingredients are actually necessary to achieve a tasty and texturally-pleasing ramen product. Many noodle companies insist on adding a long list of ingredients with some products containing as many as 48 different ingredients (14).

Tertiary butylhydroquinone, or TBHQ, is one such ingredient. On their website, Nissin advertises that most of their products contain TBHQ, an antioxidant that “helps extend shelf life” (14). What Nissin doesn’t elaborate on are the physiological effects of TBHQ on the body, which include visual disturbances upon excessive exposure in factory workers (O’Donoghue, 129) and, in a study conducted on rats who were fed TBHQ, it caused “liver enlargement…convulsions and medullary paralysis” (O’Donoghue, 129). TBHQ is an unnecessary additive and can be replaced with natural alternatives such as evaporated cane juice, salt, or brine for food preservation (Henney et al., 2010).

Sodium tripolyphosphate is another ingredient that is often used as a flavoring agent, oxidant, and oxidant stabilizer in instant ramen noodles ("Pentasodium”). Interestingly, it is also used in chemical fertilizers, adhesive and sealant chemicals, bleaching agents, and dyes, to name a few. Sodium tripolyphosphate exposure can cause serious skin, eye, and respiratory irritations as well as organ toxicity ("Pentasodium”).

A more commonly known additive that is contained in many noodle products is monosodium glutamate, or MSG, which creates a savory ‘umami’ flavor. MSG has historically been extracted from seaweed broth but is now produced by the “fermentation of starch, sugar beets, sugar cane or molasses” ("Questions”). During the production of MSG, a large amount of gaseous ammonia is released into the atmosphere during the treatment and discharge of wastewater from fermentation workshops ("Questions”).

Disodium inosinate and disodium guanylate are two other umami flavor enhancers that are commonly added to foods in place of MSG (Yacoubou, 2011). MSG, disodium inosinate, and disodium guanylate can all be successfully replaced with natural food flavorings, salt, or brine.

‘Alternative’ noodles products like Bou Soup Cup noodles and Dr. McDougall’s organic ramen noodles, for example, contain only a handful of ingredients - organic wheat flour, brine, salt, natural flavor, vegetables, potato starch, organic evaporated cane juice, spices, and lime. McDougall’s natural noodle products have a shelf life of twelve months while the standard package of instant ramen noodles has a shelf life between two and twelve months (9). Thus, it is apparent that many of the additional ‘dirty’ ingredients added for food preservation are not actually necessary as they don’t significantly increase the shelf life beyond that of their natural noodle alternatives. In addition, both flavor and textural consistency of noodles can be achieved through natural alternative.

As the main ingredient in instant noodles, wheat is also examined for possible adverse environmental impacts during production. The European Commission’s ExternE report on wheat production reveals that industrialized farms regularly overuse oxidized nitrogen and acidifying lime in the soil used to grow wheat (Bickel, 123-124). This practice causes massive soil erosion and an increase in the annual rates of Nitrogen and Phosphorus released into the soil, water, and atmosphere which, in turn, have a negative impact on our ecosystems and biodiversity (Tilman par. 10, 14).

Palm oil is yet another ingredient used in many noodle products that also comes with a dirty carbon footprint. Regular palm oil is less costly than fully certified sustainable, palm oil, but it comes with both negative environmental and social consequences. The use of regular palm oil contributes to deforestation and humans rights abuses throughout oil plantations across the tropics (Dauvergne, 34). Unfortunately for the consumer, the classification of ‘sustainable’ palm oil is riddled with political loopholes that allow manufacturers to appear more socially responsible. (Dauvergne, 34). For example, on their website, Nissin claims that they use “100% mass balance, certified sustainable palm oil” in all of their products. Mass balance palm oil refers to sustainable palm oil that has been produced on certified plantations, but mixed with ordinary palm oil throughout the supply chain (Lumpur, 2013). As a result of this loophole, companies can appear to be more environmentally responsible to the consumer, and advertise so, without actually being that responsible, and without breaking the bank. Upon comparing Dr. McDougall’s noodle product to Nissin’s, oil can be eliminated all together, as dehydration techniques can achieve the intended goal of drying the noodles.

In addition to the impact that many ramen noodle ingredients can have on our health and our environment, most of the common materials used in ‘traditional’ noodle packaging also come with a plethora of negative environmental consequences and health concerns, during all phases of the supply chain. In Nissin cup noodles, the dehydrated noodle block is placed into a polystyrene cup, sealed with a paper lid, covered with a plastic film, and placed into a lightweight cardboard holding package. This is a prime example of unnecessarily excessive material usage in the food industry. In Nissin Top Ramen noodles, which contain less packaging overall, the cylindrical block is sealed into a plastic wrap.

Plastics and styrofoam contribute to approximately 30 percent of landfill volume in the U.S. (Dilthey, 2018) and take approximately 500 years to decompose (Dineen par. 1-3). Food companies use styrofoam for a number of reasons. It has a “long shelf life, remains sanitary during storage, and is highly cost-effective” (Dilthey, 2018). Styrofoam, or polystyrene, is manufactured from petroleum byproducts (Friend, 1) and can result in significant health problems in exposed factory workers (“Styrene”).

According to the Environmental Production Agency, Styrofoam is the fifth largest source of hazardous waste in the US (qtd. in Farrelly and Shaw, 2017). During production, hydrofluorocarbons are released into the atmosphere. These substances deplete the earth’s upper ozone level and, in terms of global warming, are between ten to thirteen hundred times more detrimental to our atmosphere than carbon dioxide (Tsai par. 8).

In 2015, Nissin introduced their new, ‘microwave-friendly’, customizable cup noodle package that claims to have a 20% reduction in overall carbon emissions through “less overall exterior packaging material” (Chung, 2015). The noodle container is made from a foam-like material. Nissin removed both the plastic film that covered the original Cup Noodle container and the lightweight cardboard carrying case and replaced the styrofoam with a less familiar foam-substance. Consequently, there is a lack of published information regarding the material of their newer packaging. There is also an increase in the amount of ingredients added, from 37 in the Original Cup Noodle, to 48 different ingredients in the new ‘customizable’ cup.

Examining the materials used in alternative noodle packages reveals that traditionally-used materials are no longer necessary to achieve a durable protective packaging that is also microwavable. For example, Bou You Soup Cup noodles are contained within a microwavable and 100% recyclable noodle container, of which Maruchan has adopted a similar version for one of their noodle products. Dr. McDougall’s organic ramen noodle products are packaged within a recyclable paper container that is sourced from “responsibly managed forests” ("Dry”).

While we have yet to discover a perfect, cost-effective and biologically safe, packaging product that also comes with a 0% carbon footprint, there are many, more environmentally responsible, packaging alternatives currently in use within the food industry. It should be policy for all food manufacturers to adopt these packaging alternatives.

In comparing standard instant ramen noodles with more environmentally-responsible noodle products, it is uncovered that not all of the ingredients found in instant ramen noodles are necessary for preservation, taste, or texture. In fact, many ingredients can be replaced with more natural alternatives, or eliminated all together. Replacing or eliminating environmentally and biologically harmful additives would help minimize the energy consumption, amount of waste, and potential health implications of the ramen noodle industry. In addition, 100% recyclable or compostable packaging alternatives can and should be adopted in place of ecologically damaging materials such as plastics and styrofoam.

Bibliography

Bickel, Peter, and Rainer Friedrich, eds. “ExternE: Externalities of Energy.” European Commission. Directorate-General for Research Sustainable Energy Systems, 2005. Web. 27 Nov. 2018.

Chung Linda. Elsen, Sara. et al. "Nissin® Introduces First Microwavable Cup Noodles® With Extra Room To Customize Your Cup With Healthier Meal Choices." Businesswire.com. N. p., 2018. Web. 21 Nov. 2018.

Dauvergne, Peter. "The Global Politics of the Business of "Sustainable" Palm Oil." Global Environmental Politics, vol. 18 no. 2, 2018, pp. 34 52. Project MUSE. Web. 21 Nov. 2018

Dilthey, Max Roman."How Long Does It Take For Styrofoam To Break Down?." Sciencing. N. p., 2018. Web. 21 Nov. 2018

Dineen, Shauna. “THE THROWAWAY GENERATION: 25 Billion Styrofoam Cups a Year.” E: The Environmental Magazine 16.6 (2005): 35-342. Academic Search Premier. Web. 27 Nov. 2018

"Dry Soup Mixes | Dr. Mcdougall's Health & Medical Center." Drmcdougall.com. N. p., 2018. Web. 30 Nov. 2018.

Farrelly, Trisia A., and Ian C. Shaw. "Polystyrene As Hazardous Household Waste." Household Hazardous Waste Management (2017): np. Web. 1 Dec. 2018.

Friend, Duane. “The Pros and Cons of Styrofoam. Land and Water: Conserving Natural Resources in Illinois. Abe-research.illinois.edu. N. p., 2018. Web. 1 Dec. 2018.

"Global Demand | World Instant Noodles Association.." Instantnoodles.org. N. p., 2018. Web. 30 Nov. 2018.

Errington, Frederick Karl, Fuzikura Tatsuro, and Deborah B. Gewertz. “Introduction.” The Noodle Narratives: The Global Rise of an Industrial Food into the Twenty-first Century. Berkeley: U of California, 2013. Print.

Henney, JE. Taylor, CL. Boon, CS. Intake, Institute et al. "Preservation And Physical Property Roles Of Sodium In Foods." National Academies Press (US)(2010):. Web. 29 Nov. 2018.

Leibowitz, Karen. The Humble Origins of Instant Ramen: From Ending World Hunger to Space Noodles. Gizmodo.com. 2011. Web. 21 Nov. 2018.

Lumpur, Kuala. "RSPO Supply Chains." Rspo.org. N. p., 2013. Web. 21 Nov. 2018.

"Nissin | Transparency In Supply Chains." Nissin. N. p., 2018. Web. 21 Nov. 2018.

O'Donoghue, J.L. (ed.). Neurotoxicity of Industrial and Commercial Chemicals. Volume I. Boca Raton, FL: CRC Press, Inc., 1985., p. 129. Web. 27 Nov. 2018.

"Pentasodium Triphosphate." National Center for Biotechnology Information Pubchem.ncbi.nlm.nih.gov. N. p., 2018. Web. 29 Nov. 2018.

"Polystyrene & Health Homepage." Ejnet.org. N. p., 2018. Web. 21 Nov. 2018. From: "Are Styrene Food and Beverage Containers A Health Hazard?," Institute for Local Self-Reliance, Washington, DC, August 15, 1990.

"Questions And Answers On Monosodium Glutamate (MSG)." Fda.gov. N. p., Nov 19. 2012. Web. 30 Nov. 2018.

Schoettle, Brandon. Sivak, Michael. Tunnel, Michael. “ A Survey Of Fuel Economy And Fuel Usage By Heavy-Duty Truck Fleets” Atri-online.org. Sustainable Worldwide Transportation. U of Michigan. Report No. SWT-2016-12. 2016. Web. 21 Nov. 2018.

“Styrene: Hazard Summary” Epa.gov. N. p., 2000. Web. 21 Nov. 2018.

"Target : Expect More. Pay Less.." Target.com. N. p., 2018. Web. 1 Dec. 2018.

“Technological Secrets: Instant Ramen.” Web Japan. Ministry of Foreign Affairs of Japan. Web. 27 Nov. 2018

“The Environmental Impacts of Styrofoam”. GEC Student Union. Sustainability.wustl.edu. N.p., 2018. Web. 1 Dec. 2018.

““The Story Of Ramen” By Jonatan.” The Story of Stuff: Case Studies. N. p., 2014. Web. 21 Nov. 2018.

Tilman, David. “Global Environmental Impacts of Agricultural Expansion: The Need for Sustainable and Efficient Practices.” Proceedings of the National Academy of Sciences. 96.11 (2007): 5995–6000. PNAS. Web. 27 Nov. 2018.

Tsai, Wen-Tien. “An Overview of Environmental Hazards and Exposure Risk Of Hydrofluorocarbons (HFCs).” Chemosphere 61.11 (2005): 1539-1547. Academic Search Premier. Web. Nov 27. 2018.

Yacoubou, Jeanne. "The Vegetarian Resource Group Blog." Vrg.org. N. p., March 21.

2011. Web. 29 Nov. 2018.

Kevin Li

DES40A

Professor Cogdell

November 30, 2018

Energy of Ramen: Instant Time Savings

Instant ramen has become so ubiquitous in modern life that it is often considered a staple of any cheap student’s diet. This reputation has even garnered the vote for best invention of the 20th century in Japan, surpassing other modern marvels that one would think would be more important(ASIA-PACIFIC, 2000). The secret to its rapid spread and consumption is often attributed to its convenience, where the consumer can have a meal ready within minutes of reaching for a packet. However, conventional ramen has not taken off to this degree, and this difference results from different manufacturing processes. Although the energy used in manufacturing noodles for instant ramen is comparable to its conventional counterpart, the larger embodied energy resulting from extra processes in instant ramen results in attractive time and energy savings for consumers.

Before either product is cooked, the energy necessary to produce and process the raw noodles used in both instant and regular ramen is very similar, showcasing that differences do not occur until later in the manufacturing process. Both products contain nearly the same raw ingredients (flour, salt, and water) with the difference in shape and texture resulting from manufacturing. Of these ingredients, wheat comprises 95% overall, so its production will be the topic of analysis (Solt 2009). Energy use in agriculture is generally classified as direct, indirect, renewable, or nonrenewable where some uses can be counted for either category resulting in sums not equal to 100%. In a study done by Urmia University, these percentages are 53%, 38%, 30%, and 88% respectively. Direct energy, as it is used, refers to energy inputs such as “labor work, fossil, and electricity” defined as directly being responsible for the production of wheat. This category has a mix of primary and secondary fuels that are either used in their basic forms or are a product of external generation. On the other hand, indirect energy, such as “fertilizers, manures, and pesticides” refer to components with significant embodied energy that are heavily involved in wheat production. Almost all of these are secondary energies and are not found in nature in usable forms. Renewable and nonrenewable energy, as the names suggest, refer to whether the energy source is replenishable at the used rate, where examples of renewables are human labor or manure, while energy sources such as diesel, chemicals, and machinery are considered nonrenewable (Taghavifar 2014). After this wheat is harvested and transported to a processing facility, the next considerable energy usage is in refining it. In factories, dough production takes place in several steps which each involve certain energies. First, the wheat is milled, between heavy rollers, usually driven by electric motors. Thus, the main energy type present is electrical, which is then converted to mechanical through the motor. The resulting product is flour, which is combined with the other ingredients in large kneading machines which likewise mainly use electricity (Bushuk 2012). This breakdown applies to both instant and conventional ramen due to their compositions being virtually identical, and as such embodied energy totals do not differ until a later stage.

Beyond the production of the raw dough, different manufacturing processes differentiate the embodied energy in instant and conventional ramen. In producing conventional ramen, factories are optimized to make straight, uncooked noodles quickly, intended to be cooked at a later time. Comparatively, the purpose of instant ramen’s curved shape is to ensure longer noodles in the same volume while imparting a better texture when cooked (Goulding 2016). The machines responsible for cutting or pressing dough into noodle form once again primarily take electrical energy as their inputs, (with minor embodied energies in the form of lubrication oils or replacement parts), but their efficiencies differ due to the geometries of their product. Overall, machines producing straight noodles can do so at a much higher speed, increasing efficiency per electrical energy input (James, 2006). This is the first instance where instant ramen is observed as to having a larger embodied energy due to less efficient processes, with more differences further in production. One key difference is that instant noodles are precooked while conventional ramen comes uncooked, providing embodied energy. Ramen noodles are most commonly steam cooked, a process that involves thermal and electric energy. By heating water until boiling, steam is forced onto hanging noodles which cooks them and aids in gelatinizing the starches present. (Rywotycki, 2003) This step is absent in the production of uncooked noodles, and as such any energy present, electrical or thermal, results in the larger embodied energy present in instant ramen. Next, both noodles need to be dried in preparation for packaging, and despite the procedure being similar, energy differences still occur. This results from the remaining water content in the two forms of noodles, with the moisture in uncooked noodles being around 30%, and in cooked, 50% (Hakoda, 2006). Because thermal energy in the form of hot air is used to dry both products, the instant noodles with their larger water content yet again requires more energy input to complete the process, resulting in another embodied energy term. At this point, differences in packaging in transport were deemed to be negligible, leaving only the customer use cases to be different.

Previously, instant ramen was shown to have significantly larger embodied energy which is responsible for consumer energy and time savings. After the consumer choses either product, it is clear what affect additional processing has done. The main energy use when preparing noodles is in the boiling of water to either cook raw noodles or rehydrate instant ramen, with significant differences between the energy and time consumption. For one serving of instant ramen, it takes around a 1 kilowatt power source 1 minute to heat a cup of water to boiling (Biglia, 2017). This is an energy consumption of 60,000 Joules. After this time, it takes an additional couple of minutes for the noodles to fully rehydrate before seasoning can be added and the meal enjoyed. With conventional noodles, the heating element is on average closer to 2 kilowatts and requires around 10-14 minutes to fully cook, resulting in an energy consumption of 1.2 – 1.7 million Joules (Moran, 2018). This results in a 10 or 14 fold time saving for instant ramen as well as an energy saving of around 20 times. As discussed, this advantage is due to cooking (one of the most energy intensive steps), being done beforehand in the case of instant ramen, allowing it to possess this advantage to the consumer. This advantage heavily contributes to its popularity and growth in modern times.

In conclusion, the energy used in manufacturing the raw noodles for both types of noodles does not differ until further production processes. The larger embodied energy present in instant ramen results in less energy and time spent by the consumer. This simple phenomenon has brought a specific product to the forefront of university and pop culture, showing the difference that preloading energy can have. Its success has spurred on many attempts by products in other categories trying to emulate this strategy with everything from coffee to phone chargers, all involving using higher embodied energies to appear to be more convenient to the consumer.

BIBLIOGRAPHY

1. “ASIA-PACIFIC | Japan Votes Noodle the Tops.” BBC News, BBC, 12 Dec. 2000, news.bbc.co.uk/2/hi/asia-pacific/1067506.stm.

2. Solt, George Sekine. Taking ramen seriously: food, labor, and everyday life in modern Japan. Diss. UC San Diego, 2009.

3. Taghavifar, Hamid, and Aref Mardani. "Energy consumption analysis of wheat production in West Azarbayjan utilizing life cycle assessment (LCA)." Renewable Energy 74 (2015): 208-213.

4. Bushuk, W. Wheat: Production, Properties and Quality. Springer, 2012.

5. Goulding, Matt. “Super Noodles: the Rise and Rise of Ramen.” The Guardian, Guardian News and Media, 22 Feb. 2016, www.theguardian.com/lifeandstyle/2016/feb/22/the-rise-and-rise-of-ramen-noodle-soup.

6. James, S. J., C. James, and J. A. Evans. "Modelling of food transportation systems–a review." International Journal of Refrigeration 29.6 (2006): 947-957.

7. Rywotycki, R. "A model of heat energy consumption during frying of food." Journal of food engineering 59.4 (2003): 343-347.

8. Hakoda, Akiko, et al. "Determination of the moisture content of instant noodles: interlaboratory study." Journal of AOAC International 89.6 (2006): 1585-1590.

9. Biglia, Alessandro, et al. "Steam batch thermal processes in unsteady state conditions: Modelling and application to a case study in the food industry." Applied Thermal Engineering 118 (2017): 638-651.

10. Moran, Michael J., et al. Fundamentals of Engineering Thermodynamics. John Wiley & Sons, Inc., 2018.

Noemi Fernandez Ortiz

DES 40A

Professor Cogdell

6 December 2018

Life Cycle Paper

Waste and Emissions Caused by Instant Ramen Noodle Industry

A college students go-to meal: instant ramen noodles. They are flavorful, affordable, and convenient, who wouldn’t enjoy them! Instant ramen noodles have been consumed by millions across the world for decades. They were first created by Momofuku Ando in 1958 in Japan under his company Nissin. Since then, the manufacturing process boomed. Many more flavors were added into the collection and even more instant ramen noodle companies began to create their own take on these tasty noodles. Although the idea behind instant ramen noodles is simple, the effects its creation has had, and continues to do so, on this earth are much more complex. From the ingredients found in these noodles, like palm oil and wheat, to the packaging the noodles are sold in, styrofoam, the overall effects they have on our earth and body are negative. Although noodle waste produced during production can be beneficial, it doesn’t compare to the negative effects the overall product has. By identifying the different materials used to make instant ramen noodles, understanding the wastes and emissions produced during the manufacturing process, as well as how the environment is affected in return, becomes much easier to do.

Wheat is the key ingredient in making instant ramen noodles, without it the star of the show would not exist. Wheat is used in various foods, and it is a popular type of flour. Growing and harvesting the wheat can cause some unpopular effects. Agriculture is one of the major sources of greenhouse gas emissions. In a study researching the amount of greenhouse gases (GHG) produced from different grains, it revealed some interesting data. “Wheat and rye had higher GHG emissions per hectare than oats and barley” (Rajaniemi 2011). Other than greenhouse gas emissions being released through harvesting, instant ramen noodle workers are also affected by the manufacturing of noodles. When making the noodle dough, workers must first mix wheat flour with other ingredients. Flour dust can cause health problems for workers exposed to them on a daily basis. “...Flour workers can be exposed to bioaerosols (airborne fungi and bacteria) resulting flour-induced occupational asthma or allergic diseases” (Tsai 2008). This flour-induced asthma is also known as baker’s asthma. It is commonly diagnosed in bakers or people who work with flour regularly. “Baker’s asthma is caused by breathing in flour and grains, additives and enzymes, and other allergens… and non-food allergens like dust mites and other molds” (MacKay 2017). Breathing in flour daily will result in workers having symptoms of coughing, wheezing, shortness of breath, and chest tightness. These symptoms can generally go away after not being in that environment for a few days. In order to best prevent baker’s asthma, workers should be properly covered and the workplace should have good ventilation. Another ingredient used in instant ramen noodles that has a negative environmental impact is palm oil.

Palm oil is like a silent killer; it’s in hundreds of different products but doesn’t get noticed all too well, yet the impact its manufacturing has on the earth is deadly. “[Palm oil] is a versatile vegetable oil derived from the pulp of the oil palm” (Loki 2017), which is used in up to “50% of household products” from shampoo and candles to instant ramen noodles. The oil is primarily produced in Malaysia and Indonesia, the world’s top two palm oil producers, then it is exported to different countries. Four of the top instant ramen noodle companies have factories in California. “An estimated 15% of all palm oil imported into California goes into instant ramen noodles, and most if not all comes from Indonesia or Malaysia” (Rainforest-Safe Ramen). Instant ramen noodle companies get most of their palm oil imports through California Oils Corporation, which then gets their supply from Kuala Lumpur Kepong Berhad (KLK). “Over 80% of KLK’s palm oil shipments to the U.S. go to California Oils, accounting for 44% of that company’s total imports” (Rainforest-Safe Ramen). The main reason why palm oil has become so controversial is because of the forests affected from extracting the oil. “A hectare of palm oil plantation yields on average 4 tonnes of crude palm oil per year” (Lau 2017) Because there is such a high demand for palm oil, in the past 20 years, “300 million hectares of rainforests have been cleared”(Lau 2017). That is roughly 741 million acres, or approximately 672 million football fields, of rainforests destroyed in order to grow the oil palm plant. This isn’t good for two prominent reasons: greenhouse gas emissions and animal endangerment. The destruction of rainforests releases carbon dioxide (CO2) into the atmosphere, “...in addition to the CO2 emissions during the transformation of the crude palm oil into processed palm oil” (Lau 2017). An effect of deforestation, other than greenhouse gases, is the endangerment of species found in those areas. With palm oil, the main species suffering the consequences is the orangutan. “An estimated 1000-5000 orangutans are killed each year for this [palm oil] development” (Loki 2017). Orangutans are going extinct because their homes and sources are being destroyed. They flee their homes in order to survive but many end up dying anyways, usually from starvation, if they aren’t killed for their meat. However, many organizations are trying to stop these effects from continuing to happen. They are working on guidelines to instill in order to limit deforestation and create a more sustainable source of palm oil. This won’t be an easy task, but many companies have already pledged to use sustainable palm oil, even more have yet to do so. Apart from ingredients used in instant ramen noodle production, packaging used to sell these soups are also negatively affecting our planet.

Instant Ramen Noodles can be manufactured and sold in different forms from plastic wrappers to plastic bowls. One of the most common forms, however, is in styrofoam cups. Many instant ramen noodle companies use styrofoam because it is a great insulator. It keeps the soup warm once cooked, and it also keeps the consumer from burning themselves while they hold the cup. Sounds like a good product to use but the harmfulness of styrene outways the benefits it can have. Styrofoam, also known as polystyrene, is made up of three chemicals: benzene, styrene, and pentane. Benzene and styrene are extracted from petroleum and are both used to make polystyrene. Pentane is used as a “blowing agent” to expand polystyrene into styrofoam. Pentane makes polystyrene much lighter than its original weight. However, “...occupational exposure to [benzene and styrene] compounds carries increased risk of cancer for plant workers” (Kremer 2003). Styrofoam is a inexpensive, light, and durable material that many companies tend to use for packaging but a large amount of that styrofoam is discarded into landfills or burned. “[Styrofoam] takes 500 years to decompose, and it takes up to 25-30% of our worlds landfills… There are 57 chemical by-products released during the manufacturing of styrene, polluting our air and waterways” (Lucas 2014). Manufacturing styrofoam isn't the only time chemicals are released into the air, it also happens when it is burned after being used. “Burning styrofoam gives off 90 different hazardous chemicals, including styrene vapors and dioxins” (Kremer 2003). There are ways in which styrofoam can be recycled, but there aren’t many recycling plants available that actually do recycle it. Because of this, a majority of styrofoam is thrown out into landfill. There are alternatives to styrofoam, such as new forms using starch. “Glenn works at the ARS Western Regional Research Center in Albany, Calif… [and has] been developing and patenting innovative, "green" techniques for transforming commonplace plant starches—like the silky white cornstarch kept in kitchen cupboards everywhere—into convenient, biodegradable foamed goods like shipping liners, dinnerware and more” (Wood 2009). Although styrofoam might seem like an impressive product that can make packaging items easier, it actually does more damage to the earth and to the body in the long run. Instant ramen noodle packaging isn’t the only source of waste created by this product, it is also created in the manufacturing factories. However, this type of waste is being repurposed.

It goes without saying a factory is bound to create waste when in use. With instant ramen noodle factories, studies have shown noodle wastewater can be beneficial. There are generally two major types of wastewater. The first is liquid waste, which contains starch and the second is solid noodle waste, which contains starch, lingo-cellulose, and oil. In order to convert noodle water waste into different products, it must go through “pretreatment involving extraction followed by centrifugation is necessary to separate oil from starch and ligno-cellulose” (Karmee 2017). This process takes a lot of time, energy, and can be expensive. This process is still done because of how many products wastewater can be transformed into. Wastewater can be converted into biodiesel, bio oil, bioethanol, nutrient, and animal feed. If this wastewater weren’t converted into these products, it would be released into the environment, causing bad odor and groundwater contamination. This is because “general wastewater contains high amounts of starch” (Karmee 2017). Being able to convert this waste into various other products is incredibly environmentally conscious, if done correctly.

Although the overall idea of instant ramen noodles is supposed to be positive, convenient, and affordable for the overall population, the negative effects the product has on the earth and our health are higher. Being able to consider all the factors that make up the product, it becomes easier to understand how different ingredients can become detrimental to our environment when in high consumption like they are today. By learning more about what we eat, where it came from, and how it was manufactured, we can begin to make much more conscious decisions on what we purchase.

Bibliography

Rajaniemi, M, et al. Greenhouse Gas Emissions from Oats, Barley, Wheat and Rye Production. 2011, agronomy.emu.ee/vol09Spec1/p09s123.pdf.

Tsai, Min-Yi, and Hui-Ming Liu. “Exposure to Culturable Airborne Bioaerosols during Noodle Manufacturing in Central Taiwan.” Science of The Total Environment, Elsevier, 4 Dec. 2008, www.sciencedirect.com/science/article/pii/S0048969708010450.

MacKay, Kerri. “What Is Baker's Asthma?” Asthma.net, 26 Jan. 2017, asthma.net/living/what-is-bakers/.

“Rainforest-Safe Ramen Instant Noodles Are Cheap, Delicious, and a Key to Ending Rainforest Destruction.” Rainforest-Safe Ramen, www.rainforestsaferamen.com/.

Lau, Esther. “It Only Takes 3 Minutes to Cook Instant Noodles. But How Does That Affect the Health of the Earth?” Medium, Medium, 22 Aug. 2017, medium.com/@esther_lau/all-it-takes-is-3-minutes-to-cook-instant-noodles-but-how-does-it-affect-the-health-of-the-earth-b20d8c9264aa.

Loki, Reynard. “The Evil in Your Instant Noodles - The Industry Is Destroying Rainforests and Using Child Labor.” Alternet, July 2017, www.alternet.org/environment/how-instant-ramen-noodles-are-destroying-rainforests-killing-orangutans-and-promoting.

Kremer, Andrea. Cradle to Grave: The Life Cycle of Styrofoam . 2003, flaglerlive.com/wp-content/uploads/Styrofoam.pdf.

Lucas, Alesia. “Safer Chemicals, Healthy Families A National Effort to Protect Families from Toxic Chemicals.” A National Effort to Protect Families from Toxic Chemicals., 2014, saferchemicals.org/2014/05/26/styrene-and-styrofoam-101-2/.

Wood , Marcia. “Inventors Offer Ecofriendly Substitutes for Polystyrene.” Dark Green Leafy Vegetables : USDA ARS, Sept. 2009, www.ars.usda.gov/news-events/news/research-news/2009/inventors-offer-ecofriendly-substitutes-for-polystyrene/.

Karmee, Sanjib Kumar. “Noodle Waste Based Biorefinery: an Approach to Address Fuel, Waste Management and Sustainability .” Researchgate.net, 2017, www.researchgate.net/publication/313010184_Noodle_waste_based_biorefinery_an_approach_to_address_fuel_waste_management_and_sustainability.