Design Life-Cycle

assess.design.(don't)consume

MATERIALS

Saleem M’Boge

Research Paper

DES 40A-001

Christina Cogdell

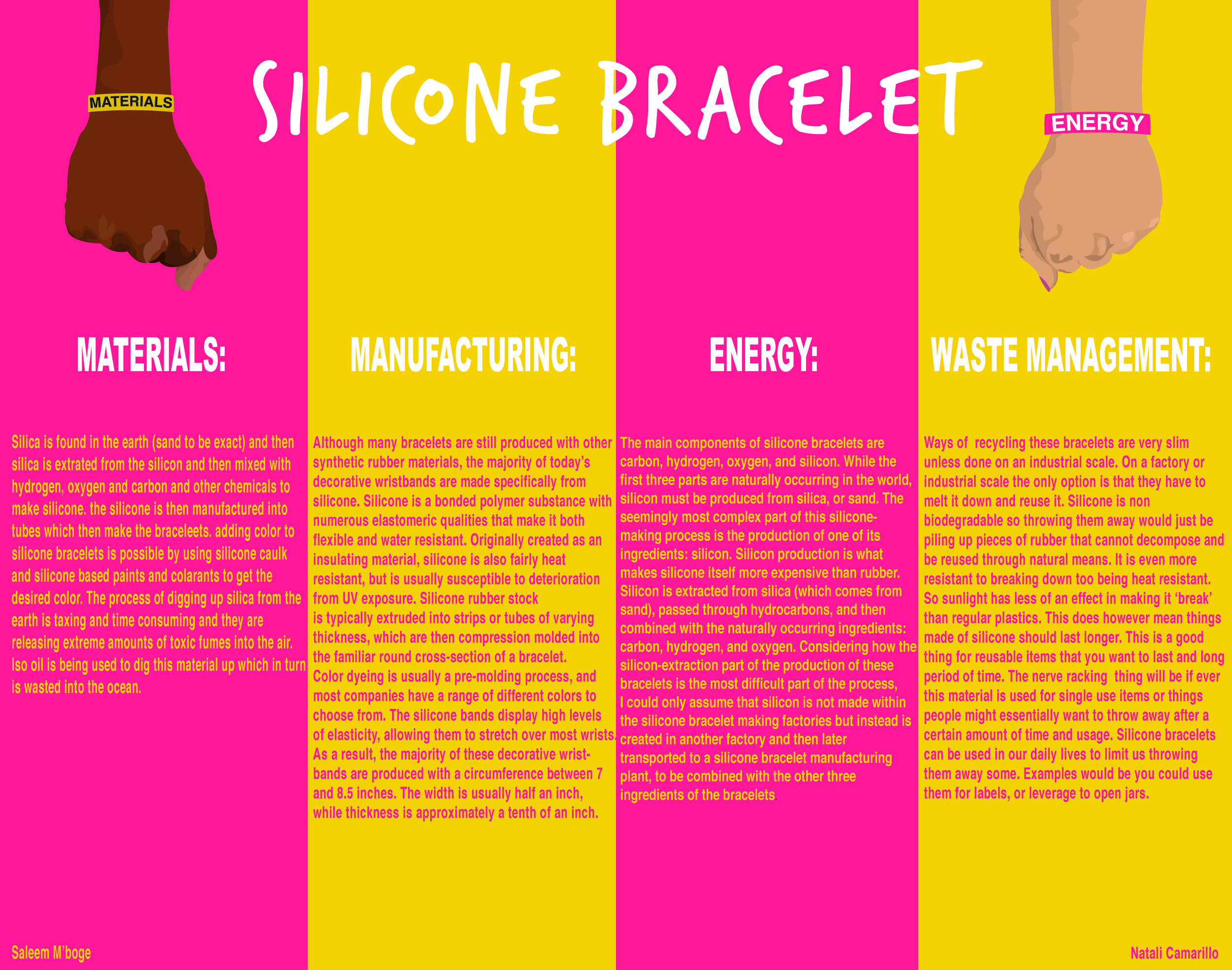

Silicone bracelets have been at the forefront of social and political movements but what happens to them before they are used and after they are used. Silicones have multiple uses in different industries and products. They can be found in aerospace and construction in the form of adhesives, coatings, and sealants because they can withstand extreme temperatures and absorb stress. They are used in electronics as sealants because they are resistant to moisture, salt, and corrosion. They’re also used to keep electronics like computers, fax machines, phones, and keyboards safe for the same reasons.

Silicone is made up of carbon, hydrogen, oxygen and silicon. You can see that one of the main ingredients in silicone is spelt different . silicon comes from silica which also comes from sand. The process to make silicon is difficult and has many stages. This hard process leads to silicone rubber being pricey compared to natural rubber.Silicone occurs only in an oxidized form, the two compounds in silicone are silicone dioxide and silicates. Silicon is the second most common element in the earth and is the most important component in inorganic materials. It is the best heat resistant and non-reactive element. Silicone material is available with elasticity and flexibility feature which make it comfortable to wear. Silicone is also referred to in the world of chemistry as “polyorganosiloxanes”.

Silicone does consist of an inorganic substance made of changing silicon and oxygen atoms, the other two chemical bonds are made of methyls which is why silicone is considered semi-organic in its nature. Silicone’s chemical structure makes it extremely versatile when it comes to its production. By using something called siloxane units with different valences silicone can be made to have different types of physical properties such as polymeric or resinous. At the same time, the organic groups bound to the silicon make way for a diverse range of modi cations. It is this type of flexibility that makes an impressive variety of silicone products: greases, release agents, antifoam agents, paint additives, paper coatings, hydrophobizing agents, high or room-temperature vulcanizing silicone rubbers, and many more. Silicones are a special group of plastics. The term “plastic” is normally used to refer to organic materials that do not occur in nature. Silicones are known as semi-organic materials since the element silicon has a strong metallic character compared to carbon.

Silicone polymer is mixed with fillers that reinforce them to make them stiff, at the end of that process the silicone becomes solid which can then be turned into bracelets. Natural rubbers, synthetic rubbers and silicone must be reinforced by using fillers to give them the necessary things such as hardness, tension, elongation and break and tear resistance . The required systematic properties can be individually added by filler called pyrogenic silica. Silicone is great for resistance from UV and weathering stress. Silicone is extremely heat resistant which is also another reason why it is used for these bracelets.

Another thing about silicone bracelets is that they can be customized with different colors and lettering. The materials used are SO-Strong, UVO or Ignite with urethane or epoxy heavy materials. SO-Strong, UVO and Ignite pigments are very concentrated and give excellent coverage and smooth and consistent color. Light use of color will cover a substantial amount of liquid urethane or epoxy material. The more you add in ratio to the volume of liquid urethane or epoxy, the more dramatic the color effect. An ideal loading range is 0.01% to 3.00% of total net weight.

Coloring of silicone bracelets is just as important as the making of them. In order to paint on silicone you would have to water the oil based paint down with silicone caulk which does evaporates into the atmosphere those chemicals in the air of the factories that make these things are not ideal for the environment. Another thing that would have to be used would be acetone to make the silicone bracelets more responsive to the paint. Acetone is also not something that is safe to be let out into the air.

Now that we have discussed the materials to make silicone and silicone bracelets we should discuss how to reuse and recycle these bracelets. Silicone bracelets have gone through multiple monumental movements such as the “livestrong” and “I love boobies”. And as those movements passed so did the need for the bracelets. The problem with using silicone to make products such as silicone bracelets is that it doesn’t have an end of life. The tactics of how to properly recycle silicone wasn’t added with the selling of silicone products. Marketing a product as waste-free, but when there is no use for it it ends up in the trash, then goes to the landfill, I don't believe that you can count it as sustainable? So the environmental effects of the silicone new hot thing that is silicone in my opinion are not the best.

Silicone is non biodegradable so throwing them away would just be piling up pieces of rubber that cannot decompose and be reused through natural means, It is even more resistant to breaking down too being heat resistant. So sunlight has less of an effect in making it ‘break’ than regular plastics. This does however mean things made of silicone should last longer. This is a good thing for reusable items that you want to last and long period of time. The nerve racking thing will be if ever this material is used for single use items or things people might essentially want to throw away after a certain amount of time and usage. Ways of recycling these bracelets are very slim unless done on an industrial scale. On a factory or industrial scale the only option is that they have to melt it down and reuse it.

But for the average person at home that probably has a hand full of these bracelets cannot get to a temperature hot enough to melt silicone, so they are stuck just throwing it away. A way to reuse silicone bracelets is by using them for basic things in life or throughout you day. You can use silicone bracelets as grip for your mugs etc. an example like that is what can be done to reuse these bracelets. reusing the silicone rubber bracelet is a better option than recycling it. Because you got them during concerts or during a promotion event, chances are they are sturdy and virtually unbreakable even after years of use. This makes them a good reusable material.

You can use them as a leverage to open jars and bottles that are too a little trouble to open. A little creativity can make them labels for drinks at parties to separate drinks for every person. A little silicone crafting can help you to create great silicone molds used to mold new items. Where silicone fails in the eco-friendly spectrum is correlative . The main material that makes the base of silicon comes from quartz, there is no shortage of that at this very moment, the hydrocarbons that make silicone come from petroleum or some type of natural gas. The way to obtain and process these materials have a good amount of environmental criticisms. Silicone is debatably more environmentally friendly than plastic, that’s because plastic is not as tough as silicone, silicone is also more stable than plastic, which means it has a lesser chance of letting chemicals get into the food when used for food storage. Using silicone can be a good option as long as you maintain it to make sure it last a very long time, and try your hardest to recycle it once you can no longer use it.

In conclusion, Silicone could take care of some of the health issues and concerns of regular plastic but it is long ways away from being a more environmentally friendly solution to plastic. In fact due to its temperature resistant capabilities like most tough plastics such as nylon cooking utensils it would be difficult to ever break down into a safe state when the material gets to a point where it is no longer being used. It really will just sit there in the environment too if its thrown away with a single thought and with recycling services taking silicone items fewer and fewer between i’d be avoiding silicone more and more till they figure it out. Silicone is a great versatile product but when is come to the safety of the environment i would not recommend it. Until there is a clear cut way to get rid of them safely and efficiently. It is not a safe material for the earth and we do not know the negative effects that it could have on us as humans let alone the planet so we should've been cautious when making the decision for silicone to be so widely used. We have created a problem with the materials that are used to create these bracelets and we have not tried to slice the problem or at least find an effective way to store them or get reuse them. It is important that we realize that these materials are hazardous for the environment and us if not recycled correctly and how we should be taking greater steps into finding solutions.

Work Cited:

“Where does Silicone Rubber come from? Find out with us today!” Silicone, 31 July 2017, silicone.co.uk/blog/where-does-silicone-rubber-come-from/.

“How Do You Manufacture Silicone? A Guide from Silicone Engineering.” Silicone, 10 Oct. 2017, silicone.co.uk/blog/how-do-you-manufacture-silicone/.

“Manufacturing and Designing Silicone Rubber Bracelets.” ThomasNet® - Product Sourcing and Supplier Discovery Platform, www.thomasnet.com/articles/plastics-rubber/silicone-bracelet-design/.

“Contact Us.” Is Silicone a Plastic?, www.lifewithoutplastic.com/store/is_silicone_a_plastic#.WnoW42KIaaM.

ENERGY

Natali Camarillo

DES 40A

Cogdell

3/10/18

Silicone bracelets are an incredibly popular trend that has seemed to disappear in today’s world but are still extremely present on many peoples’ wrists. These bracelets have been more popularly used for supportive movements, sometimes involving topics like cancer and natural disasters. Examples of these popular bracelets of the past include LiveStrong bracelets, Tsunami Relief Wristbands, and “I Heart Boobies” bracelets. Along with this common purpose of the easily produced bracelet, they’re also available to everyone to be custom made in bulk for various reasons. Other reasons the bracelets are made is for marketing from various companies, sports teams, or groups of people. Despite the seemingly complicated production process of these bracelets, they’re actually quite easy to be produced, which is why they’re able to be produced in such large quantities with varied pricing for various feature combinations. These bracelets are most likely to be spotted with text, either imprinted into the bracelet, with molded and raised letters, or with screen printed text. Despite all the features of these popular bracelets, the purpose of this essay is to explain where the materials used for the bracelets come from and the energy needed or lost in the production of these bracelets, using as much information as I was able to dig up.

The main components of silicone bracelets are carbon, hydrogen, oxygen, and silicon. While the first three parts are naturally occurring in the world, silicon must be produced from silica, or sand. The seemingly most complex part of this silicone-making process is the production of one of its ingredients: silicon. Silicon production is what makes silicone itself more expensive than rubber. Silicon is extracted from silica (which comes from sand), passed through hydrocarbons, and then combined with the naturally occurring ingredients: carbon, hydrogen, and oxygen. Considering how the silicon-extraction part of the production of these bracelets is the most difficult part of the process, I could only assume that silicon is not made within the silicone bracelet making factories but instead is created in another factory and then later transported to a silicone bracelet manufacturing plant, to be combined with the other three ingredients of the bracelets.

Producing the raw silicone is not the only process involved in making silicone bracelets. Along with the production of the synthetic rubber, to get to the form of the bracelets, producers also add dyes and use various shaping and printing methods to make each bracelet as unique as possible for each custom order. These methods seem to vary across different producers of silicone bracelets, and it’s unknown whether these differences create a difference in quality. Disregarding the possibility of the slight differences between manufacturers, I would agree that it is safe to say these bracelets have been found to be durable throughout their lifetime, making a great canvas to paint a logo or message of support.

In one specific case of silicone bracelet production, the raw materials are combined using a “mixing machine” to create the silicone rubber. There is no special process to this mixing, it is so relatively simple it has even been compared to the mixing of dough or batter. This easy process is why the production of these bracelets is quite quick and allows for mass production. The ability for silicone bracelets companies to be able to produce large quantities of these bracelets in short amounts of time is what lead me to believe the silicon component of the bracelets is produced outside of the factories, especially considering all the other products that utilize silicon as well.

Since silicon is an important component of these bracelets, I find it completely reasonable to dedicate this paragraph to a short description of the element. By weight, silicon makes up for 25.8 percent of the Earth’s crust and is the second most common element found in the crust. Within the crust, silicon is only present in its oxidized form, leading to its more complex production process. Silicon is needed for most inorganic materials of the world, which I believe speaks for the quality and efficiency of this element.

It’s known that the ingredient of the silicone bracelets, silicon, is extracted from the Earth in its oxidized form, but the source of the other elements is unknown to myself. Considering how common carbon, hydrogen, and oxygen all are in this world, I would assume they are relatively easy to collect for the production of these silicone bracelets. This belief of mine is also supported by the ease of the mixing stage of creating silicone, which may have been otherwise complicated if these naturally occurring elements were difficult to extract from our surroundings.

As for energy sources used to create the bracelets, I would find it safe for me to assume that electricity is what powers the machines used for the uncomplicated process of creating silicone bracelets. I’m sure there are exceptions to this assumption, with the occasional clean energy, but for the most part I would believe the machines within the silicone producing factories would be run by electricity.

Past the process of making the actual silicone for the silicone bracelets is the shaping of the bracelets and the customized print on the surface. I did not find any specific discussion of the dyeing process, but it was mentioned that it takes place before the silicone is shaped. The shaping process begins with silicone being taken for the process of calendaring. Calendaring is used to create sheets of the silicone, of varying thickness and widths. The line of bowls (or rollers) in the calendar are what shape the silicone into a sheet. After the sheet is produced, it is transported down the line into an oven that sets the sheet into its flat shape. These sheets are taken for the next step in silicone bracelet making, moulding. Moulding takes the sheets created by the calendar, sets them in between two etched metal plates that mold the silicone into the shape of a bracelet band. Moulding not only creates the shape of the silicon that will be used for the bracelets, but also removes any excess air from the silicone itself. The assumed strip of silicone, produced by the calendaring and moulding, is then taken to heat both ends to join them and create a circular shape than can be worn like a bracelet.

An important part of the silicone bracelet making is the application of the text or logo onto the bracelet, which makes every customized bracelet unique. There are at four major ways to letter the bracelets: debossing, colored debossing, embossing, and screen printing. Debossing is most popular way of letter formatting, an imprint mold creates imprinted text into the bracelet, using no dyes. Colored debossing is exactly like debossing but uses colors along with the imprint, to make text more visible on the silicone bracelets. Embossed letters are basically the complete opposite of debossed letters, instead of imprinted text, the text is raised using a mold as well. The last form of lettering is screen printing, which involves a silk-screen used to print text on the silicone, either on the outside or inside.

Despite the little information I found that discusses energy used by the production of silicone bracelets, its simple production process makes me comfortable with making an educated guess on the sources of energy used, with the most likely being electricity for every machine operated step of the process. Regarding the transportation of primary raw materials, the simple construction of the bracelets makes me believe that the four ingredients are brought to factories on trucks from other factories that produce silicon or properly contain the three other elements. Considering the purpose of these bracelets (marketing, support, etc.), I would easily believe that these bracelets aren’t as commonly found in your local Target as they would be from specific organizations and groups. Silicone bracelets easy customization is why these bracelets are more specifically created by smaller groups, thus making various organizations and teams a part of the distribution of the bracelets. Less directly, these bracelets come from a number of companies that provide bulk amounts of customized bracelets, available to anyone with access to the internet. Overall, in terms of parts of my essay I wished to include, I found it easy to assume some of the missing pieces in the puzzle.

One of the pieces of information I can’t quite guess about is the amount of energy spent by the machines that work to create the bracelets. I would believe that it could vary by factory and the amount of distance the raw materials need to travel. Despite the lack of information I found on this topic, I would assume that a simple production process means a low energy one. The iconic look of the silicone bracelet will most likely live on in the world of advertising, and more commonly, for various organizations and movements in this era. The fall in popularity of these bracelets as a trend does not speak to the original purpose of these easily customizable silicone bracelets, that may possibly prove to be timeless in this context.

Bibliography

1. “Where does Silicone Rubber come from? Find out with us today!” Silicone, 31 July 2017, silicone.co.uk/blog/where-does-silicone-rubber-come-from/.

2. “How Do You Manufacture Silicone? A Guide from Silicone Engineering.” Silicone, 10 Oct. 2017, silicone.co.uk/blog/how-do-you-manufacture-silicone/.

3. “Manufacturing and Designing Silicone Rubber Bracelets.” ThomasNet® - Product Sourcing and Supplier Discovery Platform, www.thomasnet.com/articles/plastics-rubber/silicone-bracelet-design/.

4. https://www.google.com/amp/silicone.co.uk/blog/where-does-silicone-rubber-come-from/amp/

5. https://www.wacker.com/cms/media/publications/downloads/6415_EN.pdf

6. “Creating of Anti-Icing Coatings Based on Nanoscale Powders of Silicon Dioxide Obtained from Silicone Waste.” Procedia Manufacturing, Elsevier, 26 Sept. 2017, www.sciencedirect.com/science/article/pii/S2351978917305930?via%3Dihub.