Design Life-Cycle

assess.design.(don't)consume

Peterson, Ashlee

DES 40A

11/23/2021

Professor Cogdell

Raw Materials – Eyeshadow Palette

I. Introduction To Eyeshadow Palette Raw Materials

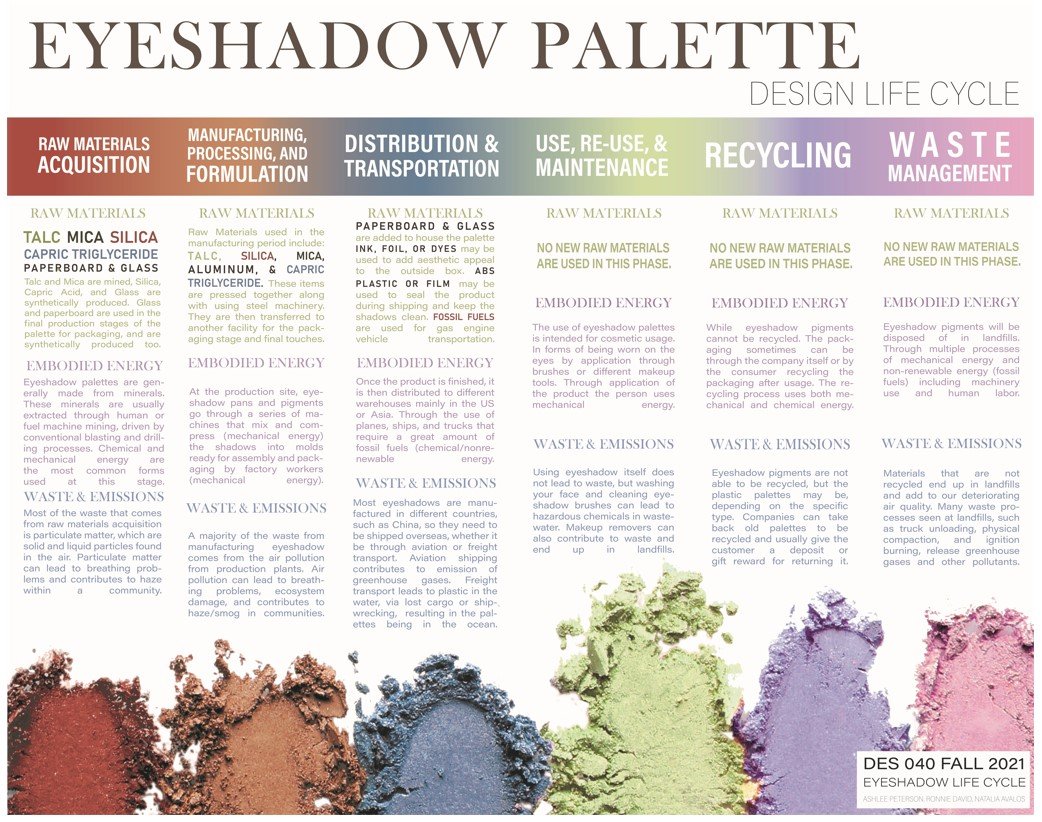

Makeup palettes in the twenty first century are often made of raw materials sourced from places unknown to the everyday consumer. A few key ingredients across all eyeshadow palettes are silica, mica, and talc, and caprylic/capric triglyceride. These ingredients must be sourced as a raw material or synthesized inorganically in a lab. Regardless of acquisition methodology, both collection processes end in environmental damage. Raw material acquisition affects the manufacturing, re-use ability, recycle-ability, and waste management of eyeshadow palettes globally. Along with this, the energy, re-distribution, and transportation of eyeshadow is widely affected by the global resourcing of eyeshadow palette minerals, which is usually raw material acquisition via mining and secondhand synthetic processing, which causes its own slew of waste and energy production. Throughout this paper I will attempt to address this life cycle of the main ingredients in the Naked 3 eyeshadow palette: talc, mica, silica, caprylic/capric triglyceride, and paperboard packaging; from ground collection to finished product.

II. Collection of Primary Raw Materials

Studying the acquisition of raw materials in eyeshadow palette production is an important and unknown aspect of the beauty world. Many makeup companies are extremely focused on life-form ethicality, from animal testing to labor sourcing, but few have shed light on the unethical practices used to source the materials needed for beauty brands everywhere. Primary raw materials, or materials taken directly from the earth, have been collected by cosmetic companies without foresight on environmental damage for years. With green chemistry and sustainability showing up on the average consumer’s radar, we must analyze the damage done by raw material sourcing. Although I cannot cover all raw materials used in cosmetics, due to scope, size, and lack of research available, a few very important key players (mica powder and talc) are well researched.

A. Mica powder is a huge aspect of cosmetic eyeshadow. Responsible for the shimmers and gleaming colors in makeup, this component is found nearly everywhere. Mica mining, however, is extremely detrimental to the environment. In the article Environmental Effects of Sand and Gravel Mining on Land and Soil…, by Ako et al., in the Journal of Geosciences and Geomatics, it was concluded that mica mines caused a reduction of farm and grazing lands, a destruction of landscape, deforestation, water pollution, and air pollution. This is as much as I could find on the environmental impacts of mining mica. Unfortunately, the data to represent this information has not yet been properly researched and published. This same narrative can be found in many other naturally mined cosmetics, spoken about below. Talc, however, is not under-researched at all.

B. Talc is a white, naturally occurring, powdery mineral used in cosmetics for absorbing moisture, and improving the feel of shadow products. It is prevalent across nearly all eyeshadows and therefore is a good material to evaluate. Talc is collected via mining practices all over the world, but for the sake of research availability, I will be referencing a talc plant in Italy- named Luzenac Val Chisone who have undergone an ecological balance analysis and published a paper on their quantified results. According to V. Bandino, G.L. Baldo, et al., who wrote Ecobalance of Talc Mineral Production, Talc is commonly collected via “selective blasting and cement filling”. Table 1, under the figures section, references the minimal materials needed to mine talc. When looking it over, the most expensive cost to mining 1 ton of talc is reported to be 4.6 liters of diesel. There are five main off gassed compounds during the mining process, with the heaviest emission being 36.8 grams of Carbon Monoxide per 1 ton of exploded mineral (table 2). In the bigger picture, producing 1 ton of talc has a cost of: 1070 megajoules in energy usage, and over 16,152 grams of CO2 (Table 5). These are significant numbers, as on average in America alone, 45,000 tons of talc were used in cosmetics (Zazenski R., Ashton W.H., et al. 219). This totals out to roughly 726,840,000 grams of off gassed CO2 from solely America’s Talc consumption (Figure 1). This same equation can be repeated with the values on table 5 to give an accurate portrayal of other forms of environmental effects of refined talc.

All of this may lead one to believe that synthetic material sourcing is a great alternative to the natural damage caused by raw material acquisition. This is a fair assumption, and as we move toward total depletion of natural resources, it may be our only option. Let’s explore the current synthetic resources used in eyeshadow palettes today.

III. Secondary Raw Materials (Synthesized Materials)

Secondary synthesized materials have their own impact on the environment in the process of eyeshadow creation. Synthetic Silica and Caprylic/capric triglyceride are specifically well researched and will be discussed in this paper.

A. Synthetic Silica is a common ingredient in eyeshadow. It can be produced in a multitude of ways, but “in brief, sodium carbonate powder is allowed to react with quartz sand at high temperatures to form sodium silicate, which is then treated with sulfuric acid to precipitate silica.” (Joglekar S., Kharkar R., et al. 492) This common method can cause environmental damage due to consumption of quartz sand, which is a naturally occurring non-renewable resource. Recently, however, many silica producers have begun to investigate using rice husk ash (RHA) as an alternative resource for silica production. RHA is a by-product in rice milling processes and can cause environmental build-up as a waste product with no use (Kumar A., Sengupta B., et al. 47). RHA has since developed into a renewed resource for mineral replacement in cements and steels, and it is now beginning its life as a secondary synthetization source for amorphous silica. Using various lab synthesizing processes, it is possible to recover over 90% of the silica contained in RHA (Shelke et al. 66). This narrative of creating a necessary chemical ingredient out of a waste resource is extremely common as demand continues to outgrow supply throughout the world. Makeup is no exception to this, but hopefully as we continue to renew materials, we can find long term solutions to our ongoing investigation into sustainable life cycles. When compared to the environmental impacts of naturally obtained silica though, RHA is an extremely ecofriendly alternative as it renews a secondary byproduct extremely effectively. The environmental impact of RHA synthesis is yet to be researched, as it is a new finding in the scientific community, and can be seen as in its infancy.

B. Caprylic/capric acid is a lauric oil derived from coconut or palm plants. Both coconut and palm plants have small amounts of caprylic acid naturally occurring in them, and therefore are greatly consumed for a small amount of final product. This makes caprylic acid manufacturing costly in both resources and time (Shilva, 102). On a greater scale, however, palm oil production has been shown to affect land, air quality, and animal biodiversity. (Carlson et al.). This makes Caprylic acid an overall poor material in the environmental sense, for its effects on earth are directionally inverse to its production value.

IV. Packaging Materials

A. Packaging is a huge aspect of the life cycle and energy cost of eyeshadow palette. L’Oréal, the parent company behind many eyeshadow palettes, is known for having high-end packaging made of plastics and mixed paperboard. When requested for comment on their packaging materials, they responded with the following statement: “We’re happy to confirm that our packaging is made of paperboard cartons made of recyclable materials.” No further information was given. While not perfect, paperboard packaging has been shown to create a “more environmentally friendly option than the plastic crate system in all studied impact categories.” according to Koskela et al., who compared cardboard and plastic delivery systems to assess their individual environmental impact throughout their life cycle. Unfortunately, paperboard is not used by all companies, so the impacts of plastic must also be considered. The effects of plastic packaging in the makeup industry was not widely available, as plastic use effects are generalized outside of the cosmetics bubble. As we all know, plastics are extremely damaging as a non-degrading material that can be toxic and dangerous to all ecosystems and life on earth. Outside the bounds of purely cosmetics, plastics are infamous. Unfortunately, the scope of plastic damage is so wide that information on just cosmetics was unavailable.

V. Conclusion

A. Raw material acquisition affects the manufacturing, re-use ability, recycle-ability, and waste management of eyeshadow palettes globally. Along with this, the energy, re-distribution, and transportation of eyeshadow is widely affected by the global resourcing of eyeshadow palette minerals, which is usually raw material acquisition via mining and secondhand synthetic processing. In this paper, I have successfully led an understanding of raw and synthetic material acquisition effects for eyeshadow palettes through accurate and detailed analysis of three key ingredients shared by most eyeshadows: talc, silica, mica, capric acid, and paperboard/plastic packaging. While much is still unresearched, as consumers we can help this process by adequately supporting brands who focus on environmental impact- from start to finish for the entire designs’ life cycle.

VI. Closing Notes

A. Unfortunately, although I spent much of my time researching this topic, many of the sources I found for various components of eyeshadow were unreliable, under-researched, or simply non-existent. I found that most of the research done on makeup ingredients has been in relation to the health and safety of humans and the toxicology of makeup, instead of the environmental sourcing, manufacturing, or ecological effects of these raw materials. I have chosen to speak on the most researched life cycle minerals for accuracy of information and ability to cite. Some sources in my bibliography were used for general research and understanding but not directly quoted within this paper.

VII. Figures

A. Table 2 and Table 5 are sourced from V. Bandino, G.L. Baldo.

Figure 1. CO2 equivalent for 1 ton of refined talc

Raw Materials Bibliography

Common cosmetic ingredient / Useful resources info

Life Analysis of a Portable Cosmetics Package

Jaccarini, P., and P. Refalo. “Life Cycle Analysis of a Portable Cosmetic Package.” Challenges for Technology Innovation: An Agenda for the Future, CRC Press, 2017, pp. 269–73. www.taylorfrancis.com, https://doi.org/10.1201/9781315198101-47.

Chapter 1 - Green Chemistry: Foundations in Cosmetic Sciences

Cannon, Amy S., and John C. Warner. "Green chemistry: foundations in cosmetic sciences." Global Regulatory Issues for the Cosmetics Industry. William Andrew Publishing, 2009. 1-16.

Formulating, packaging, and marketing of natural cosmetic products

Dayan, Nava, and Lambros Kromidas, eds. Formulating, packaging, and marketing of natural cosmetic products. John Wiley & Sons, 2011.

Sustainability Calculator: A Tool to Assess Sustainability in Cosmetic Products

Bom, Sara, Helena Margarida Ribeiro, and Joana Marto. "Sustainability calculator: a tool to assess sustainability in cosmetic products." Sustainability 12.4 (2020): 1437.

A step forward on sustainability in the cosmetics industry: A review

Bom, S., et al. "A step forward on sustainability in the cosmetics industry: A review." Journal of Cleaner Production 225 (2019): 270-290.

Sustainability: how the cosmetics industry is greening up

Sahota, Amarjit, ed. Sustainability: how the cosmetics industry is greening up. John Wiley & Sons, 2014.

Talc Info

Trace metals in cosmetic facial talcum powders marketed in Nigeria

Nnorom, I. C. "Trace metals in cosmetic facial talcum powders marketed in Nigeria." Toxicological & Environmental Chemistry 93.6 (2011): 1135-1148.

Raw materials sourcing for manufacturing in Nigeria. (Book, 2009)

Raw Materials Sourcing for Manufacturing in Nigeria. Nigeria, Raw Materials Research and Development Council, 1990.

· Badino, V., et al. ECOBALANCE OF TALC MINERAL PRODUCTION. p. 6.

Talc: Occurrence, Characterization, and Consumer Applications

Zazenski, R., et al. “Talc: Occurrence, Characterization, and Consumer Applications.” Regulatory Toxicology and Pharmacology, vol. 21, no. 2, Apr. 1995, pp. 218–29. DOI.org (Crossref), https://doi.org/10.1006/rtph.1995.1032.

Mica Info

Natural resources: Child labour in India's mica mines: The global beauty industry

Bliss, Susan. "Natural resources: Child labour in India's mica mines: The global beauty industry." Geography Bulletin 49.3 (2017): 23-31.

A, Ako T., et al. “Environmental Effects of Sand and Gravel Mining on Land and Soil in Luku, Minna, Niger State, North Central Nigeria.” Journal of Geosciences and Geomatics, vol. 2, no. 2, 2, Science and Education Publishing, Jan. 2014, pp. 42–49. pubs.sciepub.com, https://doi.org/10.12691/jgg-2-2-1.

Environmental impacts of Indian small-scale mining industry - an overview

Ghose, Mrinal. “Environmental Impacts of Indian Small-Scale Mining Industry - an Overview.” Minerals & Energy - Raw Materials Report, vol. 18, no. 2, Routledge, Jan. 2003, pp. 24–33. Taylor and Francis+NEJM, https://doi.org/10.1080/14041040310001966.\

Kirk‐Othmer Encyclopedia of Chemical Technology- Mica

Tanner, James T. and Updated by Staff. “Mica.” Kirk-Othmer Encyclopedia of Chemical Technology, edited by John Wiley & Sons, Inc., John Wiley & Sons, Inc., 2012, p. 1309030120011414.a01.pub2. DOI.org (Crossref), https://doi.org/10.1002/0471238961.1309030120011414.a01.pub2.

Silica Info

A Life Cycle Assessment of Silica Sand: Comparing the Beneficiation Processes

Grbeš, Anamarija. “A Life Cycle Assessment of Silica Sand: Comparing the Beneficiation Processes.” Sustainability, vol. 8, no. 1, 1, Multidisciplinary Digital Publishing Institute, Jan. 2016, p. 11. www.mdpi.com, https://doi.org/10.3390/su8010011.

Process development of silica extraction from RHA: a cradle to gate environmental impact approach

Joglekar, Saurabh N., et al. “Process Development of Silica Extraction from RHA: A Cradle to Gate Environmental Impact Approach.” Environmental Science and Pollution Research, vol. 26, no. 1, Jan. 2019, pp. 492–500. DOI.org (Crossref), https://doi.org/10.1007/s11356-018-3648-9.

A simple method for production of pure silica from rice hull ash

Kalapathy, U. “A Simple Method for Production of Pure Silica from Rice Hull Ash.” Bioresource Technology, vol. 73, no. 3, July 2000, pp. 257–62. DOI.org (Crossref), https://doi.org/10.1016/S0960-8524(99)00127-3.

Kumar, Anuj, et al. “Recovery of Value Added Products from Rice Husk Ash to Explore an Economic Way for Recycle and Reuse of Agricultural Waste.” Reviews in Environmental Science and Bio/Technology, vol. 15, no. 1, Mar. 2016, pp. 47–65. DOI.org (Crossref), https://doi.org/10.1007/s11157-015-9388-0.

Mesoporous Silica from Rice Husk Ash

Shelke, V. R., et al. “Mesoporous Silica from Rice Husk Ash.” BULLETIN OF CHEMICAL REACTION ENGINEERING AND CATALYSIS, vol. 5, no. 2, Jan. 2011, pp. 63–67. DOI.org (Crossref), https://doi.org/10.9767/bcrec.5.2.793.63-67.

The beauty of biocatalysis: sustainable synthesis of ingredients in cosmetics

Heath, Rachel S., Rebecca E. Ruscoe, and Nicholas J. Turner. "The beauty of biocatalysis: sustainable synthesis of ingredients in cosmetics." Natural Product Reports (2021).

Caprylic Acid Info

· Carbon emissions from forest conversion by Kalimantan oil palm plantations

o Carlson, Kimberly M., et al. “Carbon Emissions from Forest Conversion by Kalimantan Oil Palm Plantations.” Nature Climate Change, vol. 3, no. 3, Mar. 2013, pp. 283–87. www.nature.com, https://doi.org/10.1038/nclimate1702.

o Secchi, Michela, et al. “Assessing Eco-Innovations in Green Chemistry: Life Cycle Assessment (LCA) of a Cosmetic Product with a Bio-Based Ingredient.” Journal of Cleaner Production, vol. 129, Aug. 2016, pp. 269–81. ScienceDirect, https://doi.org/10.1016/j.jclepro.2016.04.073.

· Environmental Life Cycle Assessment of Caproic Acid Recovery from Brewery Waste Streams

o Shrestha - Advancing Chain Elongation Technology for Medium C.Pdf. https://deepblue.lib.umich.edu/bitstream/handle/2027.42/168053/shilva_1.pdf?sequence=1#page=121. Accessed 21 Nov. 2021.

Packaging Info

· Reusable Plastic Crate or Recyclable Cardboard Box?

o Reusable Plastic Crate or Recyclable Cardboard Box? A Comparison of Two Delivery Systems | Elsevier Enhanced Reader. https://doi.org/10.1016/j.jclepro.2014.01.045. Accessed 21 Nov. 2021.

Tin/Zinc/Other Metals Info

Toxic metals contained in cosmetics: A status report

Bocca, Beatrice, et al. "Toxic metals contained in cosmetics: a status report." Regulatory Toxicology and Pharmacology 68.3 (2014): 447-467.

Natalia Avalos

Ashlee Peterson, Ronnie David

DES 40A

Professor Cogdell

Eyeshadow Palette: Energy

As we are living in the twenty-first century, the world has become very modernized and with the rise in technology social media has influenced many people. Social media has connected people and has helped make a shift in the makeup world to make it a hobby. Now that makeup is now also being used for recreational purposes the demand for these products have increased and has impacted the environment in a negative manner. The amount of materials, energy and waste that it takes to make a variety of makeup products, including eye shadow palettes, has made a detrimental impact on the earth.

A primary material that we found to be largely used in cosmetic products especially in eyeshadows, is a mineral named talc. According to the United States Environmental Protection Agency, Office of Air Quality Planning and Standards, more than 95 percent of talc is produced in the United States coming from open pit mines and operations consist of conventional drilling and blasting methods. More specifically the machines used for mining operations are: “4LHD , 1 shuttle-train with loco diesel and 3 electrical loco with 10 to 15 lorries, 1 dumper, 1 backfilling truck with slinger belt, 2 drilling machine.” are all used (Ecobalance of Talc Mineral Production). These extracting methods are using chemical and mechanical energies that come from these machines/methods but what we could assume is that the machinery used for these processes uses non-renewable energy sources such as coal or petroleum. We also see that 106.4 kWh of electrical power per one ton of treated talc is used (Ecobalance of Talc Mineral Production). In using these non-renewable energy sources to fuel and operate these machines the emissions from them have negatively impacted the environment. As we see an increase of consumerism in these cosmetic products, eyeshadow palettes, we also see an increase in the use of these rapidly diminishing non-renewable resources (petroleum and coal).

Continuing, the next step in the production process is manufacturing the eyeshadow palette. Manufacturing an eyeshadow palette can be done throughout the world but major hubs include Asia and the US. Once the minerals arrive at the production site, they go through a series of machines that mix and compress the shadows into molds ready for assembly and packaging by factory workers (Thevi). The generally the steps when going through the series of machines include: “raw material preparation, mixing, heating (70-90 degrees), grinding, degrassing (dissolving gases from liquids), filling (molds), cooling (0-5 degrees), mold releasing, assembly” (Energy Use, Conservation, and Emissions Reductions in Taiwanese Cosmetic Industry). But another important factor is the human labor/energy it takes to individually place and inspect the eyeshadows when going into the packaging. Now according to the Environmental Engineering and Management Journal 13871.0 GJ of energy is used alone in the mixing, grinding, filling, etc. machines used. They also express that energy is also lost in production, “the total energy losses including boiler losses, distribution losses and losses due to equipment inefficiency were 3307.4”. This energy loss in production is a huge problem as the non-renewable energy sources to power the production causes environmental deterioration the more that it is used. This is also only one part of the whole production process, so it is unbelievable to think how much energy is not only going into making eyeshadow palettes but how much is lost.

Another essential part of this process is to distribute either the raw materials to production or the product itself after it has been produced and inspected. Raw materials coming from the mines are usually transferred/hauled by diesel powered equipment such as service trucks, pickup trucks, rear dump trucks, etc. (US Department of Energy Industrial Technologies Program). Once the raw materials get put into these trucks they get transferred to manufacturing to be used for production. As this equipment is powered by diesel (non-renewable), the equipment can be “highly energy intensive, accounting for 87 percent of total energy consumed in materials handling” (US Department of Energy Industrial Technologies Program). Again we can see how the production process of an eyeshadow palette is highly energy intensive due to using equipment that is energy intensive and needs non-renewable energy sources. The same goes for when transporting the product to warehouses and distributors. The products (eye shadow palette) can be transported by road (semi-trucks, etc.), air (planes), and sea (cargo ships) which are also energy intensive (Asstra). Just like the machinery used to transport raw materials, semi-trucks, planes, and cargo ships are energy intensive as they need large quantities of non-renewable energy sources to transport the product long distances.

Once the makeup palettes get distributed and in the hands of consumers its life cycle doesn’t end there. The eyeshadow palettes will most likely be used for cosmetic purposes in forms of being worn on the eyes by application through brushes or different makeup tools. Through application of the product the consumer uses mechanical energy. Once the consumer has used the eyeshadows in the palette or they have expired, the eyeshadow palette will be disposed of. Most consumers will most likely dispose of the waste through means that will have it end up in landfills. Though you can’t recycle the eyeshadow pigments themselves, some companies make their packaging recyclable. The packaging could be made of plastic or cardboard that may be cleaned and recycled properly. The recycle process consists of collection, processing (sorted and cleaned), and remanufacturing (EPA). Recycling these products/packaging can be very beneficial to the environment as well as a way to produce more sustainable packaging by being made from recycled materials. According to the article “Plastics recycling: challenges and opportunities”, recycle can also be beneficial in the aspects of energy as “high levels of recycling, as with reduction in use, reuse and repair or re-manufacturing can allow for a given level of product service with lower material inputs than would otherwise be required.”. Essentially, these methods can decrease energy consumption and materials used to create a product. While there is energy used in recycling by machines using electricity or fuel (petroleum, etc.) for cleaning and sorting plastics, there are also benefits in recycling that can decrease energy consumption overall.

Consequently, the production of a makeup palette and many other cosmetic products has detrimental effects to the environment. With the rise of consumerism for these products there is not only a rise of negative environmental effects but the production of these products are very energy intensive. There are some ways in which experts are trying to find solutions to decrease the amount of energy used and lost. Many of the problems where energy losses are seen is the inefficiency of the equipment used in manufacturing/production (Environmental Engineering and Management Journal). Also according to the Environmental Engineering and Management Journal, there are measures which can be taken to decrease the energy losses and efficiencies; such as lowering boiler temperatures below design setting as well as using daylight as an alternative light source and many more. Other ways to maximize energy in the production process is to reuse CIP water (energy efficient and sustainable) and IE3 motors (highly efficient industrial motors) (Tetra Pak). With all of these solutions combined from reusing water to finding/using more efficient motors, cosmetic production could increase and lower energy levels.

The rise of technology/use of social media combined with growing consumerism, has led to an increase in production of eyeshadow palettes and other cosmetics. The amount of materials, energy and waste in the lifecycle of a single eyeshadow palette has made a remarkable impact on the environment. Especially considering how the production of this product is very energy intensive and how energy is sometimes lost through inefficiency in machines or methods. It opens your eyes as a consumer to think about all the factors that need to be taken into account to make a single product. I also think the industry and many others like to hide the problematic aspects of production that harm the environment. Though there are many new solutions being brought up to make the production process of these products more efficient and sustainable, it is also up to the consumer to evaluate their consumer footprint. But with the influences of social media there still remains the increasing demand of cosmetics and eyeshadow palettes.

Works Cited

Gradus, Raymond. "Postcollection Separation of Plastic Recycling and Design-for-Recycling as

Solutions to Low Cost-Effectiveness and Plastic Debris." Sustainability, vol. 12, no. 20,

2020, pp. 8415. ProQuest, https://www.proquest.com/scholarly-journals/postcollection-separation-plastic-recycling/docview/2548734270/se-2, doi:http://dx.doi.org/10.3390/su12208415.

Hopewell, Jefferson et al. “Plastics recycling: challenges and opportunities.” Philosophical

transactions of the Royal Society of London. Series B, Biological sciences vol. 364,1526

(2009): 2115-26. doi:10.1098/rstb.2008.0311

Su, Te-Li, et al. ENERGY USE, CONSERVATION AND EMISSIONS REDUCTIONS IN

TAIWANESE COSMETICS INDUSTRY . Environmental Engineering and Management

Journal, Dec. 2014, www.eemj.icpm.tuiasi.ro/pdfs/vol13/no12/Full/8_567_Hong_11.pdf.

“Talc Processing”. United States Environmental Protection Agency, Office of Air Quality

Planning and Standards. July 1995.

https://www3.epa.gov/ttnchie1/ap42/ch11/bgdocs/b11s26.pdf. Accessed November 22, 2021

“The U.S Recycling System .” EPA, Environmental Protection Agency,

https://www.epa.gov/recyclingstrategy/us-recycling-system. Accessed November 22,

2021

Thevi, Jaysri. "A Cosmetic Journey". Arcgis Storymaps, 2021,

https://storymaps.arcgis.com/stories/462b2be1299840d0840dd25cb9956e7a. Accessed

November 22, 2021

“Transportation of Beauty, Fragrance and Perfume Product Shippers.” AsstrA,

asstra.com/industries/fashion-and-beauty/. Accessed November 22, 2021

“U.S. Mining Industry Energy Bandwidth Study.” US Department of Energy Industrial

Technologies Program , June 2007. Accessed November 22, 2021

“5 Production Challenges Facing Cosmetics Manufacturers – and How to Solve Them.” Tetra

V. Badino, G.L Baldo, M. Fornaro, E. Salvaia . “Ecobalance of Talc Mineral Production.”

Ronald David

Natalie Avalos & Ashlee Peterson

DES40A

Professor Cogdell

December 2, 2021

Eyeshadow Palette: Waste and Emissions

As the quality of life continues to improve, the demand for cosmetic products increases. According to “Statista”, around 1.96 billion US dollars came from eye cosmetics, with a major product being eyeshadow palettes. While eyeshadow is not a new product and has been used for many years, there has been a shift in viewing cosmetics as an art form and a hobby, due to the globalization that came along with social media. Eyeshadow can be used to enhance one’s features or can be used to create interesting artworks on a smaller canvas; the possibilities are up to the discretion of the user. The versatility of eyeshadow means that the market is large, as it reaches a different variety of individuals. Our group wanted to discover the cost of manufacturing eyeshadow on the environment, especially with an increase in the demand of cosmetics. The manufacturing of eyeshadow palettes results in the emissions of greenhouse gases, through the acquisition of materials and distribution, while contributing to large amounts of waste after its use due to the lack of recyclable materials.

One of the primary ingredients found in all eyeshadows is talc, which is used to absorb moisture and improve the overall quality of the product. Through the acquisition of talc, researchers found that “the primary pollutants of concern in talc processing are particulate matter” (US EPA). Particulate matter represents solid and liquid particles found in the air, such as dirt and soot. Such particles can pose serious health problems, should a large amount be inhaled or enter your bloodstream. As a result, the increase of talc needed for eyeshadows, leads to more particulate matter into the environment. In a talc mining site in Vermont, researchers found that the “highest observed exposures were for mining jobs involving the operation of heavy equipment to break up, move, or load raw ore from the mines and milling or shipping jobs involving the crushing of raw ore, cleaning and drying of processed talc, and bagging and packaging of the final talc product” (Rossner, Alan). Individuals working in the talc processing industry have a high exposure to particulate matter, which can lead to breathing problems. Workers are not the only individuals affected by the increase in particulate matter, as it can lead to visible haze within the area and can worsen the air quality. Acquiring materials used for eyeshadow palettes, such as talc, can have effects on the environment and continues to have an effect once undergoing the manufacturing process.

With approximately 5,000 companies producing cosmetic products, such as eyeshadow, in China, the manufacturing process can lead to waste and emissions that are detrimental to the environment. Because of the many companies that produce their products in China, “manufacturing agglomeration significantly aggravates haze pollution” (Liu, Jun) as the demand for eyeshadow increases. In this study, researchers found that as sales for an item increase, the need for more products increases, which results in creating more production plants to meet the demand. Little emphasis is placed on creating production sites that are sustainable, as the need for eyeshadow palettes are so great. As more individuals are becoming aware of the rising issue of climate change, studies have shown that policies that reduce environmental impacts of cosmetic productions “should focus on countries with a higher level of production, which are the major polluters” (Ponce, Pablo and Alvarado, Rafael). There are policies in hopes of decreasing the effects of pollution from manufacturing, however, they do not focus on the major polluters. With no focus on the countries responsible for the increasing amount of air pollution, countries are able to continue their manufacturing process, with no regard for the effects. Once the eyeshadow palettes have been manufactured, they must be distributed to outside areas in order to reach their consumers.

Distribution of eyeshadow palettes can either be through planes, ships, or through trucks, with each having their own effects on the environment. One of the primary methods of exporting goods is through aviation, however, “36% of anthropogenic sulfur dioxide, 27% of nitrogen oxides, 22% of carbon monoxide, and 17% of black carbon emitted in China were associated with production of goods for export” (Lin, Jintai). Transporting eyeshadow palettes inevitably leads to air pollution as most consumers are not in the area that they were created. Shipping goods by sea can be just as detrimental to the environment “because it is difficult to detect violations at sea and often impossible to link debris with a particular ship” (Culin, Jelena and Bielic, Toni). In that same study, the researchers wrote “legislation is often ignored by other types of vessels and shipping still significantly contributes to plastic pollution”, meaning that ships are able to contribute to plastic pollution without being held responsible. While the effects of air pollutants may not be as high as shipping goods by air, shipping by sea can lead to the increase of plastic within the ocean. Factors such as losing cargo or shipwreck can result in the eyeshadow palettes being left in the sea. Since plastic is not biodegradable, the plastic for the palettes will continue to float around in the sea. Not only do the palettes need to be shipped between countries, but they also need to be distributed within and reach the stores that sell them. This travel between manufacturing sites to the commercial stores contributes to the pollution within the air and increase in carbon dioxide. After reaching the stores and into the homes of the consumers, the eyeshadow palettes can continue to negatively affect the environment, based on the habits of the user.

While in use, eyeshadow palettes typically do not have any effects on the environment, however, there still continues to be negative effects, especially towards the health of the user. When studying the effects of applying makeup in a powder form, they found that “78% of aerosol deposition occurred in the head airways, while less than 2.5% was deposited in the tracheobronchial region, and less than 1% was deposited in the alveolar regions” (Oh, Hyeon-Ju and Kim, Jongbok). Aerosols are characterized as tiny particles that can be inhaled or absorbed through the skin and may affect the user’s breathing pattern. Through the act of cleaning makeup brushes used for eyeshadow or washing one's face, “hazardous chemicals of households or industrial drainage of cosmetics materials may be discharged into effluents of water causing high threat to human health” (Awad, A.M. and NAA Chany). The leftover particles of eyeshadow palettes can eventually lead to the water, contributing to the negative effects of wastewater. Eyeshadow palettes are responsible for some of the chemicals found in wastewater.

During the waste management stage, the plastic that holds the eyeshadow itself may be recyclable based on the plastic it is made out of, however, many palettes still end up in landfills. While completing a study in Chennai, India on the effects of trash sites on air quality, researchers found that “unloading, compaction, tipping of MSW, and open waste burning were found to be deteriorating the local air quality” (Peter, Anju E. and Nagendera, S.M.S). Although eyeshadow palettes are not the only products ending up in landfill, they do contribute to the rising amount of trash. Some companies, such as MAC Cosmetics, take back old eyeshadow palettes and reuse the plastic, in hopes to reduce waste. On the MAC website, their “Back to MAC'' initiative states, “Upon returning six empty M∙A∙C makeup containers...consumers can choose a standard M∙A∙C lipstick of their choosing as a thank you.” While the Back to Mac initiative hopes to minimize the environmental effects of their products, there is no information on their website that informs the consumer what happens to their products after they return it. They do not indicate whether the plastic containers are recycled or whether they actually end up in waste. Another drawback to these initiatives is that many consumers are not aware that they exist. This means that many individuals still throw their items in the trash, which results in the increasing amount of waste in landfills. Eyeshadow palettes can continue to have harmful impacts on the environment even after they have been thrown into landfills.

The life cycle of eyeshadow palettes can have negative effects on the environment, not only through the manufacturing and distribution process, but through the acquisition of materials and waste management processes as well. Our group wanted to research the effects manufacturing eyeshadow has on the environment, considering the increase in popularity of makeup in recent years. While makeup has now become a hobby that many individuals enjoy, companies must do their part to minimize the effects it has on the environment. Some makeup companies have been making changes in their manufacturing processes of eyeshadow palettes in order to reduce the damage, such as using different materials or using sustainable methods. Individuals should be able to enjoy the act of putting on makeup, as it provides a sense of self confidence. However, they also must be mindful of how detrimental the hobby can be. It is easy to forget the environmental impacts of a product, considering that most of the effects usually take place before the product ends up in the consumers hands. Due to the increasing demand of eyeshadows, companies must make changes to not allow the negative effects to increase in the future.

Works Cited

Awad, A. M., and NAA Ghany. "Electrochemical Advanced Oxidation of Cosmetics Waste Water using IrO Sub(2)/Ti-Modified Electrode." Desalination and Water Treatment, vol. 53, no. 3, 2015, pp. 681-688. ProQuest, https://www.proquest.com/scholarly-journals/electrochemical-advanced-oxidation-cosmetics/docview/1691296376/se-2?accountid=14505, doi:http://dx.doi.org/10.1080/19443994.2013.848671.

Culin, Jelena, PhD., and Toni Bielic PhD. “Plastic Pollution from Ships”. Croatian Association of Maritime Science and Transport, Rijeka, 2016. ProQuest, https://www.proquest.com/reports/plastic-pollution-ships/docview/1903327062/se-2?accountid=14505.

Guosheng Ma, Juan Chen. “Nitrogen and Phosphorus Pollutants in ... - Iopscience.” IOP Science, 2018, https://iopscience.iop.org/article/10.1088/1755-1315/113/1/012051/meta.

Lin, Jintai et al. “China's international trade and air pollution in the United States.” Proceedings of the National Academy of Sciences of the United States of America vol. 111,5 (2014): 1736-41. doi:10.1073/pnas.1312860111

Liu, Jun et al. “The Effect of Manufacturing Agglomeration on Haze Pollution in China.” International journal of environmental research and public health vol. 15,11 2490. 8 Nov. 2018, doi:10.3390/ijerph15112490

Oh, Hyeon-Ju, and Jongbok Kim. “Characterization of Inhalable Aerosols from Cosmetic Powders and Sustainability in Cosmetic Products.” MDPI, Multidisciplinary Digital Publishing Institute, 4 Oct. 2020, https://www.mdpi.com/2071-1050/12/19/8187.

Peter, Anju E., and S. M. S. Nagendra. "Dynamics of PM2.5 Pollution in the Vicinity of the Old Municipal Solid Waste Dumpsite." Environmental Monitoring and Assessment, vol. 193, no. 5, 2021, pp. 281. ProQuest, https://www.proquest.com/scholarly-journals/dynamics-pm2-5-pollution-vicinity-old-municipal/docview/2515064990/se-2?accountid=14505, doi:http://dx.doi.org/10.1007/s10661-021-09052-8.

Ponce, Pablo, and Rafael Alvarado. “Air pollution, output, FDI, trade openness, and urbanization: evidence using DOLS and PDOLS cointegration techniques and causality.” Environmental science and pollution research international vol. 26,19 (2019): 19843-19858. doi:10.1007/s11356-019-05405-6

Riddler, M. “Cosmetics Industry in the U.S. - statistics & facts”. Statista, 24 August 2021. https://www.statista.com/topics/1008/cosmetics-industry/#topicHeader__wrapper

Rossner, Alan et al. “Analysis of Historical Worker Exposures to Respirable Dust from Talc Mining and Milling Operations in Vermont.” Annals of work exposures and health vol. 64,4 (2020): 416-429. doi:10.1093/annweh/wxaa010

Schlummer, Martin, et al. "Emission of Perfluoroalkyl Carboxylic Acids (PFCA) from Heated Surfaces made of Polytetrafluoroethylene (PTFE) Applied in Food Contact Materials and Consumer Products." Chemosphere, vol. 129, 2015, pp. 46-53. ProQuest, https://www.proquest.com/scholarly-journals/emission-perfluoroalkyl-carboxylic-acids-pfca/docview/1671211800/se-2?accountid=14505, doi:http://dx.doi.org/10.1016/j.chemosphere.2014.11.036.

“Talc Processing”. United States Environmental Protection Agency, Office of Air Quality Planning and Standards. July 1995. https://www3.epa.gov/ttnchie1/ap42/ch11/bgdocs/b11s26.pdf. Accessed November 21 2021