Design Life-Cycle

assess.design.(don't)consume

Nealah Lee

Design 40A

Dr. Christina Cogdell

4 December 2019

Raw Materials in the Production of a Beautyblender®

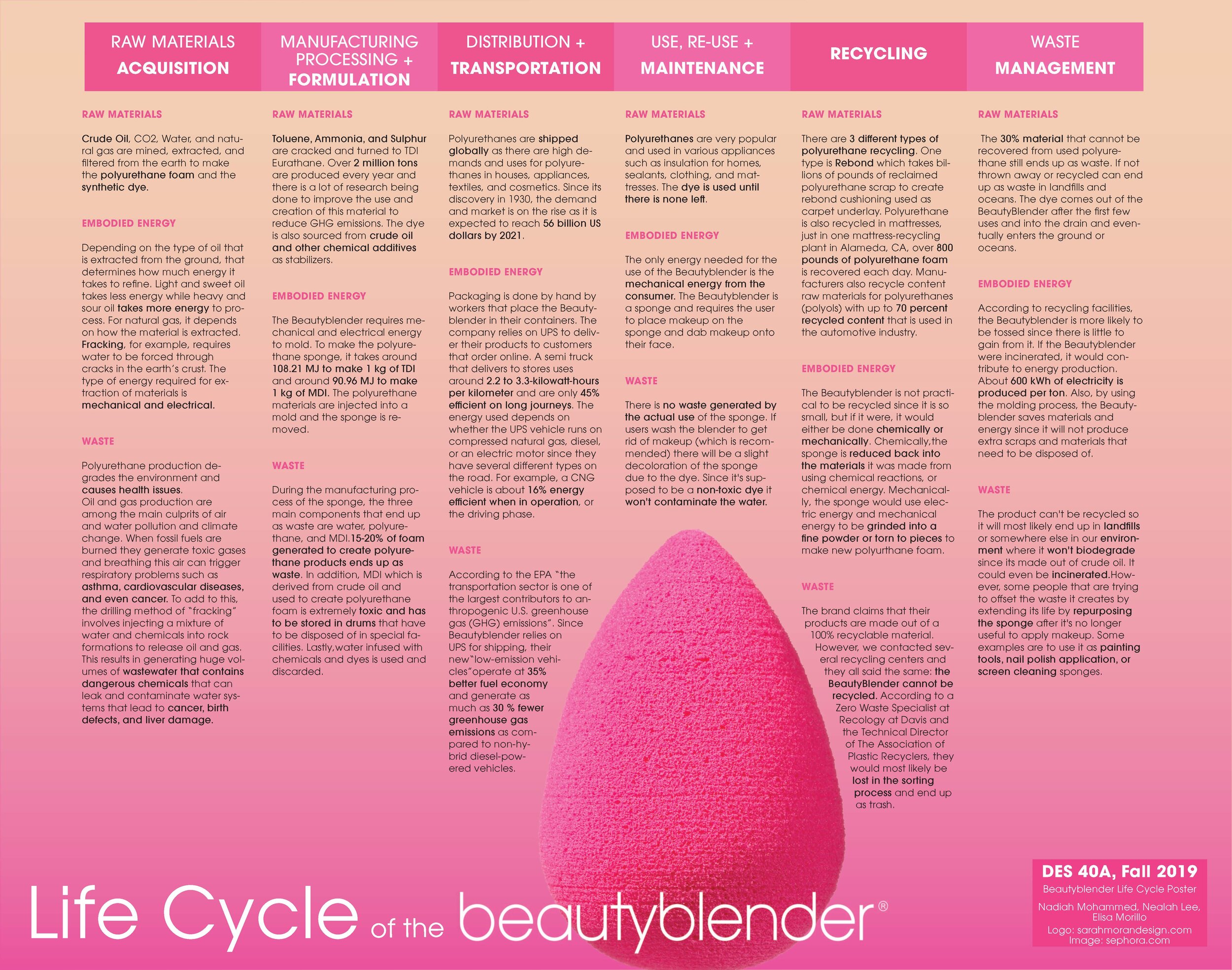

Made in the United States, the Beautyblender® make-up sponge has shaped the cosmetics industry. Produced by Rea.deeming Beauty Inc., the original BeautyBlender®(BB) has disrupted the traditional ways of applying makeup with this revolutionary sponge. Reaching $150 million dollars in sales in 2018 alone, this bright pink egg shaped sponge has continued to change the beauty consumer industry (“Beautyblender Redefines Consumer Cosmetics Market”). and is sold in major retailers such as Macy’s, Sephora and Ulta. The Beautyblender® is a popular reusable sponge and though it is small in size, contributes to the growing masses of garbage in designated landfills and litter on land and in oceans. Despite these accumulating numbers, Beautyblender® recommends its users to replace their sponge every three months and promotes themselves as an eco-conscious brand. However, the materials that make up the BeautyBlender® are derived from fossil fuels and synthetic chemicals which emit and release harmful greenhouse gases into our atmosphere which can affect larger ecosystems. From our research, the raw materials that compose the Beautyblender® are polyurethane, water, and synthetic acid based dyes that contribute to pollution in our environment and add to the toxic waste sitting in landfills while using large amounts of energy.

In this paper, I will address the raw materials that make up the Beautyblender® sponge and the dye in the life cycle assessment. The Beautyblender® is an edgeless shaped polyurethane foam that absorbs water and is dyed a pink color. Though Beautyblender® markets itself to be a recyclable product, in reality, the acquisition of polyurethane materials and copious amounts of synthetic chemicals and water outweigh the benefits of recycling a small sponge. The creation of the Beautyblender® is complicated because each of the materials needs to be chemically processed. The main materials of the Beautyblender® is the sponge foam and the dye. The sponge comes from polyurethane—a petroleum-based product. Polyurethanes exist in a variety of forms ranging from foams, adhesives, coatings, and sealants. The Beautyblender® sponge takes a common open-cell type of polyurethane foam that is also used in bedding and cushions (The Foam Factory). This open-cell foam is actually divided into two sub-categories; ester-based and ether-based polyurethane. Both types look very similar but they each have their own set of traits. Ester-based polyurethane is slightly more rigid and supportive than Ether-based foams which are more flexible and better at handling wet environments (“Ether and Ester- Based Polyurethanes”). Due to the air-y and porous structure of the Beautyblender®, I have assumed the formula takes the ether-based polyurethane due to its ability to absorb water.

The primary material of the Beautyblender® is polyurethane and the principal raw materials for polyurethane precursors are crude oil and natural gas (World Petroleum Council). Polyurethane requires refinement of crude oils, copious amounts of water, chemicals and other stabilizers. These chemicals that make up polyurethanes are formed by reacting a polyol. A polyol is an “alcohol with more than two reactive hydroxyl groups per molecule with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives,” (“How Polyurethane is Made”). From this primary raw material, Methylenediphenyl diisocyanate (MDI) and Toluene diisocyanate (TDI) are a family of organic chemical compounds are often referred to as diisocyanates and are the chemicals that form the building blocks of polyurethane. (“Frequently Asked Questions about Polyurethanes”). When these diisocyanates take either the MDI or TDI forms, they can be manipulated and produced to meet other specifications. The Beautyblender® most likely uses TDI, “Toluene diisocyanate which is primarily for flexible foam applications including furniture, bedding and carpet”. “TDI is obtained by nitration of toluene, the hydrogenation of dinitrotoluene is then obtained to produce toluenediamine (TDA), which is in turn reacted with phosgene to form TDI,” (“Diisocyanates Explained-American Chemistry”). TDA is formed when the crude oil is refined to Natural Gas as Toluene which is combined with Ammonia and Sulphur to create TDA production that is formed into TDI production (Boustead). During the formation process, carbon dioxide is used as a blowing agent to create that soft, comfortable feel of a mattress or sofa. The “more blowing agent is used, the softer the resulting foam,” Since the Beautyblender® seems to be made of a softer foam, it most likely uses a good deal of CO2 to give it the desired lightweight bouncy feel and function as an applicator (“Science and Research on Polyurethanes”). According to the American Chemistry Council, polyurethane “is one of the most widely produced plastics in the world… tens of millions of tons are produced worldwide each year.” These two materials can be found in many products today because polyurethane is the main source of many items such as mattress foams, home insulation, clothing and roofing. Since polyurethane is extracted from crude oils, and there are two different ways this can be done through modifying a natural gas or through catalytic cracking of crude oil to gasoline. Both methods cause major environmental consequences ranging from pollution to releasing additional greenhouse gases to depletion of limited resources. The polyurethane industry is currently exploring ways of increasing the energy efficiency of manufacturing processes due to polyurethanes expensive process and its wide use in not just fabric products but as insulation and coatings. The future is likely to bring further improvements in production processes, resulting in less expensive and even more environmentally friendly polyurethanes (Polyurethanes and Sustainability).

In addition to its unique edgeless shape- its iconic pink color is from a “non-toxic, water-soluble dye (Beautyblender). For this reason “your Beautyblender® may shed dye for the first couple of washes – similar to a pair of blue jeans” (Beautyblender). Though Beautyblender® does not disclose this directly, from our research, the pink color is most likely taken up by the polyurethane foam as an alkaline direct dye (Patwary, Mohammad Zillane, and Nur). Since it is a water soluble dye, its formula is most likely that of an Azo compounds which are “ water-soluble compounds...that have vivid colors, especially reds, oranges, and yellows,” Azo dyes are the most important group of synthetic colorants and represent the largest class of dyes in use today and widely used in a number of industries such as textile, cosmetics, and paper printing (Ziarani, Ghodsi Mohammadi). Azo Dyes are the simplest of dyes to produce but are derived from a not so simple process. The primary material to make Azo compounds for dyes are from cracking chemicals from crude oils and adding other chemicals and stabilizers. There are five basic steps to creating the general formula of the Azo dye, the color and pH levels vary per desired outcome. The steps are as follows: diazotization, coupling, isolation-filtration, drying, grinding, and standardization. The diazotization process involves strong acids like Hydrochloric Acid and Sodium Nitrite, with ice to control the temperature. Already in the first step of creating the dye, harsh acidic chemicals and water are used to produce a certain color. After that, coupling and isolation-filtration requires a salt along with adjusting the temperature and a dryer (Bernard). The raw materials in just creating both the polyurethane sponge and synthetic dye for the overall creation of the Beautyblender® is derived from fossil fuels and CO2. These make up sponges are sold worldwide which also require gasoline and other fossil fuels to be shipped from Rea.Deeming Beauty in Pennsylvania to getting packaged and getting to stores.

According to the Beautyblender website, to recycle the sponge “just plop them into your recycling bin” (Beautyblender). Though Beautyblender® makes the recycling process seems so simple yet in reality, recycling the make- up sponge requires a lot of water and fossil fuels just to ship the sponge to the recycling plants that it outweighs the benefits of recycling the sponge. The limiting factor is the sponge itself which wears down with use. In order to properly maintain the make-up sponge requires soap and water, which leads to buying another sponge which is expected to last the user another 3 to 4 months. The only new raw material that enters in at this step is the fossil fuels that transport the sponge to the retail stores, the garbage, or the recycling plant.

Overall, the acquisition of materials, production and disposal of the Beautyblender® is harmful to the environment. In this paper I highlighted how to obtain the key raw materials, to mass production, to distribution/sale, then to usage and eventually to the landfill. From the examples I have provided, we can conclude that the life cycle of the Beautyblender® is a long and complicated process that involves two of the highest world polluting corporations, manufacturing plastics and synthetic dyes. Both creation and use processes are very intertwined which is why it is hard to estimate the exact amounts of water needed to make and use the Beautyblender®. Though efforts are currently being made to do research to reduce the environmental impact of polyurethanes, the testing process and the large scale usage of polyurethanes over time will lead to depletion of natural gas resources and pollution of our landfills. In addition, the company recommendation of replacing a sponge every 3 months in addition to cleaning your sponge after every use with soap and water will continue to have a negative impact on the environment unless a solution is found that could reduce the amount of crude oil needed to make the Beautyblender® and other polyurethane based products.

Bibliography

“Ether and Ester-Based Polyurethane Foam: Characteristics, Differences and Uses.” The Foam Factory, https://www.thefoamfactory.com/blog/index.php/ether-and-ester-based-polyurethane-foam-characteristics-differences-and-uses.

“Frequently Asked Questions on Polyurethanes.” Polyurethanes in Frequently Asked Questions on Polyurethanes, http://www.polyurethanes.org/en/faqs.

Bernard, James “How Do You Make an Azo Dye?: First Source Worldwide, LLC.” First Source Worldwide, 3 Mar. 2017, http://www.fsw.cc/azo-dye/.

Boustead, I “Polyurethanes in Welcome to Polyurethanes.org.” Polyurethanes in Welcome to Polyurethanes.org, http://www.polyurethanes.org/uploads/documents/eco_tdi.pdf

World Petroleum Council “How Is Crude Oil Turned into Finished Products?, https://www.world-petroleum.org/edu/223-how-is-crude-oil-turned-into-finished-product.

NetSuite.com. “Beautyblender® Redefines Consumer Cosmetics Market.” NetSuite, https://www.netsuite.com/portal/customer-testimonials/beauty-blender-beauty.shtml.

Patwary, Mohammad Zillane, and Nur. Textile Fashion Study, 4 May 2012, http://textilefashionstudy.com/direct-dyes-properties-of-direct-dyes/.

“Polyurethanes.” How Polyurethane Is Made, https://polyurethane.americanchemistry.com/How-Polyurethane-is-Made/.

“Science and Research on Polyurethanes.” Polyurethanes in Science and Research on Polyurethanes, http://www.polyurethanes.org/en/what-is-it/science-research.

The Foam Factory, Open Cell Foam, Conventional Foam, Foam Sheets, Foam Slabs, https://www.thefoamfactory.com/opencellfoam/opencellfoam.html.

“THE ORIGINAL BEAUTYBLENDER®.” Beautyblender, https://beautyblender.com/products/beautyblender-original.

Ziarani, Ghodsi Mohammadi, et al. “Azo Dyes.” Metal-Free Synthetic Organic Dyes, Elsevier, 27 July 2018, https://www.sciencedirect.com/science/article/pii/B9780128156476000042?via=ihub#abs0010.

Nadiah Mohammed

Design 40A

Dr. Christina Cogdell

4 December 2019

Beautyblender: Embodied Energy

Rea Ann Silva, the founder of the Beautyblender, is a makeup artist who was searching for a tool that did it all and created it soon after. The iconic pink egg-shaped makeup sponge leaves a dewy finish by absorbing water and allowing the makeup to sit on top of the sponge rather than being soaked in. According to the company, the“aqua-activated foam” prevents the wasteful use of makeup prevalent with normal makeup sponges. Throughout my research, I constantly asked myself, “What is aqua-activated foam?” Beautyblender, which has copyrighted the term “aqua-activated foam,” reveals only that the foam is non-latex, but does not disclose any ingredients that actually compose the sponge. Although the lack of latex is good for those with a latex allergy, further investigation revealed that the sponge is made from a material just as harmful to the environment as latex. By researching similar companies and sponge specialist sites, I have found that the iconic pink egg is nothing but polyurethane foam.

Throughout this paper, I will address the energy that is needed for the acquisition of raw materials, the production and distribution of the product, and the disposal of the Beautyblender sponge. By researching the life cycle of the Beautyblender, I was able to assess the embodied energy for the product. Beautyblenders are foam makeup sponges that gained popularity in 2007, priced at 20 dollars apiece and have sold over 6.9 million sponges since then (Shah). According to the Beautyblender official website, the sponge is an “environmentally friendly product that would last several months,” whereas traditional makeup sponge are single-use (Housenick). The website also describes the material they use as an “aqua-activated foam,” but the process of manufacturing the foam is more harmful to the environment than what the company reveals. Throughout this entire process from extraction to disposal, the Beautyblender takes a significant amount of energy to produce. The Beautyblender especially needs large amounts of energy to produce polyurethane foam to create the product.

The Beautyblender is made of water-soluble dye and polyurethane foam. The water-soluble dye is from Azo compounds, which are sourced from crude oils that use mechanical energy to be refined (“How Do You Make an Azo Dye?: First Source Worldwide, LLC.”). The Azo compounds are unstable and use a lot of chemical energy as well. The dyes also require electrical energy for temperature regulation for the ice that is used in the cooling process. For the polyurethane foam, according to a report by Boustead for PlasticEurope, the raw materials used are natural gas and crude oil. Natural gas is extracted mechanically through drilling, fracking, or acidizing (“Natural Gas”). It is then transported in liquid form and must be cooled to around -260 degrees Fahrenheit, necessitating large amounts of electricity. Trucks must then transport the natural gas to polyurethane production facilities, where it is first used to make polyols and diisocyanates which are needed to create a high-quality foam (“Polyurethanes”). Polyols are needed to create a flexible foam and are made through an alkylene polymerization process. The diisocyanates required are known as tolylene diisocyanate (TDI) and diphenylmethane diisocyanate (MDI). MDI requires crude oil, and the amount of energy it takes to refine the oil depends on the type. Light and sweet oil takes less energy to refine whereas heavy and sour oil takes a lot more energy. Natural gas is added to the mix after the oil is refined, leading to a chemical reaction that produces MDA. Sodium chloride and more natural gas are added to the MDA, which results in the creation of MDI. The process of creating TDI is very similar to the MDI process. Both MDI and TDI require other raw materials to be produced, such as biomass, sodium chloride, nitrogen gas, and limestone. The energy required to fuel the production and delivery of 1 kg of TDI is about 16.46 MJ. The total energy required for the entire process, which includes the energy needed for production, delivery, transport, and feedstock energy, to create just 1 kg of TDI is 108.21 MJ (Boustead). The most common fuel sources for TDI production include coal, gas, oil, and nuclear energy. Similarly, a total of 90.96 MJ is required to produce 1kg of MDI. As shown, the entire process of extracting and creating materials for the Beautyblender takes a lot of energy.

Chemical and mechanical types of energy are used to create polyurethane foam. Flexible polyurethane foam, like the Beautyblender, represents 31% of all polyurethanes produced. As stated before, the main materials used to create polyurethane foam are crude oil and natural gas. The main chemical components of polyurethane foam are TDI and MDI, which must be handled according to the specific guidelines set by the American Chemistry Council. MDI, for example, must be transported to the manufacturer in cool temperatures. The raw materials, polyols and isocyanates, are kept in tanks that use electricity to agitate the mixture to keep the materials in liquid form. Next, the materials are pumped out from a metering device to insert the correct ratio of materials needed to make polyurethane foam. Since a lot of heat is created during the reactions, the process requires a heat exchanger that maintains the materials’ desired temperature for reactions. Having a heat exchanger is beneficial to the process of making polyurethane foam since it eliminates the loss of heat, and therefore the loss of energy (“Heat Exchangers: How They Work, and Why They Are Needed.”). When the materials are moved into the pipes, a polymerization reaction occurs and once the materials move to the end of the pipe, polyurethane is created. As opposed to rigid polyurethane foam, flexible polyurethane foam for the Beautyblender is created through a molding process. Individual Beautyblenders use a mold to create the unique shape and avoid any rough edges. The chemical reaction takes place inside the mold, and during this process, the dye can be added as well. This creates a perfect shape each time. The process of molding saves materials and energy (“Processing Polyurethane Foam - Machining vs Cast Molding.”). The process does not require to make large amounts of foam and cutting them up with machines, so it reduces the waste disposal of the excess unused foam.

Beautyblender relies on workers to package their products, or mechanical energy, as shown in a video from the YouTube Channel Harper’s BAZAAR, who got an inside tour of how the finished Beautyblender is packaged. The Beautyblenders are most likely taken straight from the destination where they were produced to the packaging facility, Rea.deeming Beauty Inc., by a shipping truck. Trucks that ship materials are usually semi-trucks powered by diesel. The amount of energy required to power a diesel truck is around 2.2 to 3.3-kilowatt-hours per kilometer and they have up to 45% energy efficiency on longer journeys (Business Insider). So, the further the manufacturing plant is from the packaging plant, the more energy it takes to ship the Beautyblenders. They are packaged by hand and are shipped in cardboard boxes. Each Beautyblender is taken from the box and placed in the final packaging that is found in the store. If a store is far away, or across the country from a shipping center, shipping by plane may be best. When delivered by air, the plane uses about 6,900 kJ per tonne-kilometer (“Energy Efficiency in Transport”). The product is sold both in-store and online. For those that do not want to leave the comfort of their home and have the makeup sponge shipped to their door, it takes quite a bit of energy as well. According to the Beautyblender official website, the company relies on UPS as their main source of shipping of their products. UPS states that the core of their company is to be environmentally friendly and they have been putting in the effort these past couple of years. Through the addition of electric vehicles and compressed natural gas as an alternative to diesel, UPS demonstrates that they care about the impact they have on the environment. The vehicles they expect to have in the future are electric and will use less energy, but that does not change the trucks they have now. Out of 108,000 vehicles they use for delivery, only 770 of those use a hybrid or electric motor (Williams). However, once they convert the motor of at least 1,500 vehicles, the company said it will be at least 20 percent more efficient in energy usage. They also have plans to add vehicles powered by CNG or compressed natural gas by 2022 (Gilroy). However, CNG powered vehicles lose around 84% of energy during the driving stage of the vehicle, so it is not as energy efficient in terms of operation (U.S. Department of Energy). Overall, the energy required to transport and deliver is not very efficient, but the companies involved with the shipping of Beautyblender and other products are interested in vehicles with less environmental impact than a regular diesel vehicle.

Once the product is purchased the consumer uses mechanical energy to apply the makeup with the sponge. This is the least amount of energy used in the life cycle of the Beautyblender. The energy needed to manufacture and produce the Beautyblender actually exceeds the energy needed during the “use” stage. The product is only to be used for three months and the company then recommends recycling it according to their official website.

While the Beautyblender can be recycled, it takes a lot of energy to do so and there is little to gain from it. The Beautyblender website claims that the makeup sponge can be tossed, “into your recycling bin at home”. However, this can lead to recycling contamination, a huge epidemic in the United States. In California, around 1,000 plants for recycling have been shut down due to the overflow of recycling contamination (Rachelson). The sponge may pose a serious threat to the process since the sponge may still have makeup residue. If recycled, flexible polyurethane foam should ideally be shredded mechanically or chemically. For example, the sponge could be grinded into a fine powder that could be used to create a new foam, but this process takes up more energy. The sponge can also be chemically recycled by using chemical reactions to break down the foam into the materials that were used to create the foam. Processes like glycolysis, hydrolysis, pyrolysis, and hydrogenation require chemical energy to complete (American Chemistry Council). However, the Technical Director of The Association of Plastic Recyclers said that even if the makeup sponges were recyclable, it would be lost in the sorting process and not very profitable. There is not much gain from recycling a small sponge and they would rather toss it. Even on a small scale, it is still not viable to use energy to get little benefit out of this sponge. If the Beautyblender were to be incinerated instead, the energy produced through incineration is about 500 to 600 kWh of electricity per ton (“Waste-to-Energy Plant.”). Incinerating the sponge would be more beneficial in contributing to the production of electricity rather than raw materials for new polyurethane and polyols. The company claims that their product can be recycled if they are tossed in the correct bin, but they do not accept used Beautyblenders at their corporate office to help with the process. A polyurethane sponge is recyclable, but that does not mean it will be recycled by processing facilities as the company intended.

In this paper, I demonstrated the energy that is needed for the acquisition of raw materials, the production and distribution of the product, and the disposal of the Beautyblender sponge. By researching the life cycle of the Beautyblender, I was able to assess the embodied energy for the product. Beautyblenders claim that they are environmentally friendly and are a better alternative to other sponges on the market, but their reduced environmental impact is limited. They have hidden their ingredients and processes through copyrighted names like “aqua-activated foam” and phrases like “water-soluble dye.” Researching the Beautyblender was very difficult due to this and we were only able to get a rough estimate of the embodied energy of the life cycle . Overall, the Beautyblender claims that their product is “eco-friendly,” but after researching the product and the energy used—it is more harmful than it seems.

Bibliography

Boustead . “Diphenylmethane Diisocyanate (MDI) .” Eco-Profiles of the European Plastics Industry Diphenylmethane Diisocyanate (MDI) , PlasticsEurope, Mar. 2005, http://www.polyurethanes.org/uploads/documents/eco_midi.pdf.

Boustead . “Tolylene Diisocyanate (TDI) .” Eco-Profiles of the European Plastics Industry Tolylene Diisocyanate (TDI) , PlasticsEurope, Mar. 2005, http://www.polyurethanes.org/uploads/documents/eco_tdi.pdf

Covestro. “Molded Flexible Foam: Technology by Covestro.” Molded Flexible Foam | Technology by Covestro, https://www.solutions.covestro.com/en/highlights/articles/theme/processing-technology/molded-flexible-foam.

“Embrace Sustainable Makeup And Recycle Your Beautyblender.” Beautyblender, https://beautyblender.com/blogs/beauty-101/sustainable-makeup-recycle-your-beautyblender.

“Energy Efficiency in Transport.” Wikipedia, Wikimedia Foundation, 27 Nov. 2019, https://en.wikipedia.org/wiki/Energy_efficiency_in_transport.

“Environment.” Polyurethane Foam Association, https://pfa.org/environment/.

“FAQ: Beautyblender®.” Beautyblender, https://beautyblender.com/pages/faqs.

Gantrade. “Methylene Diphenyl Diisocyanate (MDI) - Essential Building Blocks for Polyurethanes.” Methylene Diphenyl Diisocyanate (MDI) - Essential Building Blocks for Polyurethanes, 2 Nov. 2018, https://www.gantrade.com/blog/methylene-diphenyl-diisocyanate-mdi-essential-building-blocks-for-polyurethanes.

General Plastics ManufacturingMay. “Processing Polyurethane Foam - Machining vs Cast Molding.” AZoM.com, 23 May 2019, https://www.azom.com/article.aspx?ArticleID=18041.

Gilroy, Roger. “UPS Invests $450 Million in CNG Trucks, Stations.” Transport Topics, 9 Oct. 2019, https://www.ttnews.com/articles/ups-invests-450-million-cng-trucks-stations.

“Guidelines for Receiving and Unloading MDI .” Transportation, American Chemistry Council, Oct. 2014, https://polyurethane.americanchemistry.com/Resources-and-Document-Library/3856.pdf.

Housenick, Mandy. “Cosmetic Company Makes Its Mark with Beautyblender.” Mcall.com, The Morning Call, 29 Mar. 2019, https://www.mcall.com/business/mc-outlook-small-manufacturers-20160319-story.html

“How Do Heat Exchangers Work?” Explain That Stuff, 8 Dec. 2018, https://www.explainthatstuff.com/how-heat-exchangers-work.html.

“Inside UPS's Electric Vehicle Strategy.” UPS, https://www.ups.com/us/es/services/knowledge-center/article.page?kid=ac91f520.

Moynihan, Ruqayyah. “Electric Trucks like the Tesla Semi Are 'Pointless Both Economically and Ecologically,' According to a Vehicle-Tech Expert.” Business Insider, Business Insider, 3 Apr. 2019, https://www.businessinsider.com/this-expert-says-tesla-semi-is-economically-and-ecologically-pointless-2019-2.

National Geographic Society. “Natural Gas.” National Geographic Society, 9 Oct. 2012, https://www.nationalgeographic.org/encyclopedia/natural-gas/.

“Polyurethane.” How Products Are Made, http://www.madehow.com/Volume-6/Polyurethane.html.

“Polyurethanes.” Polyurethane Recycling, https://polyurethane.americanchemistry.com/Polyurethane-Recycling/.

“Products.” Products | FoamSciences.com, http://www.foamsciences.com/products.php.

Romba, Phil. “The Case for Natural Gas Engines.” Transport Topics, 21 Sept. 2018, https://www.ttnews.com/articles/case-natural-gas-engines.

Silva, Rea Ann. "Cosmetic blotting tool and container system and method." U.S. Patent Application No. 15/056,941.

STI Group - Industrial, and Midstream & Fabrication Services. “Heat Exchangers: How They Work, and Why They Are Needed.” STI Group - Industrial, Midstream & Fabrication Services, 22 Sept. 2014, https://setxind.com/downstream/industrial-heat-exchangers-what-they-are-how-they-work-and-why-they-are-needed/.

“Using Natural Gas for Vehicles: Comparing Three Technologies.” Energy Efficiency and Renewable Energy, U.S. Department of Energy, https://www.nrel.gov/docs/fy16osti/64267.pdf.

“Waste-to-Energy Plant.” Wikipedia, Wikimedia Foundation, 27 Nov. 2019, https://en.wikipedia.org/wiki/Waste-to-energy_plant.

“What Is Recycling Contamination, and Why Does It Matter?” Rubicon Global: Waste, Recycling, and Smart City Technology Company, 15 Oct. 2019, https://www.rubiconglobal.com/blog/recycling-contamination/.

Williams, Brett. “UPS Has a Plan to Transform Diesel Trucks into Electric Vehicles.” Mashable, Mashable, 10 Nov. 2017, https://mashable.com/2017/11/10/ups-coverting-diesel-trucks-to-electric/.

Yang, Wenqing, et al. "Recycling and disposal methods for polyurethane foam wastes." Procedia Environmental Sciences 16 (2012): 167-175.

YouTube, Harper's BAZAAR, 5 Oct. 2017, https://youtu.be/PnBN0XDkzh8 .

Zia, Khalid Mahmood, Haq Nawaz Bhatti, and Ijaz Ahmad Bhatti. "Methods for polyurethane and polyurethane composites, recycling and recovery: A review." Reactive and functional polymers 67.8 (2007): 675-692.

Elisa Morillo

Design 40A Section 4

Dr. Cogdell

December 4, 2019

Beautyblender®: Waste and byproducts throughout the Lifecyle

The Beautyblender® (BB) is a famous pink egg-shaped makeup sponge used to apply makeup that gained popularity in the early 2000s. The past year it sold 9 million units and has sold over 50 million units since 2009 (Ocbazghi). The brand recommends users to replace the sponge every three months and promotes themselves as an eco-conscious and sustainable brand. However, the materials that make up the BB are derived from fossil fuels and synthetic chemicals that can't biodegrade and will contaminate our environment.

Throughout this paper, I intend to report the information that I have found regarding produced and emitted waste as byproducts of the lifecycle of the The BeautyBlender® (BB). I will examine the waste created by raw material extraction, manufacturing, delivery, usage, and end of life of the product.

The waste generated by the extraction of raw materials to create BB is colossal and contribute to pollution in our environment as well as health issues. The sponge is made out of polyurethane- which is produced by reacting polyols and diisocyanates, both products derived from crude oil and natural gas (Europur). The synthetic acid-based dye is made out of petrochemicals which are also derived from oil or natural gas (“Synthetic Dye”). To create polyurethane and synthetic dyes both oil and gas extraction methods are used which degrades the environment and causes health issues. Oil and gas production are among the main culprits of air and water pollution and climate change. There are 1.3 million oil and gas facilities in the United State varying from active production wells to processing plants (The Wilderness Society). In addition, more than 12 million people live within half a mile of these facilities, and many are exposed to air and water pollution daily, which can lead to an array of health issues (The Wilderness Society). When fossil fuels are burned they generate toxic gases and breathing this air can trigger respiratory problems such as asthma, cardiovascular diseases, and even cancer (The Wilderness Society). To add to this, the drilling method of “fracking” involves injecting a mixture of water and chemicals into rock formations to release oil and gas (Plumer). This results in generating huge volumes of wastewater that contains dangerous chemicals that can leak and contaminate water systems that lead to fauna and flora getting sick or dying and humans experiencing cancer, birth defects, and liver damage (Plumer).

The manufacturing process of the BB also generates significant waste. During the manufacturing process, the two main components that end up as waste are chemically infused water and polyurethane foam. A study argues that 15% to 20% of foam generated to create polyurethane products ends up as waste. Besides, to create the foam and dye water is needed in large quantities. After water issued in various manufacturing stages, it gets contaminated and has to be discarded as waste. Besides, water infused with chemicals to create the sponge have to be discarded (“ Chemical Waste”). For example, MDI is a chemical that is derived from crude oil and used to create polyurethane foam. It is toxic and has to be stored in steel drums that have to be disposed of in special facilities (“Diisocyanates”).

Another aspect of the lifecycle of the BB that generates waste is the delivery and transportation of the sponge. “The transportation sector is one of the largest contributors to anthropogenic U.S. greenhouse gas (GHG) emissions” (EPA). The brand relies on UPS to deliver their product. However, BeautyBlender relies on UPS to deliver their sponges and they were an early adopter of cleaner vehicles, and today operates upwards of 2,500 low-emission vehicles that run on alternative fuels and technologies. They operate at 35% better fuel economy and generate as much as 30 % fewer greenhouse gas emissions as compared to non-hybrid diesel-powered vehicles (Scientific American). Although these trucks generate lower GHGs than regular vehicles they still generate a significant amount due to the many travels they perform. Every year more and more sponges are being created and sold which means more and more trucks that need to deliver them. Only last year there were over 9 million units sold that need to be transported to stores or directly to customers and all those trucks emit GHGs that contribute to pollution and climate change.

After the delivery of the sponge, the customers get to use the product. There is no waste generated by the actual use of the sponge. However, if users wash the blender to get rid of makeup (which is recommended) there will be a slight discoloration of the sponge that will leak into the water due to the dye. This will add chemicals to the water although there is no clear data regarding the toxicity or actual contamination of the water.

After 3 months of life, the brand suggests the users dispose of the sponge. The brand claims that their products are made out of a 100% material that is recyclable. They state, “Just plop them into your recycling bin”. However, we contacted several recycling centers and they all said the same; the BeautyBlender can't be recycled.

These are some of the responses from recycling centers I received via email:

· “We are unable to recycle any foam products at our facility including the BeautyBlender”

Sarah Benedict --Waste Zero Specialist at Recology™ Davis

· “There is no way that a polyurethane foam makeup sponge is recycled at industrial scale”

John Standish-- Technical Director at The Association of Plastic Recyclers (APR)

· “We do not recycle any polyurethane. Even if we did, an item as small as a makeup sponge would likely be lost in the sorting process and end up as trash.”

Kathy Evans--Berkeley Recycling Center

The message is clear: the product can't be recycled in facilities or even if it could it most likely be discarded as trash in the sorting process.

Even though the product can’t be recycled, some people are trying to offset the waste it creates by extending its life by repurposing the sponge after it's no longer useful to apply makeup. Some examples are to use it to clean leather products like shoes or purses or belts, clean screens, use for nail polish application, or use to paint.

Overall, BB claims their product is 100% recyclable and eco-friendly. Besides them utilizing UPS low carbon emission vehicles as a delivery method there is nothing eco-friendly about this product. It not only contributes to physical waste in landfills but the processes involved in making BB like oil and gas extraction contribute to climate change by increasing the annual emissions of greenhouse gasses (GHGs), as well as adding other contaminates our environment and harming human health. They state their product is made out of latex-free “aqua-activated foam” and non-toxic “water-soluble dye. They use such words to conceal the reality that the products are made out of crude oil and natural gas. This is a clear example of greenwashing since the materials used are not sustainable and contribute to environmental degradation and health issues. There is currently no way products made out of crude oil could be eco-friendly or sustainable. To add to this, when it comes to the end of life of the product the brand claims it can be recycled anywhere. However, we contacted several recycling centers and they all said the same; the BB can't be recycled. The best solution would be for the company to take responsibility for the recycling process and end of life of the product even though they currently don't. Even though, there are some people try to extend the life of the BB by repurposing it will still end up in landfills or somewhere else in our environment as trash.

Bibliography

“7 Ways Oil and Gas Drilling Is Bad for the Environment.” The Wilderness Society, https://www.wilderness.org/articles/blog/7-ways-oil-and-gas-drilling-bad-environment.

“Chemical Waste.” Chemical Waste - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/earth-and-planetary-sciences/chemical-waste.

“Diisocyanates.” Disposal of Waste MDI and Used MDI Storage Containers, https://dii.americanchemistry.com/Diisocyanates_Pages/Disposal_of_Waste_MDI_and_Used_MDI_Storage_Containers/.

“Fast Facts on Transportation Greenhouse Gas Emissions.” EPA, Environmental Protection Agency, 16 July 2019, https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions.

“How Much Have Package Delivery Companies Improved Their Fleets' Fuel Efficiency?” Scientific American, Scientific American, 8 June 2013, https://www.scientificamerican.com/article/greening-package-delivery-fleets/.

“Raw Materials.” Europur, https://www.europur.org/sustainabilty/raw-materials.

Ocbazghi, Emmanuel. “How the Beautyblender Became a Revolutionary Makeup Product.” Business Insider, Business Insider, 11 July 2019, https://www.businessinsider.com/how-beautyblender-became-revolutionary-makeup-product-rea-ann-silva-2019-7.

Plumer, Brad. “Fracking, Explained.” Vox, Vox, 31 July 2015, https://www.vox.com/2014/4/14/18076690/fracking.

“Synthetic Dye.” Synthetic Dye - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/engineering/synthetic-dye.

“THE ORIGINAL BEAUTYBLENDER®.” Beautyblender, https://beautyblender.com/products/beautyblender-original.

Zevenhoven, Ron. “TREATMENT AND DISPOSAL OF POLYURETHANE WASTES: OPTIONS FOR RECOVERY AND RECYCLING.” Helsinki University of Technology Department of Mechanical Engineering, 2003, http://users.abo.fi/rzevenho/tkk-eny-19.pdf