Design Life-Cycle

assess.design.(don't)consume

Nicholas Leaver

Life Cycle Analysis of Nestle Nescafe Instant Coffee: Materials

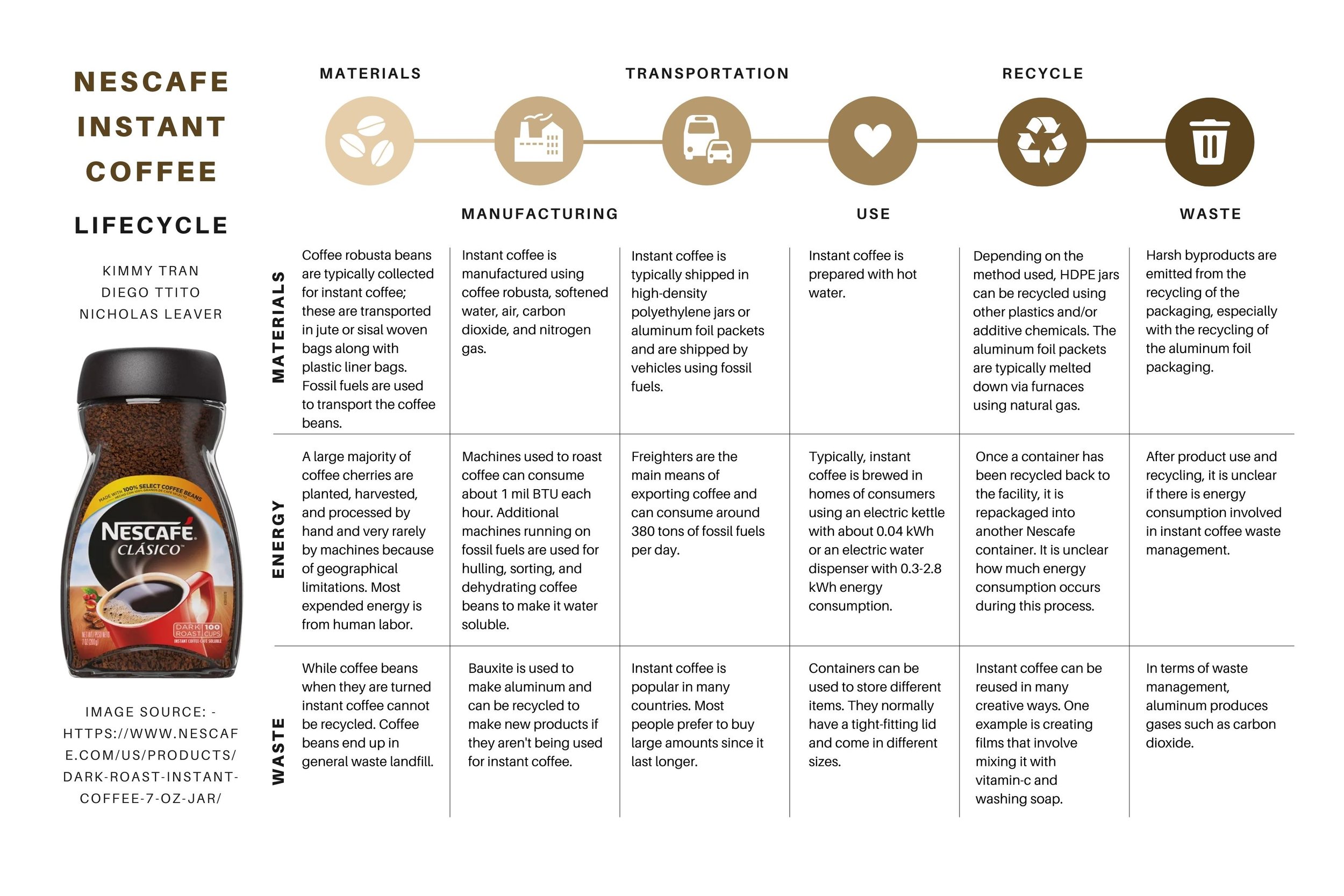

This paper will analyze the raw materials used throughout the life cycle of Nestle Nescafe instant coffee. The production of instant coffee began in the early 1900s, with the production of Nestle Nescafe starting in 1938 (Madehow, “Instant Coffee”). In 2020, the instant coffee industry reached a value of $12.1 billion USD, with the product gaining popularity in the Middle East, Eastern Europe, and Southeast Asia (Businesswire, “Global Industry Trends 2021-2026”). Instant coffee typically makes use of coffee robusta beans (Madehow, “Instant Coffee”) and, in the case of the Nescafe products, are typically packed in plastic jars (specifically, high density polyethylene) and aluminum foil packets. The transportation, manufacturing, and recycling processes of instant coffee utilize a large quantity of a variety of raw materials, many of which are non-renewable; with the popularity and demand of instant coffee increasing, the life cycle of instant coffee is unsustainable due to this use of materials.

1. Transportation of Coffee Beans

While a few of the materials used in the transportation of coffee are renewable, many of them are non-renewable and the use of these materials can be unsustainable. Coffee beans are one of the main materials used in the production of instant coffee; because of this, the transportation process of coffee beans plays a significant role in the life cycle of instant coffee. The materials used in this process include jute, sisal, plastic, and fossil fuels (TIS, “Coffee”). Coffee beans are typically transported by ship, railroad, or truck and are usually packed in clean woven jute or sisal bags (sometimes in addition to an inner plastic bag), which are then stored in shipping containers with plastic liner bags (TIS, “Coffee”). While the woven bags are made from renewable plant-based materials, larger quantities of non-renewable materials are used. The modes of transportation that are used for the transportation of coffee beans implies a large consumption of fossil fuels from this process, which leads to a great amount of carbon emissions. The plastic liner bags are also a concern as they may create a large amount of waste when they are disposed of. The combination of these factors leads to the transportation process of coffee beans to be unsustainable due to it producing copious amounts of waste.

2.1. Manufacturing Process: Product Packaging

To manufacture the plastic jar packaging, various organic compounds are used. This packaging plays a significant role in the life cycle of this product as they are used in many of Nestle’s Nescafe instant coffee products and perhaps is the component of the product itself that uses the most materials. The plastic jars are made from high-density polyethylene (HDPE) (Plastic Packaging Facts, “Resins and Types of Packaging”), in which its manufacturing process use ethylene, hydrogen, comonomer, catalyst, and cocatalyst (Patel p. 17-34). The comonomers, catalysts, and cocatalysts used for this manufacturing process are additional organic compounds (The Essential Chemistry Industry, “Polyethylene”). Since almost all the materials used to manufacture the HDPE jars are organic compounds, these materials are non-renewable as they are derived from crude oil. As the demand for this product rises, the amount of HDPE jars manufactured will also increase, which may lead to the supply of crude oil running short, considering the number of organic compounds used to manufacture HDPE. The manufacturing process of the plastic jar packaging for Nescafe instant coffee is unsustainable due to the high dependence of organic compounds.

The manufacture of the aluminum foil packaging relies on non-renewable metallic compounds. As another common form of packaging for Nescafe instant coffee, the manufacturing process for these aluminum foil packets plays a significant role in the life cycle of this product. Aluminum foil is made from bauxite, sodium hydroxide, hydrated aluminum, and cryolite (Madehow, “Aluminum Foil”). While bauxite is the most plentiful aluminum oxide ore (Madehow, “Aluminum Foil”), it is still non-renewable as its supply cannot be replenished; bauxite, along with the other materials used, can run short in supply as the demand for products with this packaging increase. The manufacture of the aluminum foil packets used for this product is therefore unsustainable.

2.2: Manufacturing Process: Instant Coffee Powder

The manufacturing process of the instant coffee powder relies on a combination of renewable and non-renewable materials. This manufacturing process plays a significant role in the life cycle of Nescafe instant coffee as it results in the main component of the product that is consumed. The raw materials used for this process are coffee robusta, softened water, air, carbon dioxide, and nitrogen gas (Madehow, “Instant Coffee”). A few of these materials, such as the coffee beans and the carbon dioxide, are renewable, while others, such as the nitrogen gas and softened water, are not; thus, the manufacturing process for the instant coffee powder itself is more sustainable than the processes for the product’s packaging.

3. The Recycling Process of the Product’s Packaging

While the use of materials during the recycling process of the plastic jars can sometimes be sustainable, it also has the potential to be unsustainable depending on which process is used. Since these jars are made from HDPE, they can withgo any of the four types of recycling processes used for HDPE. These four processes are primary recycling, secondary recycling, tertiary recycling, and quaternary recycling. Under the primary recycling of HDPE, waste HDPE is mixed with newly manufactured plastics, or it is directly reused. Under secondary recycling, waste HDPE is re-melted into a mixture of plastics. Tertiary recycling of HDPE uses additional chemicals to make new plastics from the waste HDPE. Quaternary recycling recovers only the energy from waste HDPE by combusting it; this results in polynuclear aromatics, hydrocarbons, and soot as byproducts, and the HDPE is disposed of into landfill after it has been combusted. This process is discouraged due to its harsh byproducts (Kumar, Sachin, et al, p. 893-910). The primary recycling of HDPE seems to be the most sustainable process out of the four as it has the least amount of input materials and emissions (and in the case of direct recycling, none from the process itself). However, quaternary recycling is very unsustainable as it makes little use of the waste HDPE and releases byproducts that are harmful to the environment. Despite primary recycling being the most sustainable process, all four of these processes are dependent on non-renewable resources, either as a fuel or as an input material; these processes are considerably unsustainable, apart from the direct recycling of HDPE.

The recycling process for the aluminum foil packets is unsustainable due to the reliance of non-renewable input materials and its harmful emissions. Scrap aluminum is melted down using furnaces powered by natural gas, and chloride/fluoride salts and cryolite are used to reduce the metal loss. This process results in the byproducts of carbon dioxide and nitrogen gas (Schlesinger, p. 113-120). Using these non-renewable materials to recover aluminum, while emitting byproducts that are harmful to the environment, is unsustainable as more materials are consumed and more waste is produced in the recovery of a singular material.

4. Conclusion

Most of the materials used throughout the life cycle of Nescafe instant coffee are non-renewable. As the demand for this product increases, more of these materials will be consumed by this product, making the product unsustainable as these materials cannot be replenished. The greatest material consumption is apparent in the manufacture and recycling of the product’s packaging; while this is the case, smaller sustainability concerns in the transportation and manufacture of the instant coffee powder are still apparent. To increase the sustainability of this life cycle, changes in the materials used for the product packaging and in how materials are recycled are necessary.

Bibliography

“$12.1 Billion Instant Coffee Market - Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2021-2026 - Researchandmarkets.com.” Business Wire, 30 Apr. 2021, https://www.businesswire.com/news/home/20210430005266/en/12.1-Billion-Instant-Coffee-Market---Global-Industry-Trends-Share-Size-Growth-Opportunity-and-Forecast-2021-2026---ResearchAndMarkets.com.

“Aluminum Foil.” How Products Are Made, http://www.madehow.com/Volume-1/Aluminum-Foil.html.

Bhandari, Bhesh, et al. Handbook of Food Powders: Processes and Properties. Woodhead Publshers, 2013.

“Coffee.” Transport Informations Service, https://www.tis-gdv.de/tis_e/ware/genuss/kaffee/kaffee-htm/#verpackung.

“Instant Coffee.” How Products Are Made, http://www.madehow.com/Volume-3/Instant-Coffee.html.

Kumar, Sachin, et al. “A Review on Tertiary Recycling of High-Density Polyethylene to Fuel.” Resources, Conservation and Recycling, vol. 55, no. 11, 2011, pp. 893–910., https://doi.org/10.1016/j.resconrec.2011.05.005.

Loultcheva, M.Kostadinova, et al. “Recycling of High Density Polyethylene Containers.” Polymer Degradation and Stability, vol. 57, no. 1, 1997, pp. 77–81., https://doi.org/10.1016/s0141-3910(96)00230-3.

“NESCAFÉ Sweet & Creamy Original Instant Coffee.” Made with Nestle, 18 Feb. 2021, https://www.madewithnestle.ca/nescafe/nescafe-sweet-creamy-18-sachets.

NS, Sruthi, and Suganthi A. “Cultivation, Harvesting and Processing to Produce Top Quality Coffee in Coffee Robusta L. Linden and Their Value Added Products-A Review.” American Journal of PharmTech Research, vol. 9, no. 2, 2019, pp. 147–158., https://doi.org/10.46624/ajptr.2019.v9.i2.014.

Patel, Rajen M. “Polyethylene.” Multilayer Flexible Packaging, 2016, pp. 17–34., https://doi.org/10.1016/b978-0-323-37100-1.00002-8.

“Plastic Resins & Types of Packaging.” Plastic Packaging Facts, American Chemistry Council, 6 Oct. 2020, https://www.plasticpackagingfacts.org/plastic-packaging/resins-types-of-packaging/.

“Poly(Ethene) (Polyethylene).” Poly(Ethene) (Polyethylene), 27 Apr. 2017, https://www.essentialchemicalindustry.org/polymers/polyethene.html.

Schlesinger, Mark E. Aluminum Recycling. Taylor & Francis Ltd, 2017.

“Sugar Cane.” Purdue University Center for New Crops & Plants Products, https://hort.purdue.edu/newcrop/Crops/Sugar_cane.html.

Kimmy Tran

Life Cycle of Instant Coffee: Energy

As one of the most highly traded commodities in the world, coffee production is a considerably large industry that contributes a significant amount to our current environmental crisis. Coffee can come in a variety of forms, all aiming to appeal to the modern-day consumer who is presented with all too many choices, from grounded and ungrounded coffee beans to k-cups and instant coffee. As an avid coffee drinker myself, I’m interested in what can be done to help reduce the impact that this has on the environment, even if it is just merely one industry out of hundreds of others. This paper will serve as an exploration of specifically Nescafe Instant Coffee’s life cycle, with particular focus on the embodied energy used in material acquisition/processing, product manufacturing, transportation, and consumer consumption.

Material Acquisition

No matter what form coffee products come in, there’s always the same initial step of material acquisition in the form of planting, harvesting, and processing coffee cherries. In most coffee-producing countries, the crops are grown on rural mountains— making it so that mechanized harvesting of coffee cherries is nearly impossible— and “the majority of coffee grown… is planted, picked, sorted, and processed by hand” (Mills). Generally speaking, growing and harvesting beans requires energy and energy releases a lot of carbon into the atmosphere but because coffee plants are usually grown in rural mountainous areas, there tends to be no huge industrial plants with heavy machinery. As a result, most of the energy expended is from human labor and use of simple machinery for irrigation, hulling, polishing, and grading/sorting. According to the National Coffee Association, there are two methods of harvesting coffee cherries and both are primarily done by hand. Even in the next phase of material acquisition, processing of cherries, the step is done as quickly as possible using one of two methods. The commonly used dry method requires the cherries to be spread out to dry in the sun and turned various times throughout the day to drop the cherries’ water content to 11%. Using the wet method of processing, the cherry pulp is removed, passed through a pulping machine, separated by weight classes through water channels leading to a fermentation tank, and eventually dried with the dry method (National Coffee Association). It is with this method that a combination of mechanical energy and human labor are used. This wet processing method “consumes more energy due to the fuel needed to machine sort and dry” the coffee cherries (Thomas 3). Embodied energy of instant coffee includes all the energy that goes into its production, and in this case, the material acquisition phase of the product’s life cycle is less reliant on mechanical energy and more reliant on manual human labor that can not always be quantified. Even in the rare occurrences of machine usage, there’s very little energy consumption in material acquisition as opposed to the next step of the life cycle— manufacturing.

Manufacturing

Before these processed coffee beans are ready to be transported over international waters for sale, there is an energy-intensive manufacturing process behind what turns regular coffee beans into its water soluble form. In the hulling, sorting, roasting, and dehydrating process, machinery is used to maximize turnover rates and meet consumer demand. Of the three, roasting is most “energy intensive because roasting machines operate at high temperatures, roughly 550 degrees Fahrenheit, and can consume approximately one million BTU each hour” (Alliance to Save Energy). At Nescafe, their beans are instead heated to 446 degrees Fahrenheit for over 10 minutes per batch before being rapidly cooled to 100 degrees (Milton). It is from here that the roasted beans are grounded in an industrial roller-mill grinder estimated to have a power consumption of 14-17 kilowatt-hour per ton (kWh/t) and then subsequently brewed in water. (Industrial Efficiency Technology Database). What sets instant coffee apart from its other forms is its dehydrated state that allows for water solubility. This is achieved by moving the coffee through evaporators set to 158 degrees, freezing the coffee extract, and breaking it up into granules that undergo sublimation in a pressurized vacuum (Milton). Between the production of ground coffee and instant coffee, there’s an additional step that’s taken to dehydrate the coffee grinds. With product manufacturing, a lot of meticulous steps go into making sure that the instant coffee sold in stores meet the expectations of consumers and each of these steps require a significant amount of energy.

Transportation

After successfully acquiring materials and manufacturing instant coffee, the product needs to be packaged for exporting. Since coffee plants are partial to moist, warm environments with high altitudes, coffee is almost exclusively produced in the Southern Hemisphere. In Costa Rica, they export nearly 82% of all the coffee they produce, with 40% of that account needing to be transported over 5000 miles by freighters estimated to consume “more than 16 tons of fuel per hour, which is about 380 tons of fuel per day at sea” (Mills). Like with the transportation stage of other products’ life cycles, the amount of energy used or fuel burned is significantly higher in this stage than that of other stages. This is likely due to the fact that most modern-day goods are exported from other countries, making it so that products like instant coffee have to travel great distances to get to where they are supposed to be sold. This transportation can be done via truck, plane, or even ships, which all take up a considerable amount of energy.

Consumer Consumption

Once properly manufactured and transported, Nescafe Instant Coffee can be found on the shelves of many different grocery and convenience stores. Typically, instant coffee is brewed in homes of consumers using water heated with an electric kettle, water dispenser, or microwave. An electric kettle has an “average power consumption of 0.04 kilowatt-hours. This makes the appliance’s efficiency around eighty-one percent, which is the highest amongst the stove and the microwave oven” (Mishry). An electric water dispenser can “consume between 0.3 to 1.2 kWh of energy per day to get cold water, while it uses around 2.8 kWh of energy per day to get cold and hot water” (The Home Hacks DIY). The average microwave consumes about 0.8-1.2 kilowatts-hour of electricity, depending on the temperature and time settings (Patel). At a glance, the electric kettle is the least energy consuming method of brewing instant coffee at home, but that does not necessarily mean that all coffee consumers opt to use this method over the others. There is no way to know the specific value of energy consumed in this phase of the life cycle because we can only assume based on data about popular home appliances whose wattage can significantly vary from product to product.

Since the Nescafe Instant Coffee container is primarily made out of glass and plastic, it is encouraged that these containers be recycled after being disposed of. According to Nescafe’s website, their recycled jars are taken back to the facilities to be repackaged into another container. It is unclear how much energy consumption occurs during this process and in the process of waste management.

Conclusion

In following Nescafe Instant Coffee from material acquisition, manufacturing, transportation, and consumption, we are able to learn more about the embodied energy involved in the crucial parts of the product’s life cycle. Although it’s difficult to track the specific values all through the entire lifecycle, the few values surrounding instant coffee throughout these stages are very revealing about how much energy is actually consumed. Taking into consideration this information and current societal efforts to reduce energy consumption, there’s a need to implement changes throughout the product’s lifecycle to become more sustainable.

Bibliography

“10 Steps from Seed to Cup.” NCA - National Coffee Association, www.ncausa.org/About-Coffee/10-Steps-from-Seed-to-Cup.

Burmester, Katrin, et al. “A Basic Investigation on Instant Coffee Production by Vacuum Belt Drying.” Procedia Food Science, vol. 1, 2011, pp. 1344–1352., https://doi.org/10.1016/j.profoo.2011.09.199.

“Coffee Gives Us Energy, but How Much Does It Use?” Alliance to Save Energy, 26 Oct. 2017, https://www.ase.org/blog/coffee-gives-us-energy-how-much-does-it-use.

“Dark Roast Instant Coffee.” Nescafe, https://www.nescafe.com/us/products/dark-roast-instant-coffee-7-oz-jar/.

“Energy Conservation in Coffee Processing.” Natural Resources Conservation Service Caribbean Area, United States Department of Agriculture, https://www.nrcs.usda.gov/wps/portal/nrcs/detail/pr/programs/landscape/?cid=nrcseprd1314406.

Fredrickson, Karen. “The Untold Truth of Instant Coffee.” Mashed, Mashed, 30 May 2020, https://www.mashed.com/213334/the-untold-truth-of-instant-coffee/.

“High-Efficiency Roller Mills.” Industrial Efficiency Technology Database, http://www.iipinetwork.org/wp-content/Ietd/content/high-efficiency-roller-mills.html. Accessed 30 Nov. 2021.

“How Much Power (Watts) Does a Water Dispenser Use?” The Home Hacks DIY, 2021, https://www.thehomehacksdiy.com/how-much-power-watts-does-a-water-dispenser-use/?utm_source=rss&utm_medium=rss&utm_campaign=how-much-power-watts-does-a-water-dispenser-use#:~:text=Typically%2C%20the%20water%20dispenser%20consumes,you%20around%20%24118.00%20a%20year.

“Instant Coffee.” How Products Are Made, Advameg, Inc. , http://www.madehow.com/Volume-3/Instant-Coffee.html.

Okada, M., et al. “Energy Consumption and the Potential for Conservation in a Spray-Dried Coffee Plant.” Journal of Food Science, vol. 45, no. 3, May 1980, pp. 685–688., https://doi.org/10.1111/j.1365-2621.1980.tb04132.x.

Mills, Nikko. “Examining the Carbon Footprint of Coffee.” The Eco Guide, 17 Sept. 2016, 23:49, theecoguide.org/examining-carbon-footprint-coffee.

Milton, Joshua. “How Is Instant Coffee Made? (Amazing 9 Stage Process).” Eleven Coffees, 2021, https://elevencoffees.com/how-is-instant-coffee-made/.

SanMax, Isabelle Mani. “The Rise of Instant Coffee.” Perfect Daily Grind, Perfect Daily Grind, 31 Aug. 2020, https://perfectdailygrind.com/2020/08/the-rise-of-instant-coffee/.

“The Jar That Never Dies: Nescafe Global.” Nescafé, https://www.nescafe.com/cup-of-respect/jar-never-dies.

Thomas, Shannon. “Coffee Analysis: An In-Depth Look Into Your Morning Brew.” Colorado State University, 17 July 2013.

Patel, Jayesh. “What Is the Power Consumption of a Microwave Oven?” Lets Save Electricity, 2019, https://letsavelectricity.com/what-is-the-power-consumption-of-a-microwave-oven/.

Pramulya, R. “Material Flow Analysis for Energy Potential in Coffee Production.” IOP Publishing Ltd, 2019.

“What All You Need To Know About The Electric Kettle Power Consumption? .” Mishry, 2 Jan. 2021, https://mishry.com/electric-kettle-power-consumption#what-is-the-general-electric-kettle-power-consumption.

Diego Ttito

Life cycle of Instant Coffee: Waste

Introduction

One of the most common ways people start their day is with a cup of coffee, it varies from brewing a cup of coffee using a coffee maker, to making instant coffee at home. Even though instant coffee may not be as popular as it was in the past, it is therefore of importance to examine the sources of instant coffee and the resulting patterns of production, consumption and waste. Companies such as Nescafe are seen in every supermarket with a variety of flavors to choose from. Even though coffee has a huge global market. In order to better understand the waste and emissions, it is important to conduct more research about the specific characteristics that the consumers share. Some common characteristics such as students, young and working-class individuals are the main consumers.

While most of the studies that are shown in this paper provide a deeper understanding of waste and emissions, I will also be sharing my own knowledge that I was able to learn through the many years I worked at coffee shops. Instant coffee has been the fuel that power humans to go through a regular day, in every country in the world from the smallest village to the cities in Davis. My focus for this research paper emphasizes the waste consumption from the brand known all over the world, Nescafe. As instant coffee is more affordable to the consumers, it allows for an increase in the demand in countries where the market of instant coffee such as Middle East, Eatern Europe and SouthEast Asia have similar patterns in terms of consumption. [1] Although Nescafe offers glass jars with their most recent products; there are countries that do still offer only aluminum tins. Although aluminum nescafe tin can have an impressive life cycle, it has negative environmental impacts in the long run.

Raw Materials Acquistion

There are many components to consider when it comes to what makes instant coffee, the process of getting to the last stage of making instant coffee can be very extensive. To provide context about the production of green coffee beans which involves stages such as cultivation, harvesting, drying, cleaning, roasting and ultimately packaging. [8] Nonetheless, each stage requires different amounts of energy, the life cycle of coffee can vary depending on the final product. For instance, plants that roast coffee beans, emit carbon dioxide and nitrous oxide. It is important to highlight that coffee beans can go through two processing methods such as washed and natural. [8] Those factories that brew beans in high temperatures produce a larger amount of carbon dioxide. Water is a huge component in the cleaning process before the roasting method. In summary, instant coffee is brewed in the factories before they are packaged “Instant and can coffee water requirement includes water in waste coffee grounds at the factory.” [8]

Manufactoring and Processing

Industries are adapting more machines to the processing of coffee beans for higher quality. The natural process begins right after the fruit is harvested. It can also be referred to as the dry method. This is known as the traditional method to let the cherries be dried for long periods of time under the sun, which can have an impact on the quality of the coffee. The second method is washing which requires water and dry parchment papers. [9] With the increase in the popularity of coffee, it is most likely for plants to switch to the washing method leading to the increase of water waste.

The amount of carbon dioxide of coffee roasting can also range due to the type of level such as light, medium and dark roasting levels. Next to the servings of cups of coffee that can be served. The instant coffee in Nescafe, can serve up to 111 cups of coffee for each aluminum foil and plastic lid made to keep the instant coffee to maintain freshness and quality.

Distribution and Transportation

In relation to the distribution of these, it indicated that coffee is considered the 3rd largest importer in the world. [6] In terms of location where green beans are cultivated can be located in the Southern Hemisphere. [7] The sourcing of green beans can have different alternatives than the large amounts of gas emissions that are imported internationally. According to the study of Cleaner Production, “Alternative cultivation methods for obtaining the green beans would be a much more important contribution, and assuming alternative methods available in different countries, it would be valid to obtain beans from another producer as any benefit would be likely to outweigh any additional transportation impacts.” [8] A better alternative would be to shift to countries that are sourcing domestically to reduce the amount of global gas emissions.

Recycling

When it comes to the production of instant coffee, it can be more sustainable than other products made by Nescafe such as coffee pods which are single serving. From my experience, I have advised people to recycle these sorts of aluminum cans which can be useful to preserve the quality of coffee. There are many creative ways that instant coffee can be reused if it’s not recycled. However, with the large amount of production of instant coffee, it can be assumed that these aliminum container can end up in landfills. In places like Kyoto, they end up in “clean centers” where cans are recycled and materials like plastic lids are converted into energy through combustion. [6] On the bright side, there are alternatives to help reduce the environmental impact of consumers. As mentioned above, the aluminum cans can be reused in many creative ways. For example, there is a recipe I found online for Caffenol-C-M to develop film. This solution is made with instant coffee, Vitamin C and soda. This is one of the many ways that instant coffee can be reused when not in consumption.

Conclusion

Overall, Instant Coffee is environmentally friendly to produce if adapting less machines during the production process. It is only when more machines are being used in plants that the emissions tend to be larger. Components such as aluminum are entirely recyclable, plastic slides end up in recycling plants which produce waste oil and it leads to a higer carbon footprint. The roasting methods and its carbon footprint can range when machines are being used. The main factor to shift focus would be the improvement of machinery and transportation which can assist to reduce global emissinos. As well as educating consumers about other alternatives to reused external materials can also reduce their carbon footprint.

Work Cited

[1] Wood, Laura ”$12.1 Billion Instant Coffee Market - Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2021-2026”. Businesswire.com , 30 April. 2021. Web.

[2] Abu Hannifa Abdullah, Zulhelmi Ismail, Anis Sakinah Zainal Abidin, Kamal Yusoh, Green sonochemical synthesis of few-layer graphene in instant coffee, Materials Chemistry and Physics, 2019, https://doi.org/10.1016/j.matchemphys.2018.09.085.

[3] Eng, Wee Ean. “Pretreatment of instant coffee wastewater by coagulation and flocculation”. Diss. Universiti Teknologi Malaysia, 2008. Web.

[4] “Coffee” How products are Made. Opened Nov 21, 2021. http://www.madehow.com/Volume-1/Coffee.html

[5] “Caffenol” https://caffenol.blogspot.com/2010/03/caffenol-c-m-recipe.html

[6] Hamann, Lisa. Luschnat, Kaya. Niemuth,Stephanie. Smolarz, Paulina. Svenja Golombek“CSR in the Coffee Industry: Sustainability Issues at Nestlé-Nespresso and Starbucks”. 2014. Web.

[7] “How to serve Nescafe coffee” https://www.nescafe.com/gb/about-us/faqs/how-to-serve-nescafe/. Opened 2021. Web.

[8] H.A. Hassard, M.H. Couch, T. Techa-erawan, B.C. McLellan, “Product carbon footprint and energy analysis of alternative coffee products in Japan” https://doi.org/10.1016/j.jclepro.2014.02.006. 2014.

[9] Hamdouche, Y., Meile, J. C., Nganou, D. N., Durand, N., Teyssier, C., & Montet, D. (2016). Discrimination of post-harvest coffee processing methods by microbial ecology analyses. Food Control, 65, 112-120.

[10] Michele De Monte, Elio Padoano, Dario Pozzetto. “Waste heat recovery in a coffee roasting plant” https://doi.org/10.1016/S1359-4311(03)00033-4. 2003