Design Life-Cycle

assess.design.(don't)consume

POSTER

Colgate Total Clean Mint Toothpaste Life Cicyle

Works Cited for Poster

“Ariel De Disney Moana: La Guía Esencial De La Hei Hei El Gallo De Disney Moana Guía Esencial De Walt Disney Company - Moana - Unlimited Download. Kisspng.com.” Kisspng.com, es.kisspng.com/kisspng-fhptha/preview.html.

Association, Press. “GPs Prescribing Toothpaste and Sun Cream at Cost of Millions,Figures Reveal.” The Guardian, Guardian News and Media, 9 Apr. 2015, www.theguardian.com/society/2015/apr/09/gps-prescribing-toothpaste-and-sun-cream-at-cost-of-millions-figures-reveal.

“Business and Water: Opportunities and Challenges.” Cambridge Institute for Sustainability Leadership, 5 July 2016, www.cisl.cam.ac.uk/business-action/natural-capital/natural-capital-impact-group/doing-business-with-nature/business-and-water.

“Colgate-Palmolive (CL) Stock Analysis.” Dividend Value Builder, 30 Nov. 2018, dividendvaluebuilder.com/colgate-palmolive-cl-stock-analysis/.

“Free Colgate Total Toothpaste Sample.” Fhanks, fhanks.blogspot.com/2013/03/free-colgate-total-toothpaste-sample.html.

Kulp, Patrick. “Colgate Recycles Water Conservation Ad for the Super Bowl.” Mashable, Mashable, 28 Jan. 2016, mashable.com/2016/01/28/colgate-is-paying-millions-to-recycle-an-ad-during-the-super-bowl/#8vtEJGIbGZqF.

“Is Carrageenan Safe? | Carrageenan Information | Andrew Weil, M.D.” DrWeil.com, DrWeil.com, 26 June 2018, www.drweil.com/diet-nutrition/food-safety/is-carrageenan-safe/.

LD, Jill Corleone RDN. “Is Cellulose Gum Harmful?” LIVESTRONG.COM, Leaf Group, 3 Oct. 2017, www.livestrong.com/article/448293-is-cellulose-gum-harmful/.

“Mint.” WatchOS Icon Gallery, www.watchosicongallery.com/icons/mint-2015-06-02/.

“Pin by Cindylaura on Themes in 2018 | Pinterest | Iphone Wallpaper, Wallpaper and Wallpaper Backgrounds.” Pinterest, 1 Dec. 2018, nl.pinterest.com/pin/623818985857590415/.

“Propylene Glycol Manufacturer from Pune.” Http://Www.paraschemicals.com/Propylene-Glycol.html#Propylene-Glycol, www.paraschemicals.com/propylene-glycol.html.

“Silica Structure - O2Si.” Mol-Instincts, www.molinstincts.com/structure/Silica-cstr-CT1000381975.html.

“Sodium Fluoride.” IndiaMART.com, www.indiamart.com/proddetail/sodium-fluoride-8029108688.html.

“Sodium Lauryl Sulfate | Wondercide.” Wondercide Natural Products, www.wondercide.com/sodium-lauryl-sulfate-sls/.

Treat, Jason, and Ryan Williams. “We Depend On Plastic. Now, We're Drowning in It.” National Geographic, National Geographic, 16 May 2018, www.nationalgeographic.com/magazine/2018/06/plastic-planet-waste-pollution-trash-crisis/.

Raw Materials

Shiyi, Li

DES 40A

Professor Cogdell

06 December 2018

Colgate Life Cycle - Raw Materials

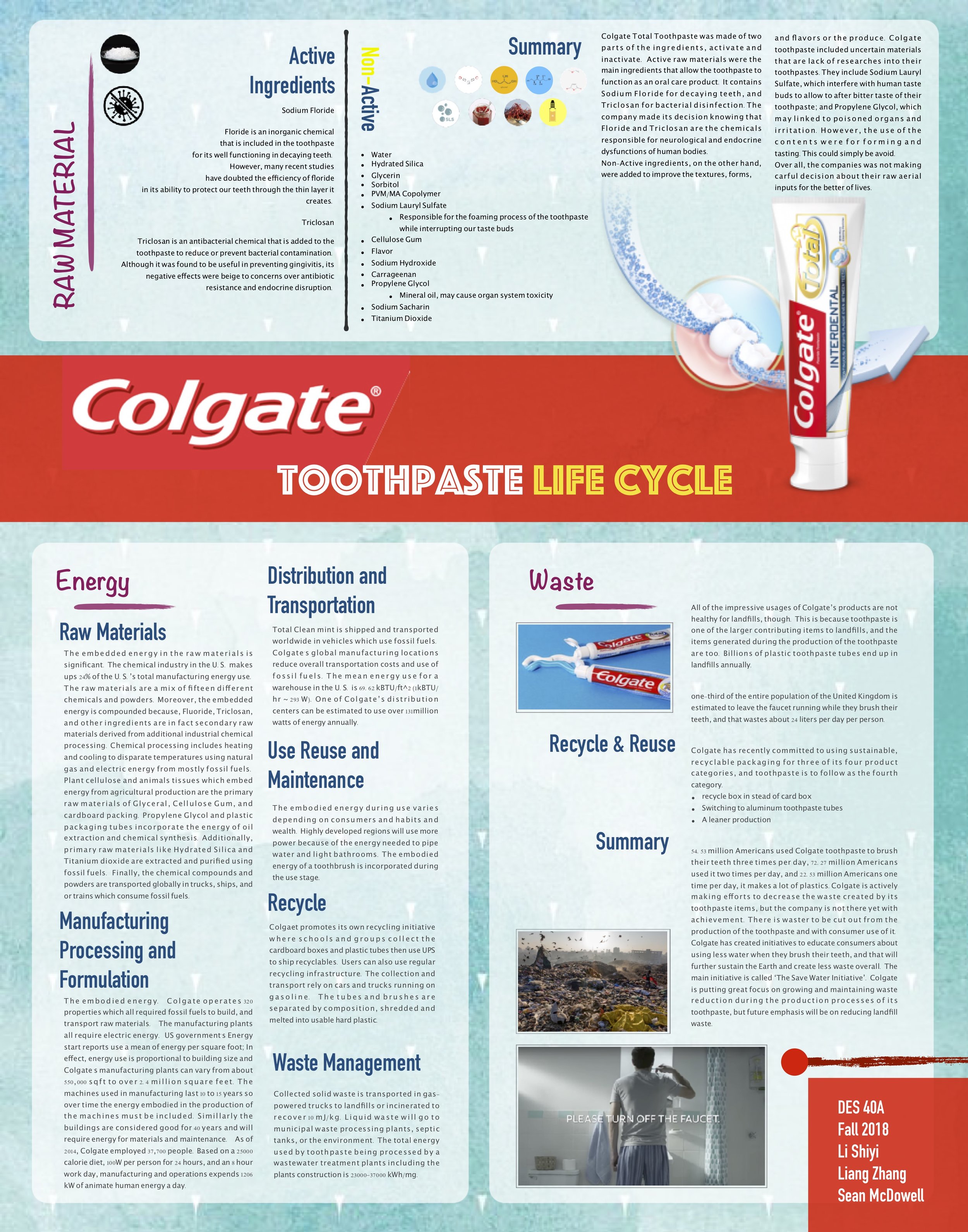

While many Americans are obsessed with the presence of organic and healthy ingredients in their diets or personal care products, only a few would pay attention to the materials that go into their tubes of toothpaste. According to a study on the frequency of toothpaste usage in the United States, 72.68 million Americans use toothpaste four times or more on an average day (U.S. Daily Toothpaste Usage). Although people consider themselves to spit most of the paste out, some of the chemicals it contains will still travel their way into human’s bloodstreams. In order to understand the white paste that people are ingesting on daily bases, a research on raw materials contained in Colgate Total Clean Mint Toothpaste was made. However, the result was utterly disappointing. As one of the world’s leading oral care companies, Colgate made several careless decisions about people by not only allowing questionable raw materials such as triclosan and sodium fluoride in their activate ingredients, but also containing unnecessary inactive ingredients, including sodium lauryl sulfate and propylene glycol in their productions.

After Colgate Total Clean Mint Toothpaste was chosen as the specified example for analyzing the company's’ recipe for its toothpaste, both active and inactive ingredients were found in its contents. They both serve a different purpose to the toothpaste, ranging from more important to less significant. Activate raw materials that go into a Colgate toothpaste are sodium fluoride and triclosan, which serve the purposes of tooth protection, bacterial disinfection and antigingivitis. On the other hand, inactive ingredients, which are substances that make the magic twist to perfect the taste and texture of the toothpaste for its better performance on the shelf life, include chemicals such as sodium lauryl sulfate or propylene glycol (Colgate Smartlabel). However, Many results from studies have been raising doubts on the safeness of those raw ingredient inputs of the Colgate toothpaste.

Being one of the most important activate ingredients in the Colgate toothpaste, triclosan does not appear to be a healthy ingredient that consumers would like to see in their toothpaste content box. The inorganic chemical was included in many personal care products in order to prevent or reduce bacterial contamination. Initially, Colgate used triclosan to help their product with a unique function to prevent gingivitis (Samuels). However, recent studies have found that triclosan is a germicide that people should reconsider its existence in toothpaste. “Triclosan is 110 percent marketing,” says Michael Osterholm, as the head of the Center for Infectious Disease Research and Policy at the University of Minnesota (Nazaryan). As the person who helps the state of Minnesota became the first state that banned most uses of triclosan, Michael’s approval and concerns over triclosan are reasonable. The antigingivitis of triclosan come at a fair price. The chemical has not only been linked to endocrine disruption and fetal bone malformations, but it has also been linked to the potential of cancer and thyroid problems. People who were exposed to triclosan face health concerns include breast, ovarian, prostate, and testicular cancer. The problem triclosan creates does not stay within the generation. Triclosan increases the chance of preterm and low birth weight babies.

Triclosan is labeled as a harmful ingredient, yet it still found its way on Colgate’s Total toothpaste. In 2011, Colgate company announced their withdraw of triclosan in all their soap products due to concerns and pressure from their customers, but the ones within the toothpaste remained (Jennings). The chemical that is not allowed in soap is currently present in toothpaste and is ready to be ingested. The company advertises their toothpaste as the "only toothpaste approved by the Food and Drug Administration (FDA) to help fight plaque and gingivitis” (Colgate Total). Although, that is not the case. “The FDA first promised to look at triclosan in hand soap in 1974; that study remains incomplete” (Nazaryan). The truth is that FDA postponed its detection on triclosan, and Colgate kept benefit from that delaying. While FDA is having trouble handling their piles of chemicals to instruct, triclosan was not the only harmful ingredient that was used to produce Colgate toothpaste.

As the second main material other than triclosan that goes into the Colgate toothpaste, sodium fluoride has long been a questionable ingredient to content in toothpaste in relation to human health concerns. On the positive side, containing fluoride in toothpaste can contribute to the decaying of teeth; on the downside, fluoride has been receiving increasing scrutiny over years being linked to the major risk factor for disfiguring dental fluorosis. Whether fluoride’s benefits were larger than its harms, the answer is debatable.

The United States has a long history of adding fluoride to drinking water in order to decay teeth. However, a study published in the journal Langmuir discovered that “the supposedly beneficial fluorapatite layer” formed on human teeth from fluoride is nearly functionless (Mercola). As a matter of fact, fluoride started as a toxic industrial waste product. Most countries in Asia and Europe have already banned or avoided the fluoridation of their drinking water (Smith). Since the swallowing of toothpaste has always been a problem for both adults and children, the existence of fluoride in toothpaste can develop into a series of health concerns. Although, only that after the unhealthy fluoride inputs in its active ingredient lists, Colgate went further. They have also included waste products in their inactive ingredient lists.

Sodium lauryl sulfate (SLS), as one of the chemicals found inside Colgate’s toothpaste, was found to be unnecessary for daily oral care. It is categorized as a chemical that serves the purpose of an emulsifier and foaming agent in the toothpaste. Studies have found that the negative effects of the chemical on human health and environment have gone overwhelmed. Initially started from coconuts, SLS has been contaminated with a toxic byproduct during the manufacturing. As the chemical creates bubbles for brushing, it also interferes with the functioning of taste buds (Marcola). This explained the aftertaste of bitterness from teeth brushing. In addition, SLS is also capable of being the gateway for different illnesses, ranging from cancer, neurotoxicity, organ toxicity, skin irritation to endocrine disruption (Eisenbraun).

The harm of SLS started with humans, but did not stay within the race. The negative effects of the toxic have been poisoning the environment as well. SLS is a chemical that is labeled as a threat to the marine biosphere, including fish, insects, and crustaceans. According to studies found by Pan Pesticides, “the manufacturers actually tried to get approval to market SLS as a pesticide for organic farmers, but the application was denied because of its potential for environmental damage” (Marcola). A toxic ingredient that is not allowed in pesticides has now ended up in people’s mouth. Colgate has made it possible for SLS to continue its harm to the well being of the public health and the environment.

Aside from Sodium lauryl sulfate, propylene glycol should also be the material to be removed from the ingredient list of Colgate toothpaste. Functioning as a wetting agent and surfactant for Colgate toothpaste, propylene glycol is an industrial mineral oil that can usually be found in antifreeze, paints, enamels, and airplane de-icers (Marcola). According to data supported by the Material Safety, propylene glycol is formed with features that can be rapidly absorbed through human skin into the body. People who were exposed to propylene glycol are concerned with prolonged contact leading to brain, liver and kidney abnormalities (Lynch). The studies and research in the field of the material are still lacking. When the safeness of propylene glycol is questionable, it is the most ideal to remove its irrelevance linked to any product that people may swallow. However, Colgate chose to side with propylene glycol.

Both triclosan and sodium fluoride, as part of Colgate’s toothpaste active ingredients, alongside with sodium lauryl sulfate and propylene glycol, part of its inactive material sources, are questionable secondary sources to contain in a toothpaste product that people ingest daily, which may result in series of health issues. As a global trade company, Colgate is not being responsible and considerable to the health of both their customers and the environment. Egyptians first started the practice of using toothpaste 5000 BC without carrying the knowledge of chemistry. As centuries and generations pass, the ingredients for toothpaste has shifted dramatically from primary sources to secondary sources. Natural ingredients were slowly transforming and being replaced by all the chemicals and industrial substance. The cheapness and convenience of the chemicals slowly affected the transition in factories. Only that the negative effects bounced back hard and fast. Cancers rates and illnesses related to chemical poisoning have been raising in decades. Factories and the production of the toxins have poisoned the environment, alongside the planet, and have made it almost impossible to retreat and recover. While it is heartbreaking for many entrepreneurs to give up the easily accessed and cheap secondary chemicals, it is possible for productions to trace back to the origins and start using primary resources again. Harmful materials like triclosan can be simply avoided to be replaced by the naturally occurring cacao extract theobromine. They function the same, except that the cocoa extract cooperates better with the human body and cause less harm to the environment. Pollutants and toxins should be stopped at the root. Not only that the environment will be preserved and recycles through the use of primary raw materials, but humans can be healthier with a longer prosper life.

Table 1. Colgate Total Clean Mint Toothpaste Ingredients, 7.8 Ounce (Colgate Smartlabel)

Materials/Purposes

Active

Sodium Fluoride

To prevent cavities and decay teeth

Triclosan

To reduce gingivitis and bacterial contamination

Non-active

Water

To dissolves substances

Hydrated Silica

To clean and polish teeth

Glycerin

To hydrate the mouth

Sorbitol

To hydrate the mouth

PVM/MA Copolymer

To support active ingredients

Sodium Lauryl Sulfate

To create foam

Cellulose Gum

To stabilize

Flavor

To improve taste

Sodium Hydroxide

To adjust pH

Carrageenan

To stabilize

Propylene Glycol

To glue liquids

Sodium Saccharin

Non-sugar sweetener

Titanium Dioxide

To color

References

Colgate. “Colgate® Total® Clean Mint Toothpaste.” Colgate Total®, www.colgate.com/en-us/products/toothpaste/ct-clean-mint.

“Colgate Total Clean Mint Toothpaste.” SmartLabel™, 3 Oct. 2018, smartlabel.labelinsight.com/product/4051754/nonFoodIngredients.

Eisenbraun, Karen. “Dangers of Sodium Lauryl Sulfate.” LIVESTRONG.COM, Leaf Group, 3 Oct. 2017, www.livestrong.com/article/174367-dangers-of-sodium-lauryl-sulfate/.

Jennings, Katie. “Colgate-Palmolive Removed This Potentially Harmful Chemical From Its Soap Products - But It's Still In Your Toothpaste.” Business Insider, Business Insider, 11 Aug. 2014, www.businessinsider.com/triclosan-cancer-causing-ingredient-in-colgate-toothpaste-2014-8.

Lynch, William. “What Are the Harmful Ingredients in Toothpaste?” LIVESTRONG.COM, Leaf Group, 14 Aug. 2017, www.livestrong.com/article/167101-what-are-the-harmful-ingredients-in-toothpaste/.

Marcola. “Toxic Toothpaste Ingredients You Need to Avoid.” Mercola.com, articles.mercola.com/sites/articles/archive/2015/09/09/toxic-toothpaste-ingredients.aspx.

Nazaryan, Alexander. “A Brush with Cancer?” Newsweek Global, vol. 163, no. 12, Sept. 2014, p. 48. EBSCOhost, search.ebscohost.com/login.aspx?direct=true&db=tth&AN=98286786&site=ehost-live.

Samuels, T.M. “Ingredients in Colgate Total Toothpaste.” LIVESTRONG.COM, Leaf Group, 14 Aug. 2017, www.livestrong.com/article/127011-ingredients-colgate-total-toothpaste/.

Smith, Gar. “Fluoride, Toothpaste and the A-Bomb.” Earth Island Journal, vol. 26, no. 1, Spring 2011, p. 15. EBSCOhost, search.ebscohost.com/login.aspx?direct=true&db=ulh&AN=59288421&site=ehost-live.

“U.S.: Average Daily Usage of Toothpaste 2018 | Statistic.” Statista, www.statista.com/statistics/278187/us-households-average-daily-usage-of-toothpaste/.

Sean McDowell

Cristina Cogdell

Des 40A

December 7, 2018

The life cycle of Colgate Total Clean mint: Embodied Energy

A tube of toothpaste's total cost is more than two minutes two times a day. How much energy does that 7.8 ounce tube of the minty paste demand in order to arrive in your bathroom cabinet? Where does all the waste go after? Knowing the energy, environmental and human costs of producing toothpaste requires accounting for every input and process throughout toothpaste’s product life cycle. Embodied energy is a term referring to the total energy cost of producing and using a product. Insights on embodied energy, waste, and raw materials informs consumers. Informed consumers permits critical questions about the health and environmental impacts of a product to be asked. Colgate dominates the toothpaste market. Colgate total clean mint is a standard product and therefore provides a relevant case study for toothpaste. Consumers armed with an understanding of embodied energy have a tool for motivating companies to reduce waste and become more sustainable. Where should Colgate and consumers focus criticism and resolve for improvement: the raw materials, production, or waste processing? Are the raw materials embodied energy comparable to the rest of the energies embodied during the products life cycle? If so, which of the raw materials has energy-intensive extraction, manufacturing, and waste processes?

Finding specific data, on Colgate Total Clean Mint’s material sources is difficult because the raw materials are purchased from several sources and many different providers [7]. The estimations of higher and lower embodied energy are based on numerous sources. Many sources are provided in percentages relative to other toothpaste or the industry’s average use. Additionally, energy and electrical energy are referred to with the assumption that the sources are mostly fossil fuels like natural gas and coal while a small portion is from renewables and nuclear [10].

Colgate Total Clean Mint’s life cycle begins with the extraction and production of the paste’s ingredients and materials of the paste for packaging. Colgate Total’s paste has fifteen ingredients [9]. The majority of the paste is abrasives and the liquid base [22]. Each of The other ingredients contributes a tenth to two and a half of a percent of the paste [22].

An easily identifiable component where the total energy embodied in Colgate toothpaste can be reduced is packaging. Colgate Total’s packaging is made of cardboard and Low-density polyethylene (LDPE recycling number 4). Cardboard is sourced from wood pulp or recycled material and Polyethylene is synthesized from oil [2,18]. Producing one kilogram of low-density polyethylene uses seventy-seven megajoules of energy [2]. For comparison, a gallon of U.S. gasoline contains 127.059321 mega joules of energy[12]. To reduce the embodied energy Colgate and consumers could seek to reduce the excess packaging of cardboard boxes around the tubes.

An immense amount of energy is needed for toothpaste because many of the ingredients are not primary raw material. For reference, in 2006 the chemical industry in the U.S. made ups twenty-four percent of the U.S.’s total manufacturing energy use (54862.9 quadrillion Joules) [4]. Many of the ingredients are secondary raw materials, derived from additional industrial chemical processing, compounding the embodied energy. For example, synthesis of the antibacterial active ingredient triclosan requires complex industrial industrial chemicals being cooled to ten degrees Celsius and then heated to a hundred Celsius [26]. Electricity is needed for cooling and electric energy or natural gas is needed for high heats, both consume fossil fuels. Furthermore, the chemicals needed to produce triclosan are not primary raw materials themselves [26]. The aluminum chloride used to make triclosan is manufactured by “reacting the aluminum metal with chlorine or hydrogen chloride at temperatures between 650 to 750 °C” [26]. Being a secondary or tertiary raw material dramatically increases the embodied energy and fossil fuel requirements. Similarly, the other active ingredient sodium fluoride is not a primary, material [23,15]. Before becoming part of toothpaste fluoride is produced from by-products of phosphate fertilizers combined with minerals and treated with sulfuric acid [23]. Not only do the chemicals used for fluoride production incorporate the energy embodied in their manufacturing but they also must be transported and further processed. Every step adds to the toothpastes total embodied energy. The acids and fluoride are transported weekly and biweekly in trucks which consume fossil fuels like diesel [15]. Operating a medium sized fluoride production plant requires twenty two hundred kilowatt hours of electricity annually (7,920 mega joules) [15]. The embodied energies of triclosan and fluoride are large because of transportation and the series of manufactured chemicals needed for manufacturing. Consumers and Colgate can promote using chemical ingredients with less processing steps or with less intermediary facilities to reduce toothpastes embodied energy.

Fillers and the liquid base make up a majority of the paste’s mass and volume. The two active ingredients only make up about half a percent of toothpaste. The remaining additives like Titanium Dioxide, Sodium Saccharin, and Cellulose Gum are present in similarly small proportions [22]. The embodied contributed is proportional to the amount of material used per tube. The proportions are important for comparing the ingredients contribution to the embodied energy. For instance, sorbitol and glycerin from a toothpaste’s liquid base makeup ten to one hundred times more of the paste than most other ingredients [22]. Sorbitol is a secondary raw material [25]. Glycerin production requires chemicals synthesised from petroleum oils, chlorine and more [18]. Additionally, sorbitol and glycerin are chemically processed from plant and animal tissues [25,18]. Plant and animal products expend fossil fuels for, fertilizers, management, and transportation [27]. The liquid base's contribution to the embedded energy is large because it’s components are industrially processed chemicals and more is needed per tube of toothpaste. Another component making up a large fraction of toothpaste are abrasives. Fillers and abrasives makeup fifteen to fifty percent of the toothpaste [22]. Hydrated Silica, an abrasive, is primary raw material mined as Diatomaceous Earth, sediment from ancient single-celled aquatic algae called diatoms [10, 12]. Thirty to a hundred times more hydrated silica is used compared to both active ingredients and transporting more weight consumes additional fossil fuels [22]. Additionally, Diatomaceous earth mining and processing requires large amounts of energy [10]. Hydrated silicas energy contribution is significant even Though it is a primary raw material. The ingredients Glycerin and Hydrated silica are both reasonable candidate for the highest embodied energy per toothpaste tube. consequently, filler and liquid base’s need be looked at most critically when seeking to reduce the embodied energy of Colgate Total’s ingredients .

Manufacturing, processing, and formulation are the next steps in Colgate Total’s life cycle. By seeking to minimize energy embodied during manufacturing toothpaste users and Colgate can save money and reduce continued environmental harm due to using fossil fuels and unsustainable sources of energy. Colgate operates three hundred and twenty properties which all required fossil fuels to build, and transport raw materials. Not only do manufacturing buildings rely on electricity and fossil fuels to operate but also the energy use is proportional to building size [14]. Colgate's manufacturing plants sizes range from about five hundred and fifty thousand square feet to over two point four million square feet [8]. In 2003, Colgate had 77 factories and used over forty five hundred kilowatt hours per ton of product (8.1 mega joules per pound) [9]. Moreover, the machines used in manufacturing last ten to five years so over time the energy embodied in the production of the machines must be included [17]. Similarly, the buildings are considered good for forty years and will require energy for materials and maintenance [17]. The infrastructure needed to manufacture a product continuously contributes to toothpaste's embodied energy. Chemical energy from food and agriculture is a component as well. As of 2014, Colgate employed thirty-seven thousand people [24]. Based on a two thousand five hundred calorie diet, one hundred watts per person a day, and an eight hour work day, manufacturing and operations expends one thousand two hundred and six kilowatts of chemical food energy a day. Manufacturing requires energy embodied in many forms including the buildings, tools, and peoples time. Fortunately more diverse forms of embodied energy provide more opportunity and opportunities for saving energy. Last year Colgate saved five hundred million dollars by reducing fossil fuel and energy use by investing five percent of their profits back into manufacturing [21]. Decreasing various inefficiencies in machines, buildings, and peoples work are effective at reducing the embodied energy of Colgate toothpaste and saves money.

The embodied energy from distribution and transportation mark where the perception of a product embodied energy often stops, hover vehicles and distribution continue to contribute to the embodied energy of Colgate Total toothpaste. Colgate dominates the global toothpaste market [7]. Operating on a global scale leads to energy used for shipping and hauling long distances in vehicles burning fossil fuels derived from oil. Colgate's largest markets are the Americas, Europe, and the Asia Pacific [7]. Colgate's global offices and manufacturing locations reduce overall transportation distances, costs, and use of fossil fuels. Operating distribution centers and warehouses embeds energy into energy toothpastes embodied energy. For example, a distribution center in the U.S. consumes over seven thousand three hundred and forty-seven megajoules per square foot a year [8,14]. The total energy of transportation and distribution is an aggregate of hundreds of vehicles and many buildings like the one above.

Embodied energy increases when consumers use toothpaste and decide how to dispose of the empty plastic container. The embodied energy during use varies depending on consumers and habits and wealth. Highly developed regions will use more power because of the energy needed to pipe water and light bathrooms. The embodied energy of a toothbrush is incorporated during the use stage. Further energy is embodied when used liquid toothpaste waste travels to municipal waste processing plants, septic tanks, or the environment [27]. The total energy estimated for processing by wastewater treatment plants including the plant's construction is twenty-three to thirty-seven-megawatt hours per milligram [29]. Finally, the end of Colgate total’s energy life cycle is to be recycled or trashed. Colgate promotes its own recycling initiative where schools and groups collect the cardboard boxes and plastic tubes then use UPS to ship recyclables [30]. Users can also use regular recycling infrastructure. The collection and transport rely on cars and trucks running on gasoline fossil fuels. The tubes and brushes are separated by composition, shredded and melted into usable hard plastic [30]. Alternatively, Collected solid waste is transported in gas-powered trucks to landfills or incinerated to recover ten mega joules per kilogram or dumped into a landfill [1]. Using toothpaste does not require much energy however, processing the waste continues to consume energy in the form of fossil fuels and maintaining waste management infrastructure.

Colgate has successfully reduced the embodied energy and costs of products like Colgate Total Mint by improving manufacturers and implementing its own recycling program, however a significant portion of Colgate's totals embodied energy is from the embodied energy of the raw materials. The beginning of toothpastes life cycle uses the most energy. Triclosan, Glycerol, hydrated Silica and the other components have each have embodied energy comparable or the energy embodied in the manufacturing distribution and disposal of Colgate toothpaste. In conclusion, to reduce embodied energy Colgate and consumers need to encourage chemical manufacturers to be more efficient or use processes which require less tertiary raw materials .

References

[1] A. Porteous Why energy from waste incineration is an essential component of environmentally responsible waste management. pp. 451-459, Waste Manag, 2005.

[2] Boustead I, Eco-profiles of the European Plastics Industry. LOW-DENSITY POLYETHYLENE (LDPE), PlasticsEurope Associlation of Plastic Manufacturers, March 2005.

[3] Britannica, The Editors of Encyclopaedia. “Saccharin.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 6 Dec. 2017, www.britannica.com/science/saccharin.

[4] Carole Tracy. Energy Efficiency and Use in the Chemical Industry. Scheihing Paul, Sousa Lou, Energetics Inc, US Department of Energy, 2001. https://aceee.org/files/proceedings/2001/data/papers/SS01_Panel1_Paper24.pdf

[5] “Cellulose Gum | Sodium Carboxymethyl Cellulose | Sidley Chemical Co., Ltd.” Cellulose Ethers/Calcium Formate/Redispersible Polymer Powder Manufacturer & Supplier – SIDLEY CHEMICAL CO., LTD, SIDLEY CHEMICAL CO.,LTD, 2018, celluloseether.com/sidleycel-cellulose-gum-sodium-carboxymethyl-cellulose/.

[6] “Chemicals Industry Profile.” Department of Energy, Office of Energy Efficiency and Renewable Energy, www.energy.gov/eere/amo/chemicals-industry-profile.

[7] “Colgate Announces 1st Quarter 2018 Results.” Colgate-Palmolive Company, Colgate-Palmolive Company, 27 Apr. 2018, investor.colgatepalmolive.com/news-releases/news-release-details/colgate-announces-1st-quarter-2018-results-0.

[8] “Colgate Palmolive :: Green Building Information Gateway.” GBIG, Green Building Information Gateway. http://www.gbig.org/collections/14124

[9]Colgate: Respecting The World Around Us, colgate sustainability report Colgate-Palmolive 2017 [PDF]

[10] “Colgate Total Clean Mint Toothpaste, 7.8 Ounce.” SmartLabel™, 2018, smartlabel.labelinsight.com/product/4051754/nonFoodIngredients

[11] “Diatomite Mining and Processing.” Diatomite Mining and Processing, International Diatomite Producers Association, 2017, www.diatomite.org/Diatomite-Mining-and-Processing.

[12] “Energy Units and Calculators Explained.” Factors Affecting Gasoline Prices - Energy Explained, Your Guide To Understanding Energy - Energy Information Administration, U.S. Energy Information Administration., 2018, www.eia.gov/energyexplained/index.php?page=about_energy_units.

[13] “EP Minerals Celebrates National Diatomaceous (DE) Day on August 31.” EP Minerals, 30 Aug. 2016, epminerals.com/news/2016-08-30/ep-minerals-celebrates-national-diatomaceous-de-day-on-august-31.

[14] ENERGY STAR Score for Warehouses in the United States. Energy Star Portfolio Manager, US Environmental Protection Agency, August 2018. https://www.energystar.gov/sites/default/files/tools/Warehouse_August_2018_EN_508.pdf

[15] Fluoridation Preliminary Engineering Design report MWH Global Inc, Presented to Sonoma County Water Agency and Department of Health Services, November 2014.

[16] Greenwood, Norman N.; Earnshaw, Alan (1984). Chemistry of the Elements. Oxford: Pergamon Press. ISBN 0-08-022057-6.

[17]Gunn, Matt. “Colgate Palmolive's 4 Steps to Creating a Global Supply Chain.” GT Nexus, Infor, 2 June 2016, www.gtnexus.com/resources/blog-posts/cpg-supply-chain-colgate-palmolive.

[18] “Glycerin.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, 2018, pubchem.ncbi.nlm.nih.gov/compound/glycerol.

[19]“Investing For Global Growth Winning With Focus” Colgate-Palmolive Company 2017 Annual Report. Colgate-Palmolive 2017.

[20] Learn Chemistry Enhancing learning and teaching with the RSC, TiO2: Manufacture of Titanium Dioxide Masterclass: TiO2 − Sheet 5 of 4, The Wolfson Foundation, Registered charity number 207890.

[21]Planet. Colgate sustainability. Colgate-Palmolive, 2012 [pdf].

[22] Solutions for Your TOUGHEST MIXING Applications in APPLICATION REPORT COSMETICS & TOILETRIES. Issue No. 57TA1, Silverson Machines, Inc.

[23] Thomas G. Reeves, P.E., THE MANUFACTURE OF THE FLUORIDE CHEMICALS. September 2000, Refer: FL-143, National Center for Chronic Disease Prevention and Health Promotion Centers for Disease Control and Prevention

[24] “Number Colgate-Palmolive Employees Worldwide 2005-2017 | Statistic.” Statista, 2018, www.statista.com/statistics/441240/number-of-colgate-palmolive-employees-worldwide/.

[25] “Sorbitol.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, 2018, pubchem.ncbi.nlm.nih.gov/compound/D-Sorbitol#section=Methods-of-Manufacturing.

[26] “Triclosan.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine. pubchem.ncbi.nlm.nih.gov/compound/triclosan#section=Use-and-Manufacturing.

[27]Total Energy Consumption for Municipal Wastewater Treatment. Municipal environmental research laboratory cincinnati OH, Environmental protection agency 1978.

[28] Woods, Jeremy et al. “Energy and the food system” Philosophical Transactions of the Royal Society of London. Series B, Biological Sciences vol. 365,1554 (2010): 2991-3006.

[29] “Census of Housing.” Census Bureau QuickFacts, United States Census Bureau, 2011, www.census.gov/hhes/www/housing/census/historic/sewage.html.

[30] “Colgate® Oral Care Recycling Program - FAQ.” TerraCycle, Colgate-Palmolive Company, 2018, www.terracycle.com/en-US/brigades/colgate/brigade_faqs.

Waste

Liang Zhang

Des40A

Professor Cogdell

12/6/18

Waste in the Production of Colgate Toothpaste

One can assume that almost every person in the United States has used a tube of Colgate toothpaste at least one time in their life. In fact, it is estimated that 54.53 million Americans used Colgate toothpaste to brush their teeth three times per day, 72.27 million Americans used it two times per day, and 22.53 million Americans one time per day (“U.S. Population: How Many Times Do You Use Colgate Toothpaste On An Average Day” 1). That is a lot of toothpaste! It is also why Colgate is the most well-known and well-regarded product in the United States for its toothpaste. All of the impressive usages of Colgate’s products are not healthy for landfills, though. This is because toothpaste is one of the larger contributing items to landfills, and the items generated during the production of the toothpaste are too. Colgate is actively making efforts to decrease the waste created by its toothpaste items, but the company is not there yet with achievement. There is a lot of waster wasting from the production of the toothpaste and with consumer use of it. Colgate is putting great focus on growing and maintaining waste reduction during the production processes of its toothpaste, but future emphasis will be on reducing landfill waste.

The first step of any supply chain to think about is how the manufacturer gets the products used to make the items it produces. There are two types of raw materials: direct raw materials and indirect raw materials (“Raw Materials – What Are Raw Materials” 1). Direct raw materials are included in the final product that is produced, and indirect raw materials are used during the production processes but do not actually end up in the final product itself (“Raw Materials – What Are Raw Materials” 1). Some direct raw materials in Colgate toothpaste are Triclosan, Fluoride, plastic, and cardboard (“Frequently Asked Questions” 2). The plastic is used for the tubing and the tube cap, and the cardboard is used for the box that the consumers takes off the shelf to buy the product. The tube cap is made by another manufacturer, and the box is too. The waste emitted by the outside suppliers is still considered to be part of Colgate’s supply chain, though, even though the production doesn’t take place at a Colgate facility.

This is all despite the fact that Colgate tries hard to not outsource the production of its components, raw materials, and finished good products (“Colgate: A Closer Look at Supply Chain Excellence” 2). Colgate produces as much as it can itself and minimizes outsourcing, but the packaging is part of what is outsourced. Not outsourcing the supply chain reduces energy use and decreases emissions used in transportation efforts, especially when avoiding needing to bring materials to the factory from all over the world. For example, Colgate manufactures its own toothpaste tubes (“Colgate: A Closer Look at Supply Chain Excellence” 2). That is unique because not many toothpaste manufacturers do that. But, it is done to reduce waste and be more environmentally sustainable. Producing the tubes instead of outsourcing them is costlier for Colgate, so it is an impressive thing that they are taking on producing the tubes themselves just to be less wasteful.

Its also important to note that producing more materials results in a leaner production process for Colgate, using a lesser amount of capacity. After all, the whole idea behind lean production processes is to eliminate as much waste as possible from the whole production process (“What Is Lean?” 1). The waste can be reduced from procurement, labor, logistics, and pretty much any part of the supply chain process (“What Is Lean?” 1). A leaner production process uses less energy. So, Colgate making its production processes leaner is reducing waster overall. This would be true even if the company was just making the process leaner in some points, and that is basically what Colgate is doing at this point.

Making the production process leaner means that each tube of Colgate toothpaste has a lower geographical and carbon footprint. A lower geographical footprint means that each component, or part, of the production process, requires lower amounts of travel across or around the globe. For example, if Colgate had chosen to instead outsource the production of its tubes, they would have likely been produced overseas. This would mean that each and every tube of toothpaste would need to travel all the way from another country before it reaches the consumer. That behavior would create a great deal of emitted pollution, so Colgate is reducing that toxic emission by producing its own tubes here in the United States even though it is more expensive. Companies really should try to avoid transporting parts of goods from one country to another just to produce an item (“Our Different Carbon Footprints” 1). Some companies even transport to many different countries before a product is finally finished. It may be cheaper to do that, but the Earth is paying a high price because such items leave heavy carbon footprints on the planet. Colgate respects that ,and they act accordingly.

A lot of people don’t think about just how much cardboard is used in the production of all of the world’s products, and this doesn’t pertain just to Colgate toothpaste. But, if a person stops to really think about it, every product they buy off of a store shelf is in a container of some sort, and many of them are in boxes made of paper or cardboard products. Before the product was put on that store shelf, it was likely in another box too. Often times, those boxes were even in larger boxes. So, a person can realize just how much cardboard is used and wasted just as a result of the person’s one trip to Walmart to buy everyday essentials. Toothpaste is no exception, but Colgate is setting out to try to reduce cardboard waste. Colgate believes that every company should do their part and that it would make a great impact on the Earth if all companies would be like them.

Colgate has recently committed to using sustainable, recyclable packaging for three of its four product categories, and toothpaste is to follow as the fourth category (“Colgate Commits to 100% Recyclable Packaging”, 1). Colgate has publicly committed to converting to recyclable packaging in its categories of Home, Pet, and Personal Care by the year 2020 (“Colgate Commits to 100% Recyclable Packaging 1). This means that even though its toothpaste will still be sold in boxes based of cardboard, that the boxes will be recyclable if the consumer chooses to do so. Obviously, Colgate cannot force consumers to recycle the product which takes to their homes, but the company can at least do its part to make recycling possible.

Colgate has also committed to redesigning its toothpaste tubes, and that would represent the fourth category being brought up to recyclable standards (“Colgate Commits to 100% Recyclable Packaging” 1). This will require redesigning the toothpaste tube to properly utilize the product capacity of the space, and the material being used. Switching to aluminum toothpaste tubes would be a great option too (“David’s Premium Natural Toothpaste” 1). That is what David’s Premium Natural Toothpaste did, but that choice is very expensive and would probably also increase freight costs because of the added weight (“David’s Premium Natural Toothpaste” 1). Billions of plastic toothpaste tubes end up in landfills annually (“David’s Premium Natural Toothpaste” 1). But, soon Colgate’s toothpaste tubes will be able to be recycled which are the same as competitor’s aluminum tubes. This is quite a change to its procurement and production process of direct materials.

The next step is putting all of the components and materials together to make the final product of toothpaste. This is referred to as the production process of the company’s toothpaste. Colgate is committed to making changes to reduce the amount of water used and wasted during its production processes (“Colgate” 65). This is still in process, though.

Consumers may not realize just how much water is used in the production of toothpaste because the final product seems thick and not watered down. The use of water is related back to direct and indirect materials. Water is indeed used in the toothpaste itself but is also used to make the production machines run in some parts. Colgate doesn’t have a clear picture of just how much water is being used yet though. An analysis of water usage is currently being conducted at Colgate, and a strategic team is being assigned by Colgate to determine ways to use less water during production (“Colgate” 65). This analysis and effort to reduce water usage is going to occur in all of Colgate’s product categories actually, and not just in its toothpaste (“Colgate” 65).

The last stage of a company or an item’s supply chain ends is when the consumer buys and uses the product. Materials are acquired, the item is produced, the items are transported to stores, and the consumer buys the product. Colgate is well aware that brushing teeth is one of the most wasteful daily processes in the lives of human beings, and it is setting out to change that. This is because too many people leave their water faucets running while they brush their teeth, and that wastes a lot of the world’s water every day. For example, one-third of the entire population of the United Kingdom is estimated to leave the faucet running while they brush their teeth, and that wastes about 24 liters per day per person (“1 in 3 Leave The Tap Running While Brushing” 1). That is a lot of water just due to teeth brushing and is so horrible for the Earth! So, Colgate has created a solution to reduce this waste.

Colgate has created initiatives to educate consumers about using less water when they brush their teeth, and that will further sustain the Earth and create less waste overall. The main initiative is called ‘The Save Water Initiative’ (“Colgate” 65). The Save Water Initiative educates consumers about turning off their faucets and even provides creative ideas for alternative ways to save water, such as filling a small portion of a cup with water to rinse both a person’s toothbrush and their mouth at the end of the process (“Colgate” 65). Colgate is a company which should be respected, because waste reduction and sustainability initiatives do not just occur in Colgate toothpaste factories, but they occur even after the product leaves the factories and stores. They also occur in consumer’s homes.

Reference

“Colgate: A Closer Look at Supply Chain Excellence.” Supply Chain Shaman, 1 May 2013,

www.supplychainshaman.com/uncategorized/colgate-a-closer-look-at-supply-chain-excellence/.

“Colgate Commits to 100% Recyclable Packaging for Three of Four Product Categories by

2020.”Sustainablebrands.com, www.sustainablebrands.com/news_and_views/

packaging/jennifer_elks/colgate_commits_100_recyclable_packaging_2020_three_four_prod.

“David’s Premium Natural Toothpaste.” David’s Premium Natural Toothpaste, davids-

usa.com/blogs/news/tagged/toothpaste-in-landfills.

“Frequently Asked Questions”. Colgate, https://www.colgate.com/en-ca/products/total/faq

“1 in 3 Leave The Tap Running While Brushing – Wasting 24 Litres of Water a Day, Finds New

Poll”. Middlesex University London, https://www.mdx.ac.uk/news/2014/05/1-in-3-leave-the-tap-running-while-brushing-wasting-24-litres-of-water-a-day-finds-new-poll

“Our Different Carbon Footprints”. National Geographic, https://www.nationalgeographic.

org/media/our-different-carbon-footprints/

“Performance.” Colgate, https://www.colgate.com/Colgate/US/Corp_v2/

LivingOurValues/Sustainability_v2/cpsus15_full_report_10_042616_Performance.pdf

“Raw Materials – What Are Raw Materials?” Debitoor, https://debitoor.com/dictionary/raw-

materials

“U.S. Population: How Many Times Do You Use Colgate Toothpaste On An Average Day?”

Statista,https://www.statista.com/statistics/289945/average-daily-usage-frequency-of-colgate-toothpaste-in-the-us/

“What Is Lean?” Lean Production, https://www.leanproduction.com/