Design Life-Cycle

assess.design.(don't)consume

Tareq, Mansour

Jeffrey Zhang, Matthew Mason

DES 40A

Professor Cogdell

Apple Airpods Raw Material Life Cycle

Apple Airpods is the company’s entry product into the wireless headphone industry. They are part of their “go wireless” initiative and are intended to replace the all too familiar white Apple headphones that used to come with every Apple iPhone product. The Airpods materials are used by many of Apple’s other product lineup and are one of their smaller electronic offerings. This small device contains some sophisticated features that require many materials to be collected from around the world.

Product Description

The Airpods have similar construction materials to the traditional wired headphone but with the added components and materials to allow wireless communication. The final product consists of three parts, left ear-bud, right ear-bud, and caring/charging case. The case is available in two variations, one with wireless charging capability and one without. Both models are constructed with the same materials and will not be differentiated in this report.

In this paper, we will look at all the raw materials used to produce the product. We will also evaluate other raw materials such as reagents that are used so that the final material can exist. The scope is limited to the material used to produce the product the final product. While Apple has vowed to be carbon neutral and has taken many steps to do so (Jackson), materials such as energy sources of production will be out of the scope of this evaluation. It is assumed energy sources will include locally available power sources of production area and due to the vast production system of this product. Material such as coal, petrol, and renewable energy such as solar and wind are all expected to be contributing sources of materials.

It is also important to acknowledge, according to Apple’s Environmental Responsibility Report (Jackson), Apple has taken extensive steps to repurpose material from their old tech. They have developed disassembly robots called Liam, that extract and separate metals in the iPhone so that they can be repurposed. While some of the materials could be and hopefully are repurposed sources, this paper will investigate the original process of acquisition of the raw materials.

Raw Materials Acquisition

First, we will look at the raw materials used in the different components of the Airpods. The three parts of the Airpods are constructed with the same base materials. The basic structure of both the Airpods and the charging case consists of a plastic case that stores within it a battery and electronic circuity. While some part material is more prevalent in the case in comparison to the ear -pods or vice-versa, those quantities are not reflected here.

Housing

The external housing of the wireless ear-pods and the charging appears to use Acrylonitrile Butadiene Styrene (ABS) plastics with some aluminum hinges. ABS is the combination of three distinct monomers (Christopher J. Ferguson): acrylonitrile, butadiene, and styrene. The three products are commonly polymerized through the process of emulsion. Common reagents are used during the emulsion include water, synthesis of latexes, and acrylic acids. All three products are produced from petroleum and coal tar. Acrylonitrile is produced by combining propylene, ammonia, and air, a process called catalytic ammoxidation. Butadiene is an organic gas that is extracted from ethylene and other alkenes (White). Styrene is produced in various ways, but they all use ethylbenzene (Chen). The ABS plastic produces the hard white exterior housing that forms the exterior of the ear-pods and charging case.

The casing is held together by incorporating adhesive. The type of adhesive is not evident, but it can be assumed Apple uses a synthetic adhesive as opposed to animal-based due to Apple’s renewable stance. Synthetic adhesives are formed by combining polyvinyl acetate (PVA), water, ethanol, acetone, and other substances (Loeschen).

Battery

For a power source, separate lithium-ion batteries are housed within the casing of all three components of the Airpods. There are four main components of a lithium-ion cell, cathode, anode, electrolyte, and separator (Ghassan Zubi).

Lithium cobalt oxide is commonly used by Apple as a cathode. Lithium is commonly extracted in the form of clay or ore, then separated from counties such as China and southwestern South American countries. The extraction process of lithium undergoes a complex brine recovery process that includes chemical reagents such as sodium carbonate. Cobalt also undergoes a similar extraction process. Graphite is the current dominant anode material used in lithium-ion batteries. An aluminum foil usually covers the cathode and a copper foil the anode. The electrolyte is a lithium salt and organic solvents. Polyethylene and polypropylene are commonly used separators.

The raw materials and reagents needed to refine all the components in a battery is a complex multi-layer material acquisition that reaches nations on every continent.

Electrical Circuitry

At the heart of Airpods is the electrical circuitry that allows it to provide its intended function. The electrical circuit in all parts has common material parts. There is the conductive circuit board, with attached integrated chipsets (IC) and the necessary inputs and outputs. In these small circuit boards, vast numbers of materials and processing go into creating every aspect tiny detail. Therefore, only primary materials will be identified.

The charging case contains a traditional printed circuit board (PCB) and the two ear-pods contain a flexible double-sided circuit. PCB is a non-conductive surface that contains a substrate of conductive metal commonly copper (PrintedCircuits.com). The board is constructed with multi-levels of thin glass fabric coated with resin. Copper foil is used as a conductive contact point. The conductive copper is laminated, imaged, and etched into the circuit. Glass fiber is made from textile-grade glass fibers called silica. The resin is usually a petroleum-based material. Solder is used to interconnect all the components. Solder is made from tin and contains some iron metals (Tu).

There are several input and output sources built into the Airpods. These include speakerphones, microphones, proximity sensors, and antennas. Apple usually uses aluminum as their preferred metal in their product. The framing of the speakerphone appears to be made from aluminum. A magnet is used that is made of a ceramic ferrite material consisting of iron oxide, strontium, and ceramic binding (Stereo Speaker). Other materials go into the speaker including adhesives glues, paper coating, plastics. The microphone is made of some similar materials with a magnet made from iron boron compounds (Microphone). The antenna is made from copper wire.

There are IC components in both charging cases and ear-pods. The case contains eight IC chips used for processing, memory, and power management. The ear-pods each have seven distinct IC chips that perform the functions of communication, programming, audio codec, power control accelerometers, gyroscope, and memory use. While each IC is distinct, its manufacturing material will be evaluated according to typical IC processes. Polysilicon, pure silicon, provides the base of IC. Polysilicon is mined in the form of quartzite. It is then refined using hydrochloric acid, coal, and hydrogen gas. The polysilicon is also doped with boron and gallium to form various transistor types. Aluminum or gold is used to mount the silicon chip inside a package made of ceramic or plastic material (Integrated Circuit).

Distribution and transportation

Apple has a complex system of acquiring materials from countries around the world. Apple work with over 200 suppliers located around the world in 28 countries (Supplier List). Fossil fuels and crude oils are likely the primary material required to move all their material across the world to their many destinations. Now this system is not limited to Airpods, and considering Apple’s distribution lineup, Airpods are a minor portion of the materials collected and used by Apple.

Material for Use and Maintenance

Once the Airpods are purchased the only material used is the energy source that is used to recharge the batteries. Considering the small size of the batteries, this energy usage is minimum.

Disposal and Recycling

Due to Apple’s choice for assembly, the Airpods are difficult to disassemble. Apple will accept Airpods as part of their waste program, but there is no evidence of what they do with them. It is probable that the majority will likely end up in landfills.

Works Cited

Apple Inc. "Apple Conflict Minerals Report." 31 December 2020. Apple.com. Katherine Adams. <https://www.apple.com/supplier-responsibility/pdf/Apple-Conflict-Minerals-Report.pdf>.

Chen, Shiou-Shan. "Styrene." Kirk‐Othmer Encyclopedia of Chemical Technology (2006).

Christopher J. Ferguson, Robert J. Hughes, Duc Nguyen, Binh T. T. Pham, Robert G. Gilbert, Algirdas K. Serelis, Christopher H. Such, and Brian S. Hawkett. "Ab Initio Emulsion Polymerization by RAFT-Controlled Self-Assembly." Macromolecules (2005): 38.

Ghassan Zubi, Rodolfo Dufo-López, Monica Carvalho, Guzay Pasaoglu. "The lithium-ion battery: State of the art and future perspectives." Renewable and Sustainable Energy Reviews 89 (2018).

IFixit. Airpods 2 Teardown. 21 September 2021. <https://www.ifixit.com/Teardown/AirPods+Teardown/75578>.

Integrated Circuit. n.d. <http://www.madehow.com/Volume-2/Integrated-Circuit.html>.

Jackson, Lisa. "Environmental Progress Report." 2020. Apple.com. <https://www.apple.com/environment/pdf/Apple_Environmental_Progress_Report_2021.pdf>.

Loeschen, Daniel. "HOW GLUE IS MADE." 27 June 2019. Mixed Direct.

Microphone. n.d. <http://www.madehow.com/Volume-7/Microphone.html>.

PrintedCircuits.com. n.d. <https://www.printedcircuits.com/printed-circuits-materials/>.

Stereo Speaker. n.d. <http://www.madehow.com/Volume-7/Stereo-Speaker.html>.

Supplier List. 2021. <www.apple.com/supplier-responsibility/pdf/Apple-Supplier-List.pdf>.

Tu, King-Ning. Solder Joint Technology: Materials, Properties, and Reliability. 2007.

White, Wm. Claide. "Butadiene production process overview." Chemico-Biological Interactions (2007): 10-14.

Matthew Mason

Christina Cogdell

DES 40A

2 December 2021

Apple AirPods Life-Cycle: Energy

In 2016 Apple unveiled their interpretation of a “wireless future”; two new iPhones with no headphone jack, and a pair of fully wireless headphones to accompany them known as the AirPods (Haskins). With their seamless integration into Apple’s product ecosystem, these new headphones quickly became popular, selling almost 50 million pairs in 2019 alone (Reisinger). But, despite being touted for their simplicity, Apple AirPods have a complex life-cycle that requires significant amounts of energy to acquire raw materials, manufacture, and distribute to consumers around the world.

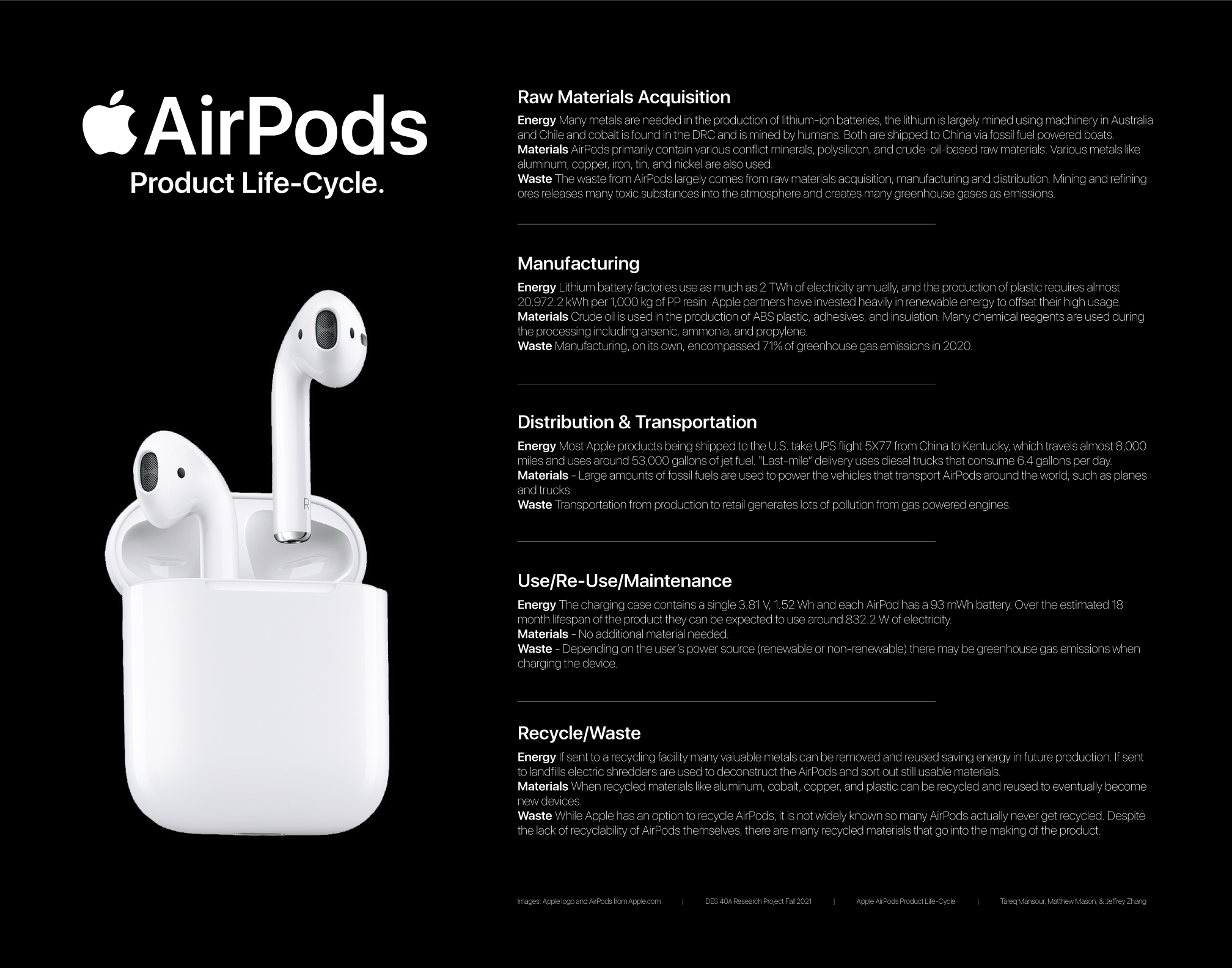

Though the label on the box may read “Made in China”, the raw-materials used in AirPods have been extracted and transported globally through methods which are extremely energy intensive. There are many different types of materials needed to create AirPods, including aluminum, cobalt, copper, and lithium, for the batteries; as well as plastics for the enclosures and rare earth elements for the speakers (Apple Environmental Progress Report 2021). Whilst some of these materials may come from recycled sources, many are extracted directly from the earth requiring energy to power machines and mines. One of the most important components of AirPods are the batteries that power the device and allow them to be wireless. Cobalt is a key component to making batteries and is found naturally in very few places around the world. A large supplier of cobalt is the Democratic Republic of the Congo, where the metal is commonly mined by humans, therefore using prime movers as the energy source (Holzman). Lithium is another key part of the battery, with almost half of the world’s lithium coming from Australia and around a fifth of the rest being mined in Chile (USGS). The most common way of obtaining lithium is through lithium brine extraction, which involves drilling down to deposits and then pumping the brine to the surface where it will dry through solar evaporation (Marshall, K). While the Sun is used as an energy source in this process, fossil fuels like coal or gasoline are likely what power the drilling and pumping equipment. There is little information on how the raw lithium is transported from the point of extraction to Asia, but we can assume that the material is moved via sea transport. Most cargo ships use around 3 gallons per ton times mile [3g/(ton x mile)], and from Australia to China is around 3,000 miles as the crow flies, therefore using a large amount of fossil fuels to power the boat (Sui). Finally when all the raw materials reach the factory, production of AirPods can begin.

In 2020 Apple’s energy usage was 2,580,00 MWh of electricity and 439,000 MWh of fuel, and of that amount a large portion likely went to product manufacturing, including the production of AirPods (Apple Environmental Progress Report 2021). Apple outsources much of the construction of the components to third party companies. China is an influential part of the lithium-ion battery supply chain as they control much of the lithium refining process and “70% of the capacity to convert cobalt ore into cobalt chemical for the battery industry” (Tarry). When assembling the battery, estimates show that large-scale battery cell factories use around 50-65 kilowatt hours of electricity per kilowatt hour of battery capacity, meaning some facilities will use as much as 2 terawatt hours annually (Kurland). Additionally the plastic enclosure and each ear piece is made from plastic, with “the average total energy required to produce [polypropylene (PP) being] 75.5 GJ [or 20972.2 kilowatt hours] per 1,000 kilograms of PP resin production” (Franklin Associates). To meet environmental goals and offset this high energy use, Apple’s manufacturing partner Foxconn, has invested heavily in renewable energy to power its factories. Between 2010 and 2013 Foxconn invested around $86 million in “carbon-reduction and energy saving projects”, including improvements to air conditioners, compressors, and the replacement of outdated technology (White). At another Foxconn factory near Hanoi, Vietnam, a rooftop solar-system was installed that produces a peak 6-megawatts and will cover about 25% of the energy use of the building (Van Thuy). Apple has also invested in many other renewable projects to lower their manufacturing footprint, such as a 40-megawatt solar farm in Sichuan, China (Marshall, C). Following production, AirPods will be packed and shipped to global markets.

AirPods are sold in over 100 countries and territories around the world, meaning they must be transported long distances which requires large amounts of energy (Kirschner). Before they are shipped to online and retail stores, AirPods are typically transported via air (Purkayastha). United Parcel Service “UPS” and FedEx flights are the most common way that Apple products are shipped from Asia to the United States (Purkayastha). For example, UPS flight 5X77 occurs six times per week, and travels the almost 8,000 mile and 17 hour journey from Shenzhen, China to Louisville, Kentucky (Flightera). To complete this one-way trip, a Boeing 747-400 airplane will on average consume around 53,000 gallons of jet fuel (Boeing). Once arrived in the U.S., AirPods will either be shipped directly to the consumer or sent to a warehouse facility where they will await delivery to retail stores, direct sales force, or wholesalers (Purkayastha). This step of the journey will either require an additional flight or ground transport by semi-trailer truck, both using petroleum fuels as an energy source. The “last-mile” distribution, or the final delivery of the AirPods to their destination, requires a diesel delivery truck that generally gets around 13.1 miles per gallon, and uses close to 6.4 gallons of fuel per day (Lammert). Once arrived at their final destination the AirPods are ready for use by the consumer.

While AirPods are being used, the frequent charging of the lithium-ion battery greatly contributes to the overall energy consumption of the product. The charging case has a single 3.81V, 1.52 watt-hour lithium-ion battery, while each AirPod contains a 93 milliwatt-hour battery, which is equal to “a little over 1% of the charge capacity of an iPhone 7” (iFixit). The batteries in AirPods are estimated to work at peak operating capacity for around 18 months, and then slowly begin to become “unusable” by not holding their charge (Haskins). Apple’s AirPods technical specifications claim that the charging case can hold a charge for “more than 24 hours of listening time”, meaning if you were to charge your AirPods every day for 18 months they would consume around 832.2 watts of electricity. The electricity used to charge them will depend on where the consumer lives and what ways the electric company generates power in the area, for example are fossil fuels or renewable energy used. When the battery of the AirPods begins to last for shorter periods of time, the user may choose to get rid of the device.

When a pair of AirPods reach the end of their life they generally go to either an electronics recycling facility or directly to the landfill. Apple’s 29-armed robotic system, Liam, is used at the recycling location to take the product apart and extract valuable materials; however in regards to AirPods it is unknown how widely used robots are in this process (Marshall, C). Robots are part of the many environmental goals put in place by Apple, including using only recycled materials like aluminum, cobalt, and copper as well as using more reused plastics (Apple Environmental Progress Report 2021). These goals aim to reduce the need of using additional energy to mine and transport new materials for future products, though it is unclear how many of these materials are currently being recycled. If the consumer does not recycle their AirPods the alternative is sending them to landfills, which requires transportation via heavy-duty diesel refuse trucks. These vehicles on average receive a low fuel economy of around 4.4 miles per gallon and move at about 16 miles per hour using lots of energy with frequent starting and stopping (Sandhu). At the landfill, after removing the lithium-ion battery, e-waste items are typically sent to a shredder where the individual raw materials can be sorted by type, making them easier to transport for other uses (ERI). Shredders at waste locations are usually powered by a three-phase current electric motor with some models having a maximum power of 15 kilowatts (Luo). Materials that cannot be reused are not saved and are sent to the landfill or the incinerator.

The life-cycle of AirPods currently uses large amounts of energy to manufacture, distribute, and use, starkly contrasting Apple’s ambitious current and future environmental goals. Currently Apple plans to make the entire company and product line carbon neutral by the year 2030, send zero waste to landfills, and create products from only recycled or renewable materials (Apple Environmental Progress Report 2021). While these goals are achievable, the current life-cycle of a small product like AirPods shows they still have a long way to go. Until they choose to begin putting the environment over profit, they will not be able to achieve their own rigorous standards.

Works Cited

2021 Apple Supplier List. Apple Inc., 2020, www.apple.com/supplier-responsibility/pdf/Apple-Supplier-List.pdf.

Apple Environmental Progress Report 2021. Apple Inc., 2021, www.apple.com/environment/pdf/Apple_Environmental_Progress_Report_2021.pdf.

Boeing. “747-400/-400ER Freighters.” StartupBoeing, May 2010, www.boeing.com/resources/boeingdotcom/company/about_bca/startup/pdf/freighters/747-400f.pdf.

ERI. Largest E-Waste Shredder At Electronic Recyclers. YouTube, 18 Mar. 2014, www.youtube.com/watch?v=erQZz9yBegI.

Flightera. “United Parcel Service (UPS) 5x77 (UPS77) SZX to ANC, ANC to SDF.” Flightera, 22 Oct. 2021, www.flightera.net/en/flight/United+Parcel+Service+%28UPS%29/5X77.

Franklin Associates. Cradle-to-Gate Life Cycle Analysis of Polypropylene (PP) Resin. American Chemistry Council (ACC) Plastics Division, Feb. 2021, www.americanchemistry.com/better-policy-regulation/plastics/resources/cradle-to-gate-life-cycle-analysis-of-polypropylene-pp-resin.

Haskins, Caroline. “Airpods Are a Tragedy.” VICE, 6 May 2019, www.vice.com/en/article/neaz3d/airpods-are-a-tragedy.

IEP. “Foxconn's Energy-Saving and Carbon-Reduction Practices.” Institute of Public & Environmental Affairs, 8 Sept. 2017, wwwen.ipe.org.cn/GreenSupplyChain/BrandStoryDetail.aspx?id=33.

iFixit. “Airpods Teardown.” IFixit, 17 May 2021, www.ifixit.com/Teardown/AirPods+Teardown/75578.

Holzman, Jael. “Low Pay, Abusive Conditions Rife at Congolese Cobalt Mines — Report.” GreenWire, 8 Nov. 2021, subscriber.politicopro.com/article/eenews/2021/11/08/low-pay-abusive-conditions-rife-at-congolese-cobalt-mines-report-282967.

Kirschner, Alex. “Apple Airpods Are Now Available.” Apple Newsroom, 25 Oct. 2021, www.apple.com/newsroom/2016/12/apple-airpods-are-now-available/.

Kurland, Simon Davidsson. “Energy Use for Gwh-Scale Lithium-Ion Battery Production.” Environmental Research Communications, vol. 2, no. 1, 2019, p. 012001., doi:10.1088/2515-7620/ab5e1e.

Lammert, M. “Twelve-Month Evaluation of UPS Diesel Hybrid Electric Delivery Vans.” National Renewable Energy Laboratory, U.S. Department of Energy, Dec. 2009, www.nrel.gov/docs/fy10osti/44134.pdf.

Luo, S, et al. “An Experimental Study on a Novel Shredder for Municipal Solid Waste (MSW).” International Journal of Hydrogen Energy, vol. 34, no. 3, 2009, pp. 1270–1274., doi:10.1016/j.ijhydene.2008.11.057.

Marshall, Christa. “Apple Hits Clean-Tech Home Stretch with IPhone-Stripping Robot.” GreenWire, 22 Mar. 2016, subscriber.politicopro.com/article/eenews/2016/03/22/apple-hits-clean-tech-home-stretch-with-iphone-stripping-robot-078857.

Marshall, Kimberly. “What Is Lithium Extraction and How Does It Work?” Samco Tech, 12 Feb. 2020, www.samcotech.com/what-is-lithium-extraction-and-how-does-it-work/.

Melin, Hans Eric. “Analysis of the Climate Impact of Lithium-Ion Batteries and How to Measure It.” Circular Energy Storage Research and Consulting, Transport & Environment, July 2019, www.transportenvironment.org/wp-content/uploads/2021/07/2019_11_Analysis_CO2_footprint_lithium-ion_batteries.pdf.

Purkayastha, Debapratim, and Adapa Srinivasa Rao. "Apple and Conflict Minerals: Ethical Sourcing for Sustainability." IUP Journal of Operations Management 14.2 (2015): 59-77. ProQuest. Web. 12 Nov. 2021.

Reisinger, Don. “Apple's Airpods Business Is Bigger than You Think.” Fortune, 14 Jan. 2020, www.fortune.com/2019/08/06/apple-airpods-business/.

Sandhu, Gurdas S et al. “In-use activity, fuel use, and emissions of heavy-duty diesel roll-off refuse trucks.” Journal of the Air & Waste Management Association (1995) vol. 65,3 (2015): 306-23. doi:10.1080/10962247.2014.990587

Sui, Congbiao, et al. “Fuel Consumption and Emissions of Ocean-Going Cargo Ship with Hybrid Propulsion and Different Fuels over Voyage.” Journal of Marine Science and Engineering, vol. 8, no. 8, 2020, p. 588., doi:10.3390/jmse8080588.

Tarry, Cameron, and Faith Martinez-Smith. “Supply Chain for Lithium and Critical Minerals Is ... Critical.” ClearPath, 11 June 2020, clearpath.org/tech-101/supply-chain-for-lithium-and-critical-minerals-is-critical/#source-8.

USGS. “Mineral Commodity Summaries 2021.” U.S. Geological Survey, 2021, doi.org/10.3133/mcs2021.

Van Thuy, Hoang. “Foxconn Vietnam, Hexagon Peak and Inpos to Build and Operate the Largest Rooftop Solar System in Vietnam.” Business Wire, 23 July 2020, www.businesswire.com/news/home/20200722006022/en/Foxconn-Vietnam-Hexagon-Peak-and-Inpos-to-Build-and-Operate-the-Largest-Rooftop-Solar-System-in-Vietnam.

White, Glenn. “Foxconn Develops Carbon-Reduction Arm to Save Energy and Promote Carbon Trading: Technology.” Manufacturing Global, 16 May 2020, manufacturingglobal.com/technology/foxconn-develops-carbon-reduction-arm-save-energy-and-promote-carbon-trading.

Jeffrey Zhang

Cogdell

DES 40A

12/2/2021

AirPods: Waste and Emissions

One of the most popular technology companies in the world is Apple. Their impact can be seen across the globe through their aesthetic designs and modern approach to electronics. As of 2021, Apple has become the world’s most valuable company. In the midst of their innovation and economic success, Apple’s environmental impact has always been a topic of concern. My group has decided to research the Apple AirPods. AirPods are the company’s first wireless earbuds offering hours of listening time and seamless connection to Apple’s other electronics. Following their release, AirPods quickly became the fastest growing product line generating billions in revenue in their first year, but their waste products are something that the company has swept under the rug. Despite the visible life cycle of AirPods being quite short, performing for two years on average, their production life cycle in terms of waste management leaves a much longer-lasting imprint. The heaviest emissions come from raw materials acquisition, manufacturing, and distribution in the form of greenhouse gases and solid waste. Even though Apple makes an effort to reduce its environmental impact in every step of the creation of AirPods, from their production to short life span to inefficiency in repair, there are many waste outputs to these devices.

Greenhouse gases are one of the top emissions from Apple. From production to manufacturing, every step of the way creates a large amount of waste. Releasing carbon into the atmosphere traps heat on the earth's surface causing a phenomenon called global warming. In recent years Apple has tried to become more conscious about their emissions and aims to be net carbon neutral by 2030 (Apple). In their environmental impact report, the company explains in detail how they have used different ways in the past year to reduce their carbon emissions ranging from recycling methods to renewable energy.

In this life cycle analysis, our group has decided to focus on a few specific, major parts of the production of the final AirPods as a whole. The life cycle of any product can be expansive if there aren’t specific delineators of where to track until. To lay down a foundation for our project without creating too many complications, we decided to focus on the product itself, disregarding packaging and other factors like the charging cable and block for the moment. We placed these limits to help us focus on the life cycle of the AirPods product since that is the most prominent use of energy in this particular life cycle. We also decided to only track the shipment of products from the manufacturers to the retailer since it would be too difficult to calculate the energy consumption of customers.

Since a portion of the waste of AirPods comes from raw materials acquisition, Apple has begun to implement significantly more recycled materials in their production. In 2020, over 25 percent of the tin used for products came from recycled sources, and the company projects to scale usage of recycled materials in the future (Apple 39). Recycled and hydro-smelted aluminium has helped Apple to reduce carbon emissions related to aluminium by 72% since 2015 as well (Apple 15). The heightened use of recycled materials along with more efficient manufacturing and switching to clean energy alternatives helped with reducing waste from mining valuable materials. This is significant for Apple because a large portion of its waste production does come from mining for rare metals. Neodymium, the magnet that makes the AirPods vibrate, and cobalt has to be mined in other countries like China and Congo. The first concern lies in Chinese and Taiwanese producers sourcing 90% of their energy from nonrenewable sources. To reach its target of becoming carbon neutral by 2030, Apple must consider cutting off some suppliers or shifting to more renewable energy sources in supplier countries. There are several issues in regards to poor working conditions, high death toll, and child labor occuring in Congo. Not only is the mining environmentally damaging and morally questionable, it increases the local community’s exposure to toxic metals that have been linked to many diseases..

Unfortunately, Apple’s waste contribution in the AirPods life cycle occurs the most during product manufacturing which encompasses 71% of greenhouse gas emissions from Apple in 2020 (Statista). The majority of manufacturing up until COVID was occuring in China but due to heightened tensions between China and the US, Apple has begun to slowly transition some of the manufacturing to Vietnam (Agostino). Despite emissions being extremely high from China, in past years, the company has been pushing for factories there to move toward renewable energy sources to reduce their carbon footprint. Copper wires, used in the production of AirPods will leave tailings through the separation of the ore releasing sulfur and other toxic waste. On top of that nickel used for plating requires massive burning of fossil fuels since the material needs to be processed thoroughly.

Even though Apple is known for its trade-in policy and recycling system, one of the few products that do not offer the option for trade-ins is the AirPod. The AirPod’s unique shape and construction offer very few options for the user once the battery begins to wear down meaning that consumers must either purchase a new set or find a third party to replace the battery for them. This system, unlike the iPhone trade-in policy, is very inefficient and uncharacteristic for the company. Although AirPods can be recycled through Apple, it is not advertised or widely known that this is an option. Some say that the reason for this is because Apple actually has to spend extra to dismantle AirPods and the parts that can be recycled are not as valuable as other Apple products (Appleinsider). This theory that recycling AirPods is not profitable for the company makes the waste of the life cycle increase greatly since people are generally not recycling Airpods once they stop performing their best. The lack of recyclability in AirPods makes it difficult for the valuable materials in the product to be used again meaning more energy will be distributed to materials acquisition.

As a company, it seems Apple is still trying to be more environmentally conscious where they can. According to their 2021 environmental report card, they appear to be taking initiative in finding greener alternative sources of energy as well as discovering more ways to reduce waste in their designs. As the company has directed over 35 million pounds of waste into landfills across the world, Apple still has a long way to go. Surprisingly, Apple doesn’t have an environmental report card for AirPods specifically like they do for every other one of their products despite AirPods being a prominent product for the company. In my opinion there is something different about the waste production of AirPods that Apple would not like to share with the public. Be it the recycling process or glue together manufacturing style, information about the environmental consciousness of Airpods have not been shared directly by the company to this day.

These points are not made to disregard Apple’s efforts to be more environmentally conscious but to point out the specific details of the life cycle of AirPods and its waste production through every process. I believe that Apple has the right intentions in finding solutions to make the company greener but the sheer scale of the company and production of millions of units per year really hinder their ability to follow through on big promises. The Airpods in particular lack adequate recyclability options, sustainable manufacturing and renewable resource acquisition.

Bibliography:

Agostino, Thalia. “The Global Journey of Airpods.” ArcGIS StoryMaps, Esri, 5 Nov. 2020, https://storymaps.arcgis.com/stories/d10c804add0644218001ba812835b88d.

Al Jazeera. “Is Apple Green? Not until Its Taiwanese Suppliers Cut Emissions.” Environment | Al Jazeera, Al Jazeera, 12 Aug. 2020, https://www.aljazeera.com/economy/2020/8/12/is-apple-green-not-until-its-taiwanese-suppliers-cut-emissions.

Apple. “Apple Environmental Progress Report 2021.” Apple Inc., 2021, www.apple.com/environment/pdf/Apple_Environmental_Progress_Report_2021.pdf.

Appleinsider. “Apple Comments on Airpods' Environmental Impact, Touts Recyclability | Appleinsider.” Google, Google, 29 May 2019, https://www.google.com/amp/s/appleinsider.com/articles/19/05/29/apple-comments-on-airpods-environmental-impact-touts-recyclability/amp/.

Beckett-Hester, Finn. “The e-Waste Problem: A Case Study of Apple.” GLOBUS, 15 Jan. 2021, https://globuswarwick.com/2021/01/21/the-e-waste-problem-a-case-study-of-apple/.

Frechette, J., & Williams, R. (Eds.). (2015). Media Education for a Digital Generation (1st ed.). Routledge. https://doi.org/10.4324/9781315682372

Haskins, Caroline. “Airpods Are a Tragedy.” VICE, https://www.vice.com/en/article/neaz3d/airpods-are-a-tragedy.

Oremus, Will. “What Really Happens to Airpods When They Die.” Medium, OneZero, 28 May 2019, https://onezero.medium.com/what-really-happens-to-airpods-when-they-die-9ba2fe97b346.

Perez, Santiago. “Is Apple Delivering on Its Environmental Claims? - E-Waste World Conference & Expo.” EWaste World Conference Expo, 12 Feb. 2020, https://www.ewaste-expo.com/is-apple-delivering-on-its-environmental-claims/.

Published by Ian Tiseo, Statista, and May 18. “Apple: GHG Emissions Share by Segment 2020.” Statista, 18 May 2021, https://www.statista.com/statistics/528586/share-of-greenhouse-gas-emissions-from-apple-by-segment/.