Design Life-Cycle

assess.design.(don't)consume

Jiaomei Mai

Professor Cogdell

DES 40A

30 November 2019

Raw Material Use in The Full Life Cycle of a Pop-up Electric Toaster Oven

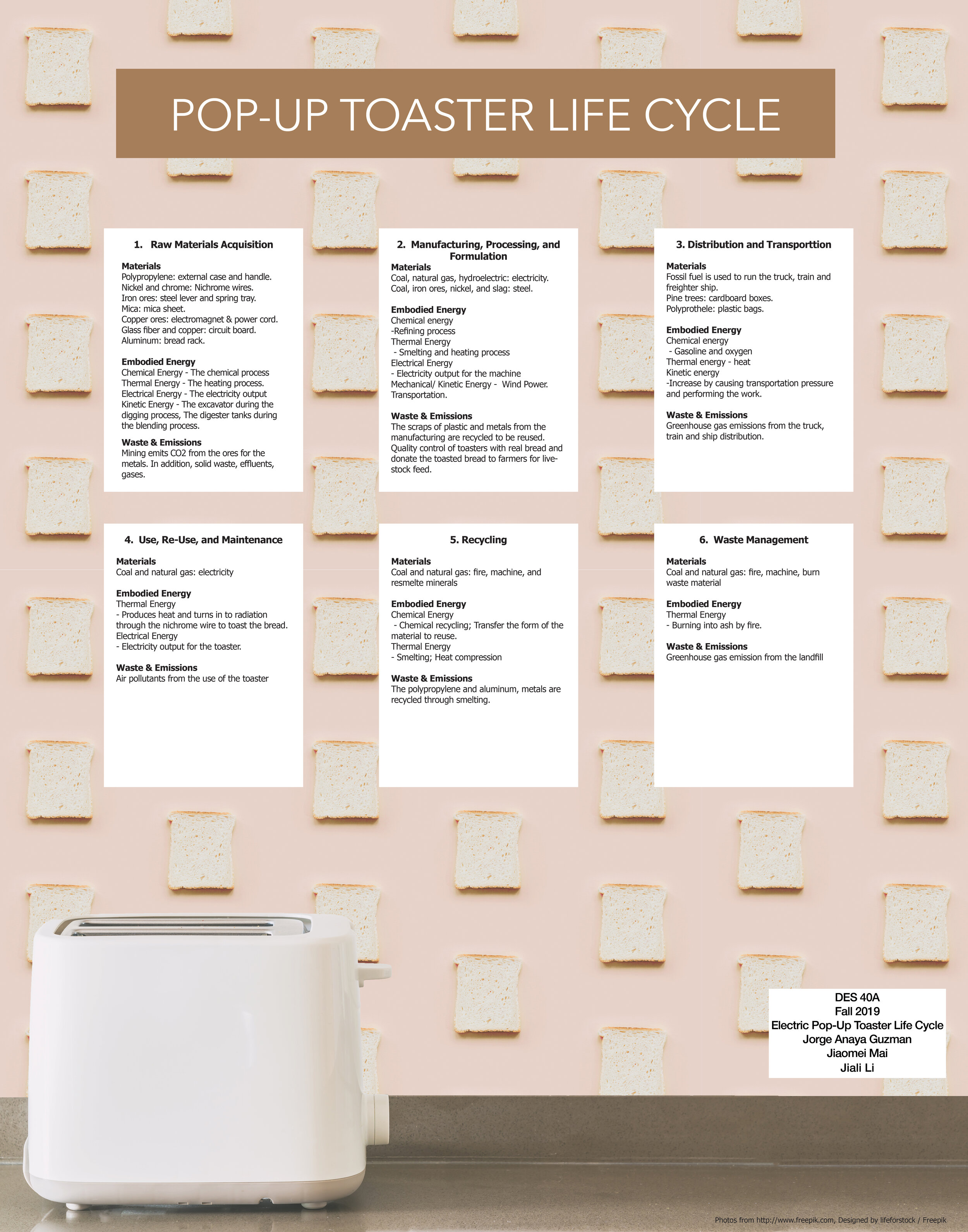

A pop-up electric toaster oven is one of the most convenient household appliances in modern American kitchen. People know that the price of a toaster is inexpensive, but they do not know how many materials are required to make a toaster oven. A small component inside a toaster would consume a lot of raw materials to make. By considering the plastics, metals, and fueling requirements used to produce a conventional pop-up toaster oven, the complexities and immense material requirements throughout its life cycle can be demonstrated.

It is necessary to illustrate the multifarious components inside a toaster so that people would understand the complexities material requirements of a toaster. The general structure of a toaster involves the external plastic case, the keeper handle, the heater sensor, the bread rack, the electric circuit board and the electric cord. The list of components of a toaster is made by mixing at least two materials from the ground of our earth. Raw materials consumption is the essential prerequisites of mass production. A toaster is produced because many different types of raw materials are mined during the materials acquisition stage, such as, iron, copper, nickel, chromium, bauxite, and coal etc. Meanwhile, several fuels are used during the rest lifecycle of a toaster. Plastics and minerals are two main material requirements in the raw materials acquisition stage.

The body of a toaster is made by heat-resistant “plastic, polypropylene”. Plastics can be decomposed from fossilized or bio-based materials, such as coal, crude oil or natural gas (Thwaites 2011). Oil refinery is used in the distillation process of plastic production. Crude oil is separated into different fractions in this process. Then, ‘Naphtha’ is an important material which is used to generate different monomers in the polymerization process. Each plastic has its own properties because the molecular structure of those monomers is different. Plastic is one type of petroleum products which is classified into two main polymer families, thermoplastics and thermosets. Polypropylene is one kind of thermoplastic. Since polypropylene is heat-resistant, it is always used in kitchen appliances, microwave-proof containers and food packaging, etc. (Plastics and Environment). The U.S is one of the large crude oil producers around the world. In 2018, 68% of total U.S crude oil production come from five states, including Texas, North Dakota, New Mexico, Oklahoma, and Alaska (“Oil: crude and petroleum products explained”). Furthermore, America imports 5.95 million short tons of coal from other countries in 2018. The top five countries are Colombia, Indonesia, Canada, Russia, and South Africa (“Coal explained: coal imports and exports”). Coal is normally mined by a large machine. It is removed by two mining methods: surface mining and deep mining. Then, coal would be cleaned at the mining site before being shipped to consumers. In 2018, the U.S imports natural gas from Canada and Mexico. About 97% of natural gas comes from Canada by pipeline. The annual imports have declined since 2007. (“Nature gas imports and exports”). It is hard to count how many raw materials use to make plastics. However, coal, crude oil, and natural gas are three important raw materials which plays an important influence on industrial production. They are also used to produce a toaster. A toaster case is composed by the thermoplastics. The second raw material requirement is metal.

The bread rack of a toaster is made by aluminum. Aluminum is an abundant metallic element in the earth crust. It is a lightweight and silvery-white metal. Aluminum is initial extracted from bauxite ores. In the United States, bauxite ore is normally imported from Jamaica and South America (Harris 2008). Bauxite ore is alternated into aluminum oxide (alumina) by adding the natural gas. Then, aluminum will be extracted from the alumina through the ‘smelting’ process. Electricity and solution are required to apply in the smelting process. At the same time, aluminum can also be produced from the recycle aluminum scrap. The aluminum scrap will be reused after the recycle processing. Natural gas is burnt to fire the aluminum scrap in this process. (“Energy needed to produce aluminum”). The molten aluminum will be poured into the large pots. In the fabricating process, aluminum liquid is cleaned at the pot-line and mixed with other metals in the furnace to make the ingots. Later, aluminum would be formed into different shapes before it is used to make many manufactured appliances (Harris 2008). Aluminum is a ductile metal which is also widely used in the different applications because its high conductivity. Aluminum would be alloyed with nickel, iron, cobalt, magnesium and manganese in order to increase the strength and corrosion resistance of the aluminum sheets. The complicative material consumption is verified while we see the industrial process of the aluminum sheet. It is obvious to spend more materials than we see above a toaster. There are many other minerals also used to make a toaster beside aluminum.

Nickel, chromium and iron are three minerals which is composed of the toaster heating device. Nichrome is an alloy which combines Nickel, Chromium, and iron. Since nichrome is high heat and high temperature oxidation resistance, it is used in building toasters, soldering iron, hair dryers and electric ovens. The component radio of Nickel and Chromium will change the resistivity of the electric heaters. The well-known resistance alloy comprised 80% Nickel and 20% Chromium which is normally used in the toaster (Flournoy 2018). In 2018, Nickel ores and scraps are imported from Canada. Almost a half of primary nickel is used to make stainless alloy and steel products. “The U.S. steel industry produces approximately 2.4 million tons of nickel-bearing stainless steel in 2018” (“Nickel Statistics and Information”). Nickel can be extracted from nickel laterite ores and nickel sulfide ores. The extraction and refining process are different between these two nickel ores. However, both nickel ores can be processed by ‘pyrometallurgical’ or ‘hydrometallurgical’ methods. Pyrometallurgical process includes roasting, smelting, and converting. The sulfur dioxide is removed from the sulfide nickel ores during the roasting stage. Then, a siliceous slag is smelted in the furnace to get an impure nickel matte. The matte will be converted into the copper-nickel matte. Last, the matte can be treated in different ways until the nickel is extracted. Furthermore, ammonia or sulfuric acid is used in the hydrometallurgical process. The sulfide and oxide nickel ores are leached and dissolved in the solution. The hydrogen is also used to refine nickel in this process. The impurities are separated from the gangues by these two manufacturing stages. (Tundermann et al, 2013). Nickel is often used as refined metal or ferronickel to make stainless steel.

Furthermore, Chromium is also used to make nichrome wire. Chromium is one of modern versatile elements which occurs worldwide. Chromium ores are large imported from South Africa in the United States. Chromium containing scrap normally comes from Canada. (“Chromium Statistics and Information”). Chromium uses widely in iron, steel and nonferrous alloys to enhance hardenability and resistance to corrosion and oxidation (Chromium-1977). Nichrome wire combines both metal properties of Nickel and Chromium. Therefore, the Nichrome wire is corrosion resistant and high electrical resistance which is widely used as the heating application for tools and appliances. The current is flowing in the nichrome wire which rises the temperature of a toaster quickly. A slide of bread is heating during this energy conversion process. Steel is made from iron. Iron ores are mined in Australia and Brazil. Iron is extracted from the iron ores which is a primary mineral source in the steel industry. (“Iron Ore Statistics and Information”). Some minerals are added to make steel, such as copper, nickel, chromium. The fabricator prefers to combine different raw materials to make different tools, machines and devices. Iron is used to make the stainless steel while copper is used to make the electric circuit board in a toaster.

The toaster base is composed by the electric circuit board and mica sheet. The older heating sensor is made by the bio-metallic: copper and steel. However, the new toaster heating sensor is called ‘electro-magnet’. Electromagnet is the center piece of the printed circuit board. Electromagnet is a length of conductive wire wrapped around a piece of metal. The conductive wire is normally made by copper. The metal is the iron rod (“How Electromagnets Work”). The circuit board is a glass fiber reinforced with epoxy resin with a copper foil bonded on to one or two sides (“Printed Circuit Board”). The circuit plate is made by copper. The copper-clad laminates are made with different matrix resin systems and reinforcements. The ‘electrical glass’ is the most common reinforcement. The resin systems are ‘fire resistant difunctional’ and ‘polyfunctional epoxies’ (Blackwell 2000). A current is flowing through the wire which creates a magnetic field around. Electromagnet is useful because it is easy to control the current in the circuit board. The new toaster uses the electromagnet to hold the “keeper” down (Brain and Looper 2018). The keeper is also made with aluminum which connects the circuit board with the heating device of the toaster. Mica is one type of silicate minerals which is normally imported from India, Brazil and Madagascar (Hedrick 1997). Mica is semi-hard pegmatite ore which is heat-resistant and non-conductive. Sheet mica is a silvery-grey sheet which is used as electrical insulators in electronic equipment. In addition, the electric wire is made by the copper. Copper is produced in Arizona, Ultra and New Mexico (“Copper Statistics and Information”). Copper is extracted from the copper sulfide or oxidized ores. The sulfide copper ores are extracted through pyrometallurgy method. The copper is obtained by thermal treatment. The oxidized ores are leached with chemical solution to dissolve the copper. This process is called “hydrometallurgy”. Copper alloys are electrical conductivity which uses in many electric products (Dhir 2017). There are many minerals used in the materials acquisition stage. Furthermore, fuels are widely used during the manufactory processing of a toaster.

Although there is no new material added into the manufacturing stage of a toaster, coal and natural gas are heavy used to run the machine. There are three stages of installing a toaster. First, the toaster case is made by the pressure molded plastic. Polypropylene is normally formed as pellets. Those pellets are putted inside to the hopper and heated to 350 Fahrenheit (177 Celsius). It will become the semi-fluid after the compound heating. The semi-fluid will be mold and cooled at a toaster case. The toaster body is ready to use (“Toaster”). Second, the manufacturer would purchase some basic components from the suppliers. The components are shipped from a manufacture to the toaster factory. Finally, they are assembled by machine in the toaster factory. Nichrome wires are wrapped automatically around the mica sheet within a machine. The spring-loaded tray is screwed between the mica sheet which is located at the toaster base. It is also connected to the bread bracket in the middle and the printed circuit board at the bottom. The electric cords are threaded into the electromagnets on the printed circuit board. The toaster body is installed after all components are building up (Curry 2016). We assume that electricity is used to run the machine during this whole process.

Coal and slag are added into the manufacturing process of steel production. In the melting process, different raw materials (iron ores, chromium, silica) are melted together in the electric furnace. Coal is added into this process involves by 8 to 12 hours of intense heat. Slag is added into the metal liquid. This mixture is called ‘molten steel’. The next process is casting. The molten steel can be shaped by blooms, billets and slabs. Stainless steel is formed into bar or wire by blooms and billets. Slabs means to formed into plate or sheet. Hardened steel is made by annealing. Annealing describes the process of heat treatment. Stainless steel is either cooled or heated under the controlled conditions to change the toughness of the metal. The heating treatment increases the strength of the steel. Different steels would be treated with different heating temperature. The annealing and descaling are using several times during the manufacturing process of steel production. The stainless steel is cut into different shapes and forms before the final step. The surface finishes are applied to the stainless steel at the final step (“How Products Are Made: Stainless Steel”). The stainless steel will become different tools and appliances after shipping to the fabricator or end user. The spring-loaded tray is made by hardened steel. The screws and pins are also made by stainless steel. It is hard to image how many raw materials are used to make stainless steel. However, many materials are used during the manufacturing process of stainless steel. At the same time, fossil fuels are mainly used to run the machines in the metal factory. Fuel sources play an important role on commodity manufacturing, transportation, and recycle stages of a toaster.

Fossil Fuel is widely used in different conveyances during the transportation stage. Crude oil and natural gas are furnished by pipeline, tanker or tank ship (“How to Make Petrol or gas from Crude Oil”). Coal and metal are transported by train, barge or truck. Some mineral ores are shipped by freighter ship. Fuels are burnt to maintain the transportation process. Furthermore, cardboard boxes and plastic bags are widely used in the product packaging. Pine trees are the important raw materials to make the corrugate cardboard. The packaging companies own their land to grow the pine trees. The limbs are removed from the trees. The trunks are shipped to the pulp mill by truck. The trunks are immersed in the sulfate solution which the ‘wood chips’ are broken down into ‘fibrous pulp’. The fibrous pulp will become the craft paper after putting into the paper machine. The craft paper will be used to make the cardboard boxes (“Corrugated Cardboard”). Moreover, the plastic wraps are normally made by polystyrene. We suppose that the toaster is wrapped by the plastic bags before putting into the cardboard box. The toaster is shipped by the big truck from the factory to the store. If the toaster is imported from other countries, the cargo ship can be used. Fuels play an important influence on the transportation stage.

Coal, natural gas and some renewable sources are used to generate electricity which impacts the normal use of a toaster. Electricity is most produced by coal and natural gas. Water and wind are less used to produce electricity in the United States. Electricity is widely used in modern life. A toaster will be out of order without electricity. In addition, Coal and natural gas are also used in the recycle and waste management process. A toaster is broken down into different pieces in the recycle center. Different components have different treatment methods. Plastics would be discarded, incinerated or recycled. Only small percentage of plastic will be reused to make other produces (Plastic and Environment). Minerals will be recycled through smelting process by the metal factory. Coal and natural gas are burnt to fire any waste materials in the recycle center. Plastics, minerals and fuels are indispensable in the full-life cycle of a toaster.

A toaster oven is consumed so much materials from creation to cassation throughout the life cycle. We do not detail all materials that are used to make a toaster because many sources are only available for the fabricator. However, it is a fact that a toaster is made by several materials. Plastics, metals and fuels are three common materials which are also widely used in many factories. It would be a problem if people are overusing the amount of those materials. What will happen when we do not have enough materials in the future? People should reduce material consumptions in the full-life cycle of a toaster.

Bibliography

Ayres, Robert U, Arnim Von Gleich, and Stefan Gossling-Reisemann. Sustainable Metals Management: Securing Our Future – Steps towards a Closed Loop Economy (2006). Web.

Blackwell, Glenn R. The Electronic Packaging Handbook, 2000.

Brain, Marshall, and Lance Looper. “How Electromagnets Works.” HowStuffWorks Science, HowStuffWorks, 28 June 2018, https://science.howstuffworks.com/electromagnet.htm.

Copper Alloys: Preparation, Properties and Applications, edited by Michael Naboka, and Jennifer Giordano, Nova Science Publishers, Incorporated, 2011. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=3021164.

“Chromium Statistics and Information.” Commodity Statistic and Information, U.S. Geological Survey, 29 Nov. 2019, https://www.usgs.gov/centers/nmic/chromium-statistics-and-information

“Copper Statistics and Information.” National Minerals Information Center, 28 Nov. 2019, https://www.usgs.gov/centers/nmic/copper-statistics-and-information.

“Corrugated Cardboard.” How Products Are Made, 28 Nov. 2019, http://www.madehow.com/Volume-1/Corrugated-Cardboard.html.

Curry, Connor. “How Toasters Are Made.” Prezi.com, 24 Mar. 2016, https://prezi.com/u7oo9hi3rrrd/how-toasters-are-made/

Deshmukh, Suresh P, Mahindra B Parmar, Ashok C Rao, and Varinder Wadhwa. “Polymer- and Wax-based Monoconcentrate Predispersed Pigments in the Colouring of Plastics.” Coloration Technology 126.4 (2010): 189-93. Web.

Dhir, Ravindra K., Jorge De Brito, Raman Mangabhai, and Chao Qun Lye. Sustainable Construction Materials: Copper Slag (2017). Web.

Flournoy, Blake. What Is Nichrome Wire Used For? Sciencing, 9 May 2018, https://sciencing.com/nichrome-wire-used-for-5871336.html

Garay, Ronald, and Ronald G. Garay. U.S Steel and Gary, West Virginia: Corporate Paternalism in Appalachia, University of Tennessee Press, 2011. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=693133.

Harrison, R. M., and R. E. Hester. Plastics and the Environment (2019). Web.

Harris, Ronald M., Society of Plastics Engineers, and Plastics Design Library, Coloring Technology for Plastics. Norwich, NY: Society of Plastics Engineers, Plastics Design Library, 1999. Print.

Hedrick, Jacks B. “Mica Sheet.” Mineral Commodity Summaries, 2009, Google, 28 Nov. 2019, https://s3-us-west-2.amazonaws.com/prd-wret/assets/palladium/production/mineral-pubs/mica/440397.pdf.

How to Make Petrol or Gas from Crude Oil, Carltfross, Youtube, 14 Dec. 2010, https://www.youtube.com/watch?v=9Py8-Xy9MKo.

“How Its Made: Aluminum.” YouTube: Documentary Tube, YouTube, https://www.youtube.com/watch?v=t4HAzfhWtqE.

Kaebernick, H., et al. “Sustainable Product Development and Manufacturing by Considering Environmental Requirements.” Robotics and Computer-Integrated Manufacturing, Pergamon, 14 Aug. 2003, https://www.sciencedirect.com/science/article/pii/S0736584503000565?via=ihub.

Kosior, Edward, et al. “Plastic Recycling.” The Royal Society of Chemistry, Publishing Home a Chemical Science Journals, Books and Databases, 19 Oct. 2018, https://pubs.rsc.org/en/content/chapterhtml/2018/bk9781788012416-00156?isbn=978-1-78801-241-6&secode=bk.

Morning, John L., and United States. Bureau of Mines. Chromium. Washington]: Bureau of Mines, U.S. Dept. of the Interior, 1977. Print. Mineral Commodity Profiles; MCP-1.

“Mica.” Minerals Education Coalition, 28 Nov. 2019, https://mineralseducationcoalition.org/minerals-database/mica/.

“NICKEL AND ITS USES.” American Journal of Numismatics, and Bulletin of the American Numismatic and Archaeological Society, vol. 27, no. 3, 1893, pp.60-61. JSTOR, www.jstor.org/stable/43585300.

“Nickel Statistics and Information.” National Minerals Information Center, U.S. Geological Survey, 28 Nov. 2019,

https://www.usgs.gov/centers/nmic/nickel-statistics-and-information.

“Printed Circuit Board.” How Products Are Made, 28 Nov. 2019, http://www.madehow.com/Volume-2/Printed-Circuit-Board.html.

“Pyrometallurgy.” Pyrometallurgy- an Overview| ScienceDirect Topics, Waste Electrical and Electronic Equipment Handbook 2012, 28 Nov. 2019, https://www.sciencedirect.com/topics/materials-science/pyrometallurgy.

“Stainless Steel.” How Products Are Made, 28 Nov. 2019, http://www.madehow.com/Volume-1/Stainless-Steel.html#ixzz65lYKsWHh

Taylor, John Campbell, and Edmund Merriman Wise. “Nickel Processing.” Encyclopedia Britannica, Encyclopedia Britannica, Inc., 5 Sept. 2013, https://www.britannica.com/technology/nickel-processing.

Thompson, Frank, “Waste Not, Want Not.” Physics Education 50.2 (2015): 258-60. Wed.

Thwaites, Thomas. The Toaster Project: Or A Heroic Attempt to Build a Simple Electric Appliance from Scratch. 1st ed. New York: Princeton Architectural, 2011. Print.

“Toaster.” How Products Are Made, 28 Nov. 2019, http://www.madehow.com/Volume-7/Toaster.html.

Tundermann, John H., et al. “Nickel and Nickel Alloys.” Wiley Online Library, American Cancer Society, 19 Apr. 2013, https://onlinelibrary.wiley.com/doi/10.1002/0471238961.1409031120211404.a01.pub3.

United States. Agency for Toxic Substances Disease Registry. Division of Toxicology Environmental Medicine. Aluminum, 2006.

Jiali Li

Professor Cogdell

DES 40A

17 November 2019

Embodied Energy used in the Process of the pop-up electric toaster

Introduction

The electric toaster is a common kitchen appliance to serve hot slice bread by toasting. Statistic shows the retail unit sales of toasters in the United States from 2010 to 2018. In 2018, approximately 17.4 million toasters were sold over retail channels in the United States. (Liu) The first model of the electric toaster “D-12” only toasts one side of the bread at a time and required someone to turn off the toaster when the slice of toast looks ready. The pup-up electric toaster today is more convenient than the original electric toaster by the technology development. However, the pup-up electric toaster involved more embodied energy compare to the original toaster because the complex components required more energy to create the multiple various parts in the toaster. In order to make the comparison, energy use in the process was grouped into definable steps, e.g., mining of virgin materials, transporting the materials, and garbage collection. (Kunz & Emmerson, p2) The life cycle of the pup-up electric toaster oven involve thermal energy, chemical energy, mechanical/kinetic energy, and electrical energy in the process of the transfering material, transportation, manufacturing, customer operation, and the waste and recycling of the pup-up electric toaster. The high energy requirements behind producing, operating, and recycling such as the process of cradle-to-grave components. It shows that the embodied energy of the product involves significantly more inputs than mere consumer operation of the pop-up electric toaster oven.

Raw Materials Aqusistion

The primary raw materials of the pup-up electric toasters are iron ores, polypropylene, mica, copper ores, and aluminum. The raw materials acquisition process including gathering, transportation, and refining. The refining process consume most of the energy in raw materials acquisition. The raw material are melt it to liquid by high temperature and formed into small pieces. These pieces are ship to the factory by transportation systems for the manufacturing process. Iron are made of limestone and coke through the heating process convent from thermal energy to chemical energy. The coke and limestone will be place in the top of the furnace to get heat by the 2200 kelvin degree burning fire from coal in the bottom of the furnace. The coke will transfer to iron oxides and the limestone will removes the slag during the heating process. The process involved electrical Energy from the electricity output to the heating machine. Thermal Energy for the heating process. Chemical Energy during the heating process. For polypropylene, the feedstock are break down to the base parts of the plastic through the heating process in furnaces by coal. These base parts will cooled into a dense liquid to propylene plastic and dry it in the mold after. The copper ores refining process in pyrometallurgy by smelting. Smelting technologies include flash smelting, Isasmelt, Noranda, or El Teniente furnaces by using sinter plants and blast furnaces. The process involved chemical Energy for the chemical process form transferring the raw material to the second raw material. Thermal Energy for the heating process. Mica is a mineral that insulating electricity. Mica will being cut off from the mica rock that usually in gneiss, schist and granite. Aluminum are from the bauxite and caustic soda. the bauxite is from lime, soda ash and water. then all the material will transfer to digester tanks to use steam pressure to blended it together. After the steam pressure process, the alumina dissolves out of the bauxite forming sodium aluminate. then the sodium aluminate will separated from the tanks which the heavier impurities settle to the liquid and piped to filter presses to remove the finer impurities suspend in the liquid. than compressed air to trihydrate it to the crystals. then heated to 2000 degree temperatures in rotary kilns to dry it and combined to the white powder aluminum oxide. The raw materials are extractioning and being shipped by trains, ships and trucks from the country all over the world to the U.S. The process involved kinetic Energy for the digester tanks during blending process. Thermal Energy during heating process.

Manufactoring Formulation

The electric pop-up toaster are made of steel, mica, polypropylene plastic, copper, aluminum and nickel. Most of the energy consumed as raw material is primary, while most of the energy consumed for power is secondary. In terms of their raw material inputs, the major energy processing industries were: petroleum refining (56% of total; NG- liquids plants (31%); coke ovens (9%); blast furnaces (2%). (Teitelbaum) Transfer the raw material to the secondary material is the first step in the manufacturing process. After the energy process of the raw material acquisition, the second raw material transfer to secondary material including mica sheet, chromium, talcum powder, plastic, nichrome. Then the secondary materials transfer to various part of the toaster including spring, bread rack, heat sensor, trip plate, level, timing mechanism, electromagnet, and browning control. These process involved the thermal energy to melt the secondary material to form it to the various part. It involved kinetic energy such as the solar power and wind power consume to thermal energy such as electricity to shape and mold the various parts from the press machine. The combining process require electrical energy that convince from the thermal energy, then the electrical energy give the machine power to convince to mechanical/kinetic energy to put all the various parts together and screw together to form the shell of the toaster. Also the small various parts will be combine by people’s hand. After the forming process, then is the packing process. The packing process are done by the packing machine which require the thermal energy convent to electrical energy then convert to kinetic energy to give the packing machine power. Some animate prime mover were involved such as human during the process, they will make sure the quality of the product is qualify the standard/the product will being pack to ship to the companies storiage, than the companies will send the product to the store for the consumer to buy.

The consumer operation

The energies use from consumer operation starting from a toaster get electrical energy from the outlet to converts the electric charges into thermal energy, thermal energy produce heat and turn in to radiation through the nichrome wire in order to toast the bread. The 2 slice electronic pop-up toaster has two mica sheet that wrap up with nichrome wire. When people push down the button, it push down the single lever which is the injector will be push down to connect the wire to the electricity to create red radiation from the nichrome wire to the bread lowering and keep the bread toast. The pup-up electric toaster know when is time to turn it off is because it has the timer to shut off power and released a pop-up spring when the slice of toast was ready. The timer change by temperature sensor. When the temperature in the toaster reaches the temperature set by the dial, the sensor picks it up and triggers the release. The thermostat are controlling the how long the current takes in order to delivered from the power line to the heating element. The heating process will stop and the power will turn off then release the locking tab when the power line reached the set temperature, then the bread will “pop up” while the tray return to its original position. After the toaster being dump in the garbage can. The garage will be ship to the landfill by the garbage trucks. And that require the energy for transportation.

Distribution and Transportation

Energy is likewise necessary for transport from the field to the processing plant and from there to the respective destination. If this energy is generate by means of fossil fuels, CO2 is produced. (Leopoldina) All process require transportation, no matter deliver the material from the origin place to the factory, deliver the toaster from factory to the companies, deliver the product from companies to the store, deliver the product from the store to the consumer, deliver the trash from the garbage can to the landfill.

The transportational process from transporting the secondary material from a manufacturer to the toaster factory and the energies use from transporting the toaster from the factory to the market require chemical energy mechanical energy and thermal energy for the transportational process. The transportational process is energy conversions that from chemical energy to thermal energy. The potential chemical energy in gasoline and oxygen are converted into thermal energy, then it transformed to the mechanical/ kinetic energy that make the trucks moves to increasing its kinetic energy by causing the pressure and performing the work.

Recycling and waste management

The last transportation part of the life circle is to deliver the trash to recycling and waste. The central recyclable of the electronic pop-up toaster is metals and plastic. The recycling process require thermal energy, chemical energy, and mechanical/kinetic energy to break down the secondary material to the raw material, then split the raw material that can be recycling by filtering the materials and extra the material that can be recycle. The material that can be recycling will be deliver to the recycling facilities and composters by trucks. The trucks require the chemical energy mechanical energy and thermal energy. Then the recycling facilities will start the recycling process. The recycling process including heat compression, chemical recycling and distributed recycling. The toaster material that cannot be recycling will be dumping to waste, then will be transporting by the garbage track to the landfills. Then the waste will being melt it. The waste process of the trash that are burning into ash by fire require thermal energy.

Conclusion

The research appear the energy used of the toaster are far more than only the energy used from the consumer operation. No matter the process of raw materials acquisition, manufacturing formulation, the consumer operation, distribution and transportation, recycling and waste management, every step in the process of the toaster require large amount of the energy. The energy and natural resources will not be enough at some point if people are continue using the same amount of the energy to produce with high consumption levels.

Bibliography

Achilias, D.S., et al. “Chemical Recycling of Plastic Wastes Made from Polyethylene (LDPE and HDPE) and Polypropylene (PP).” Journal of Hazardous Materials, Elsevier,29June2007, https://www.sciencedirect.com/science/article/pii/S0304389407009478. Accessed 27 Oct 2019

Ayres, Robert U, Arnim Von Gleich, and Stefan Gössling-Reisemann. Sustainable Metals Management : Securing Our Future - Steps towards a Closed Loop Economy (2006).Web. https://link.springer.com/content/pdf/10.1007%2F1-4020-4539-5.pdf Accessed 28 Oct 2019

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.”Residential Energy Consumption Survey (RECS) - U.S. Energy InformationAdministration(EIA), https://www.eia.gov/consumption/residential/terminology.php

Gayubo, Ana G. G., Beatriz T. Valle, Andrés T. Aguayo, Martin Olazar, and Javier Bilbao."Olefin Production by Catalytic Transformation of Crude Bio-oil in a Two-step Process." Industrial and Engineering Chemistry Research 49.1 (2010): 123-31. Web. https://pubs.acs.org/doi/full/10.1021/ie901204n# Accessed 27 Oct. 2019

Thwaites, Thomas. The Toaster Project: Or a Heroic Attempt to Build a Simple Electric Appliance from Scratch. 1st ed., Princeton Architectural Press, 2011. Accessed 25Oct.2019

Chauhan, Preeti S., et al. “Bonding Process.” SpringerLink, Springer, New York, NY, Jan.1970, https://link.springer.com/chapter/10.1007/978-1-4614-5761-9_2. Accessed 26 Oct 2019

Woodford, Chris. “How Does an Electric Toaster Work?” Explain That Stuff, 16 Sept. 2018, https://www.explainthatstuff.com/electrictoasters.html. Accessed 26 Oct. 2019

Powell, Phoebe. “Energy Forms and Transformations.” Forms of Energy. 2016,

<https://slideplayer.com/slide/9101141/>. Accessed 16 Oct. 2019

Baguley, Richard. “Appliance Science: The well-done physics and chemistry of the toaster.”cnet.com,2015,<https://www.cnet.com/news/appliance-science-the-well-done-physics-chemistry-of-the-toaster/>. Accessed 16 Oct. 2019

Gao, et al. “Battery Capacity and Recharging Needs for Electric Buses in City Transit Service.”Energy(Oxford),Elsevier,27Jan.2017,https://www.osti.gov/servlets/purl/1342660.

Kunz, Regis D and Emmerson, Mark R. “ Energy Analysis of Secondary Material Use in Product Manufacture. Resource Conservation & Recovery Division State of California Solid Waste Management Board. Nov. 1979. Print.

Malpass, Dennis B., and Band, Elliot I. Introduction to Industrial Polypropylene. Hoboken, NJ, USA: John Wiley & Sons. Web.

Raw materials for the energy transition. Leopoldina nationale Akademie der Wissenschaften. Web.

https://www.leopoldina.org/uploads/tx_leopublication/2018_ESYS_Position_Paper_Raw_materials.pdf

Teitelbaum, Perry D. Energy Production and Consumption in the United States: An Analytical Study Based on 1954. U.S. Department of the Interior. 1961. Web.

Liu, Shanhong. Retail unit sales of toasters in the U.S. 2010-2018. Statista. Web.

https://www.statista.com/statistics/514646/us-retail-unit-sales-of-toasters/

HOW IT'S MADE: Aluminum. Documentary Tube. Web.

https://www.youtube.com/watch?v=t4HAzfhWtqE

Wiley, John and Sons. Non-ferrous Extractive Metallurgy. New York. 1980. Book.

King,M, Schlesinger, M and Biswas, K. Extractive Metallurgy of Copper, Fourth Edition. England. 2002. Book.

Jorge Anaya Guzman

DES 40A

Professor Cogdell

2 December 2019

Waste and Emissions of an electric pop-up toaster

The two-slice electric pop-up toaster oven is a home appliance we don’t give too much importance. When looking at the materials that make up the materials and the technology it can be assumed its simple. The parts of the toaster are made of aluminum, copper, steel, polypropylene, hardened steel, nichrome and mica sheet; consequently, they have environmental effects in their individual life cycles. These are things we don’t consider when making a purchase for a toaster, we look at the aesthetic and the features of the appliance. By considering the production, recyclability and disposal of materials constituting a generic pop-up electric toaster oven, the complexity of the waste and emissions throughout the oven’s life cycle can be observed.

The toaster parts are made of different materials mostly of metals and plastic; however, before they are turned into parts, they undergo a raw material extraction. The outer casing of the toaster is made of polypropylene plastic, the spring and bread rack is made of aluminum, and the heating element is nichrome wire and mica sheet. The electromagnet connected to the circuit board is a glass fiber reinforced with epoxy resin with a copper foil bonded on to the sides of the board. To acquire the raw materials to build a toaster they need to be sourced through mining. For one of the metals, aluminum has to be mined and be sourced from bauxite ores. Through the “bauxite mining, red mud generation and aluminum associated with toxicity through air, water, and soil emissions are other identified environmental impacts” (Liu 2012). The process for aluminum production after its been mined from bauxite ores is refined by extracting the aluminum oxide, the Bayer process (IPCC 2019). This process creates greenhouse gas emissions and fossil fuel combustion (IPCC 2019). Chromium has a specific emission when it is sourced and transferred, it releases most of its waste to the land (Papp). For the rest of the metals they have to be mined and go through a process to get the metals out of the ores in a refining distillation system from furnaces, boilers or electricity from power stations consequently emitting CO2 (Gadalla 2006). In addition, solid waste is generated in the steel industry called blast furnace slags that become byproducts for other uses. The polypropylene plastics that are in the outer casing of the toaster require petroleum which create emissions from the natural gas and refineries that acquire the oil. After the raw materials are sourced and refined, they go through manufacturing, production and formulation of the parts for the toaster.

The manufacturing, production, and formulation process also entail much waste and emission. In the production process, metals are formulated to their respective parts and have scraps from the excess material when it is cut. To make the plastics they undergo production that has a large carbon footprint for the outer casing (Srinivisan 2011). For the unused scraps of plastic and metals they are recycled back to the production stage. During the manufacturing process I couldn’t find the specific information to the toxicity level of the wastewater that was emitted from this process but in both productions of plastic and metals solid waste is generated which can be passed through the water if it is dumped or improperly disposed of. Once the manufacturing process has been completed the assembled toasters are distributed and transported to stores.

The distribution and transportation of the toasters happen between the raw material acquisition and the distribution of the completed toasters throughout the world. When distributed through the ship, “the principal exhaust gas emission includes CO2, NOx, SOx, CO, hydrocarbons, and particulate matter” (Eyring 2005). Another form of transportation is trucks that emit greenhouse gasses into the atmosphere. After the product makes its way around the globe through distribution centers and stores, they end up in the hands of consumers to be used.

Toasters maintenance is not difficult if you upkeep the general cleaning that could possibly affect the use of the product and be re-used. When a toaster is deemed useless it is quickly assumed that it needs to be binned, but if you repair or even clean the toaster you can avoid this (Thompson 2015). During the use of the toaster there is air pollutants that come from the thermomagnetic process involved in the heating element from the nichrome wire. Schripps article about air pollutants didn’t specify which ones were emitted from the toaster; furthermore, it was a vague experiment that compared house appliances in a home, However, it was made clear that the toaster did emit a form of air pollutants into the home when used. A case study that was done in Portugal homes by Canha had more clear information on what emissions were generated when using the toaster. The particulate matter that is emitted from the use of the toaster is CH2O, VOCs, PM2.5, and PM10 (Canha 2018). It has to be noted that these emissions are greater when increasing the toast of the bread. After the toaster has no use for the consumer they are sent to recycling.

The process for recycling a toaster involves taking out the metals and the propylene plastic; however, it can only be recycled if the material is not contaminated. “Mechanical recycling, where the polymer is separated from its associated contaminants and it is reprocessed by melt extrusion” (Achilias 2007). Is one of the processes to recycle the propylene plastic of the outer casing; however, the ideal method is chemical recycling where the waste polymers can be converted to valuable chemicals or to their original polymers (Achilias 2007). The byproduct of this method is useful as feedstock for transportation fuel (Achilias 2007). As I mentioned before during the manufacturing process that scraps can be recycled and be reused. It is ideal since it requires less energy than the actual production of iron or steel and it prevents accumulation of abandoned steel products in the environment (Tuck 2019). Tuck said, “Recycled scrap consists of approximately 58% post-consumer (old, obsolete) scrap, 24% prompt scrap (produced in steel-product manufacturing plants), and 18% home scrap (recirculating scrap from current operations). Recycling of the metal scraps benefits the environment, but it has its challenges to finding uncontaminated scraps. The post-consumer scraps are salvaged to be repurposed efficiently. That cannot always be the case depending on the contamination and how diligent the process of recycling the scraps is in the production stage. The secondary material from recycling sometimes accounts for over fifty percent of the raw material supply (Sibley 2004). In the United States the steel and foundry industries are dependent on scrap, 1.1 tons of iron ore is conserved when one ton of steel is recycled (Tuck 2019). The USGS reported, “Nickel in alloyed form was recovered from the processing of nickel-containing waste, including flue dust, grinding swarf, mill scale, and shot blast generated during the manufacturing of stainless steel; filter cakes, plating solutions, spent catalysts, spent pickle liquor, sludges, and all types of spent nickel-containing batteries. Nickel- containing alloys and stainless-steel scrap were also melted and used to produce new alloys and stainless steel” (McRae 2019). Since nickel is in the heating element of the toaster, nichrome. Information wasn’t clear if it was possible to recycle this material. From the remaining parts that are not recyclable they have to be disposed of in landfills.

The waste management of toasters is a similar process to disposing trash into landfill. This happens after the parts that can be recycled are taken out and recycled. The other parts that are not recyclable have to be dumped into a landfill. Quite often does the life of the toaster skip recycling process and is dumped due to it being obsolete or the negligence of recycling the appliance so it ends up in the landfill. When it comes to landfills, we get a lot of effects from stagnant mounds of trash or covered trash. The biggest emission from landfills are greenhouse gases. One of those emission is methane; that is in relatively copious amounts for a decade or two (Tammemagi 1999). Tammemagi said “Three main consequences of decomposition are generation of acid leachate, generation of explosive landfill gas, settlement of the landfill, with potential cracking and degradation of the cover.” Toxic leachate comes from biodegradation in the landfill that can pollute our drinking water (Tammemagi 1999). Tammemagi said “Landfills contribute between 30 and 70 million tonnes of methane per year to the atmosphere, which represents between 6% and 18% of the total methane released worldwide. The explosive gas that generates under the protective cover of the landfill finds its way through the soil and to the atmosphere. Incineration is another process that occurs in landfills, but it has a large drawback by releasing contaminants into the air (Tammemagi 1999). Landfills primarily release methane, yet incineration releases more carbon dioxide that is 20 times less than methane (Tammemagi 1999). The toaster goes from cradle to grave in its life cycle.

The various steps involved in the life cycle of a toaster seem simple, but when you analyze each step, more information is uncovered. From the raw material acquisition, manufacturing, distribution, use or re-use, recycling, and the disposal into the landfill of the toaster there is waste and emissions in the life cycle of the electric pop up toaster. Most of those waste and emissions are at the beginning of the life cycle of the toaster which comes to surprise because it would seem that it would be heavier on the last steps. When looking at any home appliance when shopping, keep in mind of how much waste and emission it incurred in making the product to be on the shelf and then add the mass production of that specific item. The design of the product shouldn’t be to add more to the landfill, but to reduce that pile and add to the recyclability of each part. It should be a cradle to cradle design more than a for profit design of our home appliances, specifically a toaster.

Bibliography

“2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories.” IPCC, 2019, https://www.ipcc.ch/report/2019-refinement-to-the-2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/

Achilias, D.s., et al. “Chemical Recycling of Plastic Wastes Made from Polyethylene (LDPE and HDPE) and Polypropylene (PP).” Journal of Hazardous Materials, vol. 149, no. 3, 2007, pp. 536–542., doi:10.1016/j.jhazmat.2007.06.076.

Asiedu, Y., and P. Gu. “Product Life Cycle Cost Analysis: State of the Art Review.” International Journal of Production Research, vol. 36, no. 4, 1998, pp. 883–908., doi:10.1080/002075498193444. Accessed 27 Oct. 2019.

Canha, Nuno, et al. “Impact of Biomass Home Heating, Cooking Styles, and Bread Toasting on the Indoor Air Quality at Portuguese Dwellings: A Case Study.” Atmosphere, vol. 9, no. 6, Jan. 2018, p. 214., doi:10.3390/atmos9060214.

Chen, Wei-Qiang. “Recycling Rates of Aluminum in the United States.” Journal of Industrial Ecology, vol. 17, no. 6, 2013, pp. 926–938., doi:10.1111/jiec.12070.

Contreras, Isabel Noemi, et al. “An Analysis of Recycling High Density Polyethylene with Limited Resources.” International Journal for Service Learning in Engineering, Humanitarian Engineering and Social Entrepreneurship, vol. 13, no. 2, 2018, pp. 45–68., doi:10.24908/ijsle.v13i2.11621.

Eyring, V., et al. “Emissions from International Shipping: 1. The Last 50 Years.” Journal of Geophysical Research, vol. 110, no. D17, 2005, doi:10.1029/2004jd005619.

Gadalla, M, et al. “Estimation and Reduction of CO2 Emissions from Crude Oil Distillation Units.” Energy, vol. 31, no. 13, 2006, pp. 2398–2408., doi:10.1016/j.energy.2005.10.030.

Gleich, Arnim von., et al. Sustainable Metals Management: Securing Our Future - Steps towards a Closed Loop Economy. Vol. 19, Springer, 2006.

Kaebernick, H., et al. “Sustainable Product Development and Manufacturing by Considering Environmental Requirements.” Robotics and Computer-Integrated Manufacturing, Pergamon, 14 Aug. 2003, https://www.sciencedirect.com/science/article/pii/S0736584503000565?via=ihub.

Liu, Gang, and Daniel B. Müller. “Addressing Sustainability in the Aluminum Industry: a Critical Review of Life Cycle Assessments.” Journal of Cleaner Production, vol. 35, 2012, pp. 108–117., doi:10.1016/j.jclepro.2012.05.030.

Mcmillan, Colin A., et al. “Evaluation of the Metals Industry’s Position on Recycling and Its Implications for Environmental Emissions.” Journal of Industrial Ecology, vol. 16, no. 3, 2012, pp. 324–333., doi:10.1111/j.1530-9290.2012.00483.x.

McRae, Michele E. “National Minerals Information Center.” Nickel Statistics and Information, USGS, 2019, https://www.usgs.gov/centers/nmic/nickel-statistics-and-information.

Millet, Hervé, et al. “The Nature of Plastics and Their Societal Usage.” RSC Publishing Home â Chemical Science Journals, Books and Databases, 19 Oct. 2018, https://pubs.rsc.org/en/content/chapterpdf/2018/9781788013314-00001?isbn=978-1-78801-241-6&sercode=bk. Accessed 26 Oct. 2019.

Papp, John F. “Chromium Life Cycle Study.” U.S. Bureau of Mines Information Circular 9411: Chromium Life Cycle Study, https://pubs.usgs.gov/usbmic/ic-9411/.

Schripp, Tobias, et al. “Characterization of Particle Emission from Household Electrical Appliances.” Science of The Total Environment, vol. 409, no. 13, 2011, pp. 2534–2540., doi:10.1016/j.scitotenv.2011.03.033.

Sibley, Scott F. “Flow Studies for Recycling Metal Commodities in the United States.” U.S. Geological Survey, U.S. Department of the Interior, U.S. Geological Survey, 2004, https://permanent.access.gpo.gov/lps51872/lps51872/pubs.usgs.gov/circ/2004/1196am/index.htm.

Srinivasan, Raghunathan, and Gaurav Ameta. “Comparison of Life Cycle Assessment of Two Toasters.” 31st Computers and Information in Engineering Conference, Parts A and B, vol. 2, Jan. 2011, pp. 1011–1017., doi:10.1115/detc2011-48772.

Tammemagi, Hans. Waste Crisis : Landfills, Incinerators, and the Search for a Sustainable Future, Oxford University Press, Incorporated, 1999. ProQuest Ebook Central, https://ebookcentral.proquest.com/lib/ucdavis/detail.action?docID=273258.

Thompson, Frank. “Waste Not, Want Not.” Physics Education, vol. 50, no. 2, 2015, pp. 258–260., doi:10.1088/0031-9120/50/2/258.

“Toaster.” How Products Are Made, http://www.madehow.com/Volume-7/Toaster.html.

Tuck, Christopher A. “Commodity Statistics and Information.” Iron and Steel Scrap Statistics and Information, USGS, Feb. 2019, https://www.usgs.gov/centers/nmic/iron-and-steel-scrap-statistics-and-information?qt-science_support_page_related_con=0#qt-science_support_page_related_con