Design Life-Cycle

assess.design.(don't)consume

Erika Rivas

Professor Christina Cogdell

Design 40A

2 December 2021

MAM Comfort Pacifier: Materials

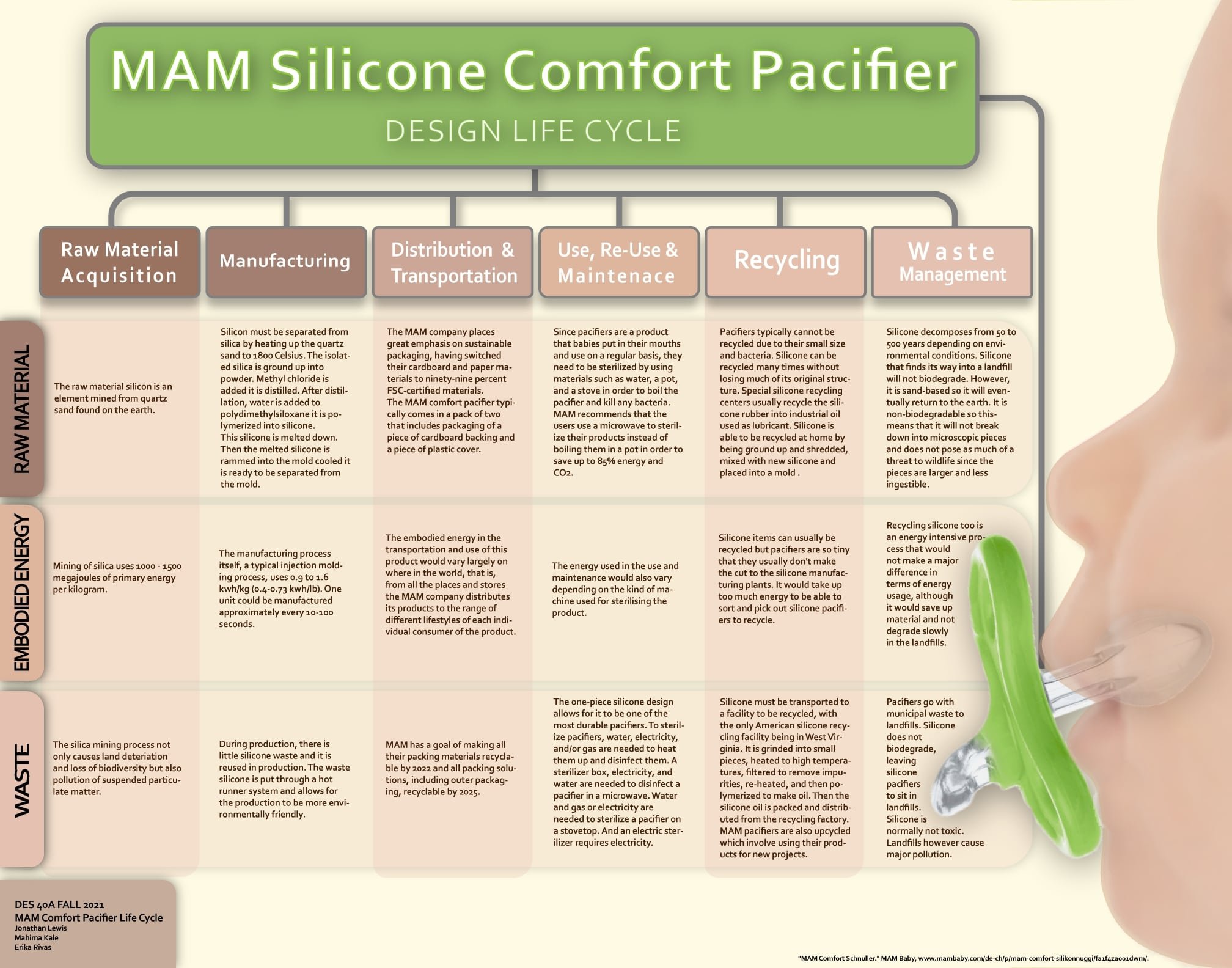

Most environmentally conscious people are fairly informed about the products they use on a daily basis and try to be aware of their products’ design life cycle from the cradle to the grave, but few take into consideration a product that was used in their own cradles-the pacifier! Pacifiers are used in most people’s lives for a short period of time in early childhood, so it is worth investigating how sustainable the product is since it does not get used for very long past infancy. The MAM company is a significant contributor to the production of pacifiers as they sell over sixty-three million baby products annually around the world in fifty-eight countries. MAM is a company that prides themselves on their sustainability efforts concerning their CO2 footprint, innovations, sustainable development goals, and using fair trade materials. With their materials in particular, they “are deeply committed to ensuring that our chosen materials are safe, of high quality and do not harm the environment,” (mambaby.com). Their MAM comfort pacifier, a one-piece pacifier designed for newborns, is a product of the company that is worth researching because it is made of only one-hundred percent silicone so there is a lot to find out about the acquisition and energy use of obtaining this material. This research paper will investigate exactly how sustainable and environmentally friendly the materials of the MAM comfort pacifier are when it comes to raw material acquisition, manufacturing, transportation, use, recycling and waste management of the product.

Investigating the raw material acquisition of a product is crucial to understanding its carbon footprint and effects on the environment in the long run because it is important to know if the material used is sustainable in the entirety of its lifecycle from cradle to grave. It is also important to question how the raw materials are extracted and where the primary source can be traced back to in order to find out if the natural resources are extracted in an environmentally friendly manner. With the Mam comfort pacifier, one-hundred percent silicone is used to create the small one-piece product. Silicone is a synthetic polymer made up of silicon, carbon, hydrogen, and oxygen, with silicon being the primary atom in the structure. Although silicon is not found in its isolated form in nature, it is quite abundant. There are hundreds of minerals that contain silicon but it is most commonly found as quartz sand, or silica sand, on beaches around the world. Silicon makes up about twenty-eight percent of the earth’s crust and is the second most abundant element that makes it up. In addition, silicone rubber only uses a small percentage of the silica that is mined. In this way, the extraction of silicon as a primary source to make silicone is sustainable judging by how abundant it is naturally.

However, the production of silicone from this quartz sand is a long and energy-extensive process. First, silicon needs to be separated from silica. This is done by heating up quartz sand to around one thousand eight hundred degrees Celsius in order to produce pure silicon. After cooling down, this isolated silica is ground up into powder. Methyl chloride is combined with this fine silicon powder and heated up in order to create methyl chlorosilane. Then, the components of methyl chlorosilane are isolated from one another through a process of distillation that includes heating the mixture up. After it is distilled, water is added so that it separates into hydrochloric acid and disilanol and then condenses into polydimethylsiloxane. Lastly, the polydimethylsiloxane is polymerized into silicone using a variety of processes depending on the specific characteristics of the product. Silicone requires high levels of energy in order to be produced from its raw material silicon as shown through its long process.

In addition to the raw materials involved in the manufacturing of silicone, there are the materials involved in the manufacturing processes of the pacifier that need to be taken into account. MAM has production plants based in Hungary and Thailand while 95% of all products are manufactured in Europe. Intertech creates the molds that the MAM company uses for their comfort pacifiers using 420 steel. 420 steel is a stainless steel composed of 12% Chromium along with carbon, manganese, phosphorus, sulfur, and silicon. In order to weld 420 steel into the shape of a mold that would fit a pacifier, it has to go through a heat treatment process that starts off with annealing and then continues with hardening. When the steel is annealed, it is heated to temperatures up to nine-hundred degrees Celsius in a furnace. Then it is cooled down in the furnace and later in the air. During this time, the 420 steel can be molded into the specific shape it needs to be. To harden the steel, it is heated up to a temperature of 1035 Celsius followed by a cooling process using either oil or air. Due to the high temperatures needed to weld the steel into the shapes for pacifier molds, 420 steel is a material involved in the manufacturing process of the MAM pacifier that uses a lot of energy.

Since MAM is an internationally selling company that ships their products to sixty countries across five continents around the globe, it is important to consider the materials involved in the transportation and packaging of the MAM comfort pacifier when it comes to analyzing its level of sustainability. When it comes to packaging, the MAM company places a lot of emphasis on sustainable packaging design, having created the SUPA (Sustainable Packaging) project in 2019. They have set clear goals and missions to reduce their environmental footprint, having switched their cardboard and paper materials to ninety-nine percent FSC-certified materials. This means that the paper products that they use are approved by the Forest Stewardship Council for being sourced from forests that are sustainably and responsibly managed. The MAM comfort pacifier typically comes in a pack of two that includes packaging of a piece of cardboard backing and a piece of plastic cover. Cardboard is able to be grinded down and shredded into a pulp to be recycled and if disposed, can be decomposed naturally within three months. While the plastic in the packaging can be shredded and melted down to be recycled into new products, plastic can take up to five-hundred years to fully decompose.

With the use of the comfort pacifier, it is important to take into consideration how materials also play a role in leaving a carbon footprint during the use phase of the product. Since, “most of the CO2 emissions are generated during the use phase of bottles and pacifiers,” there is a lot to find out about how the materials used with the comfort pacifier have a long lasting impact on the environment (mambaby.com). Since pacifiers are a product that babies put in their mouths and use on a regular basis, they need to be sterilized by using materials such as water, a pot, and a stove in order to boil the pacifier and kill any bacteria. The use of water as a material does not have a significant environmental impact since it is in relatively small amounts, but stovetops release a considerable amount of carbon dioxide into the atmosphere when in use. MAM recommends that the users use a microwave to sterilize their products instead of boiling them in a pot in order to save up to eighty-five percent energy and CO2. On their website, the company includes a CO2 calculator that calculates the amount of CO2 MAM products save if using the microwave versus the stove, which is usually less than the stove.

In the life cycle of the MAM comfort pacifier, it is crucial to look at the ways in which materials involved are able to be recycled and repurposed so that the least waste is created. When it comes to pacifiers in general, they typically cannot be recycled due to their small size and cannot be reused through donation since they carry bacteria. This creates a life cycle that often ends in the landfill. However, the raw materials used in the production and packaging of the MAM comfort pacifier are ones that can be recycled on their own given the proper cleaning and preparation. The silicone in the MAM comfort pacifier is a material that can be recycled many times without losing much of its original structure. Due to its high durability and ability to withstand extremely low and high temperatures, it can be reused many times and is fairly resistant to aging. However, silicone does get degraded each use so each time it is recycled it is considered downcycling because the end product becomes worse. In order to recycle silicone, it has to be sent to a specific recycling facility that deals with silicone, which is not common in many areas since silicone recycling is an energy intensive process and it is more expensive to recycle it than to just make new silicone. These special silicone recycling centers usually recycle the silicone rubber into industrial oil used as lubricant. However, silicone is able to be recycled at home by being ground up and shredded into smaller pieces and then mixed with new silicone and placed into a mold in order to make a new product. Even the cardboard paper and plastic packaging of the MAM comfort pacifier can be recycled. In order to recycle cardboard, it goes through a process called pulping in which it is shredded into smaller pieces and placed in a pulping machine where a chemical solution breaks down the material. Then, the fibers go into the drying process and are rolled so that they can bond together and be able to be made into new products. An advantage of cardboard is that it does not lose its durability when it is recycled. For plastic packaging, the recycling process involves sorting and shredding down the plastic so it can be melted down into pellets that can be used for manufacturing.

Although the comfort pacifier is a product that is used primarily for the beginning of life, it is important to consider the very end of its life cycle- the waste stage. MAM recommends giving up pacifier usage after three years so it does not have a very long period of use. In addition, its tendency to harbor bacteria makes the comfort pacifier a product that typically ends up in a landfill. Silicone decomposes anywhere from 50 to 500 years depending on environmental conditions. Since it is very resistant against extreme high and low temperatures and is a relatively new material that organisms cannot break down, any silicone rubber that finds its way into a landfill will not biodegrade. However, one advantage of silicone is that it is sand-based so it will eventually return to the earth. In addition, the fact that it is non-biodegradable means that it will not break down into microscopic pieces so it does not pose as much of a threat to wildlife since the pieces are larger and less ingestible. In this way, the silicone will not produce any harmful byproducts. However, the packaging of MAM comfort pacifiers contains plastic which poses a greater threat to the environment. Packaging makes up forty percent of total plastic use in the world. Plastic as a material is not biodegradable and can take up to one-thousand years to fully decompose in a landfill. This is a major problem as plastic will accumulate in landfills and end up in the environment where it will harm the health of wildlife and people when it breaks down into microplastics. In contrast, the paper cardboard used in the packaging is fully biodegradable and decomposes in less than a year.

In a world of diminishing resources and overproduction of waste, it is more crucial than ever to look into the materials in the context of the design life cycle from the cradle to the grave of widely used products. The pacifier is used in the cradles of babies around the world but unfortunately the grave at the end of the pacifier’s life cycle is almost always the landfill. MAM is a company that strives to minimize their carbon footprint through concrete sustainable development goals that are evident in the baby products that they create. In particular, the MAM comfort pacifier is a product of theirs that is worth studying in order to get an in-depth understanding of how the materials involved play a role in its sustainability throughout the design life cycle. This paper takes an in-depth analysis of the materials of the MAM comfort pacifier when it comes to raw material acquisition, manufacturing, transportation, use, recycling and waste management of the product.

Works Cited

Aliprandini, P et al. “Comparison of design, materials selection and characterization of pacifiers produced in Brazil.” The Australasian medical journal vol. 4,2 (2011)

ARIS Performance Silicones | Silicone Rubber Supplier in Singapore. “How Is Silicone Rubber Made?” ARIS Performance Silicones | Silicone Rubber Supplier in Singapore, arisperformance.com/blogs/news-and-resources/how-is-silicone-rubber-made.

“Cavity Liquid Silicone Rubber Mam Pacifier Mold Making Detail.” Intertech Machinery Inc., www.taiwanmoldmaker.com/product/mam-pacifier-mold.

“Comfort - Pacifiers - Shop " Mam Baby Personalized.” MAM Baby Personalized, www.shopmambaby.com/shop/mambaby-pacifiers/comfort-pacifiers.

Compactor Management Company. “Cardboard Recycling Process - Why We Should, Step & Its Advantages.” Compactor Management Company, Compactor Management Company, 5 Jan. 2021, www.norcalcompactors.net/cardboard-recycling-process/.

D.M. Smith, R. G. Lehmann, R. Narayan, G.E Kozerski & J.R. Miller (1998) Fate and Effects of Silicone Polymer During the Composting Process, Compost Science & Utilization, 6:2, 6-12

Emily Elveru Updated March 16, 2020. “How to Recycle Your Baby Gear.” Parents, www.parents.com/baby/gear/car-seats/how-to-recycle-your-baby-gear/.

“Fabrication Methods for Silicone Rubber: Silicone Dynamics.” Custom Silicone Keypads | Silicone Dynamics, Inc, 30 Jan. 2020, siliconedynamics.net/fabrication-methods-for-silicone-rubber/.

General Kinematics. “What Is Cardboard Made Of.” General Kinematics, General Kinematics, 7 Sept. 2021, www.generalkinematics.com/blog/the-life-cycle-of-cardboard/.

Hopewell Jefferson, Dvorak Robert and Kosior Edward 2009Plastics recycling: challenges and opportunities Phil. Trans. R. Soc.

“How Are Plastics Made?” This Is Plastics, 16 June 2021, thisisplastics.com/plastics-101/how-are-plastics-made/.

Ikhmayies, S.J. Recycling Silicon and Silicon Compounds. JOM 72, 2612–2614 (2020). https://doi.org/10.1007/s11837-020-04218-0

“In the Environment - CES - Silicones Europe.” Silicones.eu, 12 Mar. 2020, www.silicones.eu/silicones/what-are-silicones/in-the-environment/.

K. E. Petersen, "Silicon as a mechanical material," in Proceedings of the IEEE, vol. 70, no. 5, pp. 420-457, May 1982, doi: 10.1109/PROC.1982.12331.

Kyledriscoll. “Silicone Sustainability.” Design For Sustainability, 8 Aug. 2014, kyledriscoll.wordpress.com/2014/08/08/silicone-sustainability/.

LeVier, Robert R. Ph.D.; Harrison, Myron C. M.D. M.P.H.; Cook, Ralph R. M.D. M.P.H.; Lane, Thomas H. Ph.D. What Is Silicone?, Plastic and Reconstructive Surgery: July 1993 - Volume 92 - Issue 1 - p 12-167

Midland. “What Is Silicone? : Plastic and Reconstructive Surgery.” LWW, journals.lww.com/plasreconsurg/Citation/1993/07000/What_Is_Silicone_.29.aspx.

Mosaic. “The Complete Plastics Recycling Process.” Recycle Track Systems, 12 Oct. 2020, www.rts.com/blog/the-complete-plastics-recycling-process-rts/.

“Pacifier.” How Products Are Made, www.madehow.com/Volume-7/Pacifier.html.

“Pacifier.” How Products Are Made, www.madehow.com/Volume-7/Pacifier.html.

“Plastic Disposal Issues.” World Centric, www.worldcentric.com/journal/plastic-disposal-issues.

R. G. Lehmann, D. M. Smith, R. Narayan, G. E. Kozerski & J. R. Miller (1999) Life Cycle of Silicone Polymer, from Pilot-Scale Composting to Soil Amendment, Compost Science & Utilization, 7:3, 72-81

Renee Cho |January, et al. “What Happens to All That Plastic?” State of the Planet, 3 June 2019, news.climate.columbia.edu/2012/01/31/what-happens-to-all-that-plastic/.

Shit, S.C., Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. 36, 355–365 (2013)

“Silicone.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., www.britannica.com/science/silicone.

Simtec. “How Is Silicone Produced?” SIMTEC Silicone Parts, 24 May 2017, www.simtec-silicone.com/how-is-silicone-produced/.

“ Stainless Steel Manufacturers, Suppliers and Industry Information.” Manufacturers and Information, www.stainlesssteelmanufacturers.org/420-stainless-steel/#read.

Vartan, Starre. “Is Silicone Biodegradable?” Treehugger, Treehugger, 24 May 2021, www.treehugger.com/is-silicone-biodegradable-5097218.

“Where Does Silicone Rubber Come from? Learn with Us Today.” Silicone Engineering, 10 Sept. 2021, silicone.co.uk/news/where-does-silicone-rubber-come-from/.

“Why Is Silicone so Expensive? - Learn with Silicone Engineering.” Silicone Engineering, 29 July 2019, silicone.co.uk/news/silicone-seems-to-be-more-expensive-than-other-rubber-why-is-this/.

Yumpu.com. “Eco-Profiles of Silicones - Silicones Science.” Yumpu.com, www.yumpu.com/en/document/read/8815145/eco-profiles-of-silicones-silicones-science.

Mahima Kale

DES 40A Fall 2021

Embodied Energy in the Life Cycle of the MAM Comfort Pacifier

The MAM company that produces comfort pacifiers put a high emphasis on its sustainability and use of “green energy” in all aspects of its design life-cycle. This paper will examine whether the energy that goes into the raw material acquisition, manufacturing, distribution, use, recycle and waste management of the MAM comfort pacifier would indeed be sustainable and evaluate the overall embodied energy of this product. Sustainability is the way to meet our current needs and yet be able to provide efficiently for the future. The MAM baby company reports that they follow the United Nations Sustainable Development goals.

The most energy exhaustive in the life cycle of a pacifier would be the material acquisition and production aspect of producing a pacifier. This is of course assuming that the MAM company acquires its silica, which is the raw material used in fabrication of silicone, and is acquired from European silica mining sites. Acquiring them from outside Europe would distinctively increase the amount of embodied energy used in the acquisition of raw material. This assumption that they acquire it from European mining sites is based on the fact that their manufacturing sites are based in Hungary for its silicone products. Also according to recent global statistics, most silica mining lands are based in Asia followed by Europe. However, the EU tries to significantly avoid raw material import but is 80% dependent on imports of raw material. Acquiring the silica from sand through mining requires “1000 - 1500 megajoules of primary energy per kilogram”. Plus the manual labor as a prime mover adds on to even more overall embodied energy of forming silicone from silica especially in the manufacturing process. The MAM company emphasizes its product development on sustainability and green energy; silicone is one of the most effective environmental friendly plastic out there, and as of now, silicone is a sustainable material to use in production of a baby pacifier. Although raw material acquisition cannot be considered as using green energy as silica mining is extremely harmful to the environment and its biodiversity. Having a bold statement on their website about their green energy use would be false considering the raw material acquisition process through silica mining.

From raw material to the manufacturing plant of the MAM company is a long journey of large amounts of silica transport form the mining field to the manufacturing plant where the silica goes through injection molding to make it into a pacifier. The manufacturing process can be divided into three main parts, the manufacturing process, the quality control and the byproducts/ waste. The manufacturing process itself, a typical injection molding process, uses 0.9 to 1.6 kwh/kg (0.4-0.73 kwh/lb). This usage is considering the amount of energy used in melting the silica polymer at high temperatures of 360-420 degree Fahrenheit. The molten silica is when pushed into the mold at high speed and pressure. Considering this, the production of one unit of pacifier would take 10 to 100 seconds. The MAM company subjects each pacifier to 40 different quality control tests. As there is no specification on their website about the type or kind or intensity of different quality control, it is difficult to determine the amount of energy that would go into producing a unit of MAM comfort pacifier. When manufacturing silicone products, there is little to none waste. This definitely adds a plus point on the sustainability and green energy usage of silicone in the MAM comfort pacifier series and manufacturing process.

Manufacturing process also includes manufacturing of the packaging of the product. The MAM company claims to use all recyclable materials in most of their products’ packaging. However no strict action is found being taken to make sure that every product gets a second life. Many of their packaging including the packaging of the MAM comfort pacifier do not include its recyclable quality. Sending most products and its packaging to landfills. Recycling the silicone pacifiers would have majorly reduced the amount of energy required in material acquisition that costs the most energy.

Design life cycle of the MAM baby comfort pacifier would be incomplete without discussing the thermal energy produced by manual labor in the manufacturing process. The MAM baby manufacturing plant requires workers to continuously manage and run the injection molding machines. The embodied energy used up in the process of workers getting there working to produce one unit of pacifier would be difficult to formulate but should always be considered when thinking about the embodied energy in a unit of pacifier.

Compared to the raw material acquisition and manufacturing process, energy used in distribution could seem less, however, MAM comfort pacifiers are only manufactured in Hungary but distributed all around the globe. This needs to factor in the way the product, the MAM comfort pacifier, is distributed; via land, air or sea as it would drastically change the amount of energy used. Interestingly, the MAM baby company provides a CO2 calculator for each of their products. This CO2 calculator uses the average energy used in transportation of either car or train as well as the energy used for sterilizing the product. To a naked eye it seems like a reasonable calculation but skeptically it could vary largely considering the varied range of lifestyles of each individual. The energy used in the use and maintenance would also vary depending on the kind of machine used for sterilising the product. The embodied energy in the transportation and use of this product would vary largely on where in the world, that is, from all the places and stores the MAM company distributes its products to the range of different lifestyles of each individual consumer of the product.

At the end of its use, full silicone pacifiers like the MAM comfort pacifier, are usually thrown away to fill up the landfill. Silicone items can usually be recycled but pacifiers are so tiny that they usually don't make the cut to the silicone manufacturing plants. The Recycling sorting process cannot identify or process something as small as a silicone pacifier. It would take up too much energy to be able to sort and pick out silicone pacifiers to recycle. There is definitely a need for the MAM company to start its own recycling unit to save up on its own energy usage of raw material which as discussed before is extremely high yet even if they do, recycling silicone too is an energy intensive process that would not make a major difference in terms of energy usage although it would save up material and not degrade slowly in the landfills.. The degradation process of silicone in landfills is not impossible as it is made of sand to start with but it takes 50 to 500 years for any silicone to decompose.

In all the information presented and discussed in this paper, to say whether the MAM comfort pacifier is sustainable or not would not be an accurate calculation without considering all the assumptions made in this process of evaluating its value for energy sustainability. At the end of the day, the machines used in material acquisition as well as the transportation for distribution make use of non-renewable resources like fossil fuels which in the end would not make the product sustainable as the process throughout is not sustainable.

As for using green energy, the MAM baby company has put in effort to find in the most environmentally friendly raw material which definitely can be recycled but fail to look at the entire process of material acquisition to waste that almost nullifies the use of green energy and sustainable material. Furthermore, in the design life cycle of the MAM comfort pacifier, the most energy usage happens in the material acquisition part which is in mining the silica. Mining is extremely hazardous to the environment and hence questioning the green energy usage posted on the MAM company website.

Companies like the MAM baby that produce products like the MAM comfort pacifier, fail to mention the entire process to claim their product to be sustainable or not. The MAM comfort silicone pacifier, is a great material choice and very useful and efficient in its manufacturing energy usage making it a green energy product with a good sustainable choice of material. However, it fails to notice the other part of its life-cycle where the product actually uses fossil fuels and other non-renewable resources that make the product as a whole unsustainable.

Bibliography

"MAM Sustainability." MAM Baby, www.mambaby.com/why-mam/mam-sustainability/.

"About MAM." MAM Baby, www.mambaby.com/why-mam/about-mam/.

“CRM_2020_Report_Final”, chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/viewer.html?pdfurl=https%3A%2F%2Frmis.jrc.ec.europa.eu%2Fuploads%2FCRM_2020_Report_Final.pdf&clen=3562009&chunk=true

"Silicon." Energy Education, energyeducation.ca/encyclopedia/Silicon.

"Environment and Sustainability." About EUROSIL | Eurosil, www.eurosil.eu/environment-and-sustainability.

Vrachovska, Merilin. "Is Silicone Biodegradable Or Recyclable?" Almost Zero Waste, 17 Sept. 2020,

www.almostzerowaste.com/does-silicone-break-down/#:~:text=in%20general%20waste.-,How%20long%20does%20silicone%20take%20to%20decompose%3F,50%20years%20to%20500%20years

"Comparison of Design, Materials Selection and Characterization of Pacifiers Produced in Brazil." PubMed Central (PMC), www.ncbi.nlm.nih.gov/pmc/articles/PMC3562927/.

"How Pacifier is Made - Material, Manufacture, Making, History, Used, Processing, Parts, Structure, Product." How Products Are Made, www.madehow.com/Volume-7/Pacifier.html.

"How to Recycle Your Baby Gear." Parents, 9 Apr. 2015, www.parents.com/baby/gear/car-seats/how-to-recycle-your-baby-gear/.

"MAM Sustainability." MAM Baby, www.mambaby.com/why-mam/mam-sustainability/.

"The Shocking Truth About How Much Waste Babies Create." BBC Reel, www.bbc.com/reel/video/p076sbzw/the-shocking-truth-about-how-much-waste-babies-create.

"Silicon." Energy Education, energyeducation.ca/encyclopedia/Silicon

"Silicone: The Plastic Alternative." EarthHero, 19 May 2021, earthhero.com/silicone-the-plastic-alternative/#:~:text=However%2C%20silicone%20is%20rarely%20recycled,lesser%20product%20like%20playground%20mulch).

"Silicones. Powering More Efficient Energy Production and Use." Silicones.eu, 12 Mar. 2020, www.silicones.eu/silicones/benefits/silicones-powering-more-efficient-energy-production-and-use/.

"Use of Energy for Transportation." U.S. Energy Information Administration (EIA), 17 May 2021, www.eia.gov/energyexplained/use-of-energy/transportation.php.

Paper/journals:

"Energy and Exergy Analysis of the Silicon Production Process." ScienceDirect.com | Science, Health and Medical Journals, Full Text Articles and Books, www.sciencedirect.com/science/article/abs/pii/S0360544213003666.

"Life Cycle of Silicone Polymer, from Pilot-Scale Composting to Soil Amendment." ResearchGate, www.researchgate.net/publication/261589827_Life_Cycle_of_Silicone_Polymer_from_Pilot-Scale_Composting_to_Soil_Amendment.

"Life Cycle of Silicone Polymer, from Pilot-Scale Composting to Soil Amendment." Taylor & Francis, 23 2013, www.tandfonline.com/doi/abs/10.1080/1065657X.1999.10701976.

Jonathan Lewis

Professor Cogdell

DES 40A Section 2

2 December 2021

Waste and Recycling for MAM Silicone Comfort Pacifier

MAM is a baby product developer, producer, and distributor founded in Austria. MAM is well known for its pacifiers, with their first one produced in 1976. The company opened its production plants in Hungary in 1990 and Thailand in 2002. In 2019, the company developed the “MAM Comfort 100% silicone 1-piece pacifier”. This pacifier is on average thirty-two percent lighter than competitors' one-piece silicone pacifiers, according to MAM. The lightness and smaller size of the MAM comfort pacifier help it to stay in the baby’s mouth more comfortably. All of MAM’s products, including their pacifiers, are BPA, BPS, lead, and PVC-free. MAM is very focused on its environmental impact, as they have a goal of making all their packing materials “recyclable by 2022 and all packing solutions by 2025, which includes outer packaging” (MAM). In regards to recycling, MAM strongly encourages upcycling their products as opposed to throwing them away. MAM has a list of projects that include reusing their products to discourage them from ending up in landfills. MAM makes many different pacifiers and they all are made of either silicone or rubber latex. The MAM comfort pacifier is made exclusively of silicone, which may be recycled but is commonly placed into landfills or incinerated due to the lack of infrastructure for silicone recycling, which has led to an increase of experiments for alternative uses of silicone. Silicone’s development of raw material acquisition, manufacturing, transportation, use, recycling, and waste management over time has evolved to be more environmentally friendly, but it still continues to be harmful to the environment.

Silicone is regarded as environmentally friendly because of its ability to be recycled after decades of use, which makes it an environmentally friendly material. Silicone does not biodegrade, which is better for the environment because it does not get eaten by fish or animals according to EarthHero and MindsetEco. Since silicone does not biodegrade, it must be reused or recycled. Silicone can be downcycled into many different things like industrial lubricant or mulch, but it must be sent to a specialized recycling facility. ECO USA is a silicone recycling plant in West Virginia that recycles more than “8,000 metric tons of silicone every year” (ECO USA). ECO USA describes its silicone recycling process by first grinding it into small pieces, high-temperature heating, fine filtration to remove solid impurities, re-heating (redistribution) to remove moisture and impurities, and finally polymerization to make silicone oil. Silicone can also be recycled at home, according to Almostzerowaste.com, a website that explores zero-waste products, tips, and articles. This process is done by grinding silicone and placing it, along with fresh silicone in powder or liquid form, into a mold. A silicone molding kit can also be used to assist in this process. While it is very possible to recycle silicone, the majority of silicone is not and is instead thrown into landfills.

Silicone recycling is not widespread, causing products like pacifiers made from it to be placed into landfills. Used pacifiers contain bacteria and should not be donated according to Parents.com, a website that helps prepare upcoming and current parents to raise healthy children. However, that does not stop silicone from being recycled. Silicone cannot be recycled at any ordinary place, as only specialized recycling facilities can recycle it (Life Without Plastic). Additionally, silicone must be transported to a facility to be recycled, and then the silicone oil needs to be packed and distributed from the recycling factory. ECO USA is the only silicone recycling plant in the United States (ECO USA). On top of that, it completed phase one of its development in February 2021. This means that the first silicone recycling plant in the United States began full operations during the year this paper was written. Because of the lack of silicone recycling infrastructure, most silicone products are thrown away according to EarthHero, an “eco-friendly online marketplace” for those wanting to reduce their environmental impact. Silicone’s affordability, lack of recycling infrastructure, and the fact that pacifiers are not used for decades like other silicone products, cause most pacifiers to be thrown into landfills. However, that does not mean silicone does not have environmentally friendly properties.

Silicone is considered environmentally friendly because of its strength and durability, allowing for products made from it, such as pacifiers, to last a long time. In a Brazilian study from the Laboratory of Design and Materials' Selection in the Federal University of Rio Grande do Sul, researchers studied the different designs, models, and materials of pacifiers. The researchers studied pacifiers made of mixed materials where the guard and ring are made of one material and the nipple is another. The researchers tested the elongation of silicone and rubber latex nipples and found that silicone nipples performed better. The researchers also found that with pacifiers made of mixed materials, the nipple and guard are not as strong as they could be if they were composed of one material. This study shows that the most optimal pacifier should be made solely out of silicone. This is not only due to its strength and durability but also because of its environmental impacts. Silicone’s strength allows for it to last a long time, which is why it is also used for kitchen products, according to MindsetEco, a website that discusses the environmental impacts of different products to reduce waste. The FDA fully authorized silicone to be used for “food-grade applications'' in 1979 says Almost Zero Waste. Almost Zero Waste also describes that silicone's ability to withstand high and low temperatures allows for it to be more environmentally friendly due to its strength and reusability. Yet, silicone’s environmentally friendly properties have not stopped scientists from finding alternative uses for silicone after product lifetimes.

The increase of silicone waste due to the lack of recycling and it ending up in landfills has spawned experiments to find different uses for silicone. One example of an experiment that sought to use waste silicone was published in the Journey of the Chinese Chemical Society. The goal of the experiment was to use waste silicone as a solid base catalyst to convert soybean oil to biodiesel. The experiment found waste silicone as a catalyst to be “highly stable during successive runs of spent catalysts” (Dai 807). Another study aimed to use silicone polymers to replace conventional binders like cement for hazardous wastes. This study was published in the Journal of the Polish Mineral Engineering Society in 2014, and it suggests further research to develop silicone polymers that “stabilize and solidify hazardous wastes”. Lastly, a patent application was received by the State Intellectual Property Office of China in 2016 “for a synthesis method for producing 201 methyl silicone oil with waste silicone rubber,” (Global IP News). The patent describes the process in which the invention was discovered. These three examples of experiments that give silicone alternative uses have the potential to decrease the amount of waste silicone. This would allow for silicone's environmental impact to decrease if it can be used for something else rather than being thrown away. While these are examples of decreasing the environmental impacts of silicone after a product's lifetime, there are also environmental impacts during the production and use of silicone pacifiers.

The production and use of silicone and products made from it, including pacifiers, consists of using non-renewable energy and producing little waste, which both makes it environmentally friendly and not. Silicone’s production process requires non-renewable energy sources, which have a negative environmental impact. First, the silica mining process not only causes land deterioration and loss of biodiversity but also pollution of suspended particulate matter according to the Journal of Geography and Regional Planning. Then, MindsetEco describes the process of creating silicone from silica by stating, “To turn silica into silicone, the silica needs to be heated with carbon to extract silicon. This is then passed through hydrocarbons to create a polymer. The hydrocarbons that are used to make silicone originate from non-renewable resources such as natural gas and oil.” Pacifiers also need to be sterilized. MAM recommends this be done with either their sterilizer box or steam sterilizer being microwaved, an electric sterilizer, or using a stovetop. These processes require water, which can be used unsustainably. All of these processes also use energy, as they utilize electricity to heat the pacifier and/or water. However, “when making silicone there is little waste as the raw material is so expensive that the company seeks to re-use all flash or waste” (Madehow.com). The silicone used in pacifier production can be reused to reduce waste by the flash being put through a “hot runner system, which virtually eliminates all waste” (Madehow.com). This waste-reducing process during the production of pacifiers allows for pacifiers to be more environmentally friendly, even though their production process also uses non-renewable energy sources that have negative environmental impacts. Still, the use of pacifiers is not environmentally friendly because they require water and energy to sterilize them.

The lack of infrastructure for silicone recycling has caused silicone products, including pacifiers like the MAM Comfort, to be placed into landfills or incinerated. Silicone is rarely toxic, according to Life Without Plastic, MindSetEco, and Almost ZeroWaste, but landfills do cause major pollution. This has led to an increase of experiments for alternative uses of silicone while also evolving to be more environmentally friendly in its raw material acquisition, manufacturing, transportation, use, recycling, and waste management. While silicone is one of the most environmentally friendly materials for pacifiers, it still continues to be harmful to the environment through MAM’s silicone pacifiers' production, use, and afterlife of living in landfills due to it rarely being recycled.

Works Cited

“About Eco USA: A Silicone Rubber Recycling Plant in the USA.” ECO USA, https://www.ecousarecycling.com/about-us/.

“About Mam.” MAM Baby, https://www.mambaby.com/why-mam/about-mam/.

Aliprandini, P, et al. “Comparison of Design, Materials Selection and Characterization of Pacifiers Produced in Brazil.” The Australasian Medical Journal, Australasian Medical Journal, 28 Feb. 2011, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3562927/.

“Are Silicone Products Sustainable and Eco-Friendly? Let's Find Out.” MindsetEco, 11 Oct. 2021, https://mindseteco.co/is-silicone-environmentally-friendly/.

“CO2 Calculator.” MAM Baby, https://www.mambaby.com/why-mam/mam-sustainability/co2-calculator/.

Dai, Y.-M., Hsieh, J.-H. and Chen, C.-C. (2014), Transesterification of Soybean Oil to Biodiesel Catalyzed by Waste Silicone Solid Base Catalyst. Jnl Chinese Chemical Soc, 61: 803-808. https://doi.org/10.1002/jccs.201300563

EarthHero. “Silicone: The Plastic Alternative: Eco-Friendly Topics on EarthHero Blog!” EarthHero, 19 May 2021, https://earthhero.com/silicone-the-plastic-alternative/#:~:text=its%20plastic%20counterpart.-,Recycling,can%20be%20recycled%20multiple%20times.&text=When%20properly%20recycled%2C%20or%20sent,mulch%2C%20or%20another%20lesser%20product.

"ECO USA Establishes First Silicone Recycling Plant in U.S."ProQuest, Feb 16, 2021, https://www.proquest.com/blogs-podcasts-websites/eco-usa-establishes-first-silicone-recycling/docview/2489514028/se-2?accountid=14505.

ECO USA. “Silicone Rubber Recycling Process.” ECO USA, https://www.ecousarecycling.com/silicone-rubber-recycling-process/.

Elveru, Emily. “How to Recycle Your Baby Gear.” Parents, 16 Mar. 2020, https://www.parents.com/baby/gear/car-seats/how-to-recycle-your-baby-gear/.

“Mam Upcycling.” MAM Baby, https://www.mambaby.com/why-mam/mam-sustainability/mam-upcycling/.

“Mam Sustainability.” MAM Baby, MAM, https://www.mambaby.com/why-mam/mam-sustainability/.

Mishra, Ashutosh. “Academic Journals - Journal of Geography and Regional Planning - Impact of Silica Mining on Environment.” Journal of Geography and Regional Planning, Academic Journals, 30 June 2015, https://academicjournals.org/journal/JGRP/article-full-text/915EC0C53587.

“Pacifier.” How Products Are Made, http://www.madehow.com/Volume-7/Pacifier.html.

“Silicone.” Life Without Plastic, Life Without Plastic, https://lifewithoutplastic.com/silicone/.

"State Intellectual Property Office of China Receives Yangzhou Hongyuan Chemical Industry New Material Limited's Patent Application for Synthesis Method for Producing 201 Methyl Silicone Oil with Waste Silicone Rubber." Global IP News.Rubber Patent News, Aug 08, 2016. ProQuest, https://www.proquest.com/wire-feeds/state-intellectual-property-office-china-receives/docview/1809635257/se-2?accountid=14505.

Vinter, S. & Bednarik, V.. (2014). Commercially produced silicone polymers as a possible binder of Hazardous wastes. 15. 79-82,

https://www.webofscience.com/wos/woscc/full-record/WOS:000409682300014.

Vrachovska, Merilin. “Is Silicone Biodegradable Or Recyclable?” Almost Zero Waste, https://www.almostzerowaste.com/does-silicone-break-down/#:~:text=in%20general%20waste.-,How%20long%20does%20silicone%20take%20to%20decompose%3F,50%20years%20to%20500%20years.

“Waste along the Value Chain.” MAM Baby, https://www.mambaby.com/why-mam/mam-sustainability/mam-sustainability-report-2019-2020/caution/waste/.