Design Life-Cycle

assess.design.(don't)consume

Brenda Padron

DES 40A

Professor Cogdell

March 16, 2023

Raw Materials of Posca Markers

Posca markers are well-known to many artists for their saturated colors and versatile capabilities. They are manufactured by the company Uni Mitsubishi Pencil in Japan and are favored by artists all over the world. The first Posca markers were released in the early 80s and became popular amongst the graffiti community rather quickly. With its newfound popularity, the brand grew, allowing the company to expand the Posca line. There are now eight markers and over 60 colors for consumers to choose from.

Posca markers are marketed as “the everything marker made for everyone”, they have been adapted to be used on any kind of surface and the tips come in a variety of styles which make them versatile and fun to work with. According to the Posca website, these markers are great for any kind of design work including upcycling projects. The website also states that while the markers are made from recycled materials, the markers themselves are not recyclable. This research paper will evaluate the raw materials used throughout the life cycle stages of Posca markers and identify how and where these materials are sourced to better understand their impact on the environment.

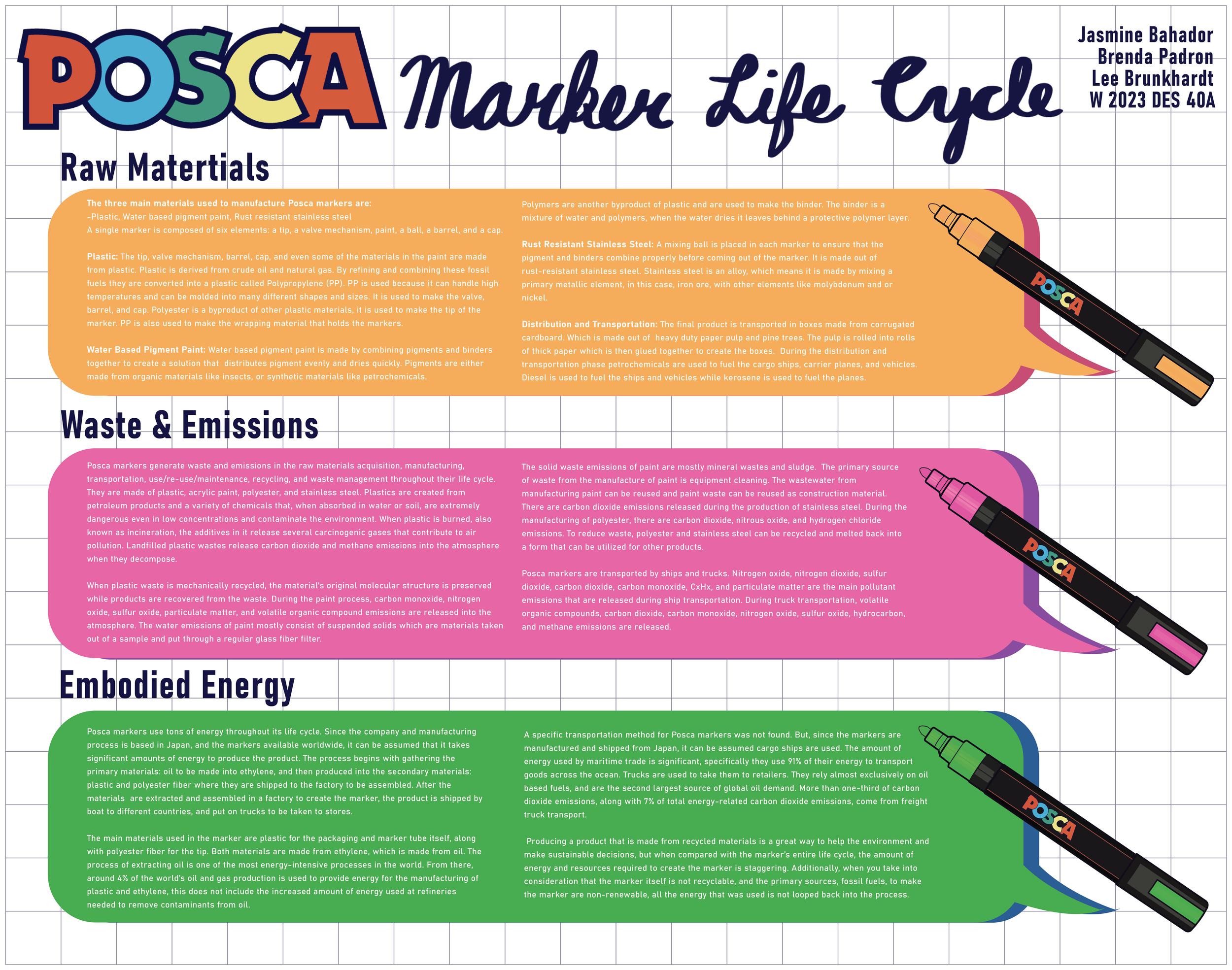

A Posca marker is composed of six elements: a tip, a valve mechanism, paint, a ball, a barrel, and a cap. The posca website states that the tip is made of acrylic, or plastic and the paint is made from a water-based pigment formulation. This is all the information the website provides about the materials used to make the markers. A general google search about markers indicates that the barrel, cap, and packaging are made from plastic and that most paint mixing balls are made from rust-resistant stainless steel. The first stage of a Posca marker’s life cycle begins with the raw material acquisition and is followed by the manufacturing, processing, and formulation stage. Plastic, water-based pigment paint, and stainless steel are all made from primary materials, which must be sourced, chemically altered, and transported before they can be turned into markers. Tracing the origin of these materials reveals crucial information about the life cycle of Posca markers.

The main material used to make Posca markers is plastic, it is used in five out of the six elements that make up the markers. Plastic is derived from two types of fossil fuels: crude oil and natural gas, which are non-renewable and are extracted from the earth using disruptive mining and drilling techniques (Kansas Corporation Commission). After these fossil fuels are extracted, they are transported to refineries where they undergo chemical processes that alter their composition.

Here crude oil is transformed into different petroleum products, some of which can be combined with gas to create plastics (Production, Use, and Fate). Additional additives are utilized during the manufacturing of plastics because they can be used to impact the properties of the material, meaning some plastics are made to perform better than others in certain situations. Resin identification codes are used to easily identify what type of plastic is being used in a product. Posca markers are labeled as “PP” which stands for Polypropylene, a plastic that is known for its “exceptional properties like fire resistance, simplicity, high heat distortion temperature, and dimensional solidity" (Amzan Alsabri). These properties make polypropylene a great choice for products like markers because the plastic can be manipulated with ease and can be used to hold liquids like paint. However, the process of making plastics creates a lot of waste and pollution, and because refineries work nonstop the amount of energy used to produce them is enormous (U.S. Energy Information Administration). Although this research paper only briefly mentions the impact of plastics on the environment it is important to note that this topic is an incredibly pressing issue that everyone needs to be aware of.

Japan relies on crude oil imports and most of the oil they acquire is imported from the Middle East Region (IEA). Unfortunately, there’s not a lot of information available on this topic; however, research suggests that most of the oil refining process and plastic manufacturing process is completed in Japan. Once the plastic is made, it is then transported, with the help of more fossil fuels, to the factories that manufacture Posca markers.

The paint used in Posca markers is manufactured in-house, and because of this, information on the paint formula isn’t available. The Posca website does mention that the paint is water-based and solvent free. Articles about water-based paints indicate that this type of paint is usually made up of three substances: pigments, binders, and solvents. Because the paints used for these markers are solvents free this section will only discuss pigments and binders. Pigments are colorful compounds that can be used to color other materials. They can be made from organic or synthetic materials and are insoluble (What is Pigments). Organic pigments have been used for centuries and are made from natural sources including plants and insects. Synthetic pigments are used more commonly now and are made from petrochemicals, another material derived from fossil fuels. Synthetic pigments are commonly used because they are less expensive to produce, and they can be manipulated to create a large variety of colors that are long-lasting but not as vibrant as organic pigments (Pfaff, Gerhard). It is not clear if Posca paint is made from organic or synthetic pigments, however, because Posca markers are mass-produced, choosing the pigment that offers low costs and high durability could be sensible.

Binders are essential to the paint-making process because they are what bind the pigment together and keep it in place after the paint dries (El-Sherbiny, Samya). Binders are also made from organic or synthetic materials, and the most common binders used for this type of paint are synthetic. Polymer blends are mixed with water to create a binder that sets once the water evaporates (Polymer Blend). Polymers are another form of plastic, which are known to be versatile besides being used for binders, polymers are also used to make polyester, which is what some of the Posca marker nibs are made of.

According to the Posca website, the water-based pigment paints they use are non-toxic, solvent free, and alcohol-free. Compared to other paints it could be argued that these paints are less destructive to the environment than others because of their non-toxic traits, which is true, however, they’re still part of a system that is severely impacting our waters. The impacts of microplastics also won’t be covered here but are equally as important to learn about.

A mixing ball is placed in each marker to ensure that the pigment and binders combine properly before coming out of the marker. Mixing balls are typically made from rust-resistant stainless steel. Stainless steel is an alloy, which means it is made by mixing a primary metallic element, in this case, iron ore, with other elements like molybdenum and or nickel (Covert, Roger, and Arthur Tuthill). The desired characteristics of the final metal product dictate what types of elements are added. Iron ore is found and extracted, through mining, from igneous, metamorphic, or sedimentary rock deposits. The largest production and export of iron ore happens in, Brazil, Australia, Canada, and India (Iron Processing). The process of making stainless steel requires a lot of energy, this is because the metals are melted in an electric furnace and refined through a complicated oxygen manipulation technique called Argon Oxygen Decarburization (AOD). Stainless steel is known for its rust-resistant properties, which come from a film that forms when the metal is exposed to air, aerated water, or other oxidizing materials (Covert, Roger, and Arthur Tuthill). Once the proper alloy composition is obtained the mixing balls are made through either extruding or casting manufacturing techniques. The final product is then shipped to Japan where it becomes an integral part of the marker.

Information on the production of Posca markers isn't available to the general public but there is information about the production of similar products. Crayola specifically has a webpage dedicated to how their markers are made. They state that the marker barrels are made by using a molding machine, which melts plastic pellets and then molds the plastic into the desired shape (How are Crayola Markers Made?). Crayola also states that assembly machines are used to put the markers together from start to finish. It is very much possible that a similar approach is used to make Posca markers. The manufacturing process of Posca markers creates byproducts like dirty water and plastic waste which only contribute to the ever-growing issues of land and water pollution.

Once the markers are made, they are packaged in packing material made from even more polypropylene (PP) and are shipped away to consumers worldwide. This marks the third phase of the life cycle, known as the distribution and transportation phase. During this phase, diesel and kerosine are used to fuel the cargo ships or freight planes that export goods out of Japan (Arba Alexandru). The final product is transported in boxes made from corrugated cardboard. The cardboard is made from heavy-duty paper pulp and pine trees. The pulp is rolled into rolls of thick paper which are then glued together to create the boxes (Corrugated Cardboard). The three final stages of the Posca marker's life cycle are the use/reuse, recycle, and waste phases. Posca markers are not meant to be reused, they have a finite amount of paint in them and once the paint runs out the marker can no longer be used. If a marker still has ink in it but the nib is no longer working properly, consumers can buy replacement nibs and continue to use their markers, except not all markers have replacement nibs available. Most PP plastic is recyclable, in this case, the Posca website does specifically state “POSCA markers are manufactured using recycled materials (PC-5M, PC-7M, PC-8K), but they're not themselves recyclable”. Unfortunately, this means Posca markers end up in landfills rather quickly because their functionality use cannot be prolonged after they run out of ink. The website does encourage its customers to find creative ways to reuse the markers to keep them out of landfills for a little while longer, but it fails to provide any creative ideas or suggestions that might encourage people to do so.

Posca markers are popular because of their vivid colors, varying tip styles, and versatility. They are made for all artists and have been designed to work on almost any surface which is why they are categorized as quality markers. Plastic is used in most of the products we interact with, and it can be applied in many ways, because of this, artists can use Posca markers to create art almost anywhere. Artists have an incredible amount of art supplies to choose from, by understanding the life cycle of these products they can decide which ones they are comfortable supporting and which ones they are not.

Bibliography

Amzan Alsabri, and Abstract Undoubtedly. “Environmental Impacts of Polypropylene (PP) Production and Prospects of Its Recycling in the GCC Region.” Materials Today: Proceedings, Elsevier, 13 Dec. 2021, https://www.sciencedirect.com/science/article/pii/S2214785321075969.

Arba, Alexandru. “Freight Transportation in Japan.” Statista, https://www.statista.com/topics/7726/freight-transportation-in-japan/#topicOverview.

British Plastics Federation. “Polypropylene (PP).” British Plastics Federation, https://www.bpf.co.uk/plastipedia/polymers/PP.aspx.

Citeseerx.ist.psu.edu. https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=b3bf6373ff41a115197c b5b30e57830c16130c2c.

“Corrugated Cardboard.” How Products Are Made, http://www.madehow.com/Volume 1/Corrugated-Cardboard.html.

Covert, Roger, and Arthur Tuthill. “Stainless Steels: An Introduction to Their Metallurgy and Corrosion ...” Stainless Steels -Nickel Institute, https://nickelinstitute.org/media/8daa78479ff950f/14056_stainlesssteels_anintroductiontot heirmetallurgyandcorrosionresistance.pdf.

“Distribution of Fossil Fuels.” Education, https://education.nationalgeographic.org/resource/distribution-fossil-fuels/.

El-Sherbiny, Samya, et al. “Preparation of Water Based Polymeric Binders for Paper Surface Coating.” Journal of Surface Engineered Materials and Advanced Technology, Scientific Research Publishing, 28 Apr. 2014, https://www.scirp.org/html/3-1180148_45378.htm.

“FAQ.” Posca, 24 Sept. 2018, http://www.posca.com/en/faq-2/.

“How Are Crayola Markers Made?” Crayola.com, https://www.crayola.com/faq/your business/how-are-crayola-markers made/#:~:text=Tiny%20beads%20of%20plastic%20are,to%20make%20new%20marker% 20barrels.

Iea. “Japan Oil Security Policy – Analysis.” IEA, https://www.iea.org/articles/japan-oil-security policy.

“Iron Processing.” Encyclopedia Britannica, Encyclopedia Britannica, Inc., https://www.britannica.com/technology/iron-processing.

Kansas Corporation Commission. https://kcc.ks.gov/images/PDFs/education/PEP_FactSheet_2017_FossilFuelEnergy.pdf.

Pfaff, Gerhard. “The World of Inorganic Pigments .” SpringerLink, Springer International Publishing, 30 May 2022, https://link.springer.com/article/10.1007/s40828-022-00166-1.

“Polymer Blend.” Polymer Blend - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/materials-science/polymer-blend.

Production, Use, and Fate of All Plastics Ever Made - Science. https://www.science.org/doi/10.1126/sciadv.1700782.

Review on the Manufacturing Processes of Polyester-Pet and Nylon-6 ... http://engineering shirpur.nmims.edu/docs/review-on-the-manufacturing-processes-of-polyester-pet-and nylon-6-filament-yarn-04.pdf.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Refining Crude Oil - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/oil-and-petroleum-products/refining-crude-oil.php.

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” Refining Crude Oil - U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/oil-and-petroleum-products/refining-crude-oil.php.

“What Is Pigments – What Are the Types of Pigments?” Meghmani, 17 June 2020, https://www.meghmaniglobal.com/what-is-pigments-what-are-the-types-of-pigments/.

Lee Brunkhardt

DES 40A

Professor Cogdell

March 16, 2023

Energy Usage In Posca Markers Life Cycle

A company based in Japan, Uni Mitsubishi Pencil, developed Posca markers in 1983. The product was created with the idea that artists would be able to use the markers wherever they were and on any surface they wanted. With a wide range of vibrant colors and capabilities, it is no surprise artists love using them. But, what artists do not know is the amount of energy that goes into producing these markers. Since the company and manufacturing process is based in Japan, and the markers available worldwide, it can be assumed that it takes significant amounts of energy to produce the product. The process begins with gathering the primary materials: oil to be made into ethylene, and then produced into the secondary materials: plastic and polyester fiber where they are shipped to the factory to be assembled. After the materials are extracted and assembled in a factory to create the marker, the product is shipped by boat to different countries, and put on trucks to be taken to stores. Overall, this paper will assess how much energy is needed to manufacture Posca markers throughout its life cycle, from extracting the primary materials from the Earth that are needed to create the pen itself to how the markers are disposed of and the impact they have on the environment.

Aside from purchasing them at the store, a majority of artists do not know where their materials come from. In reality, something as simple as Posca markers requires a significant amount of energy to be produced and the process can have an outstanding impact on the environment throughout its life cycle. Since they are popular and used by people all over the world, it is important to learn how they are made and what happens to Posca markers after they are no longer usable. For context, Posca markers use a water-based acrylic paint encased in a plastic tube, like a regular marker, and uses a polyester fiber applicator for the tip. They can be bought in sets or individually, but all are wrapped in single-use plastic. A downside to the markers is, eventually, the paint will run out. The marker is no longer usable and has to be thrown away. On the ‘Frequently Asked Questions’ section of the Posca website, they state the “markers are manufactured using recycled material, but they’re not themselves recyclable” (Posca). Unfortunately, in the end, recycling the marker after use is not possible. Most likely, it will be thrown away in the trash and taken to the landfill. And, because of the materials the marker is made out of, it will take hundreds of years for it to decompose. It is no surprise that the markers use plastic in both its packaging and tube itself, plastic is an inexpensive and durable material that can be used for a wide range of purposes. But, this is not sustainable as “around 4 percent of world oil and gas production…is used as feedstock for plastics and a further 3-4% is expended to provide energy for their manufacture” (Hopewell). Along with the 4% of oil and gas needed to make plastic, more energy is used in refineries to refine the oil into a viable product, “Thus, the world refining industry must deal with trade-offs between emissions of pollutants…due to the increased energy use at refineries to remove contaminants from oil products” (Szklo). While this does not go into the full assessment of the marker's life cycle, the process of just refining the oil into something useful gives an idea of how much energy is needed just to produce the different types of plastic used in the product. The end result is it ends up in the landfill, taking a long time to decompose since it cannot be recycled where the cycle stops and the energy that went into making the product is wasted. Furthermore, the other materials in the product and their energy are lost too at the end of the marker’s life cycle.

Posca markers contain two other components, aside from the single-use plastic wrapping and the plastic marker tube, there is also the tip or polyester fiber applicator. The polyester fiber applicator is made from ethylene and ethylene is made from petroleum oil. The process of extracting petroleum from the ground and refining it in oil refineries is “one of the most energy- and emission-intensive sectors throughout the world…the study critically reviewed and discussed the energy and environmental management including pollution control of petroleum process industries…they produce both gaseous and liquid pollutants” (A.K.). At refineries and in the on field development, the petroleum oil goes through a technological process called thermal recovery, “one of the most effective techniques for viscous oil production” (Xingchao). This step of the life cycle uses thermal energy, or heat, to convert petroleum into a viable product to be made into ethylene, which will then be used to make the polyester fiber applicator. During this step, energy is used to produce the applicator, but in the long run, creates liquid and gaseous pollution such as grease, oil, contaminated water, and waste gas. Additionally, even though the marker itself is made from recycled materials, the marker itself is not recyclable. Unlike plastic, even though it takes hundreds of years to degrade, the current type of polyester fiber applicator used in the marker is not biodegradable. And, the process of creating the ethylene for the applicator uses a lot of energy, and some of it is even wasted, “the petrochemical industry is an energy-intensive process…some amount of low-grade heat [is] wasted” (Yurong). The petrochemical industry creates a lot of pollution and uses a lot of energy to refine oil so it can be made into usable product, like the polyester fabric applicator for Posca markers, and gasoline for transportation.

Information on the specific types of transportation used to bring Posca markers from Japan to other countries was not found. All that was available was that the main distribution company was located in Japan. With cargo ships being the main source of transportation for overseas cargo, it can be assumed that this is how the markers are taken to other countries. From there, trucks will take the product from shipping ports to distribution centers, and more trucks will take them to stores, businesses, or other locations where consumers can buy them. Maritime shipping transport is the most widely used transportation for international trade, with approximately 80-90% done by cargo ships. But, as time goes on “the global transition toward a low-carbon and clean-air future becomes urgent, maritime shipping is under increasing pressure to alleviate its environmental impact” (Zhang). In the study, they estimated the life-cycle energy consumption and environmental impact of cargo ships, along with estimating the energy consumption. In summary, they stated that maritime shipping with cargo ships is one of the most widely used types of transportation for overseas trade. At this point in the life cycle, the petroleum has been pumped out of the ground and refined into oil to become ethylene, then manufactured into the plastic and polyester fiber applicator, and the marker has been put together. After, it is then shipped from Japan to all over the world by cargo ships. The energy used by maritime trade is significant, as revealed in the study by Zhang, specifically they used 91% of their energy to transport goods across the ocean, which includes the carbon dioxide emissions put out from travel. The total amount of energy used, for the biggest ship type, a bulk carrier, used 329,356 Gj throughout its entire life cycle. When it arrives at the shipping port, the markers are then loaded on trucks to be delivered to businesses for consumers to buy. Trucks are also widely used for transporting goods. The freight truck industry is “both a key enabler of economic activity and a key source of energy demand, in particular oil. Trucks rely almost exclusively on oil based fuels. They are the second largest source of global oil demand, following passenger cars and at a similar level as the entire industry sector” (Teter). Society heavily depends on trucks transporting goods from one place to another, and with this dependency comes carbon dioxide emissions that harm the environment. In the article, it states that more than one-third of tetra sport related carbon dioxide emissions, along with 7% of total energy-related carbon dioxide emissions, come from freight truck transport. At this point in the Posca marker’s life cycle, it is not close to the end. It still has to be bought by the consumer and used until it no longer works, and is thrown away since it cannot be recycled.

To reiterate, under the Posca marker website it states that their “markers are manufactured using recycled material, but they’re not themselves recyclable” (Posca). Producing a product that is made from recycled materials is a great way to help the environment and make sustainable decisions, but when compared with the marker’s entire life cycle, the amount of energy and resources required to create the marker is staggering. Additionally, when you take into consideration that the marker itself is not recyclable, and the primary sources, fossil fuels, to make the marker are non-renewable, all the energy that was used is not looped back into the process. Through this assessment of the Posca marker’s life cycle, the impact the many steps have from extraction, refining, production, to being thrown away is not environmentally sustainable. The carbon dioxide emissions, a non-recyclable product filling up landfills and creating pollution, gaseous and liquid pollution, and the lost energy in manufacturing processes create significant harm on the environment.

Bibliography

A.K., Azad, et al. “A Study on Energy and Environmental Management Techniques Used in Petroleum Process Industries.” pp. 219–230., Engineering Village, https://www.engineeringvillage.com/app/doc/?docid=cpx_M6fc101f41785d5d6046M59fa10178163190.

Hopewell, Jefferson, et al. “Plastics Recycling: Challenges and Opportunities.” Vol. 364, no. 1526, 27 July 2009, The Royal Society, https://royalsocietypublishing.org/doi/full/10.1098/rstb.2008.0311.

Lima, Lais R, et al. “Challenges in the Context of Single-Use Plastics and Bioplastics in Brazil: A Legislative Review.” Vol. 40, no. 7, July 2022, pp. 998–1006., Engineering Village, https://www.engineeringvillage.com/app/doc/?docid=cpx_M2563f5d17d6cf9109dM7a5c1017816328.

“FAQ.” Posca, Posca, 24 Sept. 2018, www.posca.com/en/faq-2/.

Satti, S M, and A A Shah. “Polyester-Based Biodegradable Plastics: an Approach towards Sustainable Development.” Vol. 70, no. 6, June 2020, pp. 395–446., Wiley Online Library, https://ami-journals.onlinelibrary.wiley.com/doi/10.1111/lam.13287.

Szklo, Alexandre, and Roberto Schaeffer. “Fuel Specification, Energy Consumption and CO2 Emission in Oil Refineries.” Vol. 32, no. 7, pp. 1075–1092., Science Direct, https://www.sciencedirect.com/science/article/pii/S0360544206002416.

Teter, Jacob, et al. “The Future of Trucks: Implications for Energy and the Environment.” 19 Jan. 2017, CORA, https://cora.ucc.ie/handle/10468/7770.

Xingchao, Yang, and Zhao Hongyan. “Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process.” Vol. 15, no. 17, Engineering Village, https://www.engineeringvillage.com/app/doc/?docid=cpx_65f00f9183574ee2a7M5c311017816355.

Xuebao, Yantu Gongcheng. “Correlation between Thermal and Mechanical Properties of Recycled Polyester Fiber and Inorganic Curing Agent-Improved Silt.” Vol. 44, no. 12, pp. 2253–2262., Engineering Village, https://www.engineeringvillage.com/app/doc/?docid=cpx_2ded6713185bc5d7ed6M5fac1017816363.

Yurong, Liu, et al. “Process Modelling, Optimization and Analysis of Heat Recovery Energy System for Petrochemical Industry.” Vol. 381, 25 Dec. 2022, Engineering Village, https://www.engineeringvillage.com/app/doc/?docid=cpx_M5a6761d618508216fb4M7d2b1017816355.

Zhang, Yiqi. “Life-Cycle Energy and Environmental Emissions of Cargo Ships.” Vol. 26, no. 6, 29 July 2022, pp. 2057–2068., Wiley Online Library, https://onlinelibrary.wiley.com/doi/full/10.1111/jiec.13293.

Jasmine Bahador

Professor Cogdell

DES 40A

16 March 2023

Waste & Emissions of Posca Markers

Posca markers were made in 1983 by Uni Mitsubishi Pencil in Japan for artists that wanted to work on the go and enjoy using paint markers for their artwork. They are water soluble, mixable, layerable, and can be used on a variety of surfaces. Posca markers are known for their vibrant colors and different sized and shaped tips, allowing artists to use them for many types of art. There are sixty-six color options including metallic, fluorescent, and glitter colors. The paint in Posca markers is non-toxic, odorless, and dries quickly. Posca markers are versatile tools that enable artists to express their creativity however they would like (POSCA website). It is important for artists to understand the environmental impact of the product they are using, therefore, this research paper aims to make artists more aware of the waste and emissions of Posca markers. Throughout their life cycle, Posca markers produce waste and emissions in the raw materials acquisition, manufacturing, transportation, use/re-use/maintenance, recycling, and waste management.

The raw materials used to make Posca markers create waste and emissions. Posca markers are made of plastic, acrylic paint, polyester, and stainless steel. The outside of the marker and cap is plastic. There is acrylic paint inside of the marker as well as a stainless steel ball that mixes the ingredients of the paint. The tip of the marker is made out of polyester. 4.5% of the world's greenhouse gas emissions are attributable to plastics. According to Paul Stegmann and others’ article, Plastic Futures and Their CO2 Emissions, “Plastics are produced from intermediate chemicals such as ethylene, propylene, aromatics, methanol and C4 streams (for example, butadiene, isobutene), which are sourced from steam crackers, refineries and methanol producers.” Plastic is durable which makes it difficult and time consuming for it to decompose. Environmental pollution is caused by careless plastic waste disposal. Plastic waste is harmful to animals because they often consume it thinking that it is food (Okunola A Alabi, et al.). Plastics are created from petroleum products and a variety of chemicals that, when absorbed in water or soil, are extremely dangerous even in low concentrations and contaminate the environment. When plastic is burned, the additives in it release several carcinogenic gases that contribute to air pollution (Kumar Raja Vanapalli, et al.). Acrylic paint is made of pigment, a binder, and a solvent. The binder in acrylic paint is also known as resin (S. Myint, et al.). During the production of synthetic resin, carbon dioxide emissions are produced. On the design life cycle website, Trina Do states that “Polyester fiber is made from synthetic polymers that are made from esters of dihydric alcohol and terephthalic acid. Each stage of production releases waste such as carbon dioxide, acid gases such as hydrogen chloride, and unstable organic compounds.” The raw materials used to make stainless steel result in carbon dioxide emissions. Posca markers do not only produce waste and emissions in the raw materials acquisition, but also during their production.

Posca markers generate waste and emissions during their manufacturing process. Manufacturing paint produces wastewater that consists of toxic chemical substances and strong smell (Larissa F. Silva, et al.). During the paint process, carbon monoxide, nitrogen oxide, sulfur oxide, particulate matter, and volatile organic compound emissions are released into the atmosphere. The water emissions of paint mostly consist of suspended solids which are materials taken out of a sample and put through a regular glass fiber filter. The solid waste emissions of paint are mostly mineral wastes and sludge. Mineral wastes are from mining operations and sludge is a byproduct of treatment of wastewater (Stella Papasavva, et al.). In the journal, Life cycle environmental assessment of paint processes, Stella Papasavva and others explain that “Some gases, such as COz, CH4, and NzO, contribute to the enhancement of the greenhouse effect when released into the atmosphere. The basic principle that lies behind this mechanism is that the emissions of greenhouse gases, which occur from industrial and natural processes, prevent the infrared radiation emitted from the earth's surface to escape into space.” The primary source of waste from the manufacture of paint is equipment cleaning. In the Center for Economics Research’s journal, Paint Waste Reduction and Disposal Options Volume I, it is stated that “air emissions from VOCs, pigment dust from air pollution control equipment, empty raw material packages, bags, and containers, bags and cartridges from paint filtration equipment, and waste paint or raw materials from accidental spills and discharge” are some of the wastes produced by paint manufacturing. According to the Center for Economics Research’s journal, Paint Waste Reduction and Disposal Options Volume II, “Solid wastes generated by paint manufacturers include spent filters, raw material packaging, baghouse dust, and dewatered sludge from in-house wastewater treatment facilities.” Liquid wastes “may consist of primarily organic solvent-borne materials, aqueous materials, or mixtures of solvent-borne and aqueous material…” The article, Hazardous Waste Listing for Dye and Pigment Production Wastes Finalized, demonstrates that pigment production wastes include “Spent catalysts, reactor still overhead, vacuum system condensate, process waters, spent adsorbent, equipment cleaning sludge, product mother liquor, product standardization filter cake, dust collector fines, recovery still bottoms, treated wastewater effluent, and wastewater treatment sludge.” When manufacturing polyester, waste and emissions are generated. On the design life cycle website, Trina Do describes that “Polymerizations, drying, melt spinning, drawing the fiber, and winding are involved in the process of productions; mainly requiring a lot of energy from water and coal in order to heat/dry the compounds to create the synthetic fiber. When heated, the emissions of the chemicals are released into the air…Also, emissions of nitrous oxide are also present.” There are carbon dioxide emissions released during the production of stainless steel. Along with producing waste and emissions during their manufacturing, Posca markers also generate waste and emissions during their use and reuse.

During their use and reuse, Posca markers create waste and emissions. The wastewater from manufacturing paint can be reused. Paint waste can be reused as construction material. In the article, Paint Waste Management in Industry, Ainul Haezah Noruzman and Nazirah Mohd Apandi explain that “... the utilization of these wastes may improve properties of concrete in terms of fresh and hardened state, bonding to the concrete substrate, increase resistance to penetration by water and chemicals, and decrease permeability. It is observed that the utilization of paint waste also used in the production of brick-making.” Surface preparation solutions for paint can be reused. According to the Paint Waste Reduction and Disposal Options Volume I, “Wastes generated during industrial paint application include the following: scrubber water, paint sludge, and filters from air pollution control; equipment cleaning wastes; aqueous waste and spent solvents from surface preparation; VOC emissions during paint application, curing, and drying; empty raw material containers; and obsolete or unwanted paint.” Posca markers cannot be refilled with paint, but if the marker stops working, you can moisten the tip with water to continue using it. Posca markers generate waste and emissions during their use and reuse, but the materials used to make them can be recycled.

The materials used to make Posca markers are recyclable. One method for managing plastic waste is through feedstock recycling. In Kumar Raja Vanapalli and others’ article Emissions and Environmental Burdens Associated With Plastic Solid Waste Management, they state that feedstock recycling “...involves several processes, like pyrolysis, plastic waste to fuel conversion, and gasification techniques for conversion of plastic waste into products that have unique properties, unlike the virgin plastic material. Moreover, the plastics undergo molecular and structural level changes during this process and get converted to much simpler raw material products that have superior thermal properties.” When plastic waste is mechanically recycled, the material's original molecular structure is preserved while products are recovered from the waste. The identification and separation of plastic polymers, which includes a variety of processes from manual sorting and selection of plastics in the waste stream to automated mechanized systems comprising cutting and shredding, is the first step in recycling (Kumar Raja Vanapalli, et al.). Ethylene is used to make plastic, polyester, and acrylic paint. According to Magda H. Barecka and others article, Economically Viable CO2 Electroreduction Embedded within Ethylene Oxide Manufacturing, “In the EO plants, a specific quantity of CO2 is used as feed to the EO reactor (CO2 is used for dilution purposes in usual fraction of 5% of the feed stream), therefore unreacted CO2 can be recycled back to the EO reactor without violating the operational constraints.” Paint that fails to satisfy quality standards or customer requirements and paint that the retailer sends back is often recycled. To reduce waste, polyester can be recycled and melted back into a form that can be utilized for other products. Stainless steel is also recyclable. In the article Stainless Steel Recycling: How to Recycle Steel, written by Montanstahl, it is stated that “Steel mills melt both steel and stainless steel scrap, once cleaned, directly in an apparatus such as an electric arc furnace. After that, the melt passes to a steel converter to remove excess carbon and nitrogen. Once carried out, at a ladle station a final analysis process allows metallurgical adjustments to the materials chemistry.” Posca markers are made of recyclable materials, but the waste management of them leads to waste and emissions.

Waste and emissions are caused by the waste management of Posca markers. Collected plastics enter a variety of management streams, such as recycling, landfill disposal, or recovery. On the other hand, discarded plastics build up in the soil which pollutes it and some of them end up entering streams and other freshwater bodies before entering the ocean and contaminating the marine environment. Plastics can go through incineration which is the process of burning waste products (Vanapalli, et al.). In Muhammad Ilyas and others’ journal, Plastic waste as a significant threat to environment – a systematic literature review, they argue that “Incineration and pyrolytic conversion of waste plastic results in the emission of hazardous atmospheric pollutants, including polyaromatic hydrocarbons, CO2 (a greenhouse gas) and persistent organic pollutants like dioxins which causes global warming and pollution.” They can also be put into landfills but this is not the best option because plastics take up a lot of space which would decrease the lifespan of a landfill. Plastics are non-biodegradable, therefore they should be recycled instead of thrown in landfills (Vanapalli, et al.). According to Public and Environmental Health Effects of Plastic Wastes Disposal: A Review, Okunola A Alabi and others reveal that “Dumping of plastics on land or landfilling plastics leads to abiotic and biotic degradation of the plastics, where plastic additives (e.g. stabilizers, harmful colorant moieties, plasticizers and heavy metals) can leach and eventually percolate into various aspects of the environment, thereby causing soil and water contamination.” Landfilled plastic wastes release carbon dioxide and methane emissions into the atmosphere when they decompose (Alabi, et al.). In the Paint Waste Reduction and Disposal Options Volume II, it is stated that for paint disposal, “Aqueous wastes and sludge were found to be either dewatered and landfilled, or mixed with solvent wastes and disposed of through fuel blending or incineration…Other solid wastes such as empty paint containers, pigment bags, masking materials etc., were disposed in landfills.” Since esterification, the method used to create polyesters, is a chemically reversible process that is simple to undo through hydrolytic enzymatic action, all polyesters are therefore believed to be biodegradable. As well as waste and emissions being created by how Posca marker waste is managed, the transportation of them also produces waste and emissions.

The transportation of Posca markers generates waste and emissions. Posca markers are transported around the world by ships and trucks. The shipping industry’s enormous utilization of fuel oil has led to a great deal of ship pollutant emissions. Fuel oil contains sulfur dioxide which can cause air pollution because it can create acid rain. Throughout the majority of the world, shipping is the primary source of emissions of particulate matter from human activity. Nitrogen oxide, nitrogen dioxide, sulfur dioxide, carbon dioxide, carbon monoxide, CxHx, and particulate matter are the main pollutant emissions that are released during ship transportation. The daily lives and health of individuals are impacted by these environmental pollutants (Guangnian Xiao, et al.). According to Fan Zhou and others’ article, A Real-Time Measurement-Modeling System for Ship Air Pollution Emission Factors, “The emission factor of particulate matter of the inland river ships was significantly higher than that of the ocean-going ships, which was mainly due to the slower speed of the ship when passing through the lock chamber and the idle state of the engine, which led to higher emissions of particulate matter for the inland river ships.” During truck transportation, volatile organic compounds, carbon dioxide, carbon monoxide, nitrogen oxide, sulfur oxide, hydrocarbon, and methane emissions are released. In the article, Methodologies for estimating pollutant emissions generated by trucks to the atmosphere, Heliana Restrepo and John Posada write that “...air pollution generated by transport can cause damage to the respiratory system increasing the risk of cardiopulmonary mortality, alteration of the lipid of the bronchial mucosa, bronchial asthma and even cardiovascular diseases.” Posca markers do not only produce waste and emissions while they are transported, but also in other aspects of the life cycle.

Furthermore, Posca markers generate waste and emissions in the raw materials acquisition, manufacturing, transportation, use/re-use/maintenance, recycling, and waste management throughout their life cycle. There is not much information about Posca markers themselves, therefore, I focused my research on the waste and emissions of the materials used to make Posca markers. Although Posca markers are a great tool for artists to use to express themselves through their artwork, the materials used to make them produce waste and emissions which negatively impacts the environment and human health.

Bibliography

Stegmann, Paul, et al. “Plastic Futures and Their CO2 Emissions.” Nature News, Nature Publishing Group, 7 Dec. 2022, pp. 272–276, https://doi.org/10.1038/s41586-022-05422-5

Christopher, J. "Plastic pollution and potential solutions." Science progress, vol. 101, no. 3, Sept. 2018, pp. 207-260. ProQuest, https://www.proquest.com/scholarly-journals/plastic-pollution-potential-solutions/docview/2103953335/se-2, doi:https://doi.org/10.3184/003685018X15294876706211.

Xiao, Guangnian, et al. "Evaluation of Ship Pollutant Emissions in the Ports of Los Angeles and Long Beach." Journal of Marine Science and Engineering, vol. 10, no. 9, 28 Aug. 2022, pp. 1206. ProQuest, https://doi.org/10.3390/jmse10091206.

Zhou, Fan, et al. "A Real-Time Measurement-Modeling System for Ship Air Pollution Emission Factors." Journal of Marine Science and Engineering, vol. 10, no. 6, 31 May 2022, pp. 760. ProQuest, https://doi.org/10.3390/jmse10060760.

Papasavva, Stella, et al. "Life cycle environmental assessment of paint processes." JCT, Journal of Coatings Technology, vol. 74, no. 925, Feb. 2002, pp. 65-76. ProQuest, https://www.proquest.com/trade-journals/life-cycle-environmental-assessment-paint/docview/212120953/se-2.

Silva, Larissa F., et al. “Treatment of Paint Manufacturing Wastewater by Coagulation/Electrochemical Methods: Proposals for Disposal And/or Reuse of Treated Water.” Water Research, vol. 101, Sept. 2016, pp. 467–75, https://doi.org/10.1016/j.watres.2016.05.006.

Myint, S., et al. “Paints Based on Waste Expanded Polystyrene.” Progress in Rubber, Plastics and Recycling Technology, vol. 26, no. 1, Feb. 2010, pp. 21–30. ProQuest, https://www.proquest.com/scholarly-journals/paints-based-on-waste-expanded-polystyrene/docview/197110115/se-2

"Hazardous Waste Listing for Dye and Pigment Production Wastes Finalized." Hazardous Waste Consultant, vol. 23, no. 3, 2005, pp. 14, ProQuest, https://www.proquest.com/scholarly-journals/hazardous-waste-listing-dye-pigment-production/docview/223701801/se-2.

Kyung-Yong, Nam, and Lim Myung-Kwan. "Life Cycle Environmental Impact Assessment and Applicability of Synthetic Resin Formwork." Materials, vol. 16, no. 2, 2023, pp. 696. ProQuest, https://doi.org/10.3390/ma16020696.

Barecka, Magda H., et al. “Economically Viable CO2 Electroreduction Embedded within Ethylene Oxide Manufacturing.” Energy & Environmental Science, vol. 14, no. 3, 2021, pp. 1530–1543. ProQuest, https://doi.org/10.1039/d0ee03310c.

Okunola A, Alabi, et al. “Public and Environmental Health Effects of Plastic Wastes Disposal: A Review.” Journal of Toxicology and Risk Assessment, vol. 5, no. 2, Apr. 2019, https://doi.org/10.23937/2572-4061.1510021.

Vanapalli, Kumar Raja, et al. “12 - Emissions and Environmental Burdens Associated with Plastic Solid Waste Management.” ScienceDirect, edited by S. M. Al-Salem, William Andrew Publishing, 1 Jan. 2019, pp. 313–342, www.sciencedirect.com/science/article/pii/B9780128131404000121.

Noruzman, Ainul Haezah, and Nazirah Mohd Apandi. “Paint Waste Management in Industry.” Journal of Advanced Research in Business and Management Studies, vol. 20, no. 1, Oct. 2020, pp. 28–33, https://doi.org/10.37934/arbms.20.1.2833.

Center for Economics Research.“Paint Waste Reduction and Disposal Options Volume I.” https://p2infohouse.org/ref/01/00951.pdf

Center for Economics Research.“Paint Waste Reduction and Disposal Options Volume II - Site Visits.” https://p2infohouse.org/ref/01/00699.pdf

Vethaak, A. Dick, and Heather A. Leslie. “Plastic Debris Is a Human Health Issue.” Environmental Science & Technology, vol. 50, no. 13, June 2016, pp. 6825–26, https://doi.org/10.1021/acs.est.6b02569.

Thompson, Richard C., et al. “Plastics, the Environment and Human Health: Current Consensus and Future Trends.” Philosophical Transactions of the Royal Society B: Biological Sciences, vol. 364, no. 1526, 14 June 2009, pp. 2153–2166, https://doi.org/10.1098/rstb.2009.0053.

Ilyas, Muhammad, et al. “Plastic Waste as a Significant Threat to Environment - a Systematic Literature Review.” Reviews on Environmental Health, vol. 33, no. 4, 6 Sept. 2018, pp. 383–406, https://doi.org/10.1515/reveh-2017-0035.

Satti, S M, and A. A. Shah. “Polyester-Based Biodegradable Plastics: an Approach towards Sustainable Development.” Letters in Applied Microbiology, vol. 70, no. 6, June 2020, pp. 395–446, https://doi.org/10.1111/lam.13287

Wang, Menglei, et al. "On-Road Emission Characteristics of Volatile Organic Compounds from Light-Duty Diesel Trucks Meeting Different Emission Standards: Investigation on the characteristics of tailpipe volatile organic compound emissions with a portable emissions measurement system." Johnson Matthey Technology Review, vol. 65, no. 3, 2021, pp. 404-417. ProQuest, https://doi.org/10.1595/205651320x15900542621515.

Dong, Yaping, Jinliang Xu, and Chenwei Gu. "Modelling carbon emissions of diesel trucks on longitudinal slope sections in China." PLoS One, vol. 15, no. 6, 2020. ProQuest, https://doi.org/10.1371/journal.pone.0234789.

Restrepo P, ,HM, and Posada H JJ. “Methodologies for estimating pollutant emissions generated by trucks to the atmosphere.” The Institution of Engineering & Technology, 18 Apr. 2018. ProQuest, https://www.proquest.com/materialscienceengineering/docview/2457324860/1D603A80F8C1485BPQ/44?accountid=14505&parentSessionId=awWQKind5X%2BRQUUNneWv7JMDtVsaz7L7T%2B6VYUSw9to%3D&parentSessionId=CJqmhs2s2Reh8olExjqKtnYeW0FREHXOWmmu69psdtM%3D

ISSF International Stainless Steel Forum. “Stainless Steel and CO2: Facts and Scientific Observations.” https://aceroplatea.es/docs/ISSF_Stainless_Steel_and_CO2.pdf

“Stainless Steel Recycling: How to Recycle Steel.” Montanstahl, 7 Nov. 2017, www.montanstahl.com/blog/recycling-stainless-steel/.

“High-Quality All Surface Paint Markers.” POSCA USA, https://poscausa.com

“Design Life-Cycle.” 2012, www.designlife-cycle.com