Design Life-Cycle

assess.design.(don't)consume

Coral Trimble

DES40A

Professor Codgell

Glade Plugins Life Cycle: Materials

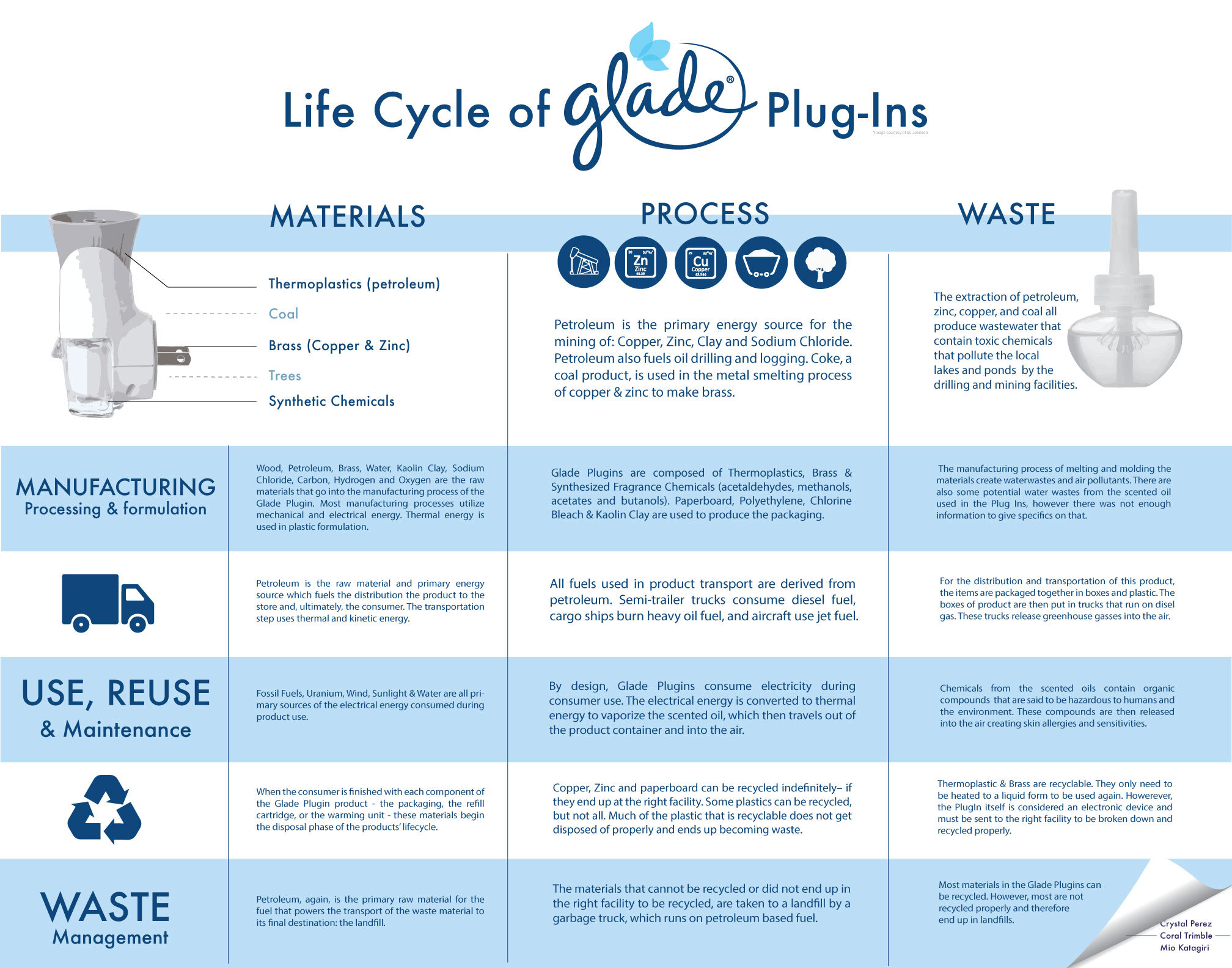

The Glade brand, part of S.C. Johnson & Son, Inc., specializes in fragrances, or, as they call it, “air care” (: “SC Johnson.”). Their list of products includes candles, car air fresheners, mists and oils. The focus of this paper will be on the Glade Plug-Ins air fresheners, which use the scented oil. The plug-in design is composed of two parts. The first is the scented oil replacement, which is basically a plastic capsule that fragrant chemicals. The second component is a plastic receptacle that plugs into an electrical outlet and acts as a warming unit for the smaller scented oil component. Glade Plug-Ins air fresheners are composed of a combination of plastics, fragrant chemicals, and brass. Each of these components are secondary raw materials, meaning they are made from primary raw materials such as crude oil, zinc, copper, and wood. This paper will analyze both the primary and secondary materials used in this product, and attempt to follow them through the entire lifecycle, from acquisition to disposal.

The plastics used in this product, for both the refill cartridge and the electrical warmer unit, are thermoplastics. Thermoplastics, as opposed to thermoset plastics, soften when heated and can therefore be reshaped and repurposed (“Plastics”). Glade states that their refill cartridge is made of 100% recycled material. Although they give no further information on the type or origin of the recycled material, I will assume the plastic used is recycled. The electrical plug in the warmer unit is made from brass. Brass is an alloy made from copper and zinc (Bell, “Here's Why Alloys Can Change the Properties of Brass.” ). As for the fragrance component, S.C. Johnson provides an ingredient list for the scented liquid that comes inside the Plugin refill cartridges. Unfortunately, you have to be a chemist to understand it, with ingredients such as “(1.alpha. (e),2.beta.)-1-(2,6,6-trimethylcyclohex-3-en-1-yl)but-2-en-1-one” and “[1-methyl-2-[(4,4,5-trimethyl-3-bicyclo[3.1.0]hexanyl)methyl]cyclopropyl]methanol” (“: SC Johnson.”). Additionally, each different scent uses a unique variation of chemicals. So, for this paper I will focus on acetaldehyde, methanol, acetate and butanol. These chemicals appear in varying forms across the different scents.

Plastic is a material derived from fossil fuels. “The raw material formation may begin by separating the hydrocarbon chemicals from natural gas, petroleum, or coal into pure streams of chemicals” (“Plastics”). Most modern day plastics are made from petroleum because it is easier to process than coal. Petroleum is obtained from the earth by oil rigs, which drill for and extract crude oil. These oil rigs are powered by electricity, which comes from a generator, which is powered by diesel fuel. So, petroleum is the raw material used as the primary energy source for extracting more petroleum, which is the raw material used to make plastic (“Oil Rigs Need Power Too.”). Once the plastic material is formulated from the petroleum, this moldable liquid plastic is formed into the desired shape for the product through a process called injection molding (“Plastics”).

Upon investigation on the S.C. Johnson website, I found that the fragrances are made from a combination of “naturally occurring, meaning extracted from plants and flowers”, “nature-identical, meaning synthetic ingredients that chemically mirror naturally occurring scents but are made in a laboratory” and “custom-made, meaning those made in a laboratory….for unique or complex new scents” (“Fragrance Facts : SC Johnson.”). I have chosen to examine acetaldehyde, methanol, acetate, and butanol as these chemicals are common in different forms across the ingredients lists for the varying scents. According to PubChem, an open chemistry database at the National Institute of Health, acetaldehyde (C4H4O), methanol (CH3OH), acetate (C2H3O2) and butanol (C4H10O) are all naturally occurring chemicals found in decaying organic matter or animal digestive systems. These chemicals are also synthesized in laboratories for manufacturing purposes, which is where SC Johnson likely gets these materials. Acetaldehyde is suspected to be carcinogenic, to cause genetic defects and, when in vapor form, to cause respiratory irritation (“Acetaldehyde.”). Butanol, in vapor form, is also found to cause respiratory irritation, along with blurred vision and light sensitivity (“1-Butanol.”). Symptoms including headaches, blurred vision and upset stomachs have been reported in humans exposed to methanol vapors, and birth defects have been observed in laboratory animals exposed to the same vapors (“Methanol.”). In pursuit of identifying where the chemicals used for the fragrances come from I contacted S.C. Johnson to inquire about the materials and origins. Unfortunately contacting the company directly was a dead end; the Customer Relations Center representative replied that the information I was requesting was proprietary and referred me back to the ingredients list on the website.

Brass, which is the material of the electrical plug, is a metal alloy composed of copper and zinc. Copper and zinc occur naturally in the earth's crust and are extracted through mining ores. Copper is found in natural deposits all over the world, and the United States is the world’s fourth largest copper producing country with mines in Utah, Arizona, New Mexico, Nevada and Montana (“Copper Mining in the United States.”). Zinc is also a commonly found element, but the United States only has one active zinc mine; “Today, there is only one operating primary zinc smelter, in Clarksville, Tennessee, which produces zinc from mines in the East Tennessee and Middle Tennessee districts” (“Zinc Mining in the United States.”). To produce brass, copper and zinc must be extracted from the ores through the smelting process. Once obtained in their pure form, these metals are combined to achieve the resulting alloy: brass. The metal smelting process requires extremely high temperatures which are achieved through burning coke, which is a product of coal (“Coke.”). Coal is a fossil fuel that is obtained from the earth through mining.

The packaging of this product is made from paperboard and polyethylene. Polyethylene, a form of plastic, is made from processed petroleum. Paperboard is made from wood pulp, which is made from trees. The production process of paperboard also requires bleach, which is composed of chlorine, caustic soda and water. Chlorine and caustic soda are extracted from sodium chloride, which is found in mines or underground wells (“Bleach (Sodium Hypochlorite.”). Glade states that their packaging is made from 100% recycled material. So, we will assume that this refers to the paperboard and polyethylene plastic. Recycled paperboard is coated with a layer of kaolin clay to provide a printing surface (Paperboard). Kaolin clay is mined in Europe and the southeastern United States (“Kaolin.”). “According to the U.S. Environmental Protection Agency (EPA), paper and paperboard packaging, accounts for nearly three-quarters of packaging materials recovered for recycling in the U.S. That is more than any other packaging material” (Paperboard).Recycled paperboard is made from reclaimed paperboard products combined with water. The water is used to separate the original paperboard materials into pulp fibers and repress them into the new recycled paperboard material.

For transportation, I was unable to locate any shipping information specific to the Glade company. However, because the shipping methods available currently are automobile, cargo ship and aircraft, and because all of these methods burn fossil fuels, I will assume that fossil fuels are a raw material consumed during the transportation of Glade Plugins. Semi-trailer trucks, the common over ground freight delivery mode of transport, burn diesel fuel (“Why Do Semi-Trucks Use Diesel?”). According to Crown Oil, a fuel provider in the UK, large ocean vessels most commonly use heavy fuel oil, which is a petroleum based fuel containing high levels of Sulphur (“Guide to Bunker Fuel - Marine Gas Oil Information.”). Airplanes, another potential mode of transportation for product distribution, burn jet fuel, which is made from kerosene, which is derived from petroleum (“Aviation Fuel.”).

Glade Plugins are designed to be plugged into an electrical outlet for the purpose of generating heat which vaporizes the fragrant oil. Therefore, this product consumes electrical energy when in use by the consumer. Electricity is a secondary energy source that can be made from many primary sources. These primary sources include: fossil fuels, nuclear energy, and renewables such as hydropower, wind power and solar energy. As of 2018, according to the U.S. Energy Information Administration, the United States generated 64% if its electricity from fossil fuels, 19% from nuclear energy and 17% from renewable energy sources (“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.”). There are many raw materials for these primary energy sources. Fossil fuels are natural gas, coal, and petroleum. Nuclear energy requires the material uranium. And, renewable energy requires wind, water, or sunlight. The topic of energy consumption will be covered further in energy section of this paper.

Paperboard can be recycled and repurposed into new paperboard products. Whether original or recycled paperboard, it undergoes the same recycling process as mentioned in the packaging section above: the paperboard is soaked in water until it separates back into wood pulp, this wood pulp is bleached with chlorine, and then the bleached pulp is reformed into new sheets of paperboard. So this process, again, consumes the raw materials of water and sodium chloride. The metals in the brass electrical plug, copper and zinc, can also be recycled and reused. “It has been estimated that at least 65% of all copper ever mined is still in use, or available for use, having been recycled over and over” (“Copper Mining and Production Processes Explained.”). In theory, plastics can be recycled. However, according to Zoe Schlanger in the article “The World is Stuck with Decades of New Plastics it Can’t Recycle,” only 9% of plastic products get recycled. She goes on to explain that not all plastics can be recycled, and that the majority of recyclable plastics can only be recycled once (Schlanger, “The World Is Stuck with Decades of New Plastic It Can't Recycle.”). Plastic waste, when not recycled correctly and ends up in landfill. The waste management of this product will be discussed further in the waste section of this paper.

Through this lifecycle analysis we can see that the primary raw material for the majority of phases of the Glade Plugins life cycle is petroleum. It is the primary raw material for plastic, which is the largest quantity material used in the product itself, as well as for the packaging. Petroleum is also the primary raw material used to produce the fuels that transport the materials to the manufacturer, the product to the consumers, and ultimately the used product to the recycling or waste management facilities. Additionally, we saw that wood, copper, zinc, kaolin clay, sodium chloride and synthetic chemicals, made from carbon, hydrogen and oxygen, make up the other raw materials that are used to produce the final Glade Plugin product. Electrical energy is also used in many steps, notably the consumer use function of the product, which is produced from a variety raw materials: fossil fuels, uranium, sun, wind, and water. This is truly a shocking consumption of resources to produce such a small and unnecessary product.

Bibliography

Fragrance Oil:

Johnson. “: SC Johnson.” SC Johnson - What's Inside, https://www.whatsinsidescjohnson.com/us/en/brands/glade/plugins-scented-oil-refills---fresh-citrus-bloss oms.

Johnson, SC. “Fragrance Facts : SC Johnson.” SC Johnson - What's Inside, https://www.whatsinsidescjohnson.com/us/en/fragrances-you-can-trust/fragrance-facts.

“Acetaldehyde.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/Acetaldehyde.

“Methanol.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/Methanol.

“Acetate.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/Acetate.

“1-Butanol.” National Center for Biotechnology Information. PubChem Compound Database, U.S. National Library of Medicine, https://pubchem.ncbi.nlm.nih.gov/compound/1-butanol.

Materials & Manufacturing Information:

“Air Freshener.” How Products Are Made, http://www.madehow.com/Volume-6/Air-Freshener.html.

Plastic:

“Plastics.” How Plastics Are Made, https://plastics.americanchemistry.com/How-Plastics-Are-Made/.

“Oil Rigs Need Power Too.” Repco, https://www.repcoinc.com/about/blog/Oil-rigs-need-power-too-bd.html.

Arena, Umberto, Maria Laura Mastellone, and Floriana Perugini. "Life cycle assessment of a plastic packaging recycling system." The international journal of life cycle assessment 8.2 (2003): 92.

Schlanger, Zoë “The World Is Stuck with Decades of New Plastic It Can't Recycle.” Quartz, Quartz, 10 Nov. 2019, https://qz.com/1738706/the-futility-of-recycling-most-plastic/.

Paperboard:

Paperboard, https://www.afandpa.org/our-products/paper-based-packaging/paperboard.

The Editors of Encyclopaedia Britannica. “Kaolin.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 19 Feb. 2019, https://www.britannica.com/science/kaolin.

Encyclopedia.com, Encyclopedia.com, 2019, https://www.encyclopedia.com/environment/energy-government-and-defense-magazines/paper-and-wood -pulp.

Bleach:

“Bleach (Sodium Hypochlorite).” Bleach (Sodium Hypochlorite), https://whatisbleach.weebly.com/.

“Bleach.” Wikipedia, Wikimedia Foundation, 9 Oct. 2019, https://en.wikipedia.org/wiki/Bleach.

Material in Electrical Plug:

“Basic Electrics: How To Correctly Wire A Plug.” Building Materials, https://www.buildingmaterials.co.uk/knowledge/how-to-wire-a-plug/.

Brass Alloys:

Bell, Terence. “Here's Why Alloys Can Change the Properties of Brass.” The Balance, The Balance, 2 Sept. 2019, https://www.thebalance.com/composition-of-common-brass-alloys-2340109.

The Editors of Encyclopaedia Britannica. “Smelting.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 12 Dec. 2017, https://www.britannica.com/technology/smelting.

The Editors of Encyclopaedia Britannica. “Coke.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 28 Aug. 2008, https://www.britannica.com/technology/coke.

Copper Mining:

“Copper Mining and Production Processes Explained.” European Copper Institute, European Copper Institute, https://copperalliance.eu/about-copper/copper-and-its-alloys/processes/.

“Copper Mining in the United States.” Wikipedia, Wikimedia Foundation, 15 Nov. 2019, https://en.wikipedia.org/wiki/Copper_mining_in_the_United_States.

Zinc Mining:

“Zinc Mining in the United States.” Wikipedia, Wikimedia Foundation, 22 Aug. 2018, https://en.m.wikipedia.org/wiki/Zinc_mining_in_the_United_States.

“Wrought Zinc and Zinc Alloys.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/technology/zinc-processing/Wrought-zinc-and-zinc-alloys.

Transportation:

“Why Do Semi-Trucks Use Diesel?” TruckFreighter.com, https://truckfreighter.com/why-semi-trucks-use-diesel/.

“Fuel Consumption by Containership Size and Speed.” The Geography of Transport Systems, 1 Aug. 2019, https://transportgeography.org/?page_id=5955.

“Guide to Bunker Fuel - Marine Gas Oil Information.” Crown Oil, https://www.crownoil.co.uk/guides/bunker-fuel-guide/.

“Aviation Fuel.” Wikipedia, Wikimedia Foundation, 7 Oct. 2019, https://en.wikipedia.org/wiki/Aviation_fuel.

Electricity:

“U.S. Energy Information Administration - EIA - Independent Statistics and Analysis.” What Is U.S. Electricity Generation by Energy Source? - FAQ - U.S. Energy Information Administration (EIA), https://www.eia.gov/tools/faqs/faq.php?id=427&t=3.

Mio Katagiri

DES40A

Professor Cogdell

Glade Plug-in Embodied Energy

SC Johnson & Son, Inc. owns Glade, which is a brand that produces mostly household fragrances. While they have many different scented products, the one that this paper will focus on is the Glade Plug-in Air Freshener. These air fresheners have two components. There is a clear plastic container that holds scented oil, which can be replaced with refills. The other component is a plastic heating element that plugs into an outlet. The oils get vaporized by the heating element and released into the air. Since the oils can be replaced and/or refilled, the plug-ins are fairly popular. The purpose of this research paper is to demonstrate the embodied energy of Glade plug-in air fresheners’ life cycles. Glade is widely advertised as a transparent company, meaning they disclose their ingredients to the public. However, their methods of manufacture are much harder to research. There is a considerable amount of energy needed to collect the materials before even producing the plug-ins, which many consumers do not take into account. Throughout the life cycle of the air freshener, energy is being used. The product contains thermoplastics, fragrance chemicals, and brass. Although the product contains other materials, thermoplastics, fragrance chemicals and brass are the most prominent pieces of the product. To create the physical product, there are multiple processes the materials must undergo. These processes all involve materials and energy. This paper will explain the energy utilized in the stages of production, distribution, and use.

It is important to note how much processing the prominent raw materials must go through before producing the actual plug-in. One of the main materials utilized in the air freshener is brass, which is an alloy of the metals copper and zinc. Since SC Johnson does not reveal what methods they use to obtain or use copper and zinc, I will explain a common way of extracting both of those raw materials. To obtain usable copper, it must be mined from ores. It is then treated to be able to be utilized in products. Approximately 90% of extracted copper is mined from open pits, rather than mined underground, contrary to what popular media typically shows (Copper Development Alliance). I will use the largest copper mining site in the world as an example of the extraction and refinement methods typically used. A copper mining company named BHP Billiton operates the mining site in Escondida, Chile. Most copper ores come from sulfide ore, which needs to go through a process called froth floatation before the copper is isolated from the ore (LibreTexts). Through mechanical and chemical energy processes, the copper can be extracted and isolated for use. Another copper mine owned by BHP is in Spence, Chile. Between the Escondida and Spence mines, the company needs to provide about 3TWh a year to keep the two mines operational. 3TWh is equivalent to1.08x1016Joules, which is around 6% of Chile’s total electricity usage (Renew Economy).

Unlike copper extraction, zinc is mostly extracted underground, rather than from an open pit. I will use the Rampura Agucha mine in India as an example, since it is one of the largest zinc mines in the world (Investing News). The zinc must undergo a froth floatation (similar to copper) before beginning the smelting process. The material is then smelted in order to isolate zinc before it is ready for use in products. The extraction and isolation process involves mechanical, chemical, and thermal energy in order to prepare and transport zinc to be used in products.

The two materials discussed above can be combined in certain processes in order to become brass. Brass is an alloy that’s widely used because of its malleable and conductive properties. The processes to create it involve both thermal and mechanical energy. The copper is added to a furnace being heated at around 1,920 ̊ F until it is melted. Once the copper has melted, varying amounts of zinc are added in. The melted combination is poured into a mold, and then is left to cool. Once cooled down, it can be rolled by machinery before being cut and coiled (MadeHow). It then needs to be transported to SC Johnson’s factories in order to be used. For the plug-ins, the brass is used for the prongs to plug into the wall. It is also plated over certain interior sections of the plastic component to conduct heat. This thermal energy transfer allows the oils to be vaporized and released into the air.

The bulk of the plastic materials in the product are thermoplastics, meaning that they are melted down to liquid form and then molded before being formed and cooled. Thermoplastics make up about 92% of plastics, since they can be molded very easily (American Chemistry Council). Since SC Johnson doesn’t offer information about their production processes, I cannot determine exactly the types of energy required when specifically implementing the thermoplastics into the plug-in design. However, we can assume that these production processes received electrical energy through the mechanical energy generated by wind turbines. SC Johnson uses wind turbines to generate electric power for their Waxdale plant, which produces Glade products. The turbines generate around 8 million kWh per year (SC Johnson). Thermal energy is the only guaranteed type of energy needed to utilize the thermoplastics, since they need to be melted down. Since many of the specific production processes are proprietary, the energy within the processing of the fragrance chemicals is also not available.

Transportation is a vital phase of a product’s life cycle, and a significant amount of energy is needed to fuel trucks, ships, and planes. Since SC Johnson does not disclose specific routes and information on transportation of the product, I will use Waxdale, their largest plant, as a basis to demonstrate the types of energy required to move the product. Trucks that carry cargo typically get around 6.5 miles per gallon (Arrow Truck). If SC Johnson hypothetically shipped their plug-ins to Davis, CA, it would require around 320 gallons of gas for the products to be shipped. Obviously, that calculation is assuming their trucks do maintain an average of 6.5 miles per gallon. However, that is still a considerable amount of fossil fuels being used whenever SC Johnson ships out products from their factories. During the steps of transportation, thermal and mechanical energy are being utilized.

The energy required during the usage stage of the product’s life cycle is fairly straightforward and consistent. While the product is being used by consumers, it is plugged into a standard 120 volt outlet. The standard air freshener plug-ins are 2.1W, which means that they use 2.1 watts per hour while they are plugged in (Richardson). The electric energy is converted to thermal energy when the brass heats up the oils to release the fragrance. As long as the plug-in is in an outlet, it is supposed to be able to function properly. Obviously, the plug-ins don’t last indefinitely, but they do have the potential to use a considerable amount of electricity over time.

After the product is thrown away, the plug-in is typically thrown away and taken to a landfill. Both the brass and the thermoplastics inside of the product can be melted down and repurposed. However, many aerosol products are just thrown away and taken to a landfill, since there is no instruction on how to properly dispose of them.

The embodied energy of a product’s life cycle is widely overlooked by consumers. Many customers would think that a product’s life cycle begins from the moment it is purchased. However, the life cycle of something begins at the extraction and collection of raw materials. A considerable amount of energy is necessary for the Glade air plug-ins to be produced. Since SC Johnson keeps their production processes hidden, calculating the total amount of energy needed for each plug-in isn’t possible with the information available. The brass and the thermoplastics both require thermal energy to be melted down and integrated into the product. A sizeable amount of energy is used for transporting the plug-ins to different locations, mostly from Wisconsin. The finished product uses electric energy during usage until it is thrown away. It is important for consumers to take into account the substantial amounts of energy and materials that simple products use and waste. Although SC Johnson is transparent with their ingredients used, they don’t reveal energy usage or production processes to the public.

Bibliography

“Copper Mining and Extraction Sulfide Ores.” European Copper Institute, European Copper Institute, copperalliance.org.uk/knowledge-base/education/education-resources/copper-mining-extraction-sulfide-ores/.

“The Extraction of Copper” LibreTexts, https://chem.libretexts.org/Bookshelves/Inorganic_Chemistry/Supplemental_Modules_(Inorganic_Chemistry)/Descriptive_Chemistry/Elements_Organized_by_Block/3_d-Block_Elements/1b_Properties_of_Transition_Metals/Metallurgy/The_Extraction_of_Copper

Parkinson, Giles. “BHP Cancels Coal Contracts, Goes 100 per Cent Renewables at Huge Chile Copper Mines.” RenewEconomy, 22 Oct. 2019, reneweconomy.com.au/bhp-cancels-coal-contracts-goes-100-per-cent-renewables-at-huge-chile-copper-mines-57884/.

Kay, Amanda. “World's Largest Locations for Zinc Mining: INN.” Investing News Network, 23 Aug. 2018, investingnews.com/daily/resource-investing/base-metals-investing/zinc-investing/the-worlds-top-3-zinc-mines-an-overview/.

“Brass.” How Products Are Made, www.madehow.com/Volume-6/Brass.html.

American Chemistry Council. “Plastics.” How Plastics Are Made, plastics.americanchemistry.com/How-Plastics-Are-Made/.

“Fact Sheet: SC Johnson's Waxdale Facility.” SC Johnson - A Family Company at Work for a Better World, 1 Jan. 2018, www.scjohnson.com/en/our-news/fact-sheets/fact-sheet-sc-johnsons-waxdale-facility.

ATSBlogM, Author. “Manage Your Semi-Truck's Fuel Use with These Tips.” Arrow Truck Sales Blog, 8 May 2017, www.arrowtruck.com/blog/2016/06/21/manage-your-semi-trucks-fuel-use-with-these-tips/.

Richardson, Adam. “The Surprising Energy Consumption of Glade Plug-Ins.” Adam Richardson, Adam Richardson, 11 Dec. 2007, www.richardsona.com/blog/2007/12/11/the-surprising-energy-consumption-of-glade-plug-ins.html.

“Rampura Agucha.” " Rampura Agucha, Hindustan Zinc, 2018, www.hzlindia.com/bussiness/operations/mines/rampura-agucha/.

“Corporate Transparency Commitment: SC Johnson Tells You More About Fragrance Ingredients.” Corporate Transparency Commitment: SC Johnson Tells You More About Fragrance Ingredients, 1 Apr. 2019, www.scjohnson.com/en/our-purpose/commitment-to-transparency/corporate-transparency-commitment-sc-johnson-tells-you-more-about-fragrance-ingredients.

“Air Freshener.” How Products Are Made, www.madehow.com/Volume-6/Air-Freshener.html.

Crystal Perez

Professor Cogdell

DES 40A

Life Cycle of a Glade® PlugIn: Wastes and Emissions

SC Johnson is a huge manufacturing company that produces household cleaning supplies and other consumer chemicals. They own Glade®, the brand known for their wide variety of air freshening products, including aerosol sprays, candles, PlugIns, etc. Our focus for this project will be the PlugIn Air Fresheners. These products play a part in keeping homes smelling fresh and clean, however is the process of creating said product as clean as the product itself? In this essay we will be attempting to follow the waste products and toxic outputs emitted, from cradle to grave, in the life cycle of a Glade® Plug-in air freshener

Our life cycle begins with Petroleum, Copper, Zinc, Coal, and Trees the main raw materials used in the production of Glade® PlugIns. These materials must first be extracted from the earth and undergo certain processes even before they enter the factories. Petroleum is drilled out from the ground through hydraulic fracturing, or “fracking,” a method that injects a mixture of water and chemicals into subterranean rock layers in order break and extract the oil needed. [1] This method is the most effective, yet the most controversial because of its environmental effects and water use. First, oil drilling is a great contributor to global warming, as it releases greenhouse gasses into the atmosphere. And secondly, a recent study states that “global water withdrawal for drilling constitutes 15% of the world’s total water consumption.” [10] This means that the water used in fracking becomes toxic, as the chemicals mixed into it contains cancer producing properties that can leak into nearby lakes and ponds. This inevitably pollutes the drinking water and effects the local communities and ecosystems. A similar result comes from the extraction of copper and zinc. The ores of the minerals are obtained through underground mining or open pit mining, which create a large amount of waste called tailings. [11] These chemical infused tailings are later dumped into local ponds and pollute nearby water sources. Mining also leaves trace metals in the soil, creating contamination and environmental health effects. [4] Coal is also acquired through a similar mining process, creating even more water and soil pollution. The last raw material needed are logs. Trees are cut down into logs with a feller-buncher, which is a motorized vehicle that runs on approximately 0.38 gallons of diesel per ton of wood. [5] These logs are now ready for the next stage. All of these raw materials are then most likely transported on diesel fueled trucks or planes to factories where they will be processed further.

The raw materials obtained in the first step, willnow be utilized for the production of thermoplastic, brass, and paperboard, which make up the Plugins and their packaging. The majority of this product is made from thermoplastics. Thermoplastics are made of petroleum-based poly resins, and additives like colorants and other chemicals, depending on the company. All the materials are melted together at approximately 580 C for three and a half hours in a factory that utilize fossil fuels, that in turn releases CO2 greenhouse gases. [15] This mixture is then poured into molds to create parts of the warmers as well as most of the oil refill pods. Now for the electrical bit of the plug-in, brass is utilized as the main material. Bass is made by smelting copper and zinc ores with coke, a coal-based fuel, followed by mixing the two metals together. The smelting process creates a great deal of waste because “the ore only contains a small fraction of the desired material, at its extraction produces CO2, SO2, and NO2.” [4] The brass will then be molded and into the electrical bit that will plug into the wall. Then for the synthetic scented oils, there is a wide variety of chemicals that are listed on the SC Johnson website: some including acetaldehydes, methanol, acetates, and butanol. The process of creating and mixing these chemicals may result in wastewater and air pollutants, however, there is not enough available information to make certain statements. The last material used in the manufacturing process is paperboard. Paperboard is made by first putting logs into a debarking drum, then feeding them into a chipper, followed by pulping the chips into fibers. These fibers are then cleaned, bleached, and shaped into paperboard. The long strips of paperboard are then covered with a layer of with pigment and dried, before the printing and cutting process. [9] This produces scrap waste from the unused chips and fibers, and water wastes, from the dyes. Now, all of the pieces of the PlugIns come together on an assembly line on factory machines and will be packaged and sent off in diesel fueled trucks and planes.

As these air fresheners are distributed around the world to be stocked at markets and convenient stores, a great deal of CO2 greenhouse gas is emitted into the air. The average freight truck in the U.S emits 161 grams of CO2 per ton-mile. [12] SC Johnson has their central manufacturing facilities in Chicago, IL and their headquarters in Racine, WI. [13] So if for example we were to estimate the CO2 production of a truck taking the PlugIns from Chicago to Racine, it would produce around 12,091.1 grams of CO2. Transporting these products then to stores at a father distances, like the 70 countries that the SC Johnson company is located in, will only multiply that number by 161 grams per mile. However, the waste doesn’t stop there, even more CO2 is released into the air as the consumer take the product from the store to their homes. Only about 2% of all the cars in the US are hybrids or electric, this means that the other 98% contribute to the greenhouse gasses (GHG). It is said that “the US transportation sector- which includes cars, trucks, planes, trains, ships, and fright- produces nearly thirty percent of all US global warming emissions.” [2] This means that this product, in its life cycle, is contributing to global warming. Regardless, after this step in its life, the PlugIn is finally in the consumer’s home ready for use and the life cycle continues, as do the distribution of waste and emissions.

During the use of the PlugIn Air Freshener there are some potential negative outputs,one including off gassing. This is caused by the ingredients found in the synthetic scented oils that are vaporized into the air. In a 2015 study, researcher and scientist, Steinemann, found that “156 volatile organic compounds (VOCs) are emitted from 37 fragranced consumer products. And of these 156 VOCs, 42 were classified as toxic or hazardous under US federal laws and each product tested emitted at least one of these chemicals.” [14] Some of the most common VOCs that she found include limonene, alpha-pinene, beta-pinene, and acetaldehyde. [14] Cross referencing those chemicals with the ingredients listed on the SC Johnson website, acetaldehyde was the only recognizable VOC that I could spot. [8] However, the investigation of whether specific Glade scents contain more VOCs would take more in-depth research by a person far more familiar with chemistry than I. What is known though, is that VOCs create pollutants that can cause headaches, respiratory difficulties, migraines, asthma attacks, and skin allergies along with other health problems. “Overall, 34.7 % of the population, reported in an online survey, that they experienced one or more types of health effects from exposure to fragranced products.” [14] SC Johnson somewhat acknowledges these potential health risks that come with the fragrances from their product. They do this by providing a list of skin allergens along with information of how to spot them. It is unclear if JC Johnson uses chemicals with the VOCs that cause these health problems. However, on their website it states that they,” excluded approximately 2,000 potential ingredients from our fragrance ingredients palette.” This might conclude that they excluded some VOC chemicals as an extra precaution and surpassed the International Fragrance Association (IFRA) standard. [8] Excluding these toxic chemicals, as well as listing their ingredients for their products are both great steps forward for SC Johnson. It is important for consumer to be aware of potential toxics in the products they are being exposed to, and it is just as important that the company providing this product are reducing the amount of toxicities in it. Now in the reuse of the PlugIns, the warmer will be re-used multiple times because it is made out of durable plastic, however the light plastic refills will not. Once the oil evaporates completely the consumer will then dispose of the plastic refill pod either in the trash or in the recycling bin. Similarly, the warmer will be disposed if it breaks or is unwanted.

Many parts of the Glade® PlugIns are recyclable; however, they require certain steps in order for them to reach the recycling process. Starting off with the oil refills, the thermoplastics used are #1 plastics, which means they are composed of polyethylene terephthalate or PET for short. [3] This is the most used plastic and is the most easily recycled. They can be thrown in any recycling bin where they will be sorted, cleaned, and shredded into small granulates or pellets. Next, they go through quality tests determining their density, air classification, melting point, and color. [6] These small bits will then be melted down into a liquid that can then be molded into the shape of the new product. This recycling process has many environmental benefits; however, it also causes some air pollution due tothe fossil fuels used to power all of the huge machinery utilized. Now as for the recycling of the warmer, it comes with its own set of pollutants and struggles as well. Since it uses electricity to function, it is now considered a household electronic device. This means that the product can no longer be carelessly thrown into the recycling bin. It will now need to be sent to the proper e-waste facility in order to be broken down and processed correctly. The consumer must first localize an establishment that accepts e-waste and send it to them. Next, they will send the plugin and other e-waste to underdeveloped countries, where they will be taken apart and sorted by hand. Then, the materials will be shredded and sorted once again using magnets to insure all the precious metals, in this case brass, has been removed. The separated brass and thermoplastics will now be shipped and sold at other facilities where the rest of the recycling process plays out. This process also contributes to the greenhouse gas emissions due to all the fossil fueled machines used, and the planes and trucks that transport the pieces to the machinery. For brass, I couldn’t find the exact process by which the metal was recycled however my assumption is that it is melted and purified before being reshaped into a new product. The melting point of brass is about 1650 to 1720 degrees F and in order to reach that temperature, fossil fuels must be used. [6] Moving on to paperboard, the last material used for this product. Paperboard can be recycled through the standard recycling bins in the consumer’s area. It will then be transported to a facility where it will be sorted, shredded into wood pulp.

Although most materials in the Glade® Plugins are recyclable, the plastics and brass in them are not usually recycled and end up in the landfills. The reason behind this is that knowledge about how to recycle and what to recycle is not that widely known. I speak with personal experience, that I did not know the difference between the various plastics and how they are recycled. I also didn’t know that the plugins cannot be recycled through your average recycling bin. And these are the first steps in successfully reducing plastic wastes. “The US alone produces about 234 pounds of plastic waste per person per year.” [7] The SC Johnson company has made some changes to acknowledge the huge plastic waste problem that they are enviably contributing to. They claim that their company removed 1.7 million kilograms of plastic from their packaging and that 94% of their plastic packaging is now recyclable. [14] However, this does not compensate for the tons of plastic they are already producing in the manufacturing of all their products. Also, thermoplastics can only be recycled a certain amount of times before it is no longer usable. After being processed so much the molecular properties of the resin are lost.“It happens because of chain-scission reactions caused by the presence of water and acidic impurities.” [14] So when the plastics are no longer usable, they are either incinerated or thrown in the landfill. Neither end point is ideal. By burning the plastics, there is the problem of the production of toxic gasses (CO2) along with ash reside containing lead and cadmium. And by throwing the plastics in the landfill, it will take anywhere from 450-1000 years to decompose through “photodegradation, thermo-oxidative degradation, hydrolytic degradation, and biodegradation by microorganisms.” [14] Moving along to brass wastes, when not properly disposed of the brass from the plugins will end up rusting in landfills. Lastly paperboard waste, if the paperboard is not properly disposed it will then end up in the landfill and will decompose through natural processes

In the life cycle of the Glade® PlugIn air fresheners there are waste and toxic byproducts generated in every stage. From the raw material acquisition, through the manufacturing stage, up until the recycling and waste management, air pollution, water wastes, soil contamination, and plastic wastes are created and pollute the earth. Even though this product’s life purpose is to keep things smelling clean, its production is nothing but dirty. Glade® PlugIns are not sustainable products and will most likely end up in landfills, contributing to the mounds of plastic we already have. If considering alternatives to help reduce waste, reed diffusers are a great option.

Works Cited

[1] “7 Ways Oil and Gas Drilling Is Bad for the Environment.” The Wilderness Society, www.wilderness.org/articles/blog/7-ways-oil-and-gas-drilling-bad-environment.

[2] “Car Emissions and Global Warming.” Union of Concerned Scientists, www.ucsusa.org/resources/car-emissions-global-warming.

[3] Cowan, Shannon. “Plastics by the Numbers.” Eartheasy Guides & Articles, learn.eartheasy.com/articles/plastics-by-the-numbers/.

[4] Dudka, Stanislaw, and Domy C. Adriano. Environmental Impacts of Metal OreMining and Processing: A Review. May 1997.

[5] Greene , Dale, and Shane Baker . “FUEL CONSUMPTION RATES FOR TREELENGTH HARVESTING SYSTEMS IN THE COASTAL PLAIN.”

[6] Greentumble. “Step by Step Process of Recycling Plastic.” Greentumble, 29 Aug. 2019, greentumble.com/how-is-plastic-recycled-step-by-step/.

[7] Holden, Emily. “US Produces Far More Waste and Recycles Far Less of It than Other Developed Countries.” The Guardian, Guardian News and Media, 3 July 2019, www.theguardian.com/us-news/2019/jul/02/us-plastic-waste-recycling.

[8] Johnson, SC. “: SC Johnson.” SC Johnson - What's Inside, www.whatsinsidescjohnson.com/us/en/brands/glade/plugins-scented-oil-refills---fresh-citrus-blossoms.

[9] Keigley, Kevin. “How Is Paperboard Made?” The Packaging School, 4 Sept. 2019, packagingschool.com/blog/2019/09/04/how-is-paperboard-made/.

[10] Kondash, Andrew J., et al. “The Intensification of the Water Footprint of Hydraulic Fracturing.” Science Advances, American Association for the Advancement of Science, 1 Aug. 2018, advances.sciencemag.org/content/4/8/eaar5982.

[11] Learning, SBCTC & Lumen. “Geology.” Lumen, courses.lumenlearning.com/geo/chapter/reading-effects-of-mining/.

[12] Mathers, Jason. “Green Freight Math: How to Calculate Emissions for a Truck Move.” EDF+Business, 6 Apr. 2015, business.edf.org/blog/2015/03/24/green-freight-math-how-to-calculate-emissions-for-a-truck-move.

[13] “SC Johnson Job Locations.” SC Johnson Careers, jobs.scjohnson.com/locations.

[14] “SC Johnson on Track to Meet Goals in Tackling Plastic Waste Crisis, Announces Results in New Sustainability Report.” SC Johnson - A Family Company at Work for a Better World, www.scjohnson.com/en/press-releases/2019/september/sc-johnson-on-track-to-meet-goals-in-tackling-plastic-waste.

[15] Steinemann, Anne. “Fragranced Consumer Products: Exposures and Effects from Emissions.” Air Quality, Atmosphere, & Health, Springer Netherlands, 2016, www.ncbi.nlm.nih.gov/pmc/articles/PMC5093181/#CR18.

[16] “Thermoplastics Manufacturing Process Overview.” Thermoplastics Manufacturing Process Overview - SEKISUI SPI, sekisui-spi.com/technical-resources/thermoplastics-manufacturing-process-overview.