Design Life-Cycle

assess.design.(don't)consume

Serina Vo

Kano Fujino-Harmachis and Saffron Munkres

DES 040 A06 - Professor Cogdell

01 December 2021

Lifecycle of Shoelaces - Raw Materials

In 2000 BC, Ancient Greek soldiers wore sandals that consisted of woven shoelaces around West Europe. Eventually, shoelaces became known in the 19th century as a fashion statement. Running shoes are not durable without shoelaces due to the grip and tension it builds to keep the shoe sustainable. Shoelaces have evolved throughout the years by changing materials from leather, hemp, cotton, jute, and ropes to synthetic fibers; however, shoelaces are still unsustainable because of the mass production waste being thrown into landfills.

There are different materials that make shoelaces unstable such as cotton and leather; however there are a few materials that are sustainable such as hemp, and jute. Cotton is a primary material that comes from the cotton fields which are taken from the grounds. Dandago states that “Cotton production is linked to other sectors of the economy, such as equipment manufacturers, food processors and transporters, creating crucial cotton supply chains” (Charli 2018). Cotton ruins the equipment of manufacturing due to consuming a large amount of water. Most equipment to make cotton fabrics uses water. Cotton is also being decreased due to the amount of cotton to make one piece of garment. In the article, The Impact Of Disaster Risk On Economic Sustainability Of Cotton Supply Chains: Evidence From Chiredzi District, Zimbabwe, it states that “The floods hit cotton farmers by washing away their crops, affecting the livelihood of many Pakistan cotton farmers and workers in the textile industry” (Charli 2018). Floods have affected cotton farmers which ruin many cotton industries. Cotton has increased in production but takes up 2.5% of the earth’s land. Leather is also a primary material made from animal skins which includes sheep, goats, calves, horses, and pigs. Leather is unsustainable because of the “massive amount of energy and dangerous chemicals” being produced to make. Leather uses different types of chemicals such as mineral salts, formaldehyde, coal-tar derivatives, and various oils, dyes, and finishes.

Hemp also known as cannabis sativa or industrial hemp is a primary material which is a plant. Hemp is typically one of the materials in shoelaces that are sustainable because it is plant based. Hemp does not damage air, water, soil, land, or any other earth resources. In the article, Material Guide: How Sustainable is Hemp Fabric, it states that “ Hemp also naturally reduces pests, so no pesticides are usually needed. Amazingly it also returns 60-70% of the nutrients it takes from the soil” (Hymann 2020). Hemps takes less energy to manufacture due to the small amount of water cycling in the machines. Lastly, jute is made out of cellulose and lignin plant materials. Jute is a sustainable material because it is an eco-friendly product that needs no intervention to grow and reproduce. Jute does not need that much land to produce compared to other types of crops.

Throughout the years, shoelaces became a little more sustainable by changing the materials into synthetic fibers such as “nylons, textured polyester, spun polyester, and polypropylene as well as traditional natural materials” (Shoelace Express 2021).These materials are secondary materials made from crude oil which also produces polymer. Even though these materials are sustainable, these materials require a large amount of water to produce. All of these materials are made out of crude oil which is a natural fossil fuel that is made up of hydrocarbons. Polyester is typically an acetate fiber because it is made with acetic acids. In the article, Everything You Need to Know About Acetate Fiber, it says that “Acetate flakes are formed by the combination of acetic acid with cellulose from wood. Acetate fiber is the second-oldest man-made fiber in the United States and was used as a coating for airplanes”(Assoune 2021). Polyester is used throughout the shoelaces such as the braided texture and the aglets. Aglets are produced by an ultrasonic heating to melt the polyester together at the end of the shoelaces which prevents the shoelaces from being unbraided. In the study, LCA Benchmarking Study On Textiles Made Of Cotton, Polyester, Nylon, Acryl, or Elastane, it states that “The impact of spinning and weaving is relatively high (for yarn thicknesses of less than 100 dtex), and from the environmental point of view, knitting is better than weaving”(Velden 2013).

Polyester is one of the more sustainable materials but it is also unsustainable because of the amount of microplastic being extracted. “Polyester has often been considered more sustainable from a consumer care standpoint – polyester garments last a really long time and require less water, energy and heat for washing. But a multitude of recent studies show that polyester sheds small pieces of plastic called microplastics with every wash”(CDFA 2021). Plastic materials are non-biodegradable and are terrible for the environment due to high increase of pollution. Plastic affects many things such as living creatures and earth’s oceans, lakes, forest, and rivers.

Nylons is a huge synthetic material used in shoelaces due to its durability and flexibility. In the article, Material Guide: How Sustainable is Nylons, it states that “...Nylons are a family of materials called polyamides, made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure, heated environment. This chemical reaction, known as condensation polymerization, forms a large polymer—in the form of a sheet of nylon” (Uren 2020). Nylon is not typically a sustainable material because it can lead to microplastic contamination, however, it is less harmful than different fabrics. Nylons are not biodegradable which becomes one of the largest sources of microplastic pollution to the ocean.

Fabric materials are being thrown away into landfills. A big portion of the landfills are coming from fast fashion. One of the biggest fast fashion products are shoelaces because you can find it on millions of people’s footwear. In the article, Fast Fashion, Sustainability, and the Ethical Appeal of Luxury Brands, it states that,“If consumers recognize the demands that fast fashion makes on the environment, they seem to block it from their consciousness” (Joy, Sherry Jr, Venkatesh, Wang & Chan, pg. 286). Consumers consistently buy shoes which usually include shoelaces. Many clothes and specifically shoes are being thrown in the dumps for being “worn out” or being “out of fashion” Consumers increasingly consider their wants rather than their needs when it comes to fashion.

Around the world, there are many clothes such as shoelaces that are affecting our living space. In the article, How Sustainable is Recycled Polyester, it explains that “Clothes are undoubtedly a big part of the problem: in the UK, a report by the Waste and Resources Action Programme (WRAP) estimated that about 140 million pounds worth of clothes end up in landfills each year” (Elven 2018). Shoelaces and other fabrics go into landfills majority of the time instead of being recycled or upcycled. Clothes are the second largest source of pollution to the environment.

Fabrics such as shoelaces can be reduced and reused, but they cannot be recycled due to the microplastic materials produced within polyester and nylons. One way to reduce landfill for shoelaces is decreasing the amount of quantity when manufacturing because most shoelaces are being thrown away when it is in a decent condition. Another way to reduce the amount of shoelaces being thrown into landfills is to upcycle them. For instance, shoelaces can be used to fix hoodies, sweaters, shirts, and pants. It can also be used as a durability to hold plants up or even used as a hair elastic. In conclusion, the materials of shoelaces have become more sustainable to the environment; however, shoelaces should be recycled rather than thrown away in landfills to reduce the amount of cluttered landfills. . Shoelaces can be upcycled into different clothing such as hoodies, pants, and shirts. Materials such as cotton and leather are less likely to be seen in shoelaces because it is unsustainable to the environment. Cotton and leather is hurting the environment due to the amount of energy needed to produce the materials. Instead of producing cotton and leather, shoelaces have used synthetic fibers to replace these materials. Synthetic fibers such as nylons, textured polyester, spun polyester and polypropylene became the new shoelace materials until it becomes more sustainable in the future.

Bibliography

Adams, Ken, et al. “Development of Emissions Factors for Polypropylene Processing.” Journal of the Air and Waste Management Association, 27 December 2011. https://www.tandfonline.com/doi/pdf/10.1080/10473289.1999.10463782. Accessed 24 October 2021.

Assoune, Alex. “Everything You Need to Know About Acetate Fiber.” Panaprium. https://www.panaprium.com/blogs/i/acetate-fiber. Accessed 24 October 2021.

Annamma Joy, John F. Sherry Jr, Alladi Venkatesh, Jeff Wang & Ricky Chan (2012) Fast Fashion, Sustainability, and the Ethical Appeal of Luxury Brands, Fashion Theory, 16:3, 273-295, DOI: 10.2752/175174112X13340749707123

Charli, Felix. “The Impact of Disaster Risks on Economic Sustainability of Cotton Supply Chains: Evidence from Chiredzi District, Zimbabwe.” Taylor & Francis, 1 June 1970, https://www.tandfonline.com/doi/full/10.1080/23311886.2019.1625742

CFDA. “Polyester.” cfda.com. https://cfda.com/resources/materials/detail/polyester. Accessed 24 October, 2021.

Elven, Marjorie van. “How sustainable is recycled polyester?” Fashion United, 15 November 2018. https://fashionunited.com/news/fashion/how-sustainable-is-recycled-polyester/2018111524577. Accessed 24 October 2021.

“Material Guide: How Sustainable Is Hemp Fabric?” Edited by Yvette Hymann, Good On You, 13 May 2021, https://goodonyou.eco/material-guide-hemp/

Shoelaces Express. “Shoelace Manufacturing.” shoelacesexpress.com, 2021. https://shoelacesexpress.com/pages/shoelace-manufacturing. Accessed 24 October 2021.

Uren, Ashlee. “Material Guide: How Sustainable is Nylon?” goodonyou.eco, 31 August 2020. https://goodonyou.eco/material-guide-nylon/#:~:text=Greenhouse%20gases%3A%20producing%20nylon%20creates,of%20environmental%20contamination%20and%20pollution. Accessed 24 October 2021.

Van Der Velden, Natascha, et al. “LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane.” Springer-Verlag Berlin Heidelberg, 4 September 2013. https://www.woodguide.org/files/2014/07/LCA-textiles.pdf. Accessed 24 October 2021.

Materials Paper:

Saffron Munkres

Kano Fujino-Harmachis and Serina Vo

DES 040A FQ 21

Professor Cogdell

The Lifecycle of a Shoelace: Embodied Energy

Fast fashion is the most common thing that comes to mind when people talk about how the fashion and textile industries are affecting our environment. At the end of the day, it is just another form of consumerism that is supported by our society. People buy a lot of clothes that they do not wear or that wear out very quickly, so they buy even more. This can be the case for shoes too, or even, shoelaces. Almost every pair of toe closed shoes comes with at least one pair of shoelaces. One is usually already laced into the shoe, and then there might be a second pair in the box that is just a different color or backup in case the first one breaks. People don't usually think about how shoelaces, including their whole lifecycle, may be unsustainable, especially given the amount of shoes in ones’ closet as well as all the extra free laces that most people don't want or ever end up using. Every product has a lifecycle, from finding and accessing the materials, to creating and distributing the product, using the product, and finally disposing of it. Shoelaces seem like simple objects; they are just braided fibers with a little plastic bit on the end right? There is more to it than that. It is important to learn and acknowledge the energy put into something, as it is often overlooked. While shoelaces are a very common item that many people use every day, the amount of embodied energy used throughout the lifecycle, mainly including the acquisition of materials, production of the shoelaces, and distribution process, is an unsustainable practice that is not healthy to our environment.

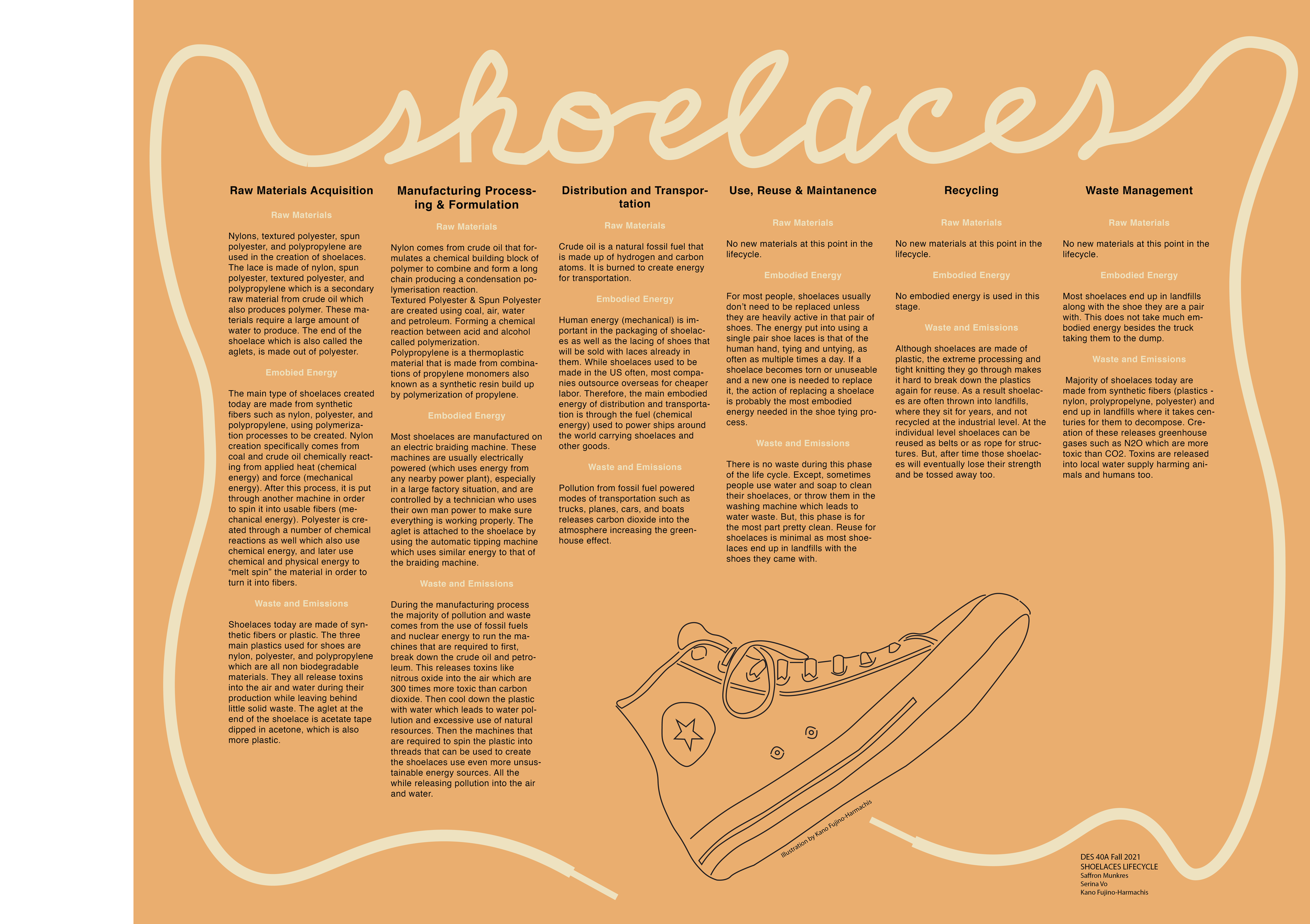

The beginning of a shoelace’s life cycle starts at the acquisition of raw materials. The most common type of shoelaces created in the current world are made from synthetic fibers such as nylon, polyester, and polypropylene, using polymerization processes to be created. Nylon creation specifically comes from coal and crude oil chemically reacting from the energy of applied heat and force (Uren). These processes require a lot of energy to power the machines that are able to produce such chemical reactions because “The plastification of polymers requires a high volume of electric power for thermal energy. Electricity based power is the common form of energy in polymer processing and provides obvious potential for a reduction in energy use and costs. (Khripko)”. These machines need energy to run, and to rely on electricity means to rely on a power plant. Power plants most commonly use fossil fuels to create energy to turn into electricity. These machines are not the only ones used in the manufacturing process either. After the polymerization of the nylon, the material is put through another machine called a spinneret (Uren) in order to turn it into usable fibers. This machine uses mechanical energy to pump the polymer through tiny holes. Then it uses more mechanical energy to spin, stretch the polymer into long fibers, untill water is also used to cool the nylon fibers, making use of kinetic energy (Alagirusamy, Das). Spinnerette machines also make use of the same type of energy sourced from fossil fuels as the polymerization machines. All of the energy used to run machines is constantly polluting the environment and is also unsustainable due to the nature of fossil fuels. A shoelace is such a tiny object, but the man made materials that make it up have a large impact. Polyester and polypropylene go through similar processes to nylon, however they are even more processed which just adds another layer of embodied energy to the creation of something so simple.

After the materials needed for a shoelace are produced and acquired, the manufacturing process can begin. Most commonly, electric machines are used, and once again, they are powered by a power plant that most likely burns fossil fuels. A large factory situation can have a room full of shoelace braiding machines, and are controlled by a technician who uses their own man power to make sure everything is working properly (madehow). On a much smaller scale, as well as more commonly in the past, man powered braiding machines were used as they are simple enough. All that used to be needed was someone to use their own man-powered mechanical energy to turn the crank and make the machine braid. In our current day and age, man powered machines are much less common especially in a huge factory operation, as there is more room for error and injury. Whether electric or not though, braiding machines have a simple job; to braid the shoelace. An automatic tipping machine adds the final touches of the lace, an aglet- the plastic end bit of a shoelace that keeps it from unraveling (madehow). The manufacturing process mainly embodies energy through power plants.

The last large amount of embodied energy in the lifecycle of a shoelace is found in the transportation and distribution process. So where are these processes taking place? “The vast majority of this synthetic production currently takes place in China, which is also the leading synthetics exporter (commonobjective)”, which then leads to the question, where is the shoelace most commonly made? It is likely that shoelaces are manufactured in similar areas to that of the shoes that they are made for. The highest shoe and footwear producer in 2020 also happened to be China, with India, Vietnam and Indonesia coming in close after (Shahbandeh). These locations are all relatively close to each other, so the distribution of materials did not take quite as much energy as later in the process. Once the shoelaces are created, they get shipped all over the world. A cargo ship can contain up to “approximately 4.5 million gallons of fuel oil (frieghtwaves).” Going around 25 MPH, a container ship can use up to 63,000 gallons of fuel per day (freightwaves). It takes a container ship of this size about 35 days to get from China to the Port of Oakland in the USA (ports.com). That is a total of 2,205,000 gallons of fuel just to transport. Although this is a hypothetical situation, the amount of energy embodied in that 35 day trip has burned so much fuel. These types of trips are happening constantly with all kinds of consumerist goods, and with many different destinations. Shoelaces just happen to be one of those many products that needs to be transported, and even though they seem so small, they are still an unsustainable product that has this type of energy in its lifecycle.

The other phases of the shoelace lifecycle use much less energy. Once someone buys a shoelace or a shoe with a lace in it, they don't require much energy except for everyday tying. If a shoelace becomes torn or unuseable and a new one is needed to replace it, the action of replacing a shoelace is probably the most embodied energy needed in the shoe tying process. For most people, shoelaces usually don’t need to be replaced unless they are heavily active in that pair of shoes, and the laces get torn or frayed, so there is not very much embodied energy in the maintenance and use of a shoelace. The other stage of the life cycle, recycling and waste management, also do not use much energy, except for the truck that takes the shoelaces to the dump with other non recyclable products.

How can such a small and seemingly insignificant product be so harmful to the environment and completely unsustainable through its energy usage? I never used to think that a shoelace used energy, but really it’s whole lifecycle embodies so much energy. Since we as humans have used up so many natural materials or found them less convenient, we have decided to create our own synthetic versions of so many materials, including fibers, to make something like a shoelace which should be a just simple braid, into a polymerization process which uses so much energy to heat and compress and filter and create our own new fibers. Fossil fuels and other waste products are constantly being burned to provide energy at power plants in order to create electricity for simple machines to do their job. Machines that are so simple that they could be powered by a human turning a crank. Instead, we pollute our earth and waste our finite resources to power these machines so that people can just sit and watch and order things online. Millions of gallons of fuel are used to transport products like shoelaces on cargo ships all around the world. Shoelaces might not be the biggest problem in the world, but as a piece of consumerism that is not sustainable to our planet, the shoelace in itself is an unsustainable product.

Bibliography

Alagirusamy, R., and A. Das. “Conversion of Fibre to Yarn: An Overview.” Conversion of Fibre to Yarn: An Overview - ScienceDirect, Woodhead Publishing, 21 Nov. 2014, https://reader.elsevier.com.

“Braiding Process.” Braiding Process - an Overview | ScienceDirect Topics, https://www.sciencedirect.com/topics/engineering/braiding-process

Common Objective. “Synthetics & Sustainable Synthetics: Global Production.” Common Objective, Common Objective, 29 May 2018, https://www.commonobjective.co/article/synthetics-sustainable-synthetics-global-production.

Khripko, Diana, et al. “Energy Demand and Efficiency Measures in Polymer Processing: Comparison between Temperate and Mediterranean Operating Plants.” International Journal of Energy and Environmental Engineering, Springer Berlin Heidelberg, 29 Jan. 2016, https://link.springer.com/article/10.1007/s40095-015-0200-2.

O Ecotextiles (and Two Sisters Ecotextiles). “Embodied Energy in Textiles.” OEcotextiles, 26 Feb. 2019, https://oecotextiles.blog/category/embodied-energy-in-textiles/

“Port of Shanghai, China to Port of Vancouver USA, United States Sea Route and Distance.” Ports.com, http://ports.com/sea-route/port-of-shanghai,china/port-of-vancouver-usa,united-states/.

“Polyester.” How Products Are Made, http://www.madehow.com/Volume-2/Polyester.html

Shahbandeh, M. “Leading 10 Global Footwear Producers, by Country 2020.” Statista, 16 Nov. 2021, https://www.statista.com/statistics/227256/leading-10-global-footwear-producers-by-country/.

“Shoelace.” How Products Are Made, http://www.madehow.com/Volume-6/Shoelace.html

Staff, FreightWaves, et al. “How Many Gallons of Fuel Does a Container Ship Carry?” FreightWaves, 16 Jan. 2020, https://www.freightwaves.com/news/how-many-gallons-of-fuel-does-a-container-ship-carry.

Uren, Ashlee. “Material Guide: How Sustainable Is Nylon?” Good On You, 16 June 2021, https://goodonyou.eco/material-guide-nylon/

Kano, Fujino-Harmachis

Serina Vo and Saffron Munkres

DES 040A FQ 21

Professor Cogdell

Research Paper - Shoelaces Waste and Emission

Shoelaces are a large commodity as the majority of the world has access to shoes. With the more recent increase in sneaker culture, shoes and therefore shoelaces, are in even greater demand. The problem with this is that a greater demand means greater production, which leads to greater pollution. Like any product, energy is required to power the machines that make the material for said product. The majority of factories today rely on fossil fuels or nuclear energy, which are not sustainable. Some materials can counteract this by being reused or recycled into another product. Shoelaces have recycling potential at the individual level as people reuse them as belts or rope to tie things together. But, in terms of industrial recycling they have little to no value -- unlike plastics, paper, and glass -- and often just end up in the landfill. Shoelaces are unsustainable for the environment through their waste and pollution via waterborne pollution, airborne pollution, solid wastes, and its lack of reuse as another product.

It’s important to study the environmental and social impact of shoelaces due to the increasing consumerism of the western world. Especially with the influence of social media among younger groups that increases the popularity of shoes, and the shoelaces that come with them. After the creation of the internet the world became even more globalized. Instant access to news from all over the world, and now products from other ends of the world can be shipped right to your door with the click of a button. Social media sites like Instagram and TikTok especially curated the explosion in sneaker culture. Plus, popular artists such as Travis Scott and Kanye releasing sneaker collaborations with shoe giants such as Nike and Adidas, only adds to the consumer desire for more shoes. This only adds to the amount of waste in the world and the continuation of linear design where products have an end date; they’re cradle to grave. However, there are companies trying to combat this. Since 2015 Adidas has partnered with the organization Parley for the Oceans in order to create products made 100% from recycled ocean plastic(Adidas). Their biggest project is the Adidas FUTURECRAFT.LOOP. All components of this shoe from the laces to the insole, except for the BOOST cushioning system, are made from ocean plastic. But, the true magnificence of this project is it’s life cycle. Most shoes and shoelaces are thrown away after they’re used. However, the FUTURECRAFT.LOOP is designed so that once a consumer has worn out their shoe, they simply take it back to Adidas and Adidas will break down the material into it’s simple plastic form and build it back up again with more ocean plastic(Adidas). Creating a never ending life cycle while at the same time continuing to clean up the oceans, which are essential to life on Earth and one of the world’s biggest carbon sinks. This circular design is the future that all materials need to have. Cradle to cradle and not cradle to grave as this planet doesn’t have the capacity to deal with any more waste and pollution. Of course, unsustainable energy sources are used to break down the old shoes into the base material. Then, to weave that TPU into a whole new shoe. But, the whole concept is trending in the right direction as circular design is the future of design if there is to be a future. Most relevant to this essay is the fact that Adidas was able to make shoelaces out of recycled ocean plastic. This is a way more sustainable material compared to anything else on the market if one only looks at the recyclability of the materials used for shoelaces. The majority of shoelaces in the industry today are made from “synthetic fibers, such as nylon, textured polyester, spun polyester, and polypropylene” plus traditional natural materials such as leather(shoelaceexpress).

While some shoelaces are made from natural materials such as leather, the vast majority of shoelaces today are made from synthetic fibers such as nylon, polyester and polypropylene which each create their own waterborne, airborne and solid wastes(shoelaceexpress). Nylon is a great material as it is extremely strong, durable, and mouldable which makes it great for multiple products and industries(Uren). Nylon is derived from crude oil and put through an intense chemical process in order to achieve its stretchiness and durability(Uren). The problem with this process is that it utilizes fossil fuels. The extraction of fossil fuels through fracking and other processes is extremely harmful to the environment, as well as not to mention finite. The processing of nylon releases nitrous oxide into the air which is “a greenhouse gas 300 times more potent than carbon dioxide”(Uren). Making nylon a very unsustainable material as it is also a plastic which is not biodegradable and takes centuries to fully decompose in landfills. Nylon production also creates water pollution as a ton of water is needed to cool the threaded fibers of the material(Uren). This consumes a lot of water which is a finite resource on the Earth, as well as contaminating it before the factories often release that used water back into the environment. Harming habitats and the animals and humans that live there. Moreover, it takes a ton of energy, fossil fuel and nuclear, to complete the production of nylon, creating waste before the product even reaches its usage. However, this is only one material used for shoelaces, maybe the others are more environmentally friendly.

Polyester is another plastic like nylon except it’s derived from petroleum, which is already created from crude oil, unlike nylon which is created straight from crude oil(Uren). This means polyester is even more processed than nylon and therefore requires more energy to make, which means even greater pollution. Polyester “ranks third behind polyethylene… and polypropylene… as the most commonly used plastic”(Uren). So despite its negative impacts on the planet it is extremely popular due to its flexibility and various uses. Polyester is also a stain-resistant material as it requires a specific type of dye for the material to hold the color(Uren). “These dyes, known as disperse dyes, are insoluble in water” and just like plastics they do not decompose(Uren). The waste from these dyes used in textile factories are often just dumped into nearby water supplies, negatively affecting animals and humans(Uren). Dye workers working with disperse dyes have reported higher incidences of cancer and lung disease(Uren). Making shoelaces from polyester is already harmful, but making colored polyester shoelaces is much worse for not just the environment but for the human workers that make those shoelaces. Polyester also uses more water than nylon during its construction process as large amounts are needed to cool the material after it has been heated to extreme temperatures(Uren). Unfortunately Polyester shoelaces are also very bad for the environment, but maybe polypropylene shoelaces are the environmentally safe decision.

Polypropylene is another plastic created from crude oil. It’s not biodegradable and requires a lot of energy to produce, creating a lot of waste. However, compared to nylon, polyester, and other plastics, it’s slightly more sustainable. “Polypropylene produces less solid waste by weight than” polyethylene(blueshoeguys). Moreover, it “can be recycled into many applications, including battery cases, paint cans, home storage, flower pots, pallets, crates, composite lumber, and more”(blueshoeguys). Other plastics are recyclable as well but some can be too thin or too processed to make use of it anymore. Polypropylene is one of the easiest plastics to recycle and large corporations such as McDonald’s and Starbucks use polypropylene for their plastic cups(blueshoeguys). Moreover, polypropylene has good elasticity and toughness as well as resistance to chemicals and tearing(blueshoeguys). It’s even a good insulator, making it very popular across multiple industries(blueshoeguys). However, this popularity makes its production even greater which impedes its ability to be slightly less toxic than other forms of plastic. The aglets at the end of shoelaces are made from more plastic too, adding more pollution to the environment(shoelaceexpress). So, unfortunately all current industry standard materials for making shoelaces are unsustainable. Even natural ones like cotton and leather aren’t sustainable due to the amount of water and feed it takes to raise cotton plants and cows. Moreover the carbon dioxide cows release into the atmosphere only adds more to the greenhouse effect. Additionally, the social impacts of those materials affect many people as agricultural workers are often overworked and underpaid. Plus, rainforests, some of the world’s largest carbon sinks, are decimated everyday just to clear space for cattle.

Shoelaces are an unsustainable product due to the energy sources used to make the product, the various material’s waste, the lack of its use for other purposes, and the overall mass production of the product. This doesn’t just hold true for shoelaces. Many products we use today are simply not sustainable due to the sheer amount of material that is produced. This is a materialistic, consumer society and the key to saving this world is not simply through finding sustainable materials and methods, as almost nothing can be sustainable now as that would just mean keeping the world at the current state where it’s at and that’s not healthy either. But, it’s through changing the social mindset on materialism and consumerism. If there was less of a demand for products then there would be less waste. This is not simply about saving the environment through science, it’s about saving it through checking large corporations and industries such as gas, coal, beef, and fashion. It’s up to everyone to save this planet.

Bibliography

Adams, Ken, et al. “Development of Emissions Factors for Polypropylene Processing.” Journal of the Air and Waste Management Association, 27 December 2011. https://www.tandfonline.com/doi/pdf/10.1080/10473289.1999.10463782. Accessed 24 October 2021.

Adidas. “ADIDAS UNLOCKS A CIRCULAR FUTURE FOR SPORTS WITH FUTURECRAFT.LOOP: A PERFORMANCE RUNNING SHOW MADE TO BE MADE.” news.adidas.com, 17 April 2019. “https://news.adidas.com/running/adidas-unlocks-a-circular-future-for-sports-with-futurecraft.loop--a-performance-running-shoe-made-t/s/c2c22316-0c3e-4e7b-8c32-408ad3178865. Accessed 30 November 2021.

Assoune, Alex. “Everything You Need to Know About Acetate Fiber.” Panaprium. https://www.panaprium.com/blogs/i/acetate-fiber. Accessed 24 October 2021.

BlueShoeGuys. “Polypropylene Leads the Way in Sustainability - Plastic Disposable Shoe Covers. blueshoeguys.com, 3 August 2017. https://blueshoeguys.com/blogs/news/polypropylene-leads-the-way-in-sustainability. Accessed 30 November 2021.

CFDA. “Polyester.” cfda.com. https://cfda.com/resources/materials/detail/polyester. Accessed 24 October, 2021.

Elven, Marjorie van. “How sustainable is recycled polyester?” Fashion United, 15 November 2018. https://fashionunited.com/news/fashion/how-sustainable-is-recycled-polyester/2018111524577. Accessed 24 October 2021.

Kirchain, Randolph, et al. “Sustainable Apparel Materials.” Massachusetts Institute of Technology, 22 September 2015. https://matteroftrust.org/wp-content/uploads/2015/10/SustainableApparelMaterials.pdf. Accessed 24 October 2021.

PSAP. “Adhesives.” Preservation Self-Assessment Program. https://psap.library.illinois.edu/collection-id-guide/adhesives. Accessed 24 October 2021.

Shoelaces Express. “Shoelace Manufacturing.” shoelacesexpress.com, 2021. https://shoelacesexpress.com/pages/shoelace-manufacturing. Accessed 24 October 2021.

Sim, Jaehun, and Vittaldas Prabhu. “The Life Cycle Assessment of Energy and Carbon Emissions on Wool and Nylon Carpets in the United States.” Journal of Cleaner Production, Elsevier, 26 Sept. 2017, https://www.sciencedirect.com/science/article/abs/pii/S0959652617322059?casa_token=VVsUG4HxUh4AAAAA%3AS-vZAMONhucr_FnDwMc0KauKJh6Fkk_onXJVB70F1nBSCWoNbBOKgw6W6UvaGuPUXjBaD-u0. Accessed 24 October 2021.

Uren, Ashlee. “Material Guide: How Sustainable is Nylon?” goodonyou.eco, 31 August 2020. https://goodonyou.eco/material-guide-nylon/#:~:text=Greenhouse%20gases%3A%20producing%20nylon%20creates,of%20environmental%20contamination%20and%20pollution. Accessed 24 October 2021.

Uren, Ashlee. “Material Guide: How Sustainable is Polyester?” goodonyou.eco, 14 May 2021. https://goodonyou.eco/how-sustainable-is-polyester/. Accessed 30 November 2021.

van der Velden, Natascha, et al. “LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane.” Springer-Verlag Berlin Heidelberg, 4 September 2013. https://www.woodguide.org/files/2014/07/LCA-textiles.pdf. Accessed 24 October 2021.