Design Life-Cycle

assess.design.(don't)consume

Lingyi Feng

DES 40A

Professor Cogdell

1 December 2019

Microwave Oven

Material

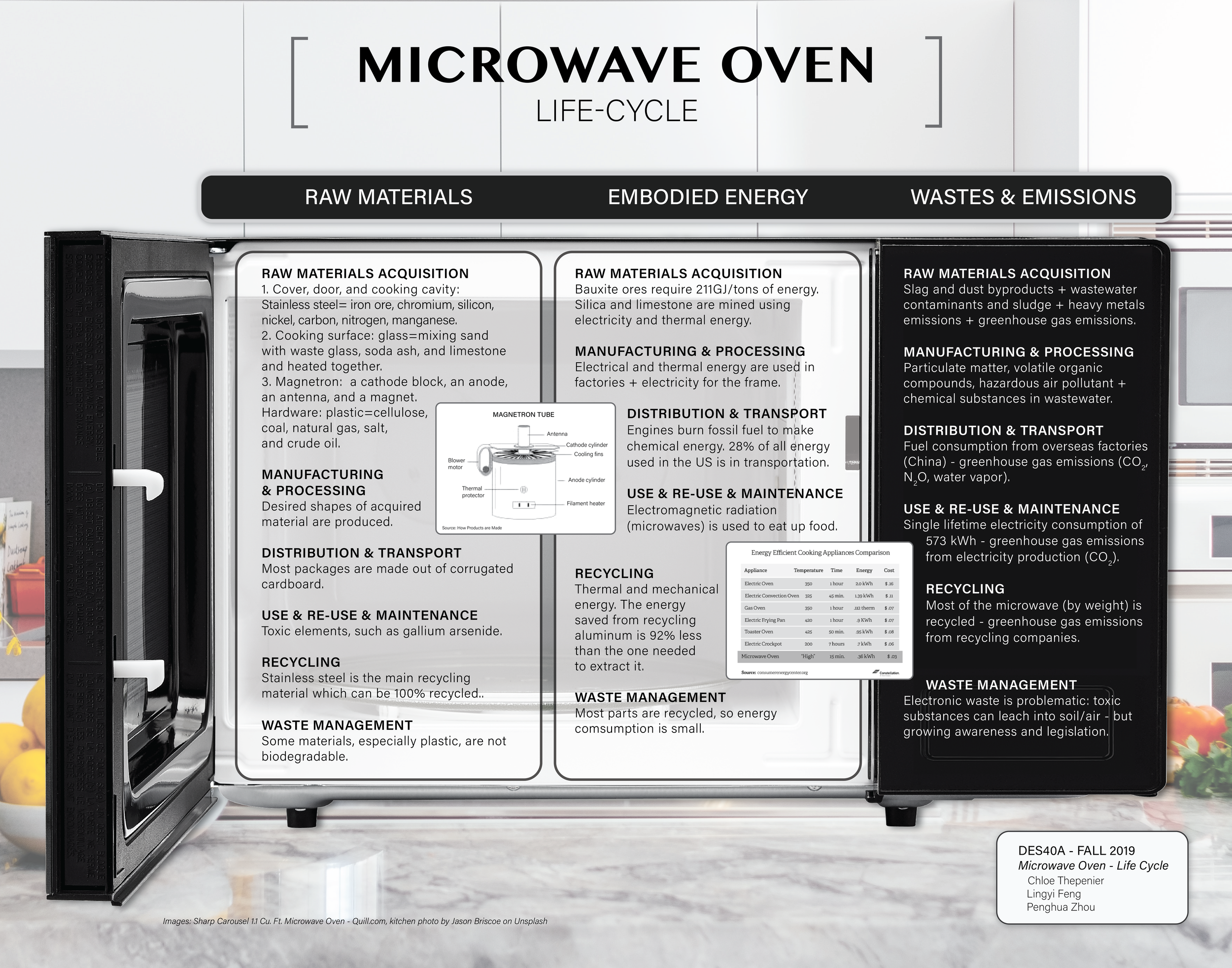

About 95 percent of American households own a microwave oven, which shows it is an essential part of our daily life (Microwave Oven). By heating food in a few minutes or seconds, the microwave oven lifted household convenience to a new level. Different parts of a microwave oven include metal cover, panels, door, cooking surface, and magnetron tube (Low). These parts are made of secondary material, such as steel, glass, and plastic. In order to acquire such secondary material, people need to extract or recombine primary material. Then these materials are manufactured to make ovens. Then microwave ovens are packed up and ready to ship. At last microwave ovens are used then recycled or waste. This is a life cycle of a microwave oven. In the essay, I will analyze the material part of a microwave oven through the whole life cycle.

In the first step, raw material acquisition, different parts of a microwave oven are made out of various materials. A cover and a door compose the outside of the microwave. The cover of a microwave oven is usually a one-piece, wrap-around stainless steel or metal enclosure. Both of them have a common material, stainless steel. Materials such as iron ore, chromium, silicon, nickel, carbon, nitrogen, and manganese that come out of the earth are made of stainless steel (Stainless Steel). Iron ore is found in sedimentary rocks. Most of the mined iron ore is used to make steel. Chromium is found mainly in chromite. This ore is found in many places like South Africa, India, Kazakhstan, and Turkey. Silicon, manganese, and nickel are all found in the earth's crust, but they have different content. Silicon is abundant elements in the earth's crust that makes up about 28% of the earth's crust (Zola). It is usually found in silicate minerals. Manganese is one component of the earth's crust. Most manganese resources are found in South Africa. For nickel, it can be found in the earth's crust, but for industrial use, it is found in ores such as pentlandite, garnierite, and limonite. Carbon can be found in many compounds like in water, iron, magnesium, and carbon dioxide. For the manufacturing process of stainless steel, the first step is melting all the primary material. Next, the mixture is cast into several shapes. At last, the steel is heat-treated and then cleaned and polished. Then steel can produce desired shapes so they can be used for manufacturing the outside coverings and doors of microwaves.

For the inside structure of a microwave, visible parts are a cooking surface and a cooking cavity (Microwave Oven). A cooking surface is generally made of glass or ceramic. The cooking cavity is made of stainless steel and is usually painted with a light color because people can easily see what inside a microwave oven. Glass and ceramic have some common useful properties. They are low production cost and easy to make into different shapes. Also, they are heat-resisting and repeatable. The most important is that they are all stable material, which means they don't react with things people put inside. Glass is made from liquid sand, which is easily acquired from the earth. But it requires an extremely high temperature to melt sand. In today's Glass making factory, in order to decrease the melting point of sand, people prefer to mix sand with waste glass, soda ash, and limestone and heated together. This process helps saves energy. The final product is glass, which is an ordinary glass. To make microwave panel, when the materials are melted, it is poured into molds to make microwave panel. The material is easy to acquire for making ceramic. They are clay and water. Once mix them, we squashed into shape, then fired at high temperature in a large industrial oven called a kiln. The end product is ceramic.

Electromechanical components and controls consist of timer motors, switches, and relays between the one-piece metal cover and the cooking cavity. Also, there are other components inside, such as the waveguide, the magnetron tube, and the stirrer fan, which are all made of metal. The hardware, including gears, pulleys, belts, nuts, screws, washers, and cables that links the different components, are made up of metal and plastic parts. Natural, organic materials such as cellulose, coal, natural gas, salt, and crude oil are the material to make plastic. Natural organic materials are raw materials which can obtain from the earth. For crude oil, it is a very complex mixture of compounds that needs to be processed before it can be used. The first step in producing plastic is a distillation of crude oil in an oil refinery. This separates the heavy crude oil into groups of lighter components, called fractions. Each fraction is a mixture of hydrocarbon chains (chemical compounds made up of carbon and hydrogen), which differ in terms of the size and structure of their molecules. One of these fractions, naphtha, is the crucial compound for the production of plastics. Then it can be made for different shapes of the plastic part required in the microwave oven (How Plastics Are Made).

The magnetron is the core part of the microwave to heat the food because the microwave oven uses a magnetron to generate microwave energy. In fact, it can be manufactured relatively easily and inexpensively because it requires few parts, a cathode blocks, an anode, an antenna, and a magnet (Sosa). Traditionally, the cathode blocks are made of pitch and charcoal or oil coke, anthracite. Recently, many cathode blocks are made by anthracite and graphite powder. Anthracite is the least plentiful form of coal. It is found mostly in the eastern part of the United States and makes up less than 2 percent of all coal reserves in the country. Graphite is a native element mineral found in metamorphic and igneous rocks. It is a plentiful resource in the world and can be used in many fields. (Tests of Various Graphitic Cathode Block Materials for 300 Ka Aluminum Reduction Cells). Anodes are large carbon blocks that are used to conduct electricity during the aluminum reduction process. Antennas are usually conductive metal that can send and receive electromagnetic radio waves. Antennas most made of copper because it is a more suitable material for antennas because it is soft and malleable and high ability to conduct electricity. It is found in the earth's crust and is plentiful and cheap metal. Magnets are made of a group of metals, ferrimagnetic, that can be strongly attracted to a magnet. These include the elements of iron, nickel, and cobalt, and their alloys. The different elements of metal are found in the earth's crust. For alloys, they are made up of two or more chemical elements, of which at least one is a metal. Most alloys are made by melting the metals, mixing them while they are liquid to form a solution, then leaving them to cool and turn solid again. These five parts compose a magnetron.

After raw material acquisition and manufacturing process, the next step in the life cycle is transportation. Microwave ovens are packed up and shipped to retailers or shopping centers. Most packages are made out of corrugated cardboard. It is a stiff, strong, and light-weight material made up of three layers of brown kraft paper. Most items were safely delivered in boxes made of corrugated cardboard. Pine trees provide the primary raw material used to make corrugated cardboard. At the mill, the harvested tree trunks are subjected to the kraft process, also known as the sulfate process, because of the chemicals used to break down wood chips into fibrous pulp. After pulping and other processing, the fibers are sent directly to the paper machine where they are formed, pressed, dried, and rolled into the wide, heavy rolls of kraft paper sent to corrugating plants to be made into cardboard (corrugated cardboard).

For use or reuse management of a microwave oven, there is little information in terms of material. When a microwave oven is broken or odd, people prefer to buy a new one. There are some methods to deal with the odd and broken microwave oven. They can be recycled or donated at the appropriate facilities. Donation facilities can help someone less fortunate gain access to a working appliance they may not be able to afford at full retail price and can buy a new one (Microwave Disposal: Safe, Non-Hazardous Options to Protect the Earth). Also, people can find a recycling center nearby. When people send microwaves to a recycling center, it is better to learn about the requirement of recycling a microwave. This is because some recycling centers required the removal of hazardous components before acceptance at recycling centers.

Most parts of a microwave oven are made from metals, such as one-piece metal cover, magnetron, and metal cavity. Metal recycling is the most common recycling currently. It is environmentally sustainable. For recycling microwaves, it is not popular recycling, and people may not be familiar with it.

Some materials can be reused or recycled from the old or broken microwave. Microwave ovens typically are made from stainless steel. The steel recycled from your microwave contributes to the 27 percent of durable goods recovered from the waste stream. The stainless steel can be 100% recycled because it made from some elements such as iron ore, chromium, silicon, and nickel. The recycling process of stainless steel is to melt down them (Is Stainless Steel Recyclable). As a result, the valuable elements are able to be extracted and reused with no degradation in performance from product to product. It forms a cycle in which the elements that extract from collect stainless steel can make new stainless steel. It is environmentally friendly and energy efficiency. Besides stainless steel, the internal parts may also contain other recyclable metals and plastic parts, for example, gears, motors, and hardware. Recycling finds another use for all of these components.

Although some material of a microwave oven can be recycled, waste management of a microwave is still a problem in present. Major large appliances, like refrigerators, typically have a high recovery rate. Retailers attract consumers by offering a discount when they buy a new one. It makes recycle easier because the retailers collect all appliances and recycle them together. However, microwave ovens are relatively small appliances, and retailers may not provide this service. The U.S. Environmental Protection Agency reports that nearly 1.6 million tons of solid waste from small appliances was generated in 2010 alone; of that amount, only 6.9 percent was recovered for recycling (United States Environmental Protection Agency). If a broken or odd microwave oven can not be recycled, it will toss out to landfill waste. Some materials, especially plastic, are not biodegradable. They can not degrade, which might stay for decades in landfills. Also, some elements are toxic, such as gallium arsenide, which is a material used in semiconductors. It harms body health since acute and chronic toxicity to the lung, reproductive organs, and kidney are associated with exposure to gallium arsenide. Thus waste management is a important issue.

Overall, the life cycle of ovens is complex. In order to make different parts of a microwave oven, people need to acquire various materials, including primary material and secondary material and manufacture them. Some can be easily obtained from the earth, especially different kinds of metals that can found in the earth's crust or rocks. Some are secondary materials such as stainless steel, glass, ceramic, and alloy, which need a more complicated process to obtain. Then in the transportation process, microwave ovens were safely delivered in boxes made of corrugated cardboard. For recycling of a microwave oven, some materials, especially stainless steel, can be totally recycled and reused in the future of producing stainless steel. Also, there are some toxic elements which are harmful to human and environment. The waste management of a microwave oven is still an issue that needs to be considered in the future.

Bibliography

“Microwave Oven.” CDs, Super Glue, and Salsa: How Everyday Products Are Made: Series 3, Encyclopedia.com, 26 Nov. 2019, https://www.encyclopedia.com/science-and-technology/technology/technology-terms-and-concepts/microwave-oven.

“Microwave Oven.” How Products Are Made, http://www.madehow.com/Volume-1/Microwave-Oven.html.

“Stainless Steel.” How Products Are Made, http://www.madehow.com/Volume-1/Stainless-Steel.html.

Woodford, Chris. “Microwave Ovens: How Do They Work?” Explain That Stuff, 17 July 2019, https://www.explainthatstuff.com/microwaveovens.html.

Low, Jeremy. Components of a Microwave Oven. 8 Oct. 2006, https://ezinearticles.com/?Components-of-a-Microwave-Oven&id=321618.

Center, Copyright 2014 Edison Tech. Microwave Ovens, https://edisontechcenter.org/Microwaves.html.

“Tests of Various Graphitic Cathode Block Materials for 300 Ka Aluminum Reduction Cells.” 2007.

Sosa, Estanislao Navarro. “Common Tubes and Their Applications.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., 15 July 2013, https://www.britannica.com/technology/electron-tube/Common-tubes-and-their-applications#ref132622.

“National Overview: Facts and Figures on Materials, Wastes and Recycling.” EPA, Environmental Protection Agency, 8 Nov. 2019, https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials.

“Is Stainless Steel Recyclable?” Calbrite, 19 Feb. 2018, http://www.calbrite.com/articles/shop-talk/stainless-steel-recyclable/.

Blog, Jiffy Junk. “Microwave Disposal: Safe, Non-Hazardous Options to Protect the Earth.” Jiffy Junk, Jiffy Junk, 20 June 2017, https://www.jiffyjunk.com/microwave-disposal-hazardous/.

“How Plastics Are Made.” PlasticsEurope, https://www.plasticseurope.org/en/about-plastics/what-are-plastics/how-plastics-are-made

Zola, et al. “Zola.” Chemicool, https://www.chemicool.com/elements/silicon.html.

“Corrugated Cardboard.” How Products Are Made, http://www.madehow.com/Volume-1/Corrugated-Cardboard.html

Penghua Zhou

Christina Cogdell

Design 40A

December 3, 2019

Embodied Energy In The Life Cycle Of Microwaves

In the US, microwaves have been commonplace in every household for several decades. Through using radiation, microwaves provide people a convenient and efficient way to cook food. Normally, the microwave transforms electrical energy into thermal energy, and maintains a stable condition for supporting households in cooking. The way the microwaves deal with energy when they are working is unique. However, this is not the only connection between microwaves and energy. Checking the whole cycle of microwaves, first, energy shows itself from the microwave’s raw material acquisition to the waste management of microwaves. In the 7-10 life span of a microwave, energy appears in every important step of microwave’s life, including its manufacturing, transporting and maintenance (Mazur, 2010). Through the contribution of microwaves towards a household, the cost of energy from microwaves is worth a lot in different aspects.

The process of getting the raw materials for microwaves costs a large amount of energy. It comes in two steps—mining and extracting. The main raw materials for a microwave includes metals such as steel, aluminum, brass, and copper; plastics, such as acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PBT), polyvinyl chloride (PVC), and polypropylene (PP); and tempered glass. The energy consumption in the mining process is covered not only by the blasting of the materials, but also excavation, crushing, transportation and grinding. As the most popular ore, the aluminum-containing bauxite ores costs 211GJ/tons of energy to get the aluminum (Jeswiet, 2016) . Aluminum is one of the most widely used metals in microwaves but it has enough bauxite to make the mining process easier. Other than aluminum, the other metals used to build microwaves have higher energy consumption. Other than metals, the energy consumption of plastic and glasses emphasize that part of the process uses chemical energy. Plastic and glass are not primary materials, but it is also notable that these materials are man-made. People combine elements to create plastic and glass, which contributes an important process of transferring thermal energy into chemical energy. For example, glass is made by melting silica, sodium carbonate, limestone and other chemical elements at 1600 degrees celsius. However, this doesn’t mean that mining and extracting are not important for glass. Silica and limestone are mined and extracted from the earth by using electricity and thermal energy. Therefore, no matter what type of main raw materials are used in microwaves, mining and extracting are always the start to utilizing energy in order to produce these materials.

After getting the raw materials of microwaves, the manufacturing, processing and formulation stages of the microwave are the other parts that show the hazardous effect of energy. The processes that are designed by different manufacturers mostly contain assembly producing lines in the factory, machine tools to build the microwaves and robots to pack the microwaves. In order to support these aspects, electrical energy and thermal energy are utilized to control them. Manufacturing microwaves starts with the cavity and the door, showing the important role of electrical energy and thermal energy. Thermal energy helps heating up the metals and shapes them into the frame of a microwave. Auto-metal forming presses are used to frame the structure of these parts. Then, they are covered with zinc phosphate, preparing it for electro-deposition.The electro-deposition works as immersing the parts in a paint tank at 200 volts for 2.5 minutes (Muzar,2010). These steps are the main stages that happen to make the frame of a microwave, and this requires electricity to function the machines. After getting the frame of a microwave, the stirrer fan and the heating system, which are designed by radiation technology, are placed inside the microwave. At this time, the main core of a microwave has already been constructed. After putting several detailed parts of microwave through machines and testing the quality of this microwave, it is then time to pack it through the palletizer robot. Through the whole process of manufacturing a microwave, except designing the manufacturing system, the prime mover of making a microwave is not animated. Both thermal energy and electrical energy that are used in manufacturing a microwave would cost emission, such as CO2. However, as a totally unused microwave, the potential of it is high during this stage of the life cycle.

Then, the new packed microwave would go on the way of its transportation. Microwave companies sell their microwaves to different countries, even overseas. Transportation tools such as aircrafts, ships and automobiles are used to deliver the microwaves. These transportation tools consume fossil fuels and release nitrogen gas, carbon dioxide and water vapor. As the main cores that drives these transportations, the combustion engines burn fossil fuels inside and turns them into chemical energy. The chemical energy is transferred into mechanical energy when the transportation tools are on their way to the destination. Usually, customers get their microwaves as soon as possible since the manufacturers are trying to provide them the fastest delivery. It seems that convenience is provided towards consumers but the energy consumption of transportation is actually huge in the US. Approximately 28% of all energy used in the United States is currently in the transportation sector(National Academies Press). Therefore, the energy consumption of transportation in the life cycle of microwaves cannot be ignored. Even though more and more electrical vehicles are used to deliver stuff recently, traditional fossil fuels are still the main resource that provides energy to the transportation tools due to its high energy density.

From the previous stages of microwaves’ lifecycle, it seems that microwaves are costing a lot of energy. However, is it worth to sacrifice this much energy just for the microwave? This answer could be showed by the maintenance of microwaves and how it works in people’s household. Unlike traditional cooking tools which strictly use electrical energy or thermal energy to cook food, the microwave transfers these energy through its special way—radiation. In the range of 3000 to 300 000 MHz, microwave radiation is defined roughly as electromagnetic radiation (Davis,2011). After getting the electrical energy from the wires, microwave spreads wavelengths from 10 to 0.1 cm which affects food in microwave energy. Microwave energy is used to heat food through single or grouped of needle-like applicators so that the optimal soft tissue is heated in less time with larger ablation zones (Manzo,1962). The energy efficiency of microwaves has been enlarged by this way. Even though microwaves have diverse sizes, the microwave energy efficiency doesn’t vary much. Normally, the smaller size microwave is more energy efficient compared to the larger microwave. Since the microwave transfers energy in its special way, among cooking tools that people usually have, microwave is the most efficient tool in heating up food. For example, heating up a frozen pizza takes around 20 minutes in an oven which utilizes the traditional way of transforming electrical energy into thermal energy. However, through using microwave, the frozen pizza could be ready in five minutes(Energy Efficient Oven). More importantly, the use of the microwave doesn’t utilize greenhouse gas and only utilizes a small amount of electrical energy. Knowing that the average national electricity rate is 12 cents per kilowatt hour and assuming a household uses a microwave which is rated for 1000 watts around 5 minutes per day, they only need to spend less than 4 dollars annually for the electrical power that caused by the microwave (Which is more efficiency?). Surprisingly, electrical power that is utilized by a microwave is even less than a digital clock. Maintaining a microwave at home won’t cause a big budget but provides an efficient way for people to cook their meals. At the same time, the life-span of the microwave could last around 7-10 years, higher than a lot of daily used electrical devices in people’s homes such as television (Crank, 2019). Having a long lifespan and taking a little energy, the energy efficiency of microwave is high compared to some other home used electrical devices.

When a microwave finishes its responsibility—heating up food for the whole family, it comes to the end stage of its life cycle—recycling and waste management. People might be curious about this part of microwaves because in the traditional mindset, electrical devices usually won’t be reused. Like most of the electrical devices, the microwave itself won’t be reused by people through easily repainting its frame, but the microwave itself follows what Ardente and Mathieux (2014) stated about other electronic devices: “reusability, recyclability, recoverability, recycled and use of hazardous substance”. Therefore, some raw materials of microwave, such as the aluminum and copper, could be highly reused or recycled in diverse ways though using energy. A retired microwave would be separated into different parts based on the category of raw materials. Then, kinetic energy is used to compress the same type of metal together. After the compression, thermal energy would be used to melt them and reform them into a part of the new product, which might not be a microwave. Through this process, chemical energy could work if people decide to change the characteristic of the metal. The recycling process also requires mechanical energy that is transferred from electrical machines through diverse machines and labors because of its complexity. People might question whether the cost of recycling these materials is worth or not. However, recycling process helps save a huge amount of energy. For example, the energy saving from recycling aluminum could be 92 percent less than energy that is used to extract aluminum from ore(Stanford University, 2015). Therefore, as the main raw material from microwave, aluminum is highly recycled after the microwave is retired. Other than metals, in a microwave, glass is also highly recycled through using thermal energy since it is 100% recyclable. During the recycling process, people add sand into the glass and use high-temperature processing equipment to heat them. Thermal energy changes the physical appearance of the glass so people can reshape them into new products. Surprisingly, one ton of recycled glass saves around 42 Kwh of energy, 0.12 barrels of oil (5 gallons), and 2 cubic yards of landfill space.So in the US, the glass recycling rate is around 33% (Stanford University, 2015). Similar to glass, the recycling process of plastic also reflects the significance of thermal energy, but compared to glass, recycled plastic saves much more energy —one ton of recycled plastic saves around 5,774 Kwh of energy (Jacoby, 2019). Other than saving energy, recycling the main raw materials in a microwave helps protect the environment through lowering the green-house gas emissions. As a result, the microwave is definitely worth to be recycled. Since more than 90% part of a microwave could be recycled, the waste management of it wouldn’t cost a lot of energy. Mechanical and electrical energy would be used to burry these non-recycled parts into the ground. If you are searching about recycling a microwave, then you will notice a lot of city governments in the US provides specific websites of providing citizens an opportunity to donate their retired microwaves and helping them to recycle the microwave or deal with the waste management. Through this aspect, the waste management in microwave could be seen as developed around the US.

In general, the lifecycle of microwave is strongly connected with energy, and as a common electrical device in most of the households, it is worthwhile to analyze how energy works with microwave. Unsurprisingly, the manufacturing stage of microwaves does cost abundant energy. Through being upgraded in terms of design towards being environmentally friendly and having a larger energy capacity, companies are aiming to improve it. Temporarily, the microwave still surprises us about energy saving during its maintenance and recycling stages. In this analysis, we do notice that the microwave could be considered as an energy efficient device at home and it still has room for improvement. The disposal and recycling ways of microwaves is worthwhile to be learnt by companies of other home-used electrical devices companies. As a home-used electrical device, microwaves contribute themselves to most of the households through an environmentally friendly way in their whole lifecycle.

Bibliography

Ardente, Fulvio, and Fabrice Mathieux. "Identification and assessment of product's measures to improve resource efficiency: the case-study of an Energy using Product." Journal of cleaner production 83 (2014): 126-141.

Crank, Josh CrankJosh, and Josh Crank. “How Much Energy Does a Microwave Use?” The Light Lab, 7 Mar. 2019, www.firstchoicepower.com/the-light-lab/energy-education/how-much-energy-does-a-microwave-use/.

Davis, Devra, and Benjamin L. Viglianti. “MICROWAVE HEAT.” Scientific American, vol. 304, no. 2, 2011, pp. 8–10. JSTOR, www.jstor.org/stable/26002370.

“Energy Efficient Ovens.” Sanctuary: Modern Green Homes, no. 17, 2011, pp. 76–78. JSTOR, www.jstor.org/stable/sanctuary.17.76.

“Frequently Asked Questions: Benefits of Recycling.” Frequently Asked Questions: Benefits of Recycling | Land, Buildings & Real Estate, Stanford University, 2015, lbre.stanford.edu/pssistanford-recycling/frequently-asked-questions/frequently-asked-questions-benefits-recycling.

Hidden Costs of Energy Unpriced Consequences of Energy Production and Use. National Academies Press, 2010.

Jacoby, Mitch. “Why Glass Recycling in the US Is Broken.” Chemical & Engineering News, American Chemical Society, 13 Feb. 2019, cen.acs.org/materials/inorganic-chemistry/glass-recycling-US-broken/97/i6.

Jeswiet, Jack, and Alex Szekeres. “Energy Consumption in Mining Comminution.” Procedia CIRP, vol. 48, 2016, pp. 140–145., doi:10.1016/j.procir.2016.03.250.

Manzo. “AN INTRODUCTION TO MICROWAVE.” Teaching Aids News, vol. 2, no. 3, 1962, pp. 1–4. JSTOR, www.jstor.org/stable/44746705.

Mazur, Lech. “Microwave Oven.” How Products Are Made, 2010, www.madehow.com/Volume-1/Microwave-Oven.html.

“Which Is More Energy Efficient? Microwave vs Toaster Oven vs Oven.” Constellation Residential and Small Business Blog, 25 Sept. 2017, blog.constellation.com/2016/05/20/toaster-oven-vs-microwave-energy-efficiency/.

Chloe Thepenier

Penghua Zhou

Lingyi Feng

DES 40A/SAS 43

Professor Cogdell

Daniel Tran

Microwave Oven

Waste and Emissions

The microwave oven is a widely used product belonging in the billion-dollar home appliance industry. Microwaves constitute an integral part of our everyday lives; their main attractive aspects are convenience and ease of use, with a simple design based on the generation of electromagnetic waves activating water molecules present in food. Microwave ovens have a relatively short lifespan of about nine years - one of the shortest in the common appliance industry (Green). This number should raise questions regarding the holistic impact of the product. In particular, waste and emissions from microwave ovens need to be assessed throughout their lifecycle. This includes the acquisition of materials such as metal, plastic, and glass; the manufacturing of electronic components and metal cavity; the average daily electricity consumption; the recycling of parts and management of electronic waste; and the transport between the various stages.

The first step of this process is the analysis of the waste and emissions from the acquisition and processing of the raw materials. The main parts of a microwave are the oven’s cavity and frame, turntable, glass tray, magnetron tube (along with transformer and capacitor), waveguide, stirrer fan, electromechanical components (motors, relays, switches), and control panel. In terms of materials, this includes metals such as galvanised steel, aluminum, brass, and copper; plastics such as acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PBT), polyvinyl chloride (PVC), and polypropylene (PP); tempered glass; and electrical ceramics (Gallego-Schmid). Steel, used mainly for the casing, is an alloy of iron and carbon. The gases resulting from steel production can be reused onsite for internal steam and electricity production, or sold. The primary byproducts are slag and dust, most of which can be reused in steelmaking. While this kind of processing is still responsible for the release of carbon monoxide and carbon dioxide due to iron sintering and energy consumption - as well as wastewater contaminants and some sludge - steel is the most recycled material in the world (“Galvanizing Process.”), with about 30% of its production being scrap-based (“Steel industry”). Copper, used in power cords and electronic parts, is responsible for emissions to air and water of heavy metals such as beryllium and arsenic. Copper mining and processing also produce sulfur dioxide, which may result in acid rain. As with other mine sites, waste rock is also generated. The plastic components are mainly involved in greenhouse gas emissions. Plastic refining is highly gas-intensive and fast growing. Microwave ovens mostly rely on thermoplastics, which can be reheated and cooled for reprocessing and recycling. Direct emissions, including methane, come from the extraction of fossil fuels to make plastic. The ceramics industry is also responsible for greenhouse gas emissions, through the decarbonisation of the clays and the burning of fossil fuels for power (“The Ceramics Industry”). Glass production similarly releases carbon dioxide. Microwave ovens are majoritively made of metals, which are the main contributors of waste and emissions. The mining of copper and iron are the most impactful processes, due to their byproducts and toxic emissions. After being processed, these materials are transported to manufacturing factories.

The manufacturing process also needs to be assessed in terms of waste and emissions. The first step is metal extrusion, to create the desired shapes. The wastes involved are hydraulic fluids, lubricants, and other oils, as well as nonhazardous waste that can be recycled or used for energy production. Particulate matter such as metal oxides, and organic compounds are also released during the process. Steel painting and curing are additional steps to consider. Electro-deposition is used to coat the metal after being treated with zinc phosphate, which is then cured at 300 degrees Fahrenheit (“Microwave Oven.” [How Products are Made]). This process results in volatile organic compound (VOC) and hazardous air pollutant (HAP) emissions, as well as smoke and odor. Treatments are usually in place to meet air discharge standards. Plastic moulding is conducted through injection. The chemical reactions involved also release VOC and HAP, as well as particulate matter. The heated environments can also cause thermal degradation of additives and lead to additional emissions (Eastern Research). The manufacturing of electronic components and circuit board is more complex and chemical substances end up in wastewater, including copper, organic matter, and ammonia (“The Pollution”). The production of the circuit board also consumes a lot of electricity, which involves fossil fuels and greenhouse gas emissions. Additionally, the production of capacitors releases butanone, which might contribute to the creation of photochemical oxidants (Gallego-Schmid). Finally, the manufacturers usually test the assembled product for 50-100 hours continuously (“Microwave Oven.” [How Products are Made]), participating again in greenhouse gas production. The last step of manufacture is quality control, with extensive measurements to meet federal regulations. There is no clear data on the emissions released from that stage. Overall, the main contributor of waste and emissions during the manufacturing process is the production of the electronic components. The method in place is more elaborate and involves various substances. Following manufacture, microwave ovens are ready for packaging and distribution.

Packaging and transport play a smaller role in the overall assessment, but still need to be considered. Microwaves are usually packaged in a cardboard box, with polystyrene foam trays for protection. The environmental impact of cardboard is relatively low since it is mostly made from recycled material and is then itself recycled again at a rate of about 84% (Gallego-Schmid). No specific data was found for foam trays. Distribution needs to be considered between each step of the life cycle, from raw materials to manufacturing facility, retailer, consumer, and end-of-life options. Most iron ores are found in Australia, Brazil, and China (“Steel production”). Assembly and manufacturing plants are generally in China. In the case of microwave ovens, we will assume 150 km of transport between processing and manufacturing facilities. Popular microwave brands such as Whirlpool, LG Electronics, General Electric, Frigidaire, Panasonic, or KitchenAid manufacture in China. To reach retailers in the U.S., another 11,600 km are necessary. Road transport to the distribution centers and later on to recycling facilities and landfills also need to be accounted for. Consumer transport to their home does not need to be included, as the distance is usually short and most likely includes other products alongside the microwave. The energy required for this distribution comes from fuel consumption, which releases greenhouse gases. Most of our transportation options rely exclusively on petroleum products; burning fossil fuels is responsible for emissions of carbon dioxide, sulfur dioxide, methane, and nitrous oxide. Once the product reaches the consumer, it enters another stage of the life cycle.

The use stage of the lifecycle of microwave ovens is probably the most obvious and most studied, in terms of consumption and emissions. Although this product spends more than 90% of its use in stand-by mode, its electricity consumption is the most impactful step in the whole life cycle (University of Manchester). A typical microwave oven consumes over 537 kWh of electricity over its lifetime, assuming 0.056 kWh per cycle and 1200 cycles per year (Gallego-Schmid). Adding to that a stand-by consumption of around 35 kWh based on the oven being plugged in at all times, we end up with a total lifetime consumption of about 573 kWh per product. According to a 2018 study, this number is equivalent to “a 7 watt LED light bulb, left on continuously for almost nine years” (University of Manchester). While we are interested here in emissions rather than consumption, the two are clearly linked: electricity is a secondary energy source and around 63% of it comes from burning fossil fuels (“Sources of Greenhouse”), which is responsible for large amounts of greenhouse gas emissions mainly composed of carbon dioxide and smaller quantities of methane and nitrous oxide. The U.S. Environmental Protection Agency (EPA) also states that the electricity sector was “the second largest source of U.S. greenhouse gas emissions” in 2017 (“Sources of Greenhouse”). In 2018 alone, the production of electricity by the U.S. resulted in 1,763 million metric tons (MMmt) of carbon dioxide emissions (“How much of U.S.”). Focusing back on microwave ovens, the use stage consumption over an individual lifetime has been evaluated at 8.9 GJ of primary energy, contributing to an equivalent of 416 kg of carbon dioxide (Gallego-Schmid). While this phase of the lifecycle currently has the most impact on the environment, it is worth noting that the current shift in energy sources towards more sustainable options, as well as increasing efficiencies have created a downward trend in terms of greenhouse gas emissions from electricity. Improvements can also be seen regarding recycling and end-of-life alternatives.

With a short lifespan of about nine years, the recycling and end-of-life waste management options for microwave ovens are especially important. A study in the United Kingdom has shown that consumers know little about the ways to dispose of microwaves, and that most of them intend to buy a similar product after discarding an older oven (Dindarian). This observation is driven in part by the repair options being most of the time at a similar or higher price tag than brand new products. Recycling and reusability are therefore crucial in avoiding large amounts of waste and emissions. Metals, which make up most of the microwaves by weight, are 95% recycled; plastic materials are “38% landfilled, 36% incinerated with energy recovery and 26% recycled” (Gallego-Schmid). The glass part and inert ceramic components are assumed to be landfilled. Overall, the rate of material recovery by weight is relatively high. This number is motivated by directives in several countries, such as the Waste Electrical and Electronic Equipment Directive in Europe stating that at least 75% of the weight of each microwave should be recycled. Some recycling companies such as CEAR in Mather, CA use an environmentally sustainable technology based on centrifugal force to separate and sort raw materials, which they claim “consumes less energy than a knife shredder of the same capacity” (CEAR). However, electronic waste (e-waste) remains an area of concern. E-waste has been “one of the fastest growing waste streams” (Tsunazawa) and requires extensive methods and processes for treatment and recovery. Potential toxic substances present in e-waste include beryllium, lead, cadmium, and mercury, which can leach into both soil and air. Fortunately, awareness and legislation are growing in many states, increasing e-waste recycling rates.

The overall assessment of the life cycle of microwave ovens shows several areas responsible for waste and emissions. The main contributors are metal acquisition and processing, manufacturing of electronic components, electricity consumption during the use stage, and e-waste management. The rise of the use phase as the most environmentally significant sector proposes areas of improvement in consumer behavior and more efficient usage. An increase in lifespan and reuse opportunities would also be helpful in lowering emissions. With over 90% of Americans having a microwave oven at home (Green), the environmental impacts of this common product over its entire life cycle should be given more consideration.

Bibliography

“Appliances Company.” Panasonic Corporate Profile, panasonic.net/ap/corporate_profile/en-index.html. Accessed 23 October 2019.

Bravieri, Rich. “Handling metal stamping wastes: Protecting the environment - - and your business.” The Fabricator, FMA Communications Inc., www.thefabricator.com/stampingjournal/article/materialshandling/handling-metal-stamping-wastes--protecting-the-environment-----and-your-business. Accessed 23 October 2019.

CEAR, CEAR Inc., 2018, www.cearinc.com. Accessed 20 October 2019.

“Denver Microwave Repair.” Lee’s Appliance & Refrigeration Service, Lee's Appliance Repair, www.leesappliancerepair.com/denver-microwave-repair. Accessed 23 October 2019.

Dindarian, A. et al. "Electronic Product Returns and Potential Reuse Opportunities: A Microwave Case Study in the United Kingdom." Journal of Cleaner Production 32.C (2012): 22-31. Web.

Eastern Research Group, Inc. “Preferred and Alternative Methods for Estimating Air Emissions from Secondary Metal Processing.” EIIP, Volume II: Chapter 9, January 2001.

Gallego-Schmid, Alejandro et al. “Environmental assessment of microwaves and the effect of European energy efficiency and waste management legislation.” Science of The Total Environment, Volume 618, 2018, Pages 487-499.

“Galvanizing Process.” American Galvanizers Association, galvanizeit.org/inspection-course/galvanizing-process. Accessed 10 November 2019.

Goldwasser, Samuel M. “Notes on the Troubleshooting and Repair of Microwave Ovens.” RepairFAQ, www.repairfaq.org/sam/micfaq.htm#micmagcono. Accessed 23 October 2019.

Green, Stephanie. “What Is the Average Lifetime of Microwave Ovens?” Hunker, Leaf Group LTD., www.hunker.com/12003628/what-is-the-average-lifetime-of-microwave-ovens. Accessed 21 October 2019.

“Household Appliances.” Statista, www.statista.com/statistics/461288/major-domestic-appliances-sales-worldwide. Accessed 30 October 2019.

“How Do I Recycle A Microwave?” Recyclebank, Recycle Rewards, Inc., 3 May 2016, livegreen.recyclebank.com/column/because-you-asked/how-do-i-recycle-a-microwave. Accessed 22 October 2019.

“How much of U.S. carbon dioxide emissions are associated with electricity generation?” eia, 25 October 2019, www.eia.gov/tools/faqs/faq.php?id=77&t=11. Accessed 10 November 2019.

James. “Timeline Overview of Product (From Raw Materials to Disposal).” How to succeed in life, asmoodle.asmadrid.org/blog/s18003/2016/11/14/timeline-overview-of-product-from-raw-materials-to-disposal. Accessed 23 October 2019.

Kim, Mincheol et al. "Application of Delphi-AHP Methods to Select the Priorities of WEEE for Recycling in a Waste Management Decision-making Tool." Journal of Environmental Management 128 (2013): 941-48. Web.

Low, Jeremy. “Components of a Microwave Oven.” Ezine Articles, ezinearticles.com/?Components-of-a-Microwave-Oven&id=321618. Accessed 23 October 2019.

Maurer, James I., and Robert M. Lacy. “Conversion and Electrodeposited Coatings:

A Total Concept.” The Parker Co., Oxy Metal Finishing Corp., Occidental Petroleum Corp.

Mendoza, F. et al. “Sustainability assessment of home-made solar cookers for use in developed countries”. Science of The Total Environment, 2018, 648, 184-196. 10.1016.

Merlo, Lisa. “Electrocoating.” Products Finishing, Gardner Business Media, Inc., 21 Feb. 2011, www.pfonline.com/articles/electrocoating. Accessed 23 October 2019.

“Microwave Oven.” Encyclopaedia Britannica, www.britannica.com/science/microwave-radiation. Accessed 23 October 2019.

"Microwave Oven." Encyclopedia.com, www.encyclopedia.com/science-and-technology/technology/technology-terms-and-concepts/microwave-oven. Accessed 23 October 2019.

“Microwave Oven.” How Products are Made, Advameg Inc., www.madehow.com/Volume-1/Microwave-Oven.html. Accessed 21 October 2019.

“Microwave Oven Stamping Die.” Progressive Stamping Die, Qingdao Hiparter Trade Co., Ltd., 18 March 2015, progressive-stamping-die.com/microwave-oven-stamping-die/itemlist/tag/Microwave%20Oven. Accessed 23 October 2019.

“Microwave Ovens.” Quamp, qamp.net/library/microwave-ovens. Accessed 23 October 2019.

“Processing.” Perforated Metal, www.perforated-metal.net/perforatedmetal/processing.html. Accessed 23 October 2019.

“Responsible E-Waste Management.” Waste Management, Think Green, www.wm.com/sustainability-services/documents/insights/Responsible%20E-Waste%20Management%20Insight.pdf. Accessed 2 November 2019.

“Sources of Greenhouse Gas Emissions.” EPA, 2019, www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions. Accessed 10 November 2019.

“Steel industry co-products.” WorldSteel Association, www.worldsteel.org/en/dam/jcr:1b916a6d-06fd-4e84-b35d-c1d911d18df4/Fact_By-products_2018.pdf. Accessed 10 November 2019.

“Steel production & environmental impact.” greenspec, www.greenspec.co.uk/building-design/steel-products-and-environmental-impact. Accessed 2 November 2019.

“The Ceramics Industry and Climate Change mitigation.” CPRAC, www.cprac.org.

“The Pollution of PCB Boards.” Gold Phoenix PCB Co., 20 July 2012, www.goldphoenixpcb.com/html/Support_Resource/others/arc_142.html. Accessed 11 November 2019.

Tsunazawa, Yuki et al. "Investigation and Evaluation of the Detachment of Printed Circuit Boards from Waste Appliances for Effective Recycling." Waste Management 78 (2018): 474-82. Web.

Turner, David A.et al. “Greenhouse gas emission factors for recycling of source-segregated waste materials.” Resources, Conservation and Recycling, Volume 105, Part A, 2015, Pages 186-197, ISSN 0921-3449.

University of Manchester. "Microwave appliance usage could be as bad for the environment as cars, suggests new research." ScienceDaily, 17 January 2018, www.sciencedaily.com/releases/2018/01/180117225424.htm. Accessed 2 November 2019.

Van Zante, Helen J. The Microwave Oven. Boston: Houghton Mifflin, 1973. Print.

Woodford, Chris. “Microwave ovens.” Explain That Stuff, 2006/2019, www.explainthatstuff.com/microwaveovens.html. Accessed 23 October 2019.

Xue, Mianqiang et al. “Waste Management of Printed Wiring Boards: A Life Cycle Assessment of the Metals Recycling Chain from Liberation through Refining.” Environmental Science & Technology 2015 49 (2), 940-947.