Design Life-Cycle

assess.design.(don't)consume

Jasmine Phan

DES 40A Winter 2023

Professor Cogdell

16, March 2023

Life-Cyle of Raw Materials for Orange Pill Bottle

Introduction:

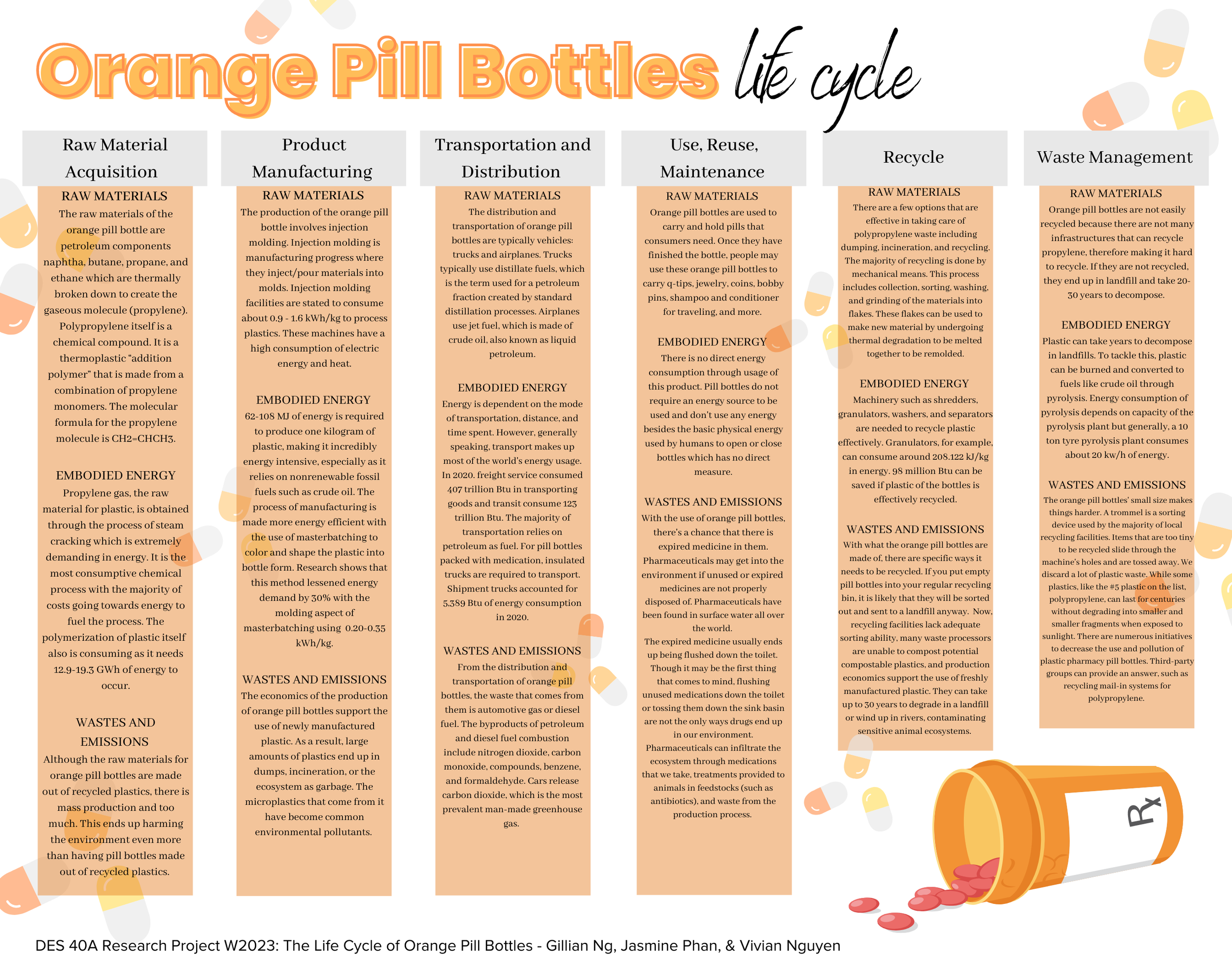

Orange pill bottles are widely distributed products that hold many consumers' pills and keep them protected from light, water, and getting lost. These bottles are made out of a clear orange material which helps prevent ultraviolet light from damaging the photosensitive contents by photochemical reactions. However, it still allows a certain amount of light that allows consumers to still see the content inside. Orange pill bottles are also referred to as “amber pill bottles.” These bottles are made of a recycled plastic called polyethylene, which is made of polymerization of propylene gas in the presence of a catalyst system, usually a Ziegler-Natta or metallocene catalyst. (Greene, 2021)

Raw Materials Acquisition:

The orange pill bottles are made out of a material called polypropylene. Polypropylene is the recycled plastic used for orange pill bottles. There are seven different types of plastic and polypropylene is number 5. Polypropylene itself is a chemical compound. It is a thermoplastic “addition polymer” that is made from a combination of propylene monomers. The combination of propylene is used to create the synthetic resin known as polypropylene. (Hosch, 2009) It is created through the polymerization of propylene gas. The process of creating polypropylene includes petroleum components naphtha, butane, propane, and ethane which are thermally broken down to create the gaseous molecule (propylene). Propylene belongs to the class of hydrocarbons known as "lower olefins," which also contain compounds with just one pair of carbon atoms joined by a double bond. The molecular formula for the propylene molecule is CH2=CHCH3. (see Figure 1) Nevertheless, polymerization catalysts can break the double bond, enabling thousands of propylene molecules to link together to form a polymer that resembles a chain (a large, multiple-unit molecule).

Polypropylene is the second most used polymer in the world. (Valco, 2021) It is also one of the fastest-growing polymers to use for production due to its properties. Polypropylene can be used in many different applications and are part of many different products. This material could be used for different disposable containers (like orange pill bottles), electronics, construction supplies, furniture, and much more. Some properties this raw material has is lower density, higher service temperature, tougher and more rigid material, greater resistance to cracking caused by external stress, and more susceptibility to oxidation and chemical attack. (Koerner, 2018) This substance is very affordable but sturdy. The exceptional heat tolerance of this plastic makes it ideal for use in machines and more. (Hosch, 2009) Since it has so many useful properties many infrastructures and companies tend to use this material for their products. It is believed that this material could displace many of the conventional materials, such as wood, metal, and glass. (Valco, 2021)

Manufacturing, processing, and formulation:

There are a few different ways to procedure polypropylene. The way that I will be talking about is a gas phase and liquid. The gas phase (see Figure 2) includes a fluidized bed or stirred reactor. (Valco, 2021) Gas-phase polymerization is flexible and affordable, and it can work with a wide range of catalysts. It is the most widely used technology in present-day polypropylene manufacturing facilities. (Valco, 2021) This phase uses gaseous monomers such as vinyl chloride, ethylene, and tetrafluoroethylene. First, the monomer gets pressure applied to it and then put into a reaction vessel containing a polymerization catalyst is performed. Monomer molecules spread to the expanding polymer chains as soon as polymerization starts. A granular solid form is obtained as the final polymer. (Steven, 2008) Another phase is the liquid phase. We must acquire power at this stage. Finally, the generated powder is transported to powder silos where it is processed into pellets with a variety of evenly distributed additives. (Valco, 2021) The liquid phase (see Figure 3) is a hybrid membrane separation method that uses water-soluble polymers in conjunction with ultrafiltration membranes to separate low molecular weight species that are dissolved in an aqueous solution. (Rivas, 2011) In an ultrafiltration system, a water-soluble polymer solution and a metal ion solution come into contact. The metal ions as a result bond to the polymer, forming new macromolecular species that are then retained by a size-exclusion mechanism while unbounded species with diameters smaller than the membrane's cutoff diameter pass into the permeate stream. (Palencia, 2015)

The production of the actual bottle occurs in an injection-molding process. Injection molding is a manufacturing progress where they inject plastic materials molten by heat are into a mold and then cool and solidify the product. (see Figure 4) The raw materials for injection molding are polypropylene granules, compressed air, and tap water. (Mannheim and Simenfalvi, 2020) Injection molding facilities are stated to consume about 0.9 - 1.6 kWh/kg to process plastics. These machines have a high consumption of electric energy and heat. (Tex Plastic, 2019)

Distribution and transportation

The distribution and transportation of orange pill bottles are typically vehicles: trucks and airplanes. Trucks and airplanes help transport the orange pill bottles from one location to another. Trucks typically use distillate fuels, which is the term used for a petroleum fraction created by standard distillation processes. (Corrosion Pedia, 2017) It is often a liquid fuel made from crude petroleum. Airplanes use jet fuel, which is made of crude oil, also known as liquid petroleum. Jet fuel can also be made from a natural material found in shale. It is called kerogen or petroleum solids.

Use/re-use/maintenance:

As stated earlier, orange pill bottles are used to carry and hold pills that consumers need. Doctors will prescribe medications for patients and they will come in these bottles. After patients have finished using their bottles, they can either recycle them or reuse them. I often use them to hold painkillers when I travel so I do not need to carry the whole original bottle. Other people may use these orange pill bottles to carry q-tips, jewelry, coins, bobby pins, shampoo and conditioner for traveling, and more. They are a good container to use to hold smaller items. In orange to maintain these bottles, people will use water to clean them which creates a lot of water waste. They could also use alcohol wipes, which also create more trash.

Recycling and Waste Management:

We must take into account that the majority of polypropylene products are not biodegradable at the end of their life cycle. (Mannheim and Simenfalvi, 2020) There are a few options that are effective in taking care of polypropylene waste including dumping, incineration, and recycling. The majority of recycling is done by mechanical means. As previously mentioned, recycling polypropylene is easy, but not always accessible. The physicochemical characteristics of the polypropylene and where/how the polypropylene plastic is attached to the product all have a significant impact on the quality of the recycled polypropylene product. At the end of the orange pill bottles’ life cycle, they are generally burned as polypropylene waste, with energy being recovered.

Although plastic number 5, polypropylene, is a material that can be easily recycled, it is not the easiest procedure. Polyethylene is a part of many different products. From the keyboards we use to car parts to pill bottles, it is hard for us to separate polyethylene plastic from other materials. This resulted in a lot fewer infrastructures that can recycle polyethylene plastic due to all the constraints it may have. Although it may be recycled and be easy to do so, many people don’t recycle it due to the material being connected to other parts and the other challenges they face trying to do so.

If the polypropylene can get recycled, it will undergo a process called the mechanical recycling process. This process includes collection, sorting, washing, and grinding of the materials into flakes. (King, 2011) These flakes can be used to make new material by undergoing thermal degradation to be melted together to be remolded. One limitation of this process is that it isn’t comparable to virgin polypropylene plastic. It is stated that if the orange pill bottles are not recycled, they will end up in landfills. It typically will take 20-30 years to decompose.

Conclusion:

Although orange pill bottles are made out of recycled material, there are a lot of issues that may arise from this product. The raw materials used to create polypropylene take a lot of electric energy and heat. In addition to the gas used to transport the product from one location to the next. In the end, more energy is used to recycle the product if accessible, which is not a guaranteed process. In conclusion, the creation of the orange pill bottle requires a lot of energy and gas and could warm the planet in the future. Although it is made out of recycled material, creating that recycled material takes a lot of energy.

Bibliography:

Greene, Joseph P. Automotive Plastics and Composites: Materials and Processing. William Andrew Publishing, 2021.

Britannica, The Editors of Encyclopaedia. "polypropylene". Encyclopedia Britannica, 6 Dec. 2017, https://www.britannica.com/science/polypropylene.

“PP – Polypropylene – Manufacturing Process of PP (Polypropylene) :: Valco Groupe.” VALCO GROUP, 17 Sept. 2021, https://www.valcogroup-valves.com/faq-2/pp-polypropylene-manufacturing-process-of-pp-polypropylene/.

Stevens, Malcolm P.. "chemistry of industrial polymers". Encyclopedia Britannica, 21 Apr. 2016, https://www.britannica.com/topic/industrial-polymer-chemistry-468716.

Author links open overlay panelBernabé L. Rivas, and AbstractWater-soluble functional polymers have attracted a lot of attention due to their potential applications in different research fields. In environmental sciences. “Water-Soluble Functional Polymers in Conjunction with Membranes to Remove Pollutant Ions from Aqueous Solutions.” Progress in Polymer Science, Pergamon, 19 Nov. 2010, https://www.sciencedirect.com/science/article/pii/S0079670010001218?via%3Dihub.

Palencia, Manuel. “Liquid-Phase Polymer-Based Retention: Theory, Modeling, and Application for the Removal of Pollutant Inorganic Ions.” Journal of Chemistry, Hindawi, 1 Mar. 2015, https://www.hindawi.com/journals/jchem/2015/965624/#B5.

Mannheim, V.; Simenfalvi, Z. Total Life Cycle of Polypropylene Products: Reducing Environmental Impacts in the Manufacturing Phase. Polymers 2020, 12, 1901. https://doi.org/10.3390/polym12091901

“Polypropylene.” Petrocuyo, http://www.petrocuyo.com/en/technology.

The Outline of Injection Molding, https://www.polyplastics.com/en/support/mold/outline/#:~:text=Injection%20molding%20is%20a%20method,the%20area%20of%20plastic%20processing.

“Injection Molding Facility Energy Consumption Summary .” Rex Materials Group, https://www.rexmaterials.com/activek/home.

“What Is Distillate Fuel? - Definition from Corrosionpedia.” Corrosionpedia, https://www.corrosionpedia.com/definition/405/distillate-fuel.

King, Purvis. “Recycling Polypropylene: How to Recycle PP & The Benefits.” Palmetto Industries, 1 Mar. 2022, https://www.palmetto-industries.com/recycling-polypropylene/.

Vivian Nguyen

Professor Cogdell

DES 40A

14 March 2023

Embodied Energy in the Life Cycle of Orange Pill Bottles

Orange pill bottles have become a standard, essential, and recognizable product with the influential role it plays in the safe delivery of prescription drugs and medications from pharmaceutical companies and manufacturers. This product is entirely made of plastic and more specifically colored orange to protect medications which may be sensitive to ultraviolet light. Orange pill bottles often include child safe and resistant caps which also contribute to the plastic usage of the overall product. Because these pill bottles are often mass produced to compensate for the universal need of medication, plastic as a material is highly relied upon and mass produced as well which has its own impacts on the environment and the energy consumption of this product. Though the life cycle of this product includes the acquisition of raw materials, production, transportation and distribution, use, recycling, and waste management, there are some steps that consume more energy than others. Upon examination of the life cycle of an orange pill bottle, it is evident that much of its embodied energy can be found in the processing and production of plastic, product transportation, and post-usage recycling and waste management.

The whole life cycle of the orange pill bottle first relies on the acquisition and processing of propylene gas, the raw material behind polypropylene or plastic, which consumes a good amount of energy. Propylene gas is first acquired as a “by-product of petroleum refining and of ethylene production by steam cracking” (The International Agency for Research on Cancer, 162-163). Acquisition through the process of steam cracking is very energy intensive with 70% of costs going towards energy to fuel the process (Ren et. al, 426). Steam cracking is known as the process that consumes the most energy out of any process within its industry, consuming about “65% of the total process energy” (Ren et. al, 425). This indicates that even before the production of the actual material plastic, energy consumption has already been set high with the acquisition of propylene gas due to the efficient yet extremely harmful methods used to do so. Following its acquisition, propylene gas must undergo other chemical processes to be transformed into polypropylene to be sent into manufacturing. This process is known as chain -growth polymerization and is done with chemical systems and reactors (“Polypropylene”). The polymerization of propylene to create plastic, like steam cracking, also consumes significant amounts of energy due to its high demand of electricity and its reliance on fossil fuels (Khripko et. al, 225-226). A large amount of electric power is consumed to create thermal energy which drives the polymerization process, thus resulting in 5-10% of production costs going towards energy consumption (Khripko et. al, 226). One specific research study found that when analyzing energy usage across four different polymer plants, about 12.9-19.3 GWh of energy was needed for polymerization processes to occur (Khripko et. al, 228). It is evident that the acquisition of the raw material, propylene gas, and its transformation into polypropylene plastic contributes to the high energy consumption of the product’s life cycle before it even reaches the production stage.

Once polypropylene has been formed, a lot of energy goes towards the production of plastic and manufacturing of the pill bottle itself with processes like molding and masterbatching to shape and color the plastic. The energy efficiency in plastic production is significantly low when compared to the production of other common materials such as wood and steel (“How Much Energy”). Anywhere from 62-108 MJ of energy is required to produce one kilogram of plastic, indicating its energy-intensivity (“How Much Energy”). This is due to the fact that the production of plastic heavily relies on nonrenewable fossil fuels which are not only harmful for the environment but also contributes to the high energy usage within this product’s life cycle. More specifically, the production of plastic often requires crude oil and natural gasses to fuel the processes (“How Much Energy”). Following plastic production comes the molding and coloring of plastics to manufacture the pill bottle itself. Though manufacturing with plastic uses a good amount of energy, the process of masterbatching is actually quite energy efficient. The process is what allows the pill bottle to have its orange color by using heat to mix pigments into existing plastic (“Masterbatch”). Due to the chemical properties of certain process components in terms of temperature, the machines have a lower energy demand thus “[helping] manufacturers reduce material costs” (“Masterbatch”). Masterbatching is also involved in injection and blow molding which shapes the plastics, thus making the shaping process also more energy efficient. Manufacturers have found that the “lower processing temperatures… [decreased] their energy requirements by 30%” as well as a reduction in processing time (Zimmermann). There is variation when it comes to specific counts of energy consumption as it is mostly dependent on manufacturers, however, “conventional wisdom is that… injection molding requires 0.20-0.35 kWh/kg” (Rex Materials Group, 2). So while the production of plastic itself is very energy intensive, the manufacturing process of masterbatching increases its energy efficiency and though we may not have access to exact numbers, it is evident that the masterbatch process contributes a lesser amount to the total embodied energy of the cycle.

Though manufacturing plays less of a role in terms of embodied energy, the movement of the product from manufacturers to companies, stores, and consumers contributes a significant weight to energy consumption. From factories, the pill bottles may be transported to pharmaceutical companies for medication packing first, straight to pharmacies or stores, or to other companies to sell the lone products. The amount of fuel and energy consumed in transportation varies based on specific distances, time spent in transport, and also form of transport. Despite lacking exact numbers for pill bottle transportation specifically, it can be inferred that its transportation consumes a significant amount of energy as “28% of total U.S. energy consumption was for transporting people and goods” (United States, Energy Information Administration). Generally speaking, the most commonly used fuel for transport is petroleum based, “[accounting] for about 90% of the total U.S. transportation sector energy use” (United States, Energy Information Administration). In 2020, it was reported that rail freight service transporting goods consumed 407 trillion Btu while transit, of all fuels together, consumed 123 trillion Btu (United States, Dept. of Transportation, Bureau of Transportation Statistics). For orange pill bottles that have been packed with medication and need shipment to pharmacies and consumers, “products are usually transported in a refrigerated or insulated truck” (“Pharmaceutical Transport”). In 2020, various shipment truck types accounted for 5,389 Btu of energy consumption (United States, Dept. of Transportation, Bureau of Transportation Statistics). This allows for the general conclusion that the transportation of orange pill bottles, and products as a whole, consumes a great amount of energy, varying based on mode, time, and distance.

Once the pill bottles reach the hands of consumers, there is no energy directly consumed in its usage. It does not require an energy source, machinery, or anything of the sort to use as its main function is to protect and store prescription medication. Consumers would have to use their own physical energy to open and close the bottles, but there is no direct measurement of energy consumption for this stage in the life cycle. There is also no energy consumption in the maintenance of this product. In terms of re-use, consumers would again have to exert their own physical energy to use the pill bottles for other purposes if they would like. Otherwise, consumers would just toss the bottles post-use. Thus, no energy is directly consumed or measured in the stage of use, reuse, and maintenance.

If consumers were to toss the pill bottles post-use, this brings the energy consumption in recycling and waste management into question. Because orange pill bottles are made of plastic, they do not get recycled very often as the “official recycling rate for plastic stands at 8.7% (de Visé). However when it does get recycled, machinery such as shredders and granulators are used to first cut plastic into finer, smaller pieces (“What Machines”). Granulators often use a good amount of energy with its “final specific energy consumption [being] … 208.122 kJ/kg” (Kankanagme, 3). Unless consumers wash their bottles prior to recycling, the bottles will have to go through a washing machine as well to remove labels or unwanted materials as well as a separation machine (“What Machines”). If recycling goes smoothly, 98 million Btu can be saved as a result (Stanfield). However, if plastic is not recycled, it goes straight to the landfill where “it may take up to 500 years to decompose, and potentially leak pollutants into the soil and water” (Cho). To manage this waste, power plants will often burn and convert plastic waste into fuels such as crude oil through a process called pyrolysis (Cho). The energy consumption of pyrolysis varies based on the type of plant and its capacity as the higher capacity, the more energy it will consume (“How Much Energy”). When looking at energy consumption by capacity, we can see that “the electricity consumption for a 10 ton tyre pyrolysis plant is about 20kw/h” (“How Much Energy”). Because pyrolysis can convert plastic to crude oil, this crude oil could then go back into the making of plastic since its production runs on this fuel. The waste management and recycling aspect of the life cycle is evidently difficult as plastic may be hard to recycle and as a result, ends up in landfills where it fails to degrade in a timely manner and will continue to pollute the environment.

Society relies on the existence of orange pill bottles to deliver prescription drugs and medications safely. However, the life cycle of these pill bottles have detrimental consequences for our environment and demand high amounts of energy to complete. We see the highest contributions to embodied energy through the conversion of propylene gas to polypropylene and plastic which involve the energy intensive processes of steam cracking and polymerization. Another big contributor to the embodied energy is overall manufacturing and production of plastic from crude oil, a nonrenewable fossil fuel. This carries over to the transportation sector of the life cycle which also requires high levels of energy to move product. While there is no direct energy consumption from use, reuse, and maintenance of the pill bottles, the aftermath of recycling and waste management have high energy costs but may also save energy if done successfully. To address the broader issues and implications such as its effects on the environment, we must strive towards more eco-friendly and sustainable means of production for the product. Because it is made entirely of plastic, a material that is not biodegradable, our over reliance on it has long lasting, detrimental effects to our landfills, thus our environment as well. This may be done by more advocacy of proper recycling methods, more energy efficient means of production, and general awareness of this design life cycle.

Works Cited

Boustead, I. Eco-Profiles of the European Plastics Industry . PlasticsEurope, Mar. 2005, http://www.inference.org.uk/sustainable/LCA/elcd/external_docs/pp_31116f04-fabd-11da-974d-0800200c9a66.pdf. Accessed 15 Mar. 2023.

Cho, Renee. “What Happens to All That Plastic?” Columbia Climate School, 31 Jan. 2012, https://news.climate.columbia.edu/2012/01/31/what-happens-to-all-that-plastic/. Accessed 15 Mar. 2023.

Contributors to Wikimedia projects. “Drug Packaging.” Wikipedia, 31 Dec. 2022, https://en.wikipedia.org/wiki/Drug_packaging. Accessed 15 Mar. 2023.

---. “Masterbatch.” Wikipedia, 14 Mar. 2023, https://en.wikipedia.org/wiki/Masterbatch. Accessed 15 Mar. 2023.

---. “Polypropylene.” Wikipedia, 7 Mar. 2023, https://en.wikipedia.org/wiki/Polypropylene. Accessed 15 Mar. 2023.

de Visé, Daniel. “The Hill.” The Hill, 1 Nov. 2022, https://thehill.com/changing-america/sustainability/environment/3712999-why-most-plastic-isnt-getting-recycled/. Accessed 15 Mar. 2023.

Editor, Site. “What Machines Are Used To Recycle Plastic?” Retech, https://www.retechmachine.com/news/what-machines-are-used-to-recycle-plastic.html. Accessed 15 Mar. 2023.

“Energy Consumption by Mode of Transportation.” Bureau of Transportation Statistics, https://www.bts.gov/content/energy-consumption-mode-transportation. Accessed 15 Mar. 2023.

“Energy Costs.” North American Forest Foundation, 24 Feb. 2019, https://northamericanforestfoundation.org/energy-costs/. Accessed 15 Mar. 2023.

International Agency For Research On Cancer. Some Industrial Chemicals IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. 1994. êlnternational Agency for Research on Cancer, 1994, https://www.ncbi.nlm.nih.gov/books/NBK507457/pdf/Bookshelf_NBK507457.pdf. Accessed 15 Mar. 2023.

Kankanamge , Raveendra Sampath Kumara Sarukkali. A Case Study on Improving Energy Efficiency of a Granulator in the Polythene Recycling Machine. June 2018.

Khripko, Diana, et al. “Energy Demand and Efficiency Measures in Polymer Processing: Comparison between Temperate and Mediterranean Operating Plants.” International Journal of Energy and Environmental Engineering, vol. 7, no. 2, Jan. 2016, pp. 225–33, https://doi.org/10.1007/s40095-015-0200-2.

“Olefins from Conventional and Heavy Feedstocks: Energy Use in Steam Cracking and Alternative Processes.” Energy, vol. 31, no. 4, pp. 425–51, https://doi.org/10.1016/j.energy.2005.04.001. Accessed 15 Mar. 2023.

Rex Materials Group. Injection Molding Facility Energy Consumption Summary . https://www.rexmaterials.com/activek_apps/rmg/assets/tcs/Facility%20Energy%20Use%20Summary%20-%20Overview.pdf. Accessed 15 Mar. 2023.

Stanfield, Savanna. “Is Recycling Energy-Efficient? (+ 5 Energy Statistics).” Citizen Sustainable, 16 Apr. 2021, https://citizensustainable.com/recycling-energy/. Accessed 15 Mar. 2023.

“Use of Energy for Transportation.” U.S. Energy Information Administration (EIA), https://www.eia.gov/energyexplained/use-of-energy/transportation.php. Accessed 15 Mar. 2023.

“What You Need to Know about Plastic Breakdown.” Sos Future, https://sosfuture.org/blogs/news/what-you-need-to-know-about-plastic-breakdown?gclid=Cj0KCQjwtsCgBhDEARIsAE7RYh1nE5sK1ETOCEEZazUvaRSWd0r2PbRMbLI6YxSSOzNNyr2IuaSEDcoaAqlqEALw_wcB. Accessed 15 Mar. 2023.

Gillian Ng

DES 40A

Professor Cogdell

16, March 2023

The Life Cycle of Orange Pill Bottles: Waste and Emissions

Everyone has seen an orange pill bottle at least once in their life because they are widely used all around the world. Orange pill bottles are mainly used for pharmaceutical and medical purposes. They are created from orange polymer and recyclable plastics, such as polypropylene. Although orange pill bottles are produced from recyclable plastics, it does not mean that they are easy to recycle. One of the main reasons is mass production. Since orange pill bottles are used widely, there needs to be a significant amount. With the number of orange pill bottles used globally, it takes a long time to degrade, and recycling centers have insufficient sorting ability, causing more waste over time.

Raw Material Acquisition and Manufacturing

These pill bottles are orange because they are made of a translucent orange polymer that prevents the contents from being damaged. The main thing that goes into making orange pill bottles is a plastic called polyethylene, a synthetic polymer. It’s made, or extruded, into a wide range of plastic items that require toughness, elasticity, lightweight, and heat resistance (Britannica, 2017). These features are required for pill bottles because the medication contained within these plastic bottles should be secured for safe use. Another term for polyethylene is “#5 plastics”, which is known to be the second-most commonly produced plastic (YesStraws, 2020). On any container or packaging made out of #5 plastics, there is a small image shown on them. The image is usually of three arrows rotated in a triangle with the number 5 in the middle. These are known as “safer” plastics to use. Because people use this type of plastic more, this harms the environment due to mass production. The economics of production supports the use of newly manufactured plastic, causing large amounts of plastic in dumps, incineration, or the ecosystem as garbage (Savage, 2022). The microplastics that come from it have become common environmental pollutants (Savage, 2022). One thing experts do realize is that microplastics are consumed by people as well. According to recent research, people ingest approximately 50,000 particles of plastic per year and inhale a comparable quantity (Healthy Human, 2022). That indicates that approximately 100,000 plastic particles infiltrate our systems every year (Healthy Human, 2022).

Transportation and Distribution

From the distribution and transportation of orange pill bottles, they emit gasoline, automotive gas, or diesel fuel as waste. These pill bottles are primarily distributed by vehicles such as trucks. The byproducts of petroleum and diesel fuel combustion include nitrogen dioxide, carbon monoxide, compounds, benzene, and formaldehyde (“Reducing Air Pollution from Cars.”). These vehicles also emit carbon dioxide, the most common man-made greenhouse gas (“Reducing Air Pollution from Cars.”). Greenhouse gases have severe health and ecological consequences, such as climate change. There is no simple way to reduce the waste emitted from the transportation and distribution of orange pill bottles. One thing that can help is electric vehicles, but this will cause transportation time to increase due to charging time for the vehicles.

Use, Re-use, Maintenance

As previously mentioned, these orange pill bottles are used for pharmaceutical and medical reasons as a way to distribute medication. With the use of orange pill bottles, there's a chance that the medicine in them will eventually expire. If leftover or expired pharmaceuticals are not correctly disposed of, pharmaceuticals will enter the environment. Pharmaceuticals have been discovered in surface water all over the globe because outdated medication is commonly thrown down the toilet (Pfizer). Though it may be the first thing that comes to mind, flushing medications down the toilet or tossing them down the sink basin are not the only ways drugs end up in our environment. Pharmaceuticals can infiltrate the ecosystem through medications that we take, treatments provided to animals in feedstocks, such as antibiotics, and waste from the production process (Pfizer).

The orange pill bottles themselves cause a lot of waste if not recycled properly, but there are many ways to reuse them instead. Some people would use them as reusable containers to store things. Others would use them in some sort of creative way, such as making art or designing something out of the orange pill bottles.

Recycle

With what the orange pill bottles are made of, there are specific ways it needs to be recycled. If you place unused pill bottles in your normal trash receptacle, they will almost certainly be separated and taken to a landfill (Daugharty, 2023). Though this plastic is very common, a limited number of curbside recycling collectors accept this kind of plastic because they are no longer disposed of at curb or drop-off sites (Ramos, 2020). Today, it is difficult for many garbage processors to compost prospective compostable plastics, recycling centers lack sufficient sorting capabilities, and production economics favor the use of recently produced plastic (Savage, 2022). These plastics can take up to 30 years to degrade in a landfill or wind up in different waterways, contaminating sensitive animal ecosystems (Daugharty, 2023). Because so many people do not know how to correctly recycle these orange pill bottles, a lot of trash frequently occurs, harming the ecosystem.

Waste Management

The orange pill bottles' small size makes things difficult. A trommel is a sorting device used by the majority of local recycling facilities (Daugharty, 2023). Items that are too tiny to be recycled slide through the machine's holes and are tossed away (Daugharty, 2023). We discard a lot of plastic waste overall. Some plastics, like the #5 plastic on the list, polypropylene, can last for centuries without degrading into smaller and smaller fragments when exposed to sunlight (Healthy Human, 2022). There are numerous initiatives to decrease the use and pollution of plastic pharmacy pill bottles. Third-party groups can provide an answer, such as recycling mail-in systems for polypropylene (Pfizer). It is critical to only take medication as directed by a healthcare expert and resolve to properly dispose of any leftover or expired medications. Local collection programs for outdated medicines can provide a secure disposal technique that saves global health and the ecosystem (Pfizer). These techniques differ depending on the state, county, and nation. In the United States, the FDA keeps a list of fixed pickup locations and periodic "take back" events, as well as guidelines (Pfizer).

The use of orange pill bottles is critical to the secure delivery of prescribed medicines in our society. The life cycle of these pill bottles is ecologically damaging and ends up creating a lot of waste. It is demonstrated that polypropylene is used in many ways and is considered to be one of the safer plastics to use. Because it is being used so much, this causes mass production of these polypropylene products. One being orange pill bottles. If they are not recycled properly, a lot of the plastic ends up in a landfill which generates more waste over time. Not only does the waste come from the orange pill bottles themselves, but other factors contribute to the total waste as well. Petroleum and gas play a big role when it comes to transporting and distributing orange pill bottles causing serious environmental and health effects. Another thing that comes into play is the contents that are inside the orange pill bottles. The medication inside is often flushed down the toilet if they are unused or expired which causes drugs to pollute the environment. There are a few ways to reduce the total waste of these orange pill bottles such as learning how to recycle the bottles and disposing of the contents inside properly. Having a general understanding of the life cycle of a product can help reduce waste and protect the environment overall.

Work Cited

Britannica, The Editors of Encyclopaedia. "polypropylene". Encyclopedia Britannica, 6 Dec. 2017, https://www.britannica.com/science/polypropylene

YesStraws. “Types of Plastic - a Complete Plastic Numbers Guide.” YesStraws, 17 Jan. 2020, https://yesstraws.com/blogs/news/types-of-plastic-plastic-numbers-guide#:~:text=%235%20Plastic%3A%20Polypropylene,Yogurt%20containers.

Savage, Steven. “A Novel Alternative to the Plastic Waste Associated with Pill Bottles.” Forbes, Forbes Magazine, 22 Nov. 2022, https://www.forbes.com/sites/stevensavage/2022/11/21/a-novel-alternative-to-the-plastic-waste-associated-with-pill-bottles/?sh=206316165c53.

Healthy Human. “Guess How Long It Takes for Plastic to Biodegrade: Forever.” Guess How Long It Takes for Plastic to Biodegrade: Forever – Healthy Human, 2022, https://healthyhumanlife.com/blogs/news/how-long-does-it-take-for-plastic-to-decompose#:~:text=And%20while%20some%20plastics%20degrade,can%20stay%20intact%20for%20millennia.

“Reducing Air Pollution from Cars.” Reducing Car Pollution - Washington State Department of Ecology, https://ecology.wa.gov/Issues-and-local-projects/Education-training/What-you-can-do/Reducing-car-pollution#:~:text=Burning%20gasoline%20and%20diesel%20fuel,common%20human%2Dcaused%20greenhouse%20gas.

Pfizer. “How to Dispose of Unused Medicine Responsibly to Protect the Environment.” Pfizer, https://www.pfizer.com/news/articles/how_to_dispose_of_unused_medicine_responsibly_to_protect_the_environment#:~:text=Improper%20disposal%20of%20unused%20or,pharmaceuticals%20getting%20into%20the%20environment.&text=In%20fact%2C%20pharmaceuticals%20have%20been,surface%20water%20around%20the%20world.&text=So%20far%2C%20scientific%20studies%20have,on%20human%20and%20animal%20health.

Daugharty, Kylie. “Why Can't You Recycle Pill Bottles Yourself?” Medical Waste Pros, Medical Waste Pros, 17 Feb. 2023, https://www.medicalwastepros.com/blog/why-cant-recycle-pill-bottles-yourself/.

Ramos, Tiana. “Reducing Plastic Waste of the Pharmacy Pill Bottle.” Medium, Medium, 27 Aug. 2020, https://medium.com/@tramos30/reducing-plastic-waste-of-the-pharmacy-pill-bottle-c59a7b5b9bb4.

Steele, Lauren. “How to Recycle Your Pill Bottles.” The Checkup, 14 Apr. 2022, https://www.singlecare.com/blog/how-to-recycle-pill-bottles/#:~:text=That%20means%20your%20prescription%20bottles,filled%20by%20Americans%20each%20year

Polymers as Solid Waste in Municipal Landfills - Tandfonline.com. https://www.tandfonline.com/doi/pdf/10.1080/10473289.1995.10467364

Waste Polypropylene Plastic Recycling toward Climate Change Mitigation ... https://pubs.acs.org/doi/10.1021/acssuschemeng.0c06311

Basile, Gabriella. “Innovation by Design: The Prescription Paper Pill Bottle, Saatchi & Saatchi Wellness.” Publicis Health, Publicis Health, 19 Apr. 2021, https://publicishealth.com/thought-leadership-blog/innovation-by-design-the-prescription-paper-pill-bottle-saatchi-amp-saatchi-wellness

Wise, Maureen. “Can You Recycle Number 5 Plastics?” Earth911, 4 Jan. 2022, https://earth911.com/home-garden/recycle-plastic-number-5/

“Guess How Long It Takes for Plastic to Biodegrade: Forever.” Guess How Long It Takes for Plastic to Biodegrade: Forever – Healthy Human, https://healthyhumanlife.com/blogs/news/how-long-does-it-take-for-plastic-to-decompose#:~:text=And%20while%20some%20plastics%20degrade,can%20stay%20intact%20for%20millennia

Drug packaging https://en.wikipedia.org/wiki/Drug_packaging#:~:text=Prescription%20bottles%20come%20in%20several,for%20the%20contents%20to%20be