Design Life-Cycle

assess.design.(don't)consume

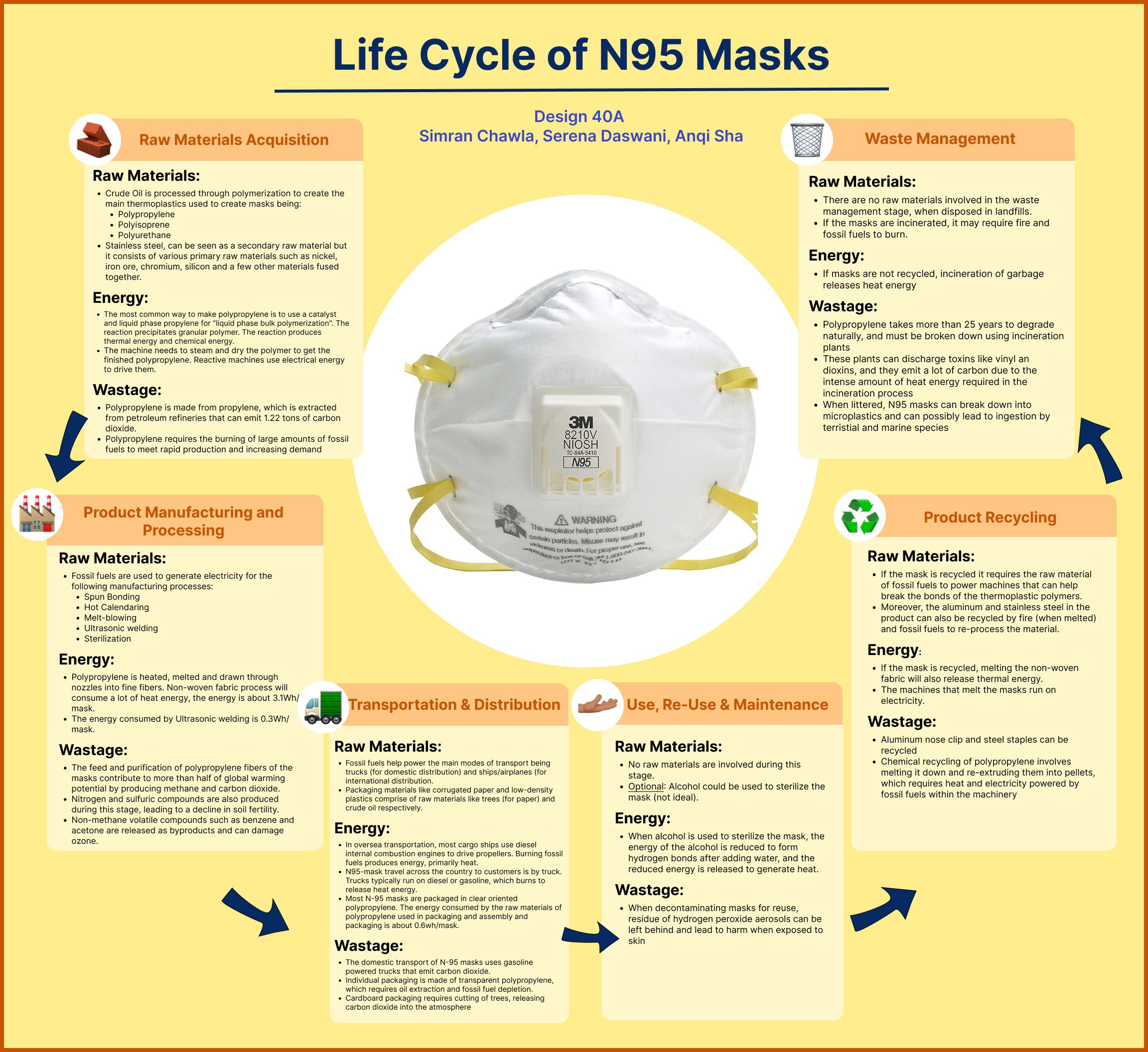

Image Citation:

Gemplers. 3M 8210V N95 Respirator with Exhale Valve, 10pk, 2023, https://gemplers.com/products/8210v-n95-respirator-with-exhale-valve?currency=USD&variant=21170360451161&utm_medium=cpc&utm_source=google&utm_campaign=Google%20Shopping. Accessed 2023.

Raw Materials

Simran Chawla

Serena Daswani, Anqi Sha

Design 40A

Professor Codgell

Covid-19, one of the world’s most rapidly spread pandemic could not have been battled without the N-95 masks. Due to the rapid spread of the pandemic, the demand of disposable and N-95 masks increased exponentially. The N-95 masks played a very important in protecting the public from the virus because it is capable of shielding 95% of the external particles and viruses, which is much higher performance compared to any other kind of mask be it surgical or re-usable cotton masks. So what are N-95 masks? They are basically face coverings that are composed of plastic polymers bound together to clean the air supply before the user breathes. Since N-95 masks contain several layers of polymers, it can be said that the higher the usage the more the filtration of the particles/viruses, however, on the downside, if the N-95 mask is worn for prolonged periods of time, breathing could get difficult. The design of the N-95 mask is very interesting because the old design was recently updated according to the preferences of consumers’ ergonomics and comfort.The main focus of this essay is to understand the kind of raw materials used in the life cycle of an N-95 mask. The main materials used throughout the process are fossil fuels to make plastic polymers, stainless steel and aluminum. Although the raw materials of the N-95 masks such as thermoplastic polymers and stainless steel can be recycled, the usage stage results in bacterial contamination which ultimately results in complete disposal of the product.

In the raw materials acquisition stage, the main material of the mask is fossil fuel derived polymers such as polypropylene (for the filters), polyisoprene (for the straps) and polyurethane (for the filters). Since a majority of the mask is made from polypropylene, the acquisition of this polymer would be looked into further. Polypropylene is a thermoplastic material derived from crude oils (fossil fuels). It is because of its “thermoplastic” properties, polypropylene can be heated up to its melting point and then remolded without any noticeable deterioration. This material needs to be processed from crude oil wherein propylene gases are polymerized using a catalyst. As a material it is resistant to chemicals, tough and has high insulation. Therefore making it a favorable material to use not only in the production of N-95 masks but also another broader range of consumer goods such as material handling, textiles, toys, medical devices and packaging. Polypropylene (along with polyisoprene and polyurethane) are polymers of thermoplastics. This means that although the material is strong and durable, the bonds between them are weak which allows for indefinite recyclability. It is also important to mention that thermoplastics in general are a more sustainable option compared to other kinds of plastics because they release lesser toxins and have a lower carbon footprint due to its recyclability. Therefore, the main material of the mask can be said to be environmentally friendly. It can hence be said that polypropylene can be completely recycled in a wide range of products including fibers, containers, etc. however this is disabled because the several layers of filters get contaminated due to consumer usage.

Another important component of the mask is stainless steel or aluminum that is used to seal the nose of the mask. The raw materials involved in stainless steel are nickel, iron ore, chromium, silicon, and a few other metals fused together. Although the process itself may consume a lot of raw materials and energy, stainless steel as a material is extremely durable and resistant to rust/ corrosion (which increases the product longevity). As it is known, stainless steel is a 100% recyclable (AISS, 2022) material because it can be melted and reused in several contexts. Therefore, these points directly relate to the main argument that helps understand the fact that the materials used in the masks are recyclable but the usage limits this.

The next idea that would be looked into is the simplicity of the materials involved in the product manufacturing stage of the N-95 masks. N-95 masks are made from 4 main materials (polypropylene, polyisoprene, polyurethane and stainless steel or aluminum), which is low as compared to other kinds of products. The product’s heterogeneity can be said to be limited which means that the variety of raw materials involved in creating the product is less. The main processes involved in manufacturing the mask include: spun bonding (a process that is used to make the base through blow melted threads of the polypropylene onto a conveyer belt to build cloth and bind it using thermal/chemical techniques), hot calendaring (to bond the central part of the mask being filtration layers with the polymer fibers) and melt-blowing (helps to add strength and the final layer to the N-95 masks. In addition to these processes, the lawyers of the mask are combine through ultrasonic welding and it is cleaned through thorough sterilization. All in all, the product manufacturing processes mentioned above are mainly mechanized and are only dependent on fossil fuels to power electricity in the manufacturing industries. While this may not be the most sustainable material to depend on due to its finite availability, several companies around the world are working towards harnessing the power of clean energy sources (such as solar, wind, etc.) for generating green power.

After the product manufacturing stage, N-95 masks undergo the transportation and distribution stage. If the N-95 masks are being distributed locally, the primary mode of transportation are trucks that utilize fossil fuels. Similarly, if the masks are distributed internationally, the mode of transportation of the masks would either be through shipping or airways, in both cases fossil fuels are essential. According to statistics, N-95 masks use 0.05 kg CO2 in each use (which excludes the transportation effects), in other words, transportation would add on to a higher cost to the environment. Now, the packaging of the mask is completed by using materials like; corrugated cardboard box derived from trees to store a multiple masks together and low-density plastics derived from crude oil that is used as a the thin plastic film covering for sanitary purposes. From all these materials, the only material that can be composted/ biodegraded is the corrugated board box (because it consists of paper). The low-density plastics do not have strength and resistance and could be highly flammable, and so simply contribute to the waste. The take away of this stage is that there exists a design failure because N-95 masks are only for a limited number of uses.

The Use, Reuse & Maintain/ Recycling and Disposal stage do not involve any raw materials because N-95 masks are made for single-use. During the use stage, the mask gets contaminated due to which it cannot be recycled and has to be disposed. So if at all there are any raw materials involved, it is in the disposal stage for incineration. Either fuels or fire is used to burn the contaminated biohazard waste. However, different methods of disposal can be adopted to make the end of life cycle of the N-95 masks more sustainable. If the stainless steel/aluminum strap (on the nose) is separated from the mask (not exactly) and then disposed it can be recycled, but this may not necessarily be practical because melting and reusing the steel would require energy. Similarly, the thermoplastic polymers can also be re-processed by breaking the bonds and recycling it, however, it is not a tangible option due to the amount of energy/raw materials that these processes would demand.

As a product, N-95 masks have proved their efficacy because it was successfully able to protect populations from contaminants and bacteria by 90.73%. The N-95 masks are designed to completely seal or fit the consumer (facially) which ensures the efficiency further. In the raw materials perspective, it can be said that the acquisition of polymers or stainless steel/aluminum is from fossil fuels, however, because of the material properties, the carbon footprint of the mask can be made low due to its recyclable properties.

On the down side, the take away of the thesis is that the N-95 masks are designed for disposal. In other words, it is made for the purpose of limited number of uses, because otherwise it can prove to be hazardous due to the accumulation of bacterial contaminants. This results in complete disposal of the masks which means that there is a high amount of waste generation in landfills or due to incineration (also if the raw materials are recyclable). If at all firms find a way to disinfect the masks and recycle it instead of disposal, it fair to state that lot of energy would be required to break the polymer bonds (of polypropylene, polyisoprene and polyurethane), melt the stainless steel or even separate the materials in the first place.

In conclusion, as it is evident in the essay, the thesis statement has been proven to a great extent. To reiterate the idea, research backs up the idea that although the raw materials of the N-95 masks such as thermoplastic polymers and stainless steel can be recycled, the usage stage results in bacterial contamination which ultimately results in complete disposal of the product. Masks itself have a number of advantages and disadvantages as observed above, however, design changes need to be made so that this product can be more sustainable.

Bibliography

Author links open overlay panelAmos Wei Lun Lee, et al. “Life Cycle Assessment of Single-Use Surgical and Embedded Filtration Layer (EFL) Reusable Face Mask.” Resources, Conservation and Recycling, Elsevier, 31 Mar. 2021, https://www.sciencedirect.com/science/article/pii/ S0921344921001877.

Chen, Stephen. “Covid-19 Masks 'Cause Plastic Fibre Inhalation – but We Should Still Use Them'.” South China Morning Post, 2 Jan. 2021, https://www.scmp.com/news/china/science/article/3116133/ covid-19-masks-cause-plastic-fibre-inhalation-we-should-still.

Henneberry, Brittany. “How to Make N95 Masks.” Thomasnet® - Product Sourcing and Supplier Discovery Platform - Find North American Manufacturers, Suppliers and Industrial Companies, 2023, https://www.thomasnet.com/articles/plant-facility-equipment/how-to-make-n95-masks/.

How Are N95 Masks Made?, 30 July 2021, https://health-desk.org/articles/how-are-n95-masks-made.

Lee, Amos Wei Lun, et al. “Life Cycle Assessment of Single-Use Surgical and Embedded Filtration Layer (EFL) Reusable Face Mask.” Resources, Conservation, and Recycling, U.S. National Library of Medicine, July 2021, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8009732/.

Rodríguez a, lNúria Boix, et al. “Environmental Implication of Personal Protection Equipment in the Pandemic Era: LCA Comparison of Face Masks Typologies.” Procedia CIRP, Elsevier, 10 Mar. 2021, https://www.sciencedirect.com/science/article/pii/S2212827121001384.

Stanborough, Rebecca Joy. “Is Polypropylene Safe and BPA Free?” Healthline, Healthline Media, 23 Sept. 2020, https://www.healthline.com/health/is-polypropylene-safe#about-polypropylene.

Talhelm, Thomas. “Thomas Talhelm.” Smart Air, 8 Dec. 2020, https://smartairfilters.com/en/blog/n95- masks-made-from/.

van Straten, Bart, et al. “A Life Cycle Assessment of Reprocessing Face Masks during the COVID-19 Pandemic.” Nature News, Nature Publishing Group, 3 Sept. 2021, https://www.nature.com/articles/ s41598-021-97188-5.

van Straten, Bart, et al. “A Life Cycle Assessment of Reprocessing Face Masks during the COVID-19 Pandemic.” Nature News, Nature Publishing Group, 3 Sept. 2021, https://www.nature.com/articles/ s41598-021-97188-5.

Wijayasundara Lecturer, Mayuri. “Millions of Face Masks Are Being Thrown Away during COVID-19. Here's How to Choose the Best One for the Planet.” The Conversation, 4 Sept. 2022, https://theconversation.com/millions-of-face-masks-are-being-thrown-away-during-covid-19-heres- how-to-choose-the-best-one-for-the-planet-147787.

Wilson, Mark. “The N95 Mask: The Untold Origin Story - Fast Company.” The Untold Origin Story of the N95 Mask, 2023, https://www.fastcompany.com/90479846/the-untold-origin-story-of-the-n95- mask.

Energy

Anqi Sha

Simran Chawla, Serena Daswani

Design 40A

Professor Codgell

N95 masks are practical for high-intensity filtration of viruses and dust. Since the outbreak of the Covid-19 epidemic, the demand for masks has increased significantly, leading people to purchase N95 masks on a large scale for more effective personal protection. Developed by Peter Tsai and his team in Tennessee, USA, in the 1990s, N95 masks have been under development for over ten years, resulting in a highly effective mask that can block tiny particles in the air. Compared to ordinary masks, N95 masks have a thicker and more protective filter mesh. Some workers and people who suffer from pollen allergies in the spring may also need N95 masks for protection against dust. Studying the life cycle of N95 masks can help us better understand environmental protection issues.

The main raw material used in manufacturing N95 masks is polypropylene, a commonly used modern plastic. This white, waxy material is widely utilized in the production of various plastic products. Polypropylene is produced using propylene as its primary raw material, with the addition of ethylene as a comonomer during synthesis. Going back even further, these chemicals are derived from oil. Gathering oil requires the use of various heavy machinery and oil drilling. The energy required to power these machines is typically generated by electricity, which is used for lifting and rotating the drilling rig. The most common method of producing polypropylene is through "liquid bulk polymerization," which involves the use of a catalyst and liquid propylene. This process generates both thermal and chemical energy and produces a particulate polymer. Subsequently, the polymer needs to be steamed and dried using reactive machines powered by electricity to obtain the finished polypropylene. Once the raw materials for the masks are prepared, the next step is to assemble them through a series of fine-processing steps.

To produce the filters used in masks, workers use machines to heat and melt polypropylene, then squeeze out it through nozzles to create many fibers finer than human hairs. These fibers are then woven together to form a synthetic plastic fiber cloth known as a nonwoven. This process requires a significant amount of heat energy, around 3.1Wh per mask. To increase the filtering effectiveness, multiple layers of nonwoven fabrics are assembled and fused together using ultrasonic welding machines. Both the heating machine and ultrasonic welding machine are powered by electricity.

In addition, aluminum wire is used to make the nose bridge of the mask. Aluminum is a lightweight metallic material that is readily available in the environment and commonly used in modern society. The production and processing of aluminum require high temperatures to melt the metal, which consumes a considerable amount of electricity. In fact, about 5% of electricity usage in the United States is dedicated to producing aluminum. The aluminum wire is then affixed to the mask's nose bridge using hot melt adhesive, which also requires heat to melt. The energy consumption for ultrasonic welding is around 0.3Wh per mask. Clear polypropylene packaging is typically used for N95 masks, which consumes around 0.6Wh per mask for the raw materials and packaging assembly. Once the masks are made and packaged, the next step is shipping them.

A large portion of the energy consumption associated with masks is related to transportation. It actually takes more energy to transport masks than to produce them. N95 masks are manufactured in factories around the world, with the primary market countries being the United States, Canada, Germany, China, and India. Most masks are transported internationally by sea from the country of origin to the destination country. During maritime transport, cargo ships are powered by diesel internal combustion engines that drive propellers. The combustion of fossil fuels generates energy in the form of heat. Once the masks arrive at the destination country, they are typically transported to retailers by trucks. These trucks are powered by diesel or gasoline engines that burn fuel to generate heat. It is worth noting that very few trucks use electricity as an energy source.

When using N95 masks, people often disinfect them with alcohol to continue to provide safer protection and reduce the number of masks consumed. Alcohol spray disinfection involves the volatilization of alcohol, which is a physical reaction. Typically, the alcohol used for disinfection is diluted with water. When alcohol and water react, the hydrogen bonds between ethanol molecules are stronger than those between water molecules, which results in the release of excess heat energy after mixing. However, N95 masks are still disposable products, and people usually do not reuse them many times. In most cases, N95 masks are discarded after being used a few times.

Most disposable N95 masks are usually thrown away with other garbage and transported to garbage treatment plants for centralized incineration, which generates both chemical and thermal energy. A small number of masks are recycled as polypropylene. The factory collects these masks, washes and sanitizes them, and melts the main body of the mask, which is made of polypropylene, at a high temperature of 700°C for further processing. The melted polypropylene is reshaped into plastic pellets to make new products, which requires the use of machines that consume electricity and generate heat. The aluminum used for the bridge of the nose in the mask can also be recycled. Scraps of aluminum are collected and melted at high temperatures, and the energy required for recycling aluminum is only about 5% of the energy needed to produce it. However, If people do not dispose of discarded masks properly, the polypropylene plastic used to make masks are difficult to decompose naturally, and incineration can also release environmentally harmful gases.

When reviewing the life cycle of the entire N95 mask, electricity and petroleum stand out as the two most significant sources of energy. The machines used to heat polypropylene, recycle polypropylene, and drill for oil all require electrical energy to operate. Furthermore, oil is the original raw material for masks and the energy source for the ships and trucks used to transport them. While burning petroleum fuels can generate electrical energy, a more eco-friendly option is to rely on natural renewable energy sources. For example, windmills and waterwheels can generate electricity, solar panels use solar thermal energy from the sun's rays to produce electricity. Additionally, geothermal energy can also provide thermal energy to generate electricity. using renewable energy as the heat source for the production of N95 masks would benefit the environment by reducing pollution and minimizing the overexploitation of oil. Despite these renewable options, most modern sources of electricity still come from natural gas, coal, and nuclear power.

In conclusion, the high demand for N95 masks during the epidemic has highlighted the significant amount of petroleum and electricity energy consumed in their production, transportation, and recycling. The various stages of N95 mask production, including the melting and molding of polypropylene fiber and the recycling and reusing of polypropylene, require high-temperature heating that primarily relies on electricity. The transportation of masks by sea freighters and trucks relies on petroleum-based fuels. Although in addition to general incineration, masks can also be recycled and reused as new energy. It is a pity that the one-time use of N95 masks has caused a lot of garbage, and very few N95 masks have been effectively recycled and reused. To address this issue, it is crucial to explore more effective recycling and reuse methods for N95 masks and promote more environmentally friendly methods in the production and transportation of masks.

Bibliography

Atılgan Türkmen, B. Life cycle environmental impacts of disposable medical masks. EnvironSciPollutRes29,25496–25506(2022).https://doi.org/10.1007/s11356-021-17430-5

Desk, H. (2021, July 30). How are N95 masks made? Retrieved March 2, 2023, from https://health-desk.org/articles/how-are-n95-masks-made#:~:text=Most%20N95%20masks%20are%20made,yoga%20pants%2C%20and%20stretchy%20fabric.

amajodina, & Ziya. (2022, February 2). How covid 19 face masks can be recycled and converted to energy. Infrastructure news. Retrieved March 2, 2023, from https://infrastructurenews.co.za/2022/02/02/how-covid-19-face-masks-can-be-recycled-and-converted-to-energy/

Emsley, John (2011). Nature's Building Blocks: An A–Z Guide to the Elements. OUP Oxford. pp. 24–30. ISBN 978-0-19-960563-7. Archived from the original on 22 December 2019. Retrieved 16 November 2017.

Majeed, Z. (2022, January 28). Covid-19: Scientists invent technology to convert medical waste into energy. Republic World. Retrieved March 2, 2023, from https://www.republicworld.com/technology-news/science/covid-19-scientists-invent-technology-to-convert-medical-waste-into-energy-articleshow.html

"Benefits of Recycling". Ohio Department of Natural Resources. Archived from the original on 24 June 2003.

Klemeš JJ, Fan YV, Jiang P. The energy and environmental footprints of COVID-19 fighting measures - PPE, disinfection, supply chains. Energy (Oxf). 2020 Nov 15;211:118701. doi: 10.1016/j.energy.2020.118701. Epub 2020 Aug 27. PMID: 32868962; PMCID: PMC7450254.

Skrzyniarz, Magdalena, Marcin Sajdak, Monika Zajemska, Józef Iwaszko, Anna Biniek-Poskart, Andrzej Skibiński, Sławomir Morel, and Paweł Niegodajew. 2022. "Plastic Waste Management towards Energy Recovery during the COVID-19 Pandemic: The Example of Protective Face Mask Pyrolysis" Energies 15, no. 7: 2629. https://doi.org/10.3390/en15072629

N95 respirators market by type, distribution channel, and geography - forecast and analysis 2023-2027. Technavio. (n.d.). Retrieved March 14, 2023, from https://www.technavio.com/report/n95-respirators-market-industry-analysis?utm_source=blog&utm_medium=rfs&utm_campaign=blogtorfs

"Meet the U.S. scientist who invented the N95 mask filter". U.S. Embassy in Georgia. August 12, 2020. Retrieved June 12, 2022.https://ge.usembassy.gov/meet-the-u-s-scientist-who-invented-the-n95-mask-filter/

Creating a Drill Site. Adventures in energy. (n.d.). Retrieved March 14, 2023, from https://www.adventuresinenergy.org/exploration-and-production/creating-a-drilling-site.html#:~:text=Drill%20rigs%20now%20run%20on,quieter%20than%20in%20the%20past.

Electricity production and distribution. Alternative Fuels Data Center: Electricity Production and Distribution. (n.d.). Retrieved March 14, 2023, from https://afdc.energy.gov/fuels/electricity_production.html#:~:text=According%20to%20the%20U.S.%20Energy,biomass%2C%20wind%2C%20and%20geothermal.

Waste and Pollution

Serena Daswani

Simran Chawla, Anqi Sha

DES 40A

Professor Cogdell

In response to the global pandemic, N95 masks were increasingly relied on to mitigate and prevent the spread of COVID-19 among the general public. The highly protective qualities of the respirator, provided by the filtering layer, make it essential in high-risk environment. However, N95 masks are mass-manufactured for the purpose of being discarded after a single use, which prompts questions regarding its journey through its environment from the start to the end of its life. Using the life-cycle analysis method, I will explore the ways in which each of the various stages of its life cycle, including the acquisition of raw materials, manufacturing and processing, distribution and transportation, use and maintenance, recycling, and waste management, produce waste and emissions. The single-use nature of N95 masks subsequently results in the lack of sustainability of its raw materials, and the time-intensive degradation of polypropylene can discharge toxins and emissions into the surrounding environment.

The synthesis of polypropylene, a plastic fiber that makes up the air filter layers, is the primary material utilized in the production of N95 masks and requires large amounts of fossil fuel consumption. Polypropylene, a material utilized for its flexibility, strength, and thermal properties, is cost-effective and incorporated within plastic products in various industries (Alsabri, et al.). A single N95 mask contains nine grams of polypropylene, and a minimum of 0.6 kilotons of polypropylene waste is produced in the United States per week (Selvaranjan et al.). The international demand for plastics is estimated to be 245 million annually, with polypropylene making up twenty-five percent of the polymer market demand (Alsabri, et al.). To keep up with the mass production and consumption of polypropylene, it necessitates more oil and natural gas extraction which places a great burden on the environment. It is important to note that polypropylene is made from the monomer propylene, which comes from petroleum refineries (Alsabri, et al.). According to the U.S. Environmental Protection Agency, petroleum refineries fall in the highest second sector of greenhouse gas emissions per facility, averaging 1.22 million metric tons of carbon dioxide (U.S. Environmental Protection Agency). In the initial stages of the product’s life cycle, polypropylene is the most important component, and its properties ultimately determine the masks’ waste production.

Within the manufacturing stages of polypropylene fibers in N95 masks, undesired gases are dispelled. The feed and purification of polypropylene contributes to more than half of the global warming potential, fossil fuel depletion, human toxicity, petrochemical oxidant formation, and acidification (Alsabri, et al.). As the purified liquid propylene enters a reaction unit to be converted into power resin, it emits heavy gases (Alsabri, et al.). Methane and carbon dioxide are among those gases that are common pollutants released, and it is estimated that 1 ton of polypropylene is equivalent to 1586 kilograms of carbon dioxide (Alsabri, et al.). Since the weight of the emissions are greater than the amount of polypropylene produced, it is vital that new forms of energy or technology are explored to cut back on these emissions to reduce overall warming potential. Nitrogen and sulfuric compounds are also produced by polypropylene, which result in terrestrial acidification, or decline in soil fertility (Alsabri, et al.). The emissions of non-methane volatile organic compounds, such as formaldehyde, benzene, and acetone contribute to the concentration of tropospheric ozone and aerosols (Alsabri, et al.). This can raise the risk for cardiovascular and respiratory diseases in human beings that are considered as carcinogenic. Fossil fuels are also depleted primarily in the feed and purification stage of the manufacturing process, as 1 kilogram of polypropylene pellets require 1.72 kilograms of oil (Alsabri, et al.). In regard to the production of the external protective layers of the mask fabric, spun bonding and melt blowing are the primary techniques that utilize polypropylene (Henneberry). High-speed hot air creates tight fibers with small pores that result in the effective filtration layer within the mask (Atilgan Türkmen). This requires the burning of fossil fuels to produce the electricity powering the machinery that thermally and chemically bonds the polypropylene fibers. The production of a single N95 mask releases 50 grams of carbon dioxide, which excludes transportation (Selvaranjan).

Transportation and packaging of the masks consists of transport of raw materials and packaging materials from manufacturers to distribution facilities, and ultimately to the consumers. Assuming that N95 masks are produced domestically, the transport is carried out on the road by gasoline-powered trucks (Atilgan Türkmen). Depending on the distance these trucks must travel, the emissions vary but can amount when these masks are mass-produced and need to meet consumer demand. In addition, packaging consists of plastic, paper, and cardboard depending on the manufacturer. Individual packaging is often made of transparent oriented polypropylene, which requires oil extraction and production into sheets (Alsabri, et al.). The masks are placed in cardboard packaging, which requires the cutting of trees and releases stored carbon dioxide into the atmosphere. There is little research on the transportation stages, as the vast number of sellers of N95 masks may have different production practices.

N95 masks, when reused, are chemically decontaminated; however, the residue that is left behind can become hazardous when inhaled or contacted through skin. Ethylene and hydrogen peroxide are primarily used for sanitizing N95 masks which focuses on reducing bacteria, retaining the efficiency and fit of the filtration layer, and elimination of chemical residues (Kumkrong et al.). Ozone, an alternate decontaminant used in indoor air treatment, has a higher penetration efficiency without leaving toxic residue (Kumkrong et al.). Higher concentrations of hydrogen peroxide are delivered in gaseous and plasma forms, and there are currently no regulation limits established (Kumkrong et al.). One study examining the residue levels on N95 masks found that a large proportion of the hydrogen peroxide in the denomination process conditions were on the hard material of the inner layer of masks (Kumkrong et al.). Although the masks were dry after decontamination, there were still surrounding gaseous forms of hydrogen peroxide and ozone (Kumkrong et al.). The study notes that using a higher temperature, exposing the masks to light, and increasing the air exchange rate can reduce the gaseous residue levels (Kumkrong et al.). It is important to understand the residual concentrations of decontaminants to ensure that individuals using the masks are not exposed and do not experience adverse health effects from contact.

Since N95 masks are considered disposable, they often end up in the landfill if not reused. Individual parts such as the steel staples and aluminum nose clip in the mask can sometimes be recycled, as it is among the world’s most recycled materials (Wijayasundara). Polypropylene undergoes mechanical recycling, in which it is separated from other materials like paper, plastics, and glass (Our Endangered World). An alternate form of recycling is chemical, which involves melting polymers using catalysts and “re-extruding them into pellets for reuse” (Our Endangered World). This method of recycling allows the materials to be used to produce different or the same product; however efficiency and quality will decrease (Selvaranjan). However, the recycling depends on the prevalence of recycling facilities in that region.

The last stage of the lifecycle is waste management, which focuses on breaking down the polypropylene fibers and other solid waste generated from packaging and production using incineration plants. Medical waste is collected, disinfected, and sealed in separate bins and then transported to incineration plants (Selvaranjan). Incineration plants are utilized in place of natural degradation processes, as polypropylene can take more than 25 years to degrade (Kilmartin-Lynch et al). Disposal can discharge toxins such as vinyl chloride and dioxins, and the incineration plans emit a lot of carbon as an intense amount of heat energy is required in this process (Selvaranjan). In addition, some N95 masks are not disposed of properly and end up being littered in oceans, which can lead to its breakdown into hazardous microplastics from processes of photodegradation and weathering (Selvaranjan). This can leave marine environments exposed to a variety of toxins and organic contaminants released by plastic pollution, leading to ingestion and possible death (Selvaranjan). It was estimated that 1.56 billion single-use masks could have entered the ocean in 2020, resulting in up to 6,240 tons of plastic pollution (Life Cycle Initiative). Accumulation of N95 masks can have disastrous effects on terrestrial and marine ecosystems, and lead to possible extinction of species.

Conducting a life cycle assessment of N95 masks provides insight on the environmental effects of the materials it is composed of the various production processes it undergoes, and its eventual use and disposal by consumers. As the N95 mask continues to be an important part of the implementation and maintenance of public health within our society, it vital that individuals are aware of the health impacts of a product that prioritizes the safety and prevention of illness.

By understanding the implications of the emissions and waste produced within all stages of the life cycle, it can eventually lead to new technologies and methods to reduce its environmental impact and increase sustainability.

Bibliography

Alsabri, Amzan, et al. “Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region.” Polymers, vol. 13, no. 21, Nov. 2021, p. 3793, https://doi.org/10.3390/polym13213793. Accessed 7 Feb. 2023.

Atilgan Türkmen, Burçin. “Life cycle environmental impacts of disposable medical masks.” Environmental science and pollution research international vol. 29,17 (2022): 25496- 25506. doi:10.1007/s11356-021-17430-5. Accessed 28 Feb. 2023.

Henneberry, Brittany. “How to Make N95 Masks.” Thomas, https://www.thomasnet.com/articles/plant-facility-equipment/how-to-make-n95-masks/. Accessed 6 Feb. 2023.

“Is Polypropylene Bad for the Environment?” Our Endangered World, 28 Nov. 2021, https://www.ourendangeredworld.com/eco/is-polypropylene-bad/. Accessed 7 Feb. 2023.

Kilmartin-Lynch, Shannon et al. “Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete.” Journal of cleaner production vol. 296 (2021): 126460. doi:10.1016/j.jclepro.2021.126460. Accessed 11 Mar. 2023.

Kumkrong, P et al. “Evaluation of hydrogen peroxide and ozone residue levels on N95 masks following chemical decontamination.” The Journal of hospital infection vol. 111 (2021): 117-124. doi:10.1016/j.jhin.2021.02.018. Accessed 3 Mar. 2023.

Selvaranjan, Kajanan et al. “Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions.” Environmental Challenges vol. 3 (2021): 100039. doi:10.1016/j.envc.2021.100039. Accessed 3 Mar. 2023.

“Single-Use Face Masks vs. Reusable Face Masks: Which Are More Eco-Friendly? - Life Cycle Initiative.” Life Cycle Initiative , UN Environment Programme , 7 Mar. 2022, https://www.lifecycleinitiative.org/single-use-face-masks-vs-reusable-face-masks/. Accessed 7 Feb. 2023.

U.S. Environmental Protection Agency. Petroleum Refineries Sector, U.S. EPA, 2013, https://www.epa.gov/sites/default/files/2016-11/documents/refineries_2013_112516.pdf. Accessed 11 Mar. 2023.

Wijayasundara, Mayuri. “Millions of Face Masks Are Being Thrown Away during COVID-19. Here's How to Choose the Best One for the Planet.” The Conversation, 11 Oct. 2020. Accessed 5 Mar. 2023.