Design Life-Cycle

assess.design.(don't)consume

Zhixiang Zeng

Des 040

12/4/19

Tesla material

The manufacture and production of Tesla cars is an intricate process that requires the production of different parts from different raw materials, which are sourced in their naturally occurring states, then processed and assembled to make the car. Indeed, there are many materials different parts that go into making Tesla cars (Cogdell). Each of these materials has the embodied energy which is the amount of energy that was used in the manufacture of these materials. Furthermore, some of these materials can be recycled and reused to form other products. Nevertheless, the production and the eventual disposal of these parts lead to the creation of wastes a factor that necessitates proper waste management.

The Tesla car

The exquisite interior of the Tesla car is made up of different materials that are meant to perform various functions. The seats, for instance, and much of the interior are covered by cowhides which are sourced directly from large scale farmers and processed before they are used in the manufacturing process (Cogdell). Furthermore, there are electric cables inside the car that are used for the transmissions of the electrical signal to the various parts of the cars as needed. This is usually bought from different suppliers both inside and outside the united states. Also, part of the structure of the car is made up of the carbon fiber, while the chassis is made up of boron steel, bauxite, and to some extent, bauxite aluminium. Moreover, the cars use tires manufactured from rubber that is made form both synthetic and natural occurring rubber (Cogdell). The company sources its batteries from Panasonic, and they contain cathodes, anodes, and electrolytes.

The embodied energy of these products includes seventy-five thousand tons of lithium hydroxide. The company also sources approximately one hundred and ten thousand coated spherical graphite and more than twenty-one thousand tons of cobalt needed for all its demand in the production process. The extraction of these raw materials produces emissions. For instance the mining process of aluminium is dangerous because if the miners are exposed to the natural product, they may develop health complications such as dementia, and if these waste products such as the dust from such mines enter water bodies which are also used by communities as a source of drinking water, the pollutant might lead to development of bath defects in women (Hettich and Stewens 760).

After the careful acquisition of raw materials from their naturally occurring state, they are processed and modeled into types that can now be mixed or formed into parts which can then be assembled into the Tesla car. For instance, the aluminium has to be rolled and mixed with iron to form an aluminium alloy. However, according to records from tesla, some of the manufacturing processes and sources of supply of other materials in the formulation stages of the raw materials are company secrets that cannot be disclosed.

The second process of manufacturing the raw materials and distribution to the various assembly points of the tesla company in various parts of the world is costly and leads to the development of a carbon footprint on t multiple components and the tesla car in general. For instance, the tesla assembly in Europe requires that sixty percent of all the parts must come from the northern part of the US (Cogdell). The cost of transporting these materials costs approximately one thousand dollars per car. Furthermore, through the use of air transport, Tesla accounts for the production of 1.7 pounds of carbon dioxide for each mile per ton of Tesla parts. If the transportation is done through the sea, land, and the trains, the emissions are 0.09 pounds, 0.4 pound, and 0.23 pounds, respectively (Cogdell).

The production of Tesla parts is done in factories that have embraced new technology and efficient production technology. This has been done to limit the output of the waste product within this process. For instance, the company has installed an automatic and highly efficient lighting system that can reduce carbon emissions. The use of robots is also crucial because they increase efficiency in the assembly line and eliminates any possibility of wastage as a result of human error or inefficiency (Cogdell). Furthermore, the company is in the process of building its battery manufacturing center, a process that will see the reduction of the embodied energy on the car battery and the use of natural sources of power in the factory.

After the assembly of the car is complete, the sales and transportation process begins to different client destinations depending on the order made through the company’s website. At the moment, the company only has four showrooms in the US, and when a car is purchased, it has to be transported by road to the various destinations in the united states (Cogdell). Indeed, the cost of shipping is inclusive in the overall price of the whole car. This, therefore, increases the energy embodiment of the overall car.

The main production cost of the various parts of the is car usually skewed to the production of lithium batteries which consume an estimated thirty-five-gigawatt hour of electric power every year (Pillot). The consumption of electrical energy does not end with the manufacture of the car, but in the whole cause of the car’s lifetime, Tesla cars consume more energy through the charging of the battery for driving and for powering other car utilities such as the radio, lighting and the sensors among others.

The fact the company manufactures all its cars in California causes the emission of a considerable amount of CO2, especially in the process of transporting the cars to the showrooms and to the different clients who have ordered the same cars in various states (Pillot). The transportation process is usually done through the road by the use of trucks a process that leads to the consumption of millions of liters of gas and the production of greenhouse gasses. Indeed, the transportation of these cars to other parts of the world other than the United States is not only expensive but also a cause for emissions of litters of greenhouse gases in the process.

There are various materials and components in Tesla cars which can be recycled or reused. This includes parts such as the charging systems and the electric cables found within the car. Furthermore, different parts of a Tesla car can be resold as parts to other car owners as a spare part (Cogdell). The solar panels that are used in the generation of electric power at the different charging stations can also be reused for the generation of electricity in other parts of the production process inside the company. They can also be sold to individual users and recycled for the manufacture of different solar panels.

Tesla cars use lithium batteries, which are electrically powered. Henceforth in its lifetime, the car can consume a massive amount of energy power depending on the level of use (Cogdell). However, concerns over the durability of lithium batteries is a significant issue to consumers of electric cars. For instance, in Tesla, the battery is usually good for the first fifty thousand miles, but afterward, the capacity of the battery to retain energy tends to decline at a fast rate (Cogdell). This, therefore, means that the company has to continue producing more batteries in case the user needs to change their car batteries. In doing so, the embodied energy of a tesla car in the course of its lifetime might be higher than projected. Even though the car itself does not produce emissions, it still uses electricity, which is produced through the burning of fossil fuels such as coal and petroleum products.

The recyclable parts of a tesla car include ten percent of the battery, parts made of steel, and rubber. Furthermore, the rare metals that are found in different components within the car such as cobalt and nickel can also be recycled (Cogdell). The owners of tesla are also able to resell or trade-in their older batteries for new ones, and in the process, reduce the embodied energy of their cars as opposed to disposing of entirely, and therefore cause an environmental hazard. Also, plastic parts in the car are usually not able to be recycled, and thus they are generally disposed of in a landfill.

Eventually, written-off Tesla cars that can no longer be scavenged for any recyclable parts are often shredded and deposited in land-fill. This predisposes the organism such as marine and land animals, to the dangers of these waste materials. Tesla cars are built to last for a maximum of ten years, after which they should be recalled for disposal by the company (Cogdell). It is impossible to determine whether all the customers will ever return their cars after ten years as some might still be using them past this time, and some might not have used their cars as much to necessitate their disposal. In the case where the cars are shredded, the batteries have to be dismantled further to avoid explosions. This process releases chemicals to the environment as emission.

The manufacture of Tesla cars is a process that involves the mining of raw materials, processing of the same, and formation of parts to be assembled into a complete car, a process that is costly in terms of energy. Furthermore, the whole process involves the emission of carbon dioxide gas into the environment which then causes global warming. Even though some parts of the car can be recycled, it is impossible to clearly state how effective has been the recycling of these parts from the different parts of the car that have been retrieved during the shredding process. For those parts which cannot be reused or recycled, they are disposed of in landfills, which then becomes environmental pollution. Tesla has however tried to minimize their dependency on electricity in the manufacturing process. However, the cars themselves use a lot of power over their ten-year lifecycle.

Works Cited

Cogdell, Christina. “Tesla Model S - Design Life Cycle.” Design Life Cycle, 2016, http://www.designlife-cycle.com/tesla-model-s

Hettich, Erwin, and Günter Müller-Stewens. "Tesla Motors. Business Model Configuration." (2017): 759-774.

Pillot, Christophe. "Lithium-ion battery raw material supply & demand 2016–2025." Proceedings of the Advanced Automotive Battery Conference, Mainz, Germany. Vol. 30. 2017.

Liangquan Yu

DES 40A

Final Project

Life Cycle of Tesla----Waste and Emissions

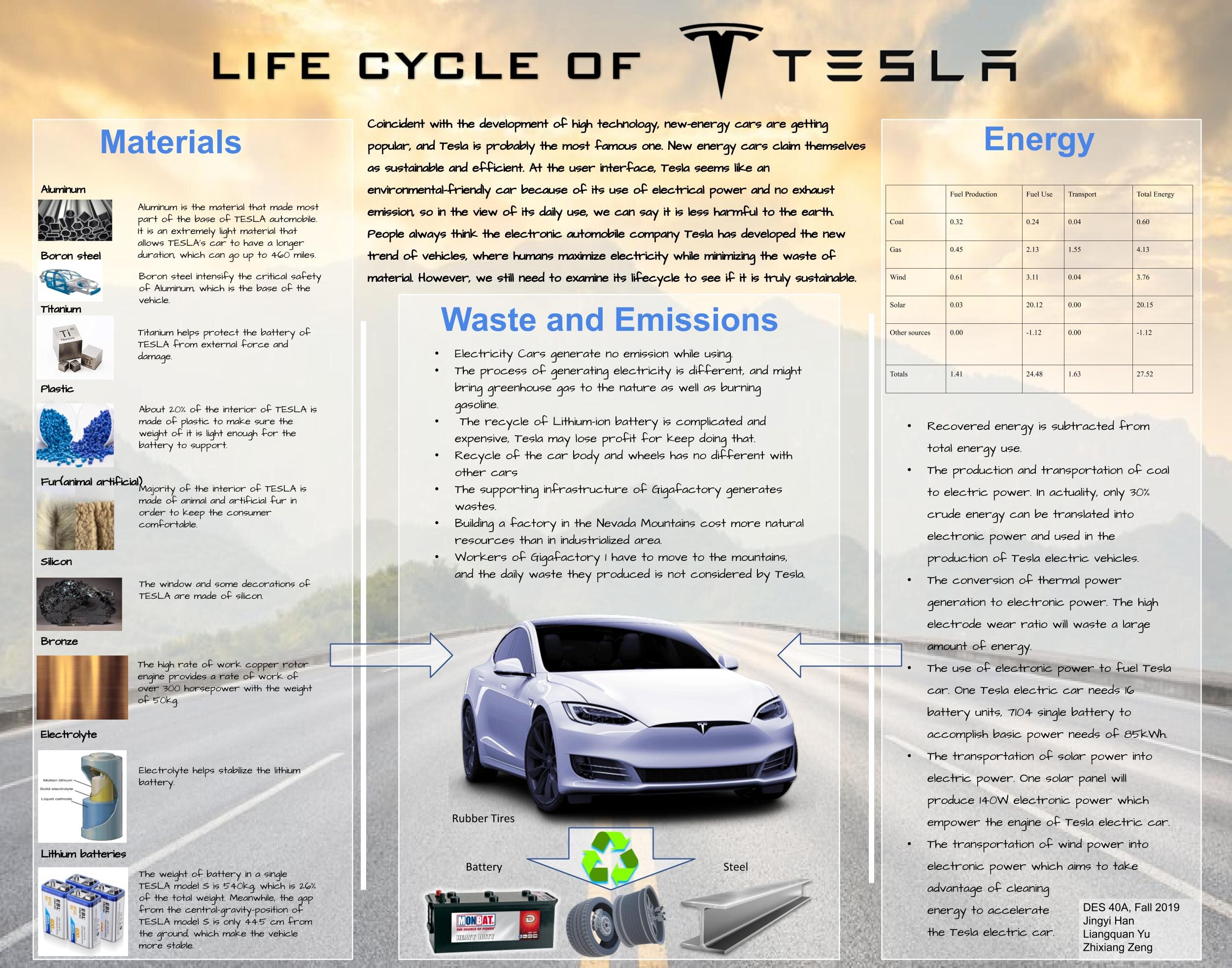

Coincident with the development of high technology, new-energy cars are getting popular, and Tesla is probably the most famous one. New energy cars claim themselves as sustainable and efficient. At the user interface, Tesla seems like an environmental-friendly car because of its use of electrical power and no exhaust emission, so in the view of its daily use, we can say it is less harmful to the earth. For example, electric cars are never prohibited in any traffic system and are especially welcomed in some air-polluted areas due to the use of new materials, and clean energy. People always thing the electronic automobile company Tesla has developed the new trend of vehicles, where humans maximize electricity while minimizing the waste of material. However, by considering its producing process and waste from the factory, we cannot fully agree that it is a totally green car. In fact, the producing process of the car and the battery may produce as many wastes as producing a traditional car did. Tesla has always depicted an environmental-friendly image of its company, which needs to be carefully reconsidered in this paper to the aspect of waste.

We have to admit that Tesla is doing well on reducing traffic exhaustions on road and its factories are powered by solar panels, which is also green methods. These green features are already well-known by people since the news is always bragging that company. However, what we ignored is that Tesla is a company instead of an environmental organization, and what they pursue is profit., which decided that when there is a conflict between building a new factory to increase output or keeping its scale to protect the environment, it always chooses the first one. For example, Tesla always tries to expand its market and increase its production, which may not coincide with the principles of sustainable. It is producing 360,000 cars per year, and E. Musk still wants more. The Giga 3 was built in 2019 in Shanghai, China, despite the city of Shanghai can hardly accept more manufacture. Also, speaking of waste, it is also not as sustainable as we think.

To begin with, we found that its factories may have some easily-ignored waste. When talking about the waste of a car, people would always focus on the emissions and recycle of its materials. However, the producing and supporting process were always ignored by people, and the overuse of natural resources is also another kind of “waste.” Its factories are propagandized by the Tesla website and some reports. The biggest one, Gigafactory 1, built during 2014-2017 in Sparks, Nevada, was a new building in the desolate mountains and was a trouble from its birth. Giga is making batteries and other accessories of Tesla, and the assembling factory puts them together. Both of them have several problems and Giga is even worse.

First, it destroyed the natural landscape in the Nevada mountains. Although the land in northern Nevada is cheap, it does not mean humans can buy cheap resources from nature. The unique sparse forest-grass landscape there was largely removed for huge factories and supporting facilities, and this is a waste of natural land resources. As it is built in that land with harm to the surrounding landscape, the building itself should be considered as a waste to the environment.

Furthermore, building such a big factory needs a lot of raw materials such as steel and glasses, which are not locally produced. Transportation of these materials is also a waste of manmade resources. It is transporting 1000 car battery sets by truck from Giga in Nevada to the assembling line in Bay Area, which is a 5-hour drive. It is an unsustainable way to transport like this and the emission of trucks is a problem to the passing area. Furthermore, some workers do not live in the barren land around the factory, they may live in Reno, Carson City or even further places. The traffic these workers have to take would also have bad exhaustion to the air, since there are too many workers (13000). If such a factory was built in a developed industrial area, or near the assembling factory in Fremont, CA, it can avoid a lot of transportation and redundant construction.

Third, the daily waste of the workers living there should be considered. Gigafactory 1 is going to be the biggest building in the world, but unfortunately, it is not a multi-purpose building. Multi-purpose building is not wildly suggested by LEED (Leadership in Environmental and Energy Design), which means the building can hold people for work and life in the same place as well as deal with the recycle reuse of different waste itself. However, the factory with 13000 workers cannot provide any other function besides producing car accessories, and workers there have to deal with their own life. According to Anjanette Damon, USA TODAY, from straining local emergency responders to exacerbating the region's critical housing shortage and taxing area roads, Tesla has brought a host of complications to the region. A large number of workers will lead to a large number of new construction houses/residence halls and increase daily waste in these little towns. Because of its distance to major cities, the daily waste may not have a good place to be recycled and reused, so that the arid inland has to deal with these wastes from the 13000 workers itself. Burning or landfilling all seems like an inappropriate way for these new towns. These invisible constructing and daily waste are never mentioned by Tesla and the major reports.

The second point is that, as it is using electricity, which is secondary energy, its pollution largely depends on how the electricity is generated. Under certain circumstances, Tesla can generate more the amount of greenhouse gas emissions than vehicles running on gasoline or diesel. For example, according to Chrissy Sexton from Earth.com, for charging stations that are used in many regions such as Britain, however, much of the electricity is still being generated by coal-fired power plants. Also, in China, where the government is advocating electrical cars, the most city is using fire plants, with unqualified coal and low-standard exhaustion treatment. Under such a situation, an electric car can produce more greenhouse gas (CO2, SO2, NO2) than a normal vehicle, even though it is not directly exhausted from the car body.

Last but not least, all these wastes I listed above are wastes that could be ignored by people, and are not considered by Tesla as part of their business plan. However, can the making process, which is truly considered by Tesla, stand up under scrutiny? Since the most unique part of Tesla is its battery, we would focus on it in this paragraph. Although Tesla claims that it is doing fully recycle of their batteries if they do have the ability to do so should be questioned. With more than 7000 batteries on a car, it is truly hard to control all the waste going. People should never deal with the lithium-ion battery together with other wastes. Furthermore, recycling batteries need a lot of processes and are expensive. Anode powder, aluminum, copper foil, electrolyte, separator, battery case, etc. should be moved separately, and some other waste could never be reused have to be dumped in a certain area. The things that can be reused again may not worth such a difficult treatment. Tesla is a new company and most of its batteries are still in use now. We cannot make sure if Tesla can keep the recycle work going on when a large number of batteries need to be liquidated 6-7 years later. So does the huge number of solar panels powered the factories that can be used for 20 years, they have similar harmful chemicals inside and need to be treated carefully after retiring. One interesting fact is that Tesla’s Gigafactory seems like lacking the necessary technologies to deal with the batteries producing line when something went wrong. According to Routers, In Apr 2017, chemicals for batteries spilled, and Tesla rejected the firefighters to do any other works besides clean up the land. Tesla had announced through official media that there is no harm to this leaking. However, people can feel that Tesla is hiding the truth and they may not be able to deal with such accidents.

In conclusion, Tesla is green is some aspects and not green in other points, and we cannot say it is truly better than traditional cars in all aspects. Speaking of its emission and waste part of the lifecycle, it is doing well in front of people’s eyes, but may not be the same behind the view. Many parts of its manufacturing process should be examined. We believe that Tesla can deal with its waste and emissions more carefully in the future and become the first truly eco-friendly car company in the world.

Berdichevsky, Gene., et al. “The Tesla Roadster Battery System Tesla Motors.” 16 Aug. 2006, http://large.stanford.edu/publications/power/references/docs/tesla.pdf.

Eberhard, Martin. & Tarpenning, Marc. “The 21st Century Electric Car Tesla Motors.”9 Oct. 2006, http://idc-online.com/technical_references/pdfs/electrical_engineering/Tesla_Motors.pdf.

Evarts, Eric C. “Report: Tesla-Panasonic Battery Waste Could Lead to Battery Flaws.” Green Car Reports, 23 Apr. 2019, https://www.greencarreports.com/news/1122728_report-tesla-panasonicbattery-waste-could-lead-to-battery-flaws.

Forfar, John. “Tesla's Approach to Recycling Is the Way of the Future for Sustainable Production.” Medium, 30 Aug. 2018, https://medium.com/tradr/teslas-approach-to-recycling-isthe-way-of-the-future-for-sustainable-production-5af99b62aa0e.

Ji, Fenzhu, et al. “Investigation on Performance and Implementation of Tesla Turbine in Engine Waste Heat Recovery.” Energy Conversion and Management, Pergamon, 29 Oct. 2018, https://www.sciencedirect.com/science/article/pii/S0196890418311993.

Liu, Kai, et al. “Materials for Lithium-Ion Battery Safety.” Science Advances, American Association for the Advancement of Science, 1 June 2018, https://advances.sciencemag.org/content/4/6/eaas9820. GBCI. “Tesla Factory.” TRUE, https://true.gbci.org/tesla-factory.

O'Kane, Sean. “Tesla Penalized for Violating Hazardous Waste Law at California Factory.” The Verge, 1 Apr. 2019, https://www.theverge.com/2019/4/1/18291091/tesla-epa-fine-hazardous-wastefremont-factory.

Peters, Adele. “Inside Tesla's 100% Renewable Design for the Gigafactory.” Fast Company, 16 Apr. 2019, https://www.fastcompany.com/90334858/inside-teslas-100-renewable-design-for-thegigafactory.

Sage, Alexandria., “Chemicals spill at Tesla battery factory, no serious injuries.” 17 Apr. 2017, https://www.reuters.com/article/us-tesla-gigafactory/chemicals-spill-at-tesla-battery-factory-no-serious-injuries-idUSKBN17J1SB

The Tesla Team. “Tesla’s Impact Report 2019.” Tesla, 15 Apr. 2019, https://www.tesla.com/ns_videos/tesla-impact-report-2019.pdf.

Jingyi Han

DES 40A

12/04/19

Life cycle of Tesla --- Energy

Tesla promotes the development of sustainable energy with electric cars, solar panels and integrated renewable energy solutions for homes ad companies (Chavan, 2018). However, recent research reveals that the energy used in the production of Tesla do harm to the social environment, which does not be environment-friendly as what we supposed to be. This paper will discuss challenges confronted by Tesla in producing electric vehicles and associated solutions for these challenges. In the end, a conclusion will be made to emphasize the thesis statement.

Engaged Tracking, an energy institution, reported that the production of Tesla electronic vehicles causes a relatively higher greenhouse than traditional fuel vehicles. The key problem is that electronics come from natural gasoline and coal. The translation from natural gasoline and coal to electronics costs a large number of energies. Moreover, the production of a Tesla electronic car will need electronic power, coal, and natural gasoline. In actuality, only 30% crude energy can be translated into electronic power and used in the production of Tesla electronic vehicles (Rosenheim 2018). The rest of 70% useless thermal energy will be wasted. Electronic power used in the production of Tesla vehicles will suffer secondary losses because of the complicated electronic route (Rosenheim 2018). For this, even the use of electronic vehicles will achieve zero emission, the production of electronic vehicles will not accomplish the goal of environment protection.

In general, electronic cars are considered as a good way to protect environment, especially the Tesla electronic vehicles. Tesla electronic vehicles promote zero emission and support the use of green energy. However, Tesla is facing three challenges in manufacturing electronic. First, the high electrode wear ratio in power transformation does not promote the environment protection. Specifically, the manufacturing of Tesla electronic vehicles needs electronic power which comes from natural gas and coal consumption. The high electrode wear ratio will waste a large amount of energy. The consumption of natural gas and coal will lead to the waste of nonrenewable resources and air pollution (Chavan, 2018). In the long-term, the social environment will be hazarded by the carbon dioxide emission and the using up of natural gasoline.

Second, Tesla electronic cars needs electronic panels which is produced by Panasonic. The price of per battery manufactured by Panasonic is quite cheap; however, the capacity of per battery is quite low. Specifically, a battery pack of 60kWh demands 14 battery units, 5376 single battery. One Tesla electronic car needs 16 battery units, 7104 single battery to accomplish basic power needs of 85kWh (Naing 2018). There are two challenges for Tesla in using batteries. One challenge is that the use of battery will demand power transformation, which is from the consumption of coal and gasoline. Another problem is the dispose of battery. In actuality, the disposed battery will not be degraded naturally and emit harmful materials to the air. The harmful air will threaten human health and ecologic balance in the long end.

Third, Tesla is suspected producing a kind of electronic vehicles that suffers excessive emission. To be specific, Tesla Model S does excessive emission in Singapore. Local department of environment protection reported that Tesla Model S will consume 444 Walt electronic power per hour. Per kWh equals 0.5-gram carbon dioxide. For this, one Tesla Model S will consume 222-gram carbon dioxide (Naing 2018). Local department of environment protection in Singapore indicates that Tesla Model S belongs to heavy pollution, as it emits more carbon dioxide than traditional gas car. Tesla electronic vehicle adopts cleaning energy in manufacturing; however, the production of cleaning energy and the manufacturing of the environmentally friend car results in a serious environment concern.

As for above three challenges faced by Tesla, some solutions may be useful. First, the manufacturing of Tesla cars can adopt lower electronic power by using cleaning energy. For example, the use of cleaning energy such as wind energy, water energy, and solar energy will be a good way to support environment protection. Meanwhile, the waste of cleaning energy will cost less than that of consumable energy. The manufacturing factories of Tesla cars are suggested to install solar panels to collect solar energy (Chavan, 2018). The natural energy will do good to social environment in the long time.

Second, batteries used in the production of Tesla electric vehicles should be renewable and degradable. Tesla company should do serious research and development in batteries. For this, the batteries can be renewable and do less harm to the social environment. Moreover, the efficiencies of batteries should be improved to meet the basic power needs. The batteries can be designed that collect solar power; therefore, the battery units will be able to produce more power than before. More importantly, materials used in the production should all be environment friendly.

Third, Tesla company should pay attention to the excessive emission caused by the transformation of electronic power. That is, the battery’s capacity should be enhanced so as to meet the demand of environment protection. The higher the capacity of battery, the lesser the battery the electronic car needs. Moreover, it is also important to reduce the consumption of electronic power. As such, Tesla company should do further research in saving electronic power. Less power needs will promote environment protection in the end.

1.

Based upon above analysis, it finds that the production of Tesla electronic vehicles does not being environmentally friend as what we supposed to be. In actuality, the energy used in the production will still cause environment pollution, as the power it needs comes from coal and natural gas. Not only is energy consumption important at the customer end-use side but Tesla should also ensure efficient use of energy in manufacturing. This will play an essential role in ensuring that Tesla focuses on creating vehicles with sustainable energy like electricity and solar and other renewable energy in a manner that does not harm the environment.

References

Chavan, V. (2018). Tesla is slashing its workforce by 7% to make a cheaper Model 3. International Business Times, 6(6), 14-18.

Naing, A. (2018). The Making of Tesla: Invention, Betrayal, and the Birth of The Roadster. Journal of International Business, 1(2), 53.

Rosenheim, J. (2018). ‘Road ahead is very difficult,’ Tesla CEO warns, sending stock down. Evolutionary Applications, 11(6), 845-852.