Design Life-Cycle

assess.design.(don't)consume

Neha Bagepalli

Professor Cogdell

DES 40A

16 March 2023

Lululemon Leggings - The Raw Materials

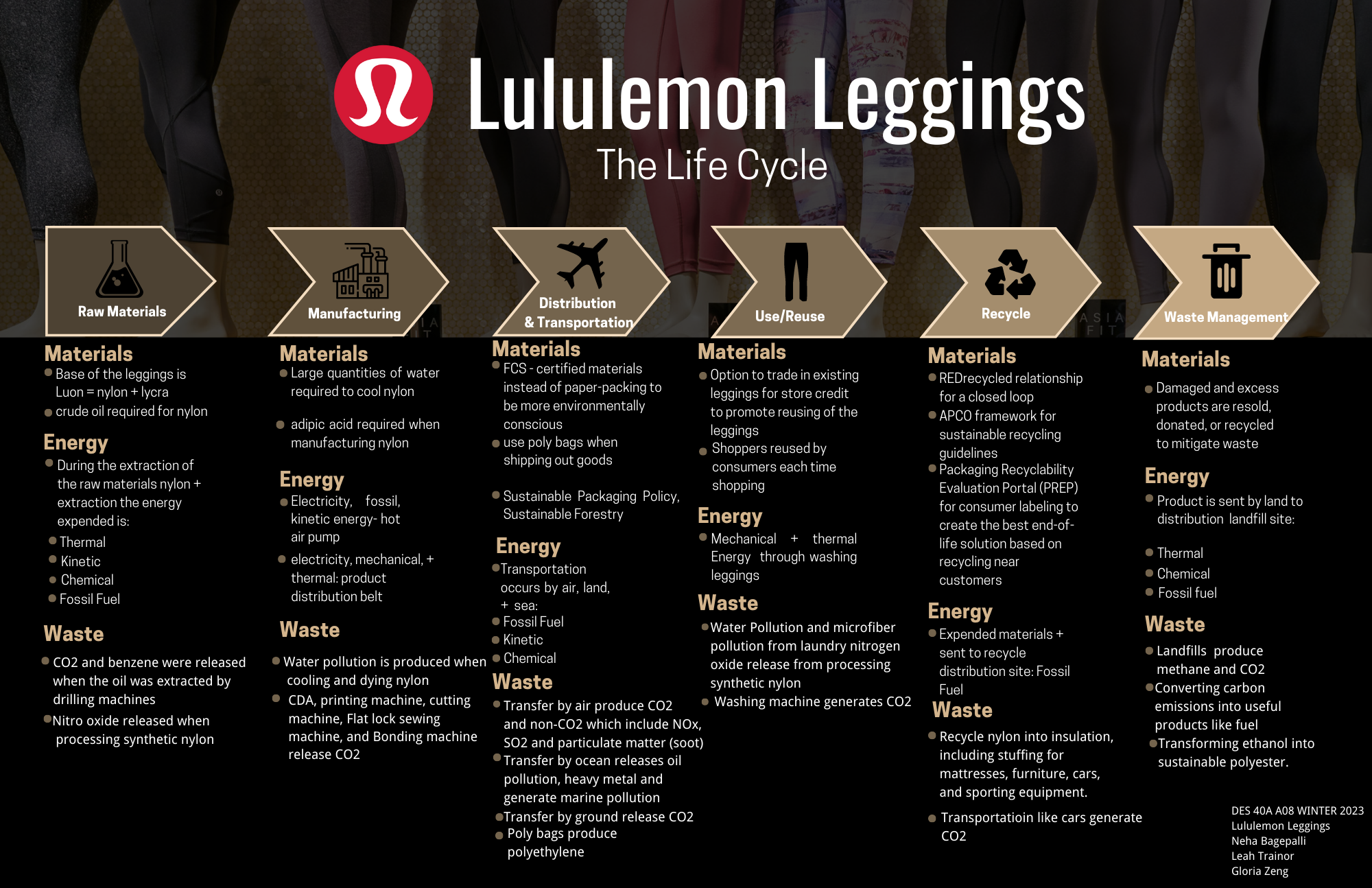

Clothing is used everyday and by everyone but many don’t even know what is in their clothing and the life it had before it came to their doorstep. Within the clothing industry, fast fashion is a growing industry that adds to major environmental problems because of the changing trends and eventually adds to the large amount of clothes already ending up in landfills (“What is Sustainable Fashion”). The ways in which fast fashion clothes are being manufactured are also extremely problematic in terms of using materials that are not sustainable and then causing lasting effects on the environment (“What is Sustainable Fashion”). Of these brands within the clothing industry contributing to environmental damage is Lululemon which is a technical athletic apparel brand (“About Us - Lululemon.”). Lululemon claims to be a sustainable company using green methods to manufacture their products but the manufacturing process of their popular leggings is one main example of their methods being far from sustainable. When examining the Lululemon leggings, it’s important to examine all parts of the life cycle to see how the product impacts the environment when it is being produced as well as after production. Lululemon, a well-known sports brand that sells popular leggings, is important to study, specifically in each stage of the life cycle, to conclude its overall environmental impact.

The raw materials required when making a product speak volumes about how environmentally friendly the product ends up being and so looking into the materials for Lululemon leggings starts the process to examine its environmental impact. The main material used in Lululemon leggings is Luon, which is a blend of nylon and lycra. These materials are blended in various forms to create different types of leggings at Lululemon which include Lextureme, Nulu, Nulux, Everlux, and others which are all made of different amounts of the Nylon and Lycra blend (“Our Fabrics - Lululemon.”). Nylon is made of synthetic polymers that are commonly used to make a variety of different types of apparel (Sewport. “What is Nylon Fabric:”). Since Nylon is fully synthetic, it has no basis of organic material and is not possible to fully recycle but can be reused in other forms. Nylon is made in a process that involves the extraction of diamine acid, combining, heating, extrusion, loading, stretching, drawing, spinning, and finally finishing. Nylon specifically has a negative impact on the environment because it requires crude oil and the process in which crude oil is also extracted, through drilling and fracking, are both processes that are bad for the environment. Moreover, nylon isn’t sustainable or biodegradable which means it adds to the damage. Lycra, similarly, is a highly elastic synthetic fiber. Lycra is made in a process where it starts with the production of a prepolymer, then a chain extension reaction, diluting, extrusion, heating, twisting, finishing, and finally weaving (Sewport. “What is Lycra Fabric:”). Both nylon and lycra are synthetic materials and all synthetic materials derived from crude oil shed microfibers, that are harmful for the environment (“Lululemon Leggings: 7 More”). Overall, the base of Lululemon leggings contains nylon and lycra which can lead to long lasting negative effects on the environment.

While the materials used specifically in the leggings play an important role, it is also extremely important to examine the materials required in manufacturing the leggings. The leggings are made from Luon, a blend of nylon and lycra and only comes from one source for the Lululemon leggings, Eclat Textile Co. in Taiwan (“The History of Lululemon”). When manufacturing the product, large quantities of water are used to cool the nylon fabric fibers and once the water is used, it often carries pollutants into the hydrosphere surrounding the manufacturing location. Additionally, when producing the nylon, adipic acid is required and this is known to be 300 times worse than the effects of CO2 on the environment (Sewport. “What is Nylon Fabric:”). Similarly, when producing lycra, the other main material in the Lululemon leggings, carcinogenic chemicals are required to be used and overall this fabric leads to significant harm to the environmental health after it’s sold to consumers because of the fact that it can’t be fully recycled without causing side effects (Sewport. “What is Nylon Fabric:”). In terms of manufacturing, Lululemon’s manufacturing is distributed over 26 countries, with the US location mainly helping brands stay up to date with fashion trends with 60 Lululemon suppliers to help meet Lululemon’s product needs and 4 distributors in Vancouver, Summer, Melbourne, and Columbus (Who Manufactures Lululemon). Of the 26 countries, claims have been made that the conditions in factories throughout Asia are poor with employees that are underpaid, overworked, and in bad working conditions (Ethan). An example of these conditions impacting the production of the leggings was in 2013 when Lululemon’s black yoga leggings were recalled due to poor quality materials and manufacturing. Throughout recent years, Lululemon has been making an active effort to maintain sustainable manufacturing and has been working to monitor the conditions to improve them overall (Baalbaki).

Once the product is manufactured, transportation is the next important category to examine. During the transportation process, Lululemon uses a variety of materials and methods. When packaging their products, Lululemon uses poly bags which are the best to ship out their products, although they are difficult to recycle (2021 Annual Report). Lululemon tries to ensure that all their packaging is recyclable at the end of the life and the packaging needed is at a minimum but poly bags are still an area they are working to improve (“Packaging and Waste”). In attempts to be environmentally conscious, Lululemon has taken action to convert their existing paper-based packaging to FSC-Certified materials which are better for the environment (“Packaging and Waste”). Although the materials and production processes used by Lululemon to create their leggings aren’t as sustainable as they should be, the company has been taking an initiative to improve their practices when acquiring materials and packaging goods. Lululemon specifically follows the Sustainable Packaging Policy where they have made a promise to work with suppliers who are able to provide Forest Stewardship Council (FSC), Sustainable Forestry Initiative (SFI), or Programme for the Endorsement of Forest Certification (PEFC) supply chain certifications for their end products (2021 Annual Report).

Various materials and methods are heavily used throughout other parts of the life cycle when the product is being used, resused, and maintained. Lululemon has a program that centers around the ideas of rethink, revive, and rediscover (“Trade in Gear for Resale”). They are working to keep their clothes out of the landfill by having options to sell lightly used clothing as well as trade in offers for store credit. Unfortunately for Lululemon, Lycra doesn’t biodegrade and even if the leggings are disposed of properly, the elastane fibers break off with every wash and overall contaminate the water supply (Sewport. “What is Lycra Fabric:”). The only way to make these fabrics better is to closely observe waste management and ensure it’s happening in the best way but that level of management would require Lululemon to implement a new system (Sewport. “What is Nylon Fabric:”). Additionally, Lululemon uses shoppers which are made for customers to take home and reuse but since they are made from a mix of materials, they are not entirely recyclable (“Waste”).

Lululemon prides themselves in being a company that prioritizes recycling and works extremely closely to monitor the recycling of their products, including their leggings, and the packaging that is part of the leggings and also mitigates the amount of waste they create. To promote their sustainable practices, recycling initiatives, and regulating waste in landfills, Lululemon follows APCO which is a sustainable framework. For example, with APCO, Lululemon stores in Australia follow a REDcycled relationship which provides a closed-loop recycling option for soft-plastics and can overall increase the effectiveness of their sustainability initiatives (2021 Annual Report). Additionally, they utilize the Packaging Recyclability Evaluation Portal (PREP) to generate their own consumer labeling to conclude the best end-of-life solution based on recycling infrastructure available to consumers all over the world. Recycling is something that is very important to Lululemon and they even have a recycling rate of 86% at their distribution centers. They achieve this by re-using boxes and heavily promoting the idea of reducing packaging waste by workers when packaging various products such as their leggings (Baalbaki). Additionally, over 90% of their products which are damaged or just in excess, are either donated, recycled, or resold in order to mitigate waste (“Packaging and Waste.”).

Lululemon is a leading athletic leisure brand in the clothing industry. While their clothes, specifically their leggings, are extremely popular, many don’t know about the methods required to produce these leggings. After close inspection, it is evident that Lululemon is attempting to implement sustainable practices but the root of some of their materials lead to irreversible damage to the environment. It’s important to educate the public about the environmental harms certain products can cause so consumers can make more informed decisions. In the future, knowing that Lululemon leggings are not as environmentally friendly as the company claims, will influence consumers' habits. It’s important that companies, such as Lululemon, continue working towards environmentally sustainable mechanisms and methods to avoid perpetuating the cycle of environmental harm.

Works Cited

2021 Annual Report & Action Plan. 11 Apr. 2021, https://corporate.lululemon.com/~/media/Files

/L/Lululemon/our-impact/reporting-and-disclosure/2021-lululemon-impact-report-final-

3-09-22.pdf.

“About Us - Lululemon.” About Us | Lululemon Athletica, https://info.lululemon.com/about.

Baalbaki, Sally, Debora J. Gilliard, and David L. Hoffman. "Is Lululemon Athletica's

Turnabournd Sustainable?" American Journal of Management, vol. 19, no. 2, 2019, pp. 26-39. ProQuest, https://www.proquest.com/scholarly-journals/is-lululemon-athleticas-

turnabournd-sustainable/docview/2264109561/se-2.

Ethan. “Where Is Lululemon Made 2023 & Who Makes Lululemon?” MadeFind.com - Know Where Your Products Made, 30 Jan. 2023, https://madefind.com/where-is-

lululemon-made/#where-do-lululemon-materials-come-from.

“The History of Lululemon.” Prezi.com, https://prezi.com/s3pa9jjvmiub/the-history-of-

lululemon/.

“Lululemon Leggings: 7 More Sustainable Alternatives We Love.” Good On You, 17 Nov. 2022, https://goodonyou.eco/alternatives-lululemon-leggings/.

“Our Fabrics - Lululemon.” Our Fabric + Technology | Lululemon France, https://www.

lululemon.fr/en-fr/c/mens/product-guides/our-fabric-and-technology.

“Packaging and Waste.” Packaging and Waste | Lululemon Athletica, https://info.lululemon.

com/sustainability/our-footprint/waste.

Sewport. “What Is Lycra Fabric: Properties, How Its Made and Where.” Sewport, Sewport, https://sewport.com/fabrics-directory/lycra-fabric.

Sewport. “What Is Nylon Fabric: Properties, How Its Made and Where.” Sewport, Sewport, https://sewport.com/fabrics-directory/nylon-fabric.

“Trade in Gear for Resale.” Lululemon, https://shop.lululemon.com/story/like-new.

“Waste.” Waste - Lululemon, https://www.lululemon.com.hk/en-hk/content/waste/waste.html.

“What Is Sustainable Fashion?” REDRESS RALEIGH, https://www.redressraleigh.org/

sustainable-fashion?gclid=Cj0KCQjwtsCgBhDEARIsAE7RYh2M9gCuVdMQcof_O_

RC5yz1jdqUAkSt70l0YeCVThpTf7npVcnFsaAmrfEALw_wcB.

Who Manufactures Lululemon? - Fashinza. https://fashinza.com/textile/who-manufactures-

lululemon/.

Leah, Trainor Gloria & Neha

DES 40A

Professor Cogdell

Word Count: 1675

Energy of Lululemon Leggings

Introduction:

Lululemon legging’s growing popularity and global outreach, raises the question of whether or not this product’s energy process is sustainable for our environment. Is the energy that goes into Lululemon leggings sustainable or are Lululemon leggings adding to the climate crisis we are faced with today? This can be determined through the dissection of the energy that goes into each stage of lululemon legging’s lifecycle. There are many different types of embodied energy that make up Lululemon leggings' life cycle. From the extraction of natural materials to the shipment of the final leggings, this process uses an abundance of energy, which can have a negative impact on our environment. Within the process of extraction, production, and transportation of lululemon leggings, the energy use is unsustainable. The coal input required for at every stage of Lululemon leggings contributes to significant portions of its environmental impact, however this also presents opportunities for improvement through transitions from coal to solar, natural gasses, or biomass as a natural energy source.

Extraction of Raw Materials Embodied Energy:

Lululemon states that they are a sustainable minimal material athleisure brand and are backed up by a wide spread outreach. Due to this widespread outreach and mass production of its leggings it is imperative to decipher what the environmental impacts that this product has on our world. Although some have studied this topic, there is a significant lack of collective resources discussing the embodied energy that goes into each phase of this product's life cycle that could show this product’s in depth analysis on its sustainability and environmental impact.

When looking into the embodied energy that Lululemon Leggings consists of, it is important to start from the beginning of their life cycle. In the early developments of this product the raw materials must be extracted and transformed into the materials that make up the leggings. Lululemon’s process to this begins in Poland or Ukraine where they use a mining process that allows them to extract the chemical, petroleum from the earth with a drill. This drill uses coal to extract the raw chemicals used to make lycra that makes up the spandex in the leggings. The macroglycol and diisocyanate are combined by heat to create the elasticity within this spandex material. The overall process of extracting these two raw materials uses thermal and kinetic energy. Twenty-two percent of lululemon legging’s carbon footprint is due to the extraction of these raw materials. Once these materials are extracted they are then transported by land, sea, and air to begin the manufacturing process. Although the length of this process is unknown, greenhouse gasses are constantly emitted making it harmful to our environment.

Manufacturing Embodied Energy:

Despite this brand claiming that they are a sustainable company and that they use minimal energy, the manufacturing process of Lululemon leggings that use an abundance of coal that emits greenhouse gasses into the environment adds to the climate crisis that our environment is faced with today. The use of coal can be seen in the early stages of this process. The manufacturing process of lululemon leggings emits the most greenhouse gasses out of the life cycle of this process. It is responsible for twenty-five percent of the gasses emitted. The manufacturing process of lululemon leggings takes up Once the raw materials are shipped to the factory, they undergo a dry spinning process that uses a pump and hot air to spin the raw materials into fabric and thread. Although there is a lack of information on the amount of time this process takes, this process has a significant negative impact on our environment due to the emissions from the coal used to heat the hot air to spin the raw materials lycra and nylon. “Both of these are fossil fuels and when heated produce multiple greenhouse gasses. Specifically nylon and Lycra’s manufacturer produces nitrous oxide (N2O), a greenhouse gas 310 times more powerful than carbon dioxide(C02)”(Kalpazanova). The coal that is burned to create these raw materials contributes significantly to the carbon footprint of the lululemon leggings.

As well as this, the manufacturing process uses an abundance of electricity that powers the factory and the production process. “The energy audit conducted for lululemon athletica Polo Park found that 87% of the electricity used by the store is its light-load and that this could be reduced with more efficient lighting systems”(Horan). Because this product is in such high demand the factories use a plethora of electricity to keep up with the high demands. This creates large amounts of gasses released into the atmosphere from the coal burnt to provide electricity to the factories. “Forty-eight percent of the electricity used by factories that make garments for Lululemon in Vietnam, Cambodia and China come from burning coal, with only 5 percent coming from renewable energy according to the Vancouver based advocacy organization”(McKenna). Although the greenhouse footprint left by the amount of electricity and coal used is at a large scale, there is room for improvement to limit these negative effects these leggings have on the environment, such as switching from a fossil fuel to a natural energy source. “The company, which employs 29,000 people directly and has 240,000 working for its suppliers, told CDP it had piloted initiatives focusing on energy efficiency, and said “opportunities also exist for our raw materials suppliers to switch from coal to natural gas, biomass and/or to renewable electricity (eg onsite solar) (Reed)”. Lululemon states that they are trying to employ less gas and energy emitting techniques into their manufacturing process, however is still a lead contributor to the gas and energy emissions in the fashion industry.

Transportation Embodied Energy:

Although lululemon legging’s manufacturing process has the largest impact on our environment, the transportation and distribution process also leaves a significant carbon footprint. The distribution process of these leggings is responsible for twenty percent of lululemon leggings' carbon footprint. Lululemon distributes its leggings by land, air, and water. “Although the majority of lululemon’s products travel by sea – about 75%, the remaining percentage still results in a much higher carbon footprint due to being transported by air”(Stephensen). Lululemon brands themselves as having fast shipping for their leggings, however because of this their shipping is mainly by air, which has a significant impact on the climate. Although “With about two-thirds of our products in the United States traveling to the East Coast, our new distribution center allows us to use more ground transportation and still deliver our products to stores and guests quickly”(Lululemon). The distribution process of Lululemon leggings begins at their base manufacturing center. These base manufacturers are located in Canada, Australia, Brazil, China, Netherland, Poland, or Africa. Ater the leggings undergo the manufacturing process, they are then transported by land through truck or train. It is unknown the length of this process, however after they reach their second distributor they are shipped overseas through air or sea. This distribution process contributes to the negative environmental impacts due to the gas emitted.

Conclusion:

Lululemon leggings are backed by a large following of consumers each year, which is why it is important to dissect the sustainability of this product's life cycle. Lululemon makes many claims on their website to being an energy efficient and sustainable company, however the gasses emitted throughout this lifecycle of their leggings argues differently. Lululemoon’s leggings main energy source is nonrenewable and adding to the climate crisis we are faced with today. Within the extraction of the raw materials, lululemon leggings use fossil fuel gasses by burning coal to be able to drill and mine for the chemicals used to make the lycra. Lululemon leggings also use fossil fuel in their manufacturing process through the burning of coal to keep their factories running and up with the mass demand of their leggings. As well as this, Lululemon uses fossil fuels through the burning of coal throughout their transportation process. Although lululemon states that they are sustainable they are using nonrenewable energy sources that have a large carbon footprint. Lululemon leggings leave behind a significant carbon footprint that is contributing to climate change. However, through the research and discovery of this product using a large amount of non reusable energy, it opens up a question for how this company could improve the energy they use to make this product. Instead of using fossil fuels, this company can make a change to limit their carbon footprint by using natural gasses such as biomass, solar, or natural gas energy sources.

Bibliography:

“Hundreds of Yoga Teachers Call out Lululemon over Coal-Powered Factories.” The Guardian, Guardian News and Media, 14 Sep. 2022, https://www.theguardian.com/environment/2022/sep/14/hundreds-of-yoga-teachers-call-out-lulule mon-over-coal-powered-factories.

Energy + Carbon, https://www.lululemon.com.hk/en-hk/content/energy-and-carbon/energy-carbon.html.

T, Renay, and Logan Hailey. “Everything You Need to Know about Lululemon: Is It Worth It? History, Community, Lingo, + More.” The Yoga Nomads, 28 Nov. 2022, https://www.theyoganomads.com/lululemon/.

Horan, Mary Rebecca. “Where's the Buzz? Why No One Is Talking about Lululemon Athletica's Sustainability Initiatives.” MSpace Home, 11 Apr. 2011, https://mspace.lib.umanitoba.ca/handle/1993/4510.

YouTube, YouTube, 7 Mar. 2017, https://www.youtube.com/watch?v=QQYjTXj89Yw. Accessed 8 Feb. 2023.

YouTube, YouTube, 6 May 2021, https://www.youtube.com/watch?v=zA5o8zse-DM. Accessed 8 Feb. 2023.

“How Ethical Is Lululemon?” Good On You, 11 Oct. 2022, https://goodonyou.eco/how-ethical-lululemon/.

Trainor 6

says:, Paisleigh Crystal, et al. “Transport.” Commodity Chain Project Lululemon Athletica, https://u.osu.edu/commoditychainlululemon/transport/.

“Environmental Impacts.” Environmental Impacts | Lululemon Athletica, https://info.lululemon.com/sustainability/responsible-supply-chain/environmental-impacts.

SeventhQueen, and Jared Wolf. “Better Brands: Is Lululemon Sustainable?” Sustainable Review, 6 Feb. 2023, https://sustainablereview.com/is-lululemon-sustainable-brand/.

“The Life Cycle Analysis of Lululemon ‘Wunder-under’ Leggings.” Prezi.com, https://prezi.com/bi0fn44ptpny/the-life-cycle-analysis-of-lululemon-wunder-under-leggings/.

Kodas, Michael. “Lululemon's Olympic Challenge to Reduce Its Emissions.” Inside Climate News, 21 Apr. 2022, https://insideclimatenews.org/news/04022022/carbon-bomb-lululemons-olympic-emissions-cloth es-manufacturing/.

Corporate.lululemon.com. https://corporate.lululemon.com/~/media/Files/L/Lululemon/our-impact/reporting-and-disclosure/ lululemon-2021-full-impact-report-final.pdf.

Gloria Zeng

Professor Cogdell

DES 40A

16 March 2023

Lululemon Essay Waste and Pollution

Lululemon is a well-known sports-leading athleisure brand that sells famous leggings under the three pillars of the three-impact agenda—Be Human, Be Well, and Be Planet (Lululemon 2021 Impact Report 9). In this essay, we will mainly focus on the Be Planet, which lululemon aims to use their legging and actions to avoid environmental harm and contribute to restoring a healthy planet (Lululemon 2021 Impact Report 9) and to examine the life cycle of six stages of lululemon.

Suppose Lululemon wants to achieve the Goal of Be Planet. In that case, they need to consider waste and pollution throughout the life cycle of making lululemon leggings while reflecting and improving on the existing problems.

Even though lululemon's legging is always known for being environmentally friendly, people ignore the pollution produced at the stage of raw material acquisition which should be noticed. Luon is the central element of making lululemon leggings composed of 86 percent nylon and 14 percent Lycra (Enjoli). Nylon is extracted from petroleum, the primary material for making leggings. Petroleum is found underground, either beneath land or ocean. Miners extract petroleum using a drilling machine. The electric drill converts electricity into mechanical energy using an electric motor. As the drill bit bites into the material drilling, the mechanical energy is converted into heat energy. The drilling process generates lots of pollution, such as fueling climate change, disrupting wildlife damaging public lands, and earthquakes disrupting our planet (7 ways oil drilling). This has a severe impact on our wildlands and communities. What's more, during the drilling process, some air toxic like benzene will be released, which creates air pollution. Benzene is known or suspected of causing cancer, particularly leukemia and other cancers of blood cells, and other serious health effects. Hence, the human labor condition of extracting petroleum is a big concern since miners are exposed by breathing in benzene and absorbed through the skin during contact with a source such as gasoline (7 ways oil drilling). In fact, of the 22 leukemia deaths, 15 occurred among workers with benzene exposure. After extracting the primary material, petroleum, the scientist will use it to make secondary raw material, synthetic nylon. Making synthetic nylon requires a sequence of chemical processes, and producing nylon creates nitrous oxide, a greenhouse gas 300 times more potent than carbon dioxide. What's more, manufacturing nylon requires large amounts of water to cool down the fiber, which can be a source of water pollution. After getting all the raw materials to make nylon, they go into the manufacturing process.

Manufacturing is the most significant contributor to waste and pollution of the entire legging life cycle because manufacturing nylon is a very energy-consuming process that contributes to environmental degradation. According to lululemon's 2021 Impact Report, the carbon footprint produced by the manufacturer is 25% of the entire life cycle. The overall leggings manufacturing process includes six stages: patterning, digital print, auto cutting, sewing, hem bonding, and transportation. The first process is patterning. In this stage, designers use laptops to break the garments into different panels by CAD. This process produces a large amount of CO2 since laptops are the energy-intensive product. Both producing and using it require much energy, generating a large carbon footprint of 422.5 kg for each device. The second stage is digital printing. Lululemon's supplier fabric cutting team uses the CAD provided by the pattern engineer. Then they will print out the pattern, then cut it (Leggings manufacturing process). The cutting and printing machines are powered by steam engine turbine which burns coal, generating air pollution. Next, much water is needed when dying the nylon, which creates tremendous water pollution. The toxic chemical compound from nylon carried in the water will flow worldwide and end up being consumed by humans and animals, which is one of the reasons which creates illness, infection, or even death of animal life. The third stage is auto-cutting. The auto-cutting machine is a cutting plotter. Since the auto-cutting machine combines a computer and a steam-powered machine, it generates twice as much CO2 as the previous two stages. Then is the sewing process. Sewing machines include a flat lock sewing machine, three needle five thread sewing machine, etc. (Leggings manufacturing process). In the sewing process, the sewing machine motors produce fumes. These toxic particles are drawn into the air-conditioning unit and ductwork. Additionally, a toxic smog particle called PM10s forms from fumes when people breathe in. These tiny particles can cause respiratory problems, especially for industrial workers who get in touch with them frequently daily. This increases their risk of getting respiratory-related problems. The last stage is Hem Bonding. The bonding machine is powered by a steam engine, which emits lots of CO2 as air pollution. After finishing producing the products, they are really to be packaged.

Lululemon produces poly bags as their product package—however, the production process release polyethylene, one of the origins of marine pollution. Due to the color and smell of polyethylene, it often attracts aquatic animals, and when they accidentally eat it, it can trigger organ damage, apoptosis, genotoxicity, and even death (Hariharan et al., 2021; Laskar and Kumar, 2019; Tiwari et al., 2020). After packaging, the product is really to ship out. Lululemon's products are traveled mainly by air and sea, generating air, water, and marine pollution. 75% of the products are shipped by air (Cox and Stephensen). The plane flight releases not only CO2 but also non-CO2 effects due to nitrogen oxides (NOx), sulfur dioxide (SO2), water (H2O) – and particulate matter (soot) (Non-CO2 effects of Aviation). The flight contributes 10 percent of U.S. transportation emissions and accounts for three percent of the nation's total greenhouse gas (GHG) production (Environmental and Energy Study Institute (EESI). The rest of the product is shipped by ocean, one of the potent sources of pollution at sea. When final products are shipped out, they are in the store and being really to sell.

When people start to use leggings, pollution is also generated. Once synthetic nylon, the significant component of the legging, has been washed, it will bring toxic elements mixed with water leach into the environment. This is a big problem because these tiny fibers will eventually end up in the ocean. These tiny pieces add to the microplastic pollution that's accumulating in the food chain and being ingested by all sorts of marine wildlife and even humans. (Resnick). Not only does the water being washed generate waste, but the washing machine itself. In fact, washing clothes uses around 19 billion cubic meters of water annually and emits an estimated 62 million tonnes of CO2-eq greenhouse gases yearly (Langenheim). When people throw their leggings away, the legging will either be recycled or end up as waste in the landfill.

Lululemon is a leader in recycling products. So far, it has recycled 75% of the material, and the rest will be turned into other products or waste. Lululemon is partnering with their product recycling partner Debrand. They recycle 75% of recyclable leggings into insulation, including stuffing for mattresses, furniture, cars, and sporting equipment. The unrecyclable leggings are processed in a waste-to-energy facility that generates electricity (Lululemon 2021 Impact Report). Besides, they also recycle a package. Lululemon's box reuse program, in effect since 2015, saves more than one million boxes annually, and teams recycle all the soft plastics and corrugate used to transport products to their facilities. What's more, in 2021, lululemon rolled out a store recycling revamp in European in order to reduce the number of leggings that ended up in the landfill. As a result, they have successfully improved the store recycling rate from 49 percent to 84 percent, saving over 40 tonnes of waste from going into landfill yearly (Lululemon 2021 Impact Report). Besides recycling materials, lululemon is also working on recycling energy. Lululemon is partnering with New Zealand-based LanzaTech, dedicated to converting carbon emissions into valuable products like fuel. Through nature-based solutions, it generates ethanol from waste carbon sources. Along with chemical partner India Glycols and textile manufacturer Far Eastern New Century (FENC), the biotech transforms ethanol into sustainable polyester (Lululemon 2021 Impact Report). Moreover, instead of using coal to run the industry, lululemon has started using renewable energy, such as wind, to reduce carbon emissions. Wind energy is emission-free, while worldwide emissions of CO2 from burning fossil fuels total about 34 billion tonnes (Gt) per year, which contains 45% of coal (Javascript required!). However, only some of the materials and energy can be recycled, and there is no way that we can eliminate all the waste the legging generates. Hence, it is significantly essential to do an excellent job of managing waste.

Waste and management is the most crucial step to consider because it accumulates all the waste from the previous five stages that cannot be recycled and will end up as pollution. For example, since synthetic nylon can only be recycled but is not biodegradable, some of them will end up as toxic water pollution. According to the data reported by Chhabra, about 10% of synthetic nylon ended up as debris in the ocean (Chhabra). To address this problem, lululemon has set the goal to use innovative plant-based nylon biodegradable in 2030. The company claims that plant-based nylon can lower the environmental impact by 93% compared to conventional polluting fabrics (Enjoli). What's more, lululemon has a new dyeing technique that adds color pigment at the raw material stage to reduce water use and carbon emissions. This plan is expected to reduce water use by at least 75 percent over traditional methods (Lululemon 2020 Impact Agenda). While waste management reduces lots of waste from the previous 5 stages, the waste management process produces waste and should also be counted. For example, there is some waste being produced in the landfills, such as objectionable odors and landfill gas such as ammonia, sulfides, methane, and carbon dioxide which are of the most concern because they can move through soil and collect in nearby buildings, causing soil pollution (Landfill Gas). This is harmful to plants, animals, and humans as a food chain because while the plant grows, they need to absorb nutrition from the soil. However, if the soil has been polluted, the plant will absorb the toxic element in its body. And when animals or humans have consumed the plant, the toxic element will carry on. What's more, a large amount of methane has been released at the landfill. Methane is responsible for more than 25 percent of the global warming we are experiencing today. It is 80 times more harmful than CO2 for 20 years after it is released (What's the deal with methane?).

In conclusion, lululemon's concept of recycling is great and has a experience of making eco-friendly improvements. Looking forward to seeing if lululemon can go even further by 2030 to reduce waste and achieves its goal of “Be Planet”.

Work Cited

“Airplane Pollution.” Transport & Environment, 2 June 2022, https://www.transportenvironment.org/challenges/planes/airplane-pollution/.

Author links open overlay panelZhuang Yao, et al. “Environmental Toxicity and Decomposition of Polyethylene.” Ecotoxicology and Environmental Safety, Academic Press, 3 Aug. 2022, https://www.sciencedirect.com/science/article/pii/S0147651322007734.

“Benzene and Cancer Risk.” American Cancer Society, https://www.cancer.org/healthy/cancer-causes/chemicals/benzene.html.

Collins, J J, et al. “Lymphohaematopoeitic Cancer Mortality among Workers with Benzene Exposure.” Occupational & Environmental Medicine, BMJ Publishing Group Ltd, 1 Sept. 2003, https://oem.bmj.com/content/60/9/676.

Corporate.lululemon.com. https://corporate.lululemon.com/~/media/Files/L/Lululemon/our-impact/reporting-and-disclosure/2021-lululemon-impact-report-final-13-09-22.pdf.

Cumbers, John. “Bio-Nylon Is the New Green: How One Company Is Fermenting a $10 Billion Market.” Forbes, Forbes Magazine, 12 Feb. 2020, https://www.forbes.com/sites/johncumbers/2020/02/11/bio-nylon-is-the-new-green-how-one-company-is-fermenting-your-future-materials/?sh=2cf52d184030.

“Department of Health.” Important Things to Know About Landfill Gas, https://www.health.ny.gov/environmental/outdoors/air/landfill_gas.htm.

Environmental and Energy Study Institute (EESI). “Issue Brief: The Growth in Greenhouse Gas Emissions from Commercial Aviation (2019, Revised 2022).” EESI, https://www.eesi.org/papers/view/fact-sheet-the-growth-in-greenhouse-gas-emissions-from-commercial-aviation.

Ho, Sally. “Lululemon Leggings Could Soon Be Made with Plant-Based Bio-Nylon.” Green Queen, 23 Aug. 2021, https://www.greenqueen.com.hk/lululemon-genomatica-bio-nylon/.

“Javascript Required!” Carbon Dioxide Emissions From Electricity - World Nuclear Association, https://www.world-nuclear.org/information-library/energy-and-the-environment/carbon-dioxide-emissions-from-electricity.aspx.

Langenheim, Johnny. “Laundry: Lightening the Load.” Environment, National Geographic, 15 Nov. 2021, https://www.nationalgeographic.com/environment/article/partner-content-laundry-lightening-the-load.

“Leggings Manufacturing Process.” NDH, 11 Oct. 2021, https://leggingsupplier.com/leggings-manufacturing-process/.

Lululemon 2020 Impact Agenda. https://corporate.lululemon.com/~/media/Files/L/Lululemon/our-impact/our-impact-agenda/2020-impact-agenda.pdf.

“Material Guide: How Sustainable Is Nylon?” Good On You, 16 June 2021, https://goodonyou.eco/material-guide-nylon/.

“Non-CO2 Effects of Aviation.” Transport & Environment, https://www.transportenvironment.org/challenges/planes/airplane-pollution/non-co2-effects/.

“Packaging and Waste.” Packaging and Waste | Lululemon Athletica, https://info.lululemon.com/sustainability/our-footprint/waste.

“Petroleum.” Department of Energy: Energy Kids-Oil Basics, https://education.nationalgeographic.org/resource/petroleum/.

“Packaging and Waste.” Packaging and Waste | Lululemon Athletica, https://info.lululemon.com/sustainability/our-footprint/waste.

“Reducing Air Pollution from Cars.” Reducing Car Pollution - Washington State Department of Ecology,

Ruiz, Angelina. “Lululemon, LanzaTech Are Reshaping Carbon Waste into Fabric.” Waste Advantage Magazine, 27 July 2021, https://wasteadvantagemag.com/lululemon-lanzatech-are-reshaping-carbon-waste-into-fabric/.

R, Sara. “What Is Smoke from Sewing Machine Motor?” Wayne Arthur Gallery, 22 Dec. 2022, https://www.waynearthurgallery.com/what-is-smoke-from-sewing-machine-motor/.

Ruiz, Angelina. “Lululemon, LanzaTech Are Reshaping Carbon Waste into Fabric.” Waste Advantage Magazine, 27 July 2021,

says:, Paisleigh Crystal, et al. “Transport.” Commodity Chain Project Lululemon Athletica, https://u.osu.edu/commoditychainlululemon/transport/.

Singh, Bikram. “Marine Pollution by Ships -Tips for Reducing & Recycling Waste at Sea.” Marine Insight, 30 Apr. 2022, https://www.marineinsight.com/environment/marine-pollution-by-ships-tips-for-reducing-recycling-waste-at-sea/.

“What's the Deal with Methane?” UNEP, https://www.unep.org/news-and-stories/video/whats-deal-methane.

“7 Ways Oil and Gas Drilling Is Bad for the Environment.” The Wilderness Society, https://www.wilderness.org/articles/blog/7-ways-oil-and-gas-drilling-bad-environment#.