Design Life-Cycle

assess.design.(don't)consume

Niki Brzezny

Professor Cogdell

DES 40A

16 March 2023

Analysis of Stained Glass: Raw Materials

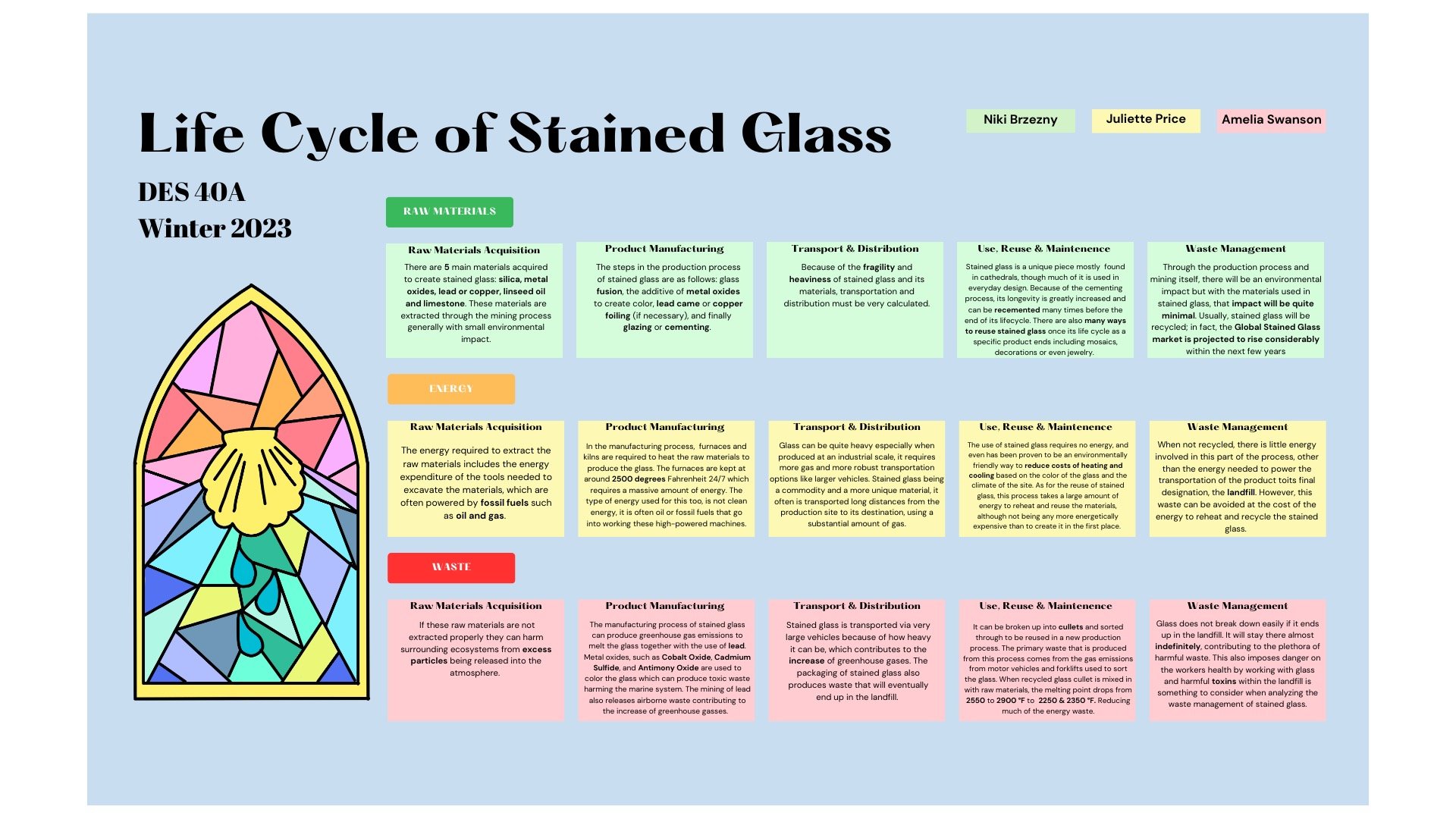

Stained glass has become a staple in many architectural structures and makings, but while it adds a touch of beauty in these scenes, architects, producers, and consumers should know how sustainable it is in our environment. After observing the life cycle of a piece of stained glass, it is important to understand the logistics behind the primary materials utilized in manufacture, how they were mined or produced and the process each goes through to complete the entire life cycle of a stained glass panel. It is understood that the materials of stained glass including silica/sand and other primary materials are generally environmentally sustainable but as a piece of glass undergoes its transformation into stained glass (a secondary material)through the addition of impurities and glazing, the level of sustainability slowly decreases. While this is true, stained glass can still be a suitable material for recycling because glass can easily be broken down and reshaped into new materials and has provided a unique touch in the world of architecture.

Knowing the history and materials of stained glass helps to better explain its life cycle after the production process is complete. According to Julie Cain’s “Stained Glass: The History, the Art and the Science”, the earliest stained glass works were created in Ancient Rome and Ancient Egypt, gaining more and more popularity in the Middle Ages. As the rise of Christianity and the Gothics peaked, so did the rise of stained glass; it was prominently used in place of walls inside cathedrals and large churches to diminish time and effort used in building thick stone walls. Not only did it introduce beauty into basic structures, but also to educate people in their own religions (Cain). Still to this day are the cathedrals standing and while their stained glass windows have been renovated or refurbished, the beginning style and sometimes original pieces of glass have been recycled (Connelly). So… how is it made?

Stained glass is a form of standard glass and is, for the most part, made up of the same materials. The first primary material that makes up stained glass is silica (which is what glass itself is made of). “Also called silica sand or quartz sand, silica is made of silicon dioxide (SiO2). Silicon compounds are the most significant component of the Earth’s crust. Since sand is plentiful, easy to mine and relatively easy to process, it is the primary ore source of silicon” says the Minerals Education Coalition (“Silica”). For this reason that silica is so easy to mine, glass (alone) will always be a plentiful secondary material to produce, thus providing plentiful resources in stained glass production. MEC also mentions that “except for temporarily disturbing the immediate area while mining operations are active, sand and gravel mining usually has limited environmental impact” (“Silica”). Because silica is the primary material used in stained glass and because of its minimal environmental impact, this first material does not pose a serious threat to the environment.

The second primary materials include the metals that chemically create the color of the glass, turning it into stained glass. Beginning with red and ending with violet, the coinciding metals, as stated by the Pittsburgh Glass Center in “What Gives Glass Its Color?”, are as follows: red=selenium-cadmium, orange=iron-sulfur, yellow=cadmium, blue=copper, indigo= cobalt, violet=manganese; if any other pure element or compound is added to these mixtures, the color can be greatly affected (“Colors and Metals”). Now, many of these metals have been documented as hazardous materials even though they are mined from the ground. For example, selenium and cadmium contain many carcinogens and any contamination or release of these elements can create environmental problems (Zwolak). Because of this posed danger, the overall sustainability or environmental friendliness of stained glass is decreased, even though the mining process has a small negative impact to the environment.

The third primary materials used in the production of stained glass are called lead came or copper foil; both are different methods used to connect pieces of glass together. According to Barragan Glass Works, lead came has been known as the traditional method in this process. Using lead, long strips are formed and placed into H or U shapes and once cooled, the pieces of stained glass are placed inside these frame like structures. Copper foil works in a similar way but requires much more attention to detail and labor to complete; it is better used for intricate glass detailing and smaller more irregular shapes (“Lead Came vs Copper Foil”). While copper is a sustainable and recyclable material, lead is not and is in fact extremely harmful when absorbed. These different methods can change the sustainability of stained glass which varies between each method.

The final primary materials incorporated into creating the actual stained glass window is the cement used to set it all together. This cement is a type of linseed oil putty made from pure linseed oil and whiting—also known as white chalk (a form of limestone); the materials are mixed to create a putty-like consistency and then used to fill the space between the lead came (or copper foil) and stained glass to create more structure (Sidler). This process is used to produce a stronger panel, reduce the speed of deterioration and increase longevity in that panel. In general, both of these materials are safe and sustainable and do not pose any serious problems to the environment as they are extracted amicably, but the question about stained glass as a whole still stands: how do all of these materials, methods and processes relate together and how environmentally friendly are they in the whole scheme of things?

The science behind the production process and how these main four materials are combined to create stained glass is the next step in analyzing its life cycle. How Products are Made discusses this process in depth: “Glass is made by fusing together some form of silica such as sand…. The color [or stain] is produced by adding a metallic oxide to these raw materials” (“Stained Glass”). These metals can range from copper oxide to cobalt to uranium and create colors ranging from ruby to blue to gold as mentioned above. What’s interesting about this, though, is that the traces of these metals trapped in the glass are the size of nanoparticles and even the slightest change in size of this nanoparticle will change the oscillation frequency and wavelength which in turn will change the color that we perceive. The smaller the nanoparticles, the more they will reflect yellow and gold hues and the larger they are, the more they reflect red hues (Cain). Additionally, the additive of these metals, no matter how small, is just enough to prevent stained glass from standard glass recycling (“Glass Recycling”).

Now, after the molten glass is mixed with the metals, it is poured into molds representing the desired object, for example, specific window shapes like cathedral glass or general infrastructural pieces. These molds are then cooled in an annealing lehr, attached together with lead came or copper foil discussed above to make bigger panels or more unique designs, prepped with final touches including the cementing/glazing process, and then packaged to be sent off. When sent off or distributed, transportation services must be very calculated and careful due to the fragility and heaviness of stained glass (Cain).

Once installed, stained glass is given the considerable responsibility of staying reliable in a variety of conditions which in turn weighs in on its life cycle. The longevity of stained glass ranges from 80 to 100 years, if taken care of properly, before it begins to weather down and deteriorate (“Stained Glass Windows”). Unfortunately, because of the trace impurities added, stained glass cannot be melted down and reused as these impurities have rendered it in a contaminating way; it also risks contaminating the recycling stream (“Glass Recycling”). On top of this, in Wahid Ferdous’s article “Recycling of Landfill Wastes”, it is mentioned that only 21% of glass is actually recycled and that “the massive volume of remaining unused wastes goes to landfill creating environmental problems. Therefore, finding new strategies of utilizing these landfill wastes is vital” (Ferdou). 80% of the world’s glass (including stained glass) is going into the landfill when it can be recycled or at the very least, reused in other products/projects. While stained glass is not compatible with standard glass recycling centers when it does deteriorate, it is a great material to be recycled into other architectural projects; people do not do so and instead, allow it to fall in the landfill. On a more positive note, in recent years, the Global Stained Glass market is projected to increase substantially as we move towards 2028 according to the research discovered by Market Watch, a capital market company that analyzes stock on a daily basis. This increase is due to the “use of Auto Industry, Chemical Industry, Consumer Goods, Other and in multiple sectors [leading] to significant growth in demand for stained glass in the market” (“Global Market Growth”). In light of this analysis, we have hope that increasing usage and demand will encourage the recycling and reuse of stained glass in the future.

Overall, stained glass contains materials that may be hazardous towards the environment and its habitants, but it is still considered a sustainable product because of its high recyclability levels. For stained glass specifically, it is not known to be a recyclable material and often ends up in the landfill; learning about it can fix this misconception and hopefully create higher recyclability rates. As we strive towards a cleaner and more eco-friendly planet, it is important to understand these points and how we can educate ourselves in the products we use to progress our environmental sustainability.

Works Cited

Cain, Julie. “Stained Glass: The History, the Art and the Science.” Science Focus, https://sciencefocus.ust.hk/stained-glass-the-history-the-art-and-the-science#:~:text=On% 20the%20surface%20of%20metal,reflects%20light%20of%20specific%20wavelengths.

“Glass Recycling.” CalRecycle , https://calrecycle.ca.gov/glass/.

“Colors and Metals: What Gives Glass Its Color?” Pittsburgh Glass Center, https://www.pittsburghglasscenter.org/sites/default/files/ documents/Colors%20and%20M etals.pdf.

Connelly, Andy. “Heavenly Illumination: The Science and Magic of Stained Glass .” The Guardian, Guardian News and Media, 29 Oct. 2010, https://www.theguardian.com/science/blog/2010/oct/29/science-magic-stained-glass.

Ferdous, Wahid, et al. “Recycling of Landfill Wastes (Tyres, Plastics and Glass) in Construction – a Review on Global Waste Generation, Performance, Application and Future Opportunities.” Resources, Conservation and Recycling, vol. 173, 2021, p. 105745., https://doi.org/10.1016 /j.resconrec.2021.105745

“Lead Came vs Copper Foil.” Barragan Glass Works, http://barraganglassworks.com/leaded-glass-vs-copper-foil.html.

“Stained Glass Market : Global Market Growth, New Trends, COVID-19 Impact and Forecast 2023 to 2028.” MarketWatch, MarketWatch, 12 Jan. 2023, https://www.marketwatch.com/press-release/stained-glass-market-global-market-growth new-trends-covid-19-impact-and-forecast-2023-to-2028-2023-01-12#:~:text=The%20Glo bal%20Stained%20Glass%20market,rise%20over%20the%20projected%20horizon.

“Stained Glass Windows.” Historic England, https://historicengland.org.uk/images-books/publications/stained-glass-windows-managin g-environmental-deterioration/.

“Stained Glass.” How Products Are Made, http://www.madehow.com/Volume-2/Stained-Glass.html.

Sidler, Scott. “How to: Make Your Own Glazing Putty.” The Craftsman Blog, 17 June 2020, https://thecraftsmanblog.com/how-to-make-your-own-glazing-putty/.

“Silica.” Minerals Education Coalition, 23 Jan. 2018, https://mineralseducationcoalition.org/minerals-database/silica/.

Zwolak, Iwona. “The Role of Selenium in Arsenic and Cadmium Toxicity.” SpringerLink, Springer US, 15 Mar. 2019, https://link.springer.com/ article/10.1007/s12011-019-01691-w.

Juliette Price

Professor Cogdell

DES 40A

16 March 2023

Energy Analysis of Stained Glass

Stained glass has been a staple in many European and Middle Eastern countries since its creation in ancient times, in Roman and Egyptian times. Since then, the forms of energy used in its production have shifted along with our energetic trends, but the general process has remained the same. It became very popular in Medieval times, where Chartes, France became a large manufacturer of the product, and although it has wavered throughout the decades and centuries since its invention, it has made a resurgence in recent years due to its energetic capabilities and use for aesthetic purposes. It is most commonly associated with Cathedrals and churches in European countries, but its history ranges far and beyond that. The look of stained glass has been an aesthetic for centuries and it continues to add a calming and beautiful vintage look to any project it is used on. The ways in which the process has changed and been improved and influenced by science and technology is a considerable aspect to this topic. Stained glass has been shown to affect building temperatures through the adaptation of wavelengths so it not only provides a designed aesthetic to a space, but it serves as an energy efficient architectural material as well.

Raw materials are extracted from the ground through a plethora of ways, many of which depend on the type of glass that is being produced and what type of materials are being used. One of these options is recycled glass which is obviously more sustainable and renewable, and the other most popular and long standing way to produce glass is simply from heating sand or some sort of silica, sand with a high concentration of silica is needed to produce the clear and sleek glass look. “by fusing together some form of silica such as sand, an alkali such as potash or soda, and lime or lead oxide” (“Stained”), and as for the coloring portion of the process, metallic oxides are added. Different oxides will produce different colors in the end product and therefore influence the glass’ energy efficiency. Copper oxide would develop into a ruby/blue-green type of color, chromium oxide would give a green color, and cobalt for blue tones, and so on for all tones and hues. As for the types of machines that are involved in this process, furnace that is able to produce very hot temperatures is needed, usually around 2500°F, or 1371°C (“Stained”). However, the process of making stained glass has not changed drastically since its creation. It has been tweaked and improved, but the general process has remained the same. Most industrial furnaces are powered by fossil fuels such as oil and gas. So even if the glass that is being worked with is recycled, it is still not the most sustainable or ecologically friendly. Another form of waste, or expenditure of energy that occurs from this process is the need for the furnaces to be rebuilt every 8-10 years (“Glass”). Once harvested, these raw materials are then put through a series of heating and cooling processes that require a lot of heat, energy, and large industrial machinery.

The machines that produce the heat required for the production of stained glass are called kilns or furnaces, and in order to produce the sleek and modern finish of glass that we see everyday they must get up to immensely high temperatures. As mentioned above, a furnace must get up to around 2500 degrees Fahrenheit, so a very potent power source is needed. Furnaces are operated with fossil fuels or oil, making the process far less ecologically friendly than in the past. Cunningham explains the difference between the different ways in which the process can be done: rolled glass, which is the most modern, the ‘muff’ glass method, and ‘crown’ glass method. While each of these techniques differ slightly, they all fall under the same practices of mixing, heating, cooling and so forth. These processes are not too time consuming, for the act of melting the glass itself, however the furnaces are often going almost all of the time. This is true for at least the larger producing facilities, but this is a very energy intensive part of the process requiring such heat for such a constant amount of time (“Glass”). One source accounts that a furnace, if turned off, takes about 6 days to reheat to its fully functioning temperature, but as every furnace differs, some have claimed to be as fast as two hours (Epiphanyglass). Either way, the energy needed to produce this amount of heat is a considerable amount. As most glass production is done at large facilities the main energy source is fossil fuels and oil. These large facilities though, and the manufacturing processes in general are not the only contributors to the detriment of the environment. The other energy expenditure that is involved in the life cycle of stained glass is the transportation and distribution of the products.

Most of the production of glass is done in a large-batch industrial setting because of the temperamental nature of the process, therefore not much transportation is necessary aside from the transport of raw materials to the facility, and then the final product from the facility to its destination wherever that may be. Even so, that amount of transportation is a consideration in its energy consumption because the gas used to power the vehicle, and the need for large trucks to transport such heavy materials time after time. Especially with the weight that this type of product, can add to the level of emissions used in the process of transportation and distribution. There is also the level of risk of damage to the products, forsaking the entire process. After considering the energetic needs from transportation and distribution is the use and reuse of the materials, examining the sustainability of the material.

It does not take energy to use the material but a large part of the draw and interest in stained glass is its ability to control temperature and climates in architectural situations. In use, the color in the glass has an effect on the amount of heat let into a space. Shaik in their research journal, Space-Age Energy Saving, Carbon Emission Mitigation and Color Rendering Perspective of Architectural Antique Stained Glass Windows quantifies the energy involved in stained glass along with the aesthetics it produces. While it was admitted that, “the amount of solar heat gain in buildings varies depending on their location, orientation, and climate type,” the findings from this research still proved influential in the energetic competency of the material. Shaik writes, ‘‘Stained glasses have significantly decreased solar heat gains compared to clear glass during the summer and winter seasons in all orientations. It is found that the stained glasses with south orientation had the lowest heat gain transmission in the summer and the maximum heat gain transmission in the winter.’’ The most influential or important finding though, aside from the effect of the orientation and climate qualifications, was that “SGs reduce carbon emissions and save cooling/heating costs. Reducing cooling and heating energy utilization decreases electricity usage and hence greenhouse gas emissions” (Shaik). As this is what draws many to be interested in involving stained glass into their projects, it is reassuring to see that it holds true. Although with reuse and maintenance, if one breaks the entire process must be recreated from the beginning which could be seen as a non-sustainable aspect of this material. The final consideration of the life cycle of stained glass comes in the form of recycling of the product and waste management of the materials.

The process for recycling stained glass is one of the most popular forms of producing stained glass because it can be created from either the raw materials like a silica based matter, or the other option is reused, recycled glass. This is the more sustainable option because the materials already exist in the particular form and far less raw material needs to be extracted from the Earth. That being said though, this is a fairly minuscule portion of the energetic tax of stained glass on the Earth. The most damage or negative influence done on the environment is due to the heating of the furnaces and kilns and their use of fossil fuels and oil in the process. Another aspect of the recycling process of stained glass comes from what happens to the portion of the material that is not recycled, and ends up in the landfill. This happens to be actually quite a large portion of the waste aspect of this material and process. The glass that ends up in the landfill remains there for upwards of 1 million years (2019)! Although, the resurgence of vintage culture and the admiration of all things old-looking had given a new life to many stained glass windows and allowed for its use in new projects therefore lessening the amount of product entering the landfill. Grosser entails the process of upcycling stained glass windows and shows how it can add an ecological and energetic advantage to the home, as well as integrating an aesthetic that creates an artistic and vintage looking feel.

Stained glass, although the process of its creation having evolved and critiqued for centuries, has made a resurgence in popularity in recent years due to its energetic properties making it a preferable choice as a building material. It has proven to affect building temperatures through the adaptation of wavelengths so it not only adds a designed aesthetic to a project, but it works as an energy efficient architectural material as well. The energy needed to produce the product is somewhat lengthy, and high-energy in its consumption, but relative to the amount of energy we are using as a humanity on this Earth, it is still a fairly sustainable product. It can be reused and recycled time and time again, but the use of fossil fuels and oils that have become the main energy source that is involved in operating the furnaces is recognized as its main drawback.

Works Cited

2019 Biennial Solid Waste Report - NH Department of Environmental Services. https://www.des.nh.gov/sites/g/files/ehbemt341/files /documents/2020-01/r-wmd-19-02.pdf.

Cunningham, Bridget. “The Science behind Stained Glass.” COMSOL, https://www.comsol.com/blogs/the-science-behind-stained-glass/.

Epiphanyglass. “Glassblowing 101.” Epiphany Studios, 14 Sept. 2020, https://epiphanyglass.com/glassblowing-101/.

Investigating the Effect of Stained-Glass Area on Reducing the Cooling, https://www.researchgate.net/publication/359364798 _Investigating_the_Effect_of_Stained-glass_Area_on_Reducing_the_Cooling_Energy_of_Buildings_Case_Study_Ankara.

“Glass Manufacturing and Glass Furnaces.” Peak Sensors, 21 Feb. 2023, https://peaksensors.co.uk/blog/glass-manufacturing-process/.

Grosser, Vicky. “Energy-Efficient Stained Glass - Renew Magazine.” Renew, 23 Apr. 2019, https://renew.org.au/renew-magazine/building-materials/energy-efficient-stained-glass/.

Shaik , Saboor et al. “Space-Age Energy Saving, Carbon Emission Mitigation and Color Rendering Perspective of Architectural Antique Stained Glass Windows.” Energy, Pergamon, 31 July 2022, https://www.sciencedirect.com/science/article/pii/S0360544222018011.

“Stained Glass.” How Products Are Made, http://www.madehow.com/Volume-2/Stained-Glass.html.

Van der Snickt, Geert. “Chemical Imaging of Stained-Glass Windows by Means of Macro X-Ray Fluorescence (MA-XRF) Scanning.” Microchemical Journal, Elsevier, 22 Oct. 2015, https://www.sciencedirect.com/science/article/pii/S0026265X15002404?casa_token=qgBhsdQvipIAAAAA%3AGnV9jusqbRKm0yA99Mmr7guzZUSXu-dMNMTOud_sNlbNzdRj5oBmNR2vCJLnQoWTt_IgD3-Ljw.

Villaro Amurrio, Izaskun. “Analysis of of the Energy Savings Gained by Protective Glazing on Stained Single-Glass Windows at Uppsala Cathedral.” ADDI, 9 Sept. 2016, https:// addi.ehu.es/handle/10810/19918.

Amelia Swanson

Prof. Cogdell

DES 40A

13 March 2023

Waste Production of Stained Glass

Stained glass is a beautiful material used in an array of historical buildings, magnificent churches, and modern architectural masterpieces. Because of its beauty, stained glass has been around for centuries and the way it is made has stayed pretty consistent with changes in resources being used. Creating the foundation consists of silica sand, soda, lime, and metal oxides. Different metal oxides provide the variety of colors stained glass reflects. The waste that is produced varies on which elements are being used to color the glass, the extraction of those materials, whether or not it is recycled correctly, and if it is being reused to its fullest potential.

Although sand is the most abundant solid substance on the planet, it is one of the most used throughout the world. This adds up over time and contributes to the overall waste produced. The extraction of all materials used to make stained glass can cause significant harm to the environment. The process of mining sand, soda ash, and lime causes major erosion “including coastal and river erosion, shrinking deltas, land-use changes, air pollution, salinization of coastal aquifers and groundwater reserves, threats to freshwater and marine fisheries and biodiversity”, (Whiting 2). It is also said that “Limestone deposits often occur in association with karst, a topography where limestone slowly dissolves away underground. The deposits result in sinkholes, caves and areas of rock fractures that form underground drainage areas.” (Csanyi 2). Ecosystems cannot handle these changes- the destruction of their habitats causes misplacement for many of them eventually changing the entirety of the ecosystem. Not to mention, the effects on workers during these production processes are incredibly bearing. The effects on respiratory health can cause major complications. “The National Institute for Occupational Safety and Health (NIOSH) requests assistance in preventing silicosis and deaths in workers exposed to respirable crystalline silica during sandblasting.” (Preventing Silicosis and Deaths from Sandblasting ). Accessing these essential substances to make glass can create substantial waste that harms the environment as well as those that are working in it.

Another substance that is used in the production of stained glass are metal oxides. Stained glass casts a hue depending on which metal oxides are used, Cobalt Oxide will result in blue or violet, Cadmium Sulfide will show yellow, as Gold Chloride will red, and Antimony Oxide will white (How Does Stained Glass get its color). “The inputs of metal oxide NPs to the environment are also growing every year, which causes potential environmental and human health risks. They are toxic to animals, microorganisms and plants at high concentrations, and they show different mechanisms of toxicity to different species.” (Zhu 1). These oxides are essential for the production of stained glass, and so depending on the amount used in production there can be a slight change in different ecosystems.

As far as waterborne waste goes, marine organisms can especially be affected by the increase of metal oxide production because nanoparticles can find their way into marine systems and ultimately turn into sedimentation amongst organisms primarily affecting sediment-dwelling and filter feeding organisms. “These organisms can absorb them in mucus prior to ingestion whereas fish could either uptake them via the gut or absorb them through their gills which could affect respiratory processes and ion transport.” (Baker 1). Currently, the effects of these nanoparticles are not sufficient enough to cause major issues but they could cause stresses on oxidative processes which could cause chronic health impact in the long run.

After color is applied the glass is then joined together from lead. Extracting lead is one of the easier elements to extract from the earth but it can be very toxic if not handled properly. “Ecosystems near point sources of lead demonstrate a wide range of adverse effects, including losses in biodiversity, changes in community composition, decreased growth and reproductive rates in plants and animals, and neurological effects in vertebrates.” (Air Pollution from Lead). As more lead is needed to be extracted, more sites are being found which can ultimately lead to an increase of waste produced from mining and production. Because lead is a toxic metal, working with it can cause major health problems throughout the nervous system, reproductive system, kidneys, and cardiovascular system. People have to take major precautions when working with lead because the airborne waste throughout labor sites can be incredibly threatening.

Lastly, stained glass is distributed and transported to different locations to then be used. Because glass is such a heavy and large object, it has to be crated and placed in large vehicles, like a ship. (How To Ship Big Stained Glass Panels). Larger transportation distributors create more emissions such as carbon dioxide and other greenhouse gases. The packaging of stained glass also contributes greatly to the amount of solid waste produced because it is so fragile, it has to be a thick material such as foam or bunches of paper. Increasing waste in the landfill, destroying habitats, releasing greenhouse gases, and creating possible harm to workers can occur when extracting the crucial elements such as lead, silica sand, soda and lime. This also includes the process of forming stained glass that requires the energy of heat to melt the glass together and apply color. However, the extremity of this can be reduced if the proper precautions are taken and the recycling/repurposing process is done efficiently.

The way in which glass is dealt with after its use has to do immensely with the overall waste produced from stained glass. If glass is not recycled properly then “it not only causes a safety hazard to workers but it can also damage the recycling facilities and increase the processing cost. The broken glass is difficult to sort by colors (stained glass) which is important as the melting temperatures are different for different colors. In addition, the heavy weight of glass can also increase the transportation cost.” (Ferdous 1). If glass ends up in the landfill it will not break down because of how it is made. “Glass does not degrade by incineration or landfilling and simply adds to the bulk of unutilized material from these treatment methods. Energy recovery from glass is also not possible; therefore, recycling of glass is the most preferred treatment method.” (Larsen, Merrild, Christensen 1). Transportation of waste can be a major contributor to harmful emissions going into the atmosphere, and because of how little glass is properly disposed of, much of it is thrown into the landfill increasing transportation rates and contributing further to the plethora of harmful waste in the landfill. The danger this also imposes on the workers health not only by having to deal with glass but also within the landfill is something to consider when analyzing the waste of stained glass.

However, there are ways to mitigate these impacts on the environment and on the workers. It is fairly easy to break down and then reuse to avoid producing more greenhouse gases. (Freestone 1).Glass can be melted and sorted through to remove any foreign objects, which would be very little in stained glass since it is mostly used for architectural reasons. Cullet (broken glass) can then be extracted and separated by color, which is then used to remelt; producing more stained glass or other products made with glass. “When recycled glass cullet is mixed in with raw materials to manufacture glass, the melting point drops from between 2550 to 2900 °F to between 2250 and 2350 °F, which is a huge energy saving. Glass cullet can be mixed in with virgin raw materials at up to 60% of the mixture.” (Brandy 3). This decreases the extraction of raw materials and greenhouse gases it takes to undergo that process as well as the emissions it takes to start from scratch. The energy waste that is produced during this process is very little, just the greenhouse gas emissions produced from the motor vehicles and forklifts used to sort and transport the glass. (Larsen, Merrild, Christensen 3). Making glass on an entirely new foundation produces much more waste compared to reusing and repurposing. But the problem is that only “21% of glass is currently recycled globally”. (Ferdous 3.3). Meaning that a majority of the stained glass is ending up in landfills contributing to the mass production of waste.

The stunning material of stained glass is one we admire everyday. The way it brings in light adds life to a room. The process in how it is made can produce waste depending on where the extracted materials are coming from, the way they are extracted, how they are then formed in a factory, and then disposed of. Yet, there are many opportunities for improvement and they are being discovered. There are little conclusions made on whether or not stained glass is necessarily sustainable because it all depends on if it is recycled and repurposed properly. Waste can be drastically reduced through these processes in the amount of raw materials being extracted from the earth and the production of greenhouse gasses emissions.

Works Cited

“Air Pollution from Lead.” Texas Commission on Environmental Quality, https://www.tceq.texas.gov/airquality/sip/criteria-pollutants/sip-lead.

Author links open overlay panelYi Zhu a 1, et al. “Recent Advances in the Biotoxicity of Metal Oxide Nanoparticles: Impacts on Plants, Animals and Microorganisms.” Chemosphere, Pergamon, 26 July 2019, https://www.sciencedirect.com/science/article/pii/S0045653519316248?via%3Dihub.

Baker, Tony J., et al. “Impacts of Metal and Metal Oxide Nanoparticles on Marine Organisms.” Environmental Pollution, vol. 186, 2014, pp. 257–271., https://doi.org/10.1016/j.envpol.2013.11.014.

Cichosz, Marcin, et al. “Changes in Synthetic Soda Ash Production and Its Consequences for the Environment.” Materials (Basel, Switzerland), U.S. National Library of Medicine, 11 July 2022, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9322306/#:~:text=The%20synthetic%20soda%20ash%20industry,soda%20ash%20industry%20by%2Dproducts.

“Environmental Hazards of Limestone Mining.” Hometown News LP, 8 Sept. 2020, https://www.hngnews.com/deforest_times/opinion/letters_to_editor/article_84440625-8b1b-583b-bf81-ad73eb922dd2.html#:~:text=Limestone%20mining%20can%20affect%20ground,that%20form%20underground%20drainage%20areas.

Faith, Martin. “How Does Stained Glass Get Its Color?: Scottish Stained Glass.” Scottish Stained GlassHow Does Stained Glass Get Its Color? | Scottish Stained Glass, 11 Dec. 2019, https://www.scottishstainedglass.com/uncategorized/stained-glass-color/.

Ferdous, Wahid, et al. “Recycling of Landfill Wastes (Tyres, Plastics and Glass) in Construction – a Review on Global Waste Generation, Performance, Application and Future Opportunities.” Resources, Conservation and Recycling, vol. 173, 2021, p. 105745., https://doi.org/10.1016/j.resconrec.2021.105745.

Frances, Milly, et al. “Stained Glass - Foil or Lead Came?” Everything Stained Glass, 18 Jan. 2023, https://everythingstainedglass.com/stained-glass-foil-or-lead-came#:~:text=The%20glass%20is%20cut%20to%20a%20pattern%20and%20then%2C%20instead,make%20it%20strong%20and%20weatherproof.

Freestone, Ian C. “The Recycling and Reuse of Roman Glass: Analytical Approaches.” Vol. 57 (2015), JSTOR, https://www.jstor.org/stable/24726946.

Geoffrey Montes, Nick Mafi. “19 Of the World's Most Breathtaking Stained-Glass Windows.” Architectural Digest, Architectural Digest, 18 Oct. 2017, https://www.architecturaldigest.com/gallery/stained-glass-windows#:~:text=Used%20as%20windows%20or%20ceilings,and%20now%20adorn%20private%20homes%2C.

“How to Ship Big Stained Glass Panels.” Gomm Stained Glass, https://www.gsg-art.com/how-to-ship-big-stained-glass-panels.html#:~:text=To%20ship%20a%20big%20piece,glass%20can%20be%20adequately%20protected.

Larsen, Anna W., et al. “Recycling of Glass: Accounting of Greenhouse Gases and Global Warming Contributions.” Waste Management & Research: The Journal for a Sustainable Circular Economy, vol. 27, no. 8, 2009, pp. 754–762., https://doi.org/10.1177/0734242x09342148.

“Preventing Silicosis and Deaths from Sandblasting (92-102).” Centers for Disease Control and Prevention, Centers for Disease Control and Prevention, 6 June 2014, https://www.cdc.gov/niosh/docs/92-102/default.html#:~:text=Abrasive%20blasting%20with%20sands%20containing,respirable%20crystalline%20silica%20during%20sandblasting.

“Sand: The Environmental Catastrophe You've Probably Never Heard Of.” World Economic Forum, https://www.weforum.org/agenda/2022/06/global-sand-mining-demand-impacting-environment/#:~:text=Sand%20minimg%20from%20rivers%20and,biodiversity%2C%22%20says%20the%20UNEP.

Searcy, Brandy. “Environmental Impact of Glass: How Sustainable Is Glass?” Rain Organica, Rain Organica, 13 Sept. 2020, https://rainorganica.com/blogs/news/the-environmental-impact-of-glass.