Design Life-Cycle

assess.design.(don't)consume

Maxfield Herrenbruck

DES 40A

December 1, 2016

Christina Cogdell

Raw Materials of JanSport Backpack

Intro

The world we live in is one of gross consumption. It is a force that drives us to new heights of material and energy use every year. This pushes where and how things are made to a global scale, since no one country alone has the resources to meet demand. From a humble hair clip, to massive sections of bridges, nearly everything we have goes on a long journey from the ground, to a finished object. Along the path of creation lie untold stories of environmental destruction caused by the manufacture of our manmade universe of stuff. Through researching what the materials are, and how they are processed to make a JanSport Right Pack backpack, we hope to gain a better understanding of the lifecycle and environmental impact of a popular product.

Plastics

With the product information provided by both JanSport’s and Macy’s commercial websites, we know that the bag is made primarily of synthetic fabrics. This in turn means that an essential raw ingredient in the bag is in fact oil. In order to determine where the oil is from, and thus the transport methods to send it, I need to make some assumptions about the regions where parts of the bag were made. Now from the tag in a JanSport bag, I found that the bag itself was made in the expansive manufacturing hub known as China. The only other part of it that I know the location of manufacture is the main fabric Cordura, which is made by Invista in Wichita, Kansas. Going forward, I’m going to assume that all other parts are fabricated in China, and will orient the acquisition and processing of materials around that.

Per data from the Energy Information Agency (EIA) database, China imports most of its oil from Saudi Arabia, Angola, Russia, and Oman. This oil is most likely sent via tankers and trains to China, while in Kansas oil is distributed via pipelines, trains, and trucks. After the oil is transported, it under goes a process known as refining. This process involves heating the crude oil to a high temperature where it boils into a vapor, and then sending it through a fractional distillation column. The column separates the oil into different types, and sends them on their way. From this process, petroleum gas is extracted, which is a common chemical used to make plastic precursors.

The primary material used in the bag is a fabric called Cordura. The company that produces Cordura, Invista, has not shared the exact process it uses to make it, but they did share that is made of a type of nylon called nylon 6,6. Nylon 6,6 is a plastic fiber made by DuPont via a process called condensation polymerization. This process involves cooking two precursors, adipic acid and hexamethylenediamine, under high heat and pressure until they start snapping together in long polymer chains. What Invista does with the raw nylon afterwards is anyone’s guess, but they state that they do custom dyeing of the fabric on behalf of their customers before they ship it off.

The material used to make the bottom of the bag was found to be synthetic suede. This information was found on Macy’s website, since on JanSport’s they just call it “leather”. While the manufacturer of JanSport’s artificial suede could not be found, the composition of a common one known as Ultrasuede by Tory could be found on their website. The fabric most resembling the one used in the JanSport bag is made mostly of polyester with polyurethane used as a binder. The most common polyester is called polyethylene terephthalate (PET) an is made by a process called polymerization, where the precursors are placed in a vacuum chamber, and heated. The precursors of PET are terephthalic acid and monotheluene glycol. The process to make the polyurethane binder is simply the reaction of two chemical types, alcohols and diisocyanates. Since there are so many combinations of those chemical groups that result in polyurethane, and the fact that Tory does not identify the exact kind used in its fabric, I was unable to find the exact precursors used in the process.

The final plastic we looked at is called ethylene-vinyl acetate (EVA) foam, which is used as padding in the shoulder straps of the bag. EVA foam is made by mixing ethylene, acetate, and vinyl in a mold of the desired shape, and letting the foam setup. While no specific information on the exact way JanSport makes their padding, it makes sense that they most likely take sheets of it, and cut it to shape.

Metal

The only part of the bag that is not some kind of plastic is the zipper pulls, which are made of zinc. Per a United States Geological Survey (USGS) minerology report, China is the world’s leading producer of zinc, which means it is probably the country of origin for the metal used in the pulls. Once the ore is mined, it must be processed into usable metal. According to the EPA, a common way zinc is processed is with a fluidized-bed roaster. Zinc ore is inserted into the roaster at extremely high temperatures. The results of the firing are put in a leaching solution of sulfuric acid, limestone, and cyanide, then passed into a purifying stage. The solution from that stage is put through electrolysis, which pulls the metal from suspension, and it is finally collected. While no solid evidence of who makes the zipper pulls can be found, they are most likely made by cast and die method.

Conclusion

The story of a backpack would on the surface seem to be a simple one, but as was shown, it is the end product of a global process. There is so much more depth to be explored with regards to sustainability, and the future of the fabrics that make up the bag. Oil based plastics are a fantastic tool for creation with the ability to morph into whatever design role we have for it, but the primary material for its creation will soon run out. The answer to the question of what will take its place could end up being one of the most valuable ones imagined.

Bibliography

"Compilation of Air Pollutant Emission Factors." US Environmental Protection Agency, EPA, Jan. 1995. Accessed 30 Nov. 2016.

Macys. Accessed 30 Nov. 2016.

Craig Freudenrich, Ph.D. "How Oil Refining Works" 4 January 2001.HowStuffWorks.com. <http://science.howstuffworks.com/environmental/energy/oil-refining.htm> 30 November 2016

Conlee, Kim. "75th Anniversary Celebrated For Nylon Plant Manufacturing Fiber For INVISTA's CORDURA® Brand Fabrics." Cordura Brand Fabric, INVISTA, 15 Sept. 2014. Accessed 30 Nov. 2016.

"Ultrasuede® GP." 'TORAY', Toray Industries, Inc. Accessed 30 Nov. 2016.

"Introduction to Polyurethanes: How Polyurethane Is Made." American Chemistry Council, American Chemistry Council. Accessed 30 Nov. 2016.

Gerard, Barbara. "How is Polyester Made?." Craftech Industries, Craftech Industries, inc, 26 Aug. 2015. Accessed 30 Nov. 2016.

"What is EVA foam and how is it manufactured?." Reference, IAC Publishing. Accessed 30 Nov. 2016.

"2013 Minerals Yearbook." USGS, USGS, Nov. 2015. Accessed 30 Nov. 2016.

"RIGHT PACK BACKPACK." JanSport, JanSport. Accessed 30 Nov. 2016.

EIA Beta, U.S. Department of Energy, https://www.eia.gov/beta/. Accessed 30 Nov. 2016.

Woodford, Chris. "Nylon." Explainthatstuff18 June 2016, www.explainthatstuff.com/nylon.html. Accessed 30 Nov. 2016.

"Backpack Construction." White Mountain, White Mountain Backpacks. Accessed 30 Nov. 2016.

Iris Li

Professor Cogdell

DES 40A, Fall 2016

30, November 2016

JanSport Right Pack Backpack - Embodied Energy

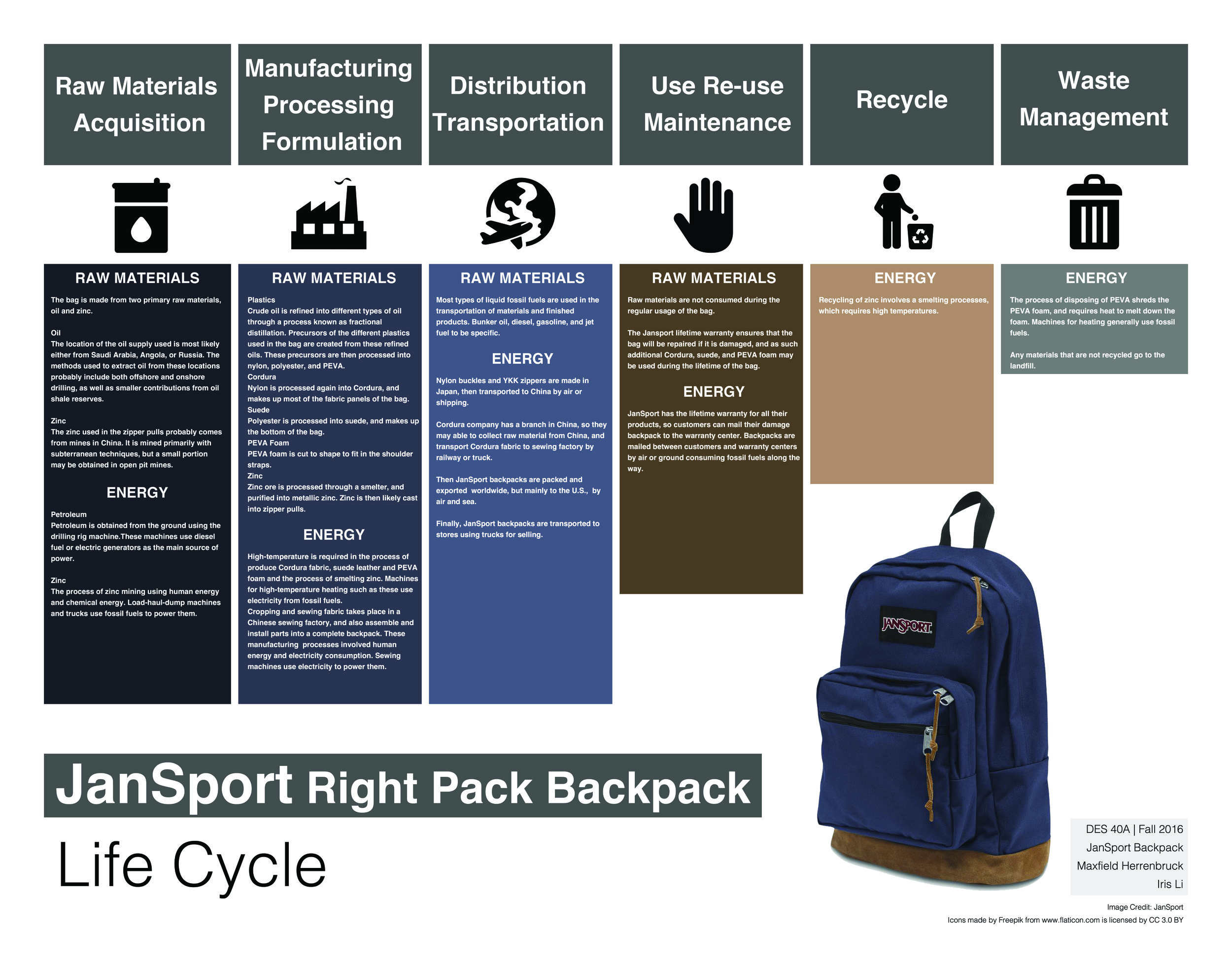

JanSport backpack is one of the bestselling backpacks among students. Students using its Right Pack Backpack as a daypack for their daily commute, because the backpack is well designed for carrying books. The backpack has comfortable padded straps, accessible front panel opening and a durable vinyl base for carrying heavy duty. JanSport sells campus backpacks around the country and they can also be found in college bookstores. JanSport is a famous brand for backpacks, owned by VF Corporation, one of the world’s largest backpack maker. Although JanSport is an American brand and sells about half of its backpacks in the United States (Horovitz), JanSport has a global supply chain to produce its products. Through researching the lifecycle of JanSport Right Pack Backpack, this paper aims to find out the energy consumption of the production processes and environment impact.

JanSport Right Pack Backpack is made of the following materials: 915 Denier Cordura fabric, Suede leather in the bottom, Polyethylene vinyl acetate foam for straps, YKK zippers, nylon buckles and thread. Cordura fabric, buckles and thread are made from nylon, and main raw material to produce nylon is petroleum. The type of YKK zipper used in JanSport backpack is made of zinc and nylon fabric.

There are various raw materials for nylon fiber are variable. Benzene from petroleum refining, furfural obtained from oat hulls and corn cobs, or 1.4-butadiene obtained from petroleum refining are sources used in commercial (Kent 437).

Petroleum is obtained from the ground using a drilling rig machine. These machines use diesel fuel or electric generators as the main source of power. The petroleum refining sector is the largest consumer of fuel in the United State manufacturing, and about 90% of onsite fuel applied to process heating (Office of Energy Efficiency & Renewable Energy). The majority fuel consumed at refineries is natural gas, and 852,067 million cubic feet were consumed at refineries annually (U.S. Energy Information Administration).

Furfural is the most important product obtained from oat hulls. To harvest oats, farmers use combine harvester, the oats run through a threshing machine and then the oats are gathered oats into shocks. These machines may either be powered by a generator using petrol or electricity. In 2013, energy consumption for growing and harvesting oats was roughly 115 dollars per planted acre of oats (U.S. Energy Information Administration).

Cordura fabric, a special fabric made of nylon by Cordura company is the main fabric used in the backpack. Since the processing and formulation of Cordura fabric are trade secrets of Cordura company, we research nylon fabric instead of Cordura fabric.

Nylon fabric is made from organic chemicals obtained from petroleum refining, used benzene as raw materials. Essentially, the fabric through a process that involves reacting large molecules using the moderate heat of about 280°C under vacuum for 2-3 hours and pressure inside an autoclave while being stirred. Molecules of hexane-1, 6-dicarboxylic acid are combined with 1, 6-diaminohexane in a chemical reaction referred to as condensation polymerization to form a type of nylon popularly known as nylon-6, 6 (Kent 437).

We cannot find out what type of leather was used in JanSport Right Pack Backpack, but we believe it is a type of cheap synthetic leather since the price of the backpack is low. Synthetic leather is made using a number of raw materials that are processed to produce polyvinyl chloride. The basic raw materials used for the production of polyvinyl chloride include ethylene and chlorine. Additives used in the production of this type of leather include the plasticizer, stabilizer and filler among a few others (Baitz, Kreißig and Byrne 2004). While ethylene is produced by refining petroleum from the distillation of natural gasses and oil, chlorine is obtained from rock salt and ultimately through the electrolytic process (Salt Manufacturers' Association).After drilling for oil using the drilling rig machine, crude oil is taken into the oil plant such as industrial process plant, where oil is processed and through the distillation process, ethylene is obtained (Manley 1998). Both the electrolytic process used to produce chlorine and the distillation process used to produce ethylene use electricity as the source of power, which obtained from such sources as wind energy, coal.

Polyethylene vinyl acetate (PEVA) is produced by blending copolymers. The raw materials used to produce Polyethylene vinyl acetate include ethylene and vinyl. This is achieved through a process referred to as copolymerization where free radical catalysts are also used. Here, a hot liquid form mixture of ethylene vinyl and acetate is sprayed into a mold, allowed to cool slightly in order to give the form some time to expand and the popping on the mold to produce PEVA material (Nagao). Vinyl is produced using two basic substances, which include ethylene and chlorine. Once the crude oil has been obtained using the drilling rig machine, it is refined through the distillation process to produce ethylene and other forms of the petroleum. Chlorine is obtained through electrolysis of brine (sodium chloride solution), which in itself is obtained from rock salt from mining ancient deposits. In some countries, the sun evaporates brine from sea water, which can then be easily collected. These processes use electricity from coal and wind sources as well as fossil fuels as the source of energy.

YKK zipper slider is made of zinc. Zinc is a natural material which occurs as carbonate, sulphide or silicate ores. Roasting is a high-temperature process that concentrates zinc sulfide into impure zinc oxide. Multiple hearth roasters are operated at about 690 °C and operating time depends on the composition of concentrate and the required amount of removal sulfur (United Stated Environmental Protection Agency).

We cannot find where JanSport get their raw materials from, but we can assume that JanSport import materials globally and transport them to China for assembly. Keng Tau Handbag Company, located at Panyu Village, Guangdong, China, produce bags for JanSport (Institute for Global Labour and Human Rights). Nylon buckles and YKK zippers are made in Japan, then transported to China by air or shipping. Since Cordura company has a branch in China, they may able to collect raw materials from China and transport Cordura fabrics to sewing factories by railway or truck. Cropping and sewing fabric takes place in a sewing factory, and also assembling and installation of parts into a complete backpack. Then JanSport backpacks are packed and exported to worldwide, but mainly to the U.S., by air and shipping. Finally, JanSport backpacks are transported to stores to be sold by using trucks.

Since JanSport Right Pack backpack uses Cordura fabric, the lifetime of the backpack is long. JanSport also has a lifetime warranty for all their products, so customers can mail their damaged backpack to the warranty center. JanSport will fix the backpack or if they can’t, they will replace the backpack or refund it (JanSport). The policy of lifetime warranty takes some energy consumption on transportation in the mailing, but it extends the lifetime of the backpack and it helps JanSport collect their product for recycling.

JanSport did not disclose any information about the recycle plan. We researched the recycle process based on the materials. The Cordura fabrics have been shown to be more durable as compared to the other types of fabrics, offering superior strengths to weight ratio. Given that it is built to last, this form of fabric and other similar nylon have also been shown to be challenging to recycle. The best recycling method and process are yet to be identified for Cordura. However, it has been shown to be a durable fabric that lasts for a long time, and thus reduces disposal and waste.

With regards to synthetic leather, Polyurethane synthetic leather production process has been found to be beneficial for solid waste recycling. In Wenzhou, one of the most affected places globally; equipment for the purposes of purifying and recycling Dimethylformamide was installed in the synthetic leather enterprise in the area, attaining a recycling rate of about 96 percent. In this process, Dimethylamine decomposed during the recycling process is first distilled and thoroughly burnt for the purposes of monitoring secondary pollution. The process was also aimed at recovering most of the wastewater during the wet process through recycling distillation. Once success was achieved in preventing pollution, the next step was towards conserving energy and cost reduction. Equipment was therefore installed to utilize waste heat in a counter-pipe boiler, allowing for 60 to 70 percent of waste heat to be recycled, and thus creating a significant reduction of waste and emission. One of the systems being used in the Xinxiang Synthetic Leather Corporation in Wenzhou has been shown to save about ten tons of coal, and thus expected to save well over 2.1 million Yuan annually (Yu, Zhou and Jiang 2012). The system, therefore, has a lot to offer given that it allows for companies to not only reduce pollution during the production process, but also save energy and reduce cost.

Although the global recycling rate of PEVA has been shown to be very low with a few companies being involved in the recycling process, PEVA can be recycled to reduce pollution. Currently, the process of recycling this material involves the use of GreenMax Hot Melt Densifier machine. The process involves shredding, heating and extruding the form to form densified ingots that are easier to manage. This final product has been shown to be easier to manage given that it reduces huge storage space required for PEVA materials and is easier to transport. Basically, the process shreds the PEVA form and requires heat for the purpose of melting down the form. The materials can then be melted down to blocks that can be easily managed. Some of the other benefits include reduction of volume ratio up to 50:1 and low utility consumption. This machine does not produce heat to be used for other purposes, and therefore only consumes energy. The machine uses electricity, which is mostly obtained from coal, wind and geothermal energy sources. It can also run on diesel generators, which basically use fossil fuels. In this case, therefore, fossil fuels are the only sources of energy that cannot be renewed (GreenMax Intco Recycling).

The recycling of zinc involves melting or smelting processes. Depending on the quality, form and purity of the zinc involved, metal can be melted and cast into new physical forms either for direct reuse or refining processes (OECD). It is estimated that about 60% of zinc is recovered and recycled.

When backpack ends up at the dump, materials needs different time for wastes to decompose in landfills. Generally, nylon fabric takes 30-40 years to “break down” in the environment (Mote Marine Lab).

Overall, JanSport backpack is a great backpack because of its durability. Since Cordura fabric is not easy to decompose in a natural environment, we cannot throw them away to the trash. The best solution is using their lifetime warranty to get the backpack fixed or replaced. Each backpack made of materials from globally and consume energy. When we buy our backpack, we should not only consider fashion, but also environmental impact – what will happen when you are no long using the backpack?

Bibliography

Baitz, Martin, et al. "Life Cycle Assessment of PVC and of principal competing materials." 2004.

GreenMax Intco Recycling. How to Recycle EVA foam? n.d. 27 11 2016. <http://www.intcorecycling.com/How-to-Recycle-EVA-foam.html>.

Horovitz, Bruce. Backpacks: A new 'badge' of cool. 20 8 2007. 26 11 2016. <http://usatoday30.usatoday.com/money/industries/retail/2007-08-19-backpack_N.htm>.

Institute for Global Labour and Human Rights. Made in China. The Role of U.S. Companies in Denying Human and Worker Rights (continued). 1 5 2000. 27 11 2016. <http://www.globallabourrights.org/reports/made-in-china-the-role-of-u-s-companies-in-denying-human-and-worker-rights-continued>.

JanSport. LIFETIME WARRANTY. n.d. 27 11 2016. <http://www.jansport.com/customer-service/lifetime-warranty.html>.

Kent, James A. Handbook of Industrial Chemistry and Biotechnology. New York: Springer, 2013.

Manley, D B. "Thermodynamically efficient distillation: Ethylene recovery." 1998. Missouri S&T - Missouri University of Science and Technology. 27 11 2016. <http://web.mst.edu/~dbm/papers/ethylene.pdf>.

Mote Marine Lab. Measuring biodegradability. Sarasota, FL: U.S. National Park Service;, 2008. 27 11 2016.

Nagao, Yoshiharu. Method of manufacturing ethylene-vinyl acetate copolymer. JP: Patent US 6646087 B2. 27 10 2000.

OECD. Recycling of Copper, Lead and Zinc Bearing Wastes. Paris: OECD, 1995.

Office of Energy Efficiency & Renewable Energy. U.S. Manufacturing Energy Use and Greenhouse Gas Emissions Analysis. Washington, DC: Department of Energy, 2012. <http://energy.gov/sites/prod/files/2013/11/f4/energy_use_and_loss_and_emissions_petroleum.pdf>.

Salt Manufacturers' Association. The Electrolysis of Brine. n.d. 27 11 2016. <https://web.archive.org/web/20070514034157/http://www.saltsense.co.uk:80/hist-chem12.htm>.

U.S. Energy Information Administration. Energy for growing and harvesting crops is a large component of farm operating costs. 17 10 2014. 27 11 2016. <http://www.eia.gov/todayinenergy/detail.php?id=18431>.

—. U.S. Fuel Consumed at Refineries. 22 6 2016. 27 11 2016. <https://www.eia.gov/dnav/pet/pet_pnp_capfuel_dcu_nus_a.htm>.

United Stated Environmental Protection Agency. "AP 42, Fifth Edition, Volume I Chapter 12: Metallurgical Industry." 10 1986. United Stated Environmental Protection Agency. 27 11 2016. <https://www3.epa.gov/ttnchie1/ap42/ch12/>.

Yu, Jianxing, Jun Zhou and Hua Jiang. A Path for Chinese Civil Society: A Case Study on Industrial Associations in Wenzhou, China. Lexington Books, 2012.